Method for increasing blasting vibration frequency of deep-hole bench

A technology of step blasting and vibration frequency, which is applied in the field of geotechnical engineering, can solve the problems of not considering the active control of blasting vibration frequency, etc., and achieve the effect of avoiding blasting dynamic instability, reducing control difficulty, and increasing safe permissible vibration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention improves the position and number of initiation points, divides the charge section into N initiation sections (N≥1), and sets the initiation point at the midpoint of each initiation section.

[0025] Several specific embodiments of the present invention will be further described below in conjunction with the drawings.

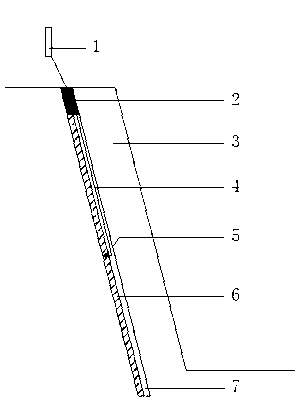

[0026] see figure 1 , Is a schematic diagram of the central detonation, that is, the detonation method in the case of N=1. Under the premise of ensuring the effect of blasting and fragmentation, the detonation point is set at the midpoint of the charge section.

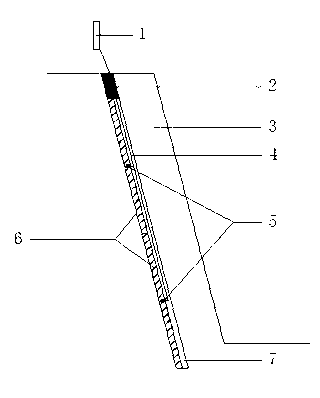

[0027] see figure 2 , Is a schematic diagram of two-point detonation, that is, the detonation method under the condition of N=2. Under the premise of ensuring the blasting and crushing effect, the charge section is equally divided into two detonation sections, and the two detonation points are set at the midpoint of each detonation section.

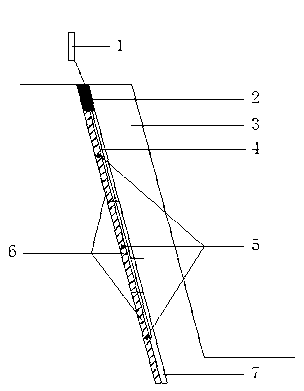

[0028] see image 3 , Is a schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com