Sound-absorbing coating material and preparation method thereof

A coating material and sound absorption technology, applied in the coating and other directions, can solve the problems of poor sound absorption performance, poor combustion resistance of foamed polystyrene, hidden safety hazards in buildings, etc., and achieve a simple spraying construction process, excellent absorption Excellent sound performance and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

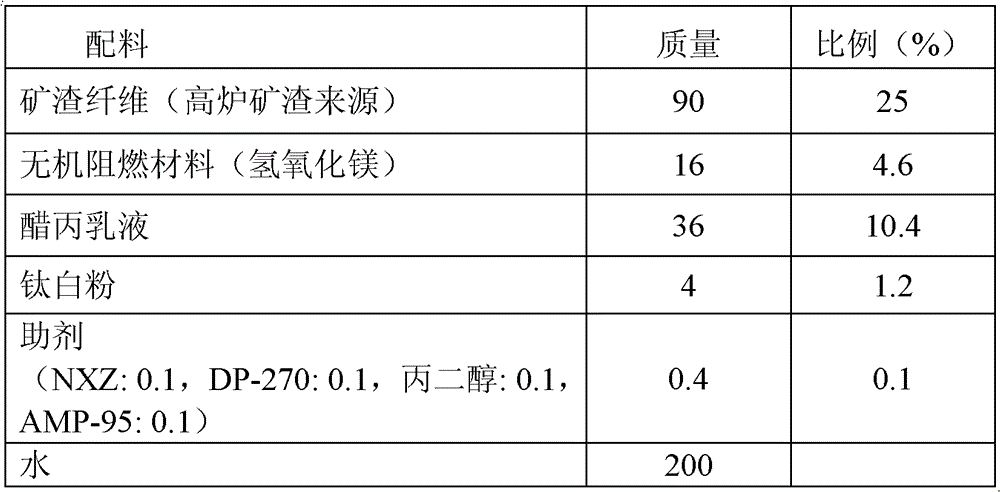

[0042] The preparation of the sound-absorbing coating material is completed according to the following ingredients and the above-mentioned preparation method.

[0043]

[0044] Prepare the coating material according to the above ingredients and methods, spray it on the cement fiber board, the coating thickness is 5mm, and use the standing wave tube method (GBJ 88-1985 "Standard for the Measurement of Sound Absorption Coefficient and Acoustic Impedance Rate of Standing Wave Tube Method") To test the sound absorption coefficient, use the standard GB 8624-1997 "Classification of Combustion Behavior of Building Materials" to test the fire performance.

[0045] After testing, the NRC of the coating has a sound absorption coefficient of 0.43, indicating that at least 40% of the noise is absorbed by the material, which can significantly reduce noise pollution.

[0046] The combustion performance test shows that the coating does not release harmful substances, and the combustion re...

Embodiment 2

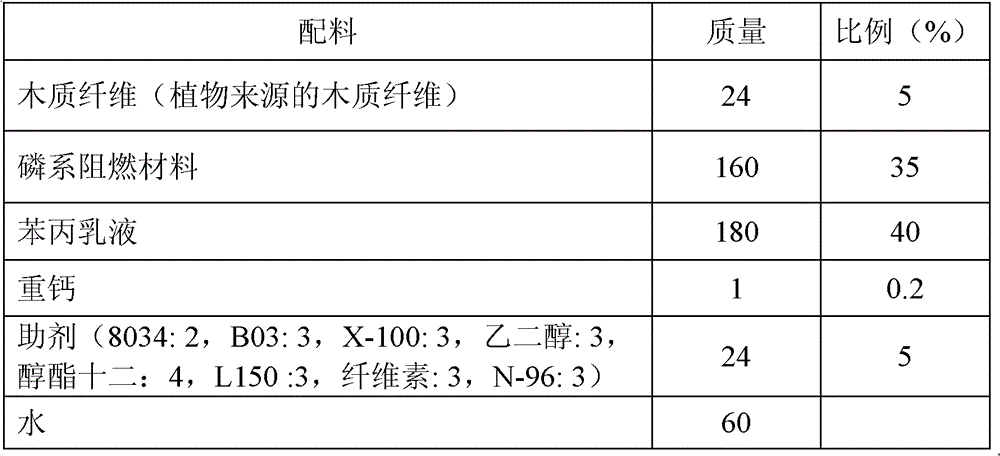

[0048]

[0049] The function test was carried out by the same method as in Example 1, and the thickness of the coating was 10 mm. Results: The NRC tested by the standing wave tube method is 0.45; the coating is non-combustible.

Embodiment 3

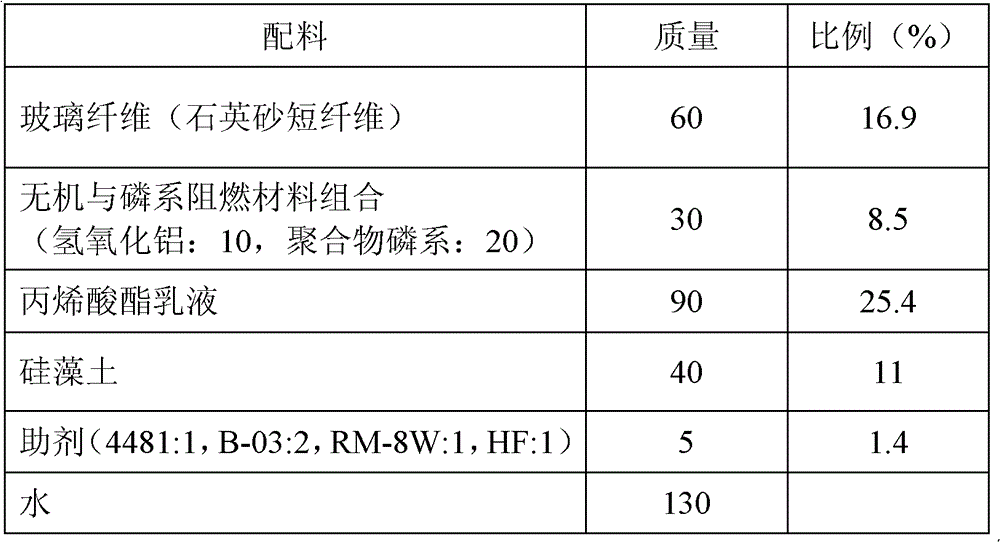

[0051]

[0052] The function test was carried out by the same method as in Example 1, and the thickness of the coating was 8 mm. Results: The NRC of the coating standing wave tube test is 0.46; the coating does not burn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com