Novel visual intelligent super-fluid cast-in-place concrete pile device and construction method

A concrete and superfluid technology, applied in earth-moving drilling, drilling equipment and methods, sheet pile walls, etc., can solve problems such as high cost, poor pile quality, waste of concrete, etc., and achieve easy understanding of technology and shorten construction. The effect of time and vibration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] Example:

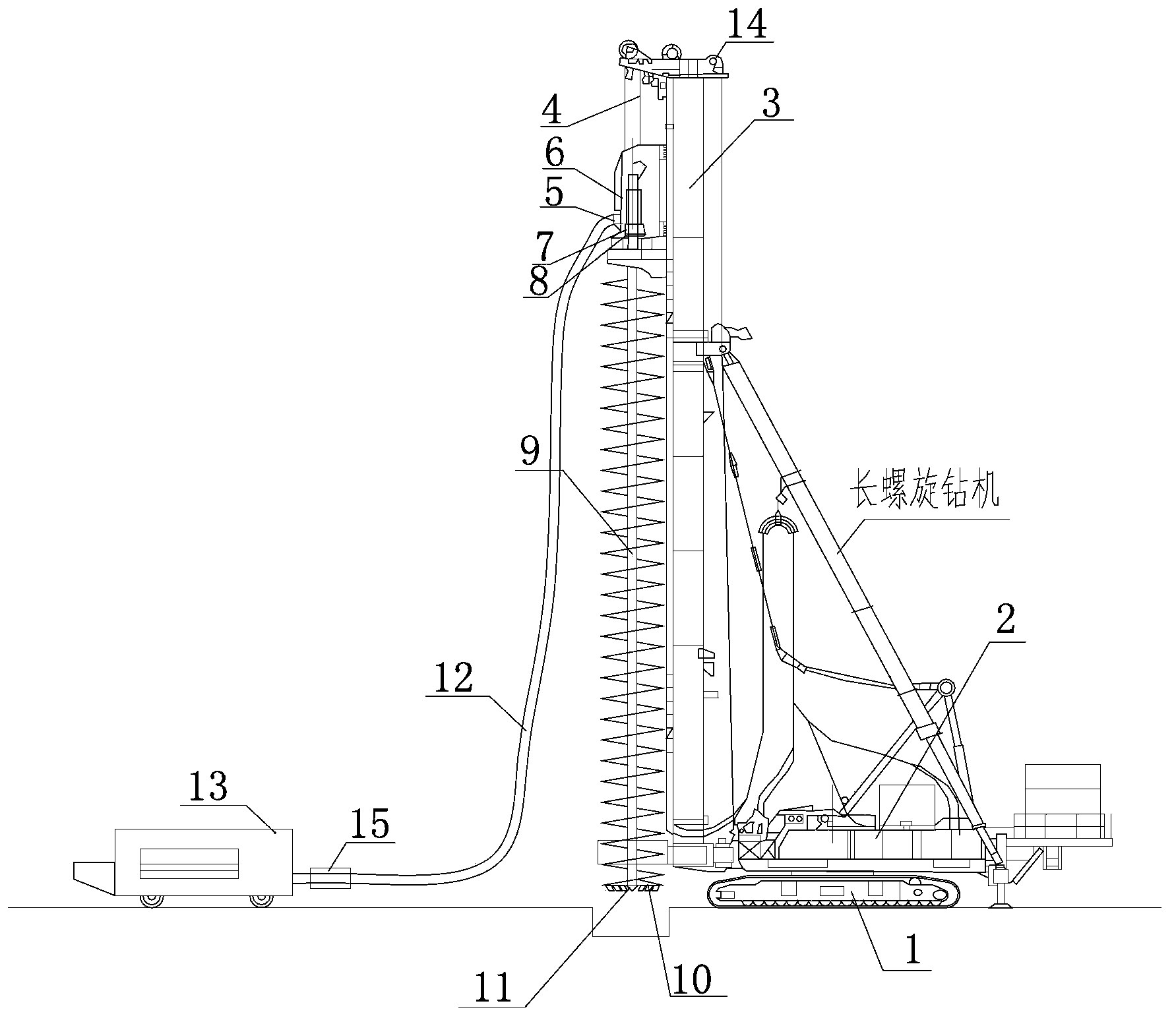

[0025] Such as figure 1 As shown, a new type of visual intelligent superfluid concrete pouring pile device, the device includes walking and crawler main engine 1, winch 2, guide rod 3, steel wire rope 4, feed port 5, power head 6, gearbox 7, Reducer 8, auger rod 9, drill bit 10, discharge port 11, pump truck conduit 12, concrete pump truck 13, flow meter 14, depth sensor 15, the hoist 2 and guide rod 3 are fixed on the main machine 1 Above, the power head 6 is connected to the top pulley of the guide rod through the wire rope 4, and the wire rope 4 drives the power head 6 to go up and down, and the power head 6 is connected to the auger rod 9 through the gearbox 7 and the reducer 8 in turn, 9 The lower end is connected to the drill bit 10, and the drill bit 10 is provided with a discharge port 11. The discharge port 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com