The linear vibrator is set on the relaxation screen at the feeding end

A technology of linear vibrator and feeding end, which is applied in the direction of filter screen, chemical instrument and method, solid separation, etc. It can solve the problems of reduced screening efficiency of vibrating screen, easy adhesion, insufficient vibration capacity of single-axis circular vibrator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

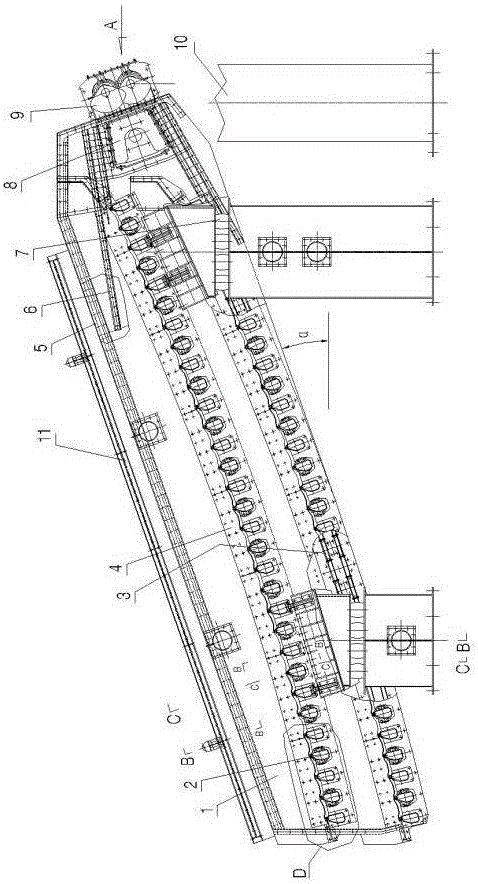

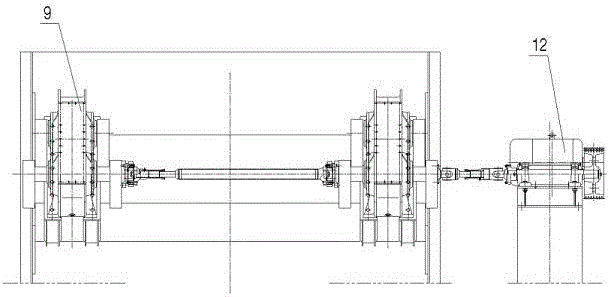

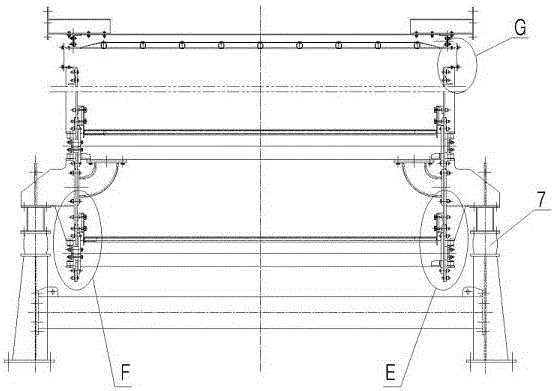

[0009] An embodiment of the present invention is described below with reference to the accompanying drawings, which is a double-layer arc-curved screen relaxation screen mainly composed of a screen frame, a lower beam, an elastic screen, a vibrator, a dust cover, an elastic support device and a support column. The screen frame 1 is installed on the pillar through the elastic supporting device 7 , and the vibrator 9 is driven by the motor transmission device 12 . The lower beam of the screen frame 1 is composed of a fixed beam 14 and a movable beam 15, and the movable beam and the fixed beam are arranged alternately; the fixed beam 14 is connected to the side plate 13 of the screen frame through a ring groove rivet; the two ends of each movable beam 15 are connected by The block 18 passes through the reserved hole on the side plate of the screen frame, and connects with the positioning channel steel 22 and the reinforcement plate 20 on the outside of the side plate 13 to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com