Coreless cylindrical vibrating motor

A vibration motor, cylindrical technology, applied in electric components, control mechanical energy, electrical components, etc., can solve the problems of weakening vibration motor torque, shortening motor life, breakage, etc., to reduce current consumption, low current consumption, fast response characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The desired example of the present invention is described in detail below with reference to the accompanying drawings:

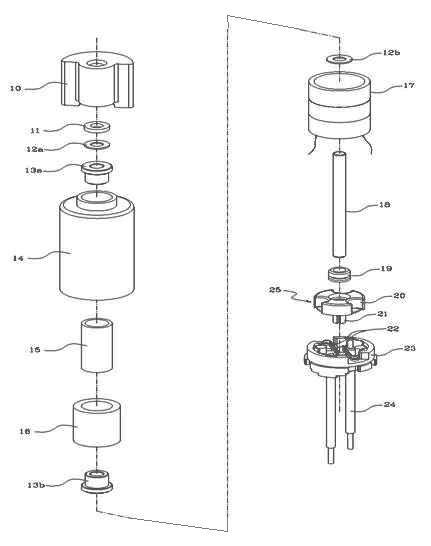

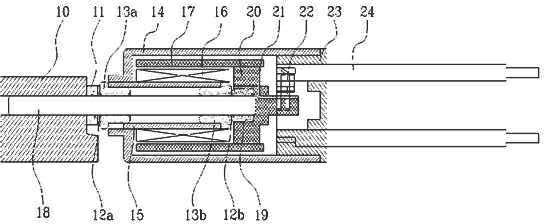

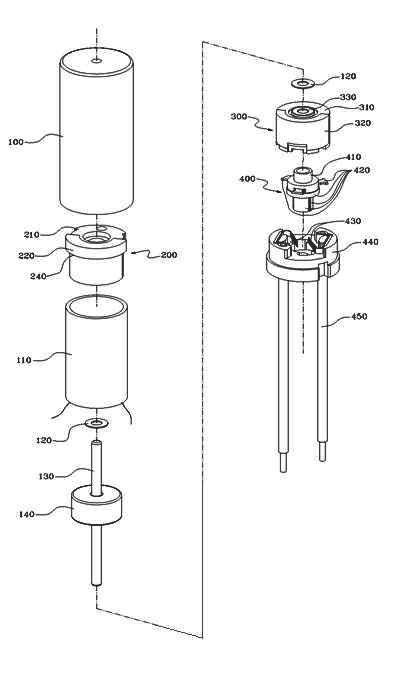

[0049] image 3 In order to decompose and demonstrate the constituent elements of the cylindrical vibration motor of the present invention, Figure 4 for assembly image 3 The internal sectional view of the cylindrical vibration motor of the constituent elements, Figure 5 In order to illustrate the cross-sectional view of the combination relationship between the vibration source on the upper part of the rotor and the coil applicable to the vibration motor of the present invention, Figure 6 In order to illustrate the brush terminal applicable to the vibration motor of the present invention and the plan view of the brush terminal for adjusting the brush fixed on the terminal, Figure 7 It is an explanatory diagram of the assembly method for installing a commutator in the lower vibration source suitable for the vibration motor of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com