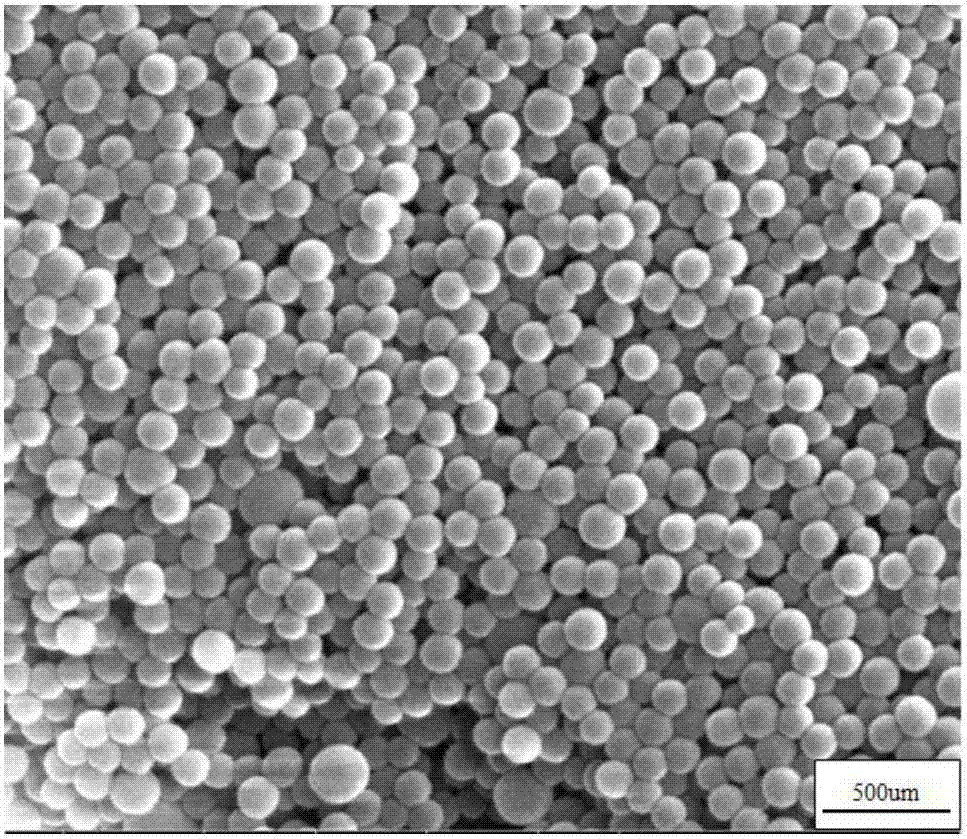

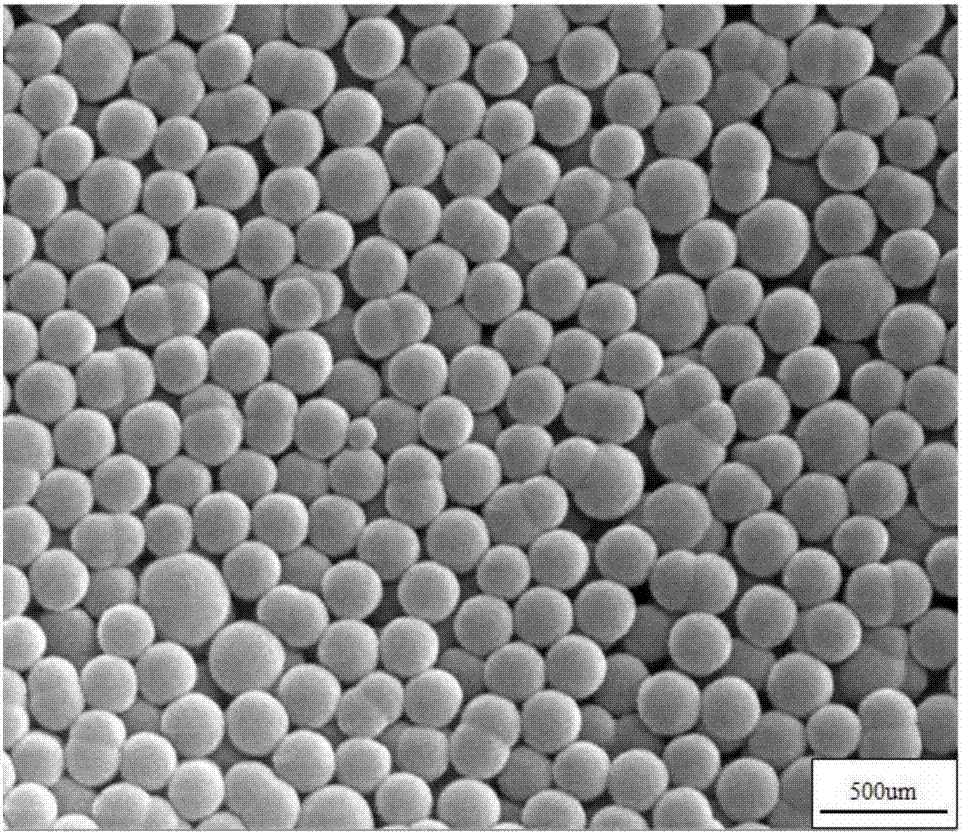

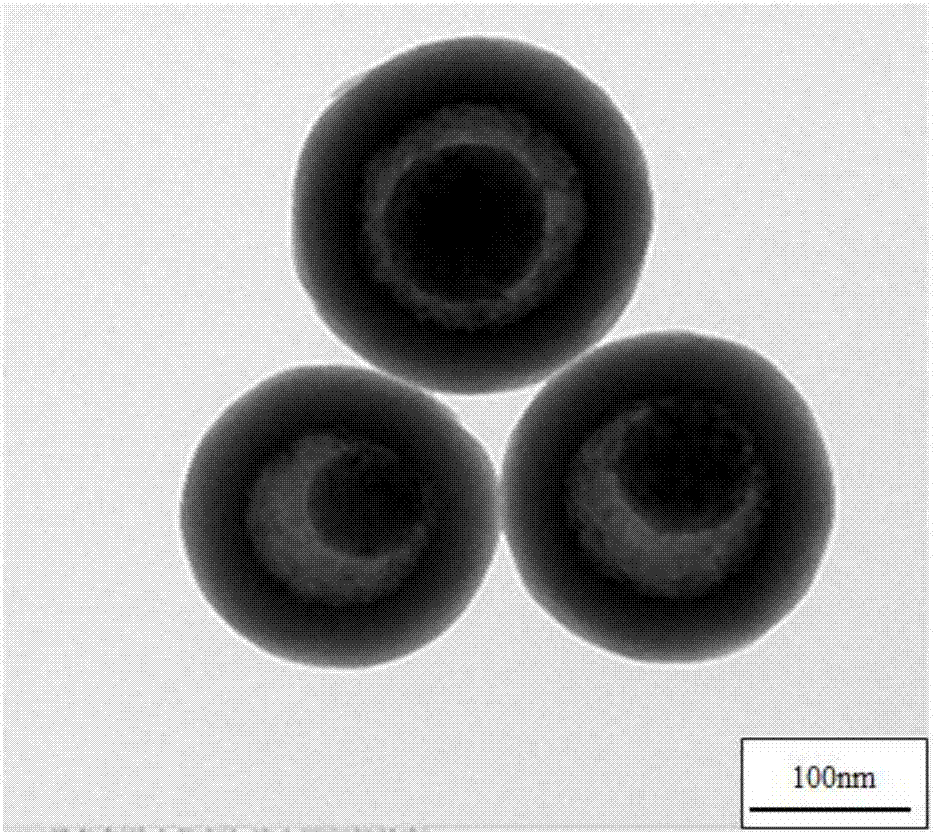

Method for preparing sound-absorbing material through doping of core-shell microspheres

A technology of sound-absorbing materials and microspheres, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of poor sound-absorbing performance, and achieve the effect of improving sound-absorbing performance, improving sound-absorbing performance, and improving sound-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Embodiment 1: In this embodiment, a method for preparing sound-absorbing materials doped with core-shell microspheres is specifically carried out in the following steps:

[0013] Defoaming the polyurethane prepolymer under the conditions of temperature 60℃~80℃ and pressure -0.05MPa to obtain the polyurethane prepolymer defoaming; 3,3'-dichloro-4,4'-diamino Diphenylmethane melts into a liquid state under the condition of an oil bath at a temperature of 110°C to obtain liquid 3,3'-dichloro-4,4'-diaminodiphenylmethane; the vibrating core-shell Nanoparticles, liquid 3,3'-dichloro-4,4'-diaminodiphenylmethane, toluene and polyurethane prepolymer are mixed to obtain a reaction system, the reaction system is poured into a mold, and then heated at a temperature of 60 ℃~80℃ and a pressure of -0.05MPa to remove air bubbles. After defoaming, transfer the reaction system to the vacuum drying oven together with the mold. Raise the temperature of the vacuum drying oven from room tempe...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of 3,3'-dichloro-4,4'-diaminodiphenylmethane to polyurethane prepolymer is 3:20. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the mass ratio of the polyurethane prepolymer to toluene is 1g:0.4mL. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com