Low-frequency micro-perforated sound-absorbing composite material and manufacturing method thereof

A sound-absorbing composite material and a composite material technology are applied in the field of low-frequency micro-perforated sound-absorbing composite materials and their manufacturing, which can solve the problems of complex fabrication of space absorbers, high manufacturing costs, and inability to be widely used, and achieve a good potential economy. Benefit, low cost, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to the mass ratio, take 100 parts of EPDM and 10 parts of zeolite powder to prepare the sound-absorbing composite material according to the following steps:

[0035] The first mixing:

[0036] (1) Keep the temperature of the rollers on the twin-roll mill at room temperature;

[0037] (2) Add 100 parts of EPDM rubber between the rollers;

[0038] (3) Add 10 parts of zeolite powder to the rubber again, knead the EPDM rubber and the zeolite powder, due to the difference of the surface rotation speed of the two rollers, do artificial auxiliary mixing with a cutter to make the uniform mixing;

[0039] (4) The total mixing time is 20 minutes. After the mixing is uniform, the mixing material is peeled off from the roller, and then shredded into mixed granules for hot pressing.

[0040] The second step of hot pressing:

[0041] (1) Spread the kneaded scrap evenly in the mold, clamp the upper and lower molds with steel plates, and use a layer of PE film between the ...

Embodiment 2

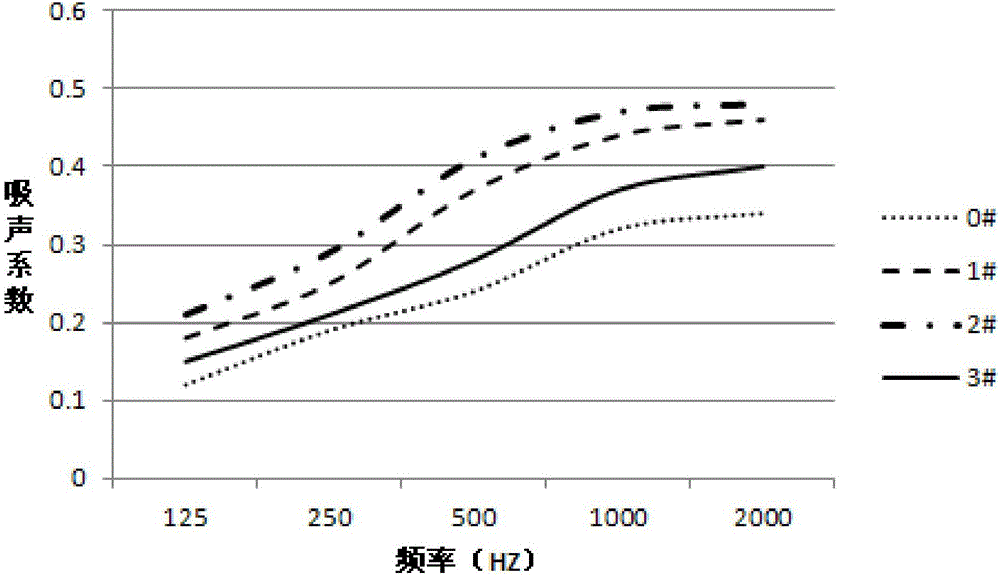

[0048] According to the mass ratio, 100 parts of EPDM and 10 parts of zeolite powder were taken, and the steps of preparing the sound-absorbing material were the same as those in Example 1. The process differs from Example 1 in that the micro-perforation diameter of the rubber-based composite material is 0.5 mm, the aperture ratio is 0.5%, the thickness is 1 mm, and the composite material density is 9.9 g / cm3. The sound absorption effect of the final formed composite material is as follows figure 1 shown in 2#.

Embodiment 3

[0050] According to the mass ratio, 100 parts of EPDM and 10 parts of zeolite powder were taken, and the steps of preparing the sound-absorbing material were the same as those in Example 1. The process is different from Example 1 in that the micro-perforation diameter of the rubber-based composite material is 0.5 mm, the pore diameter is 2.5%, the thickness is 1 mm, and the density of the composite material is 9.9 g / cm3. The sound absorption effect of the final formed composite material is as followsfigure 1 shown in 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com