Folded plate buckling type railway metal sound barrier unit plate

A technology of unit panels and sound barriers, which is applied in construction, noise absorption devices, etc., can solve problems such as heavy weight of unit panels of sound barriers, instability of unit panel longitudinal structures, loss of sound absorption function of sound barriers, etc., so as to improve structural rigidity , Enhance the stability of occlusal locking, improve safety and anti-fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

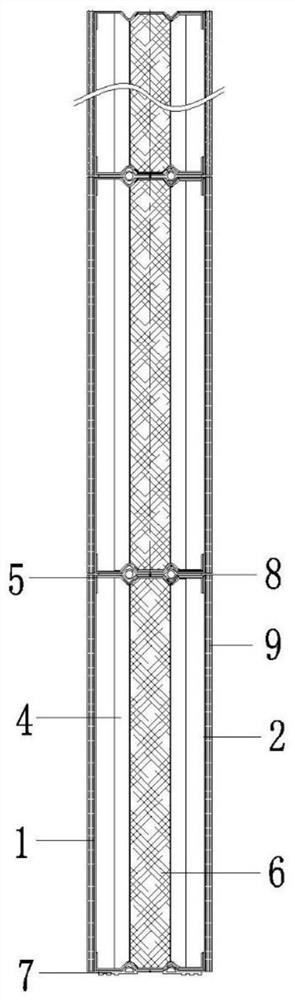

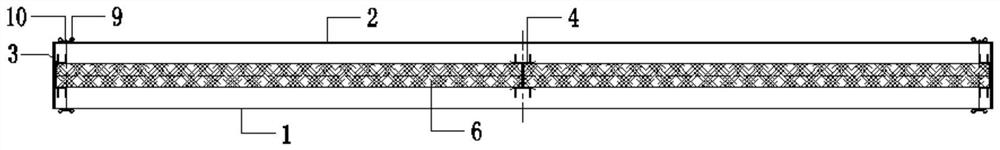

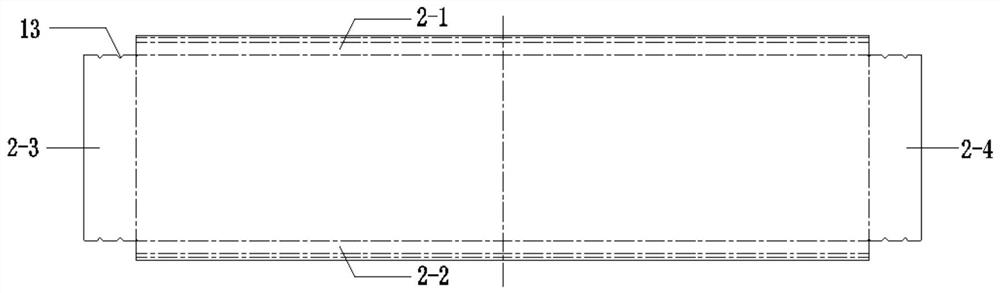

[0067] Such as figure 1 As shown in the figure, it is a side view cross-sectional schematic diagram of the folded plate fastening type railway metal sound barrier unit plate of the present invention. Among them, 1 is the bent panel, 2 is the bent back plate, 4 is the middle vertical brace, 5 is the horizontal brace, 6 is the sound-absorbing component, 7 is the decoupling rubber pad, 8 is the rubber pad between the boards, and 9 is the board column Adhesive pads. The bent panel 1 is formed by bending the four sides of a cross-shaped plate to the same surface, an aluminum alloy plate, and the thickness of the plate is at least 1.5 mm; the bent back plate 2 is formed by bending the four sides of a cross-shaped plate to the same surface It is made of an aluminum alloy plate with a thickness of at least 1.5 mm; the upper and lower side plates of the bent back plate 2 each have a V-shaped groove, and the upper and lower side plates of the bent panel 1 have two V-shaped grooves, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com