Bionic non-smooth surface polyurethane foam board with cylindrical pits and preparation method

A technology of polyurethane foam board and non-smooth surface, which is applied in the field of bionic non-smooth surface polyurethane foam board and its preparation, can solve the problems of staying and vacancy, and achieves the improvement of sound absorption performance, sound absorption performance and absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Design and manufacture of biomimetic non-smooth morphological polyurethane foam panels with semi-cylindrical dimples.

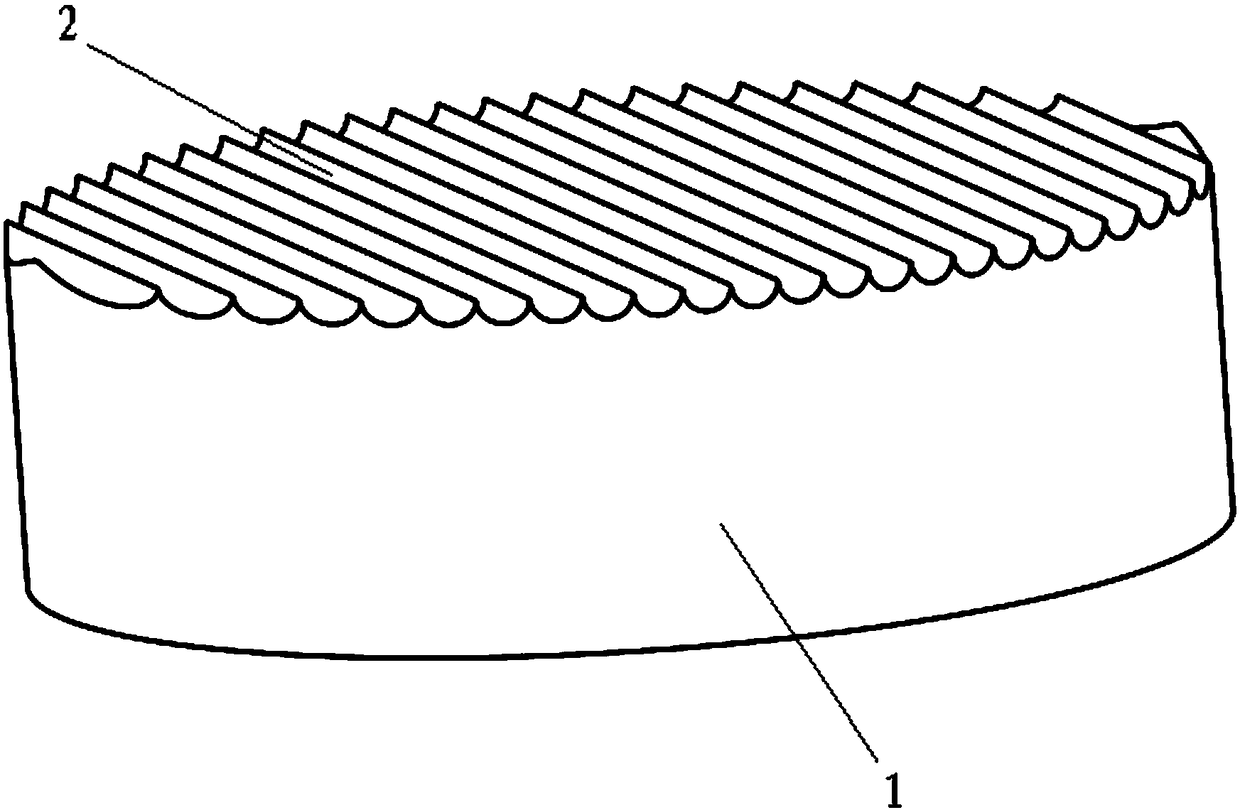

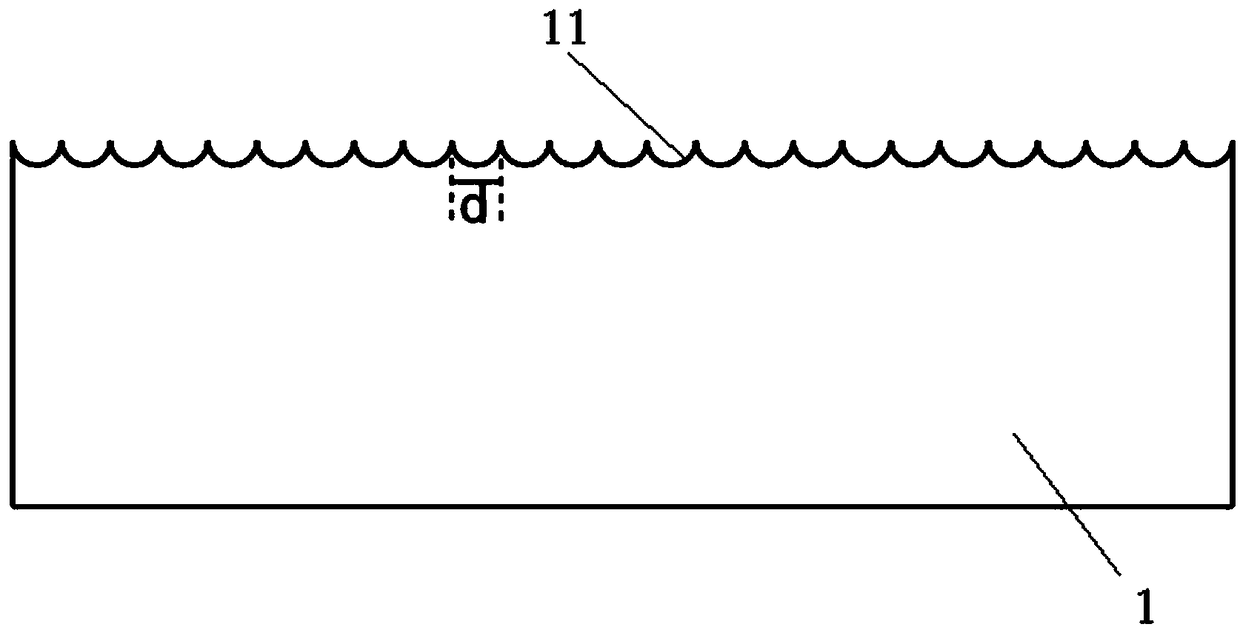

[0046] refer to figure 1 with figure 2 , the non-smooth surface shape of the polyurethane foam board is formed by semi-cylindrical pits 11 arranged uniformly on the surface of the substrate. The distance L between the semi-cylindrical pits 11 is 4mm. Substrate 1 is made of polyurethane raw material, and the overall material thickness is 30mm. Compared with the polyurethane foam with smooth surface of the same substrate material, the designed and manufactured polyurethane foam with semi-cylindrical pits has significantly improved sound absorption performance at intermediate and high frequencies, and the quality has decreased by 4.4 %.

Embodiment 2

[0048] Design and manufacture of biomimetic non-smooth form polyurethane foam panels with semi-elliptical cylindric pits.

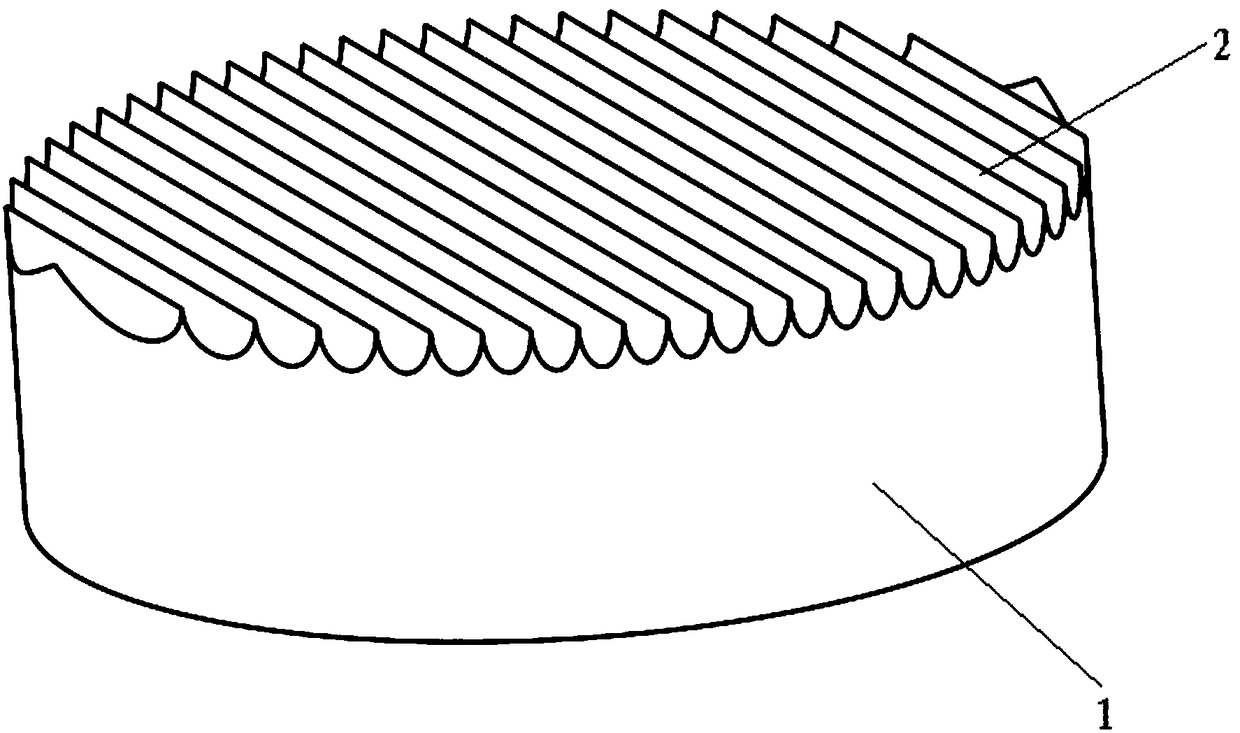

[0049] refer to image 3 with Figure 4 , the non-smooth surface shape of the polyurethane foam board is formed by the semi-elliptic cylindrical pits 12 arranged uniformly on the surface of the substrate. The axis a is 4 mm, and the distance L between adjacent semi-elliptic cylindrical pits 12 is 4 mm. Substrate 1 is made of polyurethane raw material, and the thickness of the overall material is 30mm. Compared with the polyurethane foam with smooth surface of the same substrate material, the designed and manufactured polyurethane foam with semi-elliptic column pits has significantly improved sound absorption performance at mid-frequency and high-frequency, and its quality is reduced. 5.3%.

[0050] In summary of the above embodiments, the positive effects obtained by the present invention can be seen from the following sound absorption performance comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com