Patents

Literature

152results about How to "Reduce dry density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

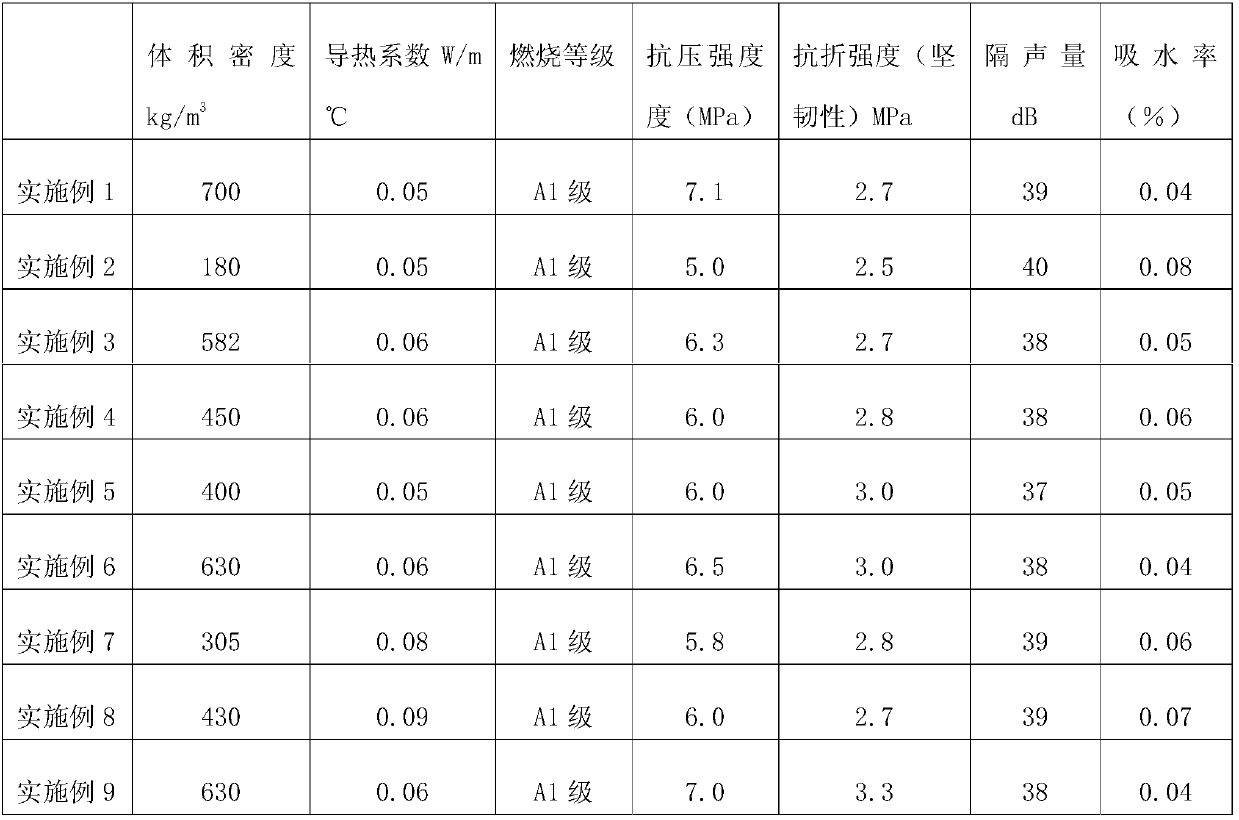

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

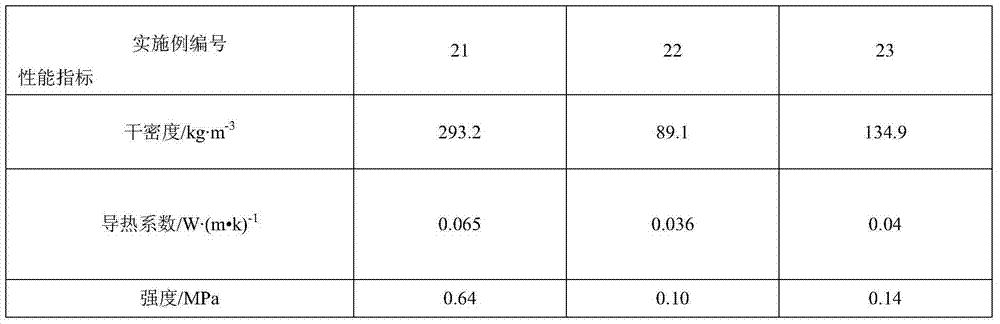

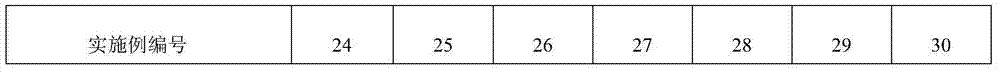

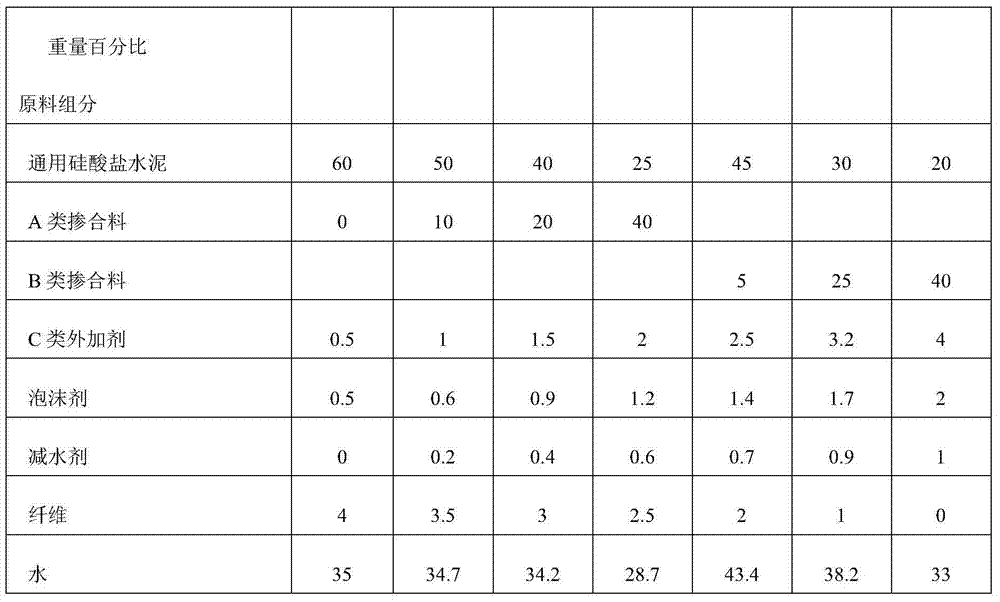

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

Tunnel fire retardant coating and preparation process and construction process thereof

InactiveCN101880145ASimple processImprove water retentionSolid waste managementPortland cementAluminum silicate

The invention provides a powdery mixture of a multi-component tunnel fire retardant coating, which is prepared from 582 resin, Portland cement, sepiolite, ammonium dichromate, light calcium carbonate, aluminum silicate, fly ash hollow floating beads, wollastonite powder, argil, cellulose ether, a concrete expanding agent, tin oxide and polypropylene fiber. The powdery mixture is prepared by throwing the fire retardant coating into a V-shaped forced mixer according to the proportion of the components; stirring the mixture for 10 to 15 minutes to prepare the powdery mixture; stirring water and the fire retardant coating powder in a weight ratio of 0.8-0.85 into thick paste; and spraying a tunnel from the waist to the top with spray painting equipment to reach the predetermined thickness.

Owner:成都威邦科技有限公司

Ultra-lightweight concrete and preparation method thereof

The invention relates to ultra-lightweight concrete and a preparation method thereof. The ultra-lightweight concrete is prepared from the following components in parts by weight: 100 parts of a cementing material, 40 to 45 parts of water, 0.45 to 0.55 part of a water-reducing agent, 10 to 15 parts of latex, 0.35 to 0.45 part of polyvinyl alcohol fiber, and 68 to 88 parts of hollow glass microbeads. During preparation, the materials are prepared first; the cementing material, water, the water reducing agent and the latex are added and stirred; then polyvinyl alcohol fiber and the hollow glass microbeads are added in sequence; injection molding and demoulding are carried out to obtain a semi-product; the semi-product is put into a curing chamber for standard curing, so that the ultra-lightweight concrete is obtained. Compared with the prior art, the ultra-lightweight concrete and the preparation method have the advantages that industrial waste slags are sufficiently utilized to serve as a raw material; the prepared ultra-lightweight concrete is low in dry density, high in compressive strength, good in heat preservation and insulation effect, energy-saving, environment-friendly, and wide in application range.

Owner:TONGJI UNIV

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

Desulfurized-gypsum-base lightweight spraying gypsum mortar

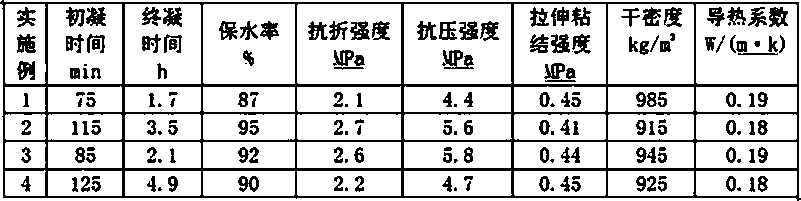

Disclosed desulfurized-gypsum-base lightweight spraying gypsum mortar is composed of the following compositions in parts by weight: 50-65 parts of desulfurized gypsum, 20-30 parts of building sand, 3-5 parts of vitrified microsphere, 10-20 parts of stone powder, 0.1-0.5 part of a retarder, 0.1-0.3 part of cellulose ether, 0.02-0.04 part of an air-entraining agent, and 0.05-0.1 part of starch ether. The desulfurized-gypsum-base lightweight spraying gypsum mortar employs mechanical spraying for construction, possesses the dry density less than 1000 Kg / m<3>, the heat-conduction coefficient of 0.20 W / (m*K) and the compressive strength lager than 4.0 MPa, and possesses the characteristics of being light in weight, low in heat-conduction coefficient, high in strength and suitable for mechanical spraying construction, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

Ultra-light-weight foam concrete and manufacturing method of same

InactiveCN102863193AReduce dry densityLow thermal conductivityCeramicwareFoam concreteThermal insulation

The invention relates to an ultra-light-weight foam concrete and a manufacturing method of the same. The manufacturing method comprises the following steps of: slowing stirring water, a cementing material, a water reducer and basalt fiber at a speed of 120rpm for 2 minutes after being mixed uniformly, quickly stirring the water, the cementing material, the water reducer and the basalt fiber at a speed of 240rpm for 2 minutes, mixing foam and cement paste, adding hydroxyethyl methyl cellulose into the mixture, stirring the mixture at a speed of 120rpm for 2 minutes to obtain paste, pouring the paste into a mould, putting the paste into a curing chamber for standard curing after being demoulded, and standing the paste for 28 days to obtain the ultra-light-weight foam concrete. Compared with the prior art, the ultra-light-weight foam concrete provided by the invention has the advantages of small dry density, low thermal conductivity and high compressive strength, can be made into a sheet material with a fire rating A and applied in an external thermal insulation system, and has the advantages of short curing time and no easy for surface pulverization.

Owner:WUHAN UNIV OF TECH

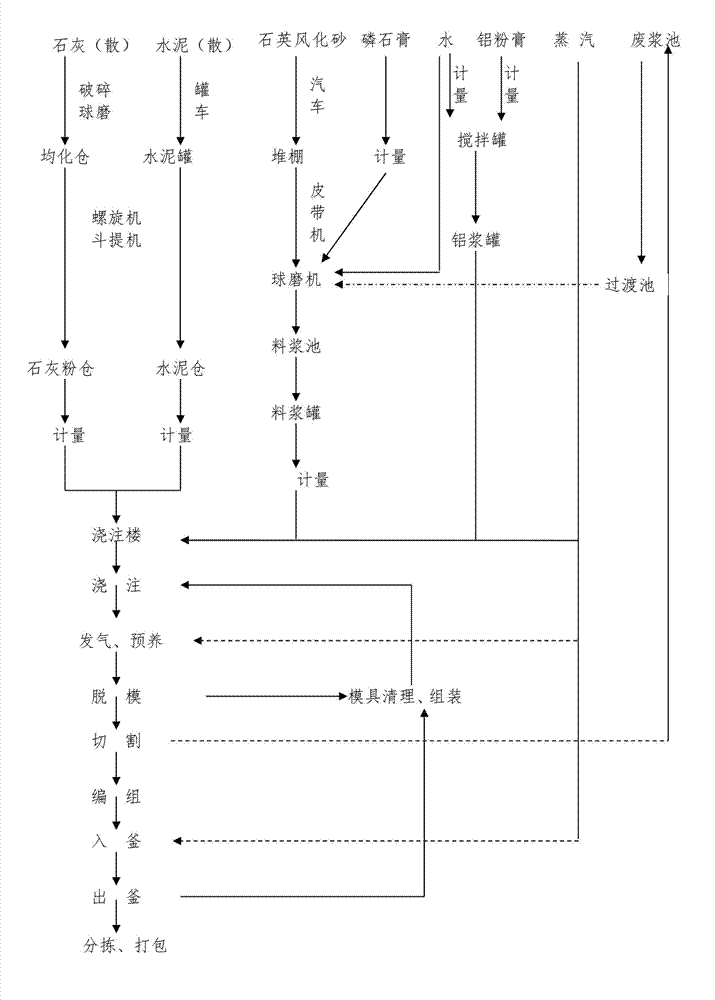

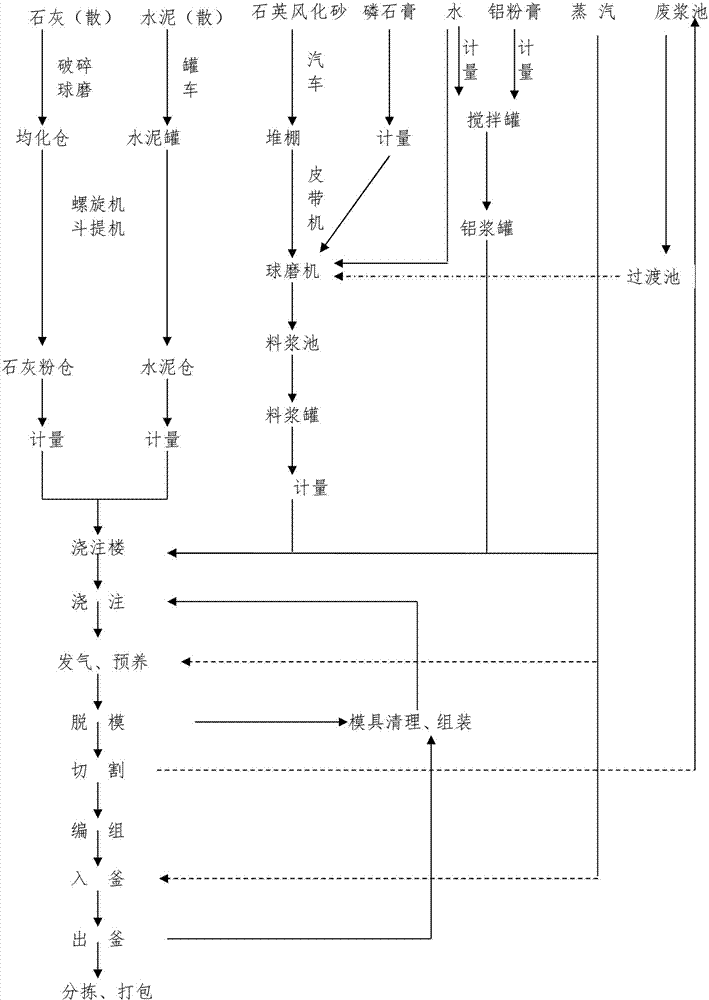

A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand and preparation method thereof

ActiveCN104774031AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention discloses an A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand. The A2.0 B04 grade high-performance autoclaved aerated concrete block is prepared from quartz eroded sand, cement, quick lime, industrial waste phosphogypsum, aluminum paste and water. The dry density of the concrete block is 415kg / m<3>, the cube crushing strength average value is 2.1 MPa, the single unit minimum value is 1.9 MPa, the ratio of splitting tensile is 0.19, the frost quality loss is 3.7%, the frost strength is 1.7 MPa, the heat conductivity coefficient (dry state) is 0.116 W / (m.K), the dry shrinkage value (standard value) is 0.22 mm / m and the percent of pass is greater than 98%. The raw material processing method is reasonable, the formula calculation is scientific, the production process is simple and the production waste can be recycled. The concrete block is a novel energy-saving and environmentally-friendly wall material and is suitable for industrial process.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Fireproof insulation board of aerated concrete of B02-level light sand

The invention discloses a fireproof insulation board of aerated concrete of B02-level light sand. The constituents and weight percentages of the fireproof insulation board are as follow: 45-55% of quartz sand, 12-16% of lime, 24-37% of cement, 5% of gypsum, 0.25-0.35% of aluminite powder and 0.2-0.6% of composite admixture, wherein the composite admixture is admixture with composite stabilizing, toughening and waterproof functions, and the constituents and weight percentages are as follow: 25-30% of sodium abietate, 22-26% of chlorinated paraffin, 24-28% of petroleum ether and 20-25% of organo-siloxane. The fireproof insulation board has the advantages that the fireproof insulation board compensates the disadvantages and defects of the prior art, overcomes the production difficulties, andimproves the casting stability when reducing dry density of the aerated concrete product of the sand, so as to conveniently transport and construct the product, and meet huge demands of the construction market and energy conservation and environmental protection requirements of people on building materials in cities.

Owner:天津滨海天筑永利建材有限公司

Dedicated gypsum based self-leveling mortar for floor heating backfill

InactiveCN109516755AReduce sensitivityFacilitate construction quality controlAluminum silicateMetakaolin

The invention belongs to the technical field of building materials and specifically discloses dedicated gypsum based self-leveling mortar for floor heating backfill. The dedicated gypsum based self-leveling mortar is prepared from water and powder, wherein the powder is prepared from the following ingredients in mass fraction: 5 to 30% of anhydrous fluorine gypsum, 5 to 30% of phosphorus buildinggypsum, 0.5 to 10% of alpha-high strength gypsum, 20 to 50% of fine sand, 5 to 20% of light calcium carbonate, 1 to 8% of cement, 0.01 to 1% of active roasted metakaolin, 0.1 to 2% of lime, 0.1 to 2%of lithium based bentonite, 0.1 to 1% of nano calcium sulfate whisker, 0.1 to 0.5% of magnesium aluminum silicate, 0.1 to 1% of sodium sulfate, 0.01 to 0.05% of hydroxypropyl starch ether, 0.1 to 0.5%of modified amino acid gypsum retarder and the like; the mass ratio of the water to the powder is (0.28 to 0.35) to 1. When the self-leveling mortar is prepared, a lot of solid waste can be consumed;furthermore, the ground construction efficiency and the ground flatness of buildings are improved.

Owner:HENAN QIANGNAI NEW MATERIALS CO LTD

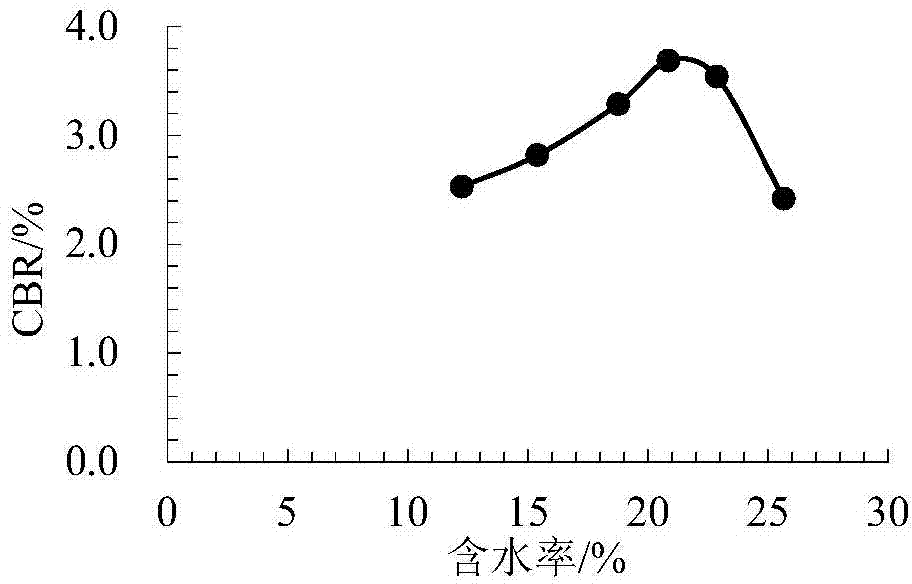

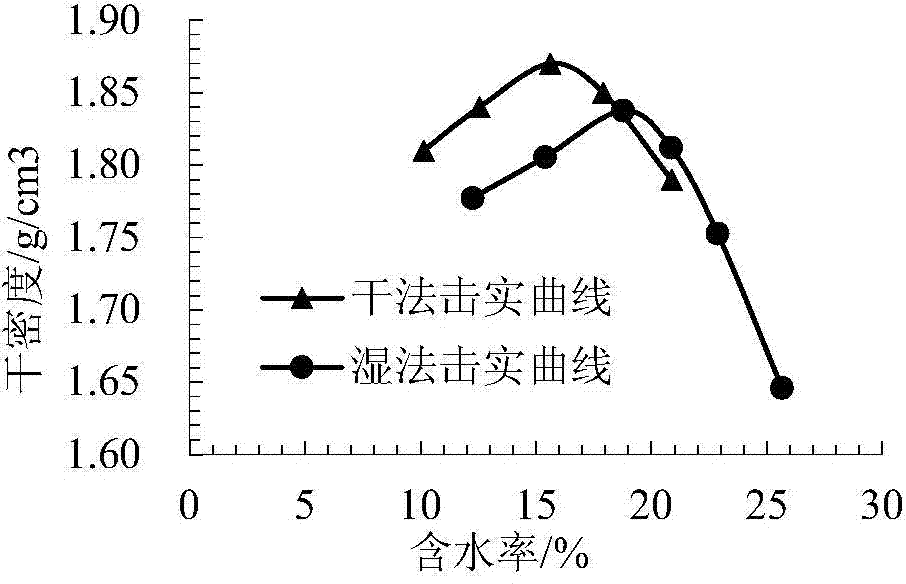

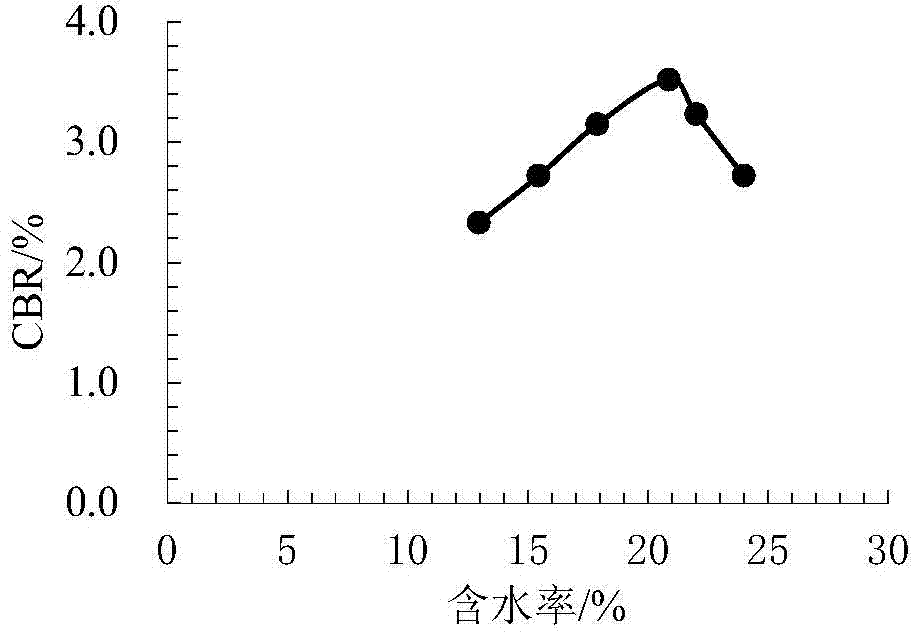

Method for compacting expansive soil roadbed

ActiveCN104120640AImprove bearing capacityImprove water stabilityRoadwaysSoil preservationSoil scienceNatural water

The invention discloses a method for compacting an expansive soil roadbed. The method comprises the following steps: preparing test pieces by adopting a wet process, testing the CBR of the test pieces different in water contents one by one, drawing a CBR-water content curve to obtain a curve for showing the change of the CBR of expansive soil along with the change of the water contents omega 1, omega 2, omega 3, omega 4 and omega 5, selecting a point with the CBR value being greater than or equal to 3% in the curve, wherein the water content omega of the expansive soil corresponding to the point is used as a control water content of field compacted soil, and obtaining the soil sample dry density corresponding to omega by performing a compaction test, wherein the soil sample dry density corresponding to omega is used as a roadbed compacting control dry density rho. Through the method, the expansive soil with the relative high natural water content easily achieves the compaction control water content and dry density, so that the purposes of fully, reasonably and directly using expansive soil filler, guaranteeing the construction quality of the expansive soil roadbed and quickly constructing can be achieved. The method is simple, convenient to operate, good in water stability, suitable for compacting soil roadbeds manufactured by poor fine-grained soil such as expansive soil, high liquid limit soil, and red clay, and capable of greatly increasing the utilization rate of the poor soil filler.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Damping sound-insulating spraying mortar

The invention discloses a damping sound-insulating spraying mortar. The damping sound-insulating spraying mortar is a bagged damping sound-insulating dry-blend spraying mortar prepared through mixing of an inorganic cementitious material, a filling material, an organic cementitious material and an additive under stirring; and the motor is stirred on site and uniformly sprayed on a base layer by using a spray coater. The motor comprises, by weight, 25 to 35 parts of cement, 5 to 15 parts of fly ash, 25 to 50 parts of fine and light aggregate, 10 to 40 parts of rubber powder, 0.6 to 5 parts of redispersible powder, 0.1 to 0.3 part of methylcellulose ether, 0.02 to 0.1 part of short fiber and 0.01 to 0.1 part of a water reducer. The damping sound-insulating spraying mortar can improve the sound reduction index of a wall and a ceiling when sprayed on the wall and the ceiling, and can replace a leveling layer of a floor and improve the impact sound reduction index of the floor when sprayed on the floor; and the damping sound-insulating spraying mortar can totally cover a variety of special-shape structures to form an effective sound-insulating layer and can be constructed in a variety of complex environments with narrow space.

Owner:XIAMEN JIADA GREEN CONSTRUCION ENG CO LTD

Carbon-based composite building wave absorption and heat preservation material and preparation method thereof

The invention discloses a carbon-based composite building wave absorption and heat preservation material and a preparation method thereof. According to the preparation method, carbon-based wave absorbing agent, common silicate cement, expanded and vitrified small balls, re-dispersible latex powder, hydroxypropyl methyl cellulose, wood fiber, polypropylene fiber, surfactant, foam stabilizer, waterreducing agent, coupling agent, water and the like are adopted; and the material is obtained by adopting the steps of stirring, pouring molding, curing and the like. The material has the advantages of good wave absorption performance and heat insulation performance, low apparent density, low cost, high fire resistance, durability and the like, and is easy to construct. The material can be used for pouring roofs and walls of buildings, so that aims of electromagnetic radiation protection and energy conservation of the buildings are fulfilled.

Owner:CHONGQING UNIV

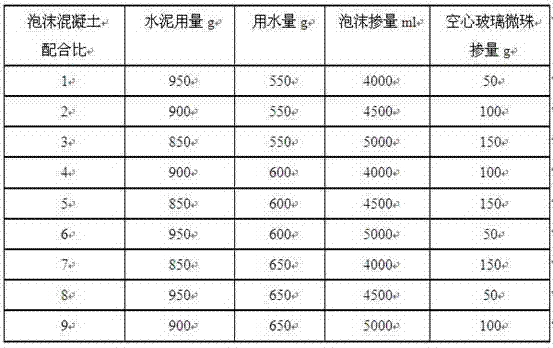

Preparation of hollow glass bead foam concrete

InactiveCN102924022AReduce dry densityImprove thermal insulation performanceCeramicwareFoam concreteAluminate

The invention provides a foam concrete insulation material which is prepared by blending hollow glass bead partially-replaced cement and foaming agent and a preparation method of the foam concrete insulation material. The insulation material comprises components, by weight, of 5%-15% of hollow glass bead partially-replaced cement and foaming agent with 1000g of rapid hardening sulphoaluminate cement as a standard, the water-binder ratio is 0.55-0.65, and the volume of foam mixing amount is 12.5-17.5 times of the volume of cement. In a preparation process, a neat paste blender is used for evenly blending cement slurry, then hollow glass beads are gradually added, half of residual mass of the hollow glass beads is added, foams are added after slow and even blending, and molding is carried out. The hollow glass beads have the advantages of light weight, high compression strength, low thermal coefficient, good flowability and the like, and compression strength and balance performance of the prepared foam concrete can be guaranteed under a precondition that the dry density is lower than 190kg / m3.

Owner:SHENYANG JIANZHU UNIVERSITY

Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

InactiveCN107602106AImprove fire insulation and weather resistanceImprove fire performanceCeramicwarePore distributionEnvironmental resistance

The invention provides a graphene-based foamed ceramic insulation wallboard, which is made of the following components: potassium sodium feldspar, ceramic waste residue, graphene, vermiculite, high-temperature co-solvent, expanded graphite, zirconia, clay, stable agent and debonding agent. Using potassium sodium feldspar and ceramic waste slag as the base material, adding graphene and vermiculite to make the board more lightweight, high-strength, thermal insulation, and improve the performance of the board such as fire resistance, insulation and weather resistance, using expanded graphite as a foaming agent, using high temperature The foaming process can better control the density, pore distribution and pore size of the board, achieve better heat preservation and light weight effects, and make a board with remarkable anti-aging, corrosion resistance, heat insulation, sound insulation, waterproof and impervious, fireproof and fireproof. , lightweight, high-strength, non-cracking, green and environmental protection and other comprehensive performance in one foam lightweight wallboard.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Low-density aerated concrete product and preparation method thereof

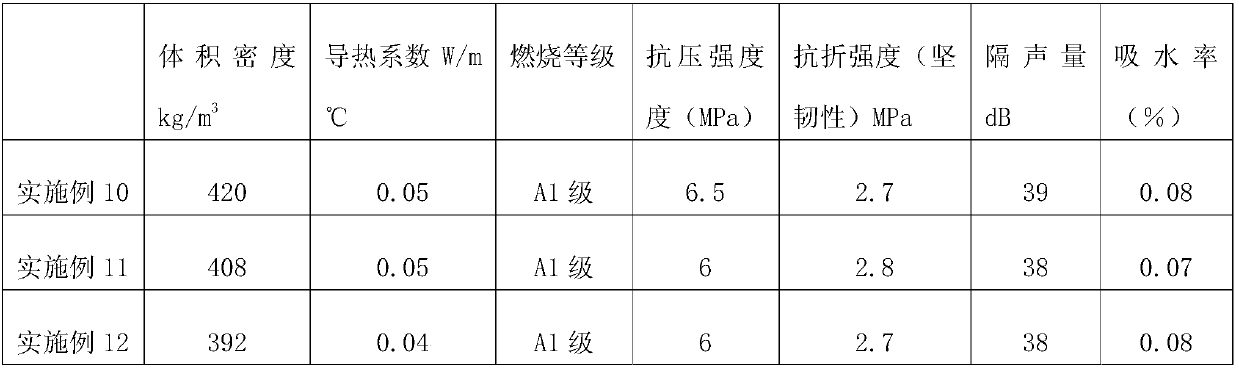

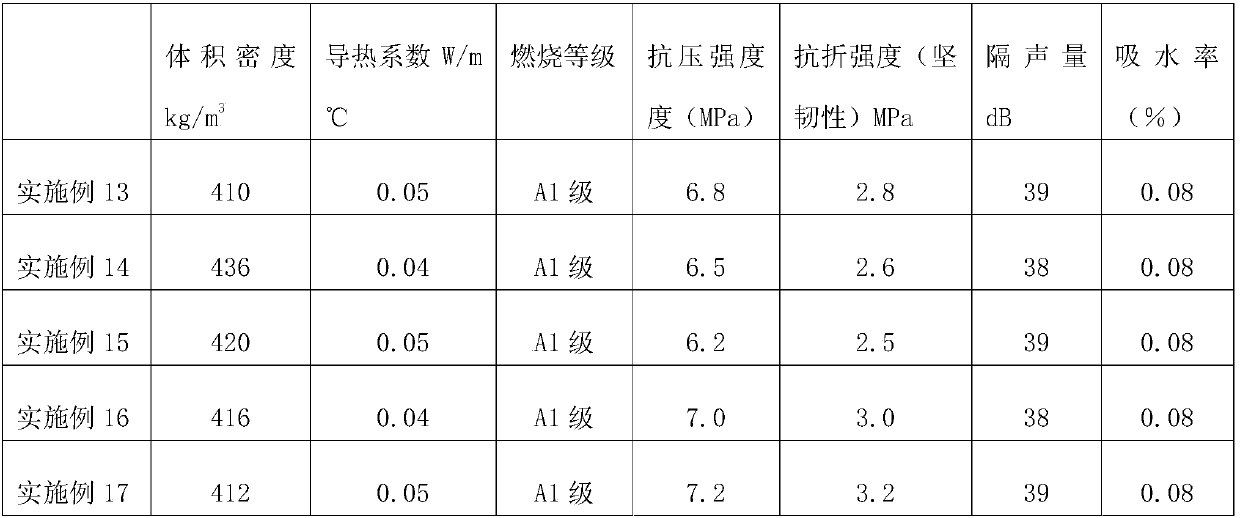

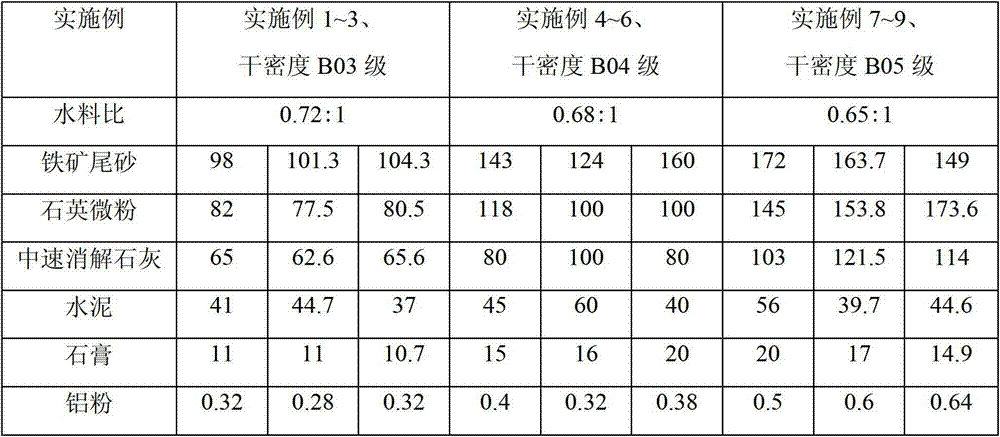

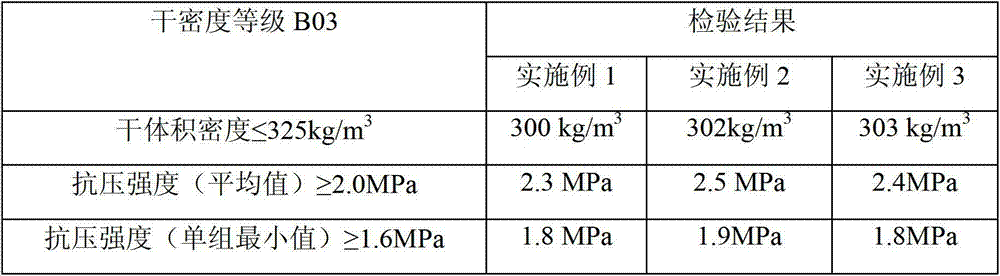

The invention discloses a low-density aerated concrete product and a preparation method thereof, and belongs to the technical field of building materials. The preparation method adopting quartz micro powder and iron core tailing, which are respectively 25%-35% and 30%-40% of a dry material, as the primary materials comprises the following steps of: adding cement and lime for cementing; initiating by aluminum powder; and adjusting the component proportion and the steam-curing environment to prepare a light high-strength aerated concrete product with desiccated bulk density of 300kg / m<3>-525kg / m<3> and absolute-dry compressive strength of 2.0 MPa-3.0 MPa. According to the preparation method disclosed by the invention, low-carbon, environment-friendly and energy-saving production concept is adopted, and the quartz micro powder and iron ore tailing, which are discarded after quartz sand ore-dressing, are adopted as the primary materials for producing the low-density autoclaved aerated concrete product as the wall self-insulation material.

Owner:山东高阳建材有限公司

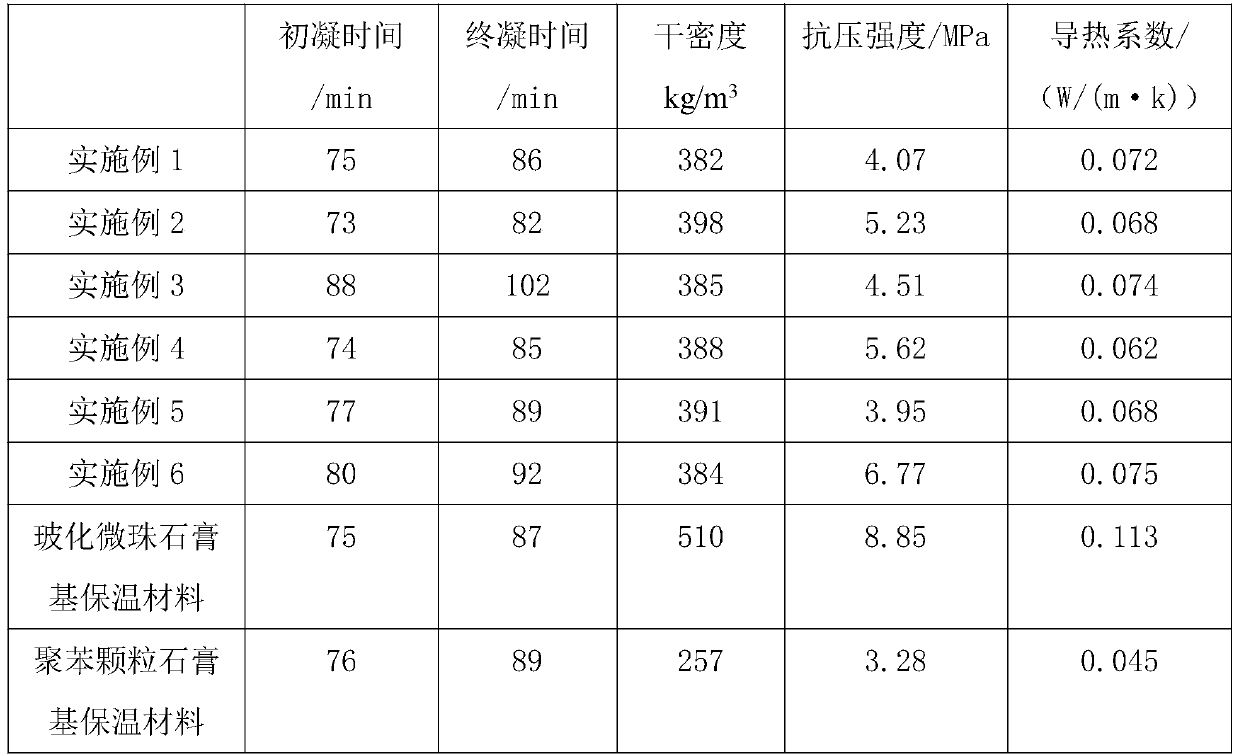

Gypsum-based composite lightweight thermal-insulation mortar and preparation method thereof

The invention provides gypsum-based composite lightweight thermal-insulation mortar. The mortar comprises, by weight, 60-80 parts of gypsum powder, 1-2 parts of polyphenyl granules, 10-15 parts of glazed hollow beads, 5-10 parts of cement, 1-2 parts of redispersible latex powder, 0.2-0.6 part of a water-retaining agent, 0.2-0.6 part of a gypsum retarder, 0.3-0.8 part of a water reducer, 0.2-0.8 part of polypropylene fiber and 60-80 parts of water. The glazed hollow beads and the polyphenyl granules are mixed by selecting a proper grain composition and then combined with semi-hydrated gypsum, apreparation mode is simple, the consumption of a gel material is reduced, the cost is low, the dry density is reduced, the mortar is high in anti-cracking performance, low in shrinkage deformation, high in ductility and good in construction performance, the self-compactness is good, and the heat preservation performance is excellent.

Owner:NANJING UNIV OF TECH

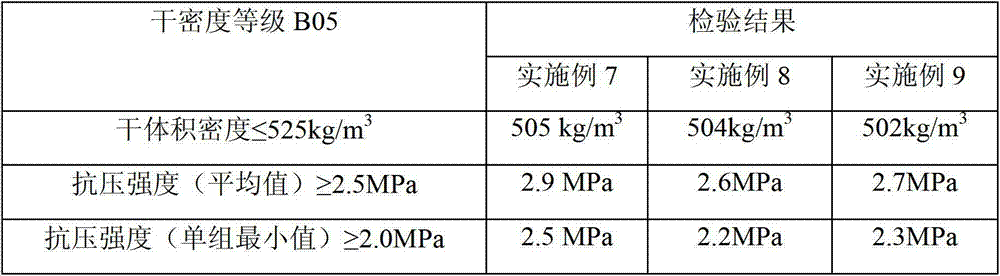

A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand, and making method thereof

ActiveCN104844106AInhibits digestive reactionsResolve fast digestionCeramicwareIndustrial wasteAluminium

The invention provides an A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand. The high-performance A3.5 B05 grade autoclaved aerated concrete block is made by using the quartz weathered sand, cement, quicklime, industrial waste phosphogypsum, aluminum powder paste and water as raw materials. The dry density of the block is 509kg / m<3>, the average cubic compressive strength of the block is 3.6MPa, the single component minimum of the block is 3.2Mpa, the split-to-compression ratio is 0.20, the mass loss after freezing is 2.8%, the strength after freezing is 3.1Mpa, the heat conduction coefficient (dry state) is 0.1251W / (m.K), the drying shrinkage value (standard process) is 0.32mm / m, and the qualified rate is greater than 98%. The method has the advantages of reasonable treatment of raw materials, scientific formula calculation, concise production flow, recycling of production wastes. The block is a novel energy saving and environmental protection wall material, and can be industrially produced.

Owner:HUBEI YITONG CONSTR ENG CO LTD

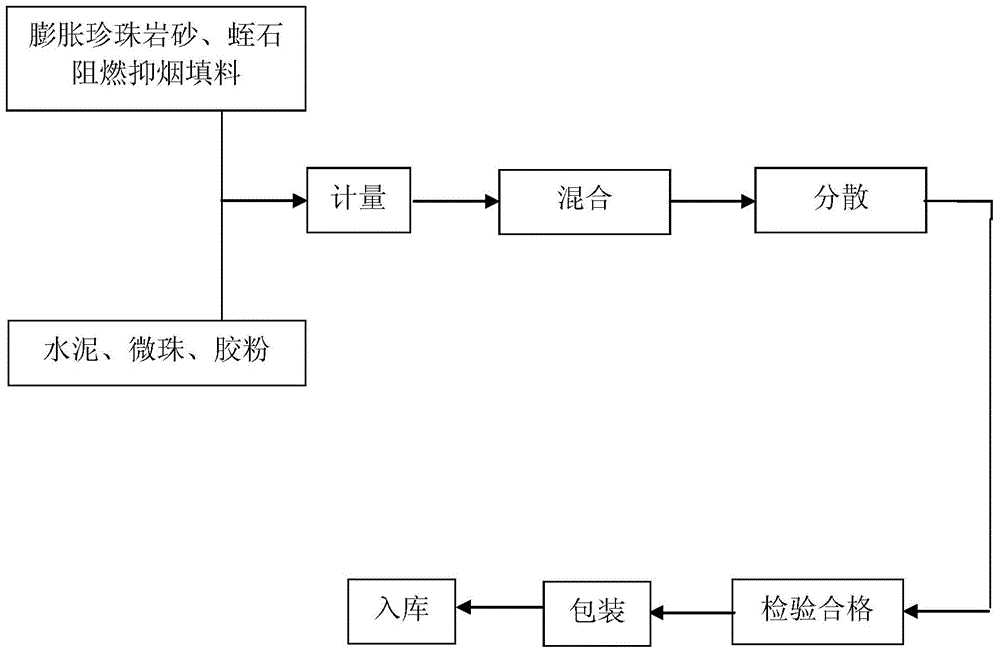

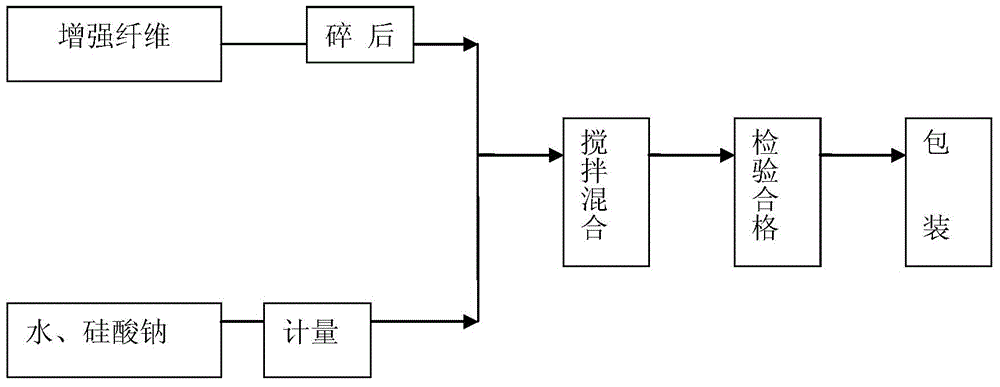

Smoke-suppressing type outdoor flame retardant steel structure fireproof coating

The invention provides smoke-suppressing type outdoor flame retardant steel structure fireproof coating and a manufacturing method. The coating comprises an adhesive, powder, aggregate, a flame retardant, a smoke-suppressing agent and a reinforcing material. The powder except cement and the adhesive are powdered and sieved, reinforcing fiber is uniformly dispersed, and all the additives, the powder and the cement are mixed according to a ratio, activated and fully stirred. A thermal insulation property of the coating is achieved by utilization of heat reflection of added hollow microbeads and characteristics of expanded perlite. Smoke-suppressing and flame retardant properties of the coating are achieved by utilization of characteristics of the added flame retardant and the added smoke-suppressing agent. The coating has rigidity of the cement and flexibility of polymer, and coatings of the coating are low in density, good in adhesion property, water proofness and flexibility, high in adhesive force, not liable to be affected with damp, not liable to powder and not liable to shed.

Owner:MARINE CHEM RES INST

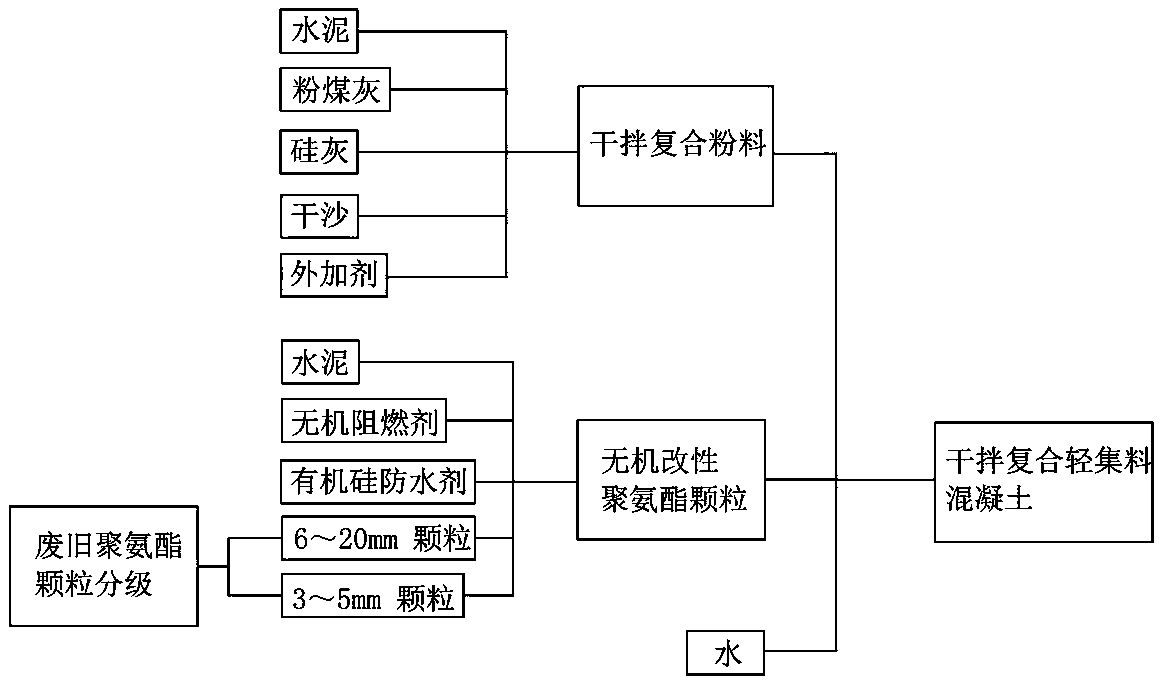

Dry-mixed composite light aggregate concrete based on inorganically modified polyurethane particles

The invention relates to dry-mixed composite light aggregate concrete based on inorganically modified polyurethane particles and a preparation method of the dry-mixed composite light aggregate concrete. The concrete is prepared from raw materials in parts by weight as follows: 38-135 parts of the inorganically modified polyurethane particles, 162-485 parts of cement, 30-127 parts of fly ash, 23-50parts of mineral powder, 3-50 parts of silica fume, 37-740 parts of dry sand, 4.6-19.7 parts of an admixture and 105-380 parts of water. The preparation method comprises the following steps: 1, wastepolyurethane particles are subjected to grain size grading; 2, the graded waste polyurethane particles are inorganically modified; 3, the cement, the fly ash, the silica fume, the mineral powder andthe admixture are added to a dry powder stirrer for uniform stirring and mixing, and dry-mixed composite powder is obtained; 4, the dry-mixed composite powder is mixed with the inorganically modifiedpolyurethane particles, water is added for stirring, and the dry-mixed composite light aggregate concrete is prepared.

Owner:河南格林循环电子废弃物处置有限公司

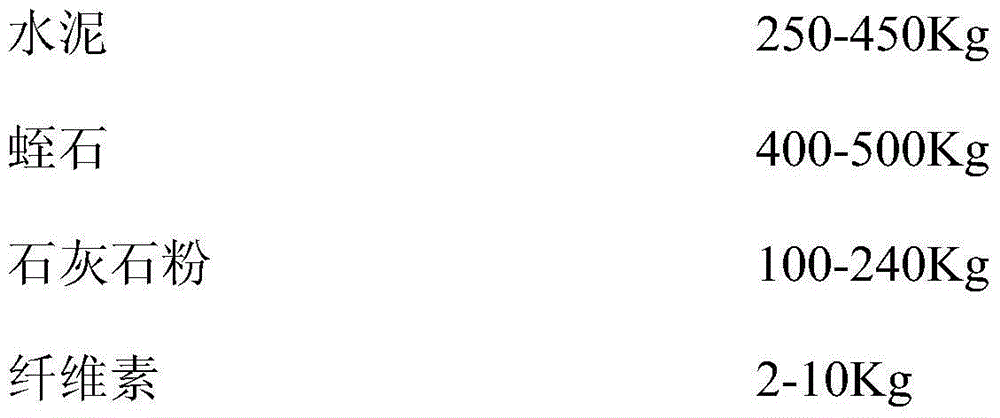

Tunnel lightweight inorganic fireproof composite material

ActiveCN101200380AMeet construction requirementsSignificantly reduce drynessLayered productsFiberFireproofing

The invention provides a light inorganic fireproofing composite material for tunnel, which is compounded by three layers of materials from inside to outside; the first layer is spray inorganic fireproofing material, the components of which comprise inorganic fireproofing fiber, expanded vermiculite powder, expanded graphite powder and ordinary Portland cement; the second layer is surface fireproofing material, the components comprises ordinary Portland cement, mica powder, gypsum and talcum powder; the third layer is fireproofing decorative material, which is a fire-retardant single-side composite aluminum foil. The composite material has the advantages that: the fire endurance is high; the thermal conductivity in hydrocarbon fire scene is extremely low; the fireproofing result is excellent; the self quality loss in fire is less without melting and dropping; the weight is light; the weathering is good; the sound-absorbing is good and the high-frequency drying reduction is obvious; the cost is low; the construction strength is less and the charge is low; furthermore, the ornament is good and the surface is smooth and beautiful surface, thereby the invention can mainly be used in the fire protection for the tunnel wall.

Owner:应急管理部四川消防研究所

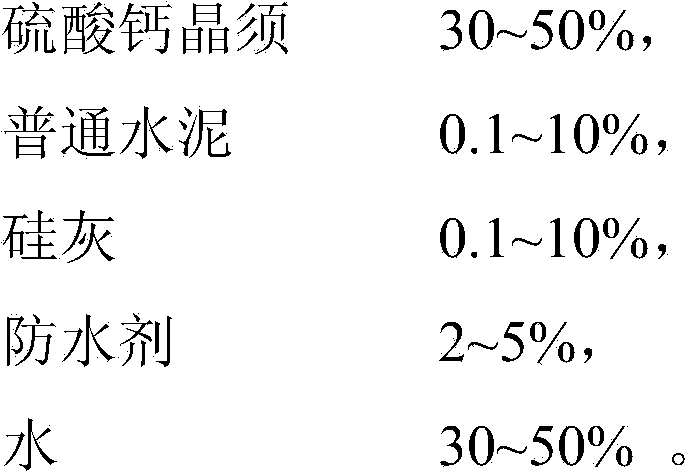

Inorganic calcium sulfate whisker heat retaining panel and preparation method thereof

The invention discloses an inorganic calcium sulfate whisker heat retaining panel. The inorganic calcium sulfate whisker heat retaining panel is characterized by being prepared from the following raw materials in percentage by weight: 30-50% of calcium sulfate whisker, 0.1-10% of Portland cement, 0.1-10% of silica fume, 2-5% of water-proofing agent and 30-50% of water. The invention also discloses a preparation method of the inorganic calcium sulfate whisker heat retaining panel. The inorganic calcium sulfate whisker heat retaining panel provided by the invention has the advantages of Al-grade fireproofing, light weight, high strength, excellent waterproof property, low heat conductivity coefficient and the like and is a high-quality heat retaining panel for building external walls, which has practical application value. According to the preparation method, a one-step molding method is adopted, and the technological processes comprise dry material premixing, liquid material premixing, pulping, standing still, molding, demolding, drying, high-temperature thermal treatment and the like.

Owner:SHANGHAI UNIV

Graphene and stone tailing based foaming light heat insulation board and preparation method thereof

InactiveCN107721453AHigh hardnessImprove high temperature resistanceCeramic materials productionCeramicwarePore distributionFireproofing

The invention provides a graphene and stone tailing based foaming light heat insulation board. The graphene and stone tailing based foaming light heat insulation board is prepared from the following components of a stone tailing, clay, graphene, calcium carbonate, vermiculite, a high temperature cosolvent, expanded graphite, a stabilizer, a dispergator and a pigment. The heat insulation board usesthe stone tailing as the base material, the graphene and the vermiculite are added, then the board better achieves the advantages of light weight, high strength and heat insulation, the performancesof fireproofing, insulation and weatherproofing of the board are better improved, the expanded graphite is used as a foaming agent, the high temperature foaming process is used, the sectioned thermalinsulation mode is adopted in sintering, the hardness, the high temperature resistance and the flame retardance performance of the heat insulation board are improved, the density and the pore distribution of the board are better controlled, the better effects of heat insulation, light weight and high strength are achieved, and the heat insulation board further has the functional characteristics offireproofness, sound insulation, waterproofness, anti-aging, corrosion resistance, green and environmental protection.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Lightweight waterproof modified expanded perlite insulation board and production method thereof

The invention discloses a lightweight waterproof modified expanded perlite insulation board and a production method thereof. The modified expanded perlite insulation board comprises the following components in parts by weight: 25 to 40 parts of cement, 5 to 8 parts of fly ash, 2 to 5 parts of methyltrimethoxysilane, 5 to 10 parts of a polyacrylate emulsion, 50 to 70 parts of modified expanded perlite, 0.7 to 2.9 parts of sodium dodecyl benzene sulfonate, 5 to 10 parts of an additive, 1 to 3 parts of quicklime, 0.1 to 0.5 part of PP fiber, 0.5 to 2 parts of carbon fiber, 5 to 10 parts of kaolin, 4 to 10 parts of water glass and 10 to 20 parts of water. The modified expanded perlite insulation board provided by the invention uses cement, fly ash, kaolin, PP fiber and organic and inorganic matters as raw materials, so industrial and mineral waste materials are effectively utilized; meanwhile, no toxic and harmful substance is added, so greenness and environmental protection are achieved. The modified expanded perlite insulation board provided by the invention has the advantages of extensively available raw materials, low cost, simple production process, facilitation to operation, capability of meeting the demands of different building materials, and good social and economic benefits.

Owner:XINYANG CITY OF CRYSTAL ENG MATERIALS CO LTD

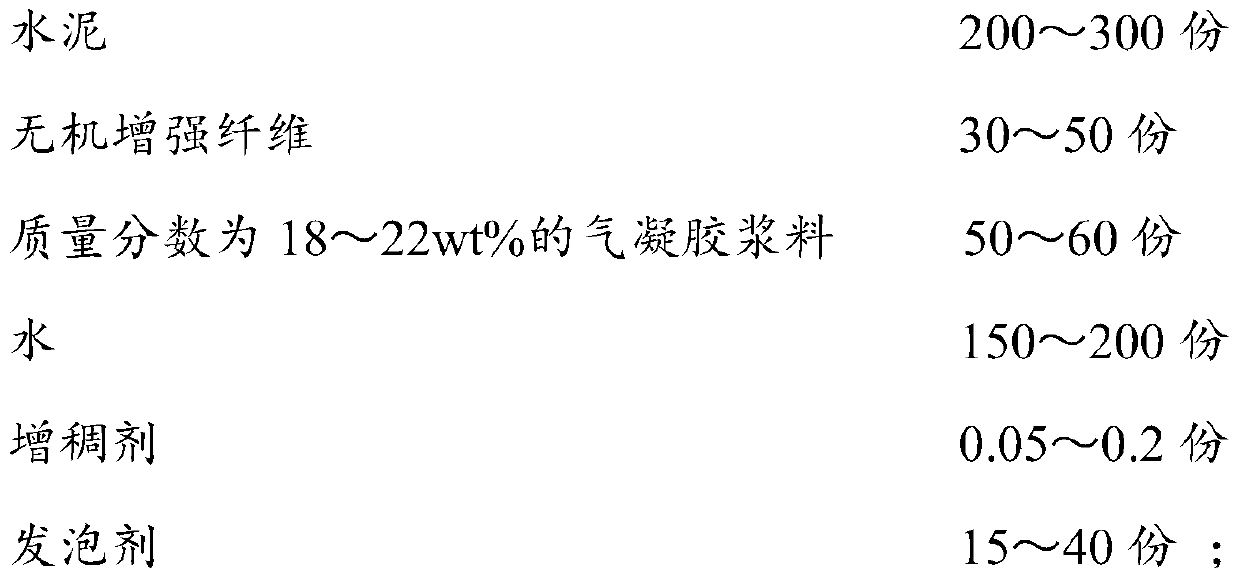

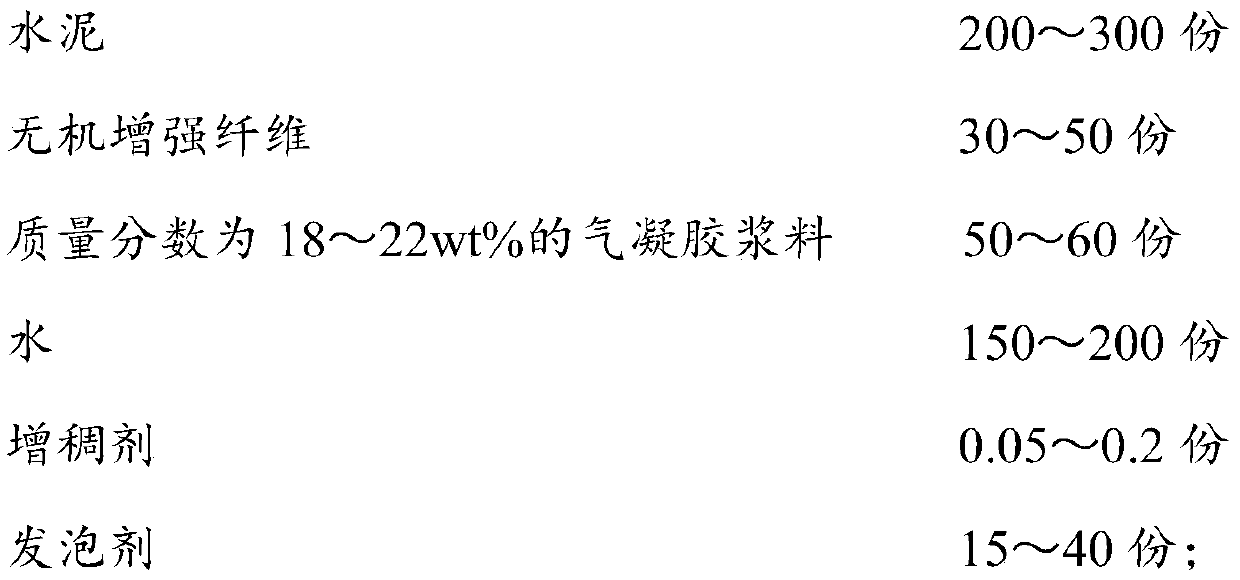

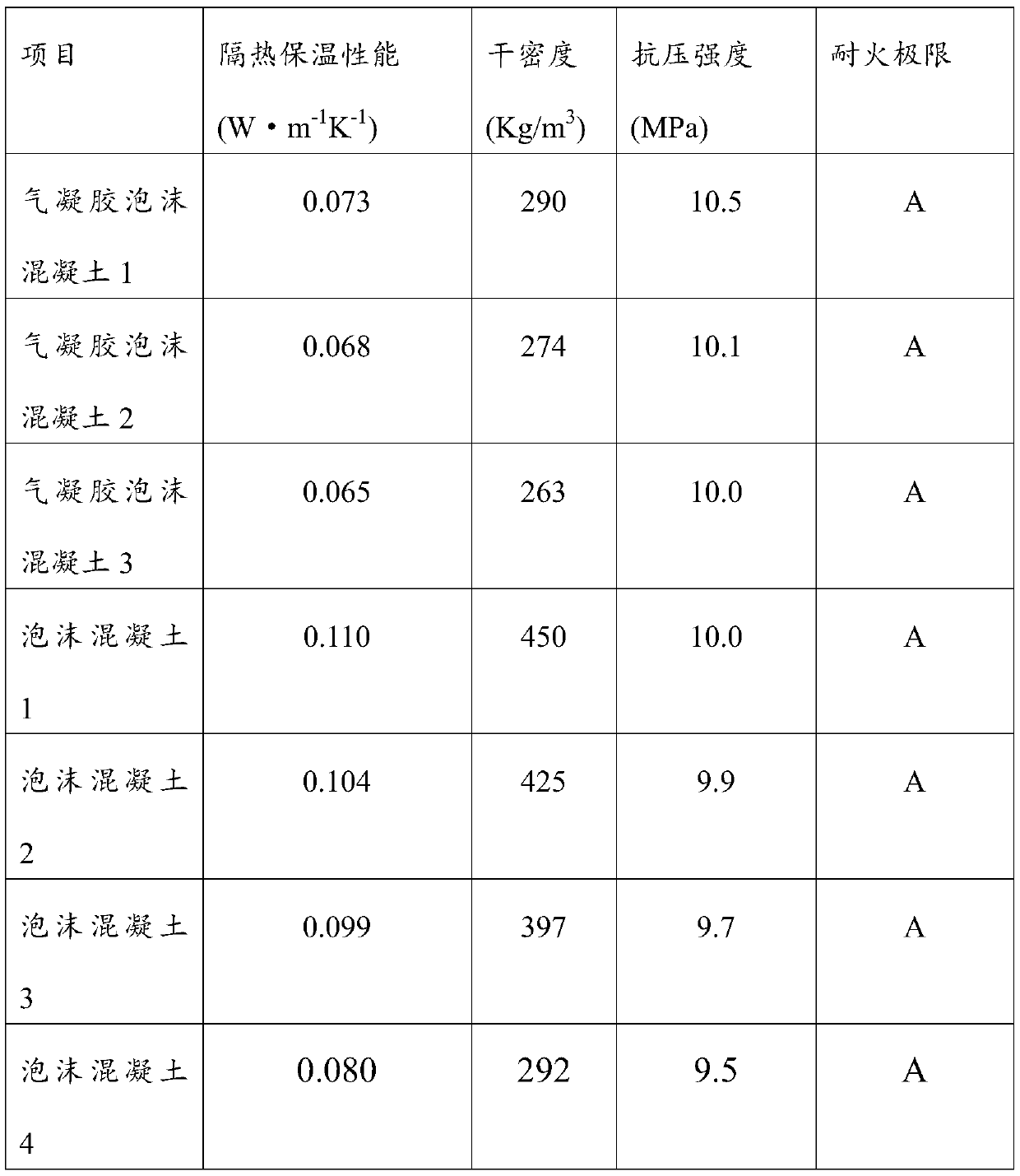

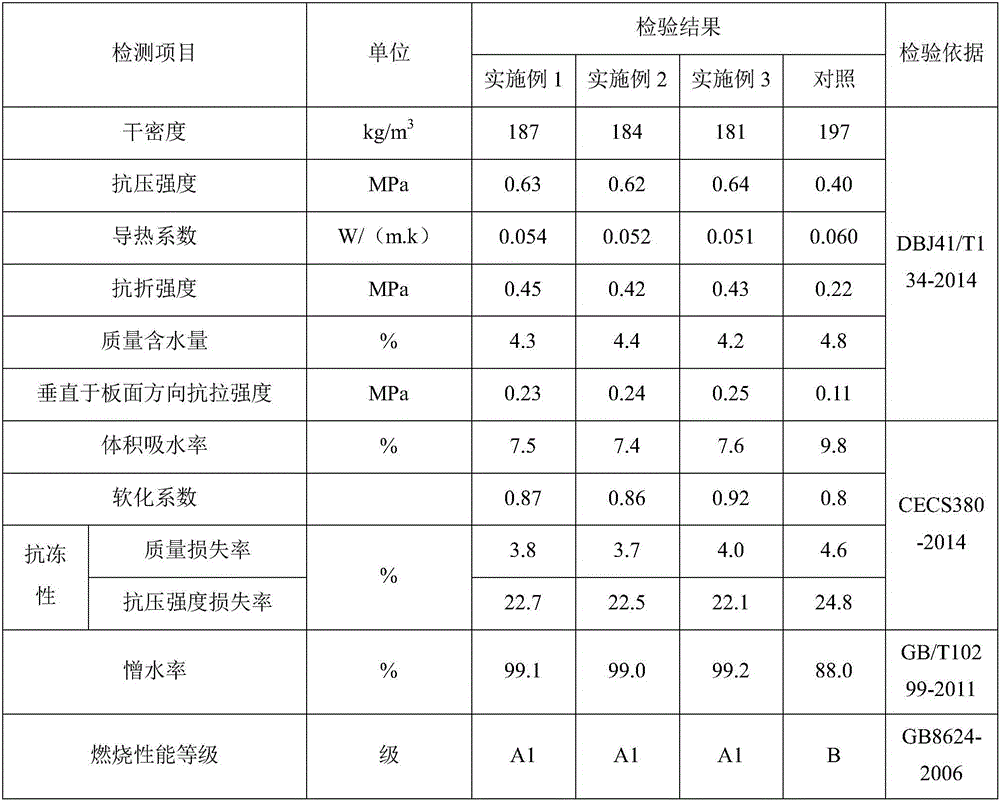

Aerogel foam concrete and preparation method and application thereof

InactiveCN110803938AImprove insulation effectImprove sound insulationCeramicwareFoam concreteCompressive resistance

The invention belongs to the field of building materials, and particularly relates to aerogel foam concrete and a preparation method and application thereof. Aerogel slurry is added into the concrete,on the premise that the compactness is not reduced, the heat insulation, heat preservation and sound insulation performance of the foam concrete can be enhanced, the dry density of the foam concreteis reduced, and the foam concrete with very small density, high formability and good compressive strength can be obtained under the condition that the porosity is low.

Owner:SHENZHEN AEROGEL TECH CO LTD

Mineral fiber enhanced modified expanded perlite insulation board and production method thereof

InactiveCN106186921AImprove fire performanceHigh strengthCeramic shaping apparatusFiberHazardous substance

The invention discloses a mineral fiber enhanced modified expanded perlite insulation board and a production method thereof. The mineral fiber enhanced modified expanded perlite insulation board comprises in parts by weight, 25-40 parts of cement, 5-8 parts of coal ash, 2-5 parts of methyltrimethoxysilane, 5-10 parts of polyacrylate emulsion, 3-5 parts of mineral fibers, 50-70 parts of modified expanded perlite, 0.7-2.9 parts of sodium dodecyl benzene sulfonate, 5-10 parts of additives, 1-3 parts of calcined lime, 0.1-0.5 part of PP (polypropylene) fibers, 1-2 parts of sodium silicate and 10-20 parts of water. The mineral fiber enhanced modified expanded perlite insulation board takes the cement, the coal ash, the mineral fibers and other organic and inorganic matters as raw materials, industrial and mining waste materials are effectively used, toxic and harmful substances are not added, and the insulation board is green and environmentally friendly.

Owner:XINYANG CITY OF CRYSTAL ENG MATERIALS CO LTD

Modified-expanded-perlite insulation board and production method therefor

The invention discloses a modified-expanded-perlite insulation board and a production method therefor. The modified-expanded-perlite insulation board is prepared from the following ingredients in parts by weight: 18-25 parts of cement, 5-8 parts of fly ash, 2-5 parts of triethoxysilane, 5-10 parts of polyacrylate emulsion, 50-70 parts of modified expanded perlite, 0.7-2.9 parts of sodium dodecylbenzene sulfonate, 5-10 parts of additive, 0.1-0.5 part of PP fibers and 10-20 parts of water. According to the modified-expanded-perlite insulation board disclosed by the invention, the cement, the fly ash and other organic and inorganic matters serve as raw materials, so that wastes of industry and mining are put into effective use; and hazardous and noxious substances are not added, so that the modified-expanded-perlite insulation board is green and environment-friendly. The modified-expanded-perlite insulation board disclosed by the invention is wide in source of raw materials, low in cost, simple in production process and easy in operation, can meet the requirements of different building materials and has good social and economic benefits.

Owner:XINYANG CITY OF CRYSTAL ENG MATERIALS CO LTD

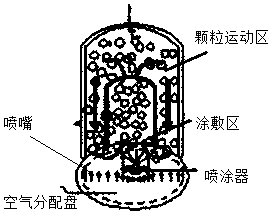

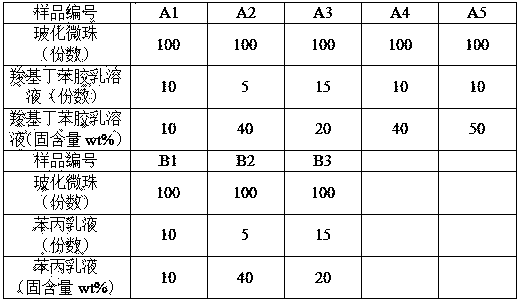

High-performance modified glass bead and surface modification method thereof

The invention discloses a high-performance modified glass bead and a surface modification method thereof. According to the surface modification method, the surface of the glass bead is covered by adopting carboxylic butadiene-styrene latex, so that the intrinsic strength of the glass bead is improved while the water absorption rate of the glass bead is reduced. The modified glass bead is applied to thermal insulation mortar, so that the consistency of the mortar is ensured, the water consumption of the thermal insulation mortar is reduced, the dry density is reduced, the specific strength is enhanced, the heat conduction coefficient is reduced, and the strength and insulation performance of the mortar are improved. Only a modifier is used in the surface modification method of the glass bead, the surface modification process can be finished by single equipment, namely a bottom spraying type fluidized bed, the process is simple, the manpower is reduced, and the method is suitable for large-scale production and application in a factory.

Owner:广州石井力展新型建筑材料有限公司 +2

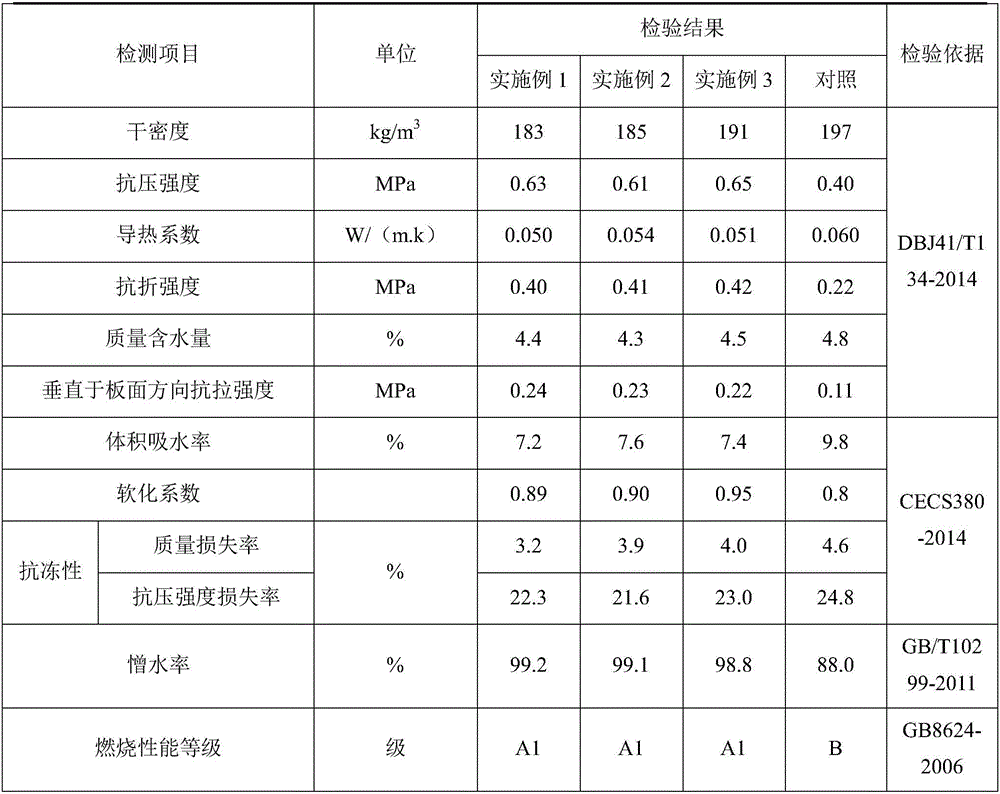

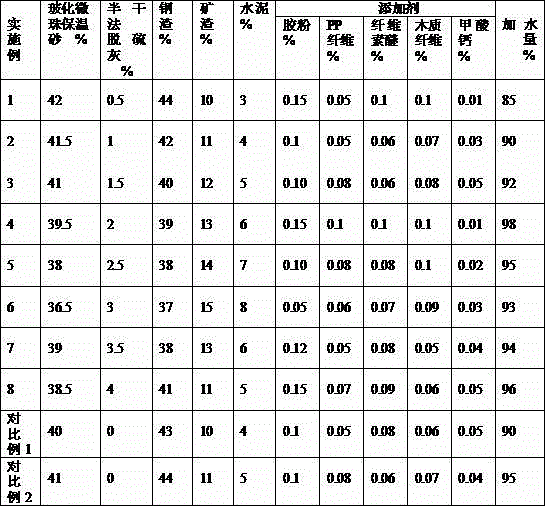

Thermal insulation mortar containing semidry method desulfurized fly ash and preparation method therefor

Provided is thermal insulation mortar containing semidry method desulfurized fly ash. The thermal insulation mortar containing semidry method desulfurized fly ash comprises the following raw materials, by weight, 10-15% of ore slag with a granularity of being less than or equal to 0.074mm, 36-42% of thermal insulation sands with a granularity of being less than 2mm, 0.5-4% of semidry method desulfurized fly ash with a granularity of being less than 1mm, 36-44% of steel slag with a granularity of being less than 2mm, 3-8% of cement and 0.2-0.5% of additives. In addition, water with a weight of being 85-100% of the total weight of the added glass bead thermal insulation sands is added. The preparation method is as follows: the semidry method desulfurized fly ash and the steel slag are dried; the semidry method desulfurized fly ash and the steel slag are crushed; the semidry method desulfurized fly ash, the steel slag, the cement, the ore slag and the additives are stirred and mixed; water is added and the mixture is stirred uniformly; glass bead thermal insulation sands are added and the mixture is stirred uniformly; packaging is carried out and the product is standby. The defect can be overcome that the stability is poor when steel slag is employed as an inorganic thermal insulation mortar materials, the pollution problem caused by desulfurized fly ash stockpiling can be solved effectively, and the desulfurized fly ash integration utilization is raised.

Owner:武钢集团有限公司

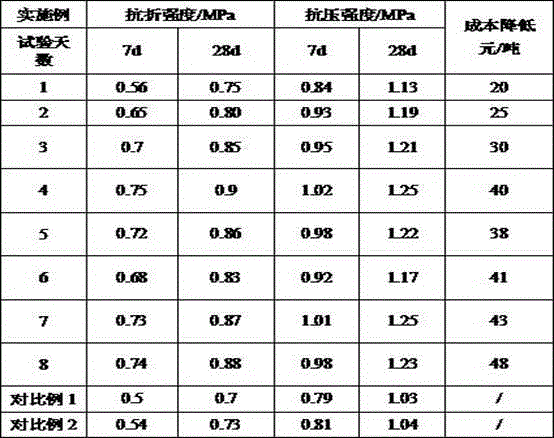

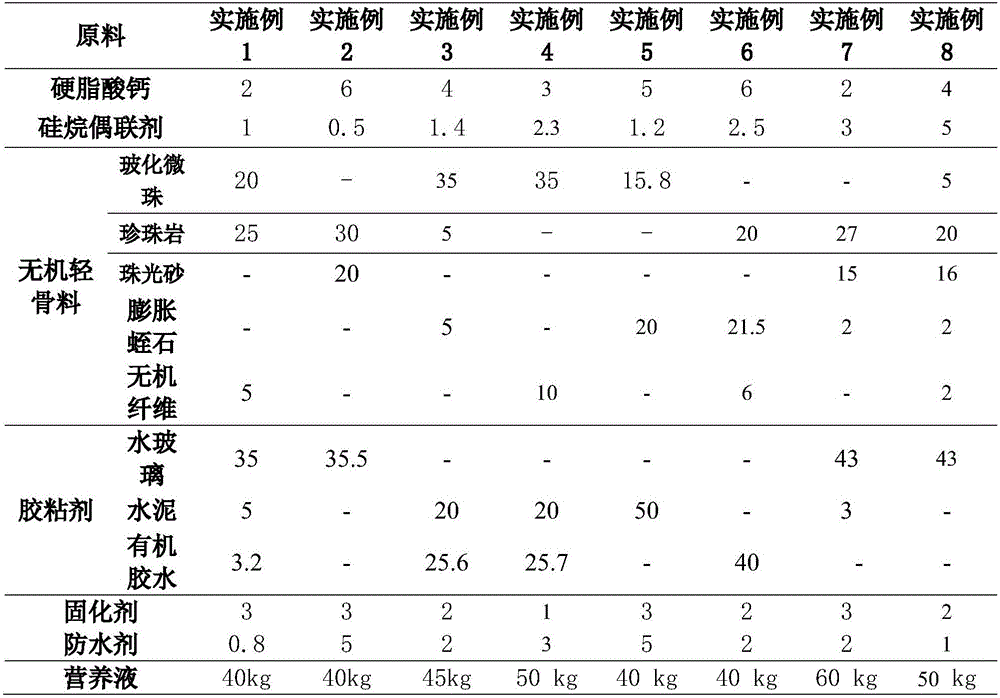

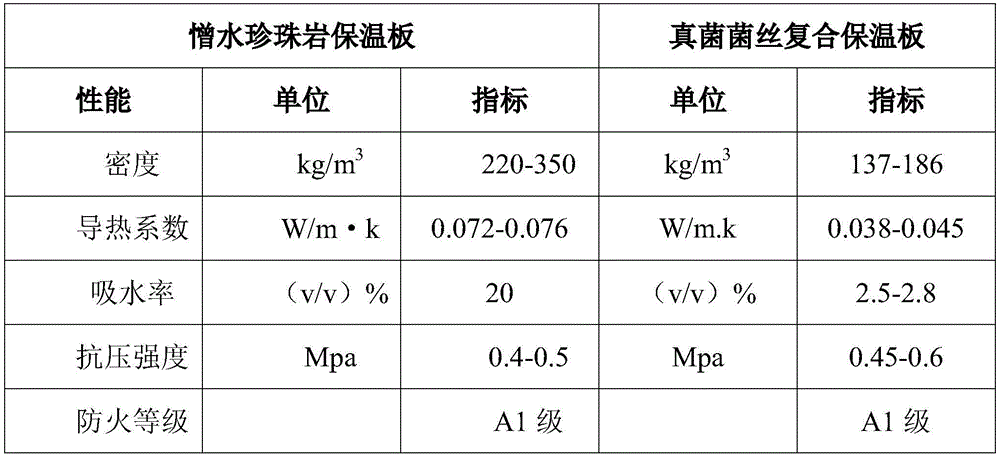

Fungal hypha composite thermal insulation board and preparation method thereof

InactiveCN106380166AImprove thermal conductivitySimple processFungiCrack resistanceThermal insulation

Belonging to the technical field of building materials, the invention relates to a preparation method of a thermal insulation material, in particular to a fungal hypha composite thermal insulation board and a preparation method thereof. The main raw material of the fungal hypha composite thermal insulation board is inorganic lightweight aggregate, the raw materials of the fungal hypha composite thermal insulation board include fungal hypha, the inorganic lightweight aggregate and a nutrient solution suitable for cultivation of fungal hypha are mixed uniformly to prepare a medium, the medium is employed to culture fungal hypha, and the obtained hypha mixture takes the place of the inorganic lightweight aggregate and is pressed to form a thermal insulation board. The thermal insulation board has the characteristics of excellent thermal insulation properties and crack resistance.

Owner:杭州欣阳保温节能建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com