Polyurethane foam plate with rib-shaped bionic non-smooth surface and preparation method of polyurethane foam plate

A technology of polyurethane foam board and non-smooth surface, which is applied in the field of bionic non-smooth surface polyurethane foam board and its preparation, can solve problems such as stay and vacancy, and achieve improved sound absorption performance, improved sound absorption performance, and increased absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Design and manufacture of polyurethane foam panels with biomimetic non-smooth morphology of triangular ribs.

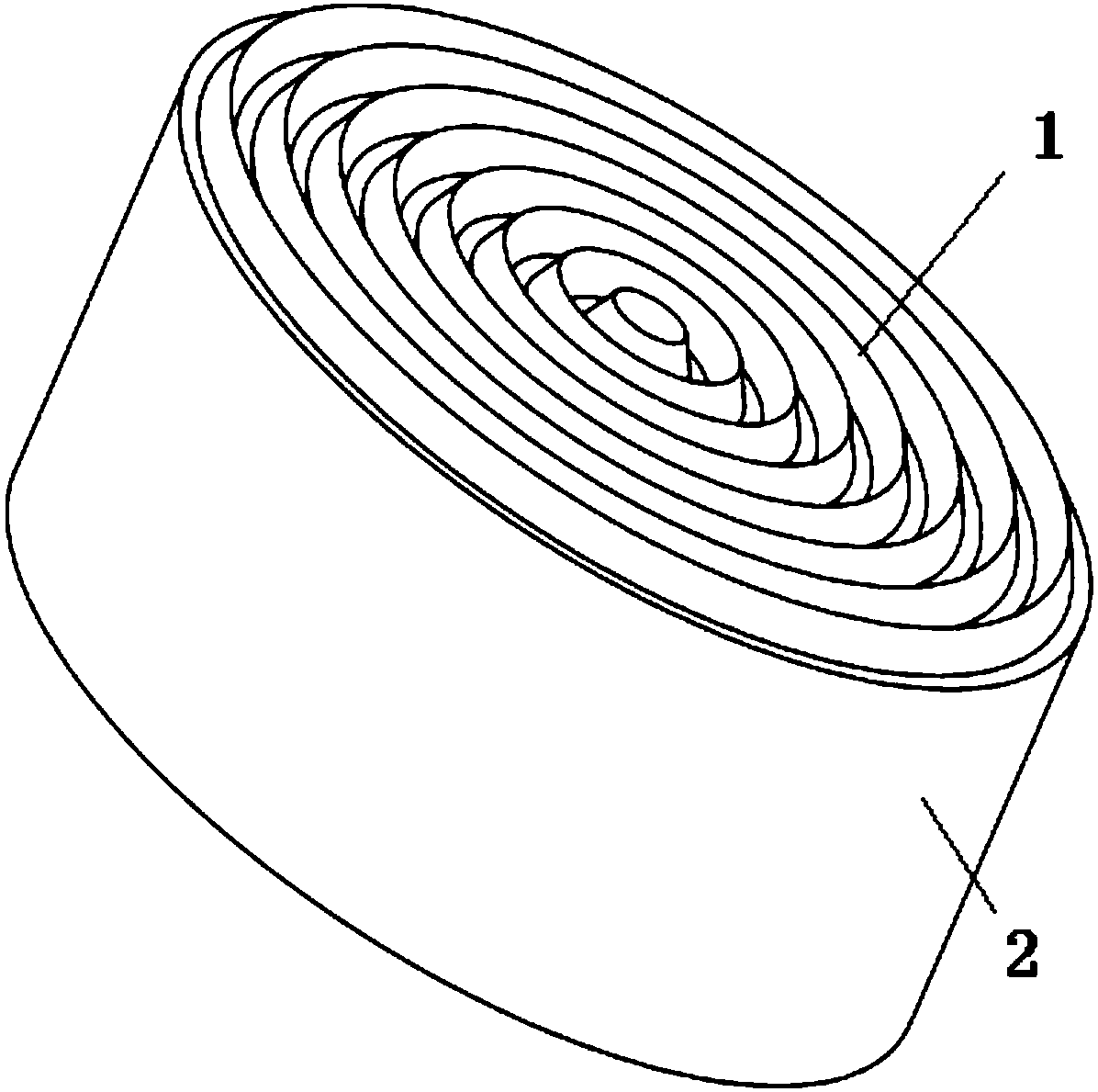

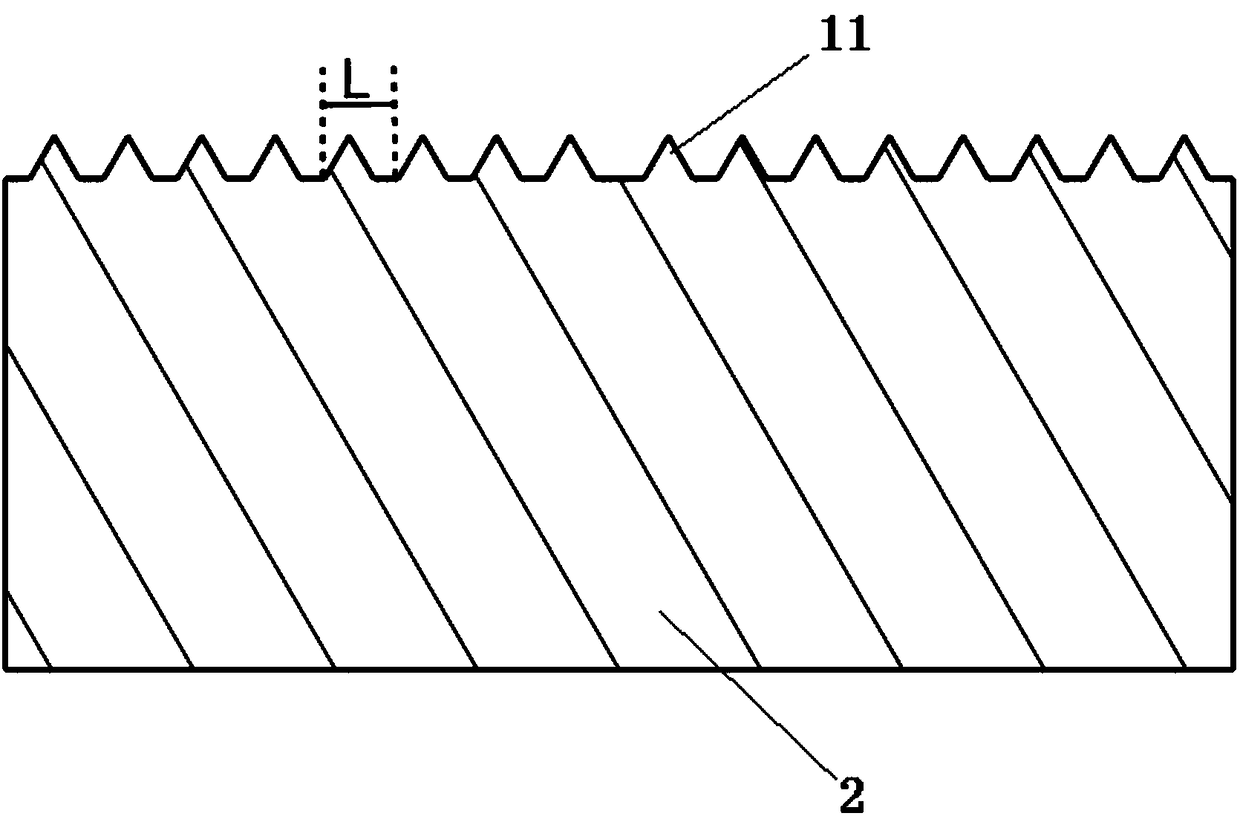

[0047] refer to figure 1 and figure 2 , the non-smooth surface shape of the polyurethane foam board is formed by triangular ribs uniformly distributed in concentric rings on the surface of the substrate. The cross-section of the triangular ribs is an equilateral triangle with a side length of 5 mm. The shape distance L is 7mm. The base body 1 and protrusion 2 are made of polyurethane raw materials, and the material thickness is 30mm. Compared with the smooth surface polyurethane foam of the same base material, the triangular rib-shaped polyurethane foam designed and manufactured has significantly improved mid-frequency and high-frequency sound absorption performance, and the quality is reduced by 5.5 %.

Embodiment 2

[0049] Design and manufacture of polyurethane foam panels with biomimetic non-smooth morphology with trapezoidal ribs.

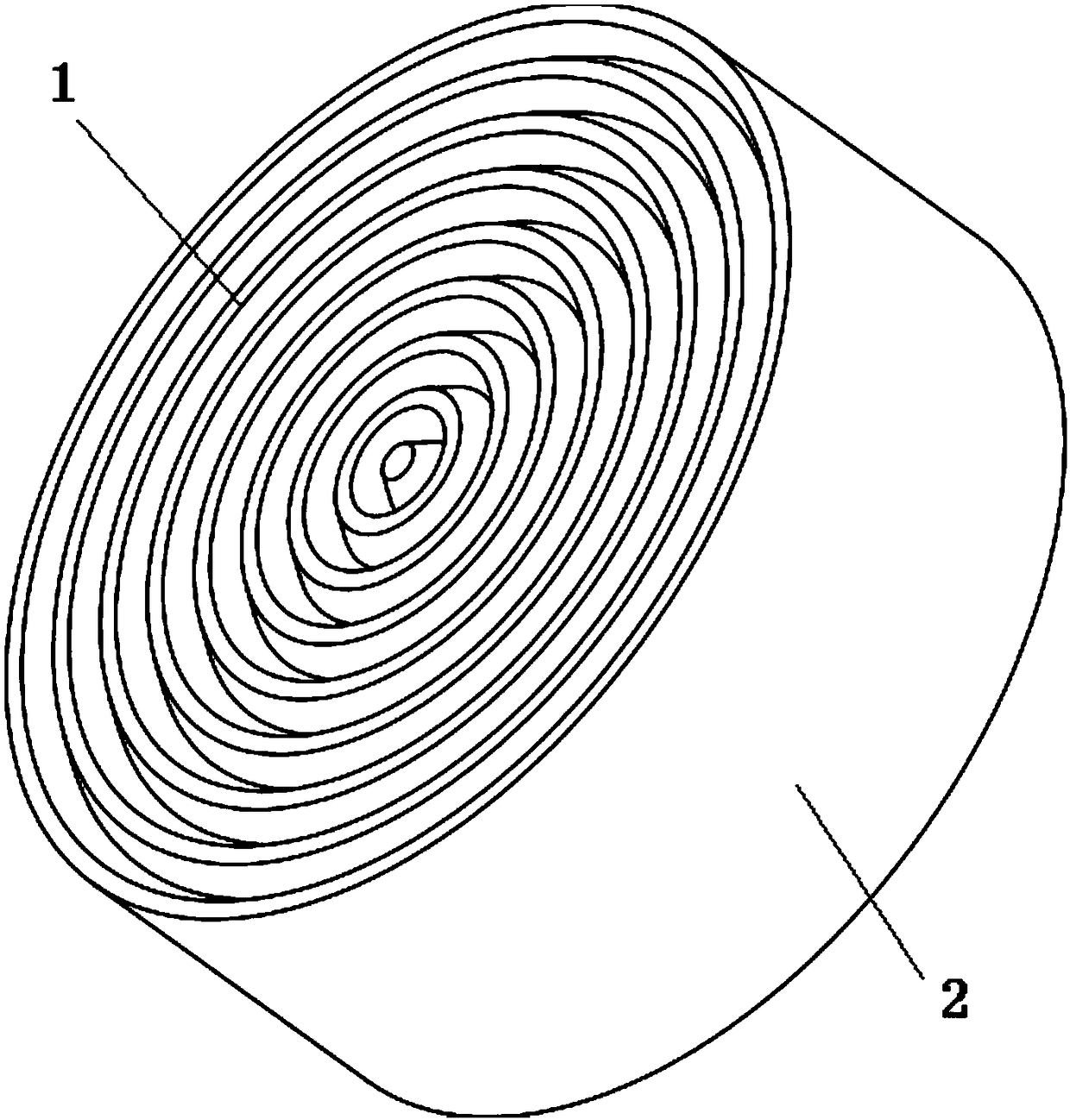

[0050] refer to image 3 and Figure 4 , the non-smooth surface shape of the polyurethane foam board is formed by trapezoidal ribs that are evenly distributed in concentric circles on the surface of the substrate. The cross-section of the trapezoidal ribs is an isosceles trapezoid. is 5mm, and the distance L between adjacent trapezoidal ribs is 5mm. The base body 1 and protrusion 2 are polyurethane raw materials, and the thickness of the material is 30mm. Compared with the smooth surface polyurethane foam of the same base material, the designed and manufactured trapezoidal rib-shaped polyurethane foam has significantly improved mid-frequency and high-frequency sound absorption performance, and the quality is reduced by 4.8 %.

[0051] In summary of the above embodiments, the positive effects obtained by the present invention can be seen from the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com