Construction process for road with piping shaft

A technology for road construction and pipeline wells, which can be applied to roads, roads, artificial islands, etc., and can solve the problems of uneven road surface, affecting driving comfort, and inconvenient concrete vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

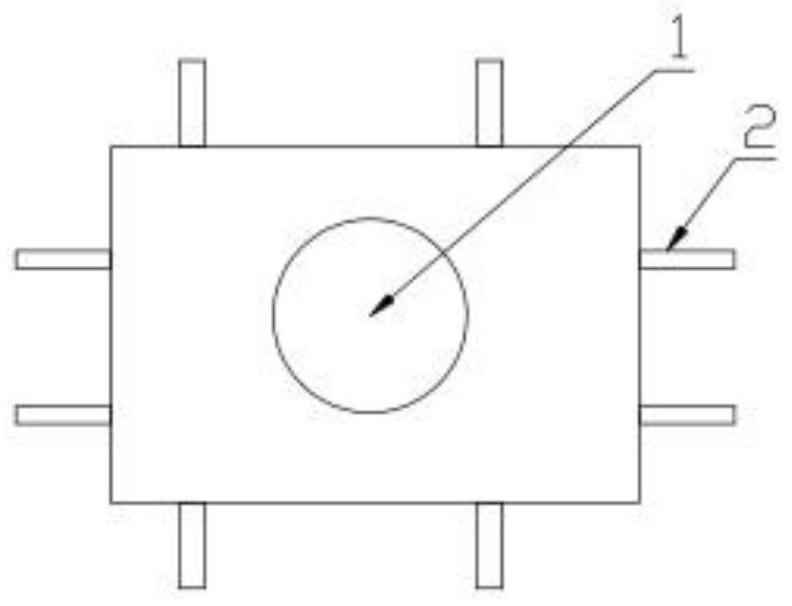

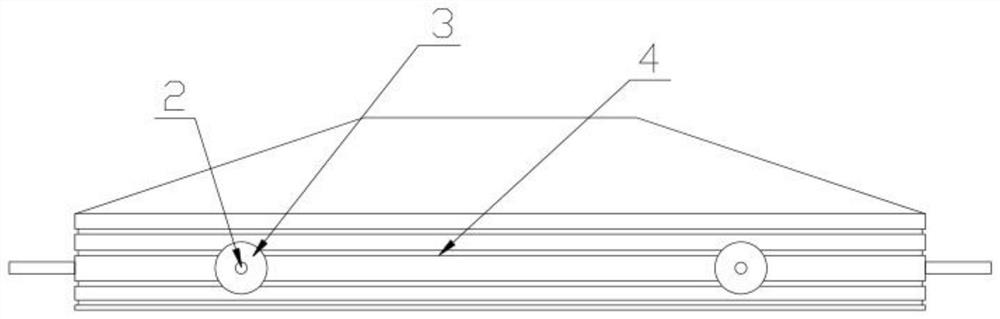

[0014] Such as figure 1 and figure 2 The one shown has a pipeline well road construction process, including subgrade excavation and cleaning, laying the base, base shaping, pouring concrete, and cement concrete surface layer construction. The above processes are prior art, and will not be elaborated here. Before construction, the pipe well kit is prefabricated in the factory, and the side of the pipe well kit is a straight plane. In this embodiment, the pipe well kit is a cuboid structure as a whole, and there is a through hole 1 for the pipe well to be embedded in the middle. The prefabricated pipe well kit is socketed Outside the pipe well, make the upper surface of the pipe well kit as flush as possible with the pipe well. After the pipe well kit is connected, pour concrete, and then carry out normal cement concrete surface construction. In order to reduce the possibility of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com