High-performance modified glass bead and surface modification method thereof

A technology of vitrified microbeads and surface modification, which is applied in the field of inorganic thermal insulation materials, can solve the problems of incomplete vitrification sealing, high product brittleness, and easy cracks, etc., and achieve the improvement of mortar strength and thermal insulation performance, and the reduction of thermal conductivity. The effect of increasing the intrinsic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

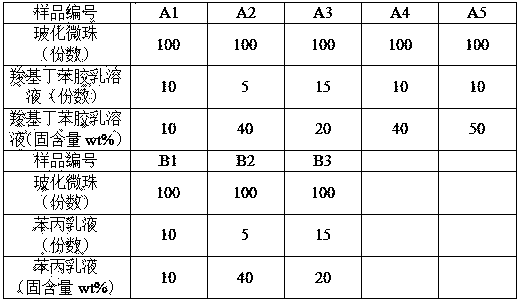

[0019] A high-performance modified vitrified microsphere comprises the following components in parts by weight: 100 parts of vitrified microspheres, and 5-15 parts of carboxylated styrene-butadiene latex solution.

[0020] Preferably, the bulk density of the vitrified microbeads is 110-120 kg / m 3 .

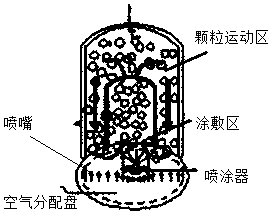

[0021] Preferably, the solid content of the carboxylated styrene-butadiene latex solution is 10-50%. A method for surface modification of high-performance modified vitrified microspheres, comprising the following steps: placing the vitrified microspheres in a bottom spray fluidized bed, the vitrified microspheres flow under the action of air flow, and carboxylated styrene-butadiene latex solution After being atomized by an intermediate sprayer, it is sprayed on the surface of the vitrified microspheres flowing through the coating area, and dried to obtain high-performance modified vitrified microspheres; the composition of the high-performance modified vitrified microspheres is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com