Photo-sensitive material solidification layer forming method in 3D (three-dimensional) printing and structure for implementing such method

A photosensitive material and 3D printing technology, applied in the field of 3D printing, can solve problems such as the damage of the isolation film, the misalignment of the printing layer, and the failure to form, and achieve the effect of reducing deformation and avoiding shear force and friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

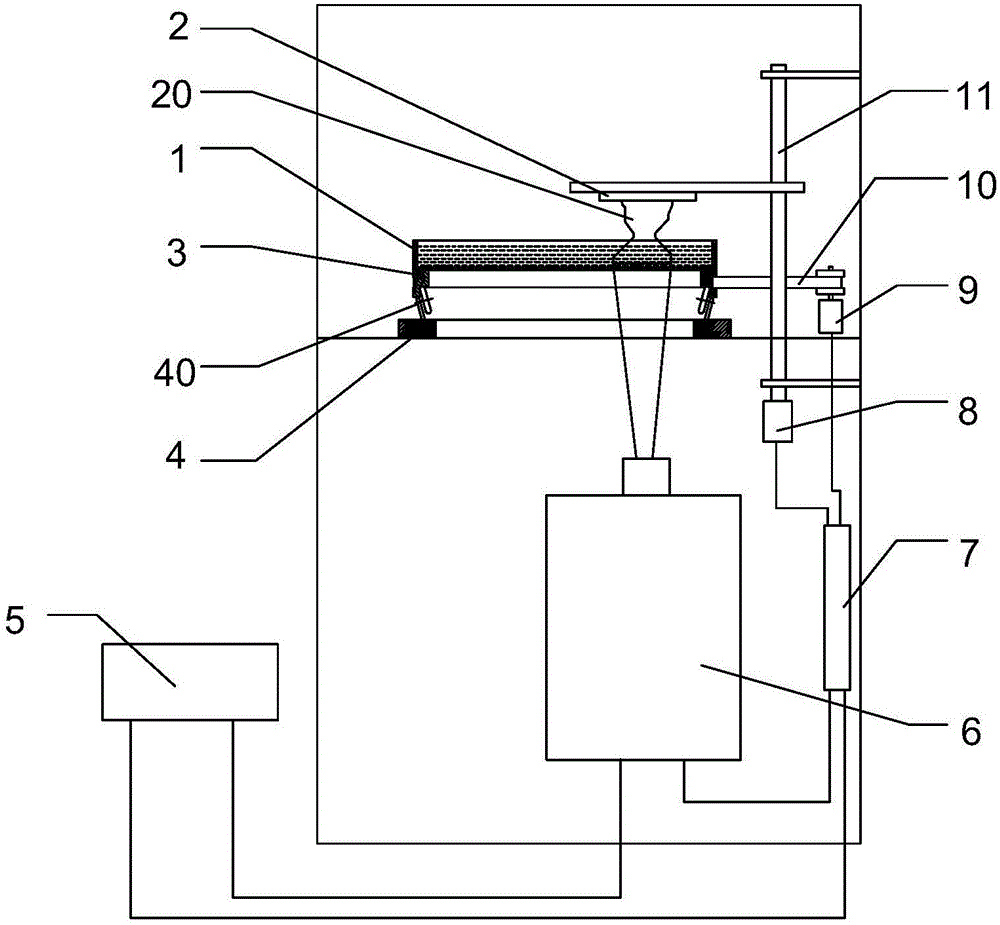

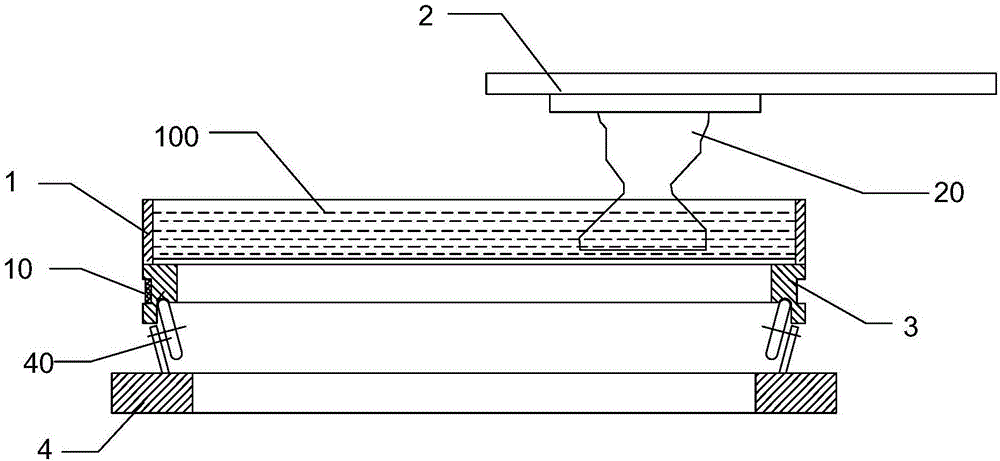

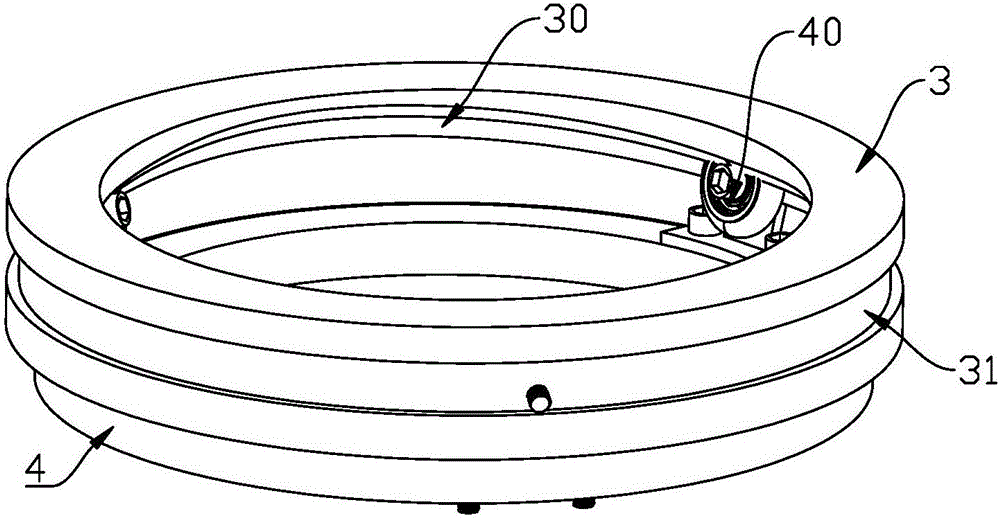

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0031] A method for forming a solidified layer of a photosensitive material in 3D printing, comprising the following steps:

[0032] S1, the liquid photosensitive material for 3D printing is placed in a horizontally rotatable container with a light-permeable bottom, and a component for lifting the printed object is placed above the container, forming a gap between the bottom of the component and the bottom of the container There is a space, which is filled with light-sensitive material;

[0033] S2, turn on the light source to irradiate the photosensitive material in the space from the bottom of the container, where the photosensitive material forms a solidified layer under the irradiation of the light source, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com