Patents

Literature

32results about How to "Fast vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

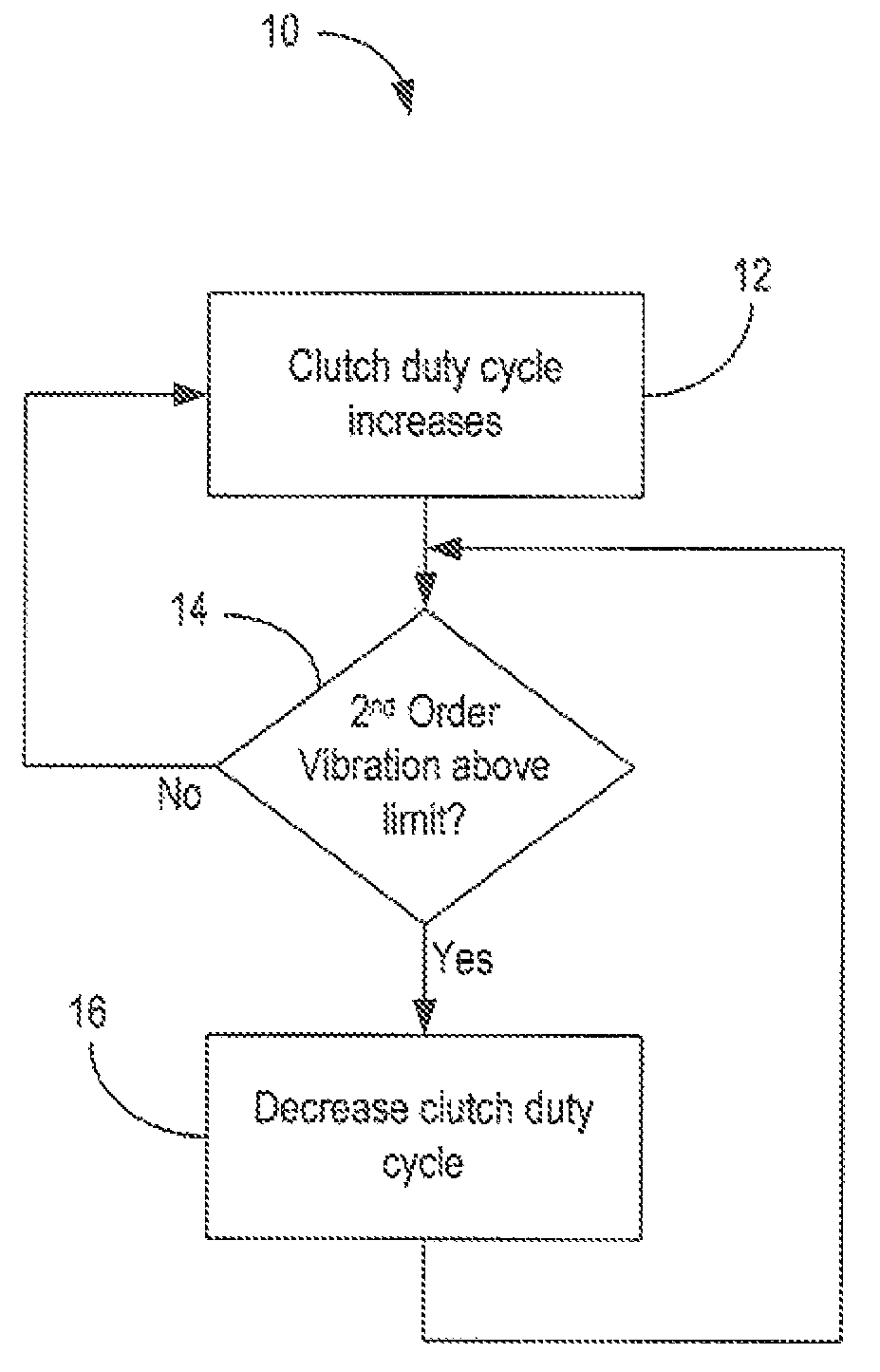

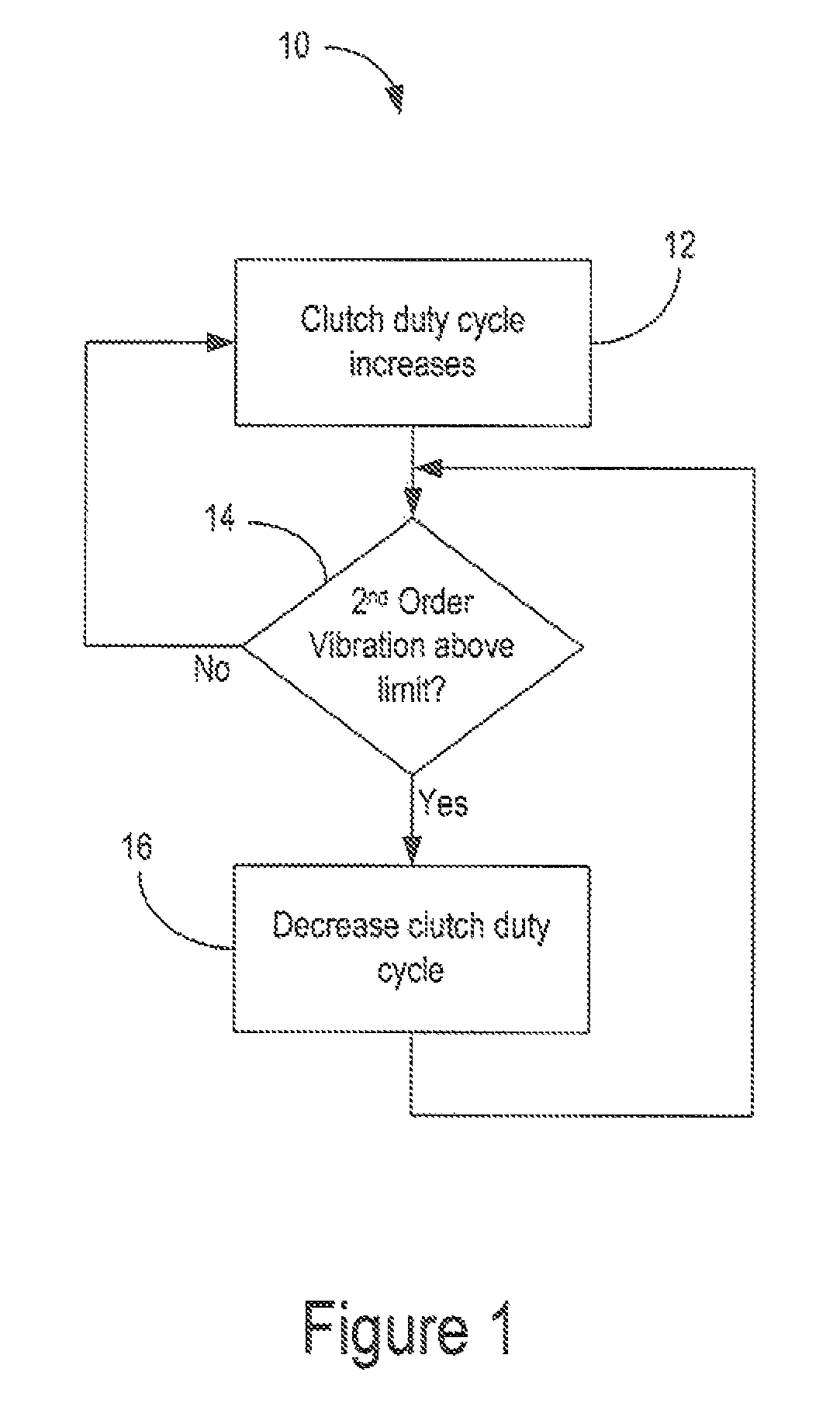

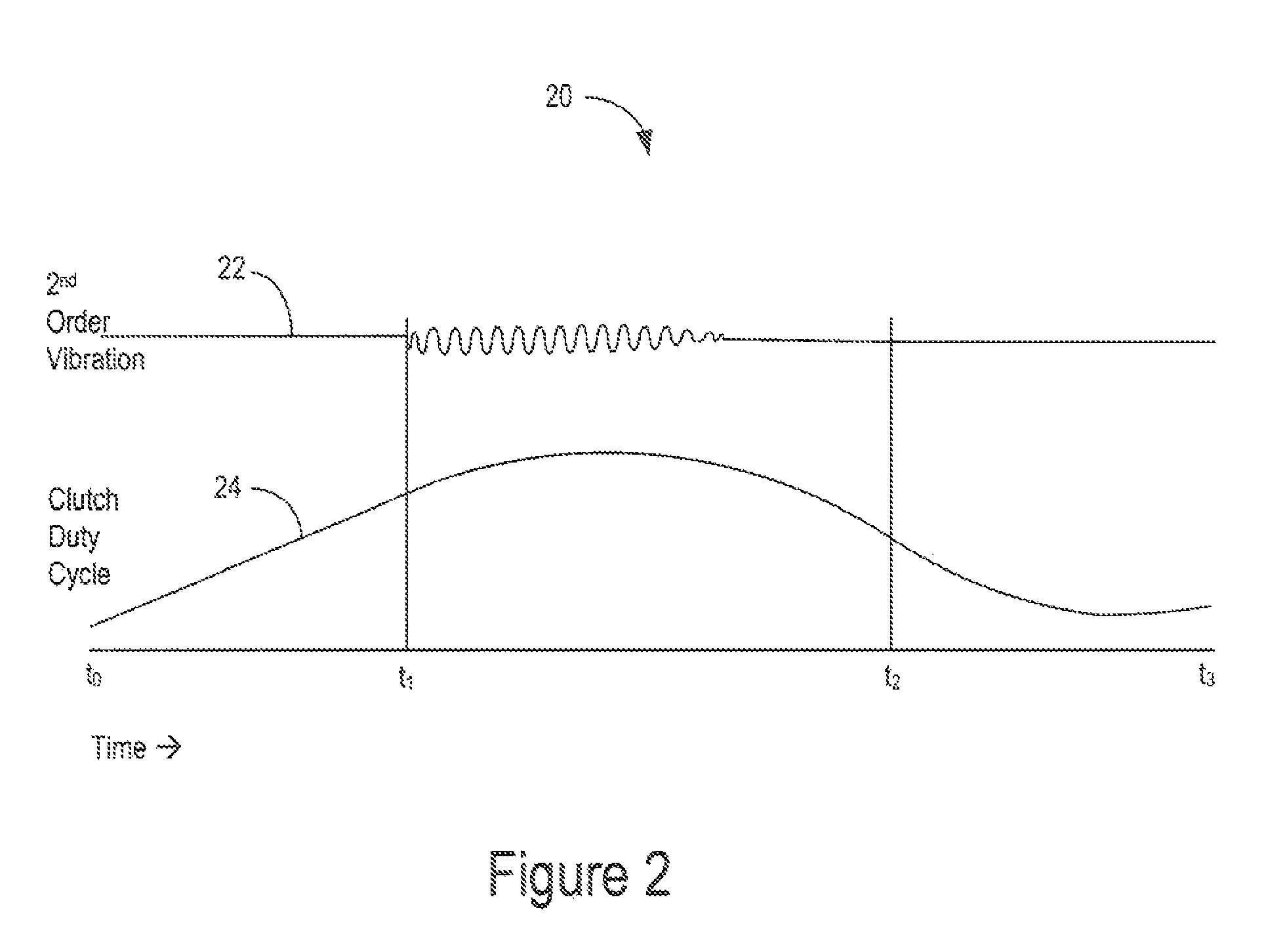

Systems and methods for detecting and reducing high driveline torsional levels in automobile transmissions

ActiveUS20080288146A1Improve the level ofReduce distractionsDigital data processing detailsGearing controlDrivetrainFuel efficiency

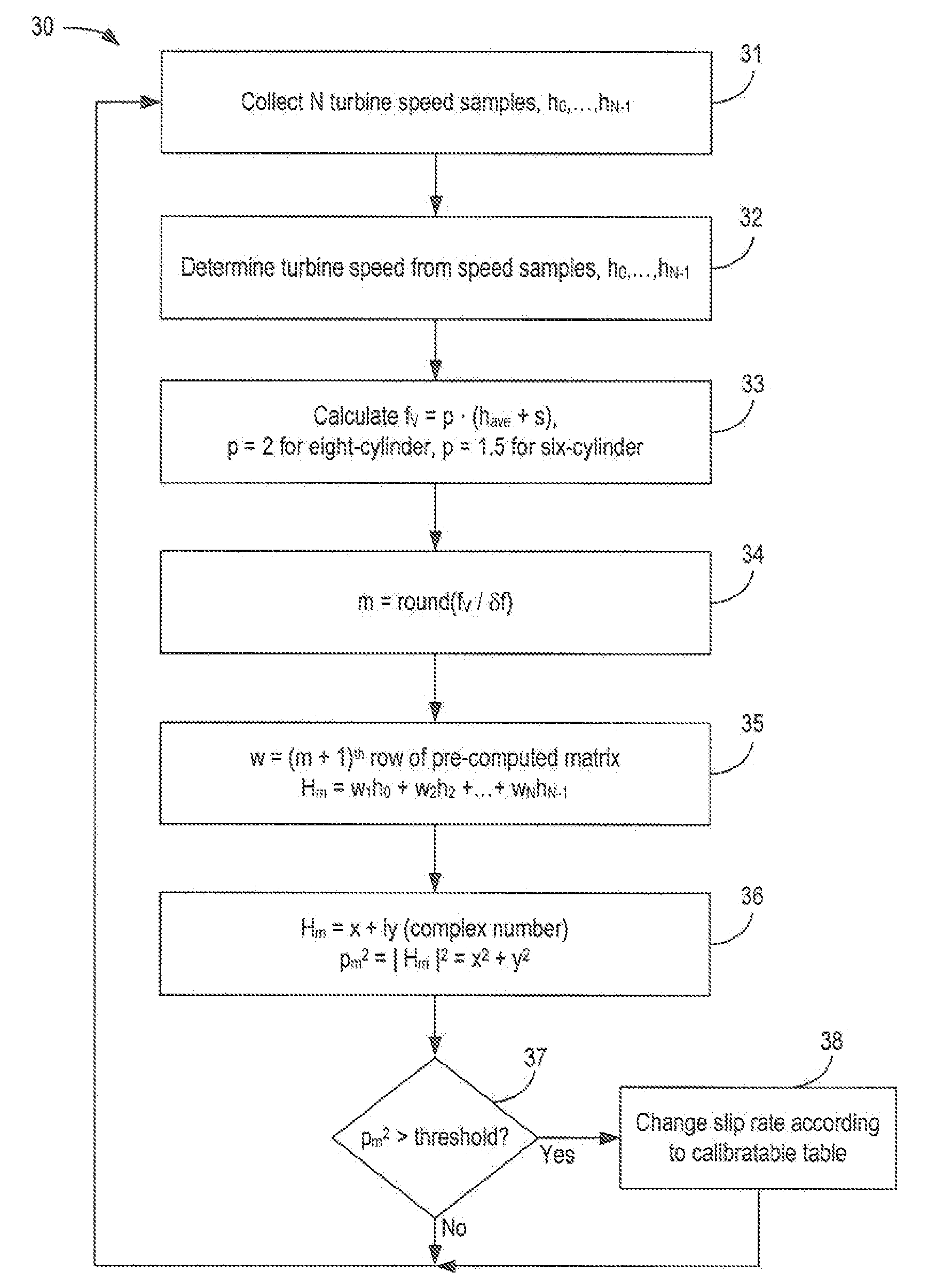

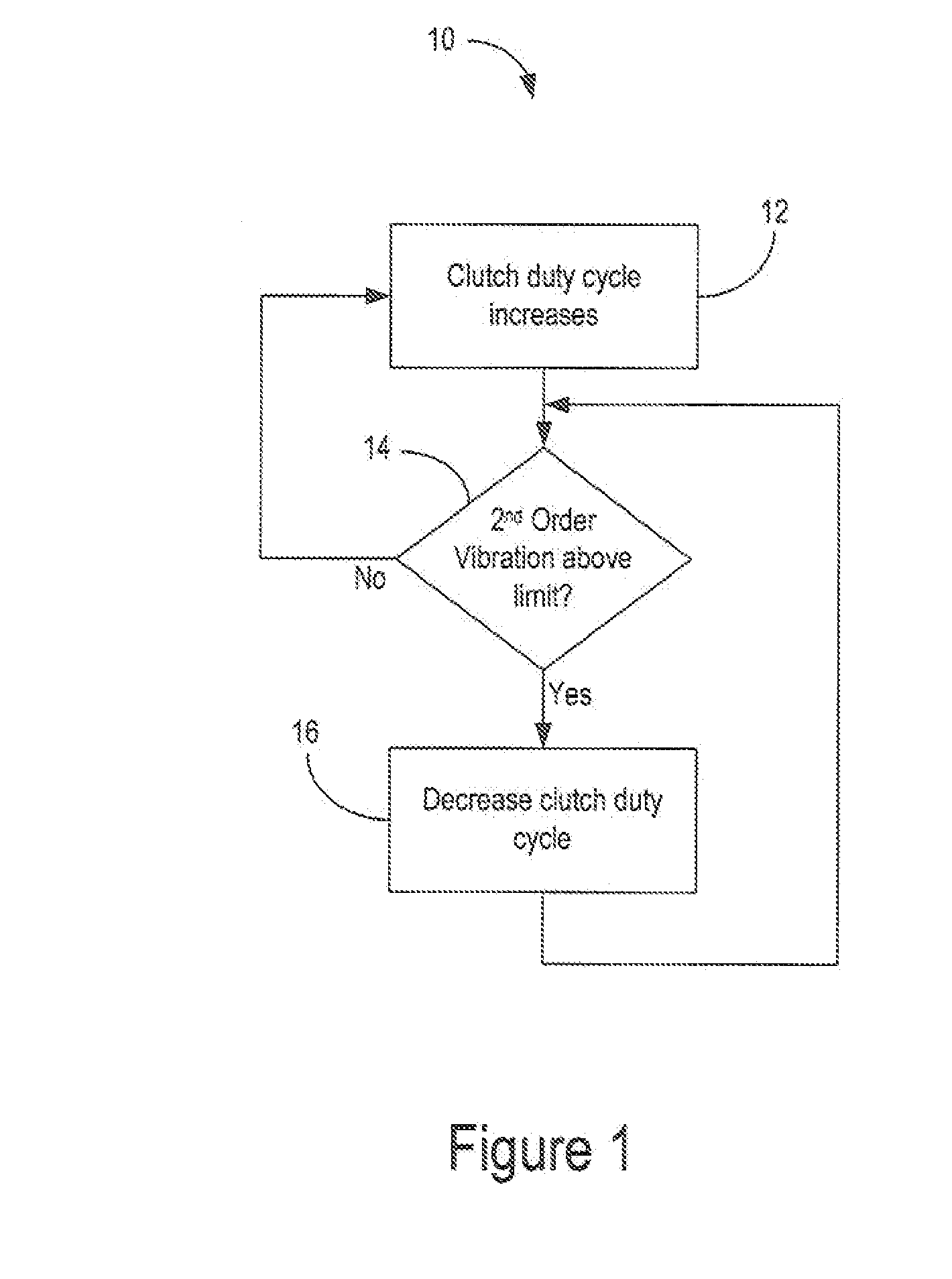

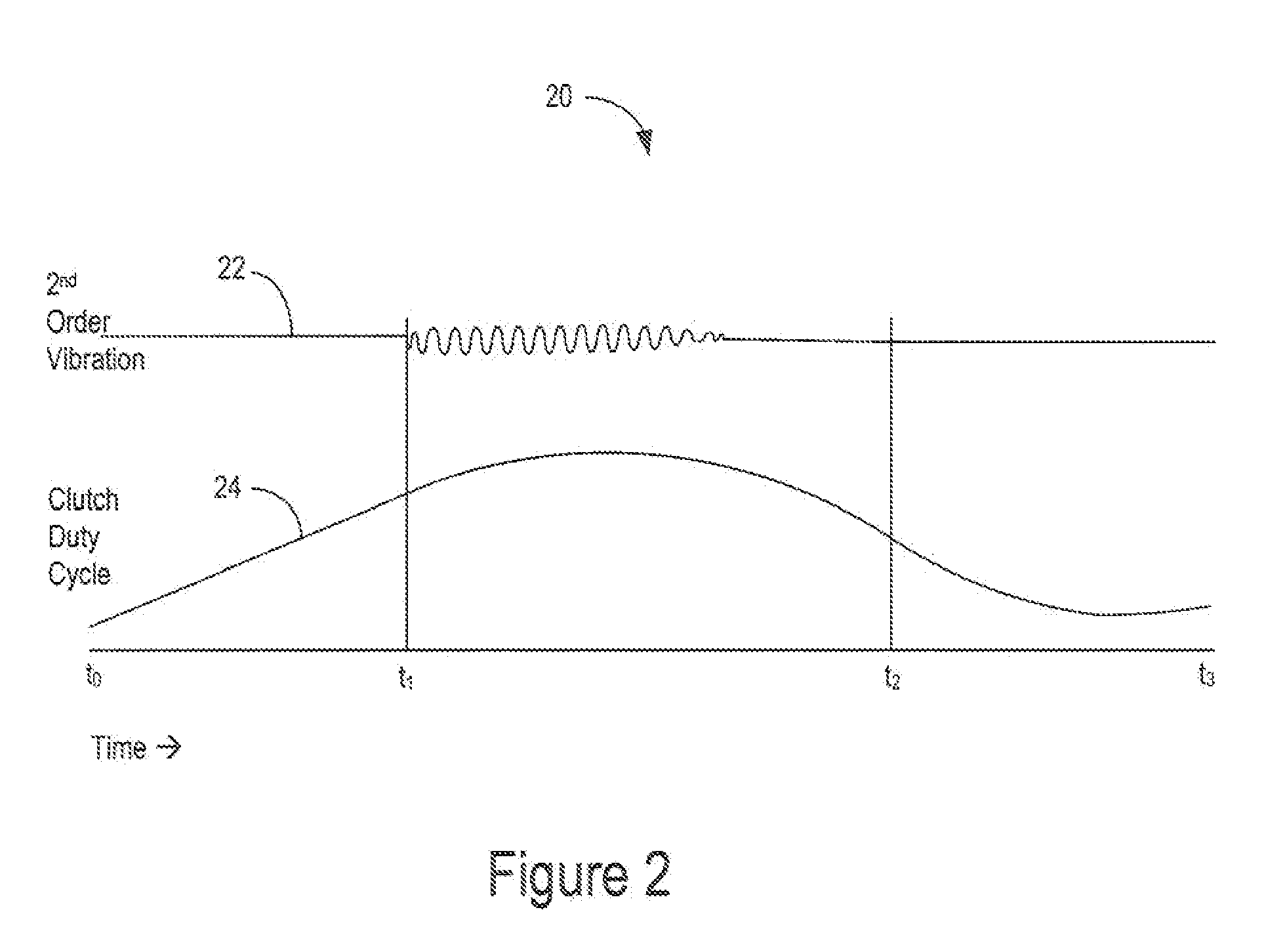

The present disclosure provides systems and methods to detect and reduce any high driveline torsional levels, such as due to the cylinder deactivation in variable displacement system engines or aggressive lock-up strategies for fuel efficiency, in automobile transmissions. The present disclosure utilizes a controller in an automobile to operate a computationally thrifty method for quickly detecting noise and vibration disturbances in the transmission. This quick detection enables fuel economic calibrations that aggressively reduce the disturbances by controlling slip in a launch device of the transmission. As problem disturbances arise, they are detected before occupants notice objectionable behavior. Once detected, the disturbances are reduced, such as by increasing launch device slip, which effectively intercepts the objectionable disturbances before they are transferred through the entire drivetrain. The present disclosure can also apply to launch devices in Dual Clutch Transmissions and Electronically-controlled Manual Transmissions.

Owner:FCA US

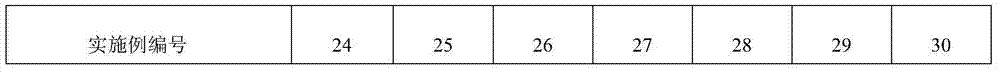

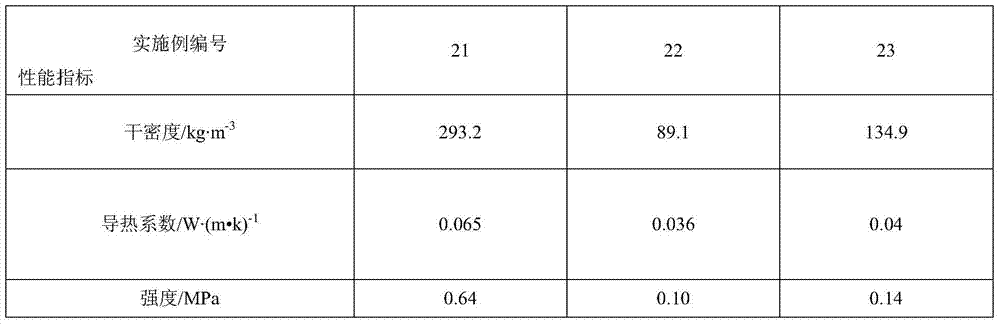

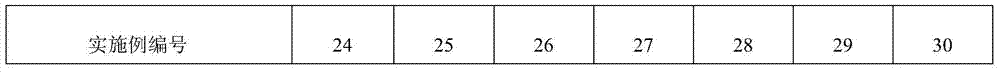

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

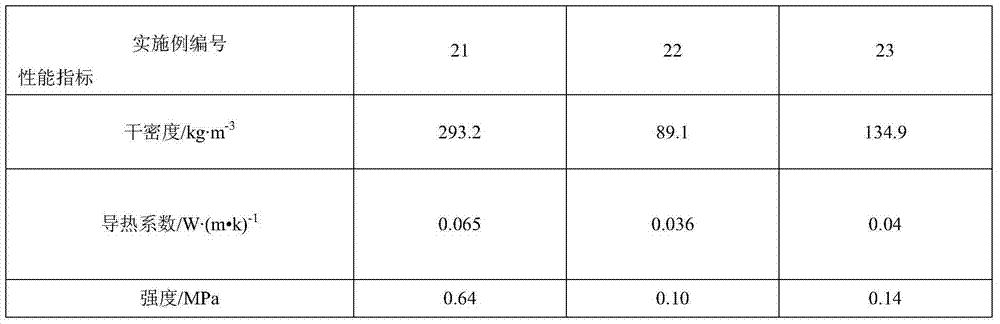

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

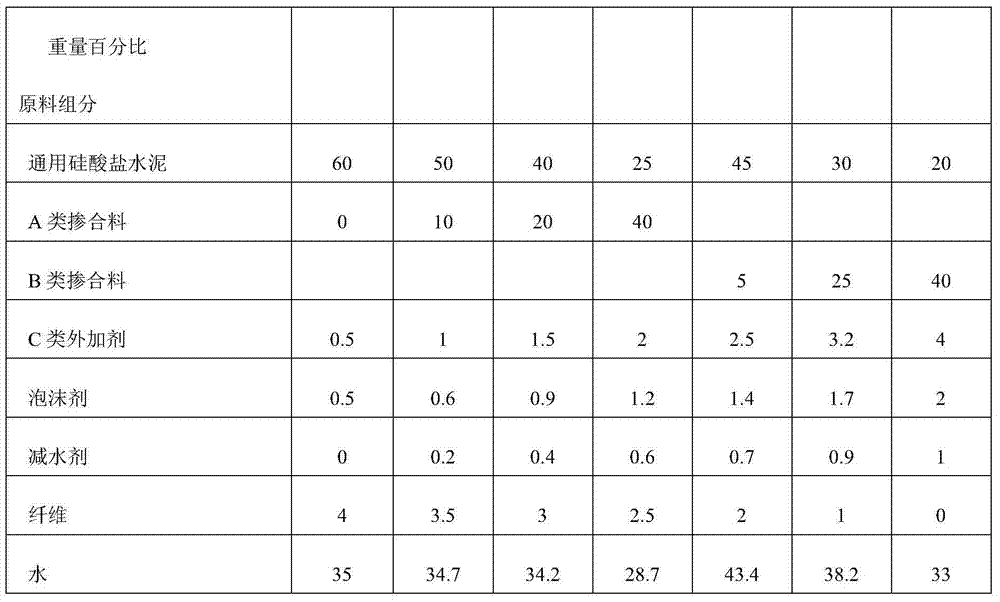

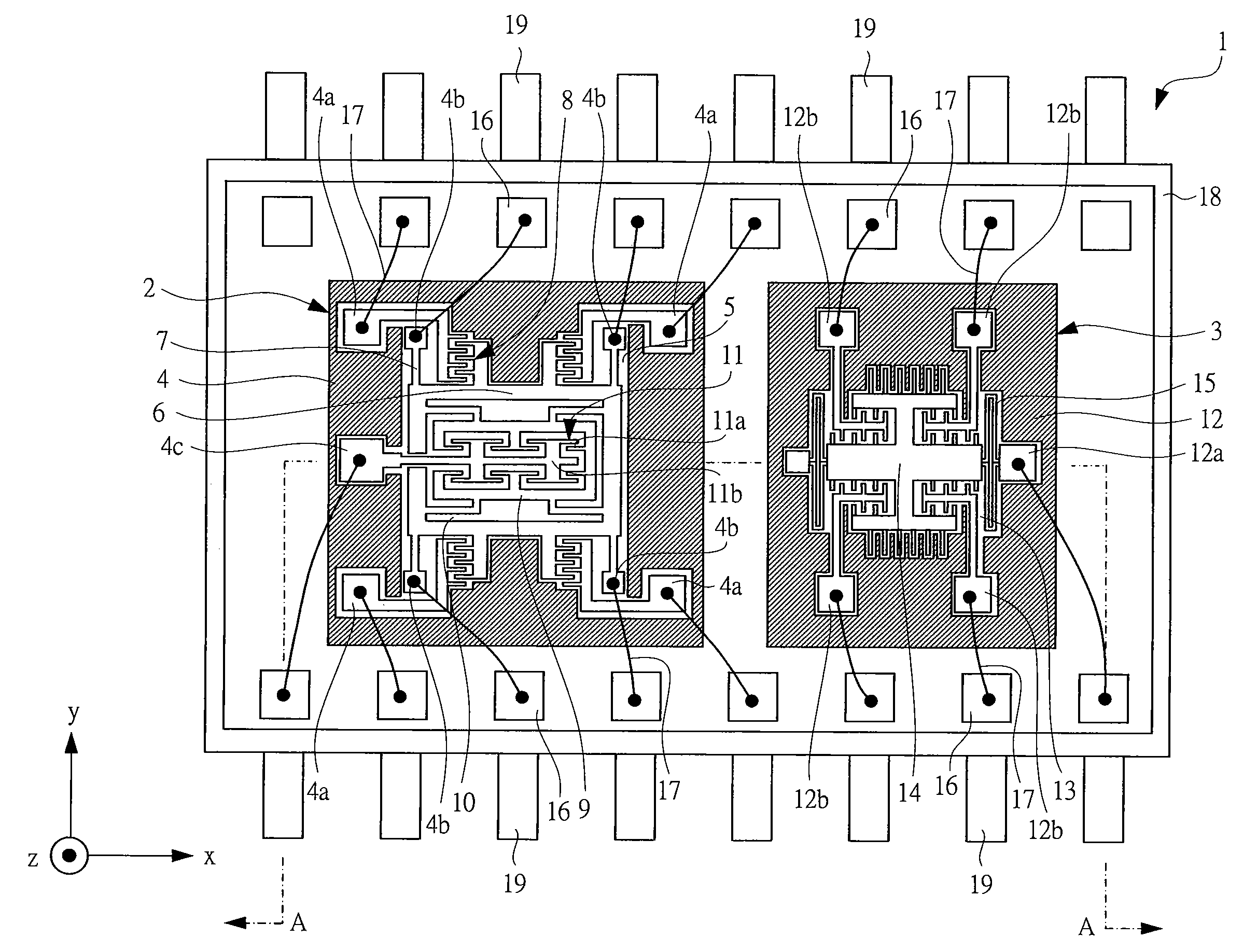

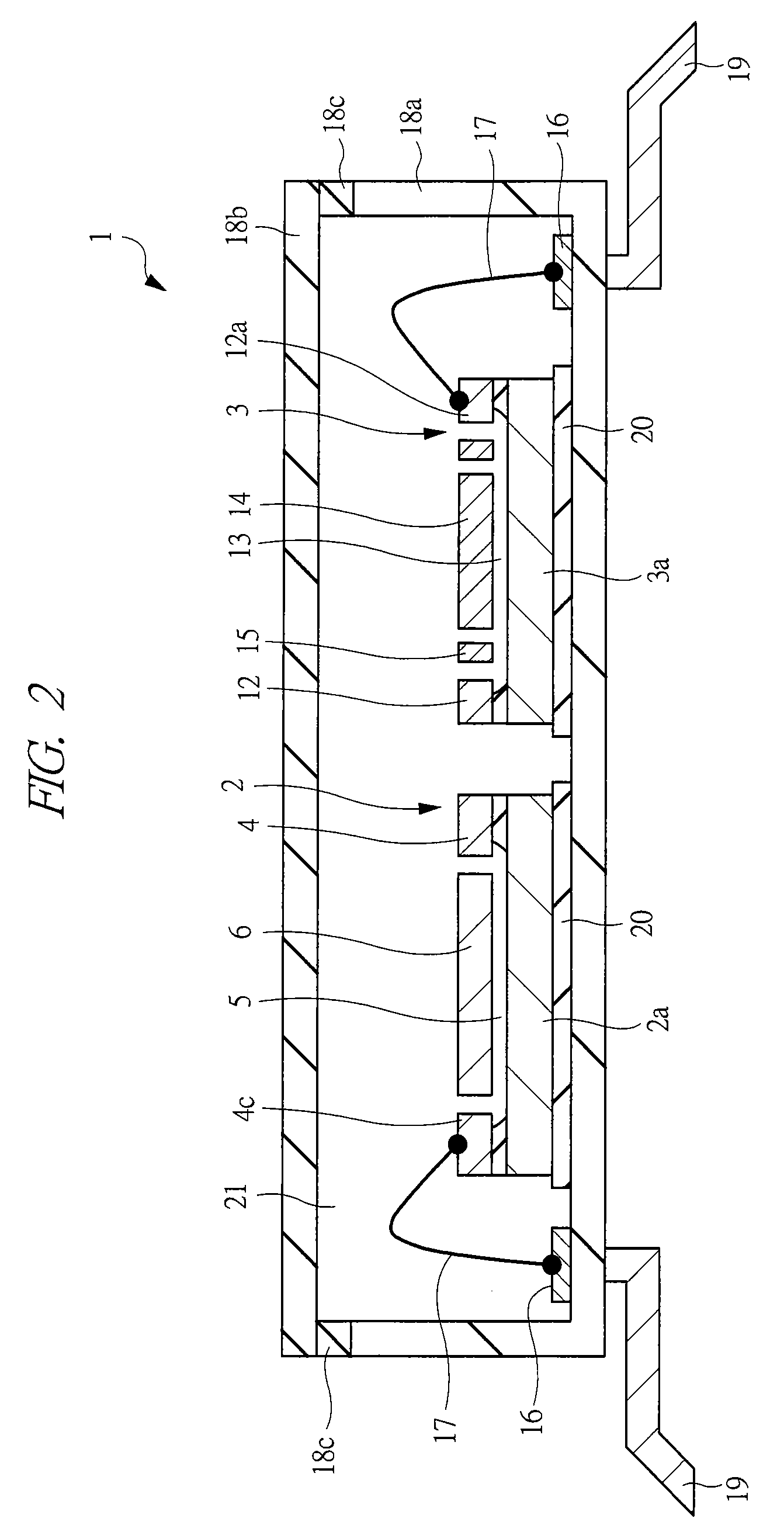

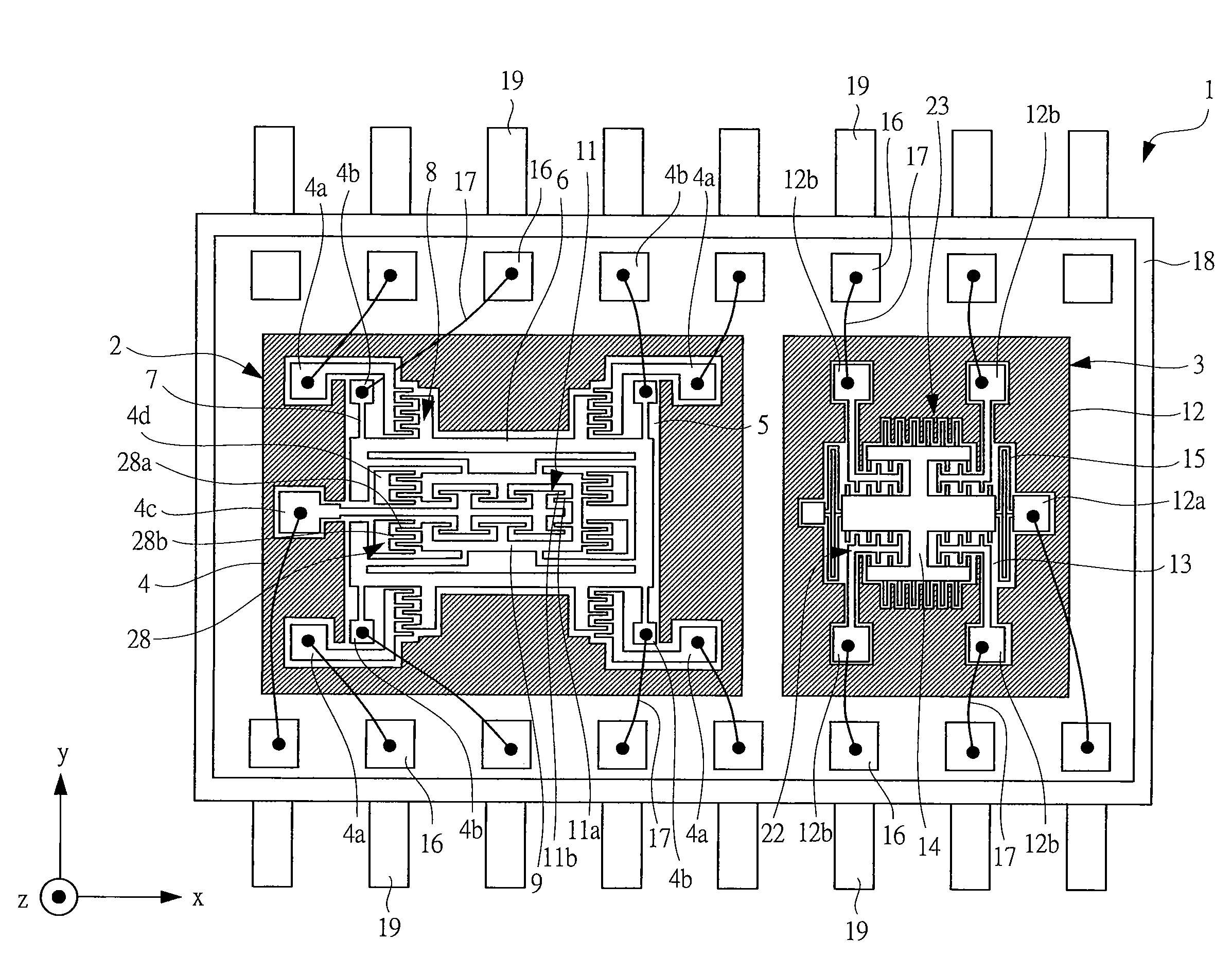

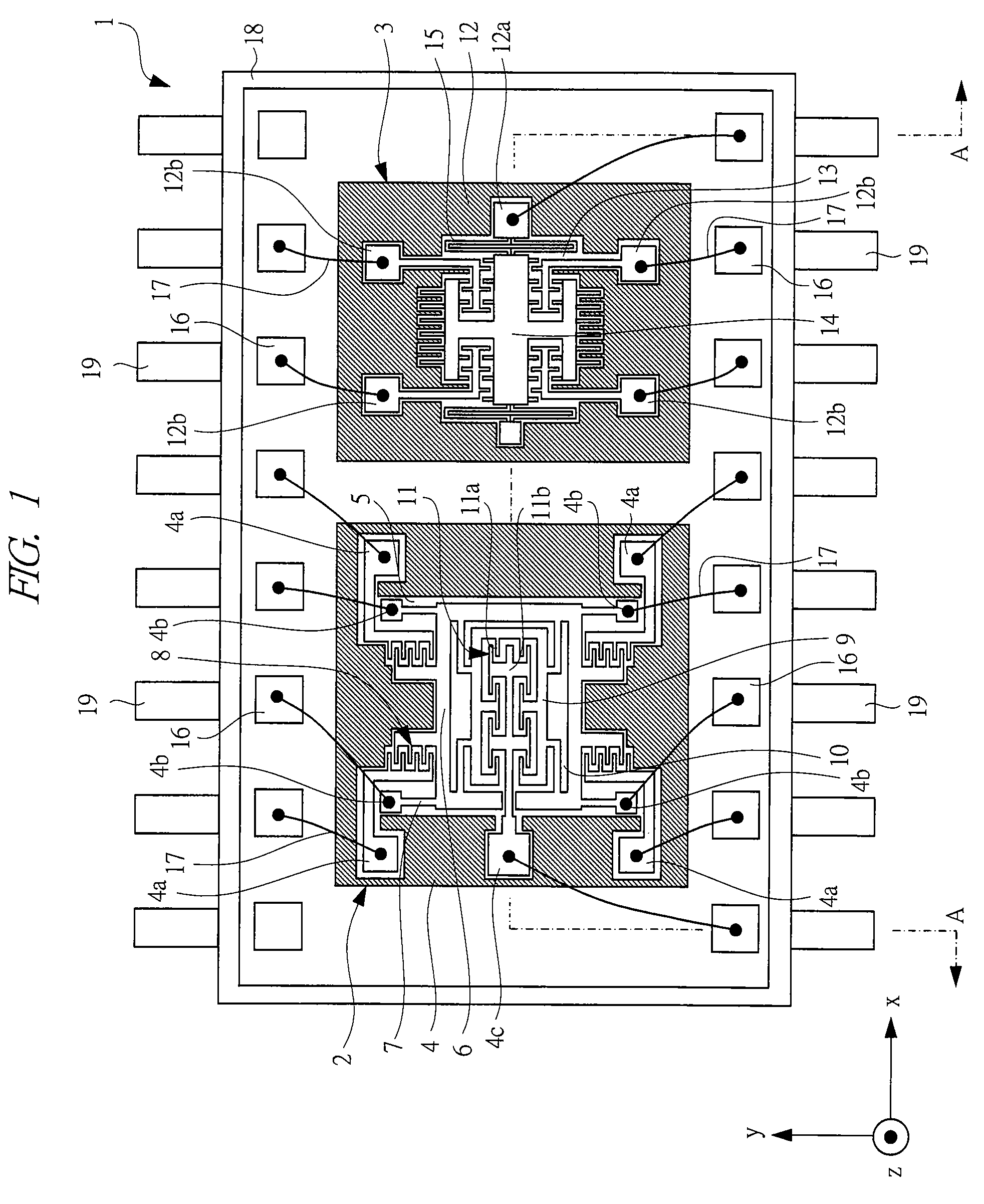

Inertial sensor

ActiveUS20090183568A1High detection sensitivityAvoid displacementAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorHigh acceleration

An angular rate sensor and an acceleration sensor are sealed at the same sealing pressure. The sealing pressure at this time is put into a reduced pressure state below the atmospheric pressure in view of improving a detection sensitivity of the angular rate sensor. Even in the reduced pressure atmosphere, to improve the detection sensitivity of the acceleration sensor, a shift suppressing portion (damper) for suppressing shifts of a movable body of the acceleration sensor is provided. This shift suppressing portion includes a plurality of protruding portions integrally formed with the movable body and a plurality of protruding portions integrally formed with a peripheral portion, and the protruding portions are alternately disposed separately at equal intervals.

Owner:HITACHI LTD

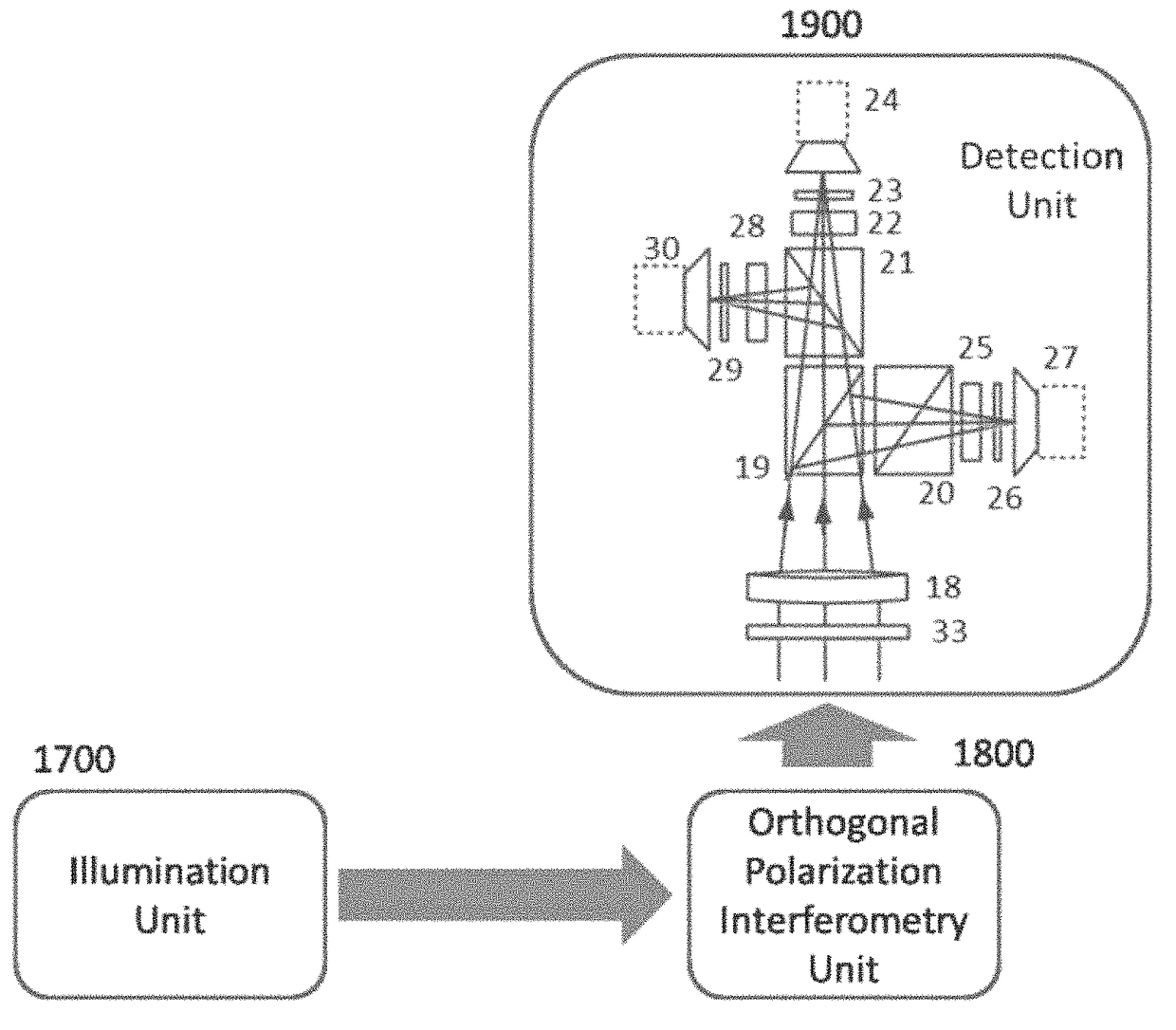

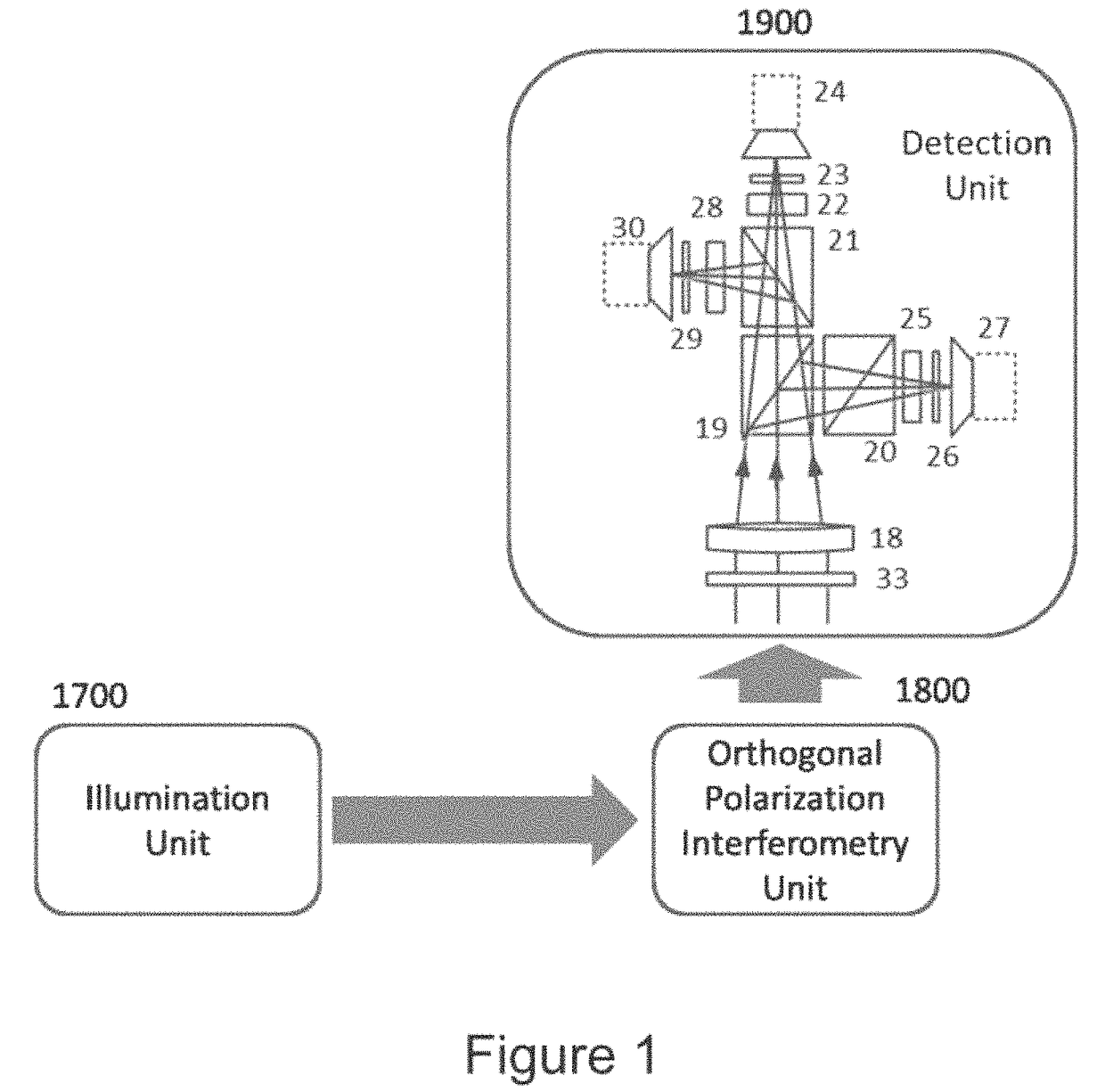

Multiple wavelengths real time phase shift interference microscopy

ActiveUS9880377B1Fast displacementFast vibrationPhotometryUsing optical meansUltra high speedPhase shifted

A system microscopy system and method that enable obtaining high resolution 3D images in a single shot are presented. The system is an ultra-high speed, real time multi wavelength phase shift interference microscopy system that uses three synchronized color CCD cameras. Each CCD is equipped with a precision achromatic phase mask which in turn allows obtaining π / 2 phase shifted signals in three different wavelengths simultaneously.

Owner:PHOTONICSYS

Inertial sensor

ActiveUS8250920B2High detection sensitivityIncrease speedAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorHigh acceleration

An angular rate sensor and an acceleration sensor are sealed at the same sealing pressure. The sealing pressure at this time is put into a reduced pressure state below the atmospheric pressure in view of improving a detection sensitivity of the angular rate sensor. Even in the reduced pressure atmosphere, to improve the detection sensitivity of the acceleration sensor, a shift suppressing portion (damper) for suppressing shifts of a movable body of the acceleration sensor is provided. This shift suppressing portion includes a plurality of protruding portions integrally formed with the movable body and a plurality of protruding portions integrally formed with a peripheral portion, and the protruding portions are alternately disposed separately at equal intervals.

Owner:HITACHI LTD

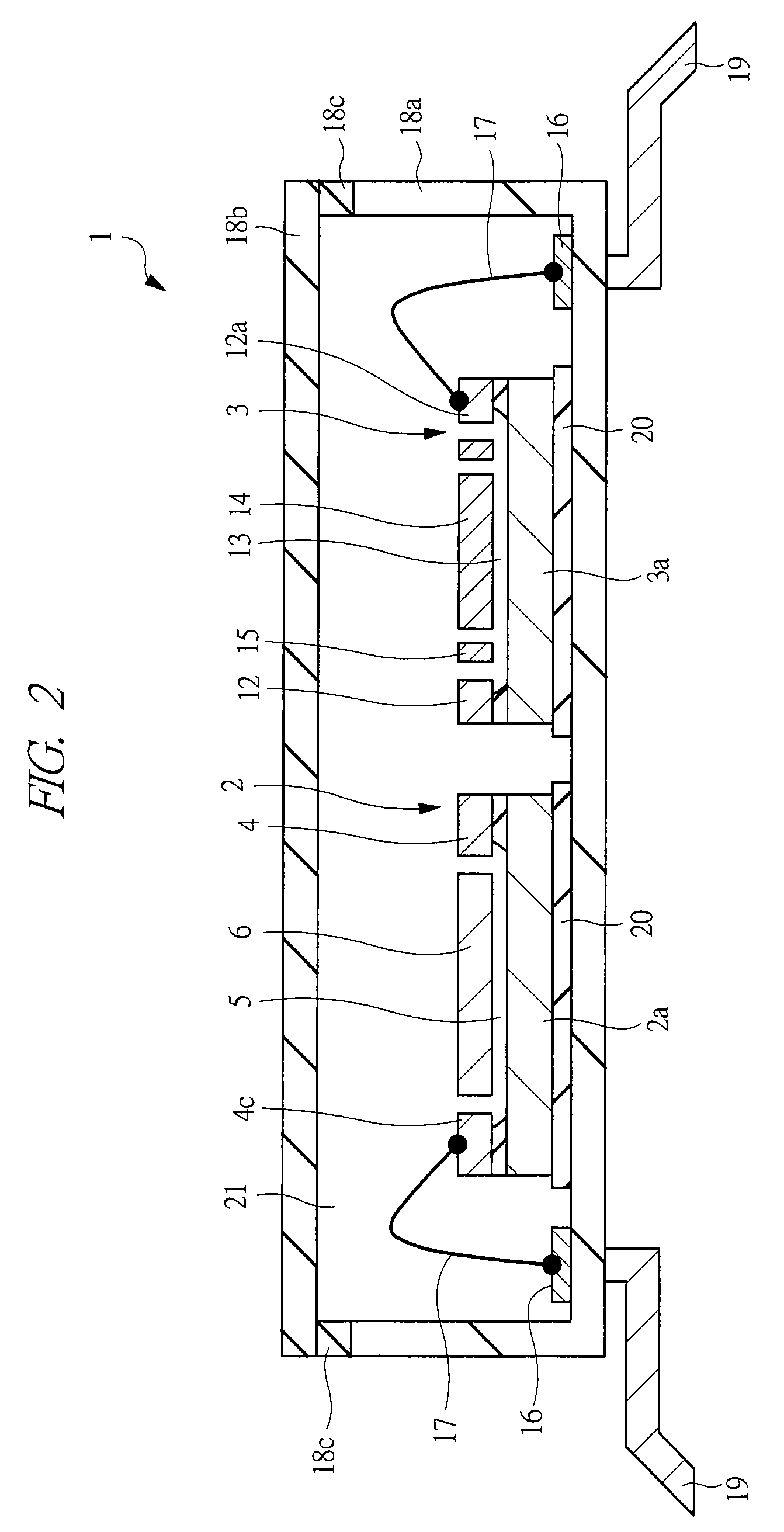

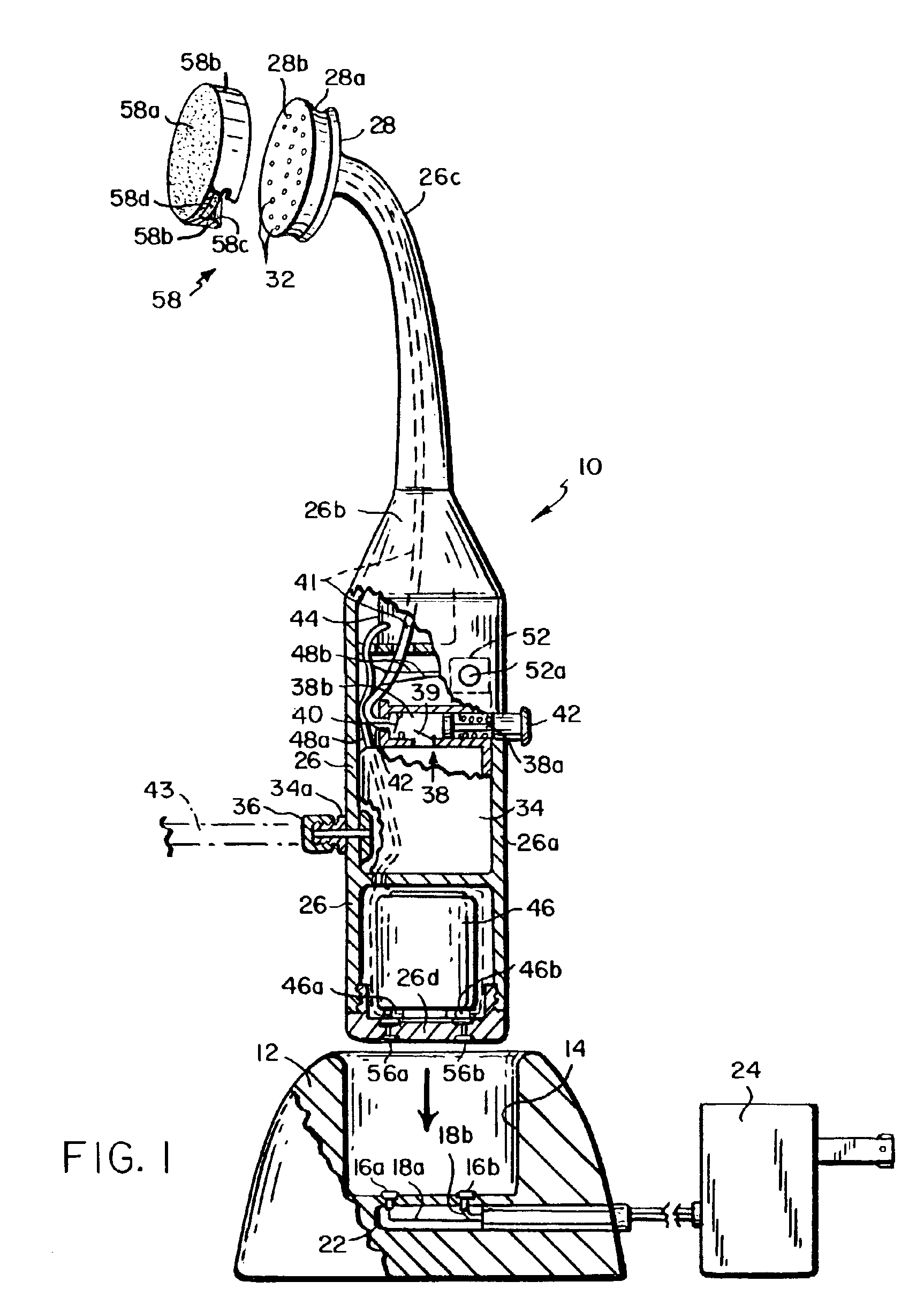

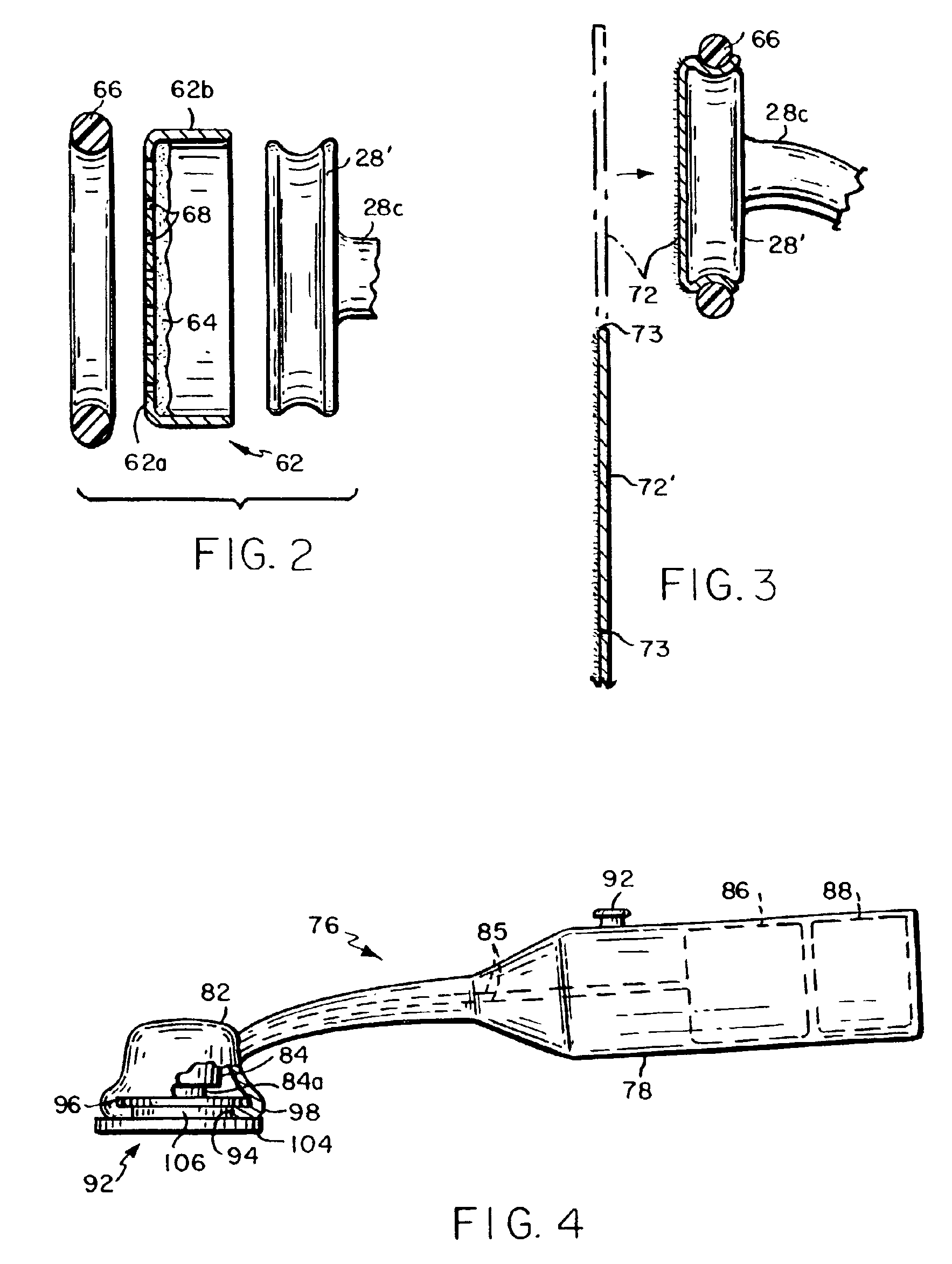

Hand held nail polish removal tool

InactiveUS6990984B2Easy to useEasy to adaptCurling-ironsCurling-tongsElongated neckRechargeable cell

A hand held nail polish removal tool includes a housing having a main body connected by an elongated neck to a head. An abrasive member is removably attached to the head and the tool contains a vibrator for causing the abrasive member to vibrate so that when the abrasive member is positioned against a finger or toe nail, the abrasive member will abrade away any polish on the nail. The polish removal process may be accelerated by applying a solvent to the abrasive member. This may be done by dipping that member in a solvent or by incorporating a solvent dispensing system in the housing which allows a solvent to be delivered via the head to the member's abrasive surface. Preferably, the tool is powered by rechargeable battery in the housing. Various different abrasive cover members for attachment to the head are also disclosed.

Owner:BEAR INK CORP

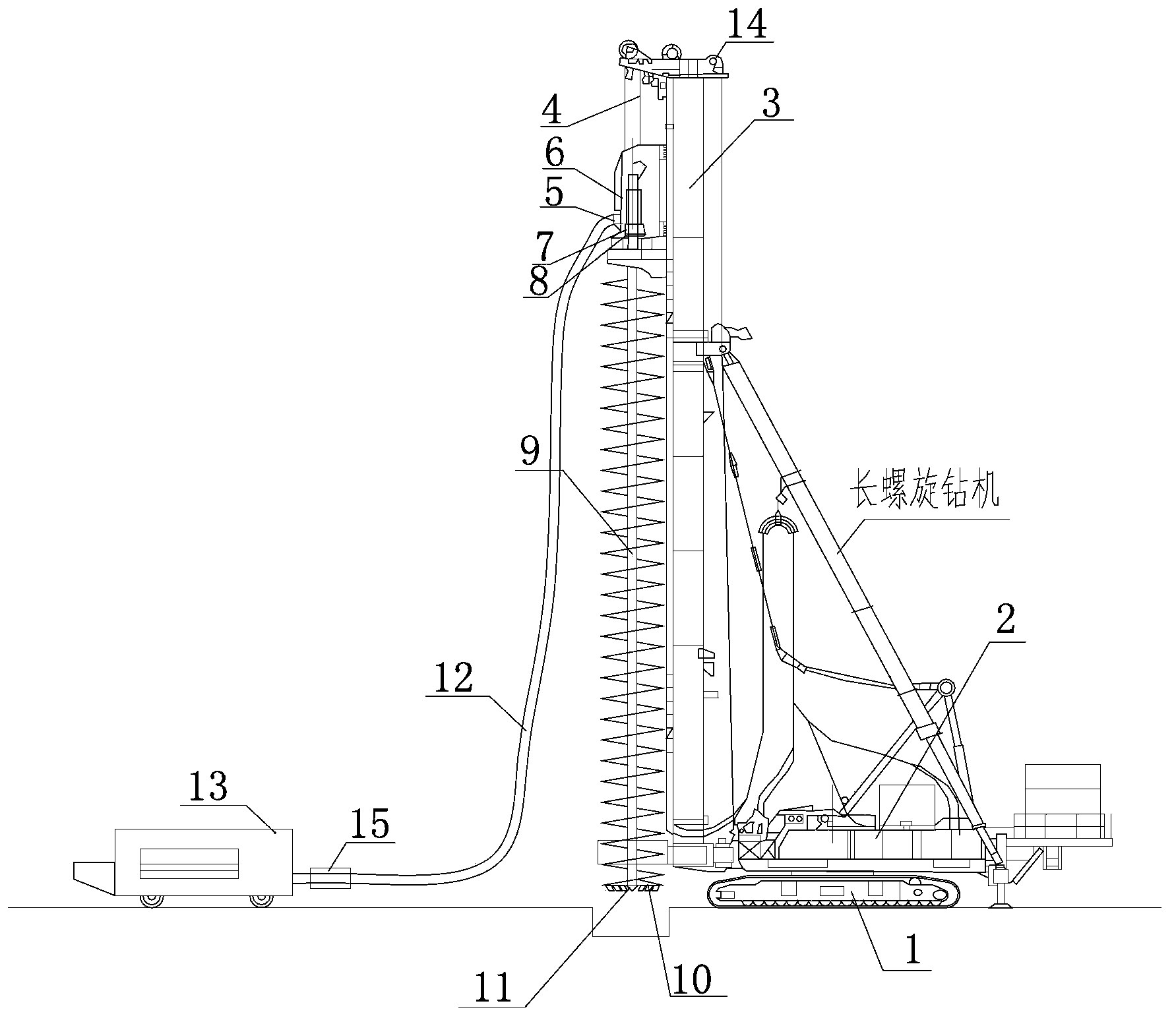

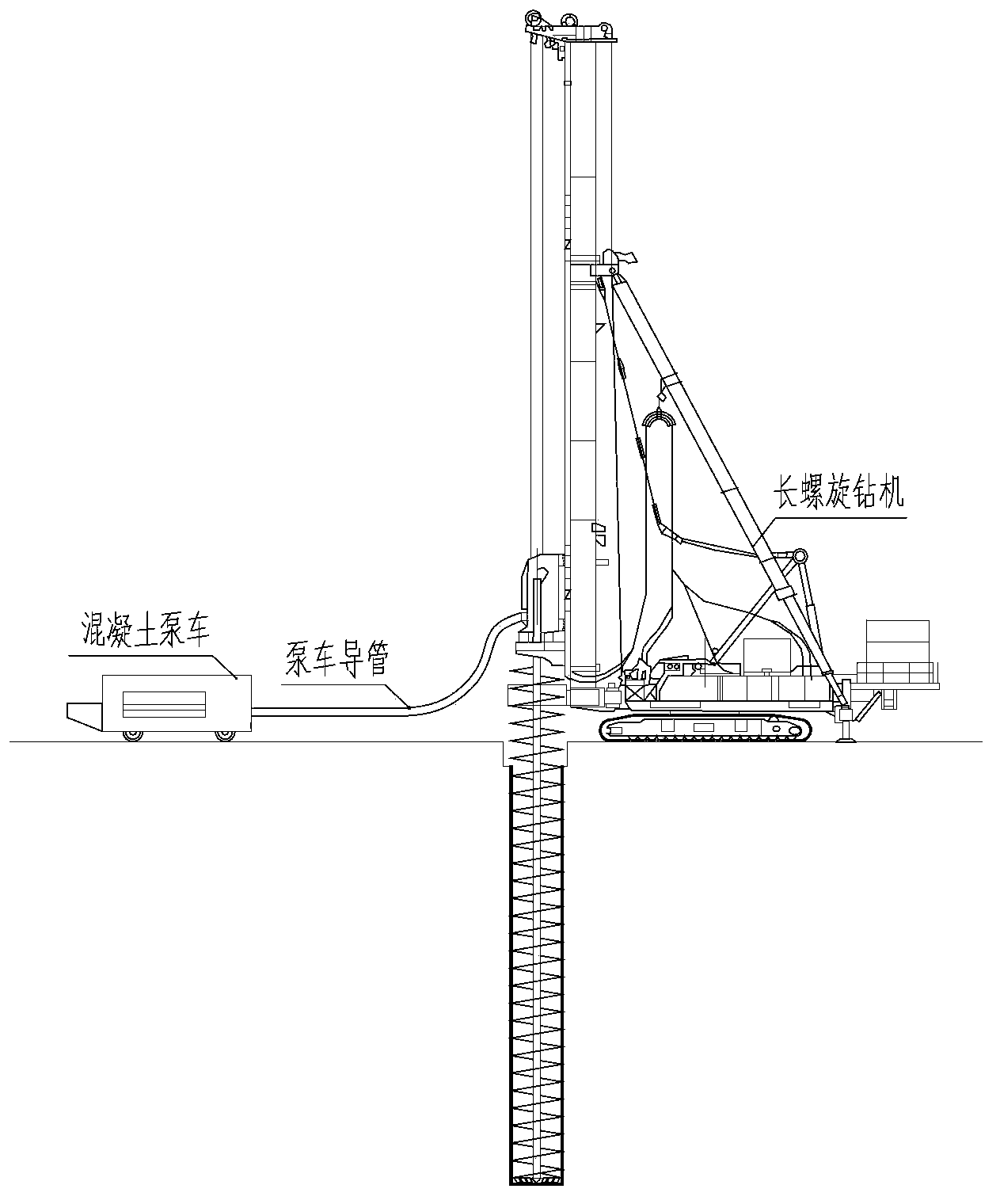

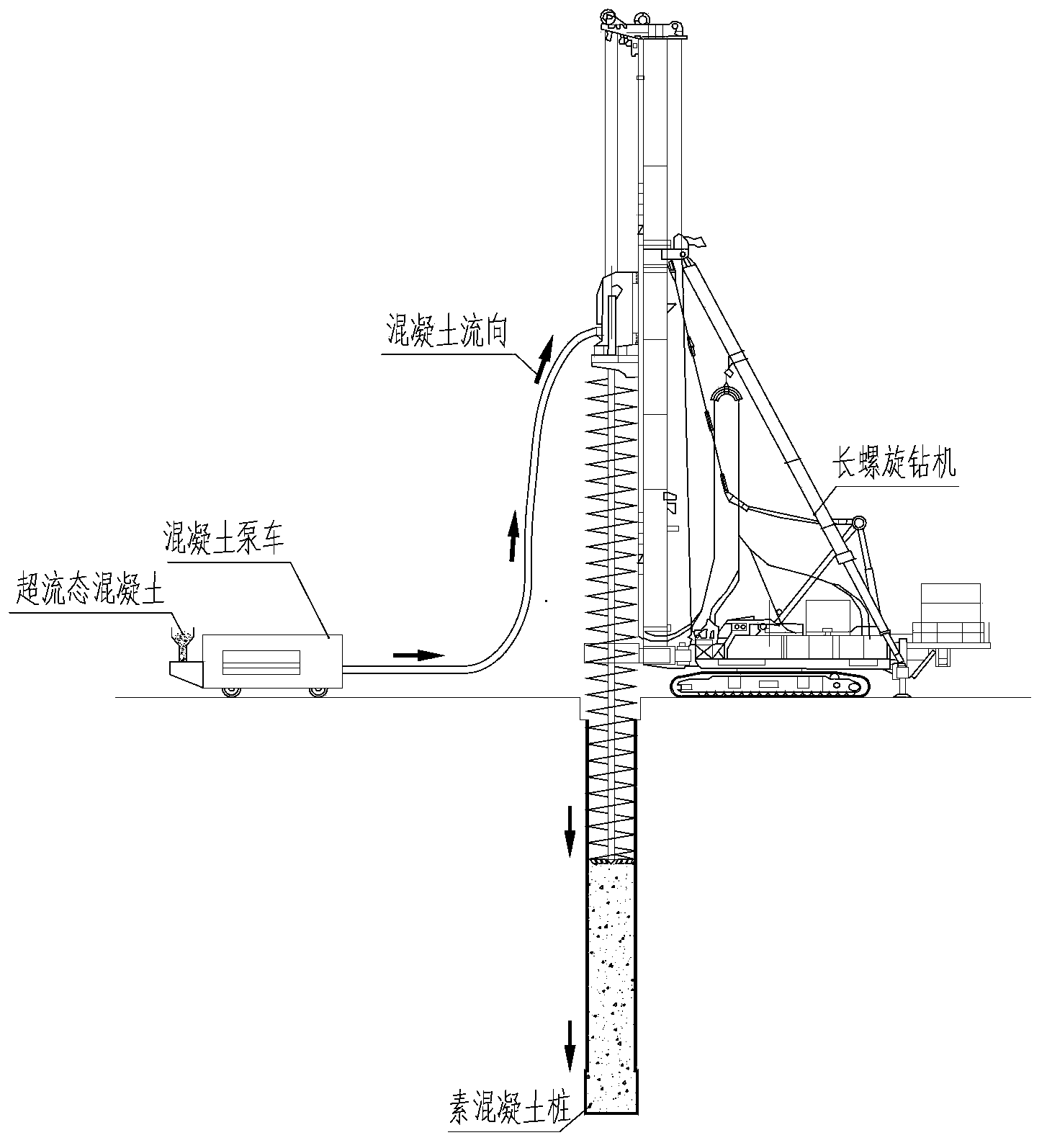

Novel visual intelligent super-fluid cast-in-place concrete pile device and construction method

InactiveCN104250970AShorten construction timeImprove construction efficiencyRotary drillingRotary-drilling machinesWinding machineEngineering

The invention relates to a novel visual intelligent super-fluid cast-in-place concrete pile device and a construction method. The novel visual intelligent super-fluid cast-in-place concrete pile device comprises a walking and crawler type main machine, a winding machine, a guide rod, a steel wire rope, a feed inlet, a power head, a gearbox, a speed reducer, a spiral drill rod, a drill bit, a feed outlet, a pump truck guide pipe, a concrete pump truck, a flow meter and a depth sensor, wherein the winding machine and the guide rod are fixedly arranged on the main machine, the power head is connected with a pulley arranged at the top end of the guide rod through the steel wire rope, the steel wire rope drives the power head to ascend and descend, the power head is sequentially connected with the spiral drill rod through the gearbox and the speed reducer, the lower end of the spiral drill rod is connected with the drill bit, the feed outlet is formed in the drill bit and is provided with an iron sheet, the iron sheet is fixed by a bolt, the concrete pump truck is connected with the feed inlet through the pump truck guide pipe, and the pump truck guide pipe is provided with the flow meter. The invention also provides the construction method of a novel visual intelligent super-fluid cast-in-place concrete pile. The construction method comprises the steps of firstly, drilling to a design depth by a long spiral drilling machine; then, forwards rotating or directly lifting the drill rod; continuously infusing super-fluid concrete in a hole through a drill bit valve while pulling out the drill rod; finally, inserting a steel reinforcement cage after pulling out the drill rod. Compared with the prior art, the novel visual intelligent super-fluid cast-in-place concrete pile device and the construction method, provided by the invention, have the advantages that no noise or vibration is generated, a soil compaction performance is not generated, intelligentization is realized, the quality is ensured, the cost is reduced, the construction period is shortened, and the like.

Owner:SHANGHAI CHENGDI CONSTR +1

Systems and methods for detecting and reducing high driveline torsional levels in automobile transmissions

ActiveUS9174645B2Improve the level ofFast noiseDigital data processing detailsGearing controlDrivetrainFuel efficiency

The present disclosure provides systems and methods to detect and reduce any high driveline torsional levels, such as due to the cylinder deactivation in variable displacement system engines or aggressive lock-up strategies for fuel efficiency, in automobile transmissions. The present disclosure utilizes a controller in an automobile to operate a computationally thrifty method for quickly detecting noise and vibration disturbances in the transmission. This quick detection enables fuel economic calibrations that aggressively reduce the disturbances by controlling slip in a launch device of the transmission. As problem disturbances arise, they are detected before occupants notice objectionable behavior. Once detected, the disturbances are reduced, such as by increasing launch device slip, which effectively intercepts the objectionable disturbances before they are transferred through the entire drivetrain. The present disclosure can also apply to launch devices in Dual Clutch Transmissions and Electronically-controlled Manual Transmissions.

Owner:FCA US

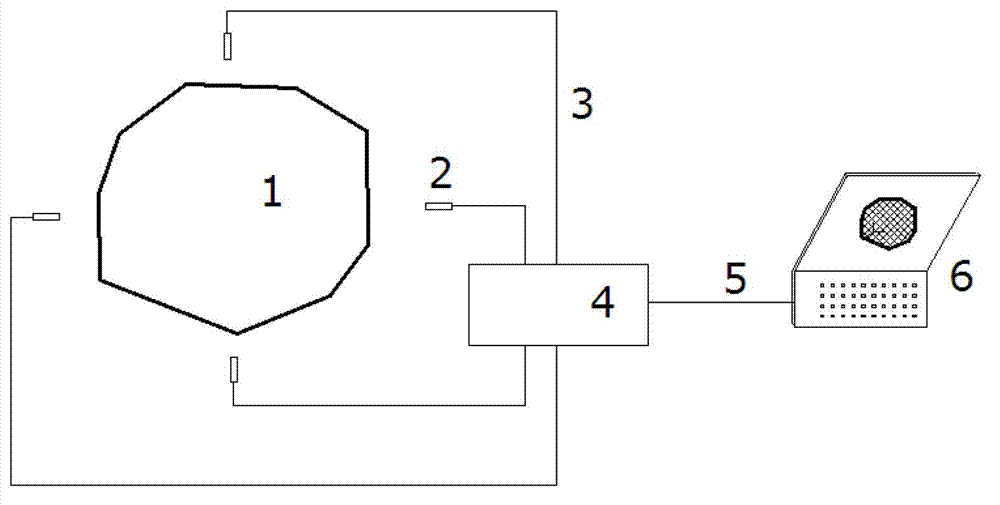

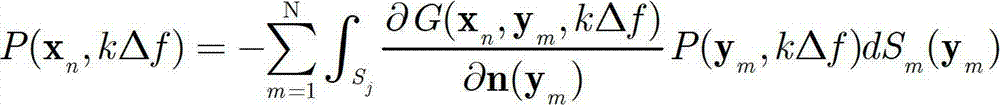

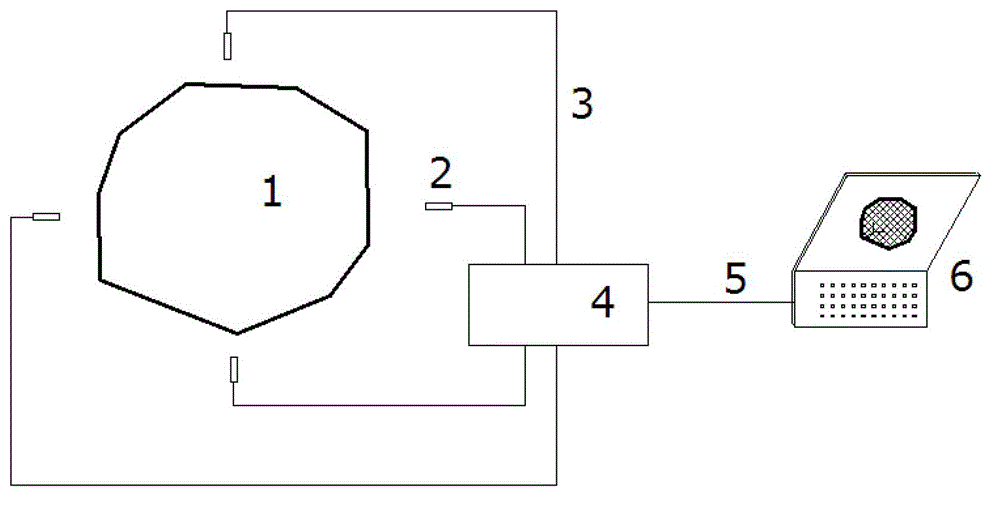

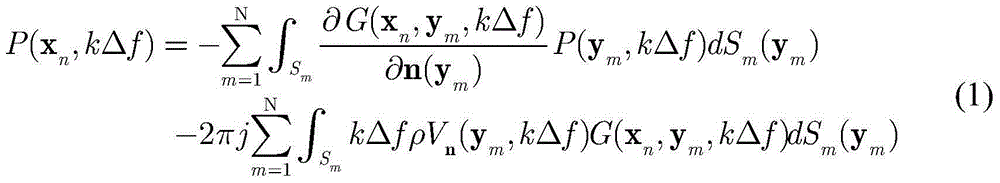

Method for noncontact measurement of boundary vibration and application of method

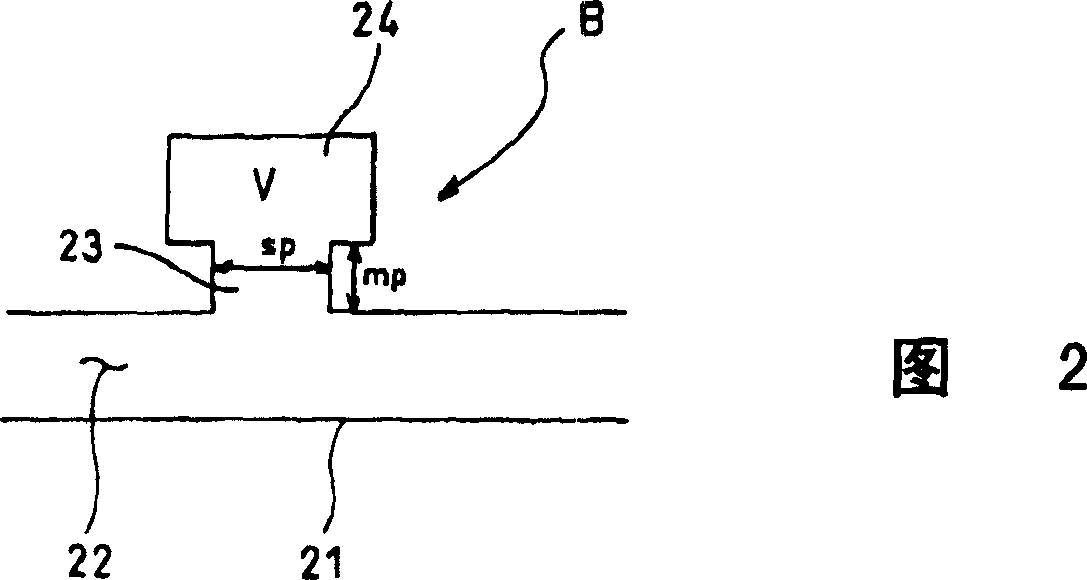

InactiveCN102853902ANo errorHigh precisionSubsonic/sonic/ultrasonic wave measurementSound sourcesRectangular coordinates

The invention discloses a method for noncontact measurement of boundary vibration and an application of the method. The method comprises the following steps: firstly, a rectangular coordinates system is established in a three-dimensional space, and 2N sound pressure sensors are arranged around a measured object, and the geometric coordinate vectors of the 2N sound pressure sensors are determined; data acquisition cards are used for synchronously sampling signals of the 2N sound pressure sensors, time domain sound pressures are measured through the sound pressure sensors, and frequency domain complex sound pressures are obtained through conducting Fourier transform on the time domain sound pressure; vibration complex speeds and vibration complex sound pressures of the surfaces of discrete units can be obtained on the basis of routing calculation of frequency-domain complex sound pressures of the sound pressure sensors, and the numerical integration of structure units obtained by computer virtual discrete as well as numerical integration of acoustic boundary elements; and the sound intensity values of the structure surfaces are obtained through the vibration complex speeds and the vibration complex sound pressures of the structure surfaces to recognize the position and the strength of a sound source.

Owner:XI AN JIAOTONG UNIV

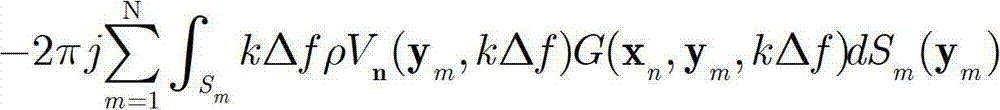

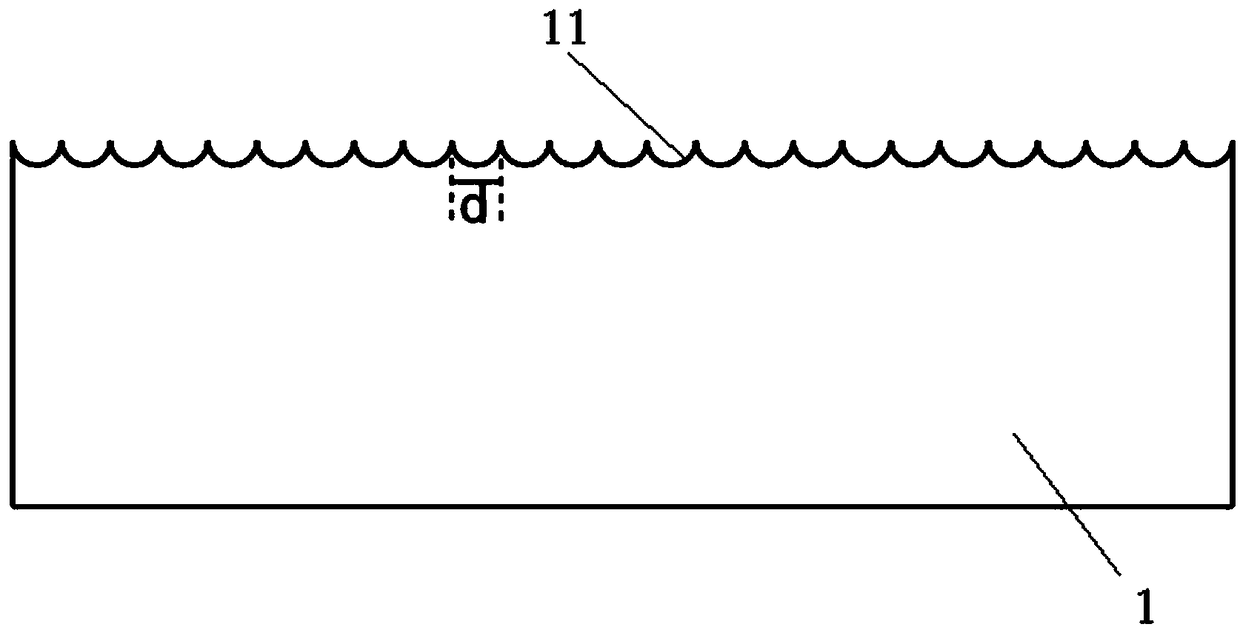

Bionic non-smooth surface polyurethane foam board with cylindrical pits and preparation method

PendingCN108281132AImproved sound absorptionImprove the sound absorption coefficientSound producing devicesEngineeringNoise reduction

The invention discloses a bionic non-smooth surface polyurethane foam board with cylindrical pits. The bionic non-smooth surface polyurethane foam board comprises a base board, the cylindrical pits are arranged on the upper surface of the base board, the cylindrical pits and the base board are structurally integrated and made of polyurethane, and the cylindrical pits include uniformly arranged semi-cylindrical pits and semi-elliptic cylindrical pits. The polyurethane foam board can show excellent sound absorption performances within a narrow thickness range, so that the purposes of sound absorption and noise reduction are achieved.

Owner:JILIN UNIV

Method for increasing blasting vibration frequency of deep-hole bench

ActiveCN103322872AIncrease the blasting vibration frequencyReduce damageBlastingDetonatorRock engineering

The invention discloses a method for increasing blasting vibration frequency of a deep-hole bench. The method includes steps of distributing blast holes as blasting requirements, completing a charging structure in the blast holes, dividing a charging section into N (N>1) detonating sections and setting detonating points in middles of different detonating sections, and detonating by means of detonators, wherein the length of the detonating sections is not less then twice of the damage radius. By the method, blasting vibration frequency of rocks in the range of 20-110 m around a blasting source can be increased, damage degree of the rocks is reduced, natural frequency of neighboring buildings can be avoided, and blasting power unstability due to resonance of the neighboring buildings is avoided. The method can be used for blasting excavation construction in rock engineering fields such as water conservancy and hydropower, mines and traffics.

Owner:WUHAN UNIV

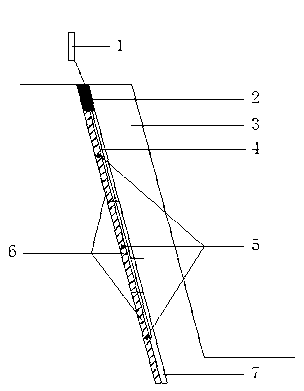

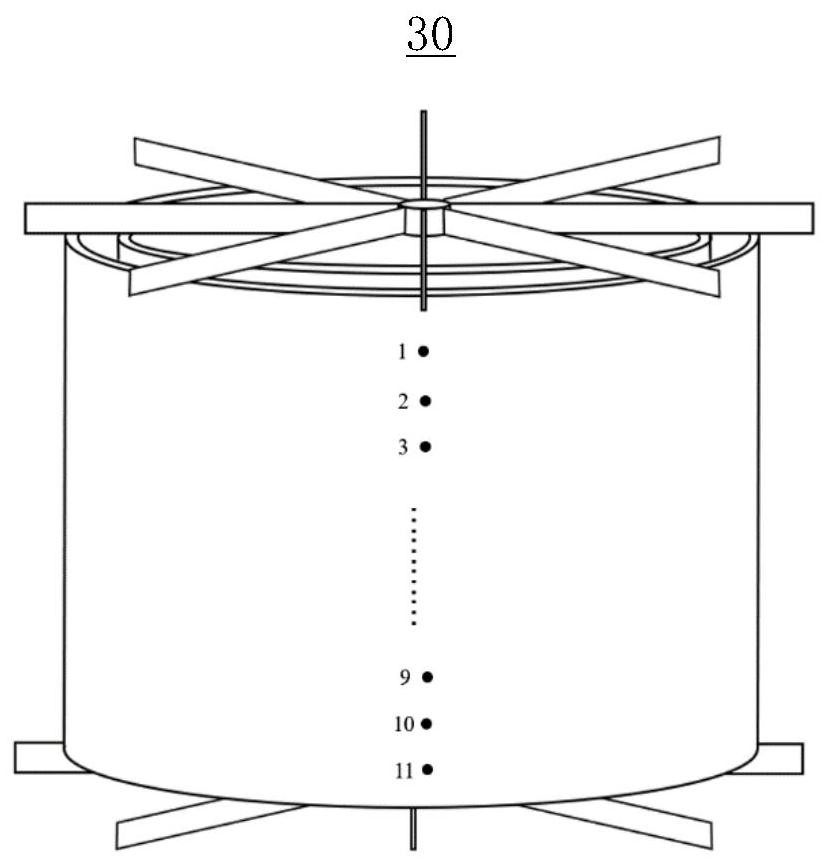

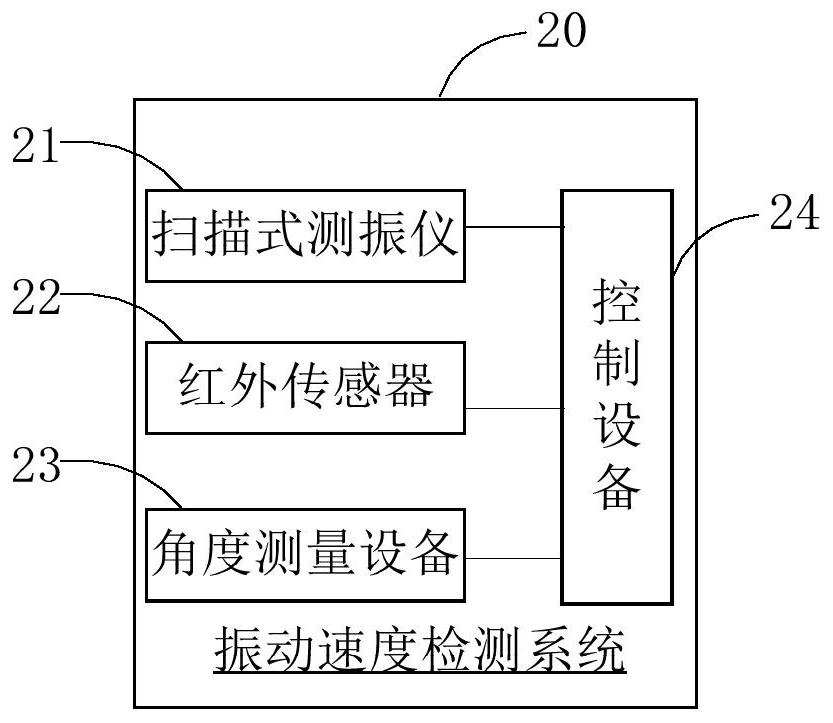

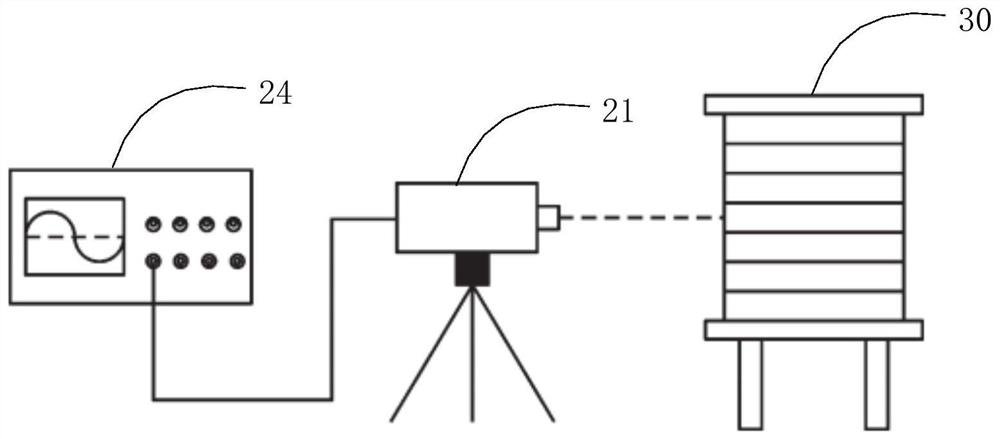

Electric reactor vibration speed detection method and device, control equipment and storage medium

ActiveCN112393797AImprove accuracyFast vibrationSubsonic/sonic/ultrasonic wave measurementNuclear energy generationVibration velocityProcess engineering

The invention relates to an electric reactor vibration speed detection method and device, control equipment and a storage medium. The electric reactor vibration speed detection method comprises the steps that correction included angles between multiple vibration to-be-detected points of an electric reactor and laser emission points of a scanning type vibration meter are determined; and the initialvibration speed of the surface of the electric reactor detected by the scanning type vibration meter is corrected according to the plurality of correction included angles, so that the vibration speedof the to-be-measured vibration point in the horizontal direction is obtained, and the accuracy is higher. According to the electric reactor vibration speed detection method provided by the embodiment of the invention, the technical problem that the accuracy of the surface vibration speed of an existing dry-type air-core electric reactor is relatively low in the prior art is solved, and the technical effect of improving the accuracy of the surface vibration speed of the dry-type air-core electric reactor is achieved.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

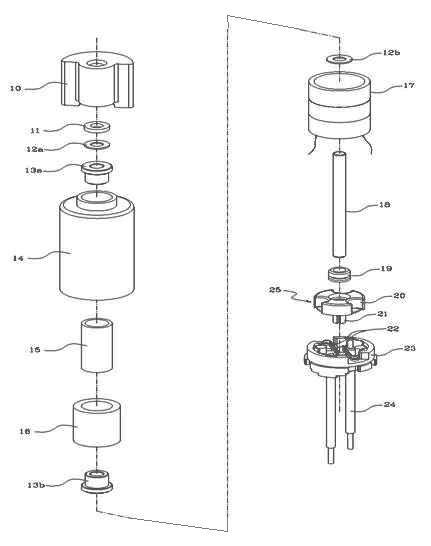

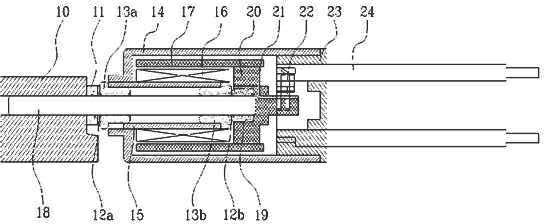

Coreless cylindrical vibrating motor

InactiveCN102111033ABad deformationReduce current consumptionMechanical energy handlingElectrical conductorCurrent consumption

The invention relates to the technical field of vibrating motors, and more particularly relates to a coreless cylindrical vibrating motor which is arranged in a portable electronic device such as a mobile phone, a personal digital assistant (PDA) and the like and causes vibration when necessary. A rotor comprises a coil, first and second vibration sources and a commutator, wherein the coil is accommodated in a stator; the first and second vibration sources are separated from each other by a magnet and arranged oppositely, a center shaft is inserted in the first and second vibration sources, and the first and second vibration sources induce vibration when rotating eccentrically from the center shaft; and the commutator is fixed on the second vibration source and is run through by the center shaft. The rotor is arranged in a rotation space in a shell and can rotate; an electric brush is supported on an electric brush terminal, and is in electrical contact with a conductor commutator segment of the commutator; the electric brush terminal is pressed into one end which is fixed on the upper part of the open shell and is used for accommodating the center shaft for fixed supporting; and a vibrator is arranged in the shell but not outside the shell, so the length of the shell and the length of the coil arranged in the shell can be prolonged, and then low current consumption can be embodied, and the abrasion between the commutator and the electric brush can be reduced. Besides, the two vibration sources are combined with rotation in the coil, so the response speed can be improved, and high vibration force can be generated. The coreless cylindrical vibrating motor has the advantages of low current consumption, quick response, long service life, high vibrating force and the like.

Owner:WENDENG YONGBAI MICRO MOTOR CO LTD

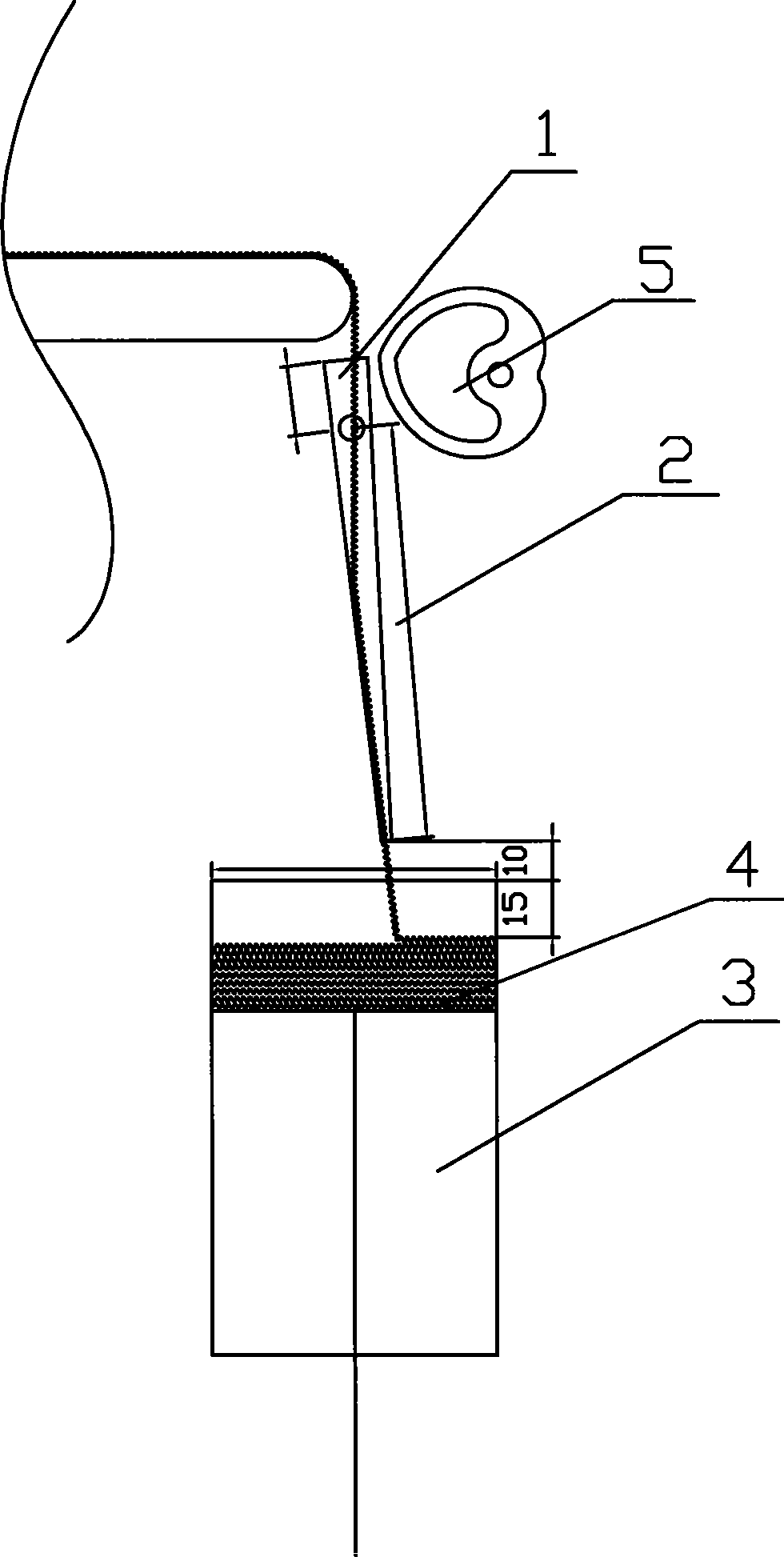

High-speed polypropylene fiber filament tracking laying device

InactiveCN101543314AIncrease the lengthFast vibrationTobacco smoke filtersEngineeringPolypropylene fiber

The invention provides a high-speed polypropylene fiber filament tracking laying device which relates to the technical field of polypropylene chemical fiber filament laying equipment for tobaccos. The device comprises a swinging arm, a swinging bucket, a filament containing barrel, a supporting plate and a cam, wherein the lower end of the swinging arm is connected with the swinging bucket, the filament containing barrel is arranged below the swinging bucket, the supporting plate is arranged in the filament containing barrel, and the cam is arranged at one side of the swinging arm. The high-speed polypropylene fiber filament tracking placing device is characterized in that the length from the lower end of the swinging bucket to the upper end surface of the filament containing barrel is 10 mm, and the height from the upper end surface of a tobacco filament bundle on the supporting plate to the upper end surface of the filament containing barrel is 15 to 20 mm. The invention ensures that the filament bundle can be laid smoothly without being rolled, and the purpose of high-speed production at the filter tip forming speed can be achieved.

Owner:DARE TECH

A general-purpose Portland cement-based ultra-light physical foaming foam concrete

The invention discloses a general-purpose portland cement-based ultra-light physical foaming foam concrete, which is characterized in that: the components and weight percentages are 20%-70% of general-purpose Portland cement, and 0-40% of A-type admixtures % or / and B-type admixture 0-40%, C-type admixture 0.5%-4%, foaming agent 0.3%-2%, water reducing agent 0-1%, fiber 0-4%, and water 25% ~60% is made by mixing, molding and curing. The universal Portland cement-based ultra-light physical foaming foam concrete of the present invention has the characteristics of ultra-low dry density, low thermal conductivity, high strength, wide source of raw materials, low cost, simple preparation process, and easy selection of maintenance process; it is suitable for As insulation engineering, floor heating engineering, backfill engineering, anti-seismic energy-absorbing, lightweight cushion, catalyst carrier materials, it is especially suitable for external wall insulation systems, roof insulation systems, composite insulation walls, and buffer energy-absorbing systems.

Owner:SOUTHWEAT UNIV OF SCI & TECH

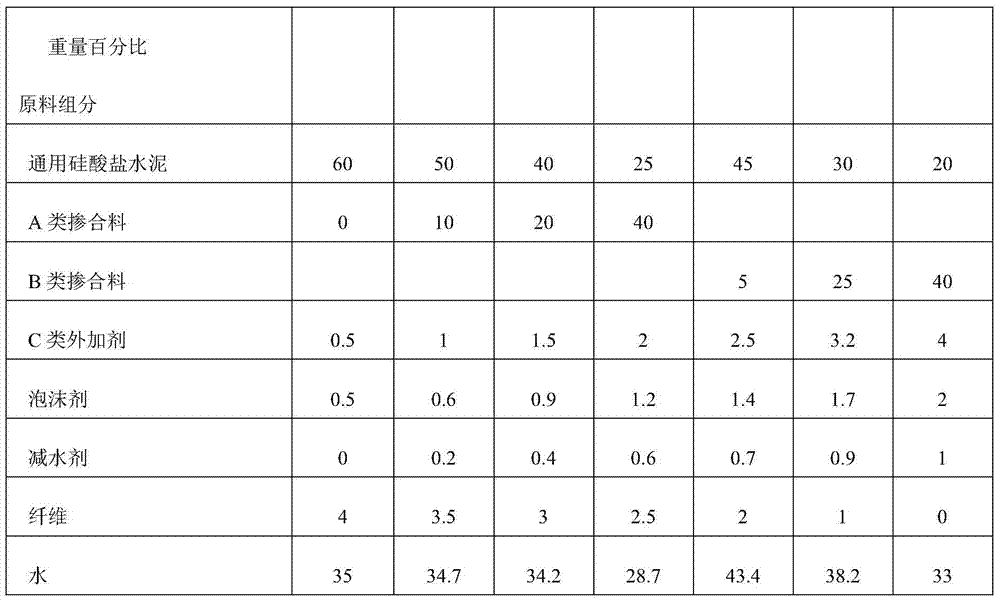

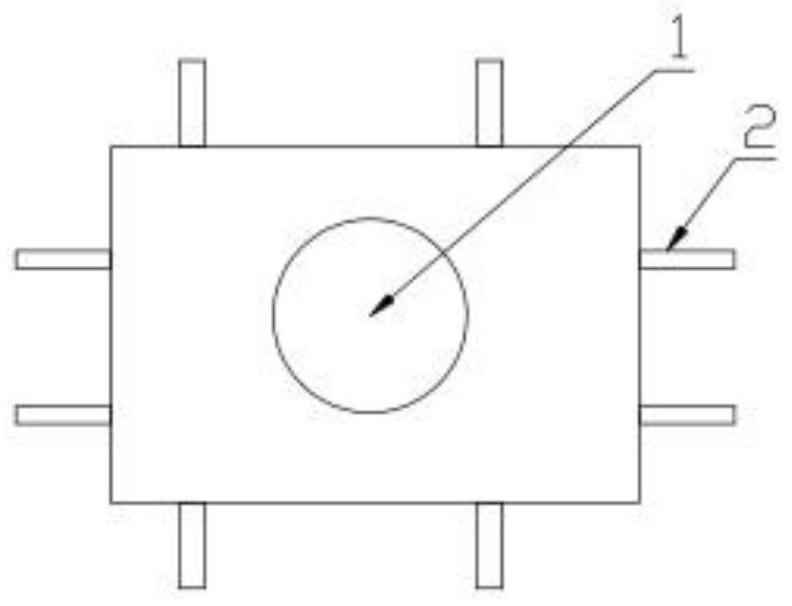

Surgical instrument cleaning device

InactiveCN111714223AFast vibrationGood cleaning effectDiagnosticsSurgerySurgical instrumentHigh energy

The invention relates to the technical field of surgical instruments, and discloses a surgical instrument cleaning device. The surgical instrument cleaning device comprises a mounting frame, wherein atransmission box is fixedly mounted on the lower portion of the left portion of the mounting frame; supporting plates are fixedly mounted on the mounting frame on the left and right parts of the transmission box; sliding rods are fixedly mounted on the upper and lower inner walls and the left and right outer walls of the transmission box; and the outer walls of the upper and lower and the left and right sliding rods are all sleeved with return springs. According to the surgical instrument cleaning device, through the arrangement of the transmission box, the supporting plates, the sliding rods, the return springs, a power shaft, eccentric blocks, shaking blocks, a cleaning table, supporting shafts, shaft brackets, limiting cylinders, adjusting knobs and sliding rails, two-time mechanical vibration is achieved, the vibration speed is high, and the cleaning effect is good; cleaning dead corners and bacterial virus are not prone to occurring, and the practicability is high; and one rotating source provides power for two variable vibration sources through a belt wheel, a guide wheel and a transmission belt, secondary cleaning is achieved through two times of vibration, high energy consumption of secondary cleaning is prevented, and safety of patients and doctors during use is guaranteed.

Owner:李群飞

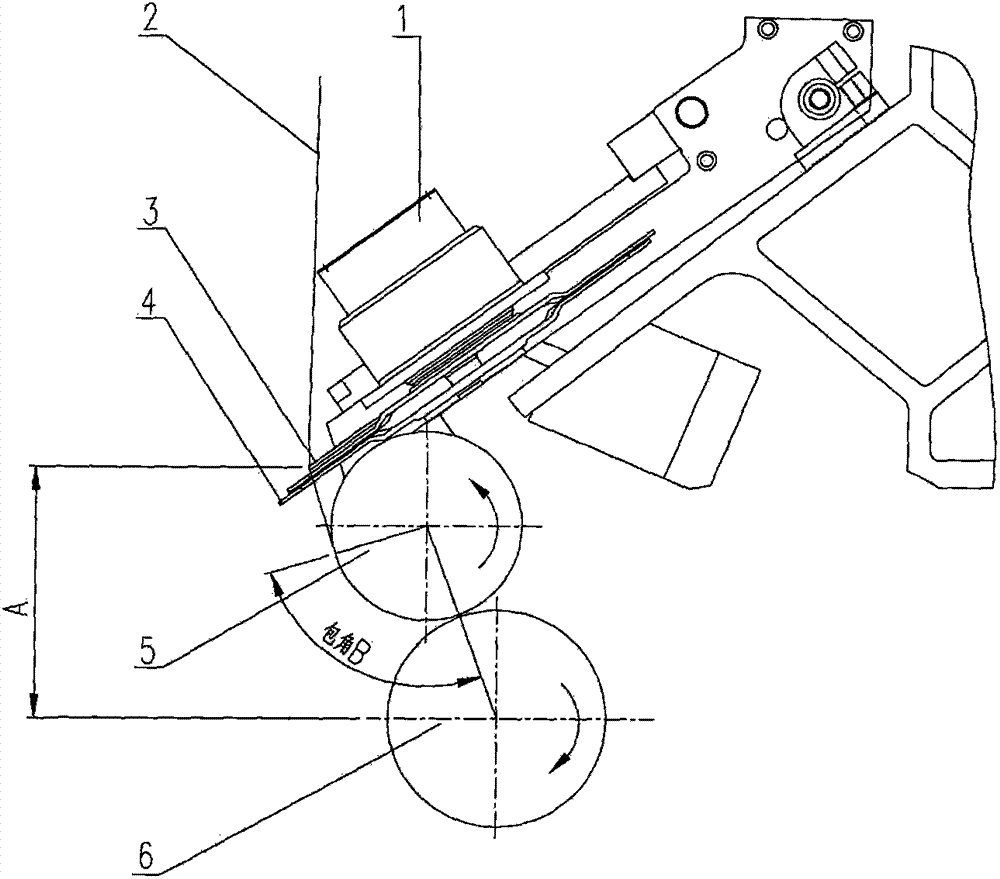

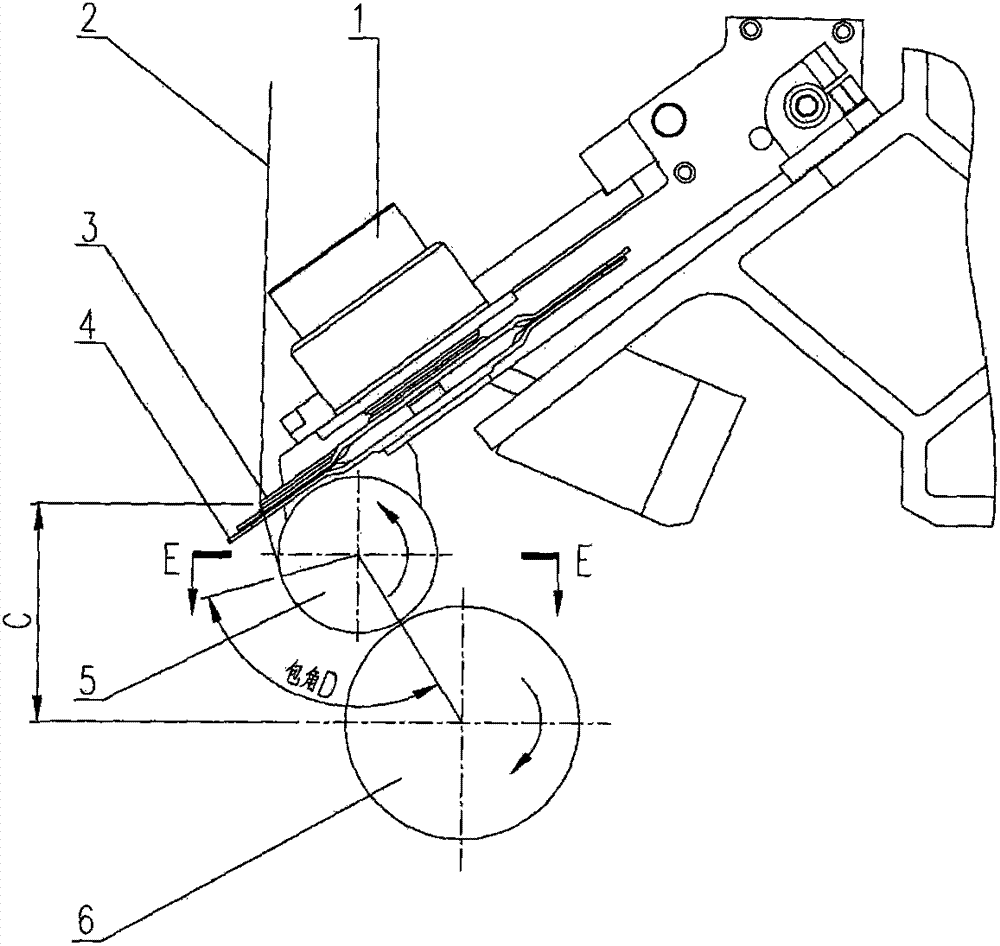

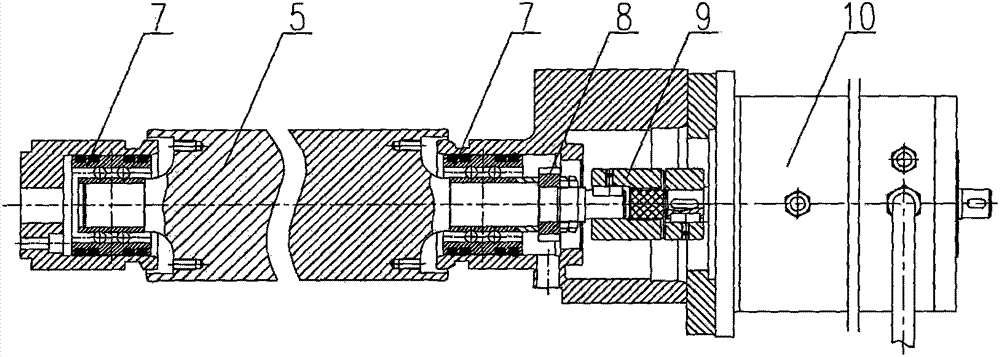

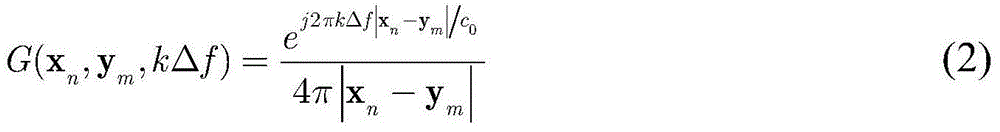

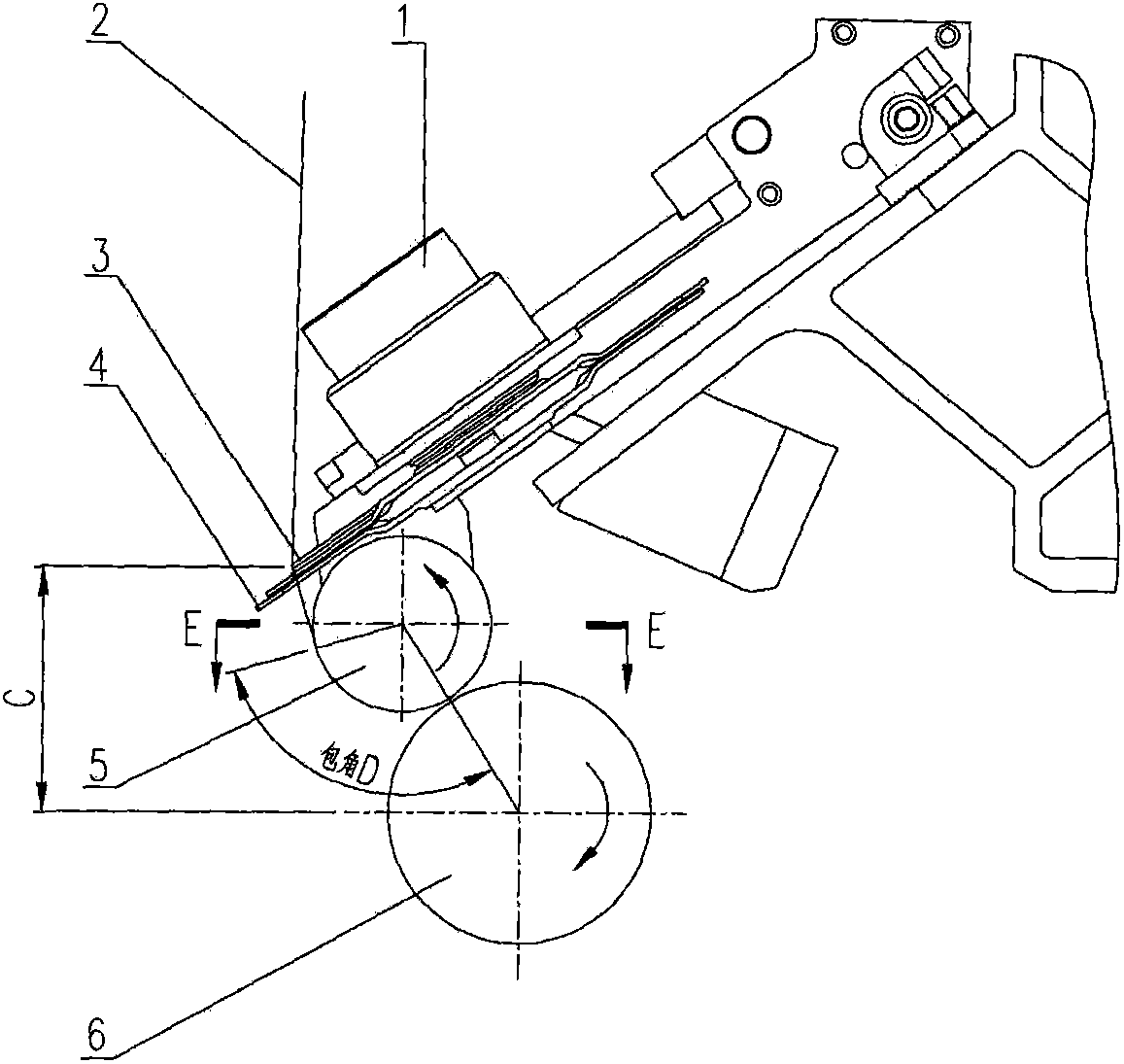

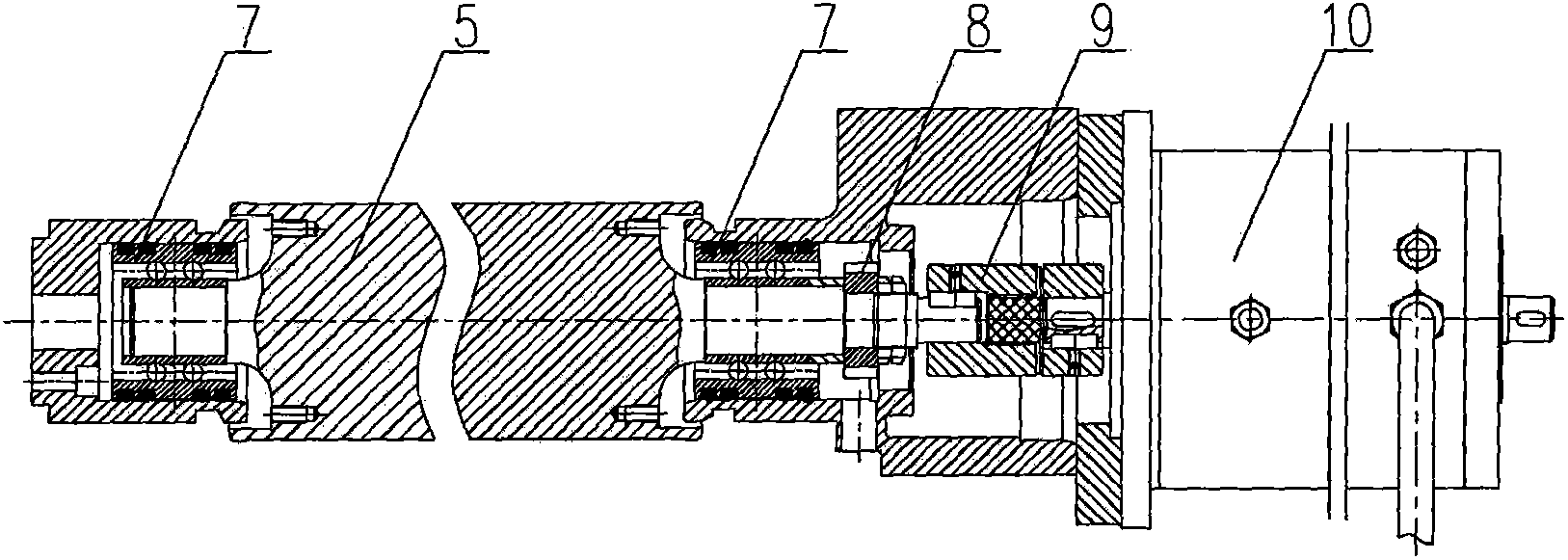

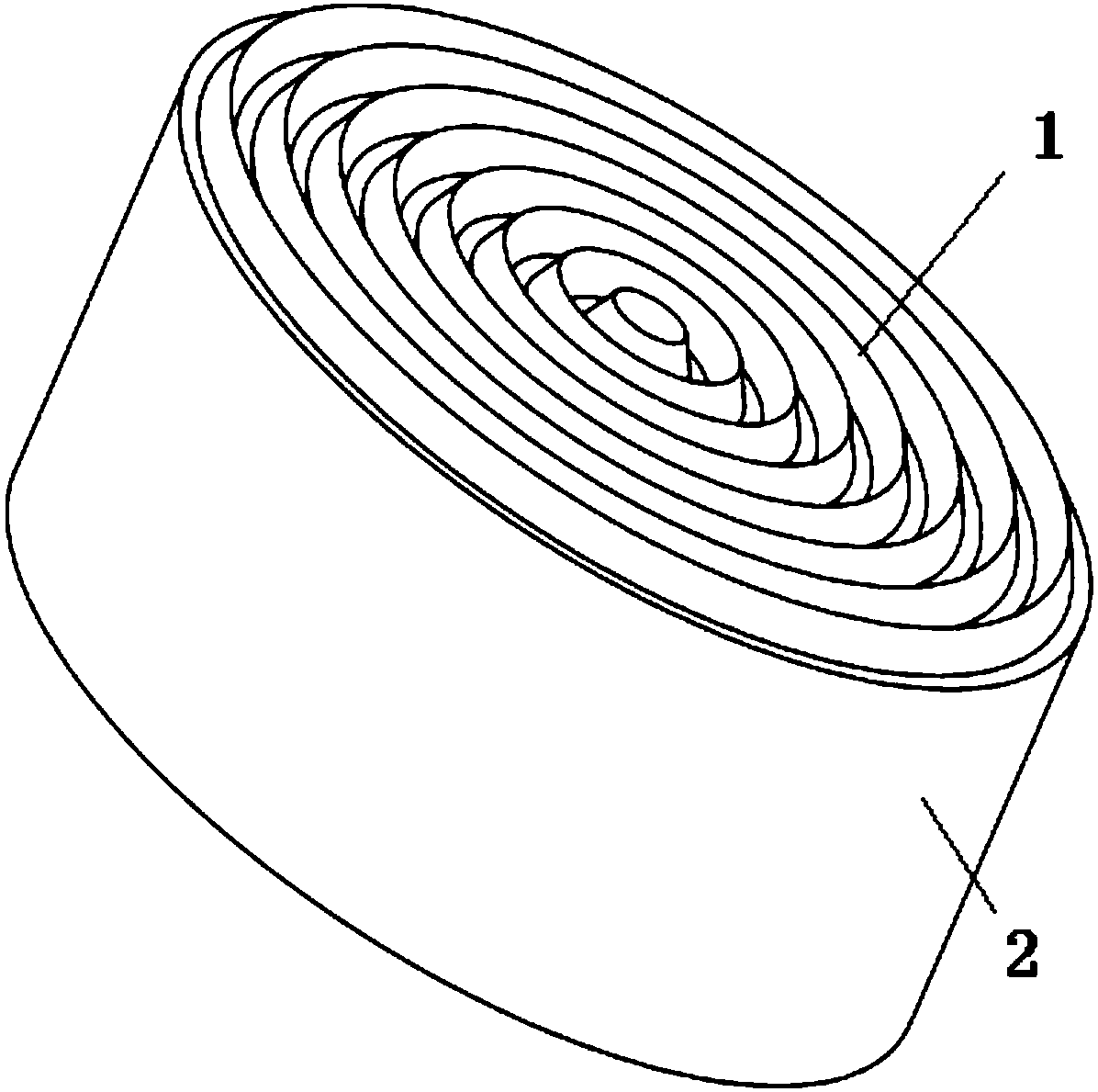

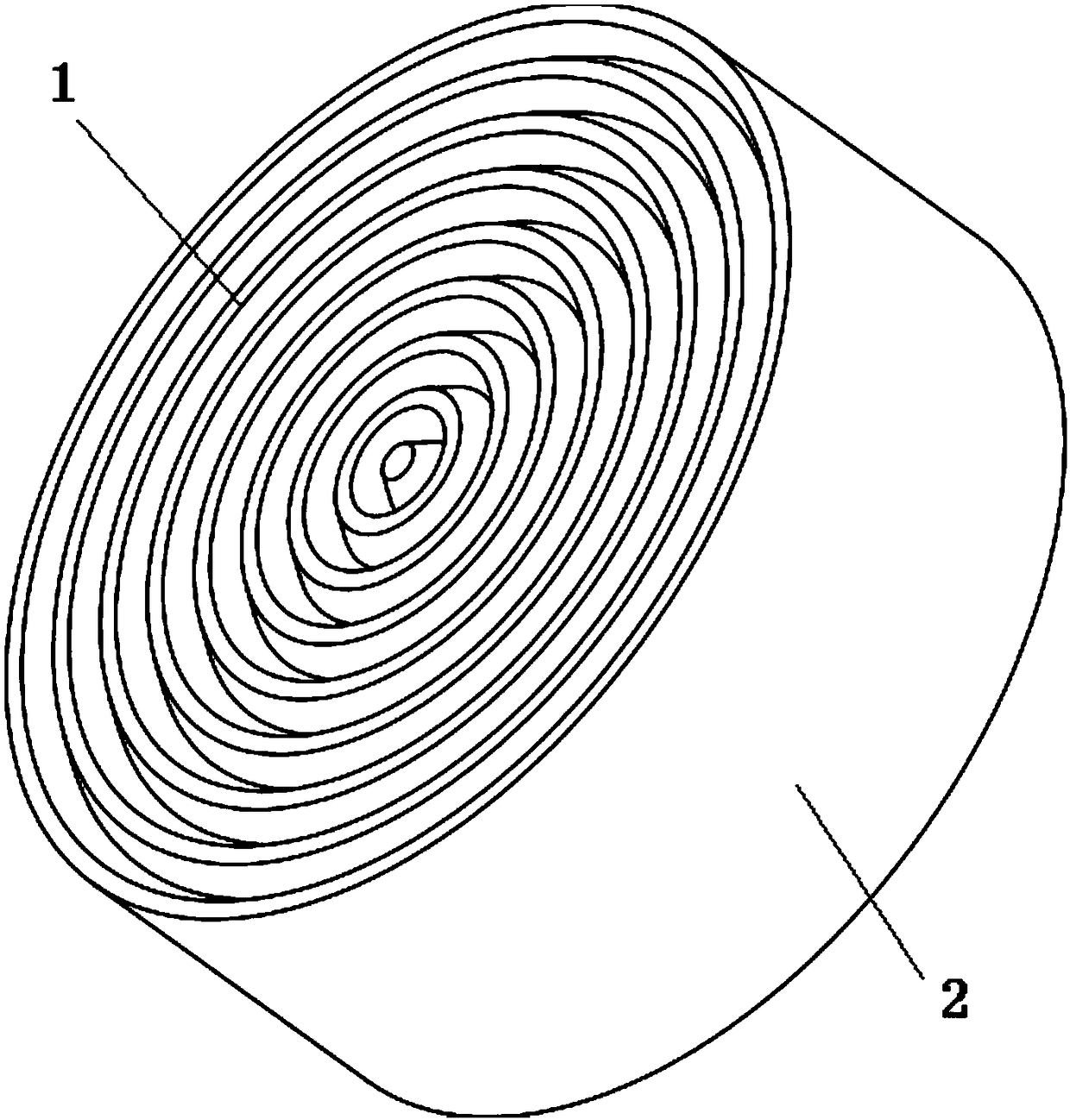

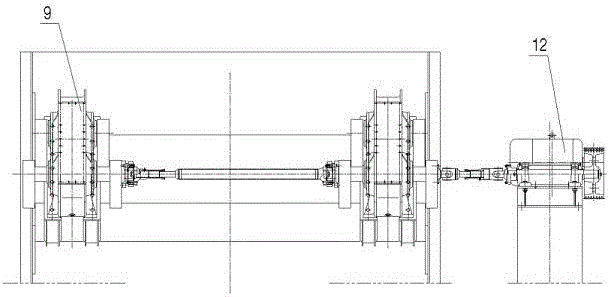

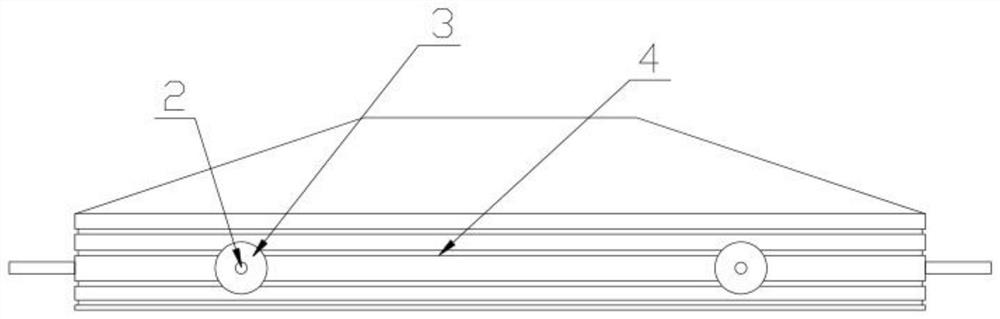

Press roll for filament winding head

The invention relates to a chemical filament winding device, in particular to a small-diameter press roll for a chemical filament winding head. The press roll body is a solid roll body; shaft heads at two ends of the press roll are supported by bearings; one end of a press roll shaft is connected with a motor through a coupling; a speed measuring wheel is arranged between the bearings and the coupling; the press roll body is equipped with a balancing hole; and the length C of a filament bundle between a forming board and a bobbin chuck shaft is less than A, and a wrap angle D of the filament bundle on the press roll is greater than a wrap angle B. By utilizing the press roll device for the chemical filament winding head, winding speed of the chemical filament winding head is increased;d meanwhile, forming and unwinding properties of a spinning cake are improved.

Owner:北京德厚朴化工技术股份有限公司

Method for noncontact measurement of boundary vibration and application of method

InactiveCN102853902BNo errorHigh precisionSubsonic/sonic/ultrasonic wave measurementSound sourcesRectangular coordinates

The invention discloses a method for noncontact measurement of boundary vibration and an application of the method. The method comprises the following steps: firstly, a rectangular coordinates system is established in a three-dimensional space, and 2N sound pressure sensors are arranged around a measured object, and the geometric coordinate vectors of the 2N sound pressure sensors are determined; data acquisition cards are used for synchronously sampling signals of the 2N sound pressure sensors, time domain sound pressures are measured through the sound pressure sensors, and frequency domain complex sound pressures are obtained through conducting Fourier transform on the time domain sound pressure; vibration complex speeds and vibration complex sound pressures of the surfaces of discrete units can be obtained on the basis of routing calculation of frequency-domain complex sound pressures of the sound pressure sensors, and the numerical integration of structure units obtained by computer virtual discrete as well as numerical integration of acoustic boundary elements; and the sound intensity values of the structure surfaces are obtained through the vibration complex speeds and the vibration complex sound pressures of the structure surfaces to recognize the position and the strength of a sound source.

Owner:XI AN JIAOTONG UNIV

Press roll for filament winding head

The invention relates to a chemical filament winding device, in particular to a small-diameter press roll for a chemical filament winding head. The press roll body is a solid roll body; shaft heads at two ends of the press roll are supported by bearings; one end of a press roll shaft is connected with a motor through a coupling; a speed measuring wheel is arranged between the bearings and the coupling; the press roll body is equipped with a balancing hole; and the length C of a filament bundle between a forming board and a bobbin chuck shaft is less than A, and a wrap angle D of the filament bundle on the press roll is greater than a wrap angle B. By utilizing the press roll device for the chemical filament winding head, winding speed of the chemical filament winding head is increased;d meanwhile, forming and unwinding properties of a spinning cake are improved.

Owner:北京德厚朴化工技术股份有限公司

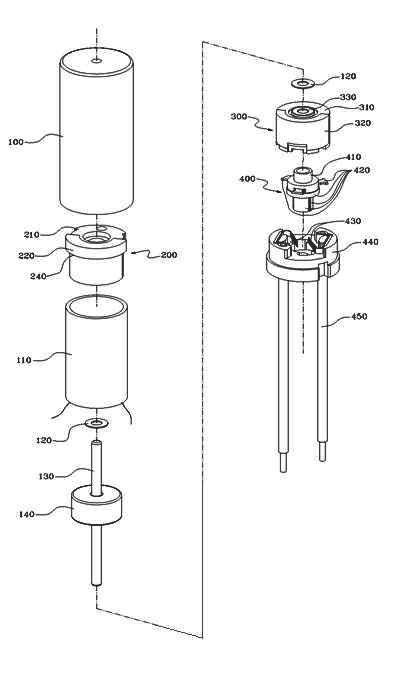

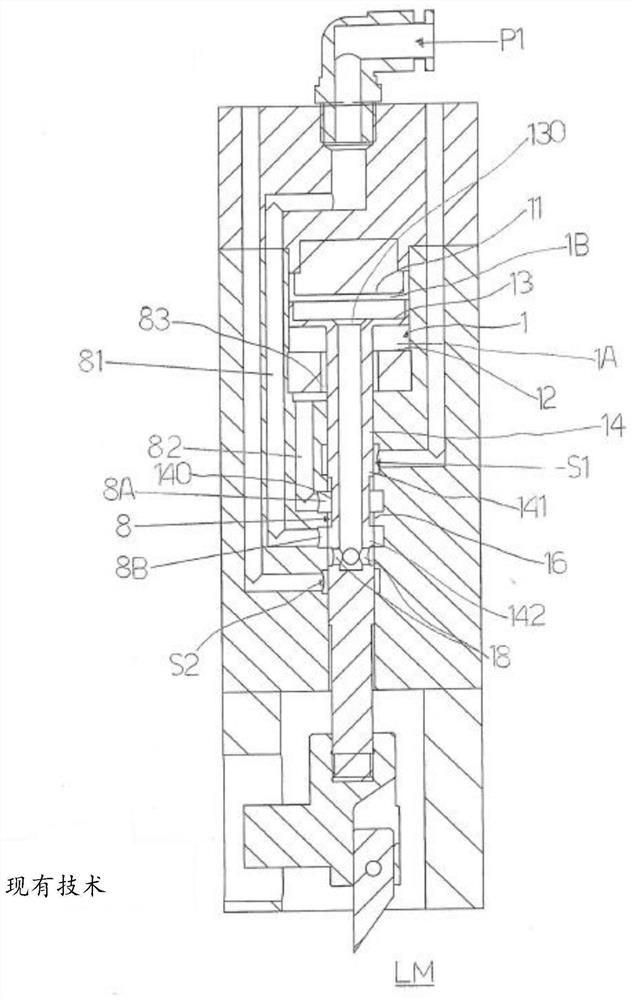

Pneumatic cutting device with oscillating blade for leather cutting machines

InactiveCN113518566AFast vibrationAvoid vibrationMetal sawing devicesShoemaking devicesEngineeringMechanical engineering

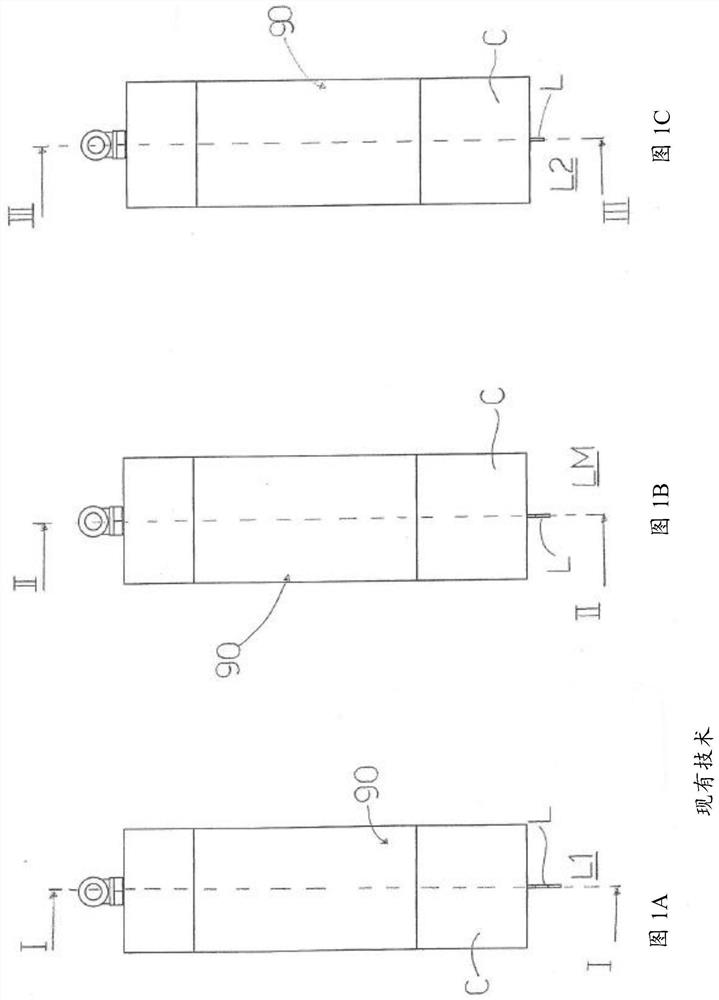

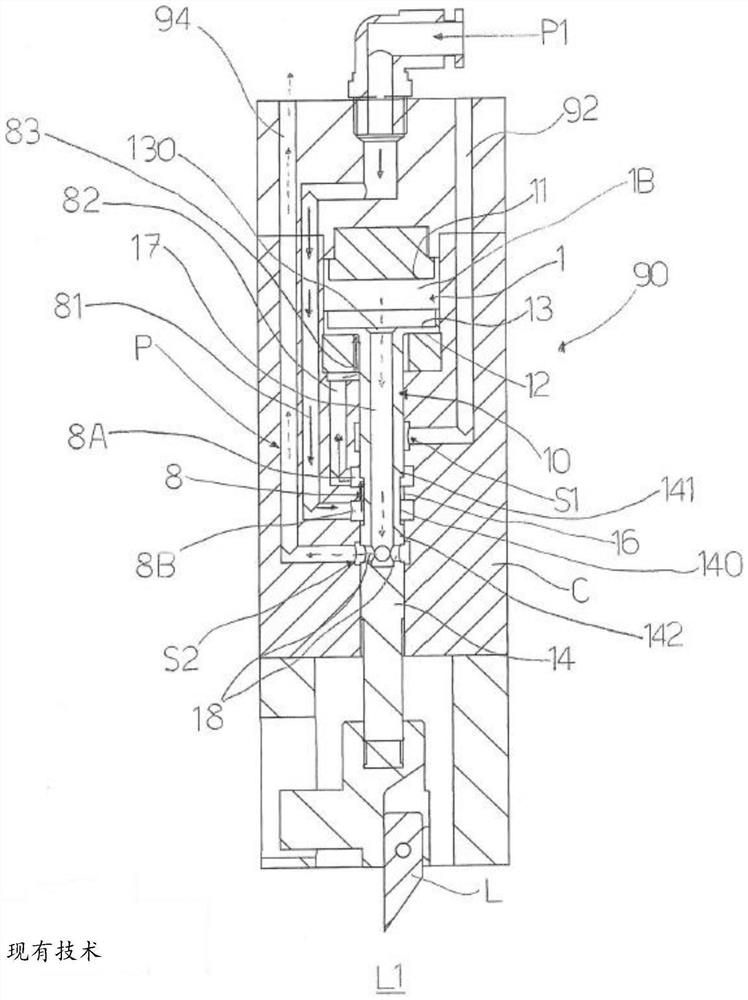

An improved pneumatic cutting device (100) comprises an oscillating chamber (1); an oscillating piston (10) having a head (13), predisposed in the oscillating chamber (1), and a rod (14) connected to a cutting blade (L); a pneumatic activating system (P) communicating with the oscillating chamber (1) so as to pneumatically activate the oscillating piston (10) to oscillate in the oscillating chamber (1) and thus cause the cutting blade (L) to oscillate vertically. A first lower cylindrical cavity (162) is present under the oscillating chamber (1), and a second upper cylindrical cavity (161) is present over the oscillating chamber (1), and the rod (14) comprises a first lower rod part (22), in the first lower cylindrical cavity (162), and a second upper rod part (21), in the second upper cylindrical cavity (161). The pneumatic activating system (P) comprises: a main annular switching chamber (30) and an annular discharge chamber (40), realized in a portion of the walls of the second upper cylindrical cavity (161). The second upper rod part (21) cooperates with the pneumatic activating system (P) for the switching of the oscillation stroke of the oscillating piston (10).

Owner:TESEO SPA

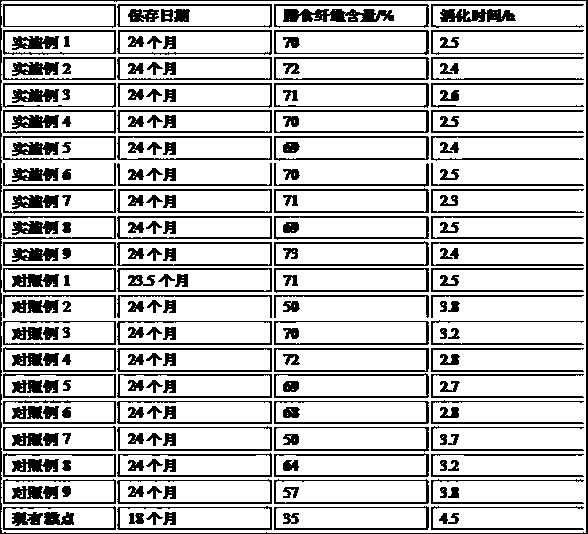

Digestion-aiding cake containing myrtle and preparation method thereof

InactiveCN109349307AVersatileImprove antioxidant capacityDough treatmentModified nutritive productsSuccinic acidDigestion

The invention relates to a digestion-aiding cake containing myrtle. Forming compositions of the cake comprise the following raw materials in parts by weight: 30-40 parts of flour, 7-10 parts of eggs,2-5 parts of cream, 5-10 parts of white granulated sugar, 0.5-2.5 parts of active dry yeast, 1-4 parts of the myrtle, 3-8 parts of ficus carica, 0.5-1.5 parts of polygala tenuifolia soup, 0.1-0.5 parts of magnesium stearate, and 1-5 parts of pine nuts. The method is capable of preparing the cake by using a ficus carica extract, wherein the cake contains a lot of nutrient substances required by a human body, and contains malic acid, oxalic acid, succinic acid, citric acid, fatty acid, lipase, dietary fibers and the like. After these substances enter the human body, the body can be aided to digest food, the effect of relaxing bowel is achieved, and functions of the cake are enriched.

Owner:唐国文

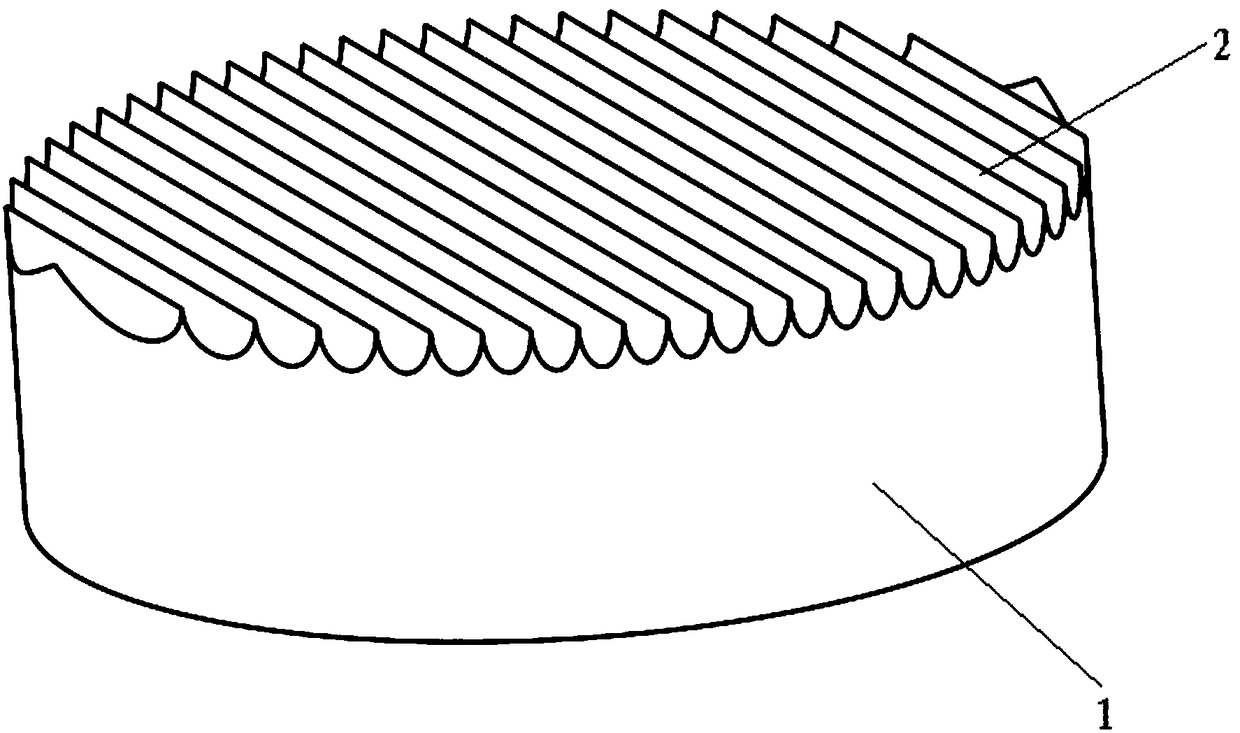

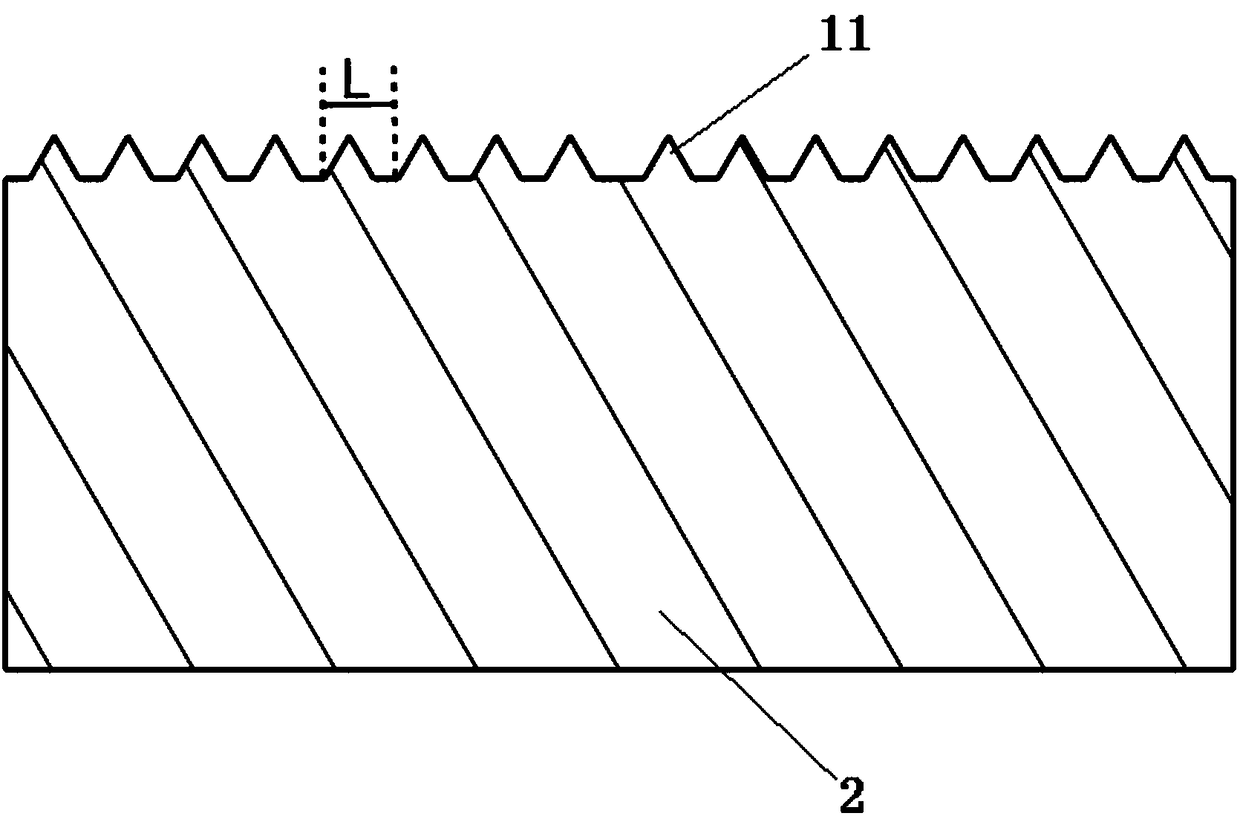

Polyurethane foam plate with rib-shaped bionic non-smooth surface and preparation method of polyurethane foam plate

PendingCN108269565AImproved sound absorptionImprove the sound absorption coefficientSound producing devicesEngineeringPolyurethane

The invention discloses a polyurethane foam plate with a rib-shaped bionic non-smooth surface. The polyurethane foam plate comprises a basal plate, wherein the upper surface of the basal plate is provided with a bulge; the bulge and the basal plate are of an integral structure and respectively made of polyurethane; and the bulge is a triangular rib body or a trapezoidal rib body which is uniformlydistributed in a concentric circular ring shape. The invention provides the polyurethane foam plate with the rib-shaped bionic non-smooth surface and a preparation method. In a smaller thickness range, the sound absorption performance is excellent, and a purpose of absorbing the sound and reducing the noise is achieved.

Owner:JILIN UNIV

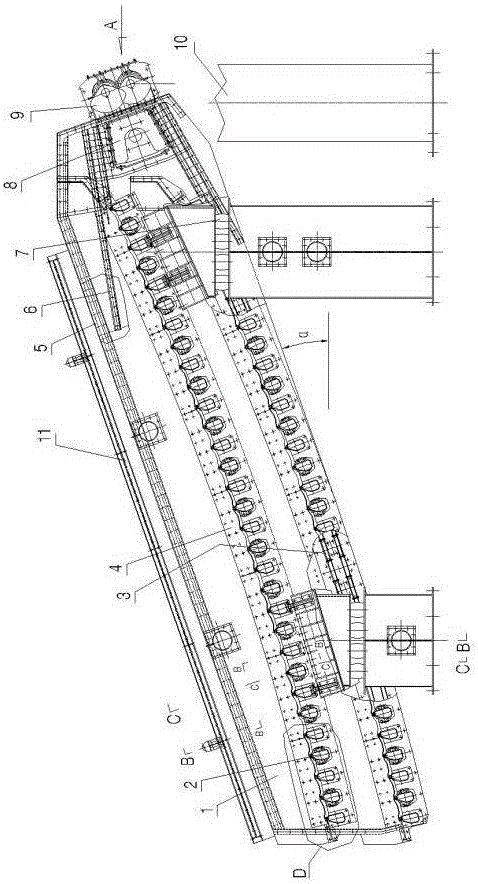

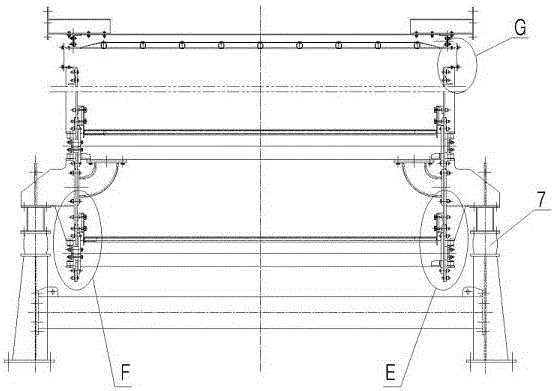

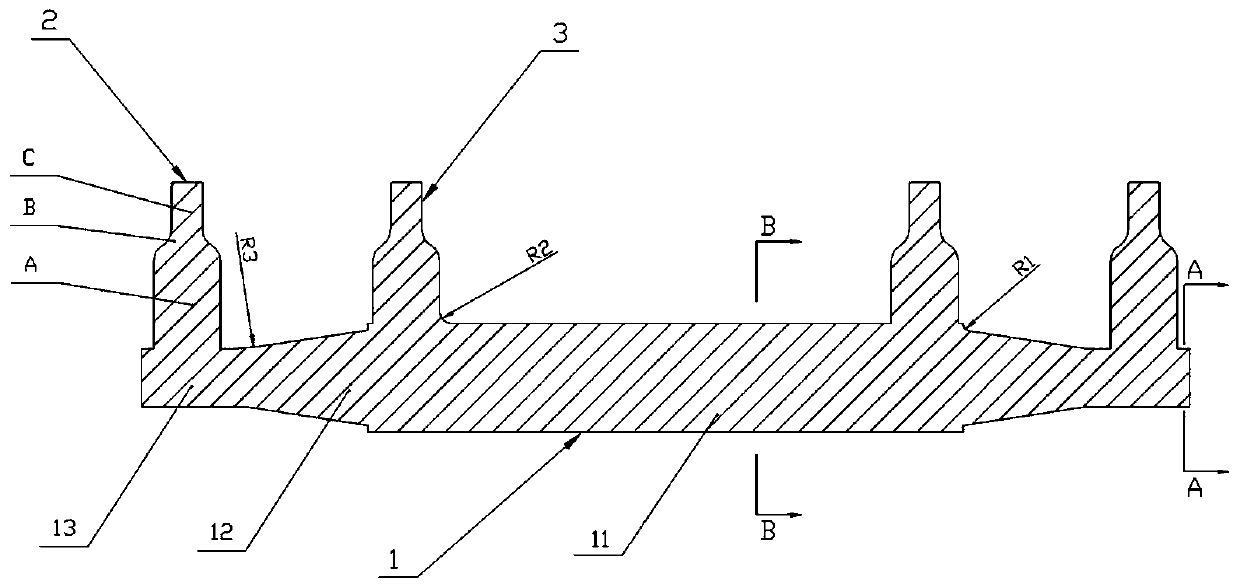

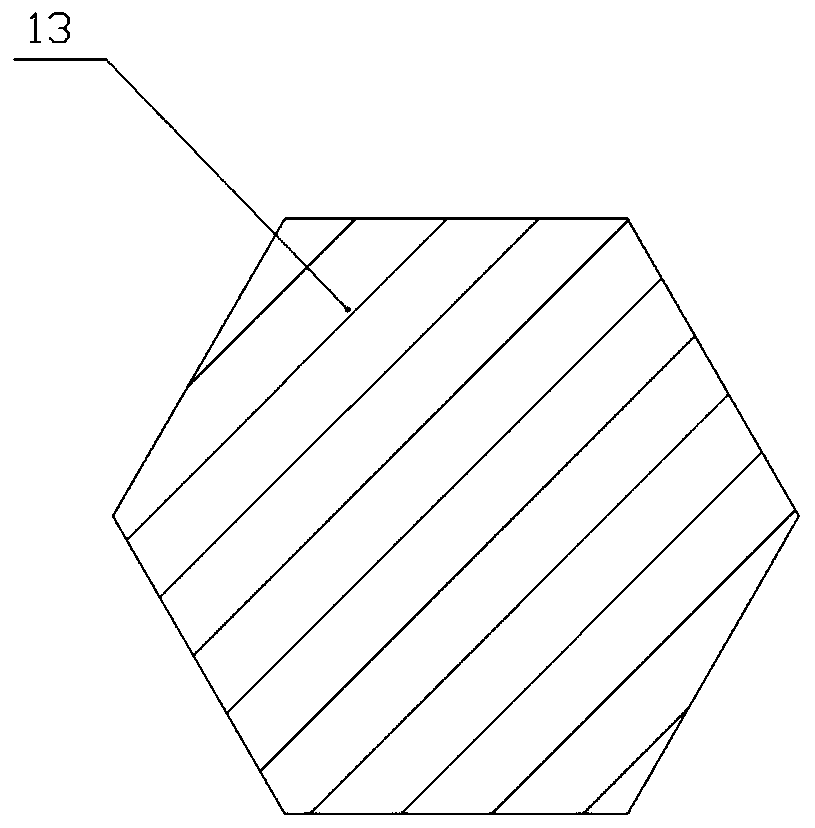

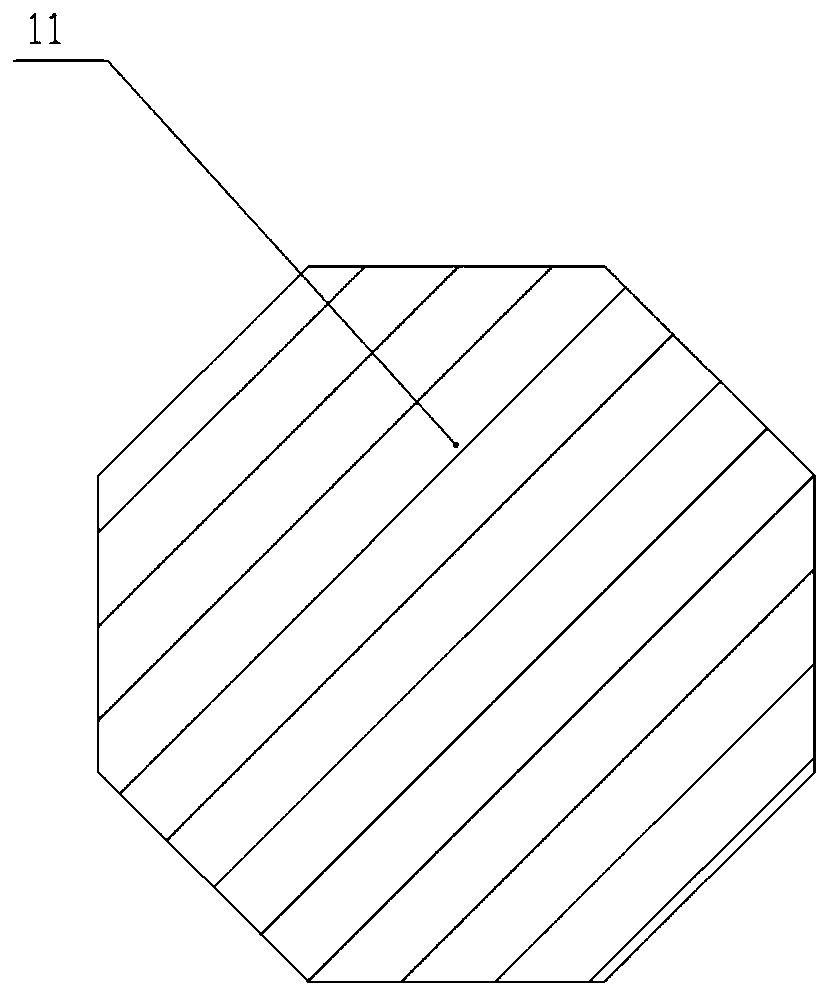

The linear vibrator is set on the relaxation screen at the feeding end

The invention provides a tension and relaxation screen with a straight-line oscillator arranged at the feeding end, belongs to the sub-mechanical field of oscillating screens and solves the problems that existing tension and relaxation screens are prone to having meshes blocked off and insufficient in processing capacity. Lower cross beams of a screen frame are composed of movable cross beams and fixed cross beams which are arranged in an alternate mode; the fixed cross beams are connected with screen frame side plates; the movable cross beams pass through the screen frame side plates through connecting blocks and are connected with locating beams at the outer sides of the side plates, so that movable cross beam sets are formed; the upper side and the lower side of each locating beam are connected with guiding tracks located on the screen frame side plates through rubber shearing springs; one side of each piece of elastic screen net is installed onto the corresponding fixed cross beam, and the other side of the corresponding piece of elastic screen net is installed on the corresponding movable cross beam. The double-shaft straight-line oscillator is installed at the feeding end of a screen box through a trapezoid oscillator mounting beam; screen surface sealing plates are arranged between the side plates of the screen box and the elastic screen net. By means of the tension and relaxation screen, the effect for screening high-viscosity materials is improved, no mesh is blocked off, and high production capacity screening is achieved. The screen can be applied to efficient material screening in such industries as coal, mine, building material, urban garbage and waste water preliminary purification.

Owner:鞍山恒竣机械设备有限公司

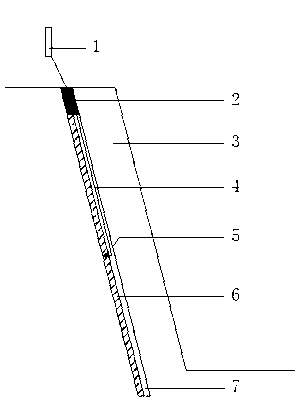

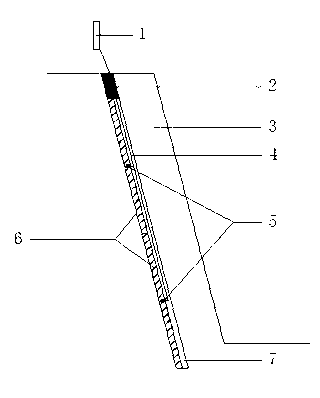

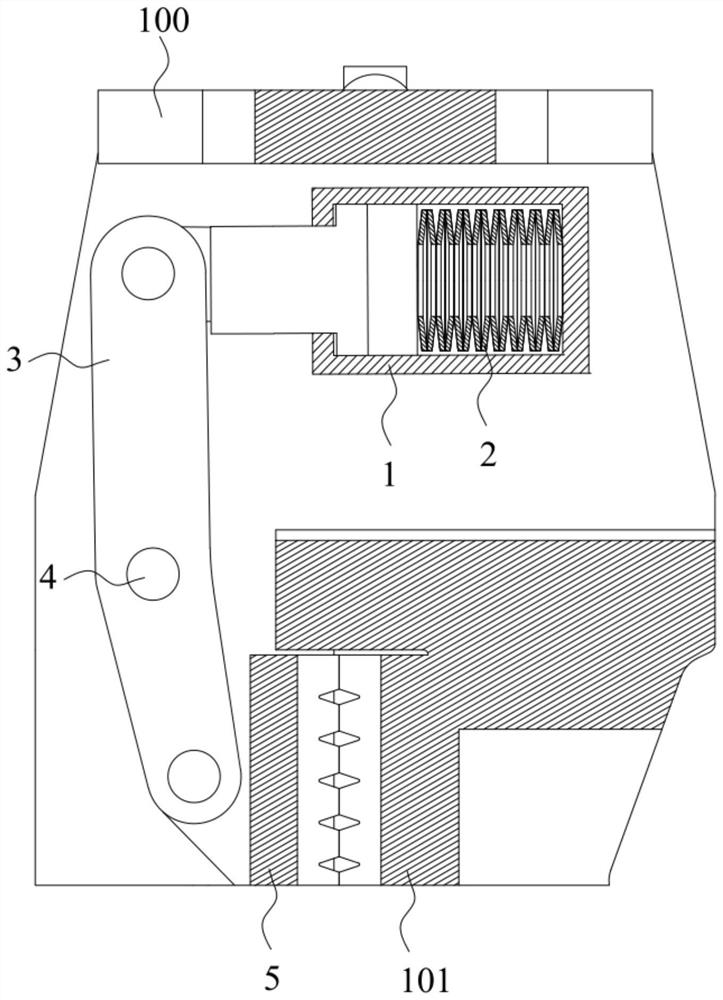

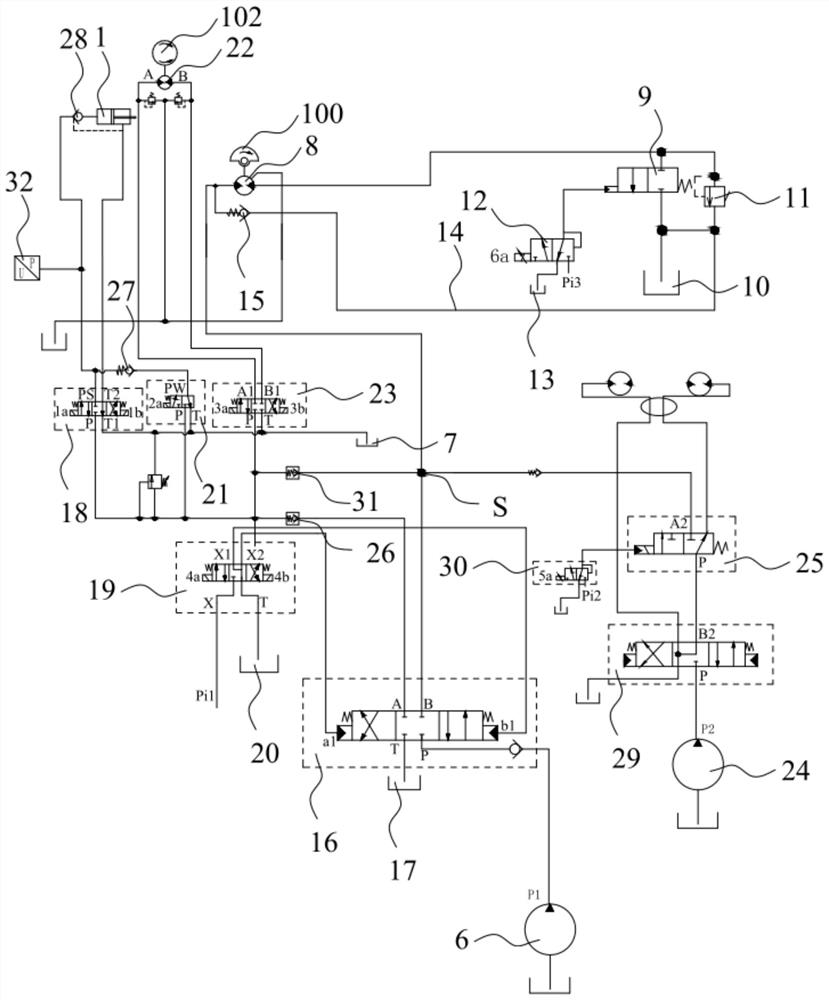

Clamping device and hydraulic system of pile driver

PendingCN112942347AImprove securityAvoid damageServomotor componentsBulkheads/pilesStructural engineeringMechanical engineering

The invention discloses a clamping device and a hydraulic system of a pile driver, and relates to the technical field of engineering machinery. The clamping device of the pile driver is arranged on a hammer body of a vibration hammer head and used for clamping a pile, the clamping device comprises a clamping oil cylinder, a connecting rod and a clamping piece, wherein the clamping oil cylinder is fixed to the hammer body, a piston and a piston rod connected with the piston are arranged in the clamping oil cylinder, an elastic piece is arranged in a rodless cavity of the clamping oil cylinder, the two ends of the elastic piece in the telescopic direction abut against the inner wall of the clamping oil cylinder and the piston, the extension direction of the connecting rod and the extension direction of the piston rod form an angle, one end of the connecting rod is slidably connected with the piston rod, the connecting rod is rotationally connected with the hammer body through a rotating part, the rotating part and the two ends of the connecting rod are arranged at an interval, the clamping piece is slidably connected with the other end of the connecting rod, an abutting portion is arranged on the hammer body, and the elastic piece can enable the piston rod to stretch out of the clamping oil cylinder to drive the clamping piece to move so that the pile can abut against the abutting portion. According to the clamping device, clamping can be achieved through the structure of the clamping device, so that clamping disengaging can be avoided, and safety is improved.

Owner:SHANDONG LINGONG CONSTR MACHINERY

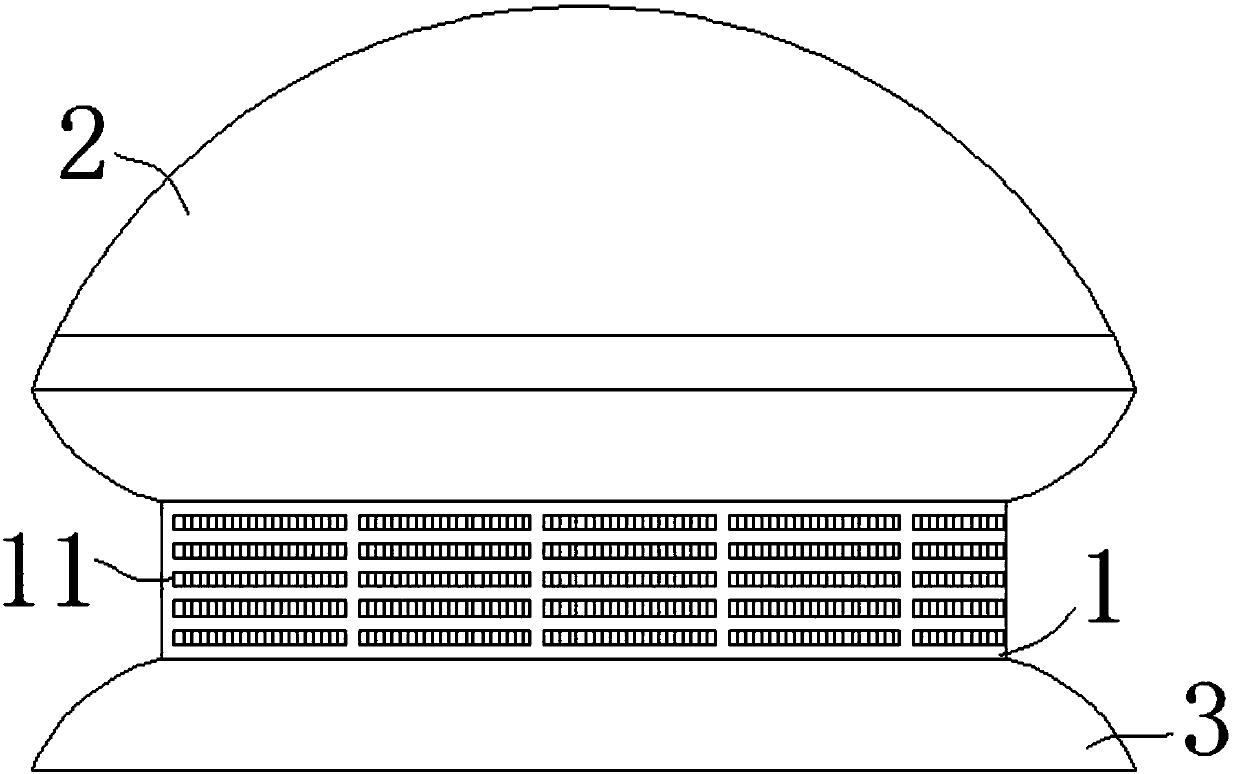

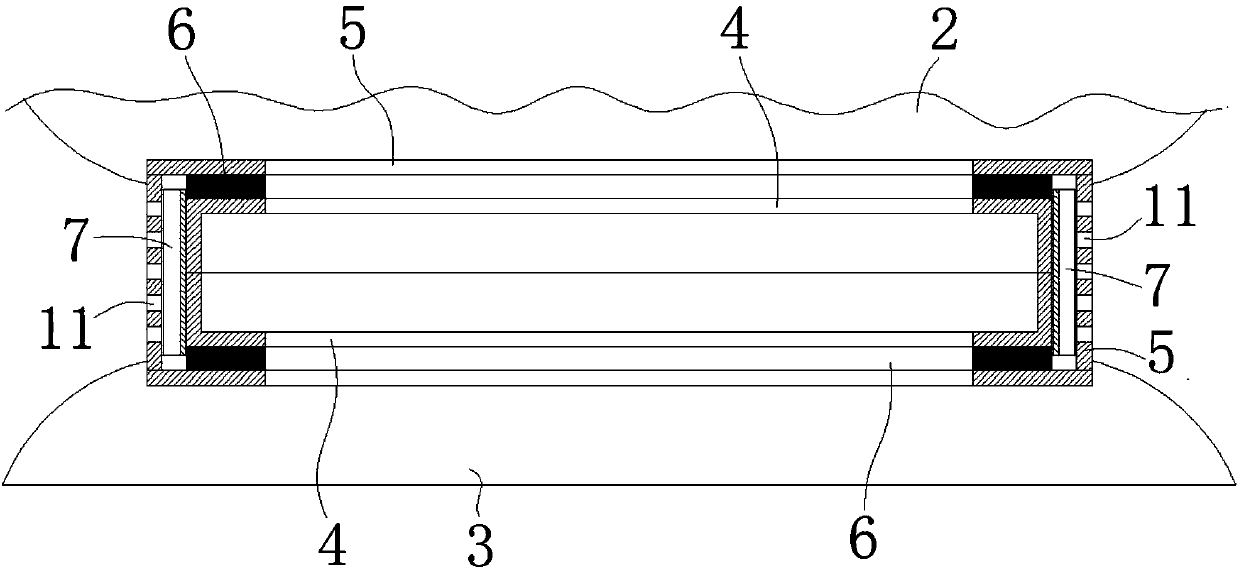

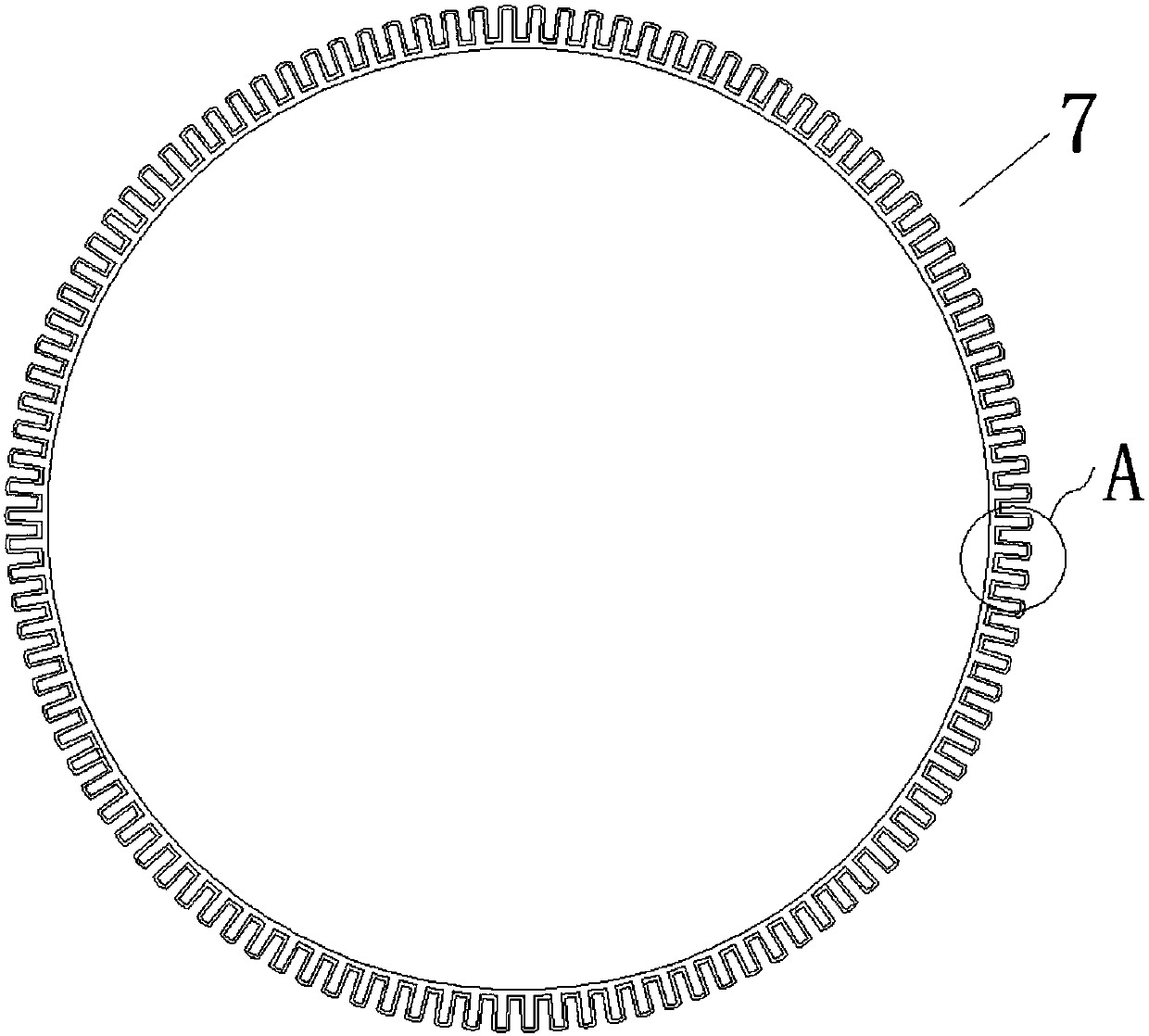

360° omnidirectional tweeter

ActiveCN105282669BTrue restorationImprove the sound effectElectrical transducersSmall amplitudeHigh energy

The invention relates to a 360 degree all-round sound-producing high frequency loudspeaker, which comprises a magnetic circuit structure, wherein the magnetic circuit structure comprises a first circle-shaped conductive magnet and a second circle-shaped conductive magnet that sleeves an outer side of the first circle-shaped conductive magnet; high energy magnets and a circle-shaped diaphragm module are set between the first circle-shaped conductive magnet and a second circle-shaped conductive magnet; the high energy magnets are symmetrically set at upper and lower sides of the first circle-shaped conductive magnet; and the circle-shaped diaphragm module is set between the two high energy magnets that are set at upper and lower sides of the first circle-shaped conductive magnet. According to the invention, a folded diaphragm is enclosed to be a circle shape, thereby increasing the diaphragm area, increasing the air driving amount and realizing the advantages of small amplitude of the diaphragm, fast vibration speed and faster sound-transmitting speed; and an impedance curve to be straight, so the loudspeaker is easily driven and the distortion is lower.

Owner:多米亿(苏州)智能科技有限公司

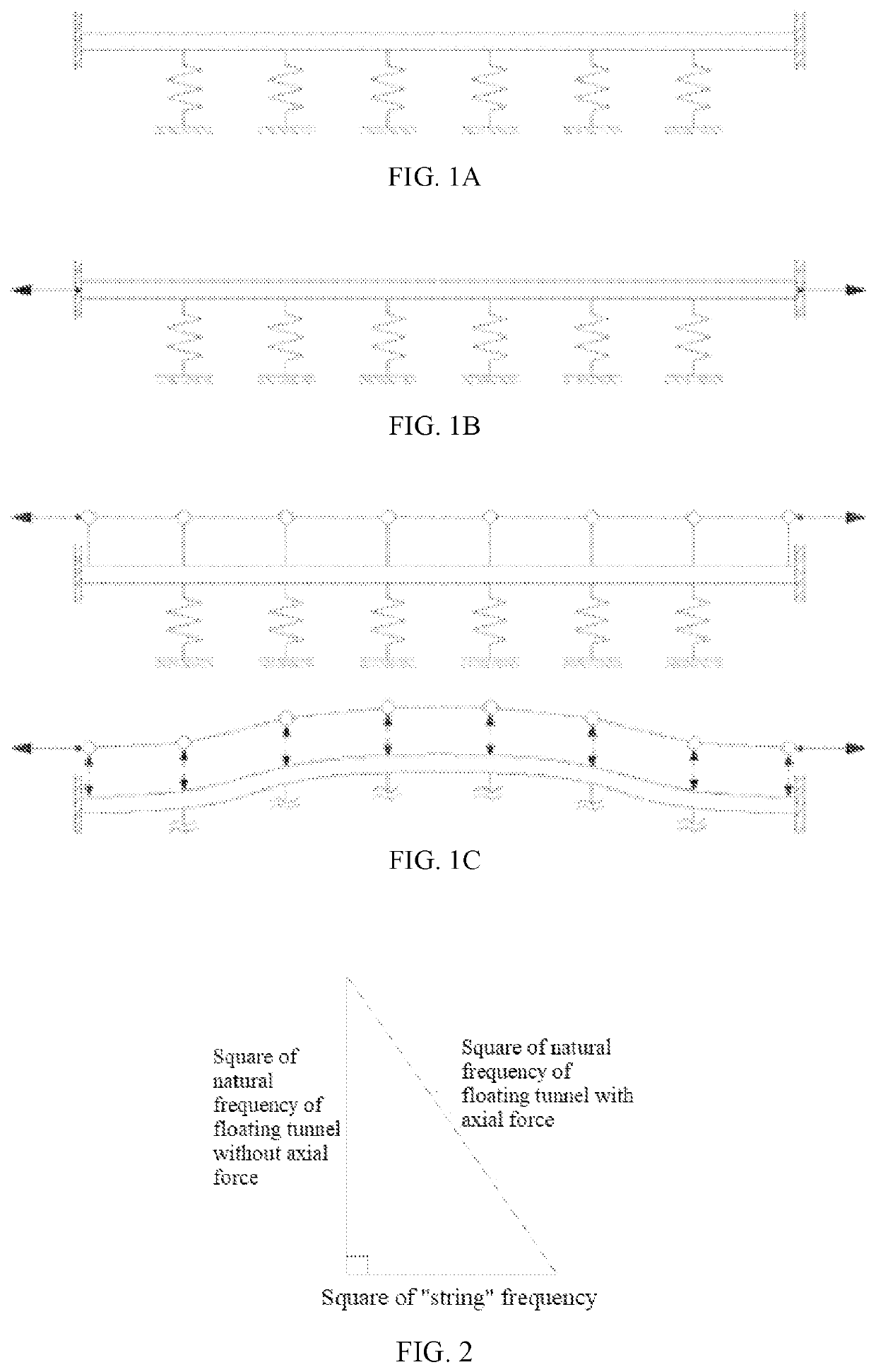

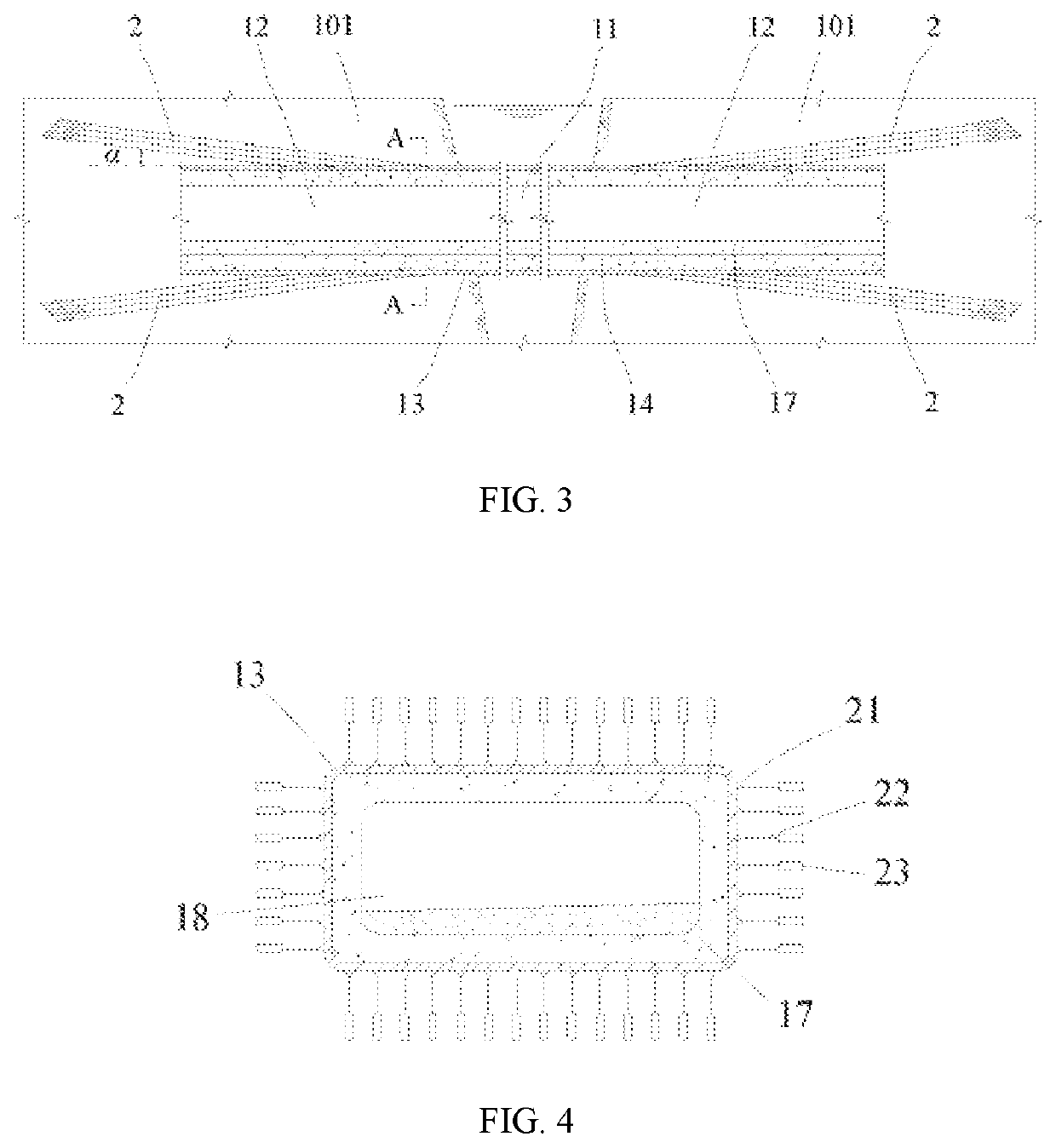

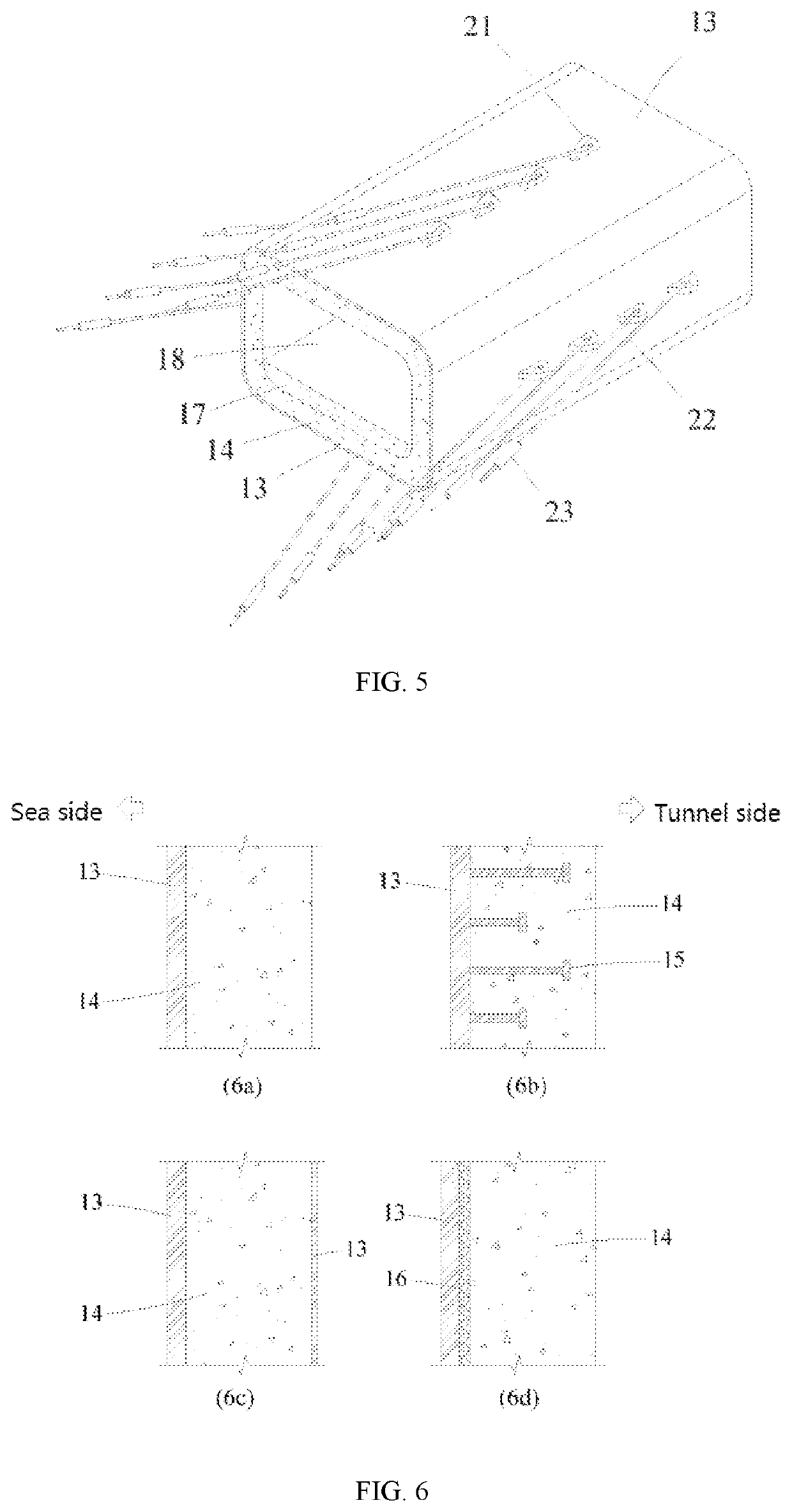

Floating tunnel shore connecting system, floating tunnel, and floating tunnel construction method thereof

PendingUS20220325495A1Reduce stress changesHorizontal stiffness and vertical stiffnessArtificial islandsUnderwater structuresRiver bedElectric cables

A floating tunnel shore connecting system, a floating tunnel and a floating tunnel construction method are disclosed, where the design method of the floating tunnel is to apply axial tension along one end or two ends of a tube body respectively; The floating tunnel shore connecting system comprises a joint section located at the end of the tube body, which can move along the axial direction and is connected with a tension device for applying axial tension; The floating tunnel comprises a tube body and a hollow cavity, wherein the tube body comprises a floating section and a shore connecting system at two ends, and both joint sections are provided with tension devices. The design method and structure of the floating tunnel provided by the present invention, by applying the axial tension of the tube body, can significantly increase the horizontal stiffness and vertical stiffness of the whole floating tunnel tube body, improving the natural vibration frequency of the tube body, and the safety and reliability of the floating tunnel are improved; It is beneficial to the long-term use of the cable and the foundation anchored on the seabed or the riverbed. The construction risk is also lower, and the cost is also lower, which effectively saves the construction cost, and is easy to implement and popularize the project.

Owner:CHINA COMMUNICATIONS CONSTRUCTION

A Large Vibration Horn for Ultrasonic High-speed Vibration Assisted Machining

ActiveCN109013259BAvoid damageGuaranteed disengagementBroaching accessoriesMechanical vibrations separationVibration amplitudeEngineering

The invention discloses a high-amplitude vibration amplitude variable rod for ultrasonic high-speed vibration auxiliary processing. The high-amplitude vibration amplitude variable rod is a whole pieceand includes a main body rod and a plurality of amplitude variable rod bodies, the main body rod is a diameter variable rod arranged in the length direction of a tool workbench, the amplitude variable rod bodies are the amplitude variable rod bodies with the rod diameter reducing from the tool workbench to a cutter pulling cutter box, and the bottom end of each amplitude variable rod body is connected to the variable diameter position of the main body rod. When used, the energy can be concentrated on a smaller area because the rod diameter of each amplitude variable rod body reduces from thevibration penetrating-in end to the transferring-out end, the vibration is amplified and transmitted to the cutter pulling cutter box and a pulling cutter, the high vibration speed is achieved, high vibration speed requirements when a turbine disk tenon groove is processed are met, and the surface quality is improved; and the amplitude is enlarged, the fact that cutter teeth are completely separated from a workpiece within a vibration frequency cycle, the possibility of a tool hitting the workpiece when the tool is returned from a non-cut-off material is avoided, the machining efficiency can be improved, the damage caused by the interference to the tool can be reduced, and the service life of the tool is prolonged.

Owner:CENT SOUTH UNIV

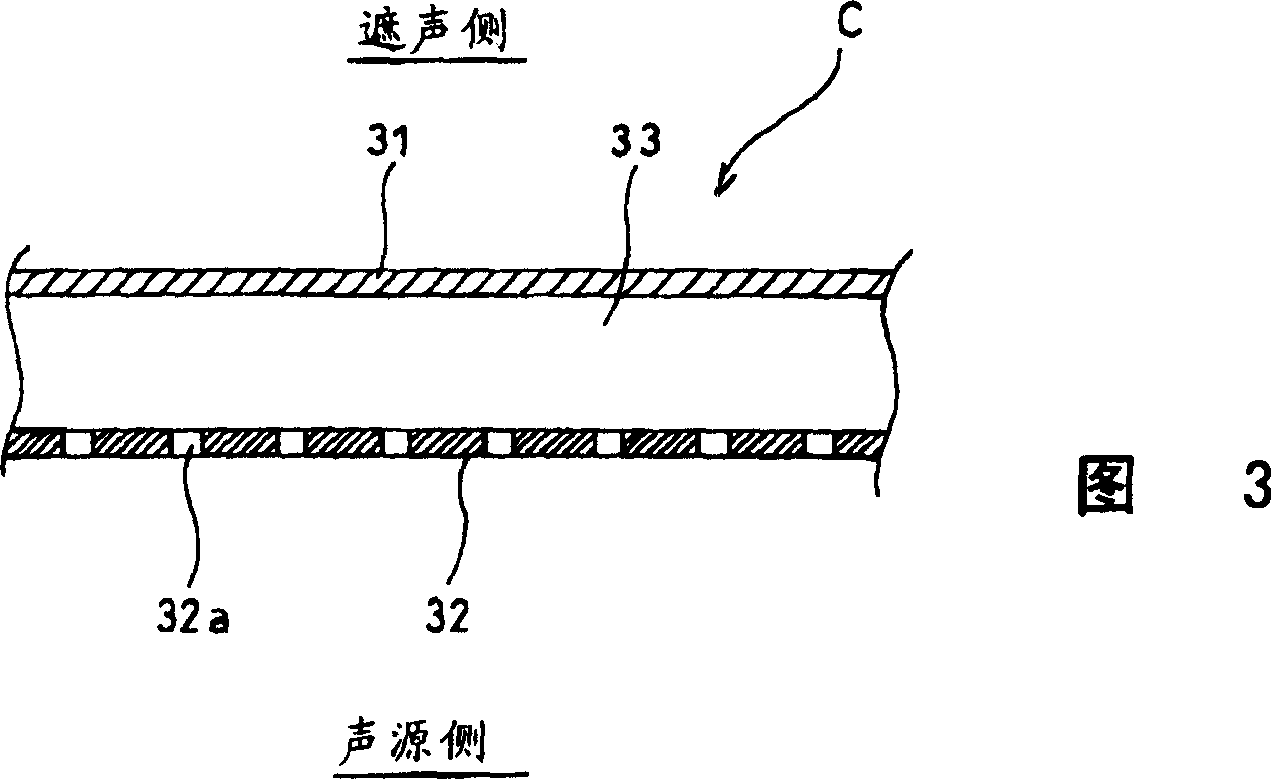

Noise reduction structure of porous plate

ActiveCN1311186CImprove the noise reduction effectFast vibrationSilencing apparatusPipe elementsStructural engineeringEngineering

Provided is a small noise reduction structure capable of exhibiting full noise reduction performance over a wide frequency bandwidth. The noise reduction structure D comprises a cylindrical duct 41; a perforated panel 42 extended inside the duct 41 along the axial direction of the duct 41 and positioned to define the duct cross section of the duct 41; and partition panels 43 by which the duct 41 defined by the perforated panel 42 is axially partitioned into a plurality of cells 44. The intervals at which the partition panels 43 are installed are adjusted so that b F16L 55 / 02 F01N 1 / 02 7 13 1 2004 / 5 / 21 1573199 2005 / 2 / 2 1311186 2007 / 4 / 18 2007 / 4 / 18 2007 / 4 / 18 Kobe Steel Ltd Kabushiki Kaish Japan Utsuno Hideo Yamaguchi Zenzo Tsugihashi Kazuki Komura Kazyo Kimura Yasumasa Honke Koichi wen dapeng yang songling 72001 The Company Ltd. of the Chinese Patent Agency (Hong Kong) Zi Building 22, Yingjun Centre, No.23, Gangwan Road, Hong Kong Wanzi Japan 2003 / 5 / 23 146579 / 03

Owner:KOBE STEEL LTD +1

Construction process for road with piping shaft

PendingCN111827040AImprove vibrationFast vibrationArtificial islandsIn situ pavingsPipingStructural engineering

The invention provides a construction process for a road with a piping shaft. The process comprises the steps of roadbed excavation and cleaning, base layer laying, base layer shaping, concrete pouring and cement concrete surface layer construction. Before concrete pouring construction, the piping shaft suite is prefabricated in a factory, the side edge of the piping shaft suite is a straight plane, the prefabricated piping shaft suite is connected to the exterior of a piping shaft in a sleeving mode, the upper surface of the piping shaft suite is flush with the piping shaft as much as possible, concrete pouring is conducted after the piping shaft suite is connected in the sleeving mode, and then normal cement concrete surface layer construction is conducted. In the construction of the road provided with the piping shaft, the prefabricated square piping shaft suite is connected to the exterior of the piping shaft in a sleeving mode, then concrete pouring operation is conducted, and therefore concrete around the piping shaft can be vibrated more conveniently and rapidly, no trace is left, and the road surface is smoother.

Owner:湖北烜豪建筑工程有限公司

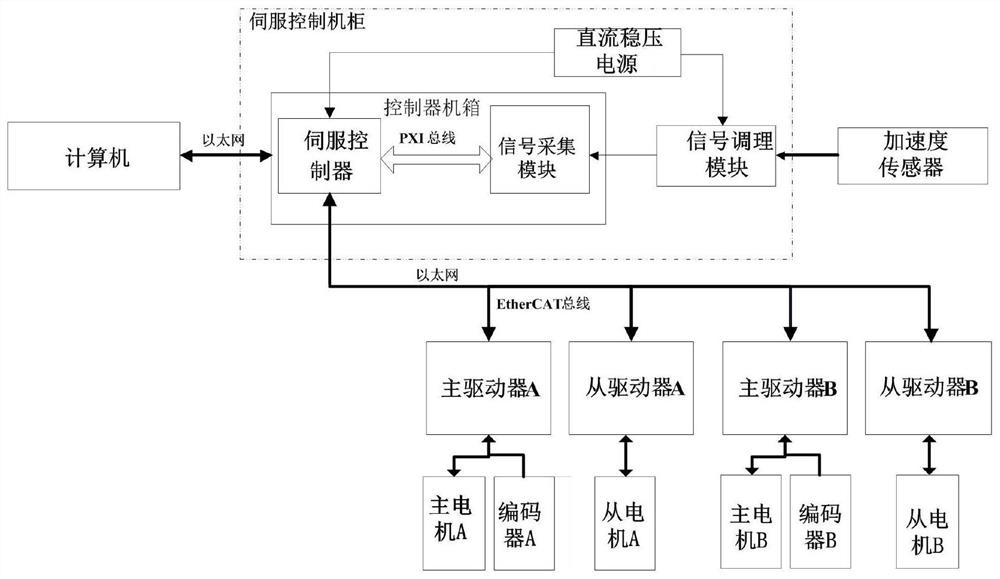

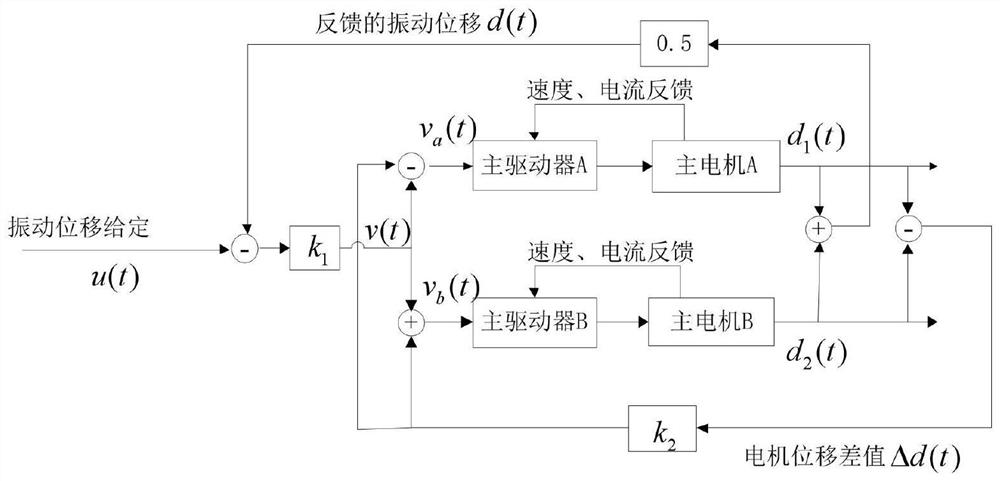

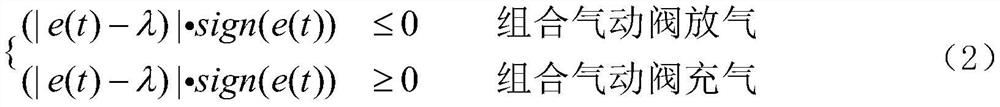

Servo control method and control device for linear electric type medium and low frequency excitation device

PendingCN113934182AFast vibrationGood control precisionNumerical controlControl functionWaveform distortion

The invention discloses a servo control method and a control device for a linear electric type medium and low frequency excitation device, which integrate a multi-motor combination parallel drive servo control function, an all-digital bus communication function and a static support cylinder pressure control function, and can realize servo control of a medium and low frequency excitation device system in a linear motor drive mode. Speed synchronous control, position differential suppression control and master-slave motor force following control methods are adopted, and strict synchronization of the vibration speed of four motors or double motors is achieved; static support cylinder constant pressure control is introduced, so that the effect of dead weight of a moving part and a product can be achieved, dynamic force output by the linear motor is more symmetrical, and the waveform distortion index in high-precision vibration control is excellent; a universal bus interface based on an EtherCAT bus communication protocol is adopted, a controller and multiple sets of motor drivers form a control looped network, and high-speed real-time transmission and implementation monitoring of multiple paths of signals including force, current, speed, displacement, acceleration and the like are achieved.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com