High-speed polypropylene fiber filament tracking laying device

A high-speed, wire laying technology, applied in the application, tobacco, e-liquid filter and other directions, can solve the problems of affecting the forming speed of the mouth stick, the tow lifting disorder, etc., and achieve the effect of accelerating the vibration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

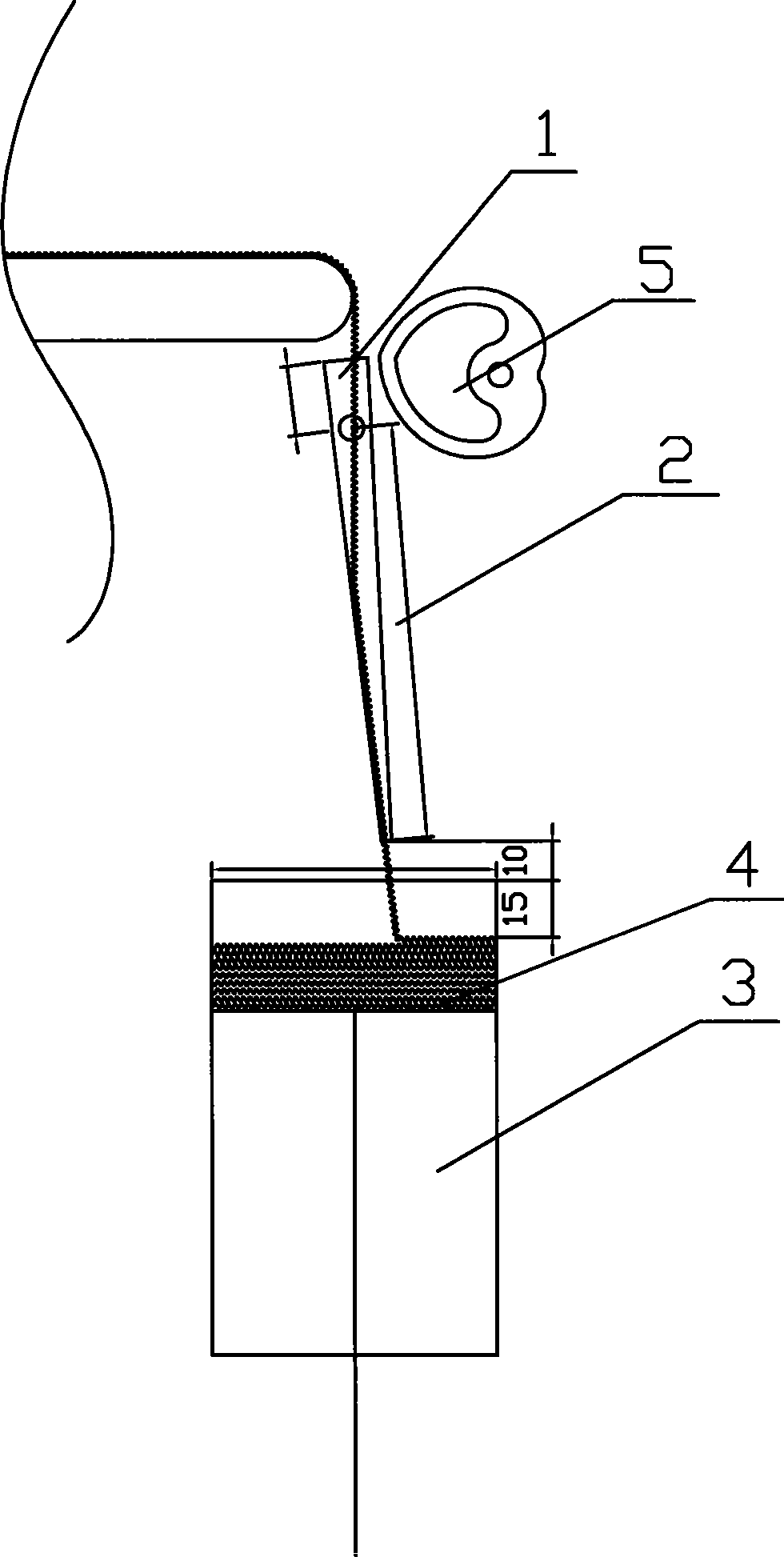

[0010] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0011] like figure 1 As shown, the present invention comprises a swing arm 1, a swing bucket 2, a silk bucket 3, a supporting plate 4, and a cam 5. The lower end of the swing arm 1 is connected to the swing bucket 2, and the bottom of the swing bucket 2 is provided with a silk bucket 3. Supporting plate 4 is set in 3, and cam 5 is set on one side of swing arm 1; The height of the end face is 15-20mm.

[0012] The cam is how it was designed in the picture. The swing arm (1) is pulled towards the cam (5) by the spring, and the cam is rotated by the cycloid motor at a certain angular velocity, and the swing arm is deflected outward by the cam at a certain angular velocity ω1. When the swing arm turns to the farthest point, As the cam rotates, the swing arm is pulled inward by the cam to deflect at a certain angular velocity ω2. ω1=ω2, and the angular v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com