Method and apparatus for coating diamond-like carbon onto particles

A diamond and particle technology, which is applied in the field of coating diamond-like carbon on particles and equipment, can solve problems such as inability to promote ion bombardment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

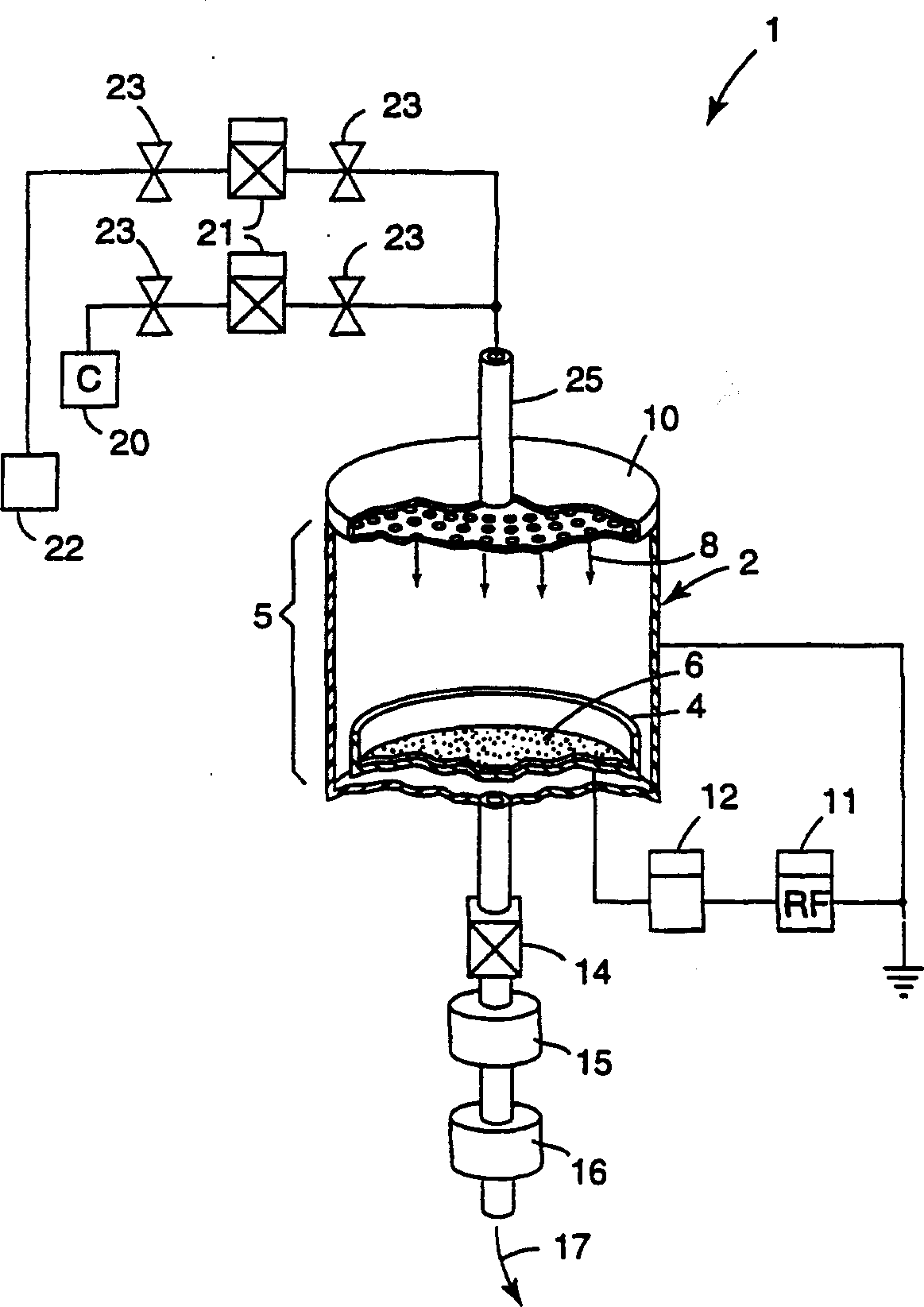

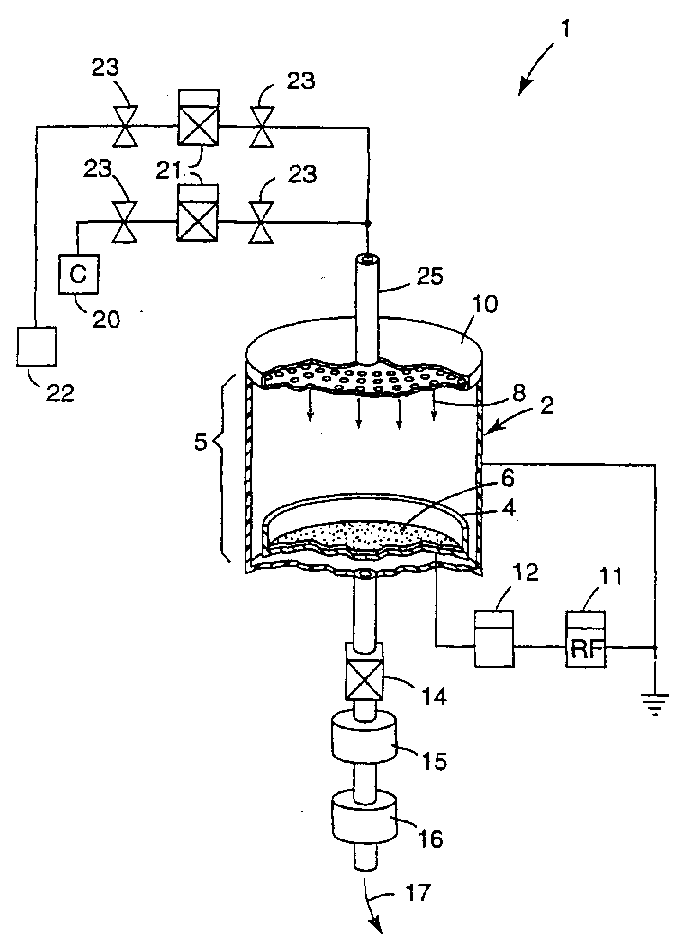

[0084] This example illustrates the deposition of DLN on oxide-coated phosphor particles, where the particles are placed on a vibrating plate in a capacitively coupled plasma reactor.

[0085] A commercially available parallel-plate capacitively coupled plasma reactor (model 2480 from PlasmaTherm, St. Petersburg, Fl) was modified for DLN deposition. The reactor has a grounded reaction chamber electrode containing a powered electrode approximately as figure 1 As shown, the difference is that the power-connected electrode includes both the aluminum disc 4 that puts the particles and the aluminum plate that is connected to the power supply under the disc. The aluminum disk is used as part of the electrode because it is conductive. 50 g of oxide-coated phosphor particles (available from Durel Corporation, Chandler, AZ, model 729 with 3000 Å thick SiO 2 :TiO 2 coating, particle size 25-30 μm). The pressure in the reactor was pumped down to below 0.65 Pa, and the temperature was...

Embodiment 2

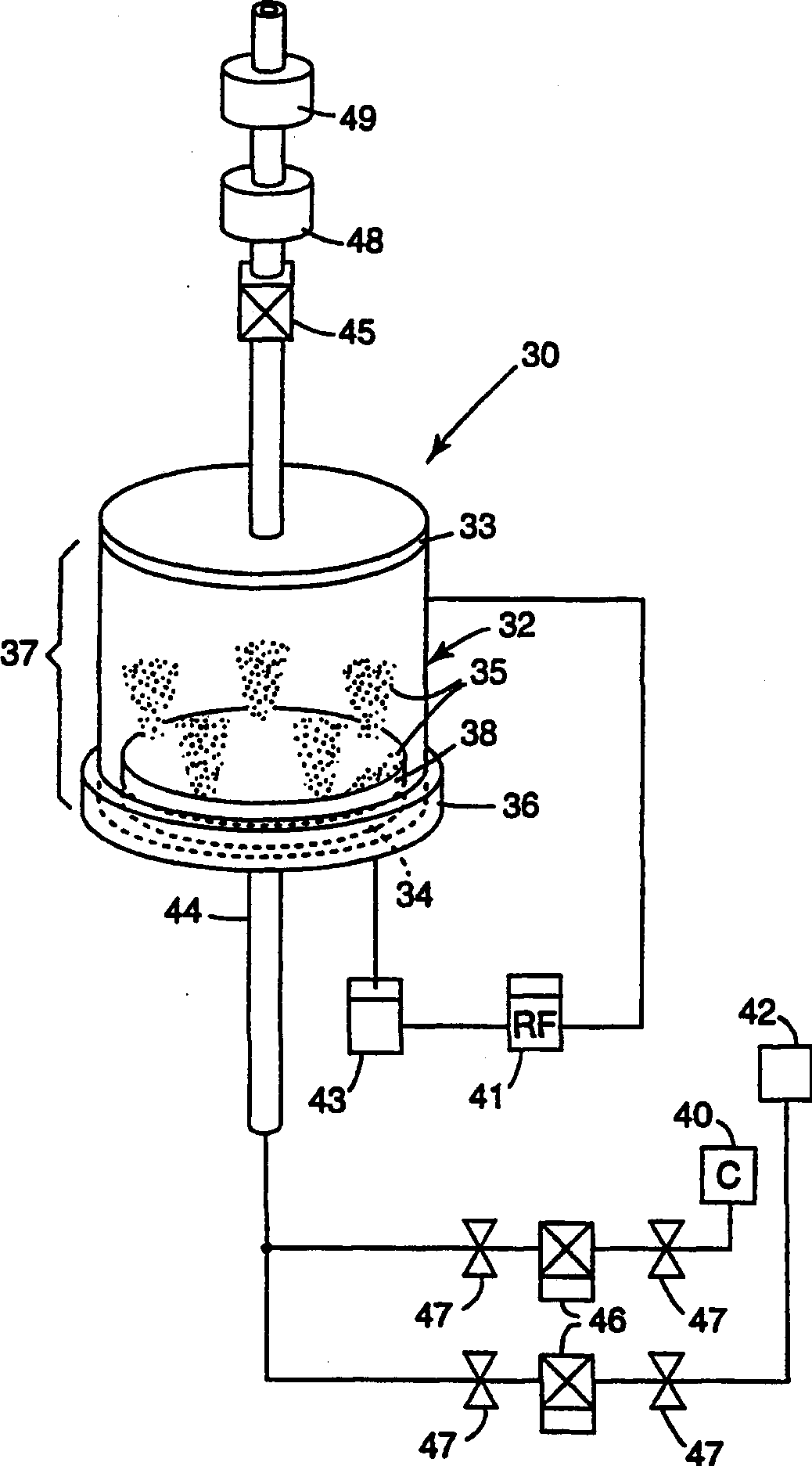

[0088] This example illustrates the preparation of dense networks containing carbon and fluorine. The reactor system used was a capacitively coupled asymmetric parallel-plate plasma reactor roughly as figure 2 shown. The particles are placed on the quartz material directly above the charged planar electrodes. The reactor was used as the ground electrode. A spouted bed was used to agitate the particles.

[0089] The reactor has an aluminum tube of 15.2 cm inner diameter x 15.2 cm height, closed at one end by an aluminum plate with a pump connection. The bottom of the aluminum tube incorporates the electrodes, glass frit and plastic insulating plate. The powered electrodes communicate with the RF power supply through the matching network. Phosphor particles (400 g, type 729 from Durel Corporation, with 300 nm thick SiO 2 :TiO 2 coating, particle size 25-30 μm) was placed on the frit. Pump the system pressure to below 0.0013kPa. Introduce perfluorobutane (C 4 f 10 ), ...

Embodiment 3

[0091] This example illustrates the preparation of a dense network of carbon, hydrogen, and silicon on abrasive grains in which the grains were previously cleaned with an argon plasma. The reactor system used was a parallel plate plasma reactor roughly as figure 2 shown. The particles are placed on a frit directly above a charged planar electrode in a parallel plate plasma reactor. The reactor was used as the ground electrode. A spouted bed was used to agitate the particles.

[0092] The reactor has an aluminum tube of 15.2 cm inner diameter x 15.2 cm height, closed at one end by an aluminum plate with a pump connection. The bottom of the aluminum tube incorporates the electrodes, glass frit and plastic insulating plate. The powered electrodes communicate with the RF power supply through the matching network.

[0093] 400 g of silicon carbide particles (size 80, US Tyler Mesh) were placed on the frit. Pump the system pressure to below 0.0013kPa. Before the deposition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com