Patents

Literature

103results about How to "Control swing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

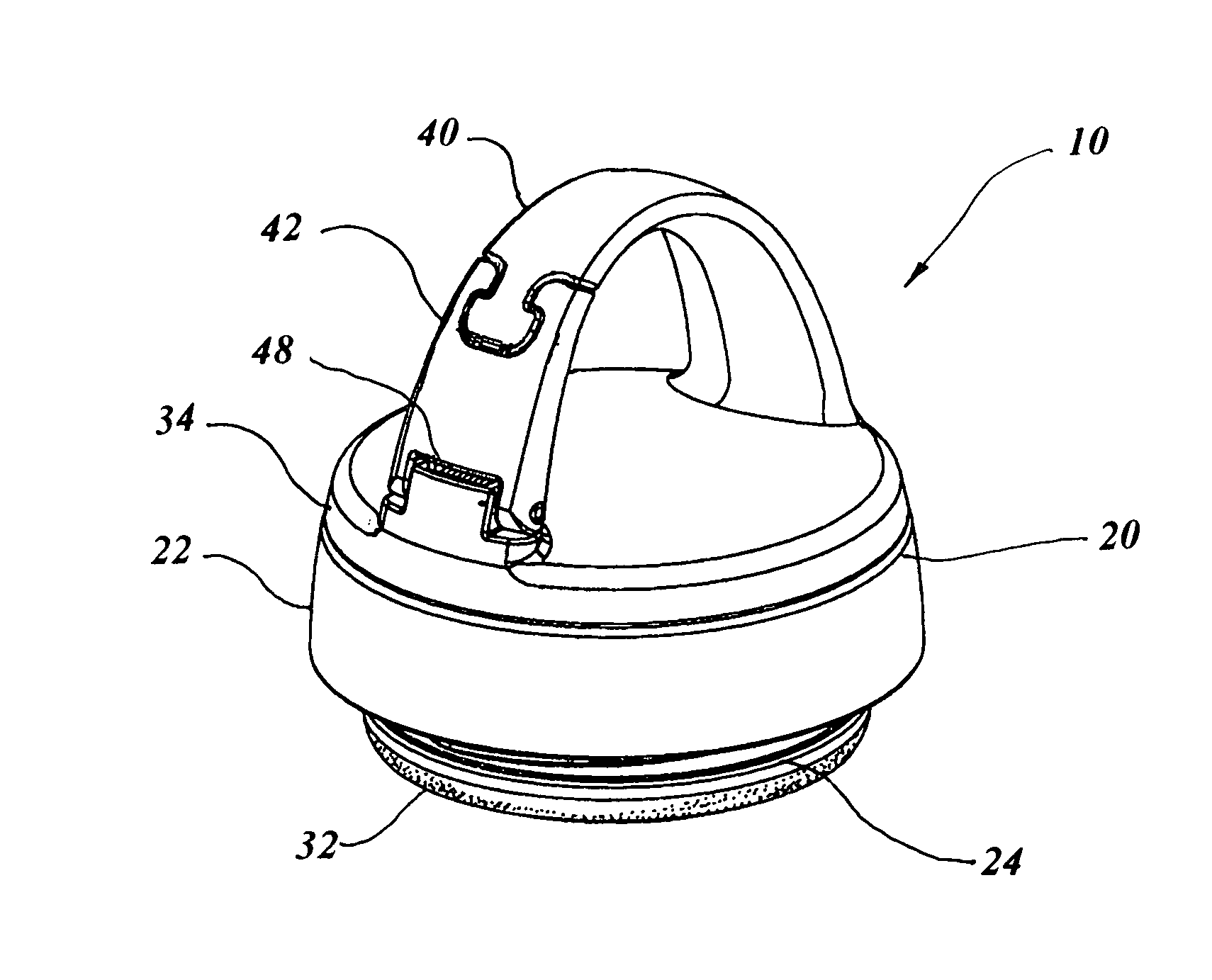

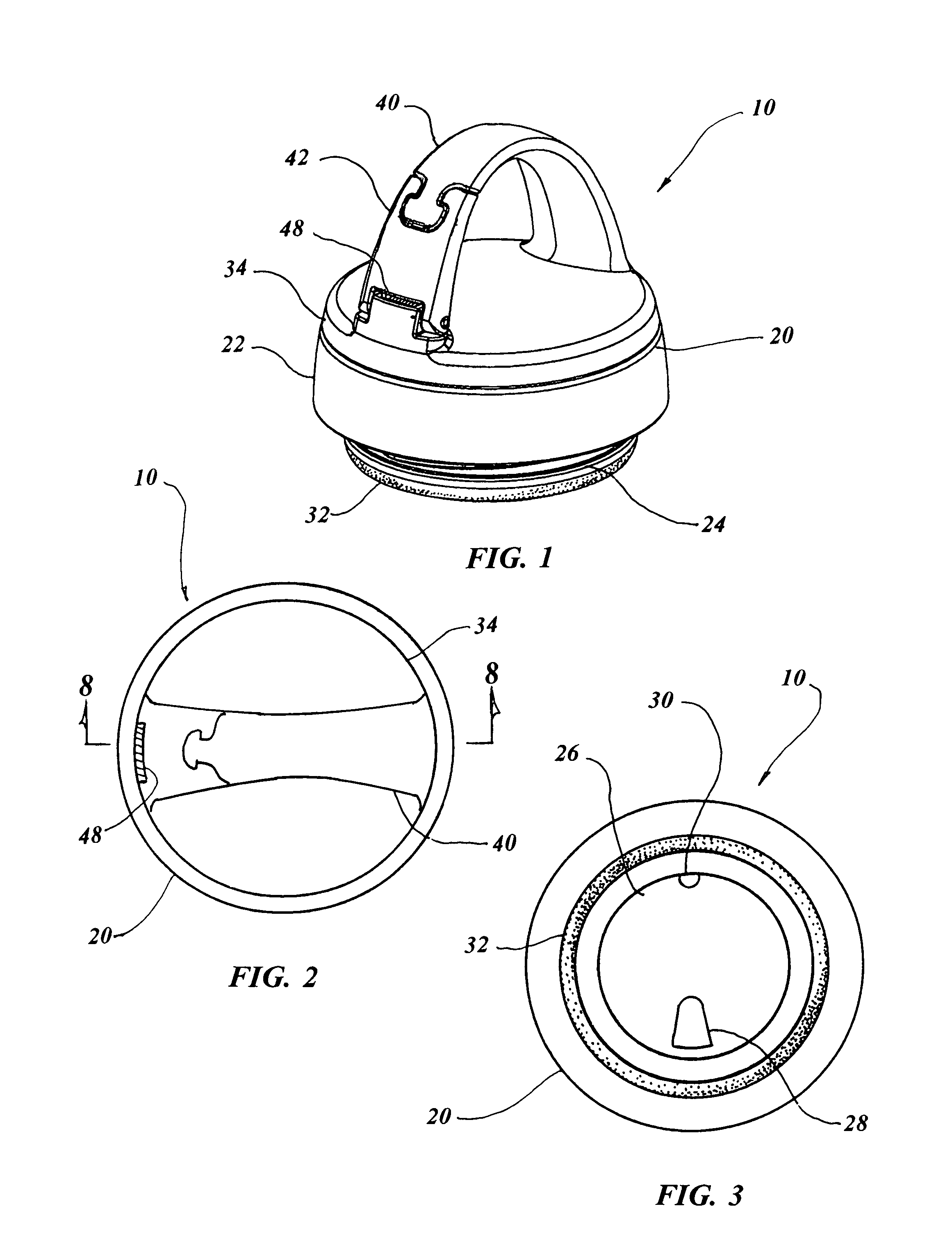

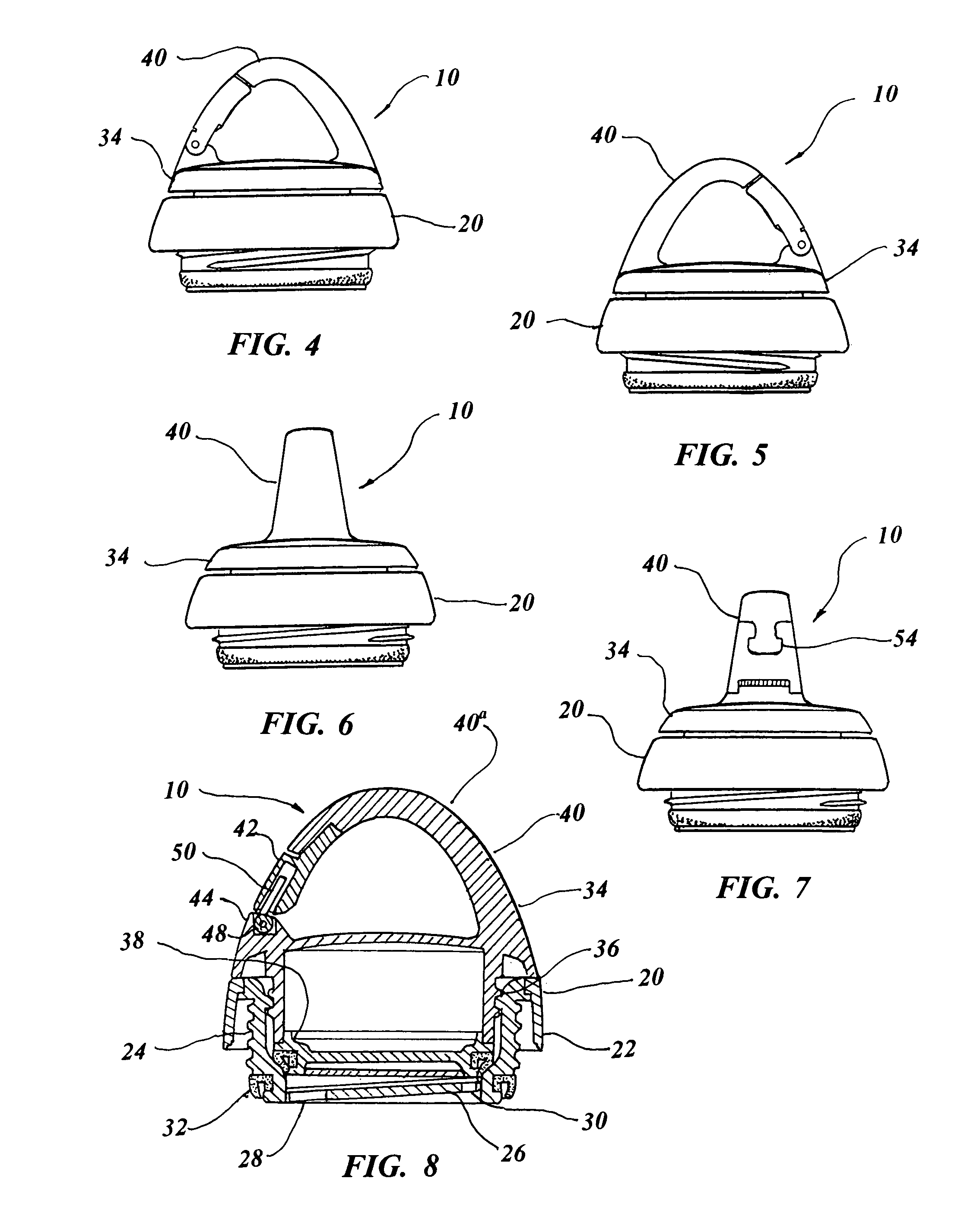

Latched handle container lid

A container lid with a latch handle is taught that incorporates a drinking lip, having a flared brim, configured to interface with a liquid container. A lip sealing ring is disposed on the drinking lip creating a watertight fit between the lip and the container. A lid body, having lid male threads, is configured to interface with container lid female threads, and the lid body includes a bottom cover which forms a dead air space for insulation purposes within the lid. The lid body incorporates a vertical arched handle with a snap-in hinged spring loaded latch for quick release attachment of the container lid and container securely to an object. A lid sealing ring is disposed on the lid body forming a watertight fit between the lid body and the container drinking lip.

Owner:LIN SHIN SHUOH

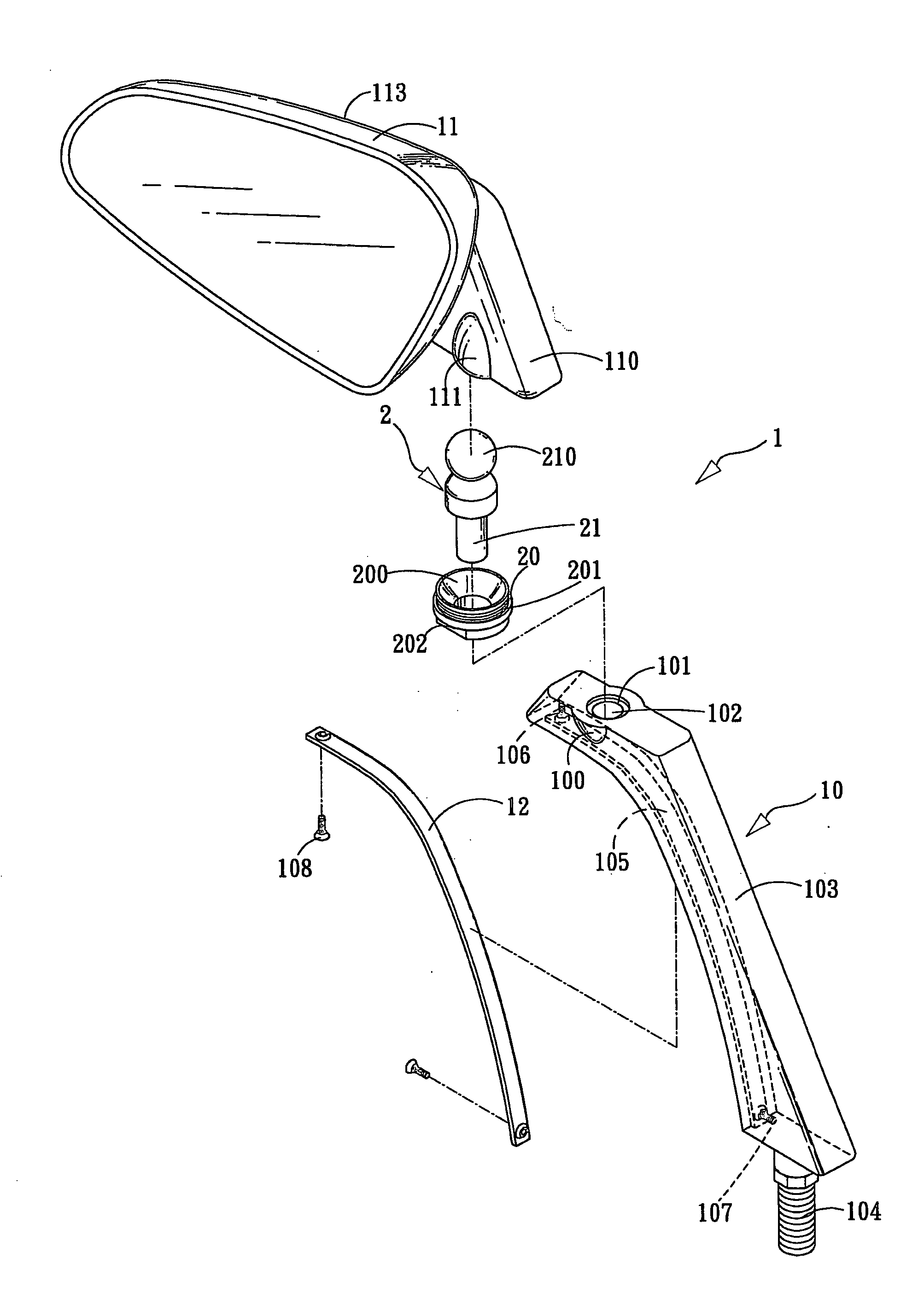

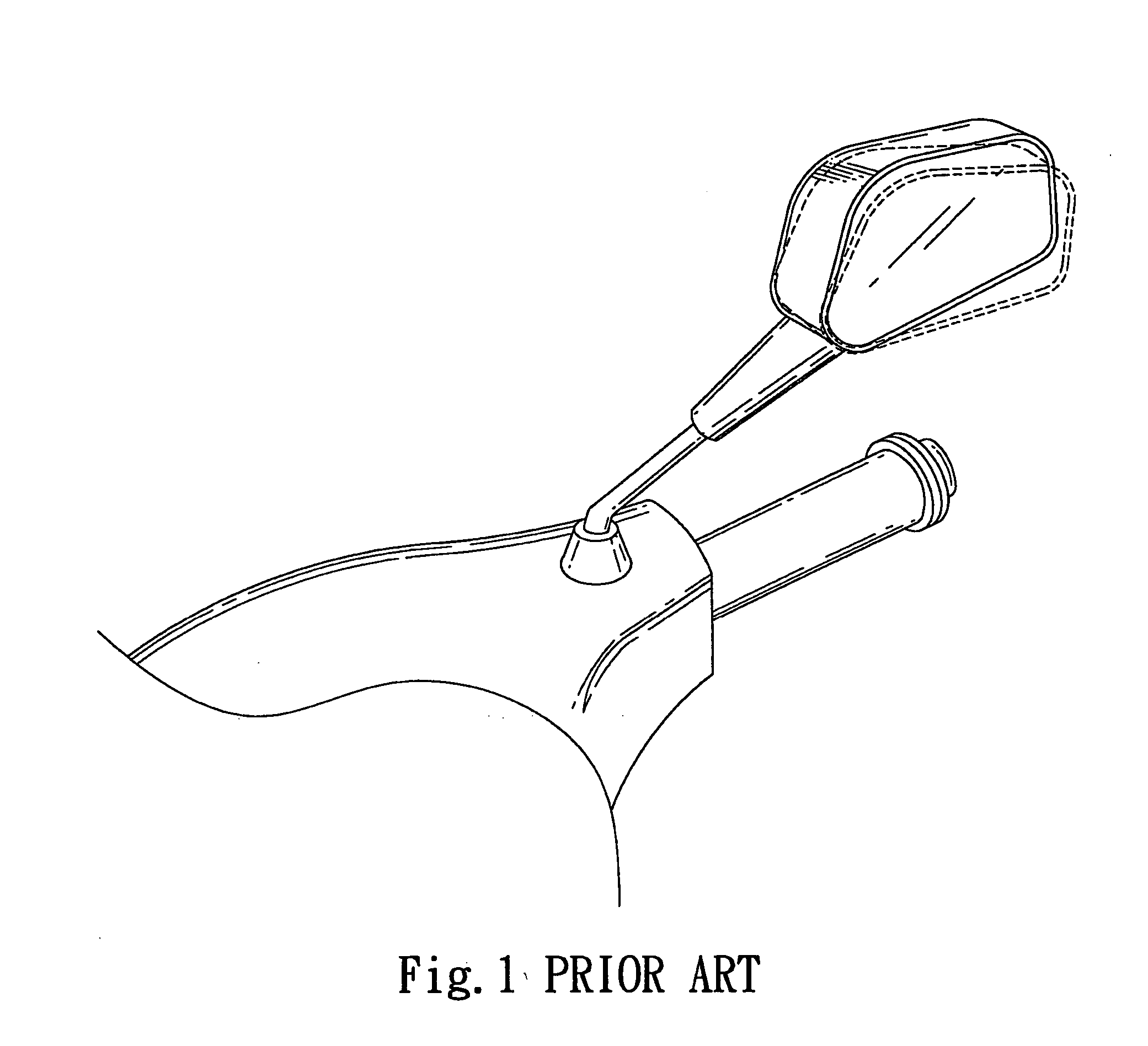

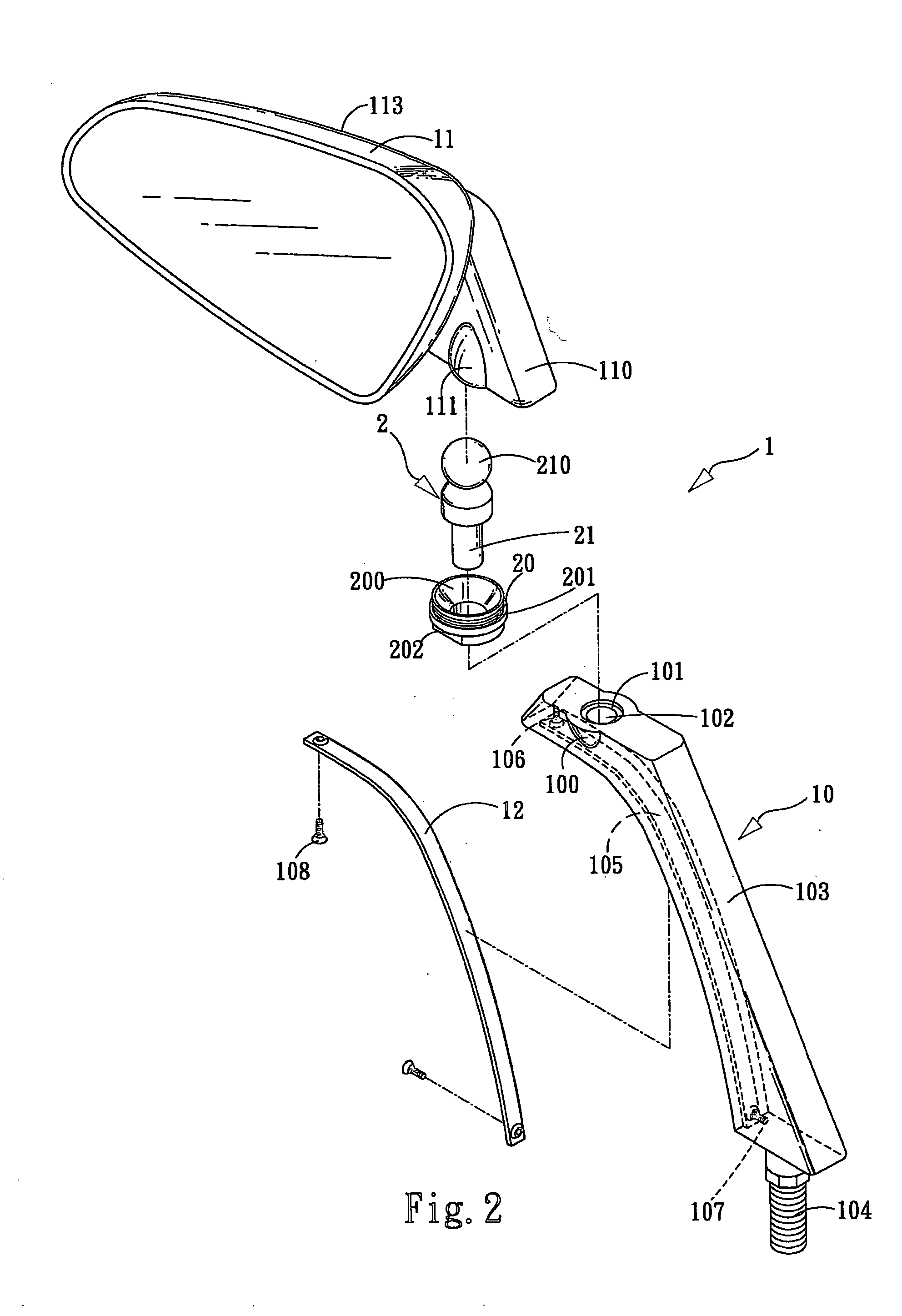

Mirror of motorcycle with swivel mount

InactiveUS20050237643A1Making safeDirection is limitedCycle mirrorsMountingsVertical planeUniversal joint

A mirror assembly of motorcycle is disclosed. The assembly comprises an arm mechanism including an arm secured to a handlebar, and a bore on the top end; a mirror mechanism including a threaded hole on a bottom of a connecting member thereof; and a universal joint mechanism including a ring-shaped seat secured to the threaded hole, and a post having a top ball, the ball being substantially enclosed by the mirror mechanism and the seat and pivotably supported on the seat when the post is inserted through the seat into the bore for fastening. The mirror mechanism is operative to either turn freely about the ball on a horizontal plane or turn about the ball on a vertical plane in a limited angle.

Owner:WU HSIU LI

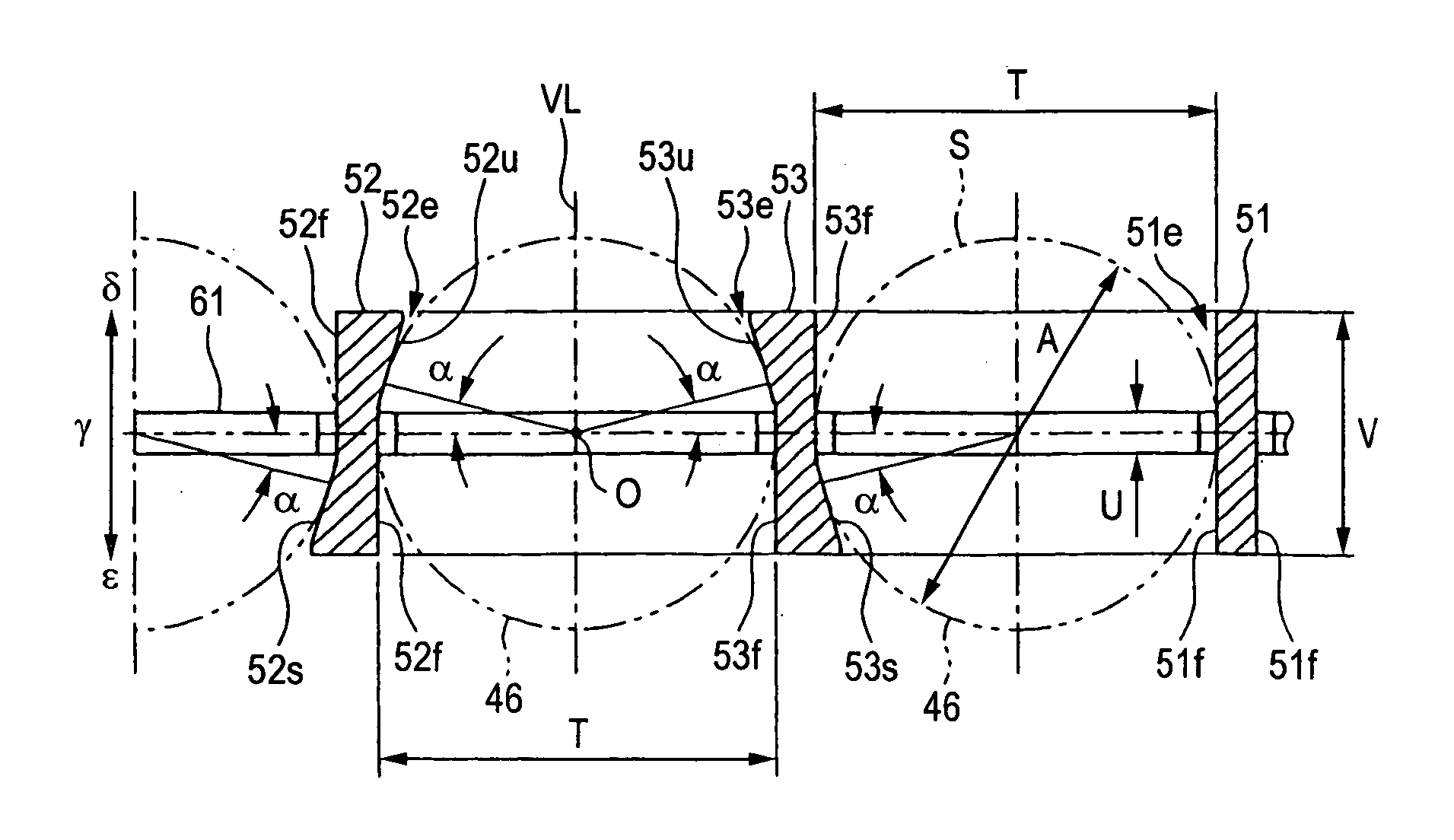

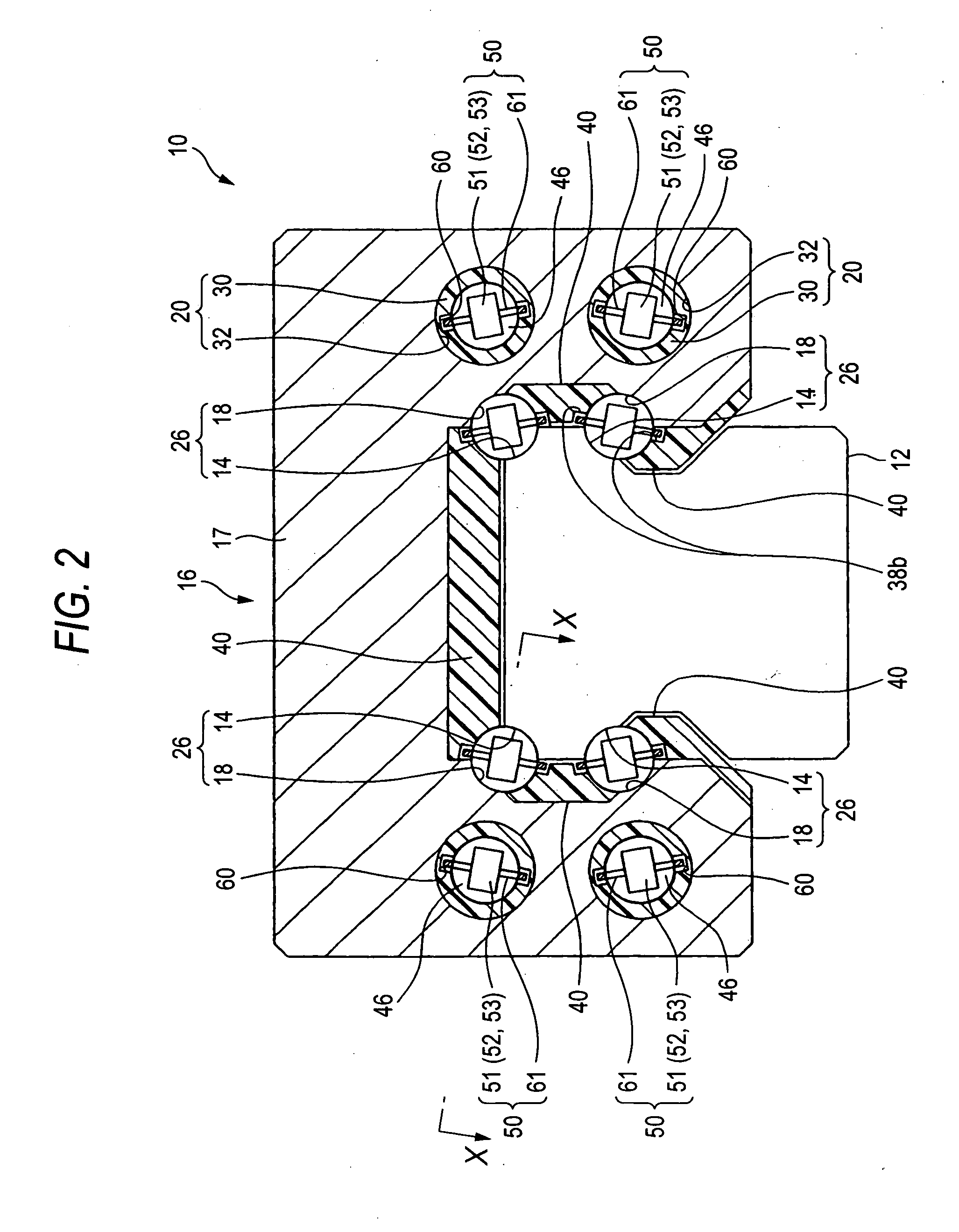

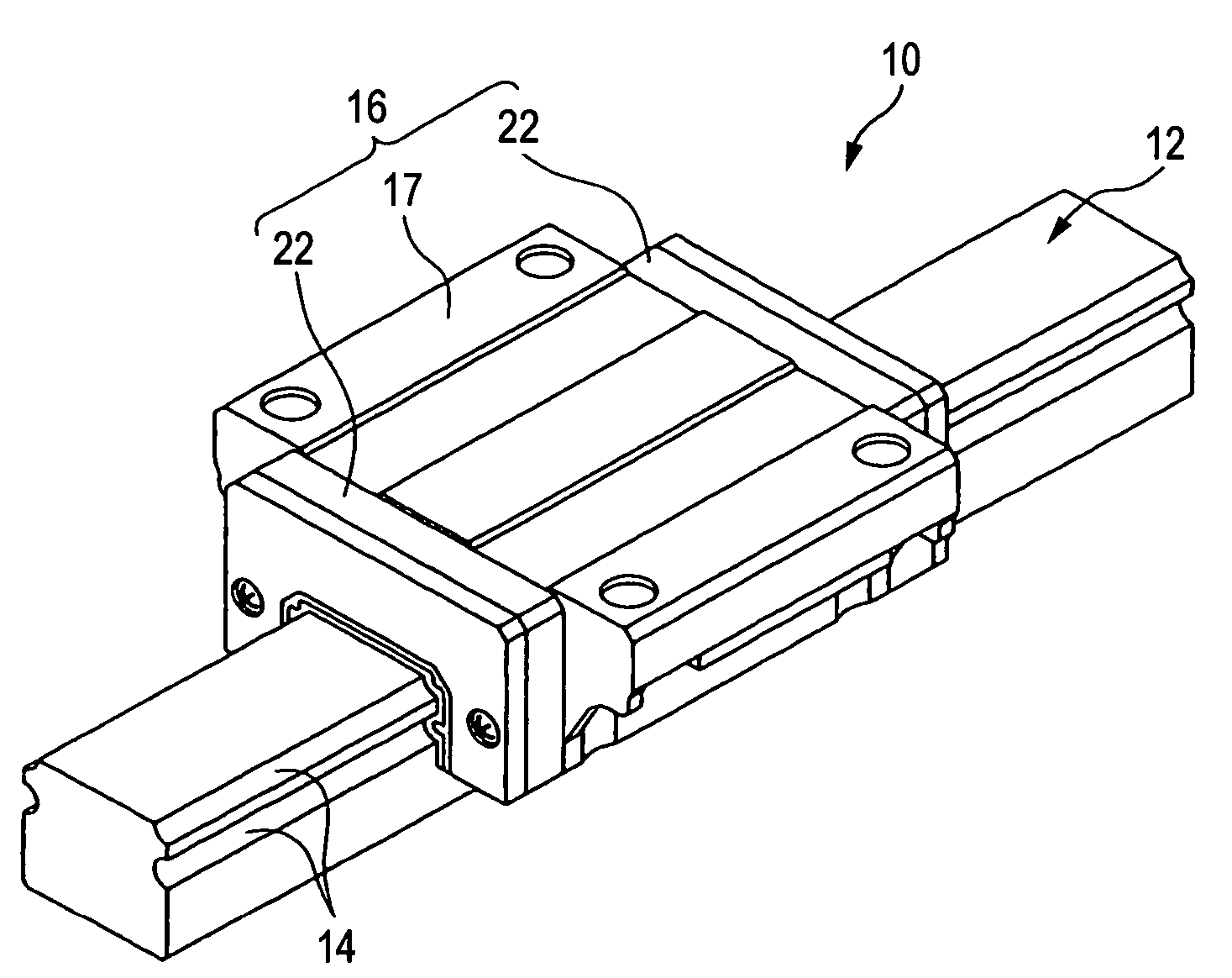

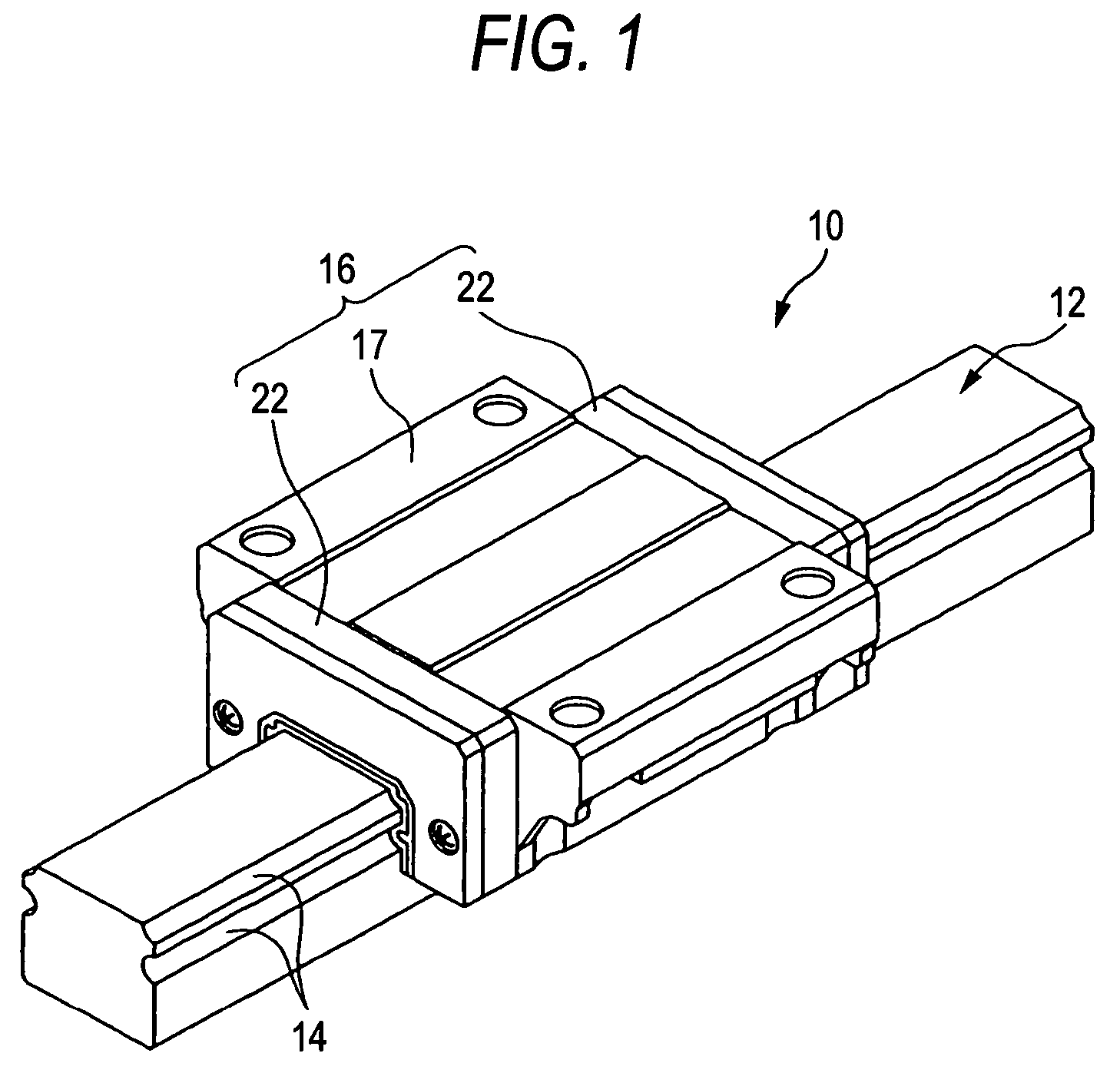

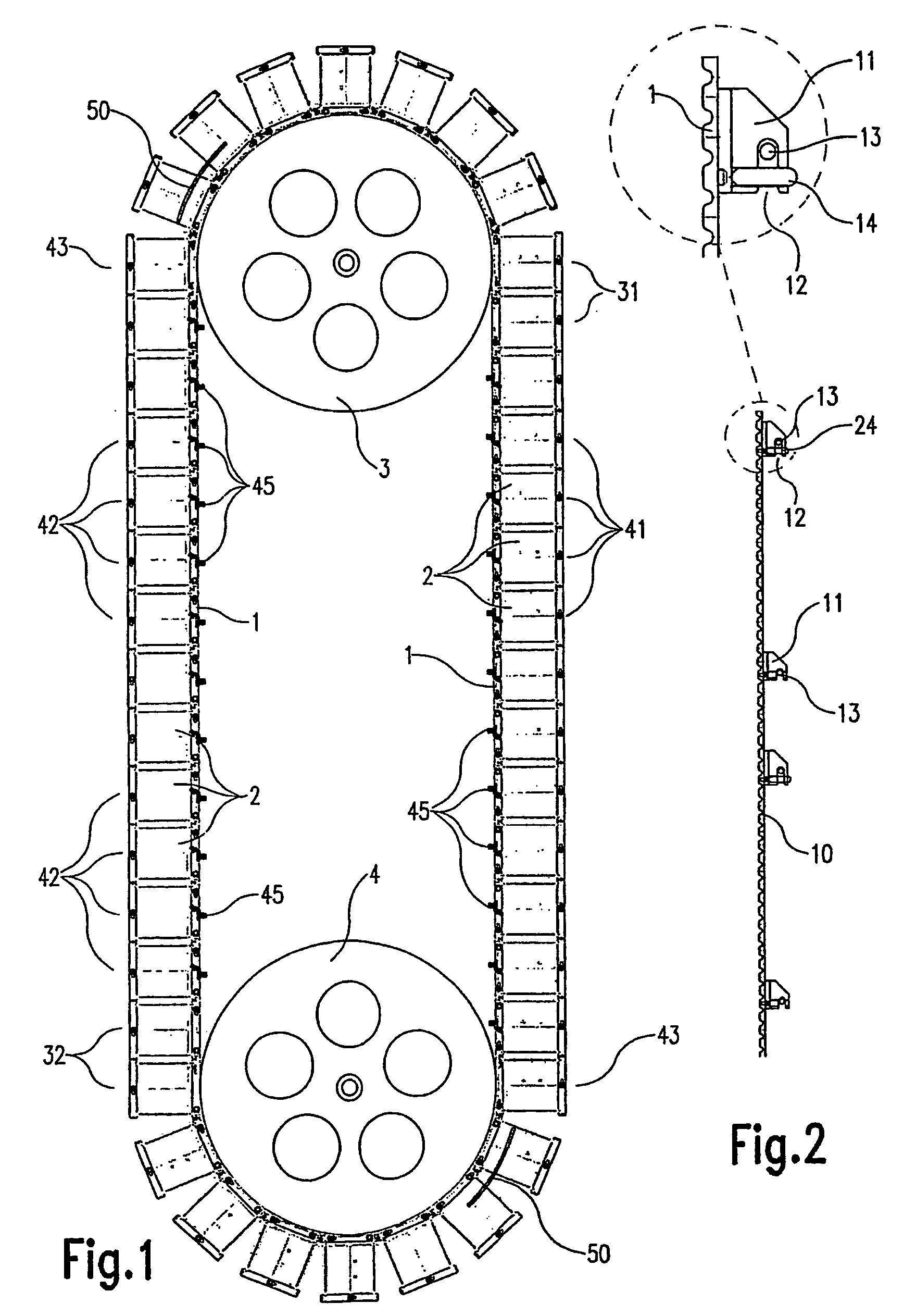

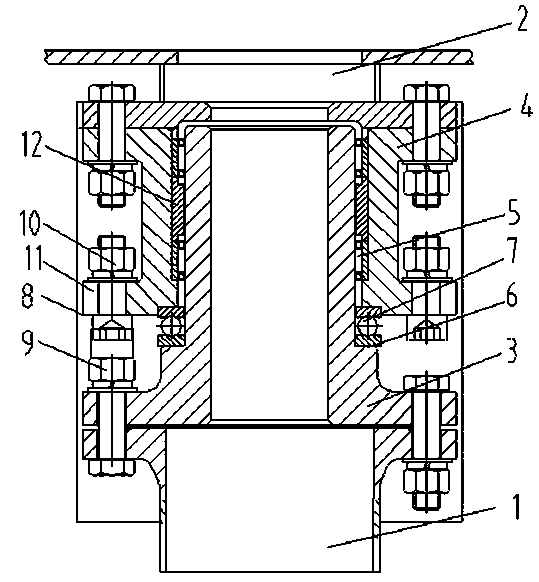

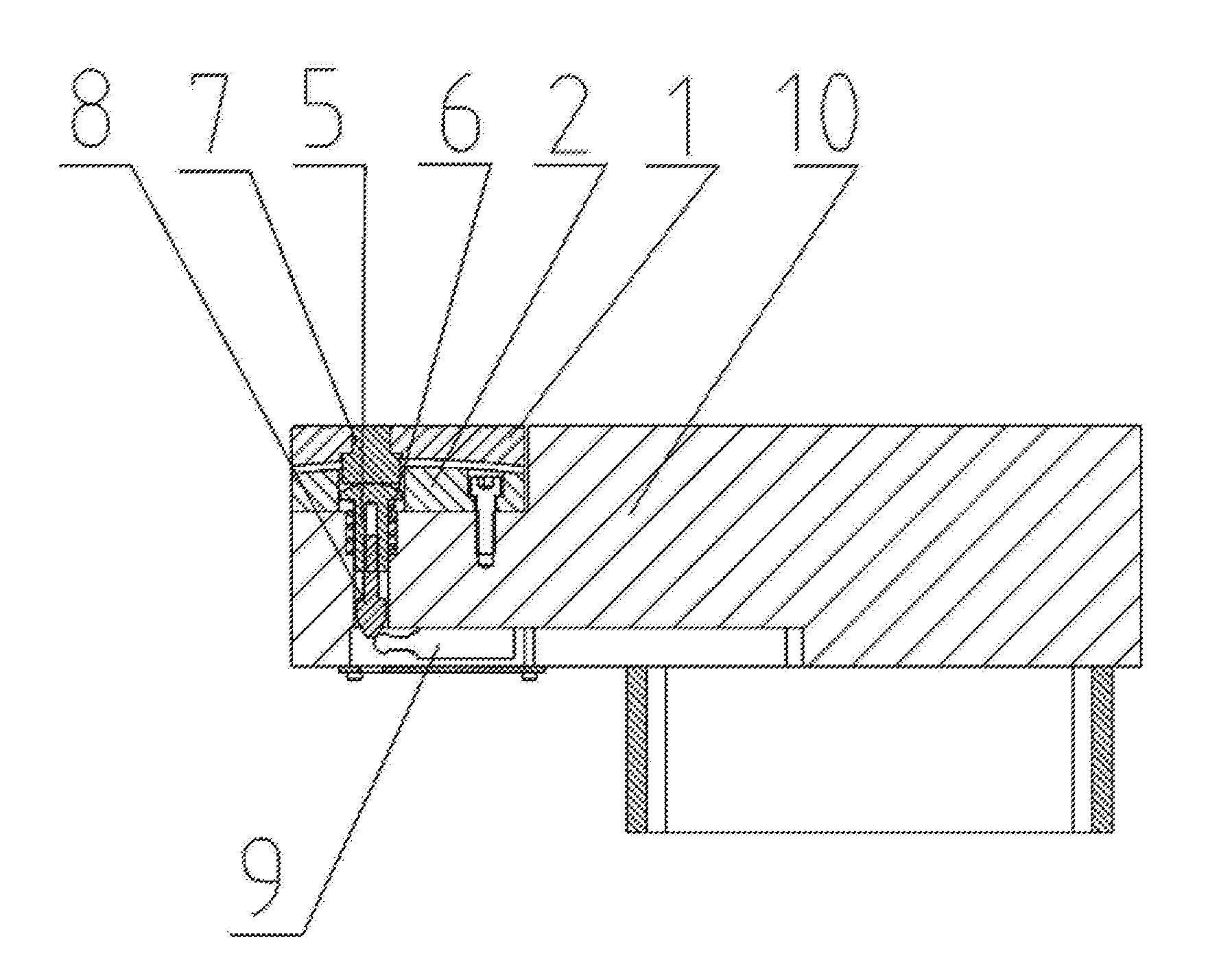

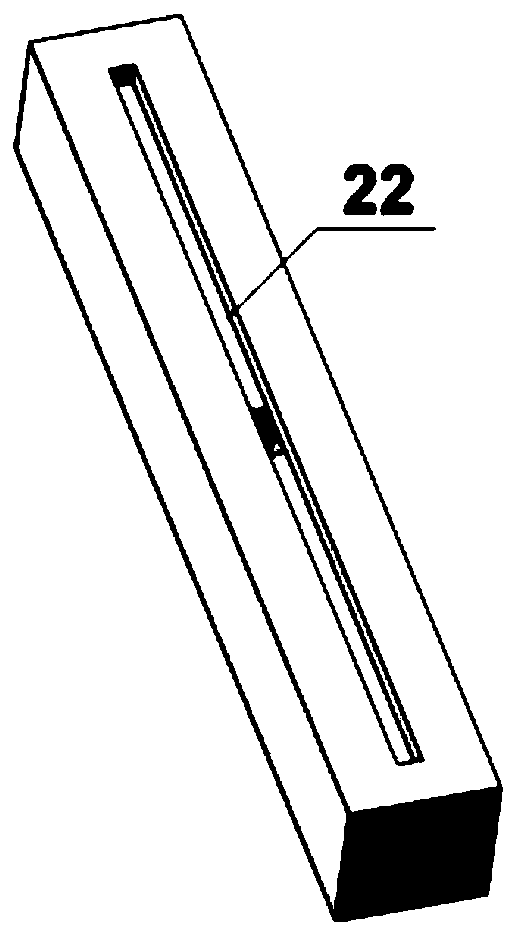

Rolling element accommodating belt for linear guide apparatus and linear guide apparatus

ActiveUS20070076989A1Easy to installControl swingLinear bearingsRolling contact bearingsEngineeringLinearity

There is provided a rolling element accommodating belt for a linear guide apparatus which has a guide rail, a slider having a load rolling element guiding face which constitutes a rolling element track path together with the guide rail, a pair of direction converting paths and a rolling element return path, a plurality of rolling elements circulating within an endless circulation path defined by the rolling element track path, the pair of direction converting paths and the rolling element return path; and a guide groove. The rolling element accommodating belt includes a plurality of spacer portions interposed between the rolling elements, coupling arms to be guided by the guide grooves and rolling element accommodating portions accommodating the rolling element. The spacer has an inward abutting face abutting on the rolling element so as to prevent the rolling element from moving to inner diameter side of the endless circulation path.

Owner:NSK LTD

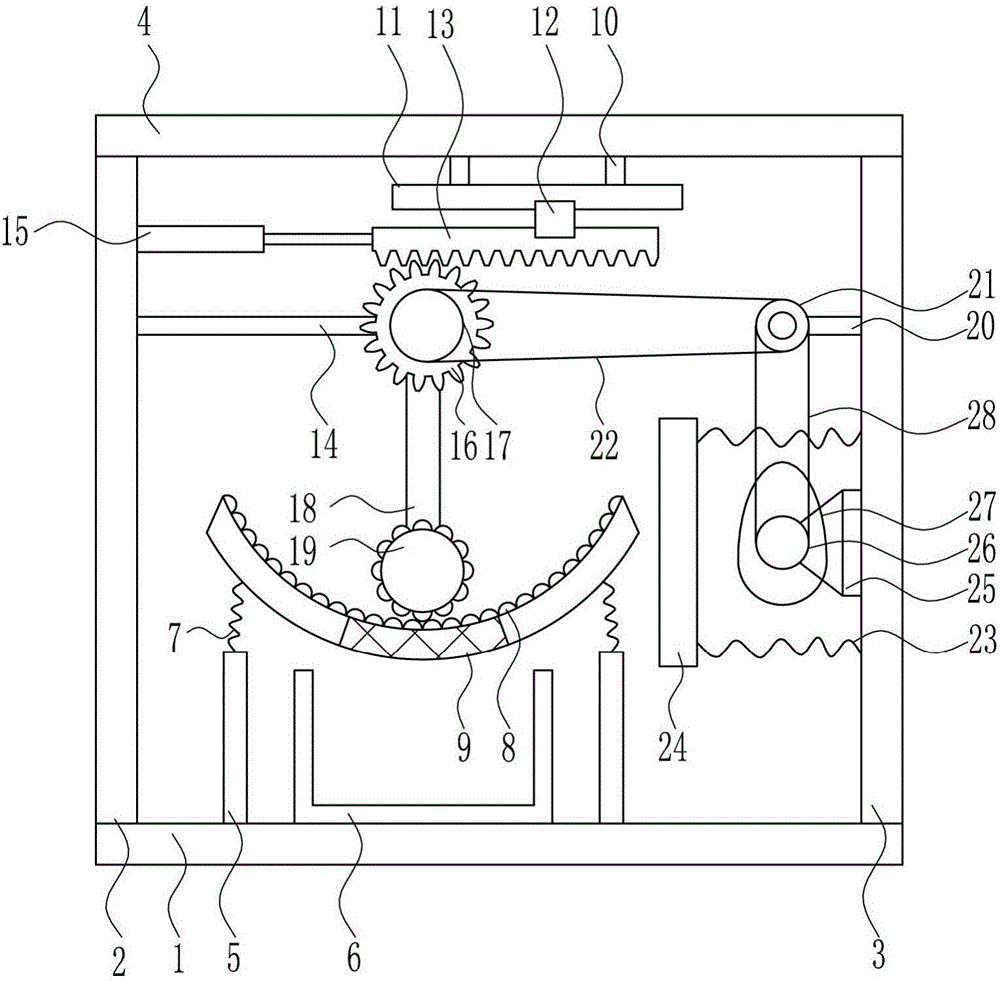

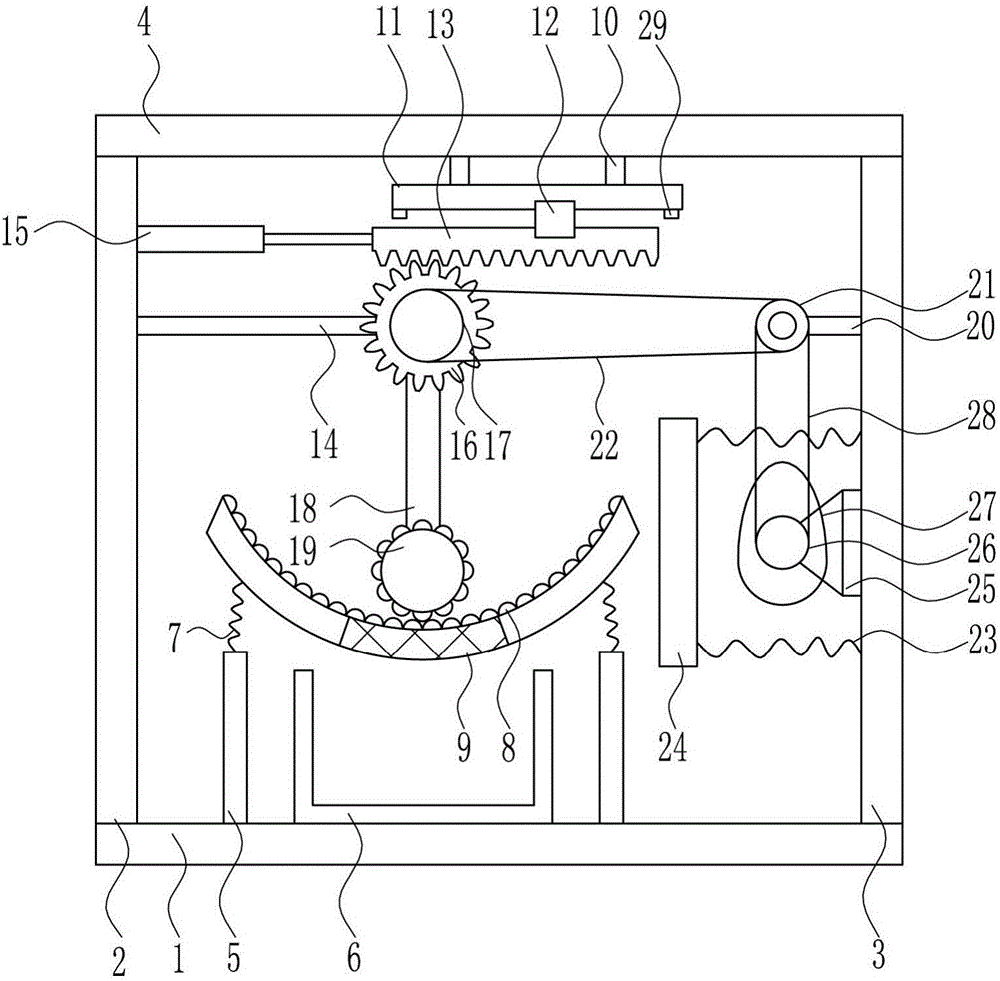

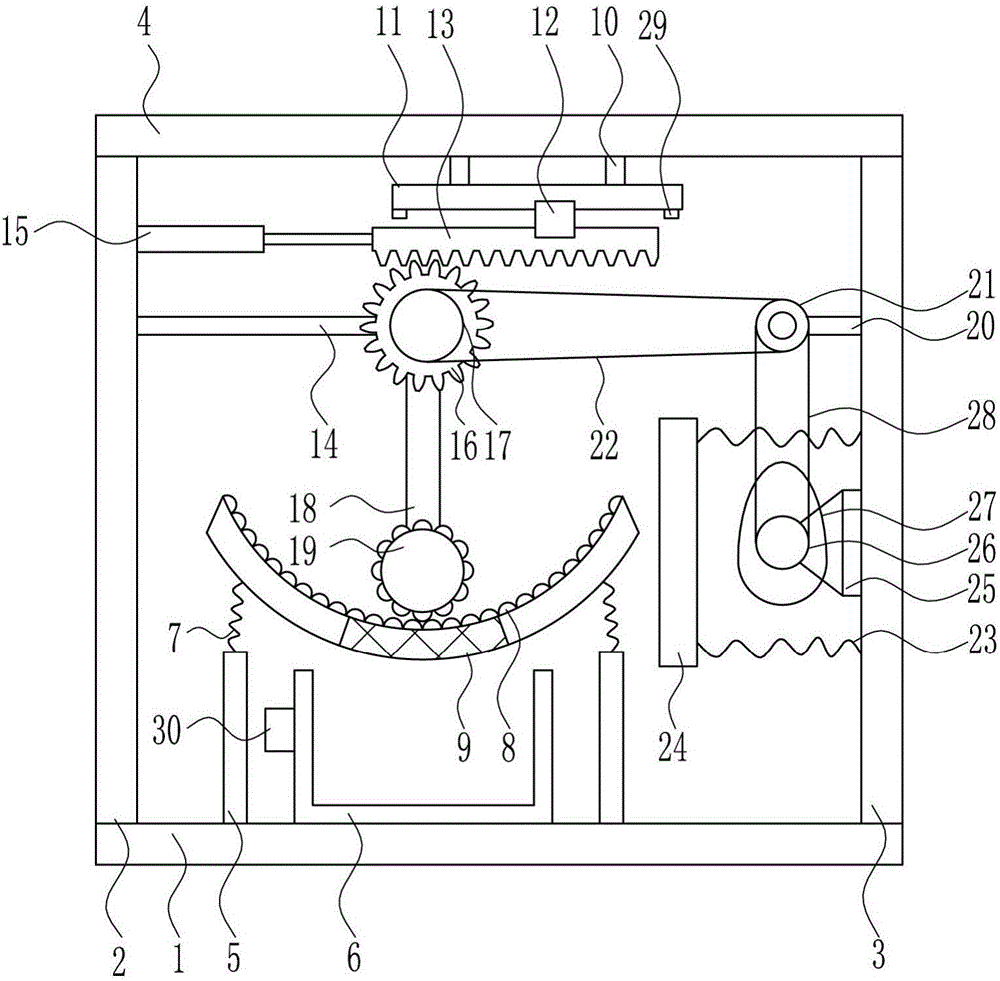

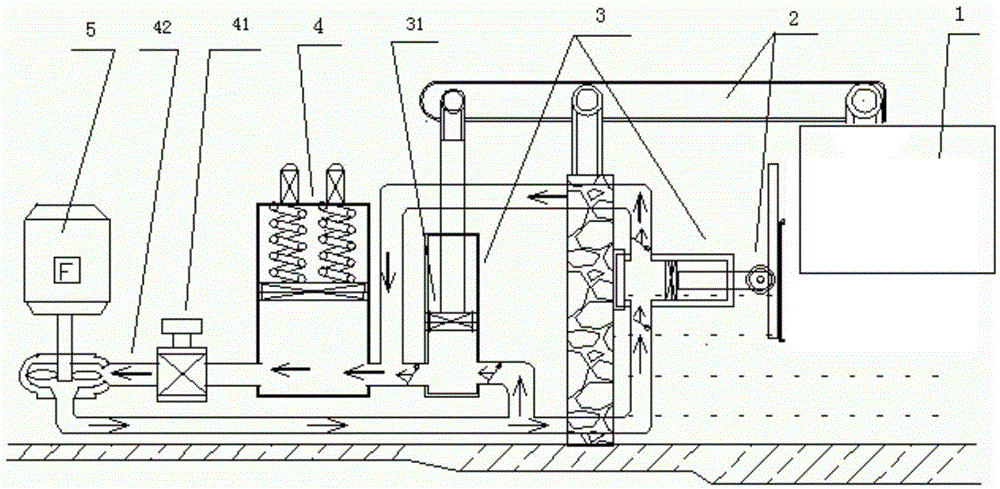

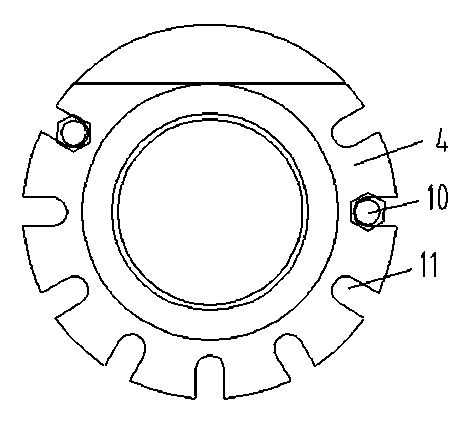

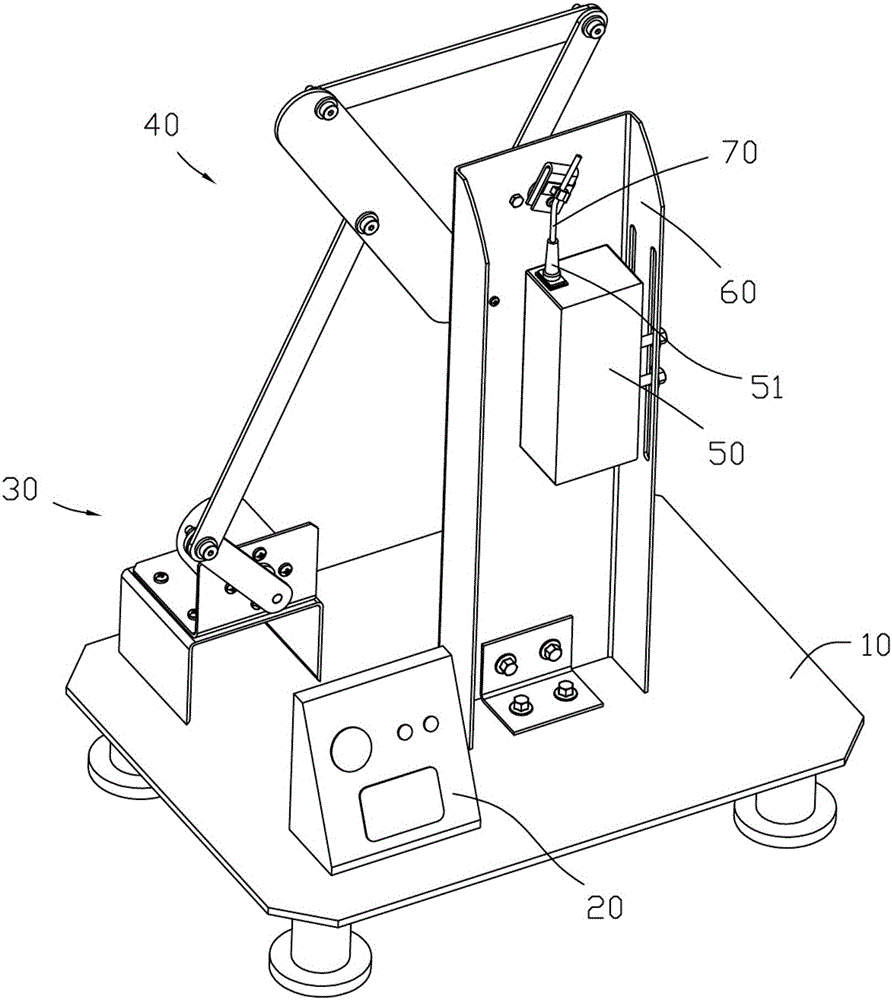

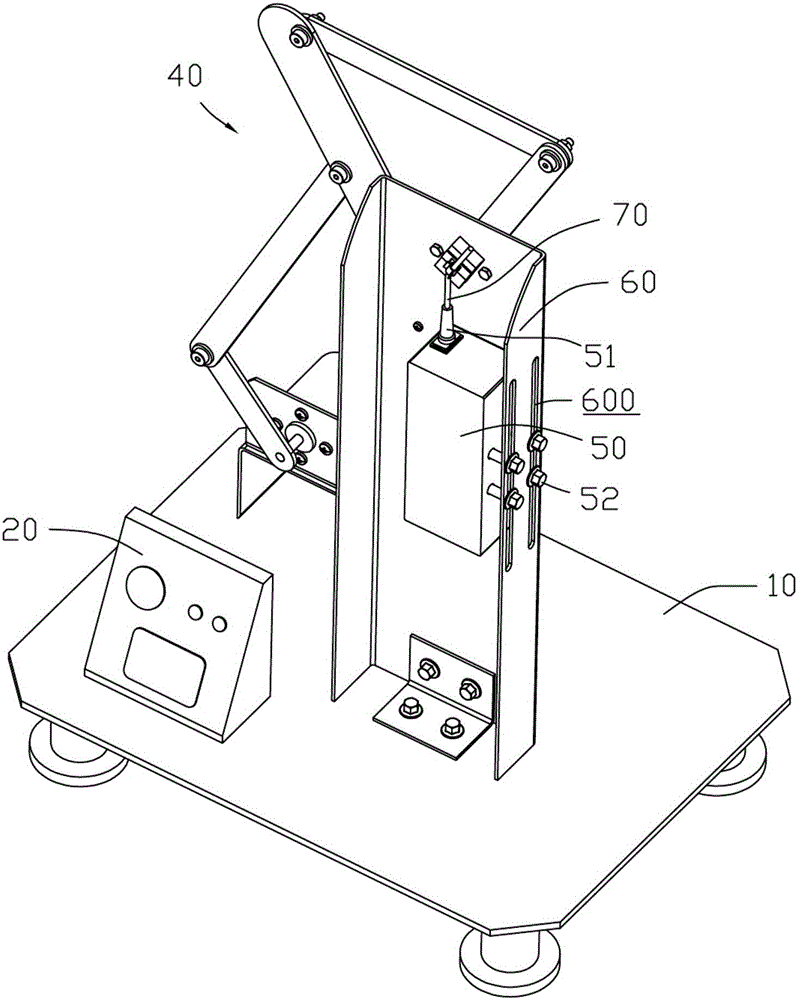

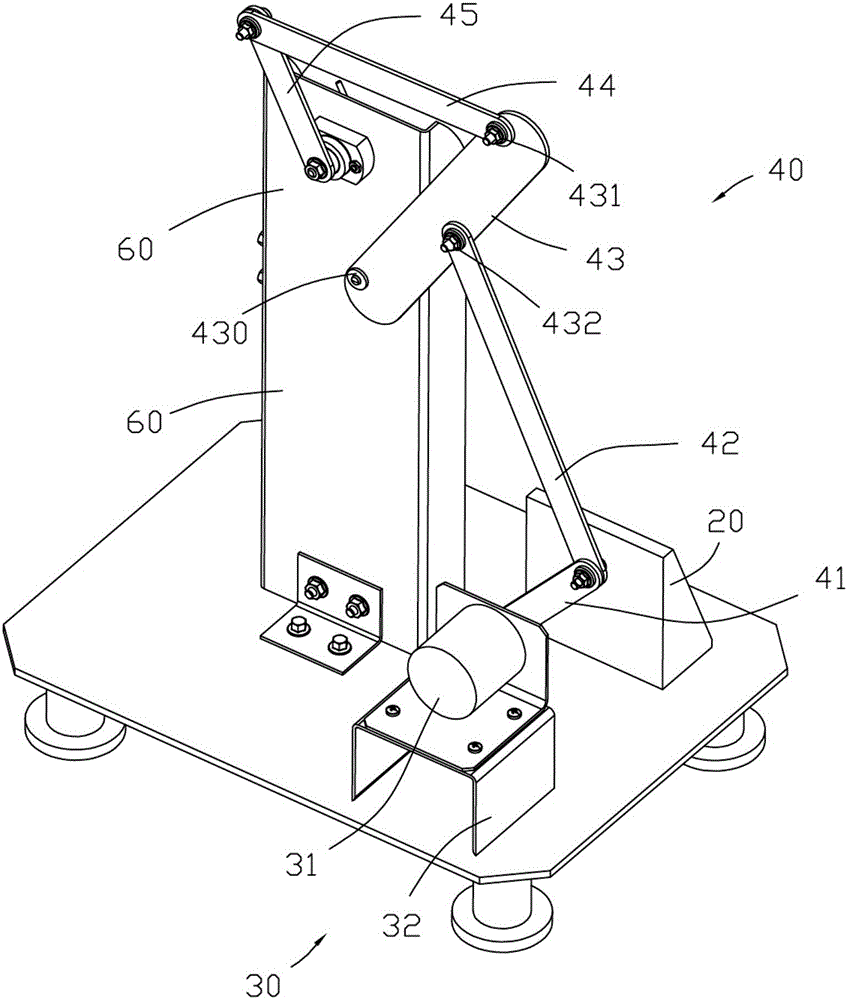

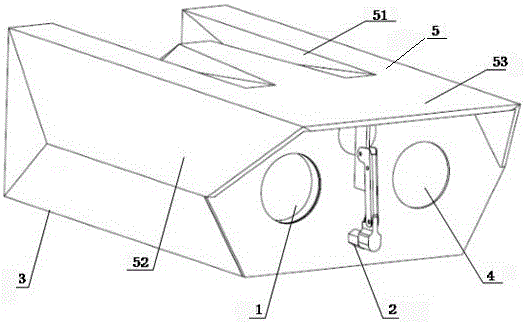

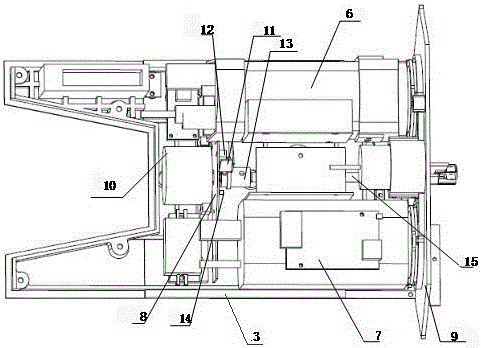

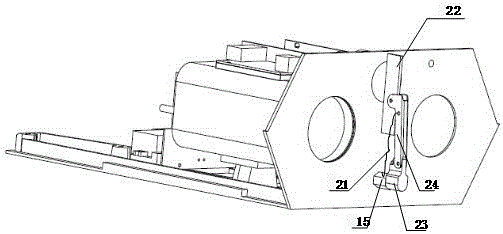

Rapid grinding device metal materials for 3D printing

ActiveCN106180736AControl rotationControl swingAdditive manufacturing apparatusMetallic materialsPolymer chemistry

The invention relates to a grinding device for metal materials for 3D printing, in particular to a rapid grinding device for metal materials for 3D printing. By the adoption of the rapid grinding device for the metal materials for 3D printing, the technical purposes of excellent grinding effect, high work efficiency and simple structure are achieved. For achieving the technical purposes, the rapid grinding device for the metal materials for 3D printing comprises a bottom plate, a left support, a right support, a top plate, first supporting rods, a collection frame, first springs, a grinding cylinder, a screen plate, a supporting base, a sliding rail, a sliding block, a rack, a second supporting rod and the like. The left support is arranged at the left end of the top of the bottom plate. The right support is arranged at the right end of the top of the bottom plate. The first supporting rods are symmetrically arranged on the left side of the top of the bottom plate. By the adoption of the rapid grinding device for the metal materials for 3D printing, the effects of excellent grinding effect, high work efficiency and simple structure are achieved, the metal materials can be ground rapidly, the work benefits are increased for enterprises, and the rapid grinding device is reasonably provided with a reinforcing rib.

Owner:NANTONG DONGFANG PLASTIC CO LTD

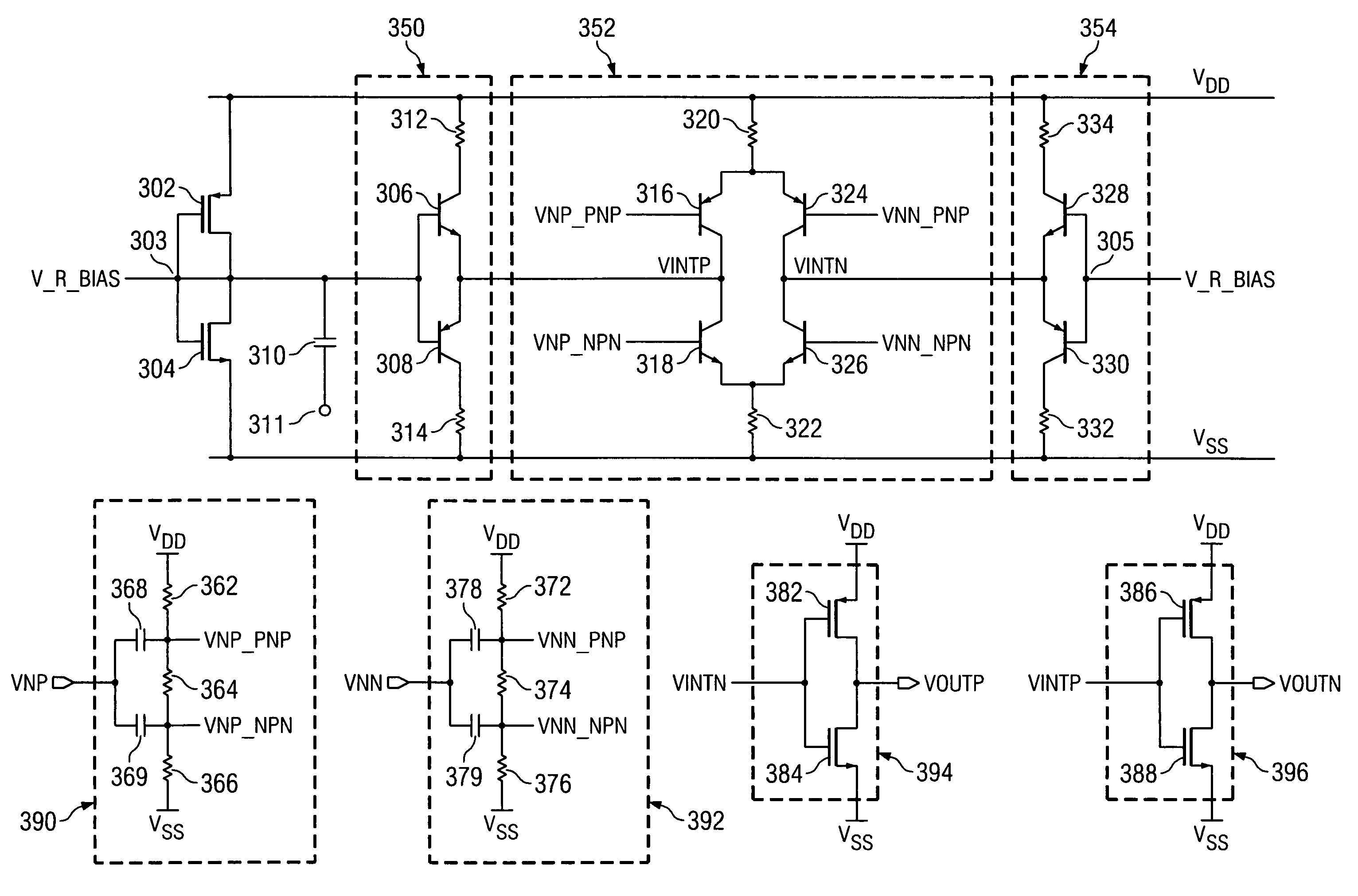

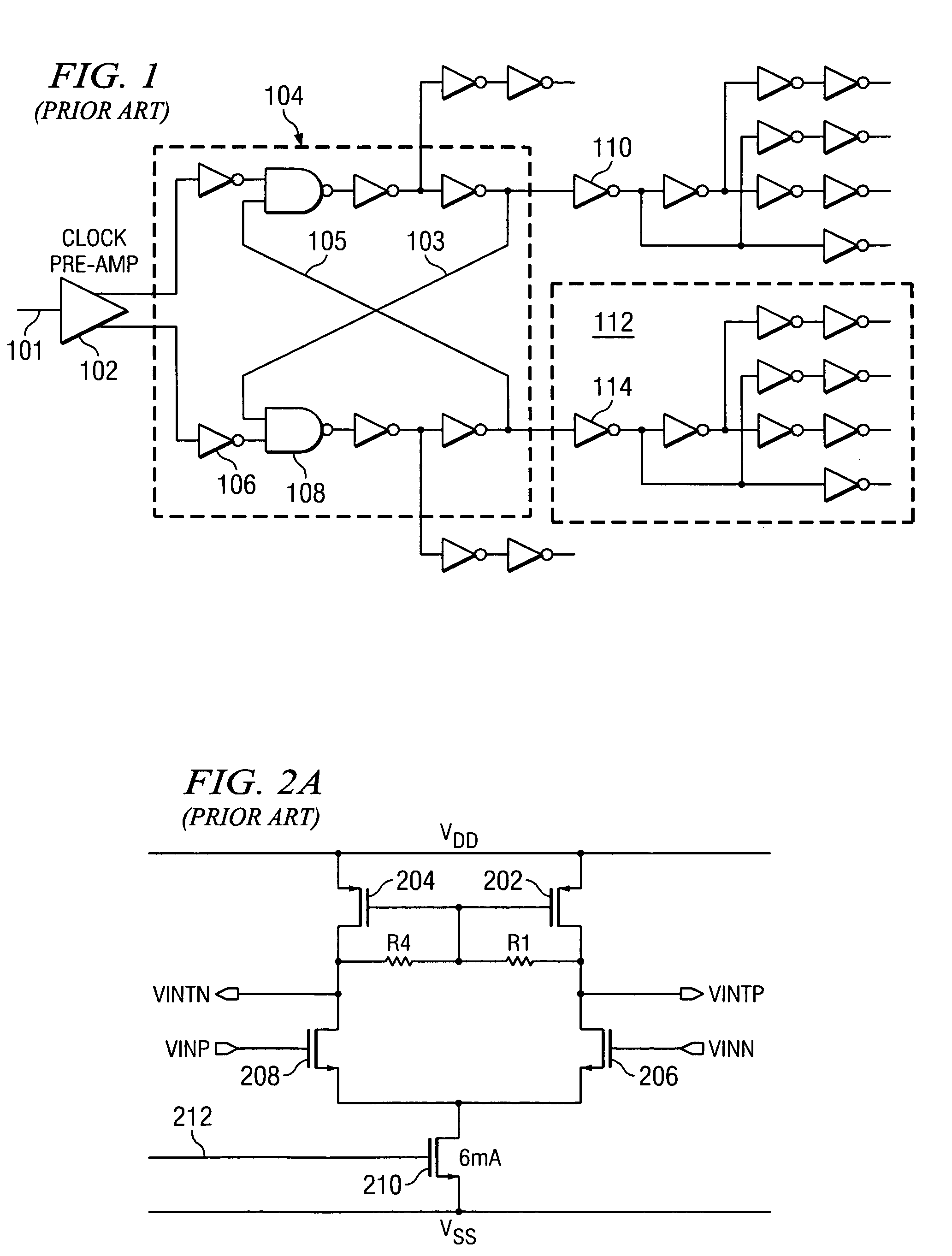

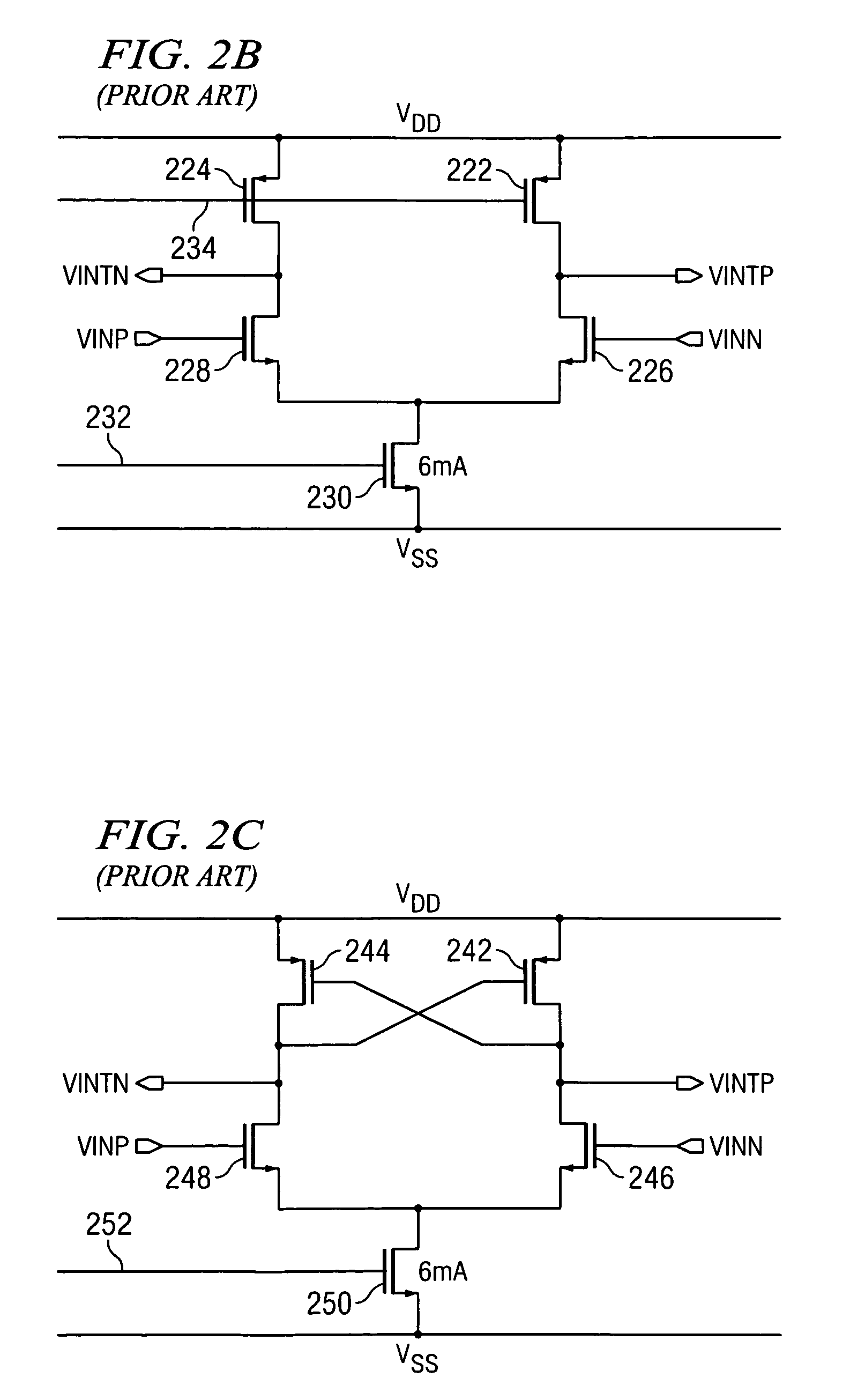

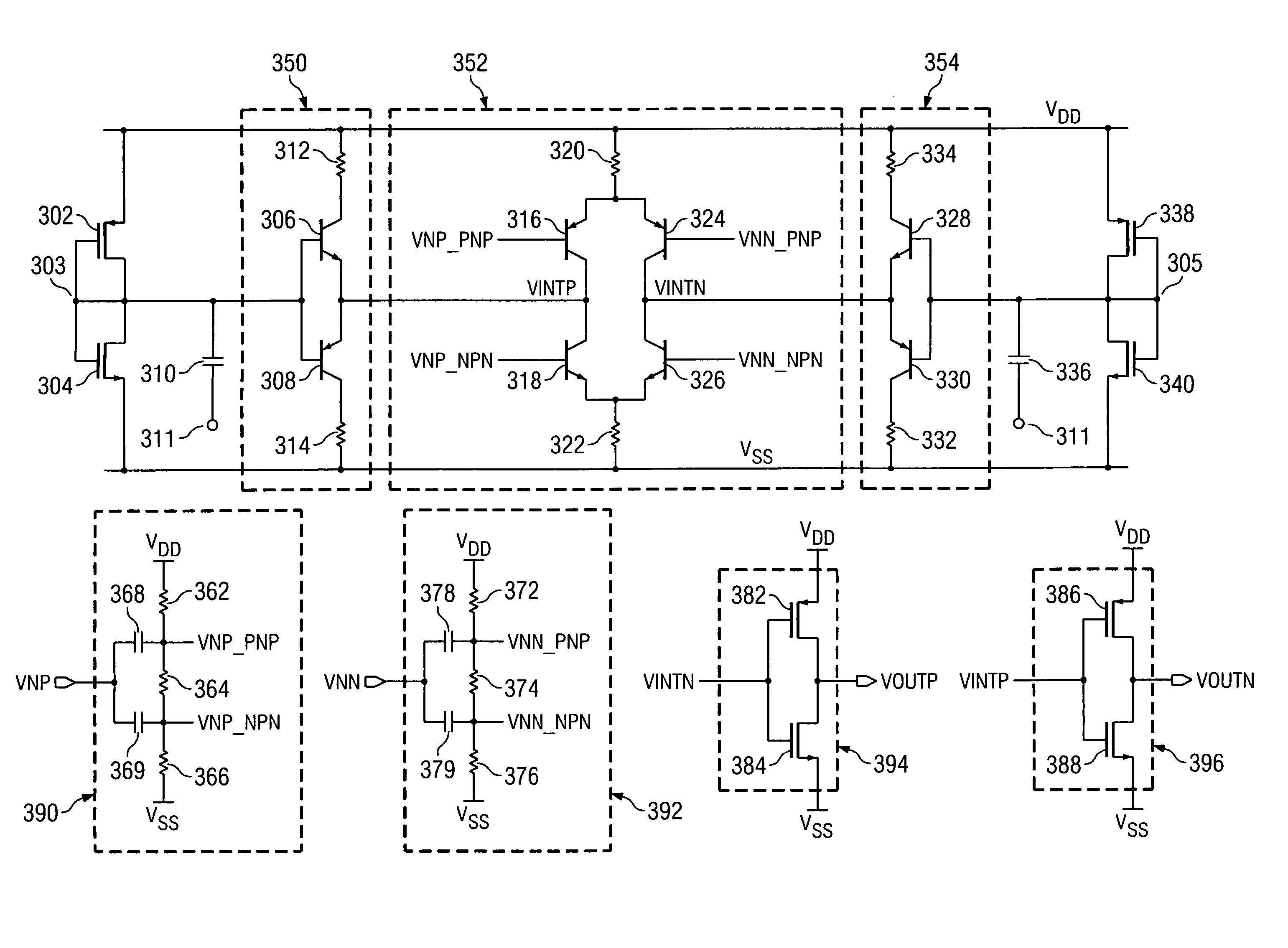

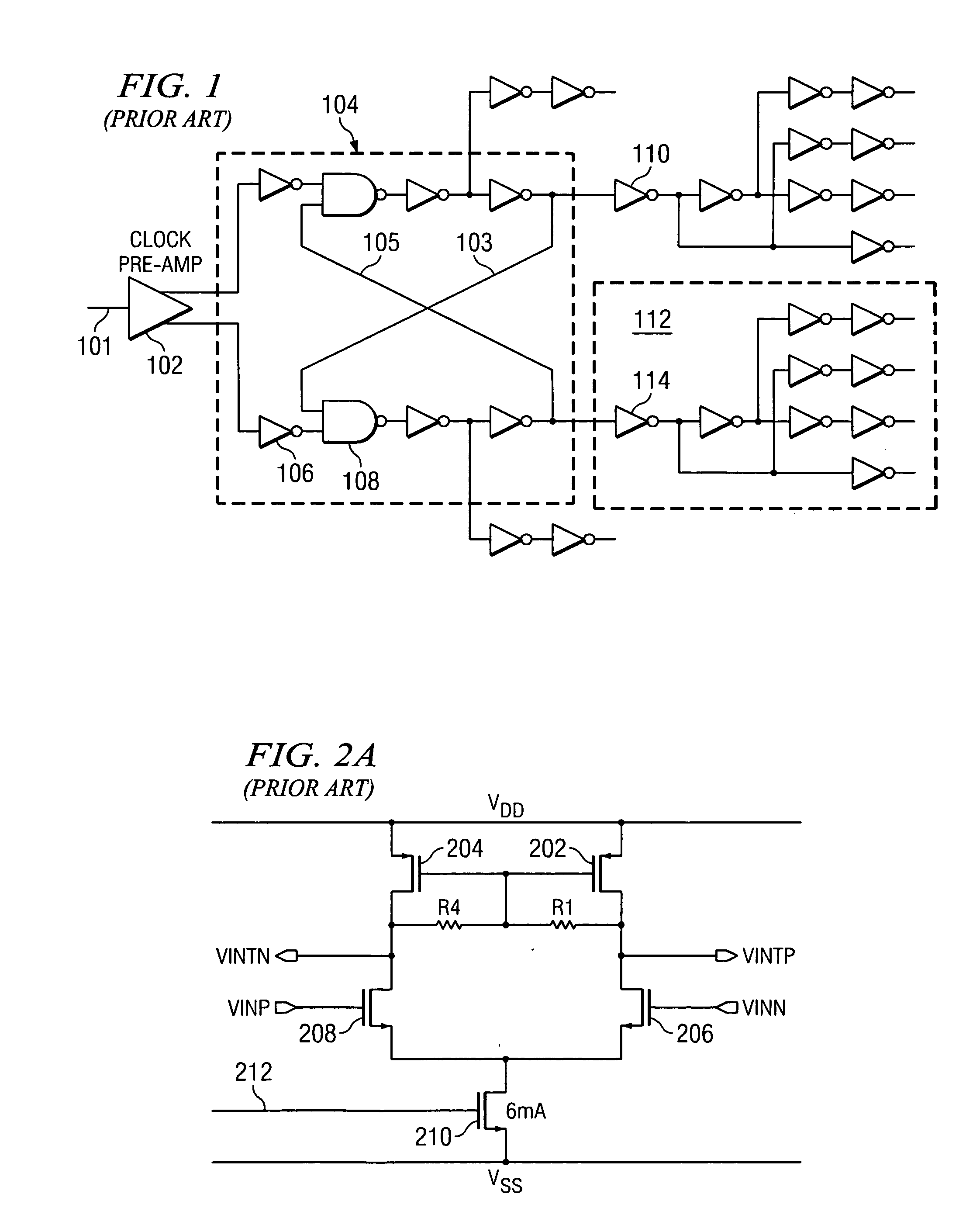

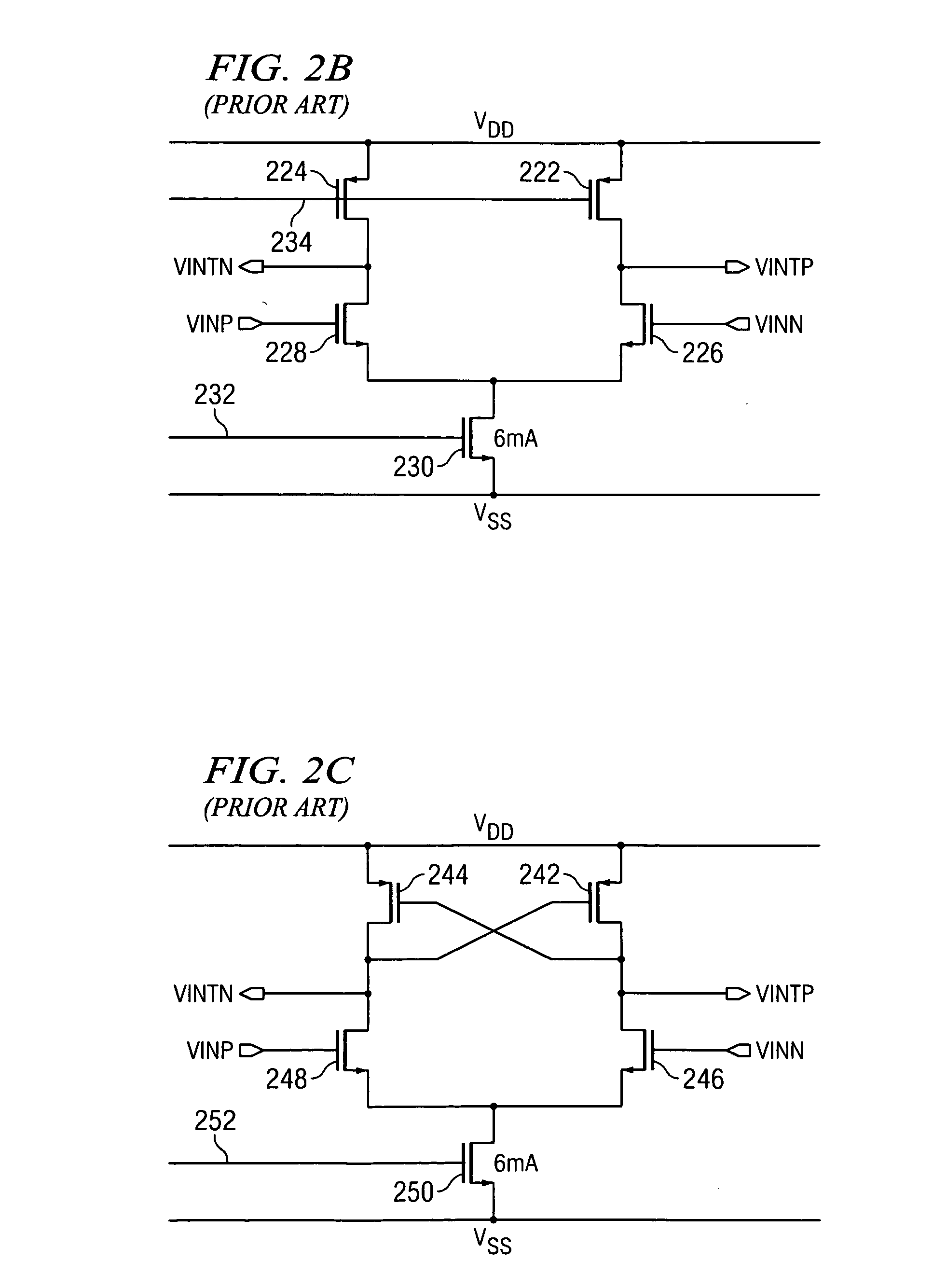

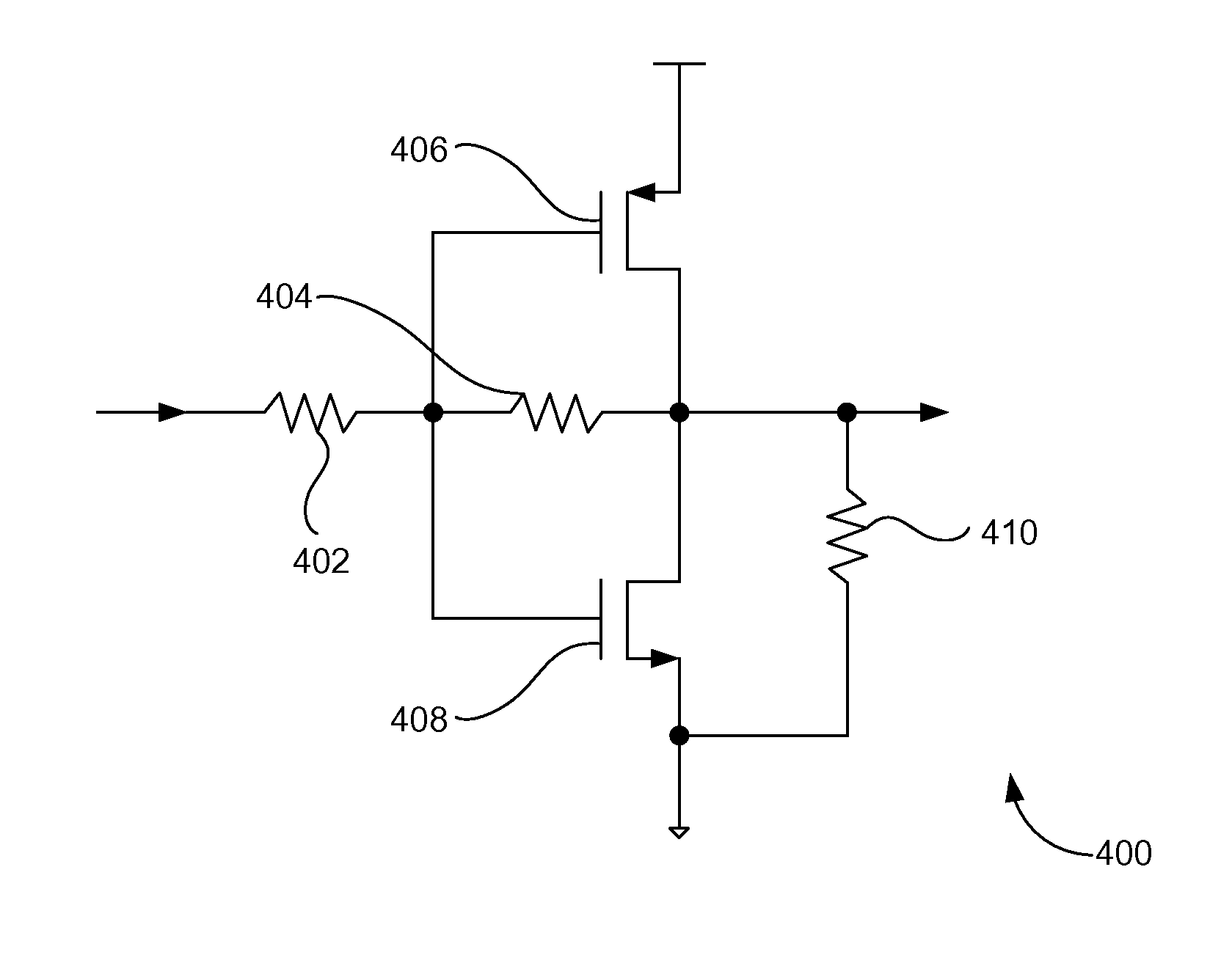

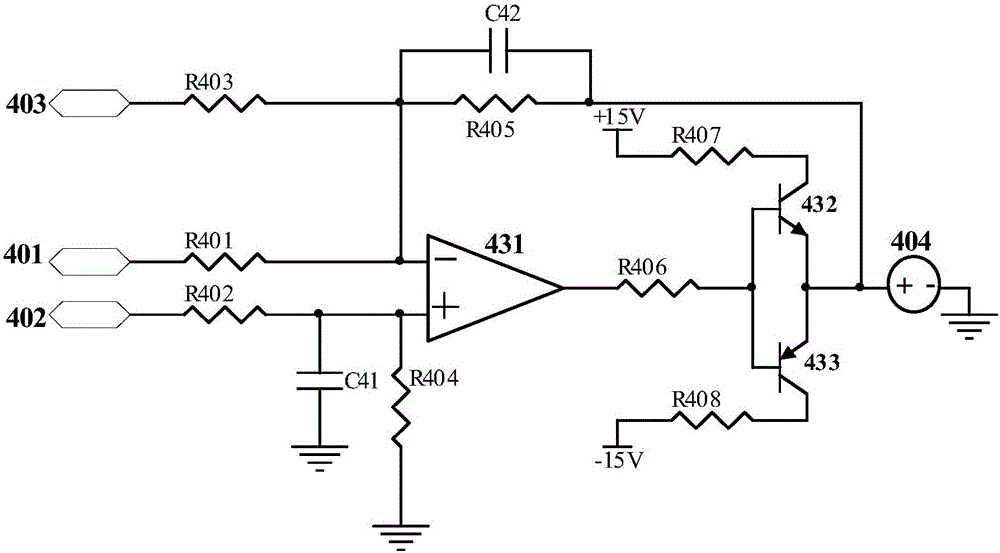

Method and apparatus for improved clock preamplifier with low jitter

ActiveUS7345528B2Avoid saturationControl swingAmplififers with field-effect devicesArbitary function generatorsMOSFETPower inverter

A clock signal preamplifier comprises complementary pairs of differentially coupled transistors, with an output signal coupled to an inverter further comprising a totem-pole arrangement of complementary MOSFET transistors. The input signal to the preamplifier is typically sinusoidal, and the output signal is rectangular. Preferably, the differentially coupled transistors are bipolar, and a pair of diode clamper circuits with bipolar transistors is preferably coupled to the complementary pairs of differentially coupled transistors. A reference voltage source is coupled to the control terminals of the clamper transistors. A reference voltage source, which preferably comprises a totem-pole arrangement of complementary MOSFET transistors with its output node is coupled to its input node, provides a reference voltage for the diode clamper circuits. Preferably, MOSFET transistors of the reference voltage source and MOSFET transistors of like kind of the inverter are configured to have substantially identical threshold voltages.

Owner:TEXAS INSTR INC

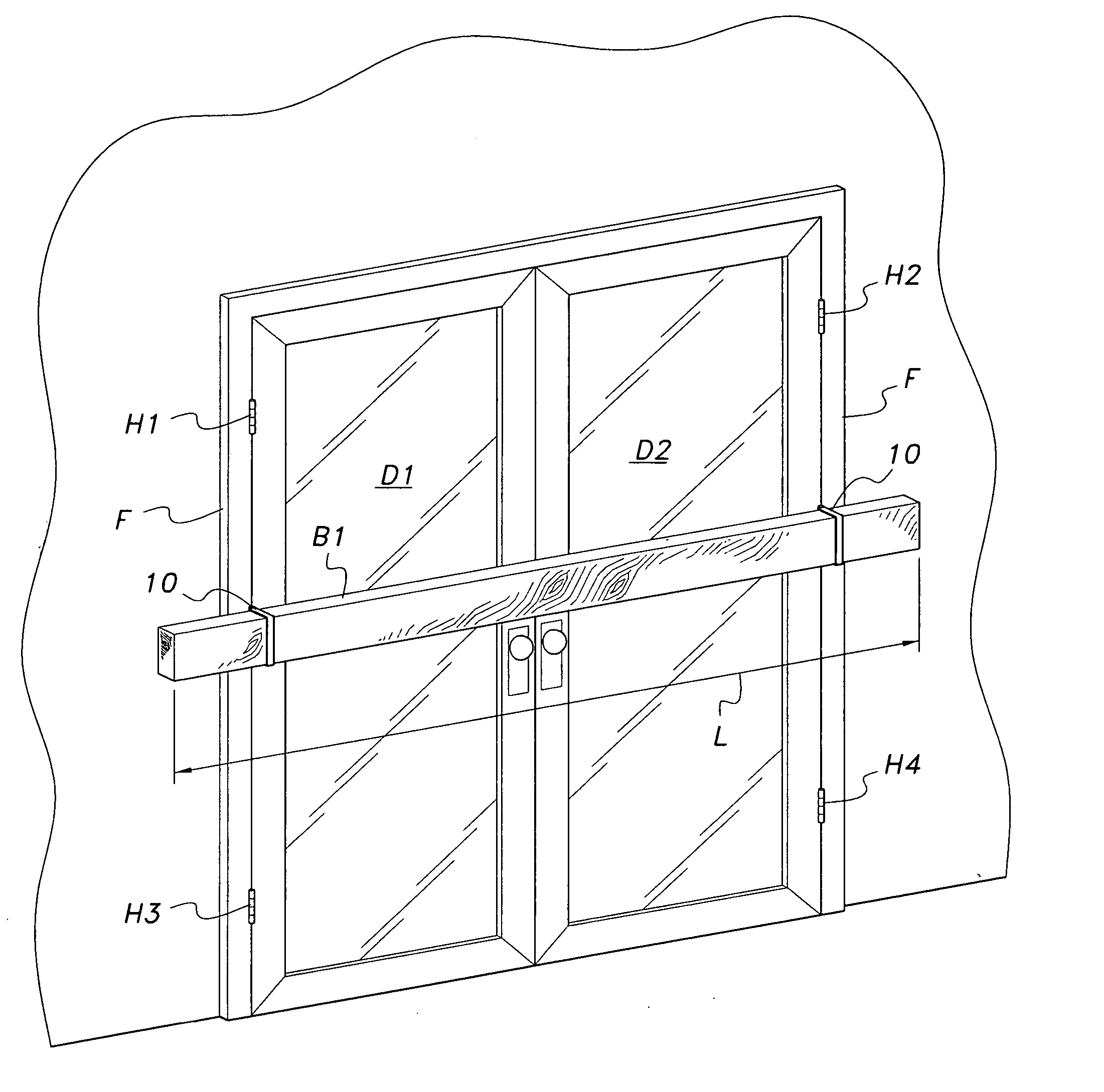

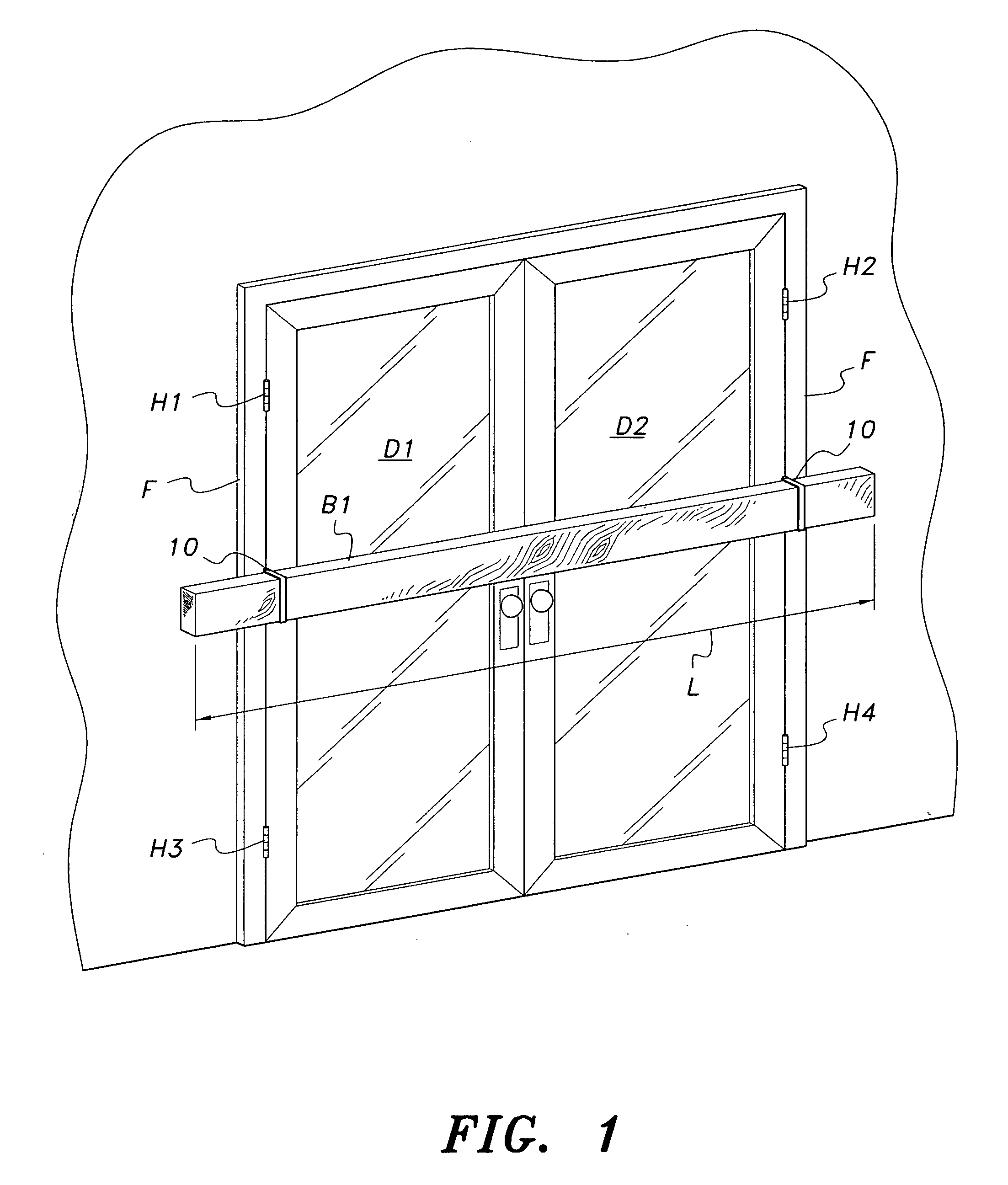

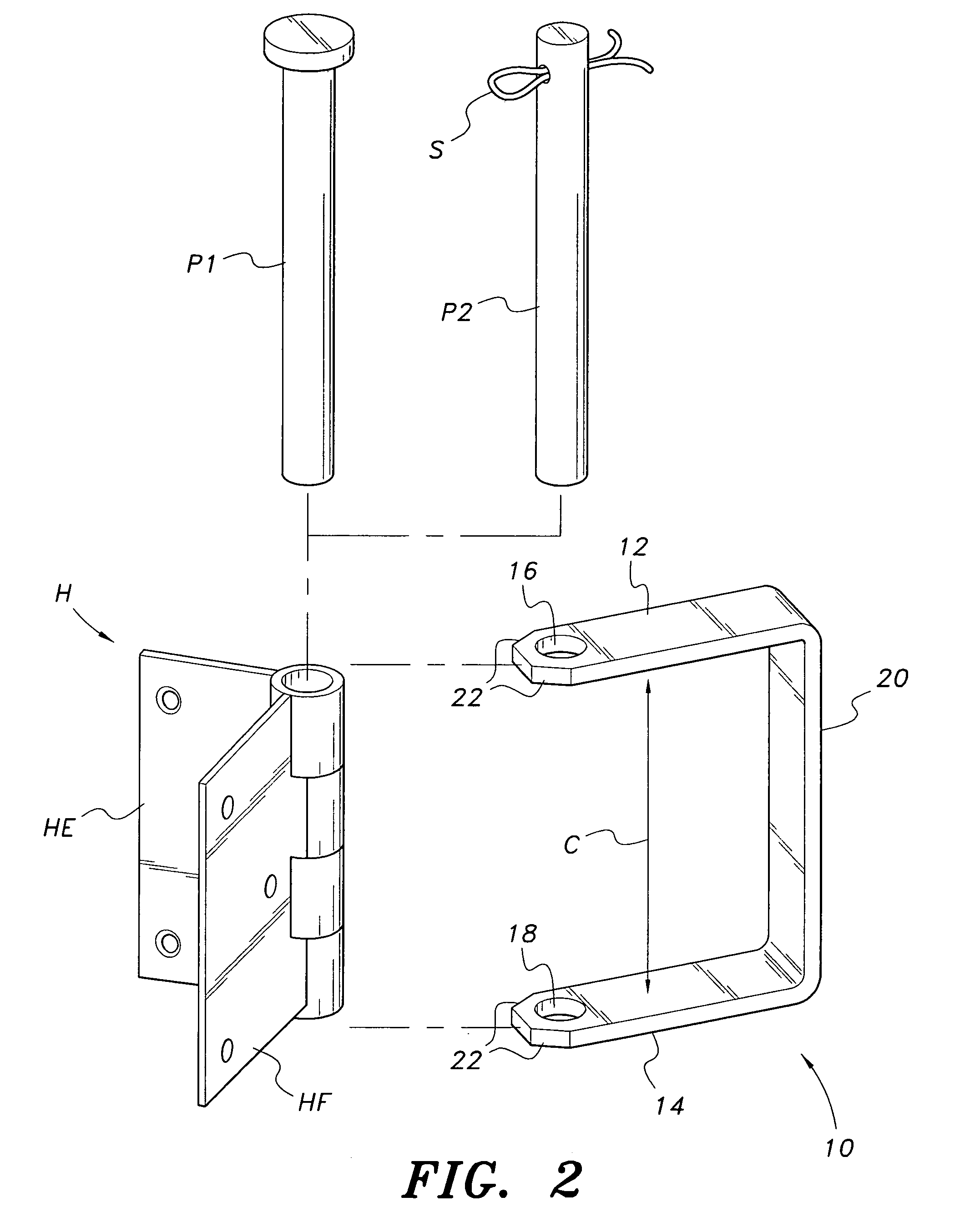

Double door security device

InactiveUS20070158957A1Avoid damageControl swingWing accessoriesWing fastenersMechanical engineeringHinge angle

The double door security device uses at least two opposed hinges of the double door pair to secure corresponding door bar retainers to the door frame structure. The hinge pin is removed and the door bar retainer is placed upon the hinge, with a hinge pin of suitable length reinstalled through the hinge to secure the door bar retainer pivotally to the hinge. The door bar retainer, in combination with the hinge, defines a door bar passage for the removable installation of a door bar therethrough. The retainers may be configured to accept door bars having various cross sectional shapes, e.g. two by four lumber, square and round tubing and pipe, etc. The hinge attachment ends of the retainers are preferably beveled to minimize marring of the door and door frame adjacent to the hinge, and to serve as a door stop limiting the opening swing of the door.

Owner:KRAMER ROBERT E +2

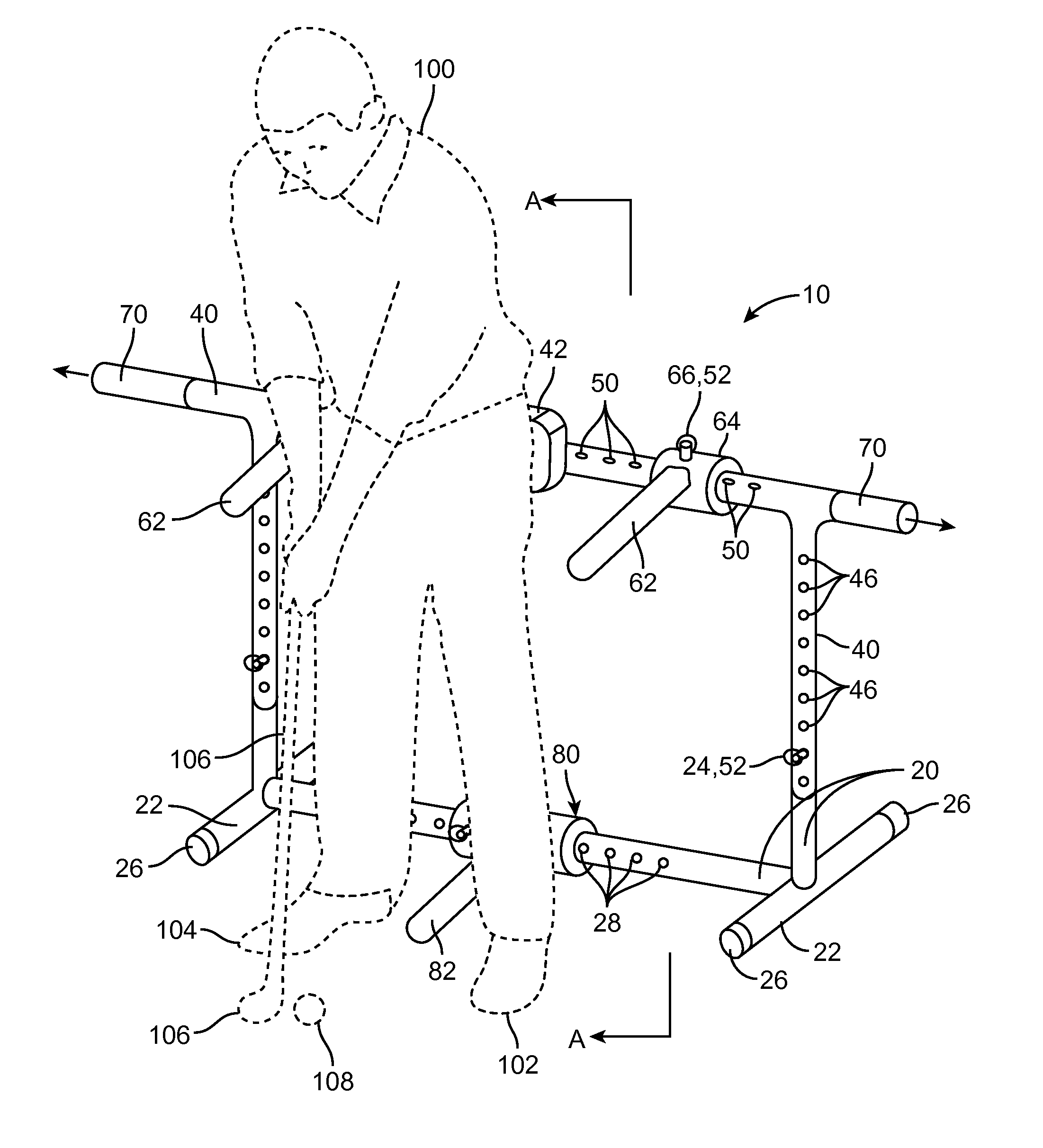

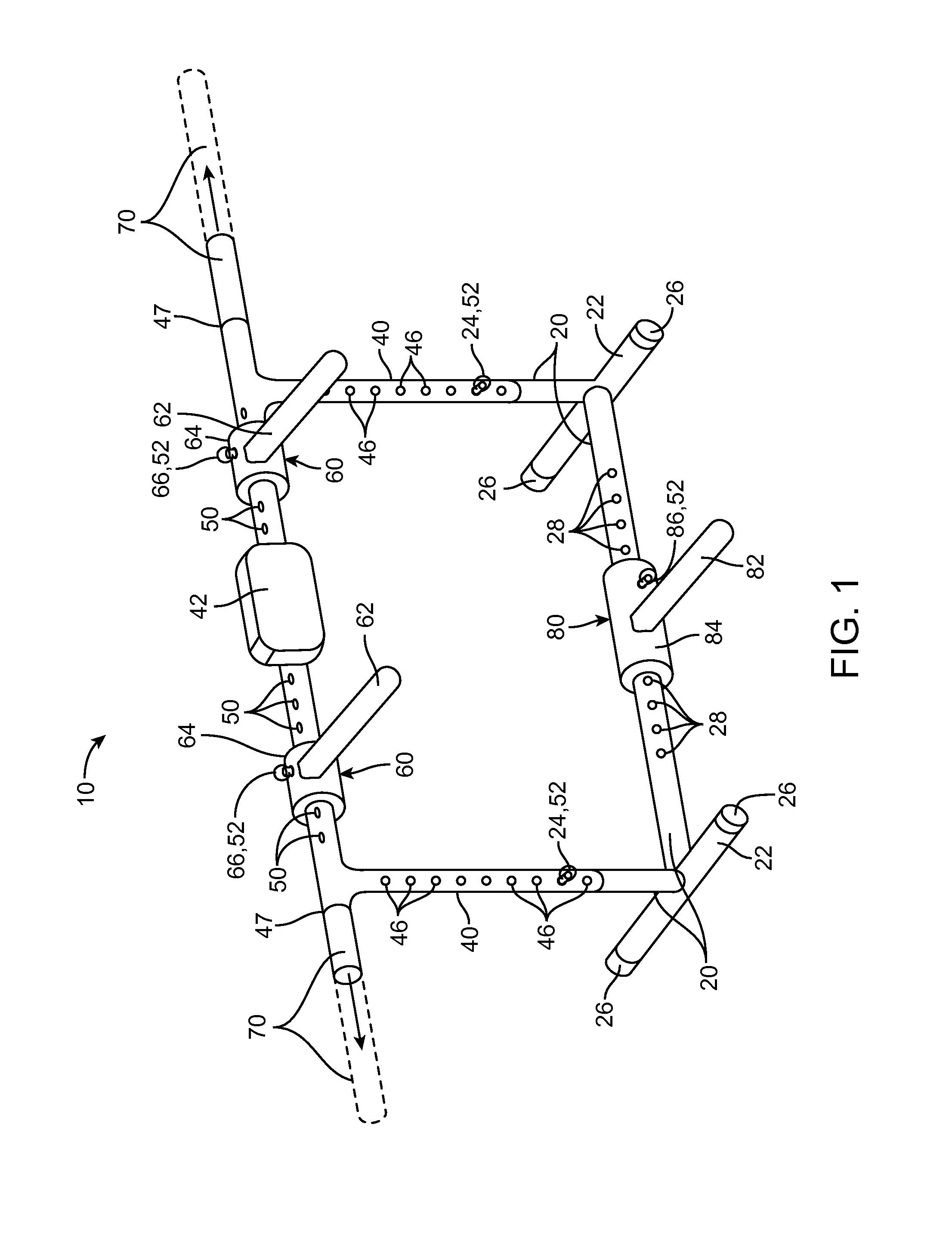

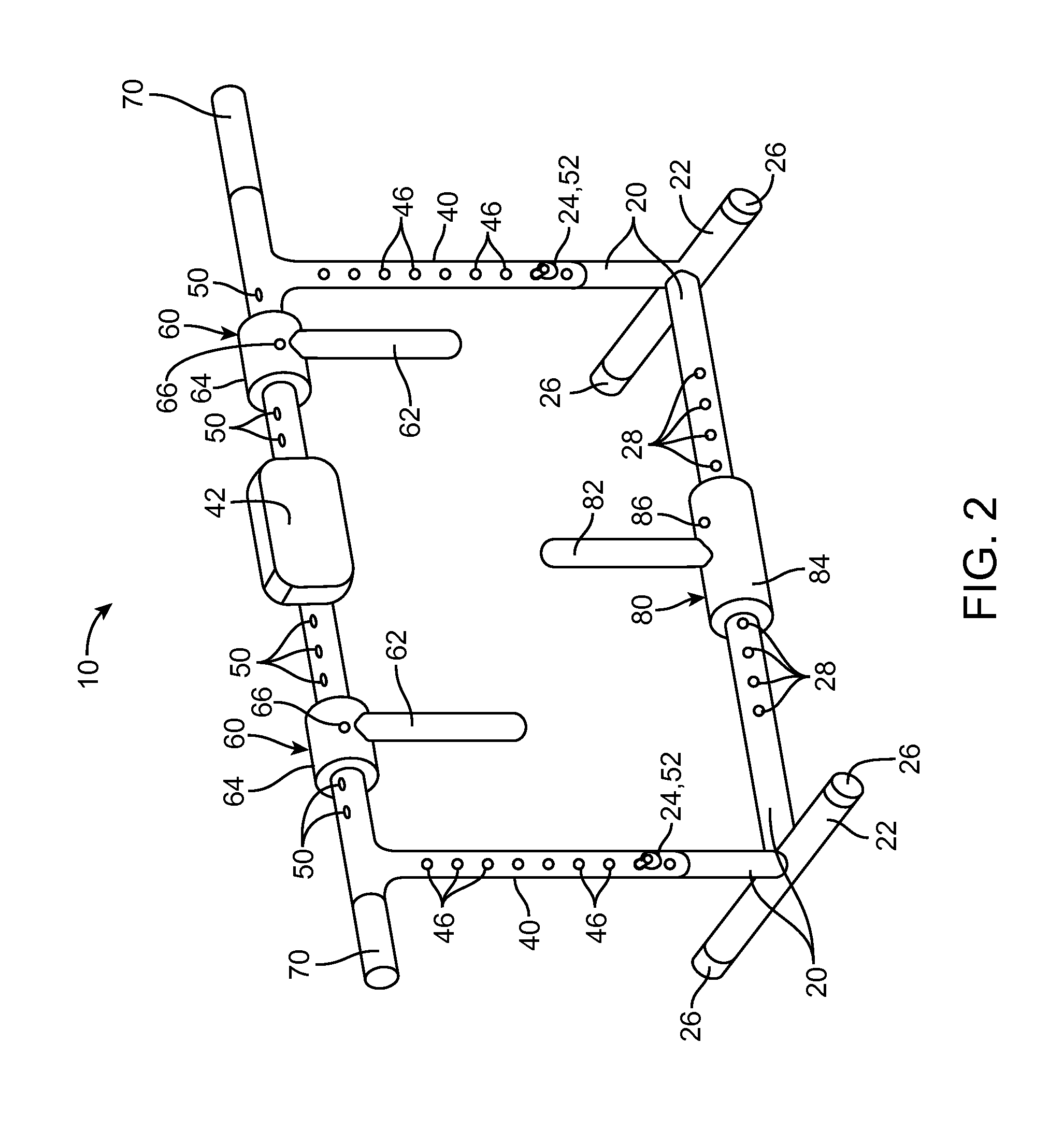

Lower body golf training aid

A golf training apparatus which aids golfers in perfecting their swing and associated body movements comprises a cushion and posts mounted to a frame which restricts a golfer's movement while in a golf stance and during a golf swing in order to develop a proper golf swing technique. A set of bars help the user to feel the proper rotation of their hips during a swing while avoiding unwanted lateral movement. The apparatus also comprises adjustable rods which extend sideways and forwardly from the frame to help a golfer to practice their swing path by keeping the swing within the rods. A golf ball alignment bar is located at a middle location at the base of the frame to help the golfer to consistently place the ball in the proper position prior to the golf swing.

Owner:MCCULLOUGH R JAKE

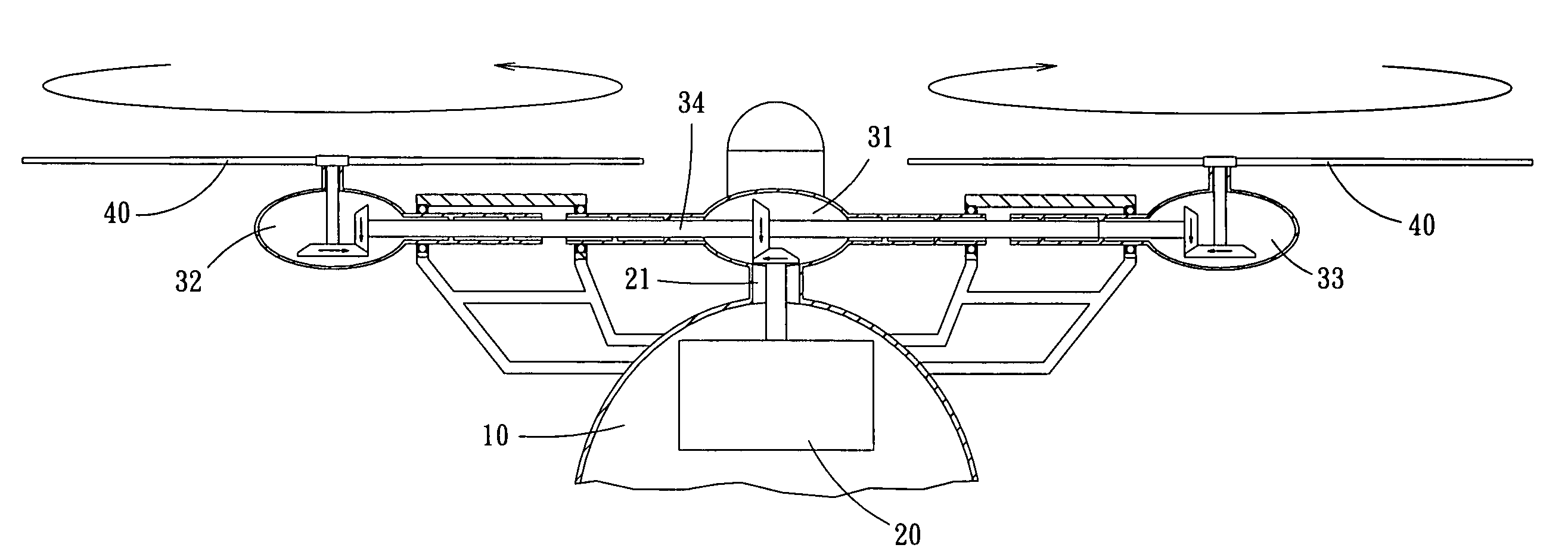

Dual power helicopter without a tail rotor

Owner:LI HONG FU

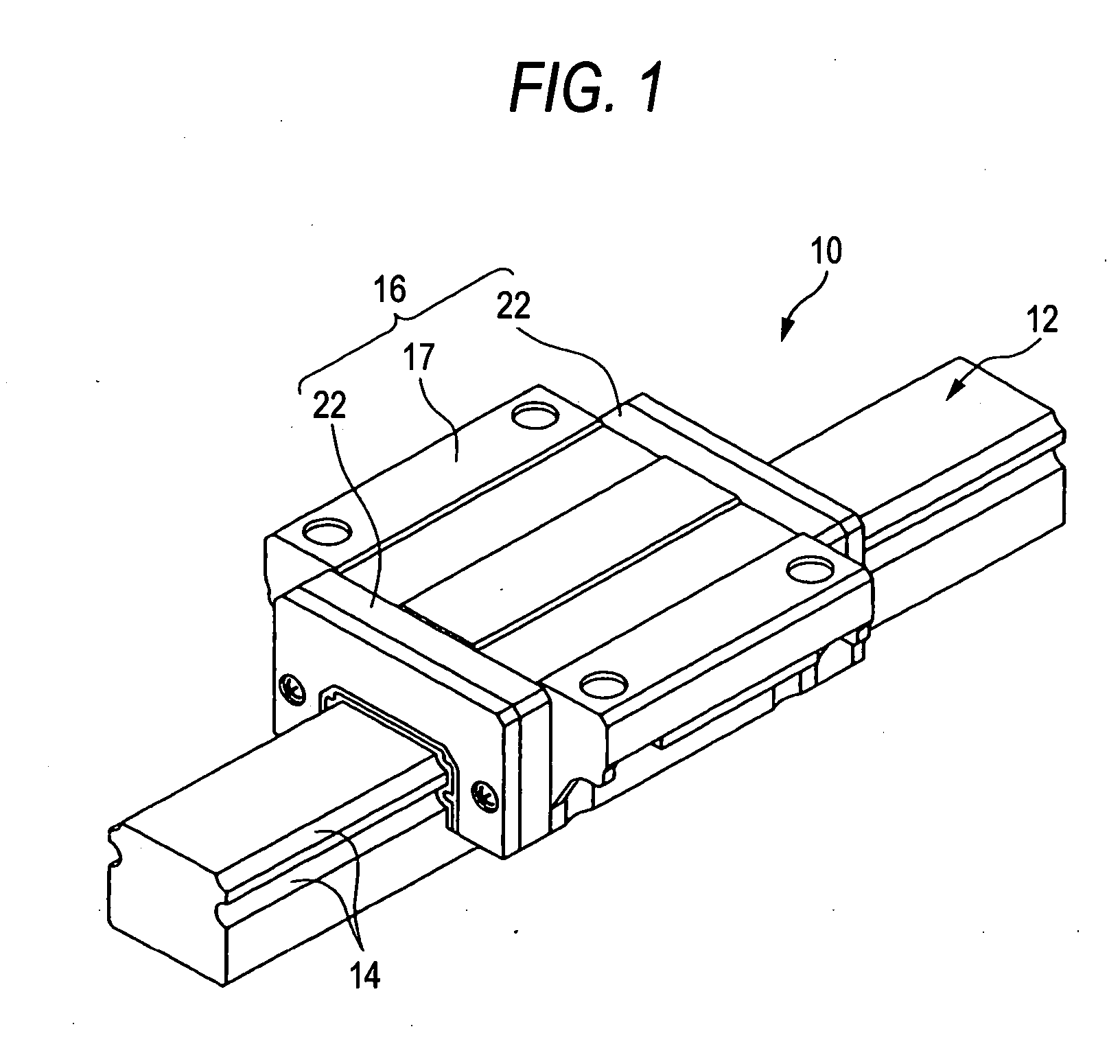

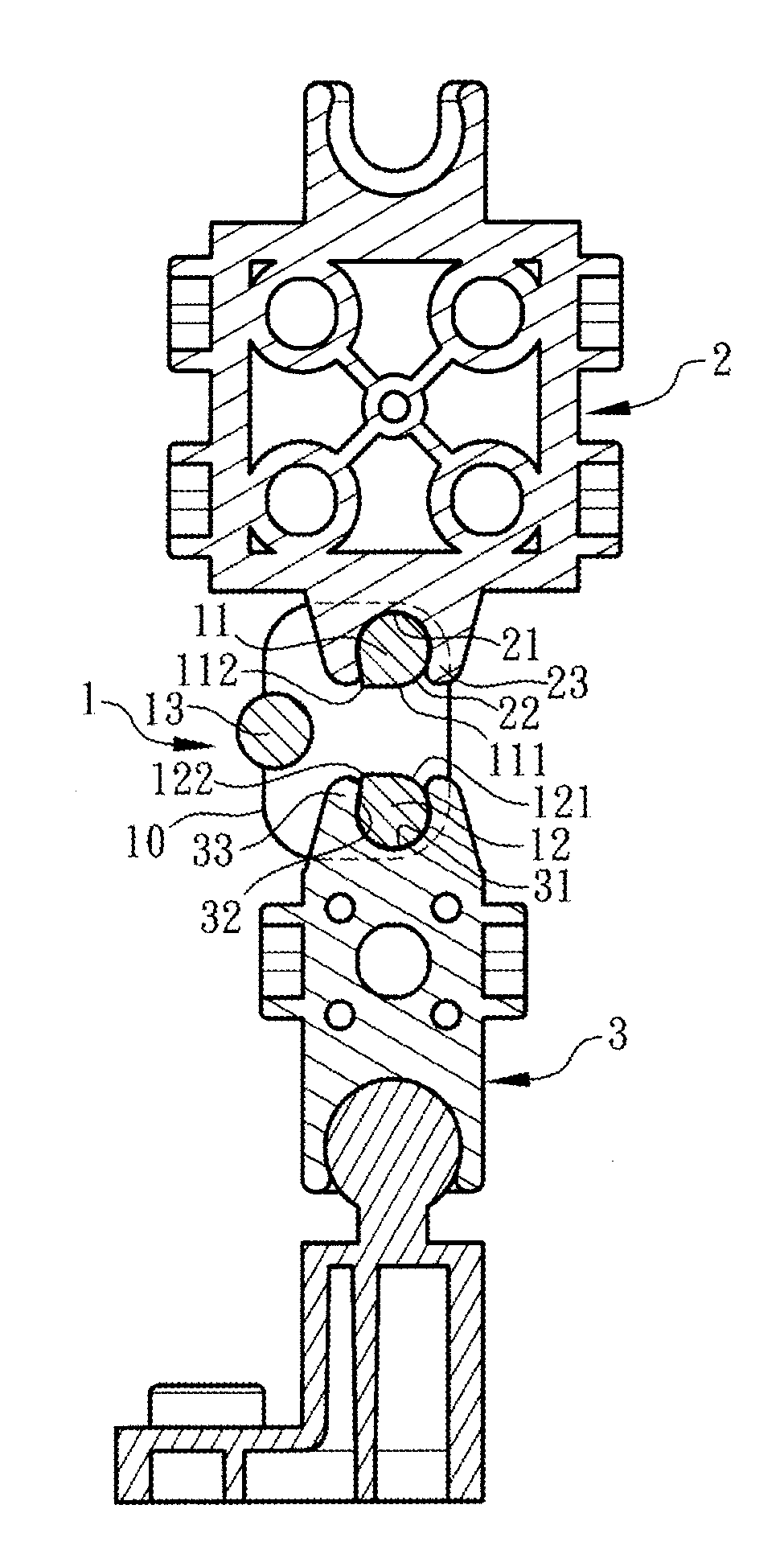

Rolling element accommodating belt for linear guide apparatus and linear guide apparatus

ActiveUS7798718B2Easy to installControl swingLinear bearingsRolling contact bearingsEngineeringMechanical engineering

There is provided a rolling element accommodating belt for a linear guide apparatus which has a guide rail, a slider having a load rolling element guiding face which constitutes a rolling element track path together with the guide rail, a pair of direction converting paths and a rolling element return path, a plurality of rolling elements circulating within an endless circulation path defined by the rolling element track path, the pair of direction converting paths and the rolling element return path; and a guide groove. The rolling element accommodating belt includes a plurality of spacer portions interposed between the rolling elements, coupling arms to be guided by the guide grooves and rolling element accommodating portions accommodating the rolling element. The spacer has an inward abutting face abutting on the rolling element so as to prevent the rolling element from moving to inner diameter side of the endless circulation path.

Owner:NSK LTD

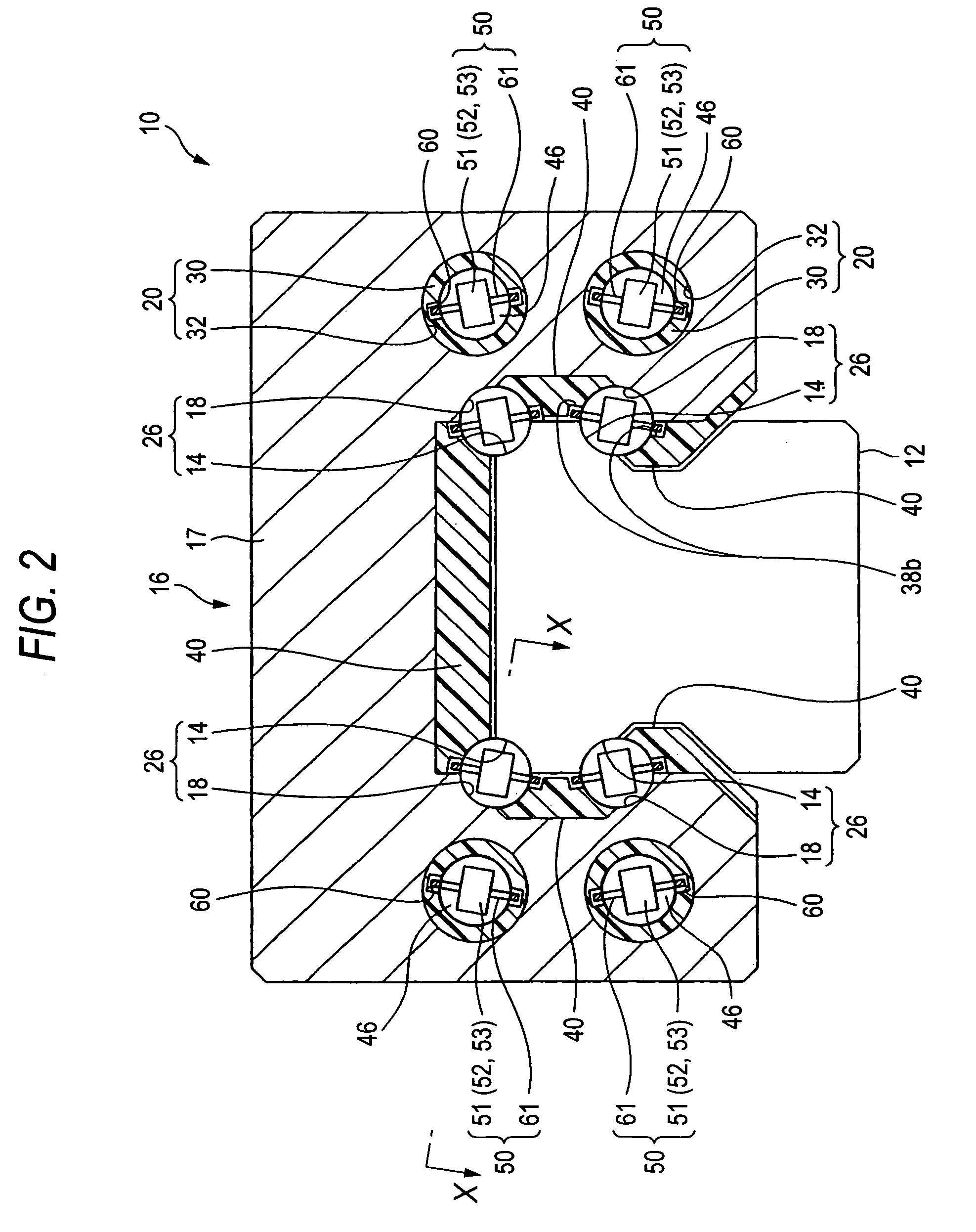

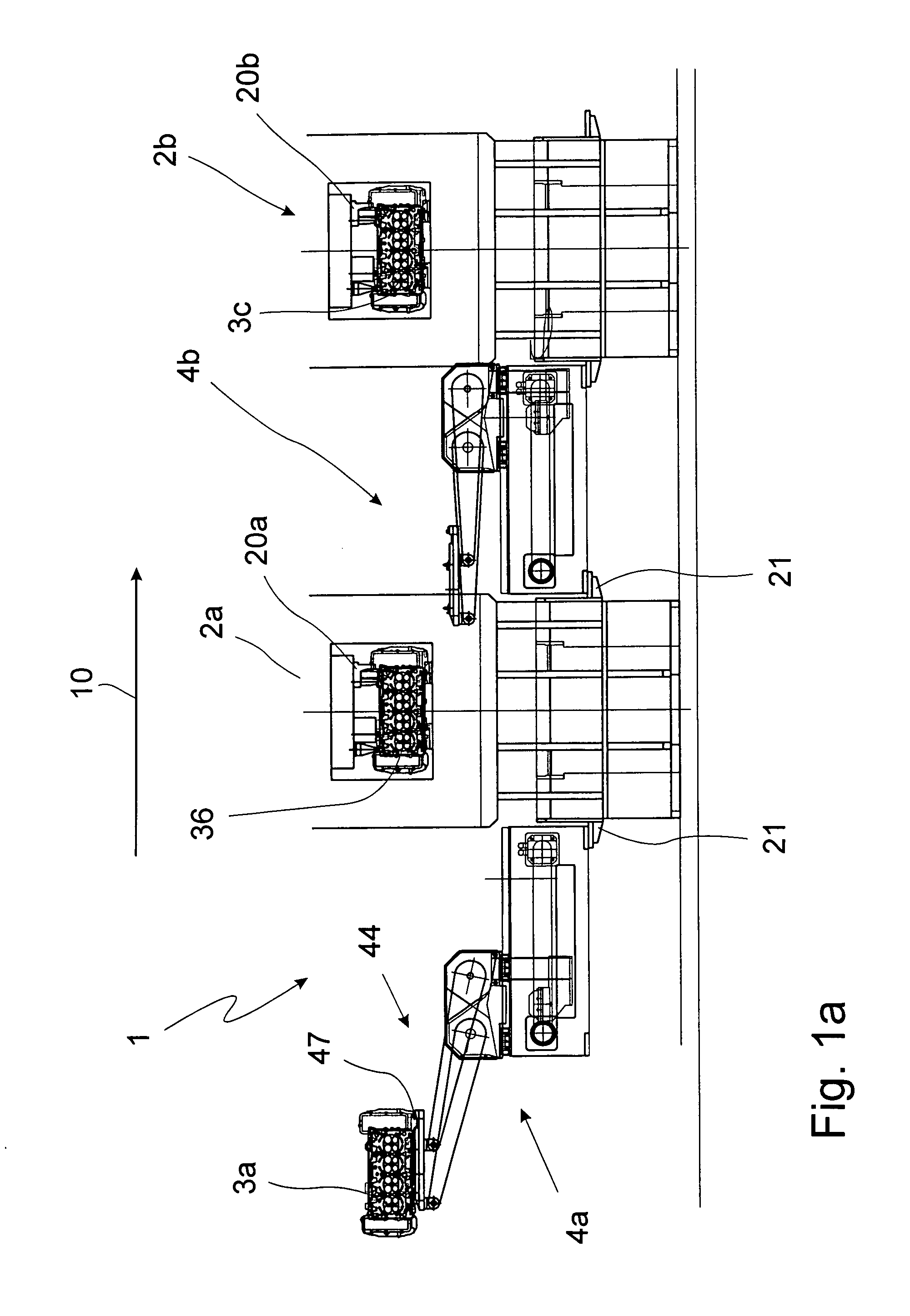

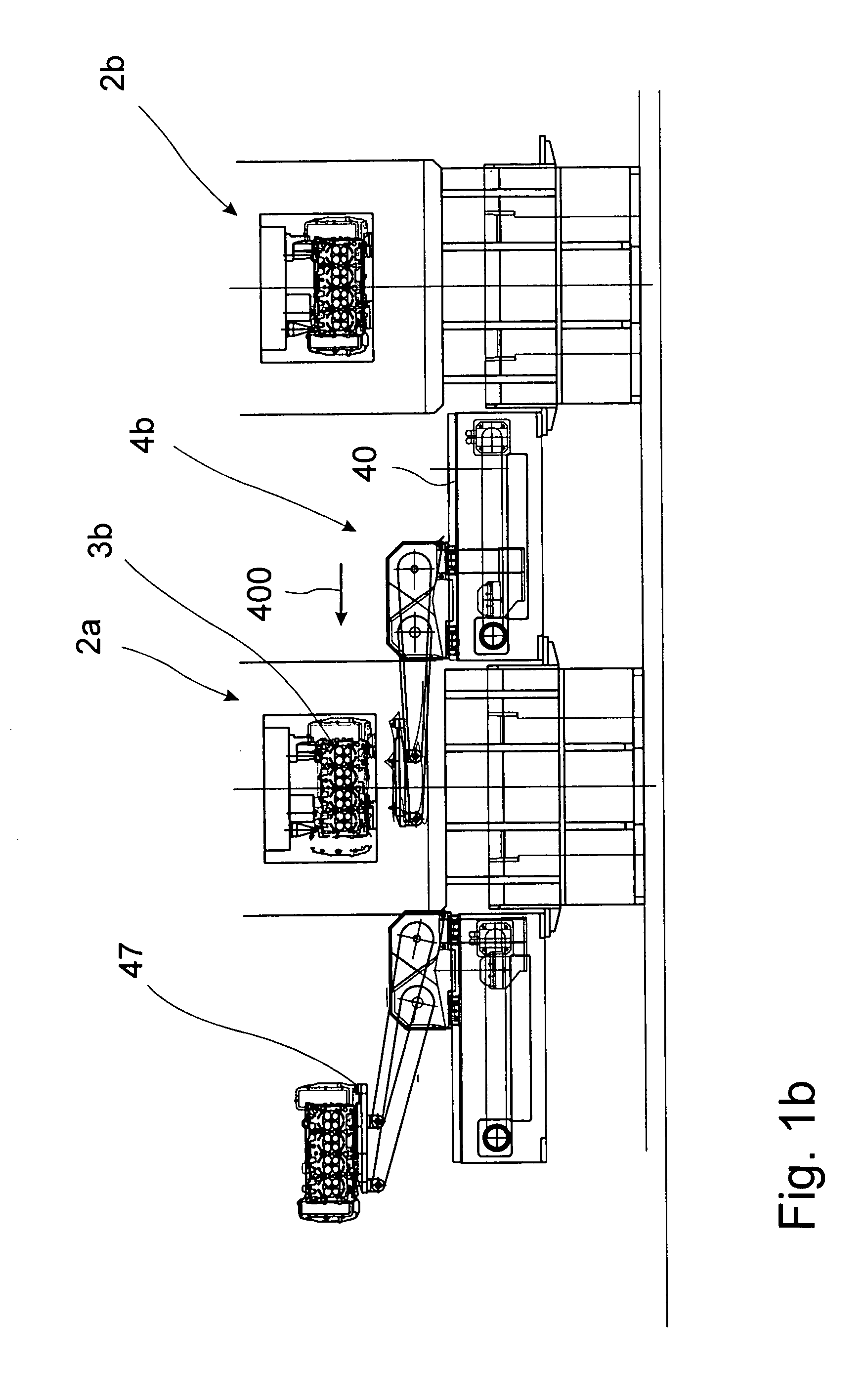

Machining line

InactiveUS20080075565A1Reduce energy consumptionReduce consumptionConveyorsAutomatic workpiece supply/removalEngineeringAssembly line

The invention refers to a machining line, in particular a transfer line or assembly line, comprising a multitude of machining stations arranged one after the other in the direction of machining, and the machining station serves for machining work pieces, wherein at least one machining station is designed as special station. The invention is characterised by the fact that between two adjoining machining stations one conveying device each is provided.

Owner:GROB WERKE & K G

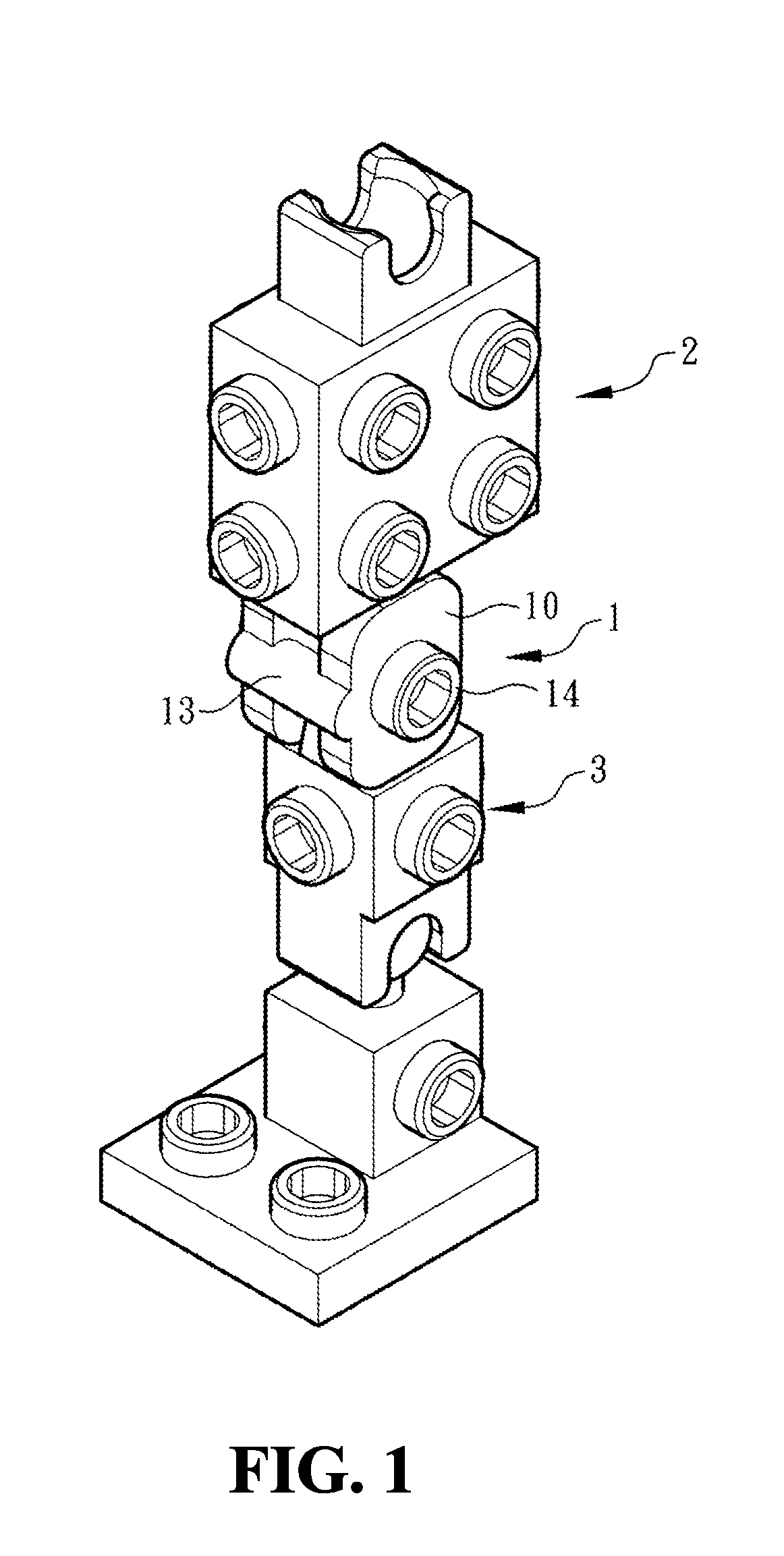

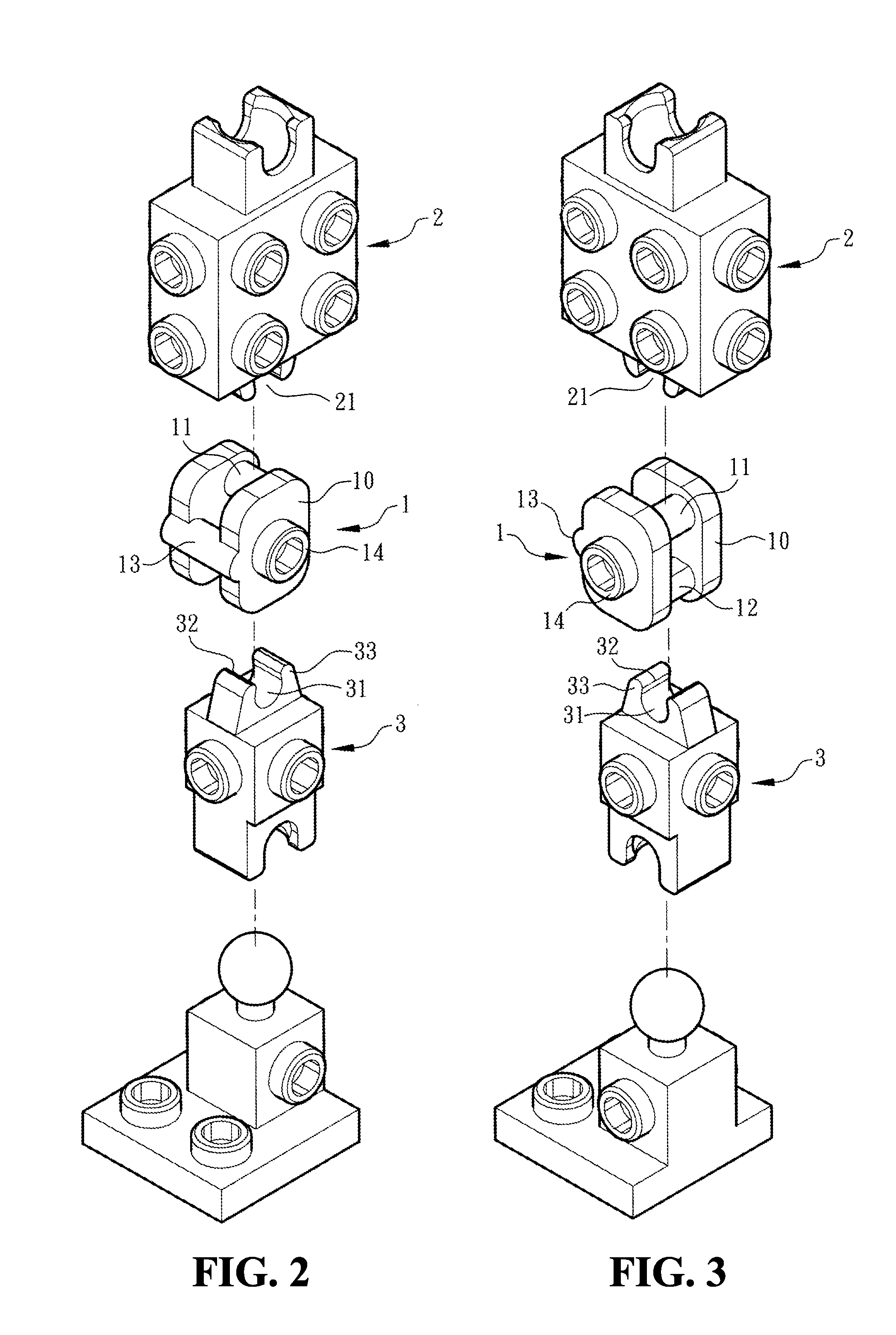

Joint brick for building block

A joint brick for a building block is pivotally connected between the building blocks to work as a joint of the limbs. The joint brick includes two side plates and two axial post disposed between the side plates to be pivotally connected with engaging recesses of other building blocks. When the axial posts disposed at a top end and a bottom end of the joint brick are pivotally connected with other building blocks, the limbs can substantially swing, extend and bend relative to each other to make playing the building blocks more convenient and more interesting.

Owner:T FUN

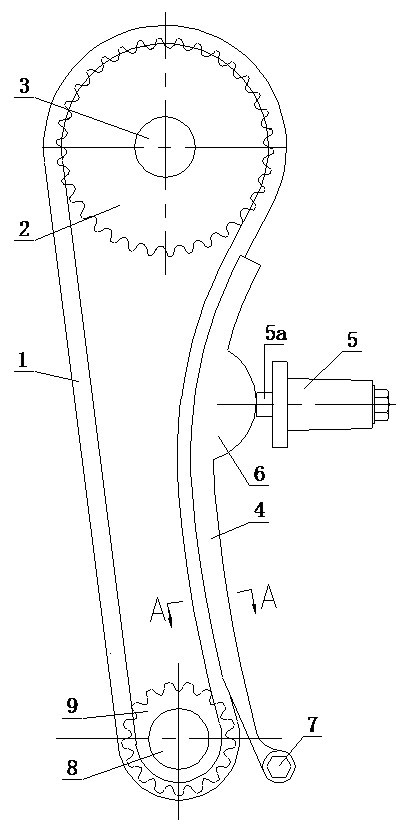

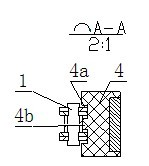

Timing drive mechanism for motorcycle engine

InactiveCN102011621AEasy maintenance and testingExtended service lifeValve arrangementsGearingInterference fitLow noise

The invention discloses a timing drive mechanism for a motorcycle engine, which comprises a timing chain and a tensioning device. The tensioning device comprises a tensioning plate and a tensioner; one side of the tensioning plate is in a convex arc shape and is attached to the timing chain, and the other side of the tensioning plate is provided with a convex bag; the tensioner is fixed on a cylinder body and is provided with a tensioning rod; and one end of the tensioning rod is arranged in the tensioner, and the other end of the tensioning rod stretches out under the action of a spring and is opposite to the convex bag. The improvement is that: the bottom of a groove is provided with a smooth plane; the coordination distance between the timing chain and the side wall of the groove is less than 0.1mm; the convex bag is provided with a limiting hole; one end of the tensioning rod opposite to the convex bag is positioned in the limiting hole and is in interference fit with the limiting hole; and a limiting plate is arranged below a crankshaft sprocket. The timing drive mechanism has the advantages of small vibration, low noise, long service life, convenience of maintenance and the like.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

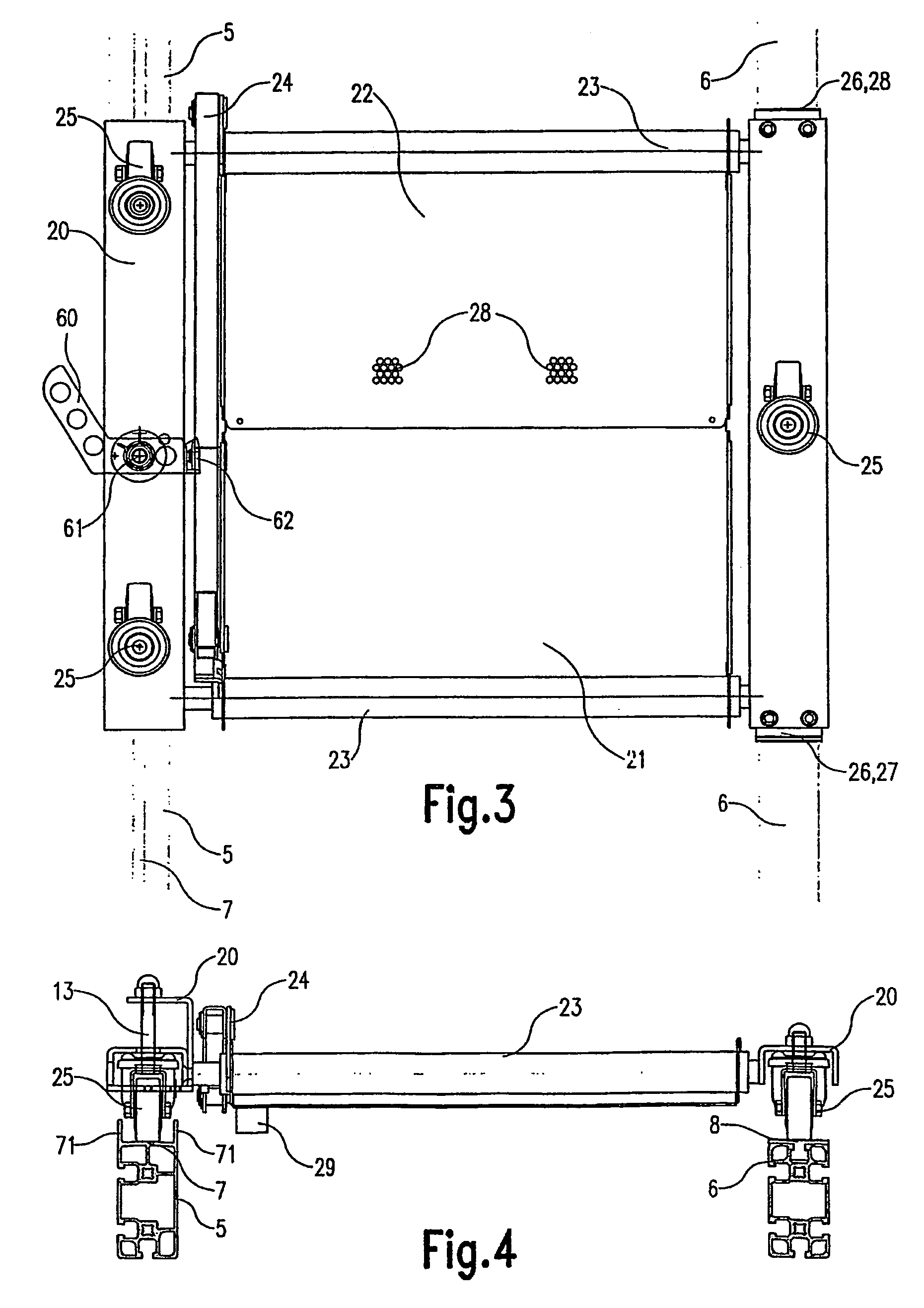

Apparatus and transport container for transport and controller discharge of a load

InactiveUS7128202B2Reduce the impactSuppress noiseConveyor partsMechanical conveyorsLocking mechanismEngineering

An apparatus includes a frame with a guide for at least one displaceable transport container, a drive element for carrying the container in an endless track, a resetting device for placing a container in a starting position and a discharge station for selectively relieving a container of a load. The containers are provided with a movable carrying panel for receiving the load, including at least two tilt trays which extend between tilt axes located on both sides. The trays can be selectively titled between a transporting position and a discharge position, and are provided with a locking mechanism for locking the trays in the transport position. The resetting device is adapted to co-act with a passing opened container to place the trays thereof in the transport position, and the discharge station is able to selectively unlock the locking mechanism of a passing transport container to thus release the trays.

Owner:EUROSORT

Method and apparatus for improved clock preamplifier with low jitter

ActiveUS20060255859A1Rapid waveformLittle added timing jitterAmplififers with field-effect devicesArbitary function generatorsMOSFETAudio power amplifier

A clock signal preamplifier comprises complementary pairs of differentially coupled transistors, with an output signal coupled to an inverter further comprising a totem-pole arrangement of complementary MOSFET transistors. The input signal to the preamplifier is typically sinusoidal, and the output signal is rectangular. Preferably, the differentially coupled transistors are bipolar, and a pair of diode damper circuits with bipolar transistors is preferably coupled to the complementary pairs of differentially coupled transistors. A reference voltage source is coupled to the control terminals of the damper transistors. A reference voltage source, which preferably comprises a totem-pole arrangement of complementary MOSFET transistors with its output node is coupled to its input node, provides a reference voltage for the diode damper circuits. Preferably, MOSFET transistors of the reference voltage source and MOSFET transistors of like kind of the inverter are configured to have substantially identical threshold voltages.

Owner:TEXAS INSTR INC

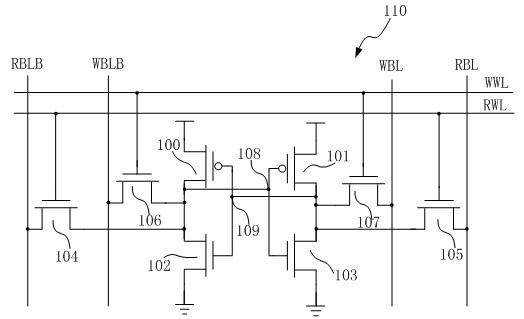

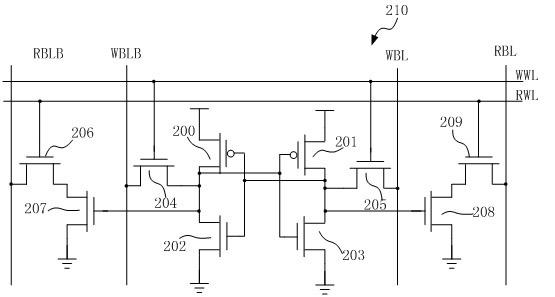

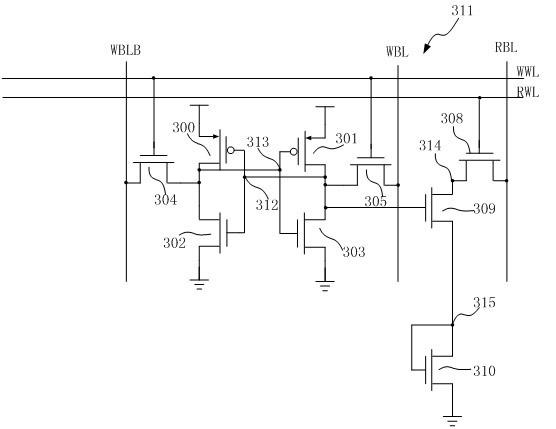

Storage unit capable of controlling bit line oscillation amplitude for register file

InactiveCN102136297AReduce power consumptionEasy to convertDigital storageMode controlProcessor register

The invention belongs to the technical field of the design of the storage unit of an integrated circuit, and in particular relates to a storage unit capable of controlling the bit line oscillation amplitude for a register file. The storage unit comprises two phase inverters, two write transistors, two read transistors, two read insulating tubes and two mode control transistors in a cross mode, wherein the two phase inverters are coupled between a power supply and the ground. When a mod signal is under a power supply voltage, a pseudo earth wire voltage approaches to a power ground; and when the mod signal is on the power ground, the pseudo earth wire voltage is a certain middle-point voltage. The storage unit can limit the oscillation amplitude of a readbit line to lower the power consumption of a register file; and under a certain special condition, bit line full swing is required to adapt to requirements. The control unit provided by the invention can conveniently realize conversion between the full oscillation amplitude and the low oscillation amplitude of the bit line.

Owner:FUDAN UNIV

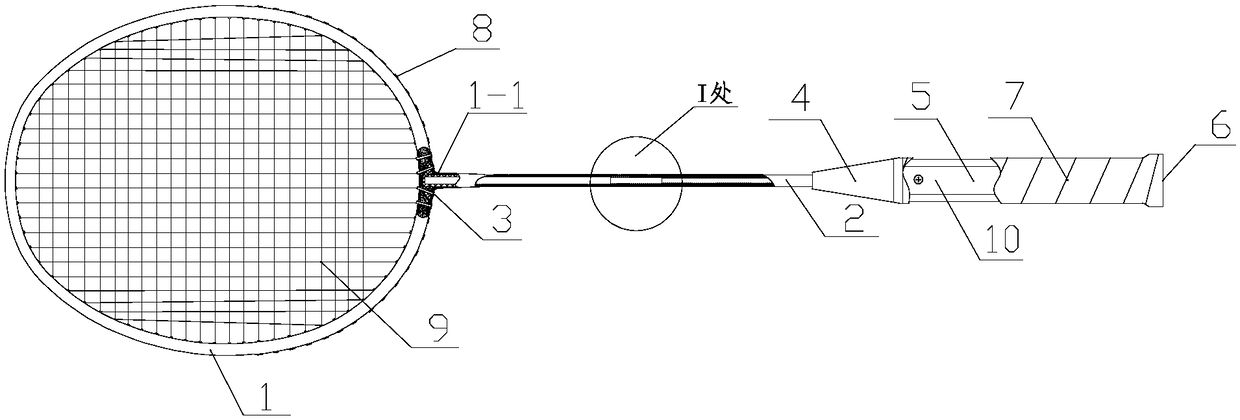

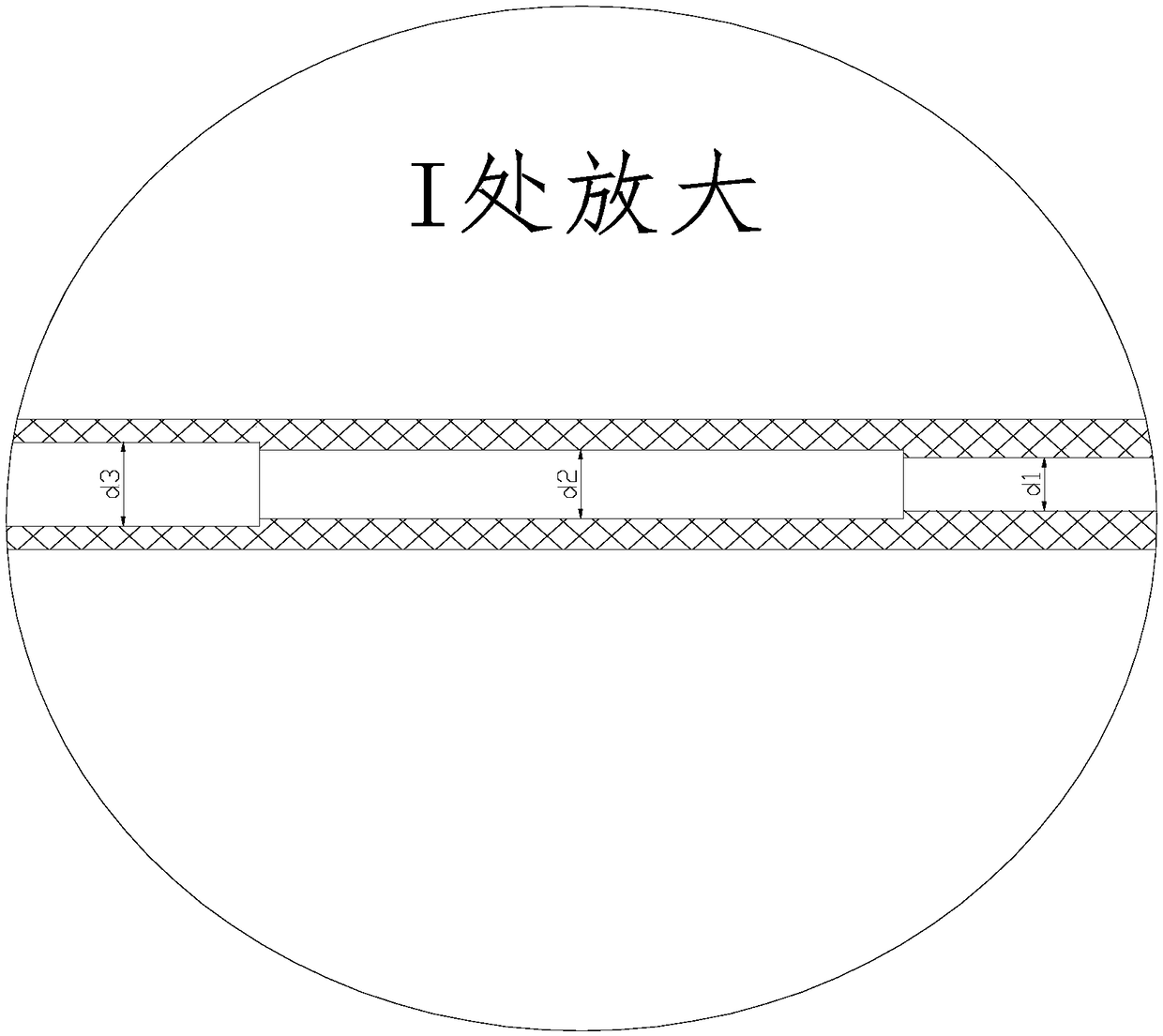

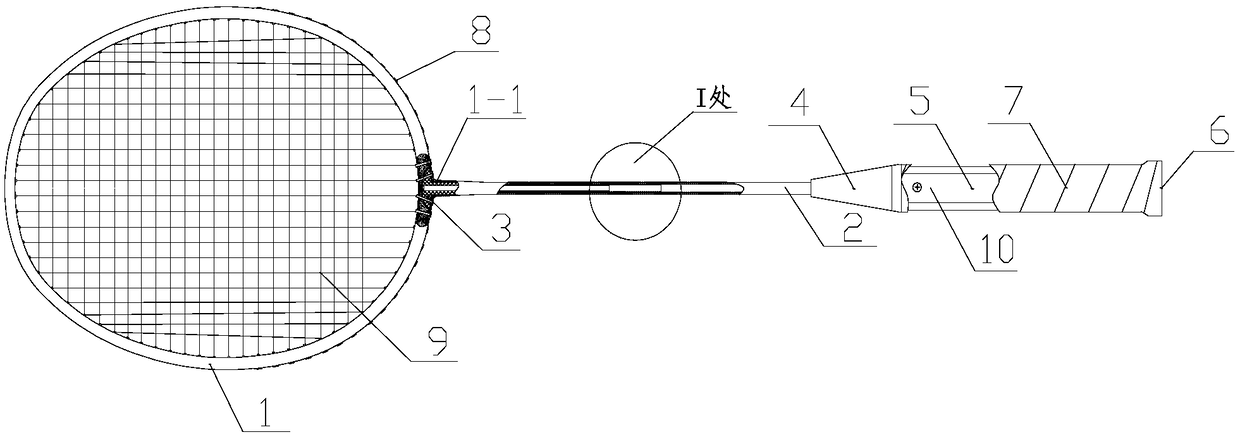

Badminton racket and production method thereof

The invention relates to a badminton racket and a production method thereof. The badminton racket comprises a racket frame, a racket rod and a connector, wherein the racket rod and the connector are connected with the racket frame, the rear end of the racket rod is provided with a front sleeve and a racket handle, the rear of the racket handle is provided with a rear sleeve, handle leather is winded around the racket handle, racket strings penetrates through the racket frame through string protecting nails, the racket rod is of a hollow structure, the outer diameter of the hollow structure isuniform, and the inner diameter of the hollow structure gradually decreases or increases gradually in steps from front to back. The badminton racket and the production method thereof have the advantages a bending position of the racket rod is set, so that that the swing amplitude of the racket face of the badminton racket after batting is adjusted, the return speed, batting strength and launch angle of the badminton racket are adjusted, thereby obtaining a high-performance badminton racket suitable for characteristics of different play styles; since the rigidity of the bending position of theracket rod is lower than that of other parts, the badminton racket is divided into two parts by the bending position of the racket rod, and the two parts of the badminton racket are connected throughthe bending position; due to the action of inertia force, when the head of the badminton racket performs batting, the batting strength is increased, and the batting speed is accelerated, so that the vibration feedback to a batter after the badminton racket performs batting is obviously reduced, thereby reducing sports injuries.

Owner:南京胜利体育用品实业有限公司 +1

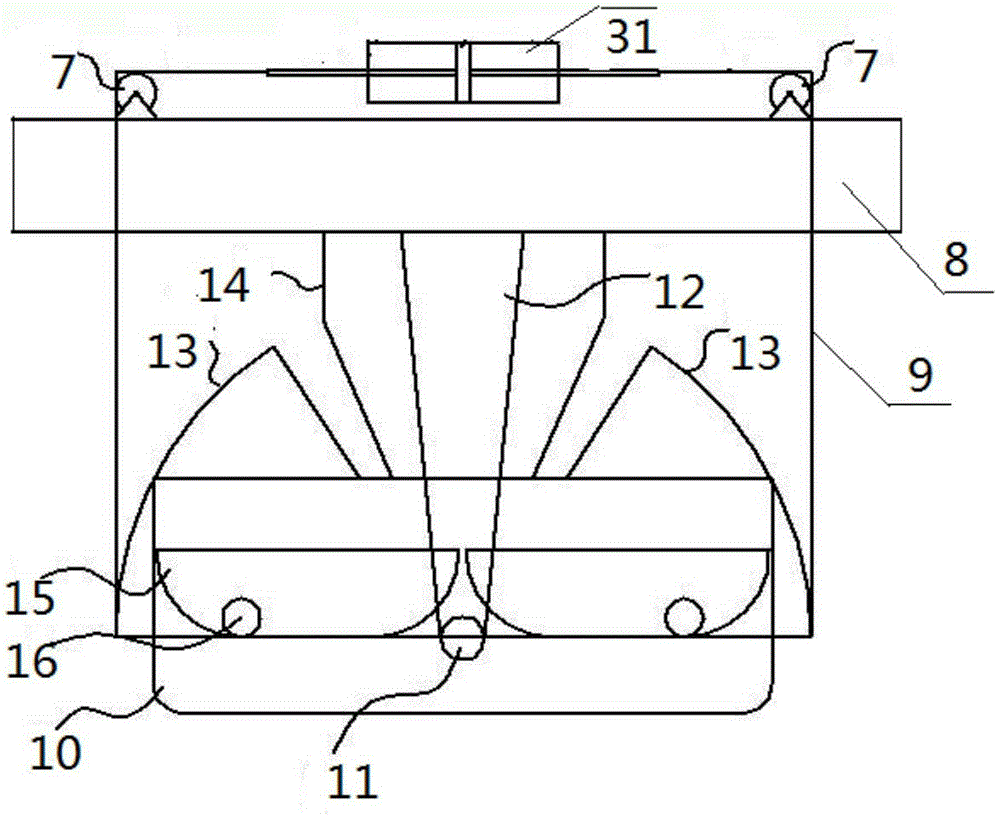

A three-dimensional wave energy power generation device

ActiveCN103925147BEfficient collectionThe pull is smooth and smoothMachines/enginesEngine componentsEnergy transferSea waves

The invention discloses a three-dimensional sea wave energy power generation set. The three-dimensional sea wave energy power generation set comprises an energy harvesting device, an energy transferring device, an energy conversion device and an energy storage device. The three-dimensional sea wave energy power generation set is characterized in that the energy harvesting device comprises a swinging floating platform, the swinging floating platform is connected with a platform through a plurality of supporting rods, the platform is fixedly connected with one end of each supporting rod, the swinging floating platform is in movable hinge joint with the other end of each supporting rod, the hinge joints serve as the center of the swinging floating platform, the bottom surface of the swinging floating platform is of an arc shape, arc-shaped grooves are symmetrically formed in the two sides of the interior of the swinging floating platform with the joints of the supporting rods serving as the center, and weights are contained in the arc-shaped grooves. According to the three-dimensional sea wave energy power generation set, energy can be harvested more effectively through the energy harvesting device, so that energy harvesting efficiency is improved.

Owner:STATE GRID CORP OF CHINA +1

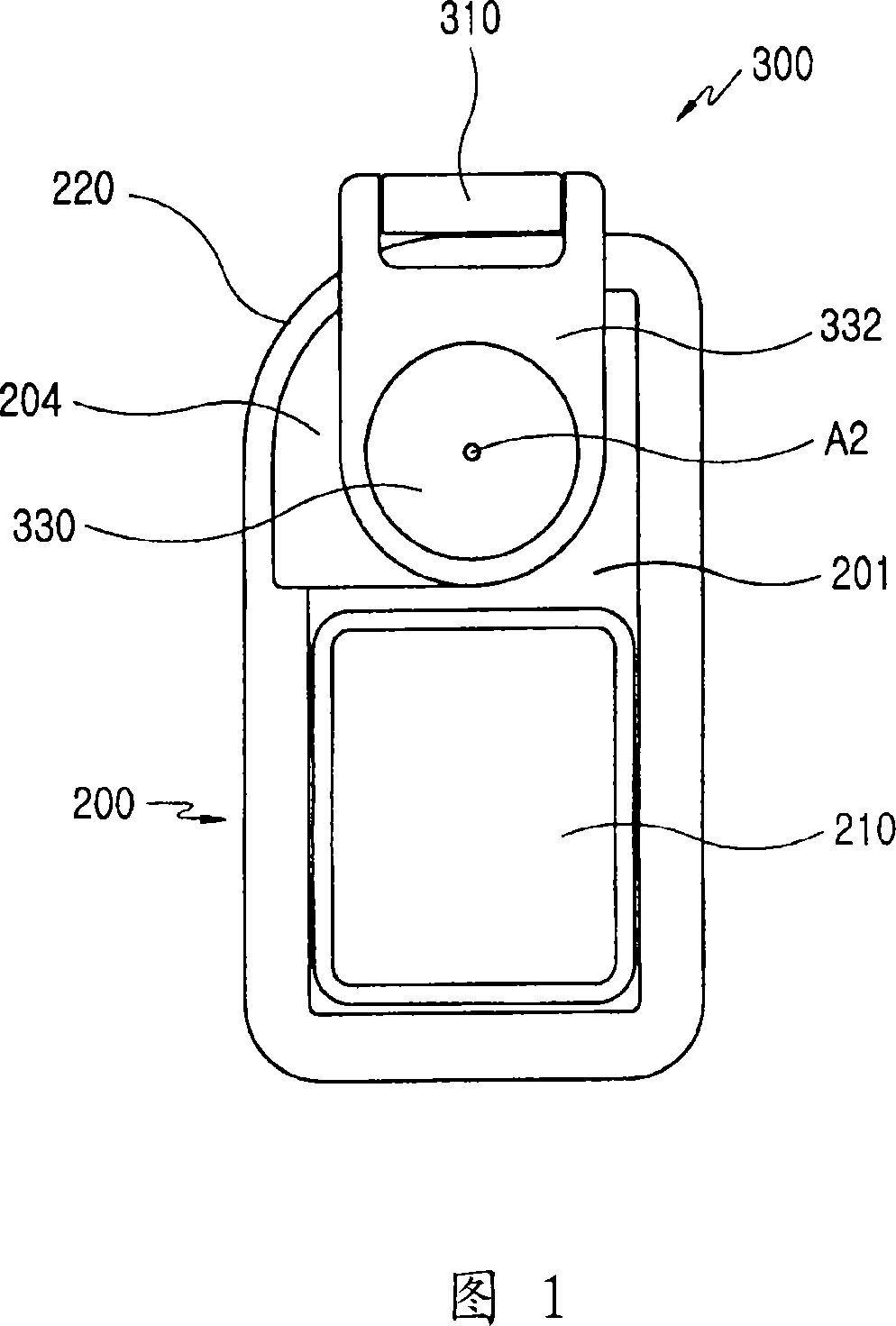

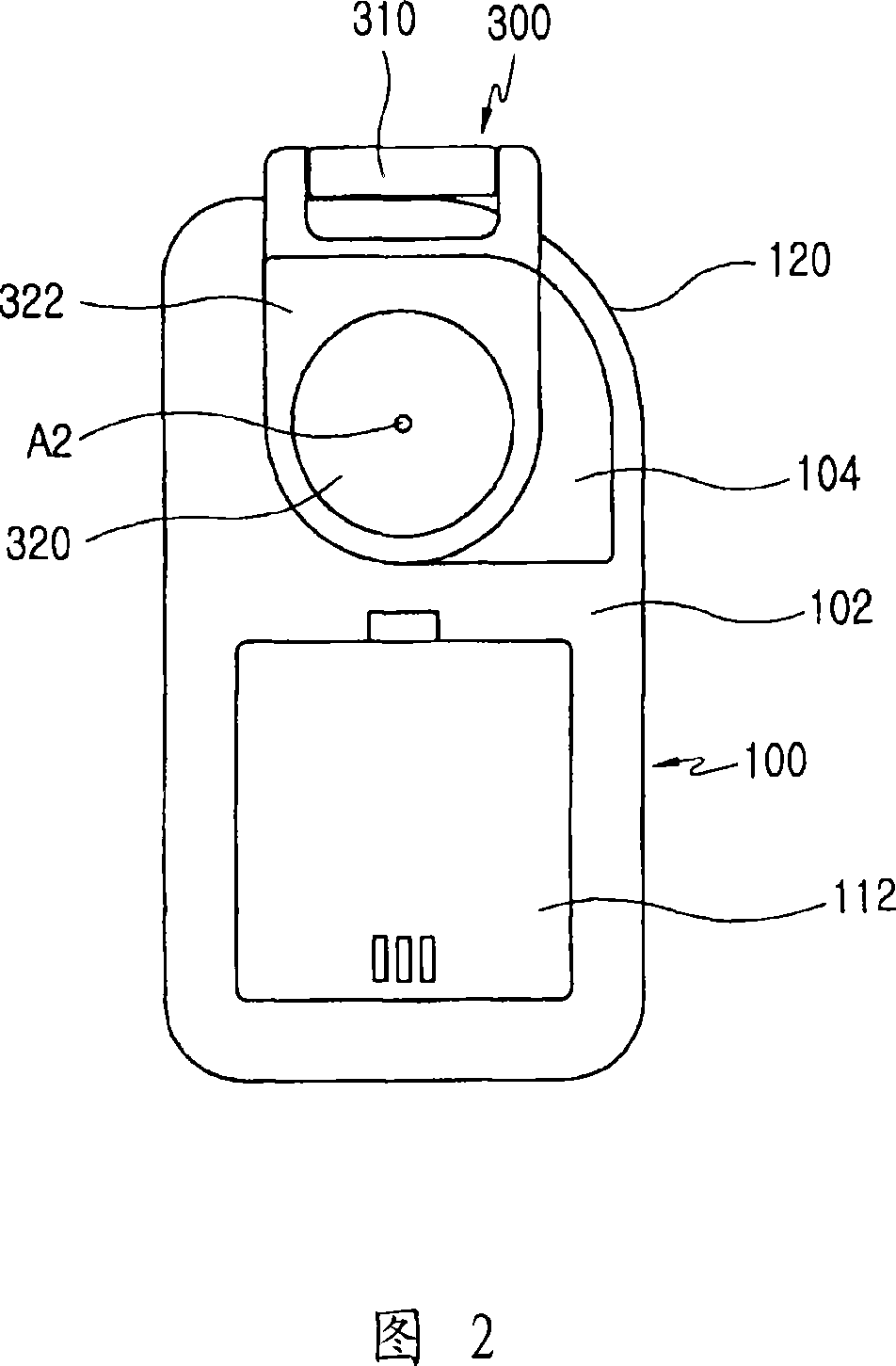

Dual-axis rotation folder-type mobile communication terminal and hinge device thereof

InactiveCN101123628AControl swingWing accessoriesRadio/inductive link selection arrangementsEngineeringDual axis

Owner:SAMSUNG ELECTRONICS CO LTD

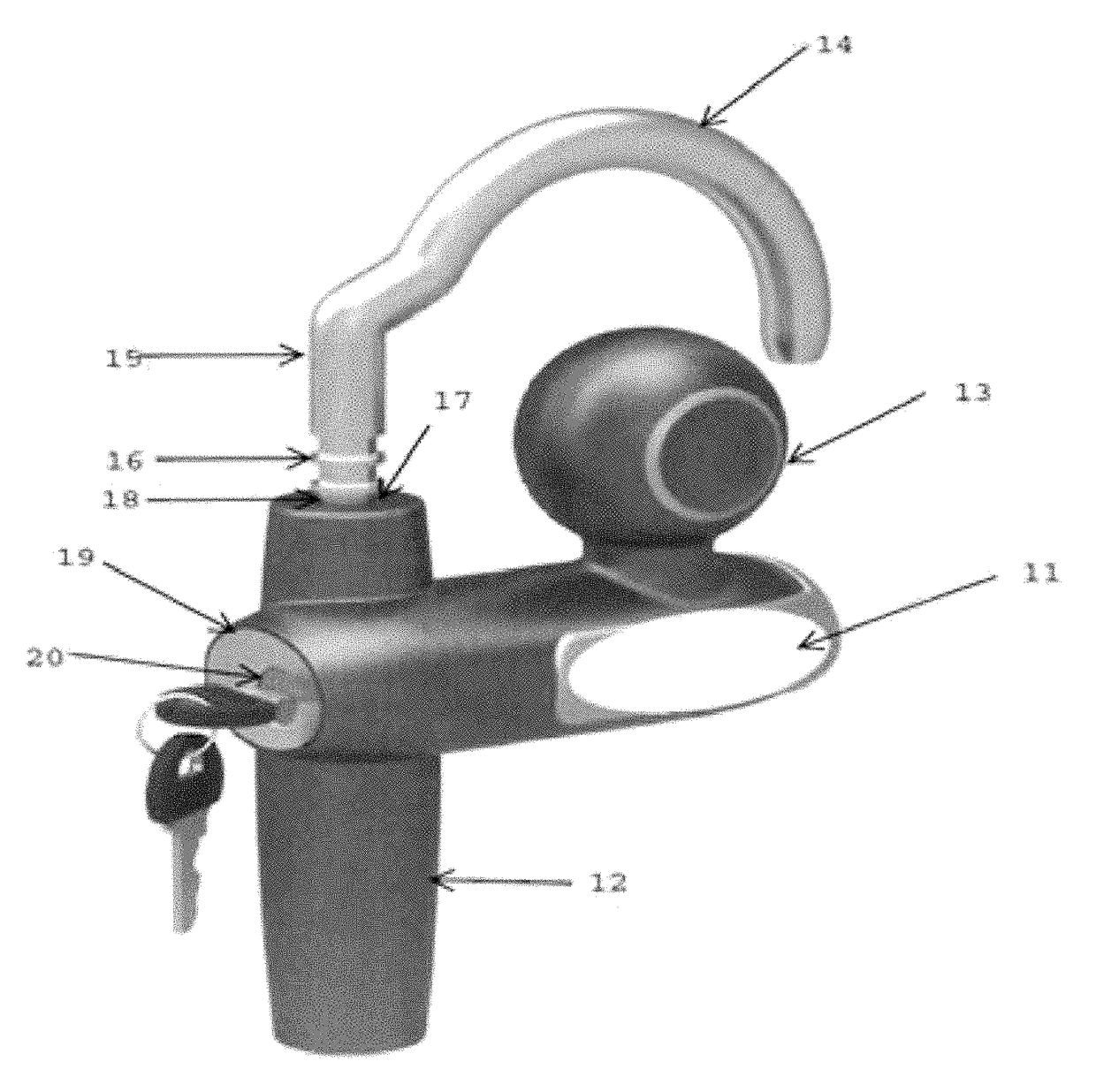

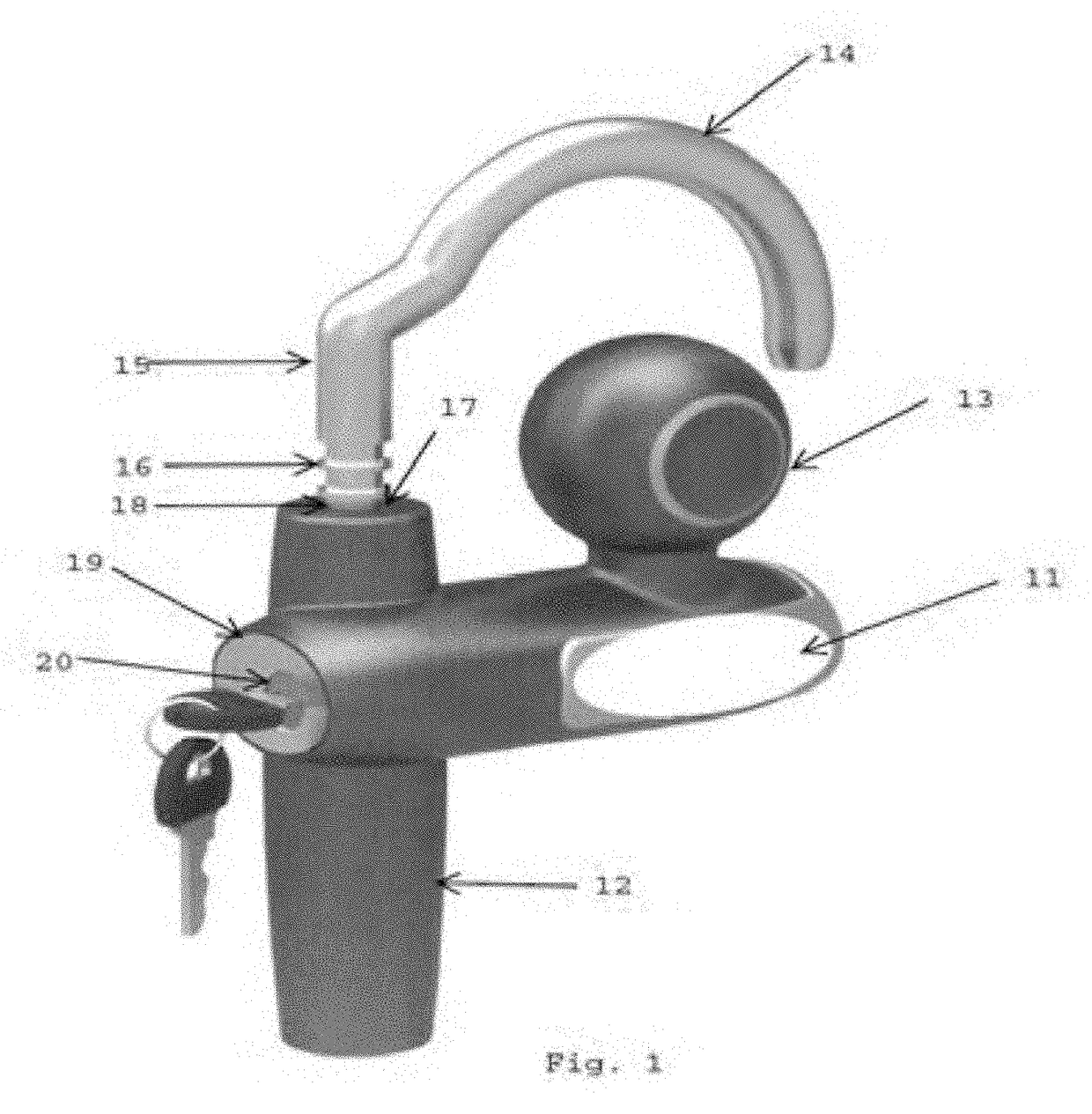

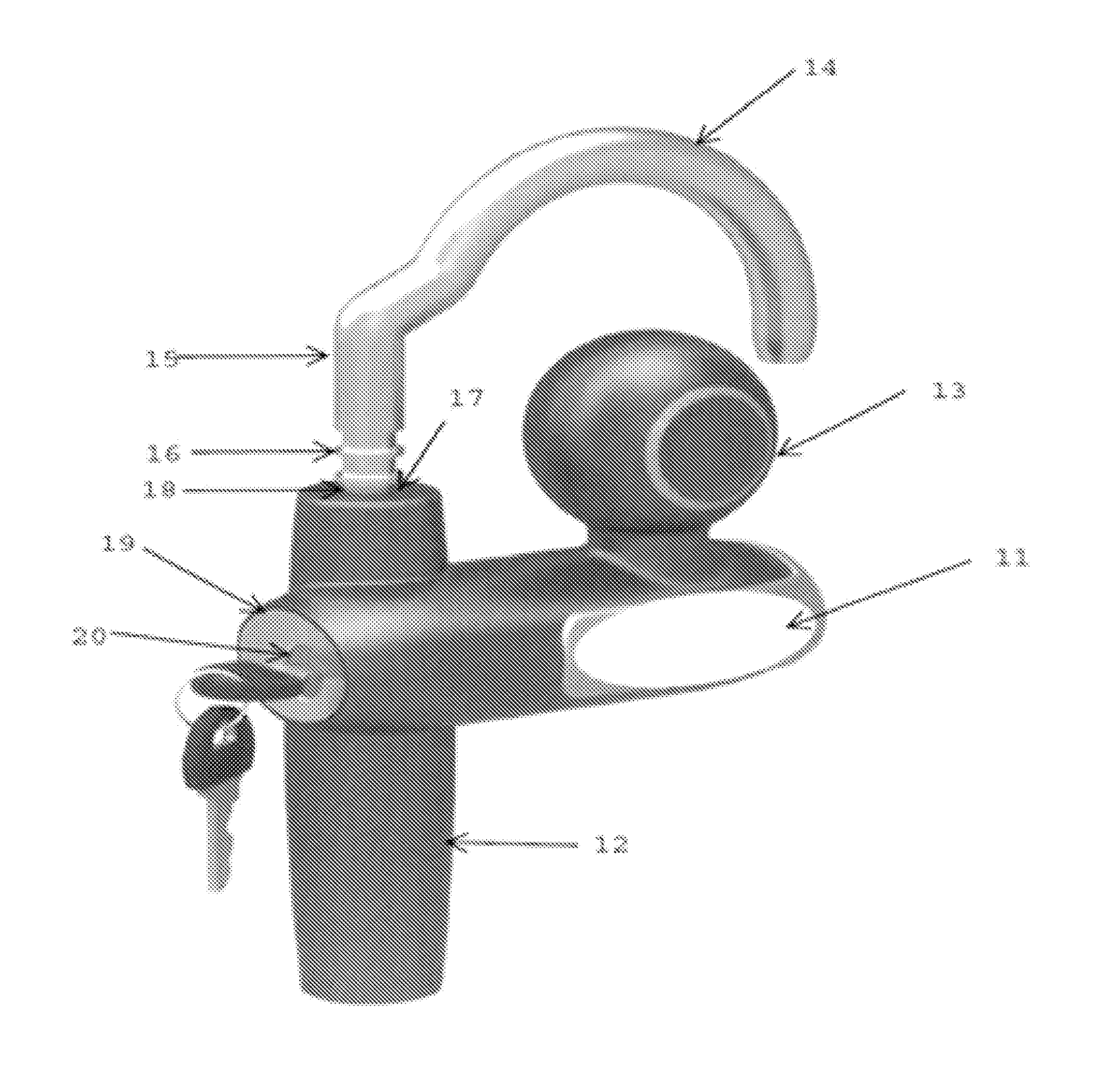

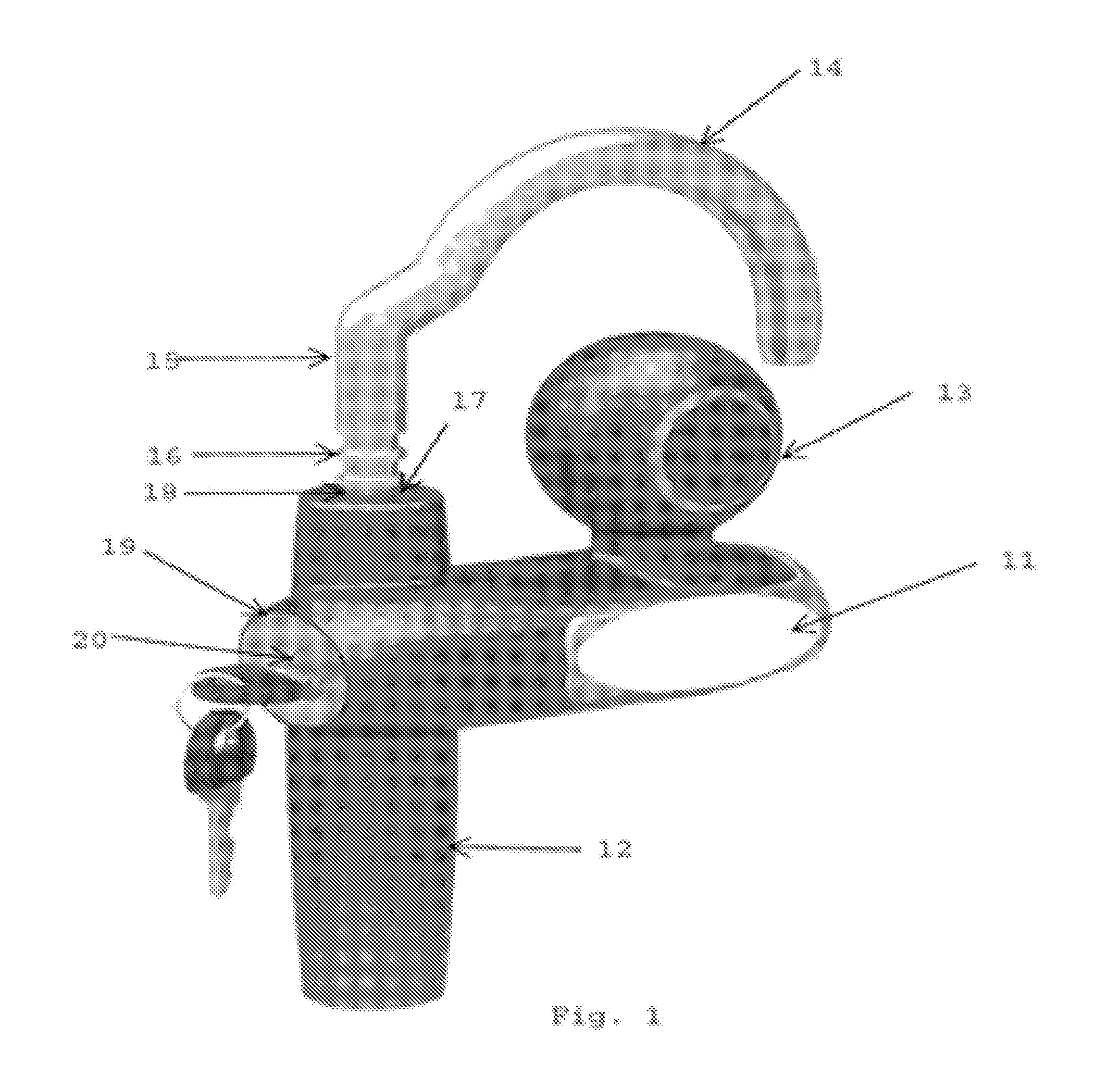

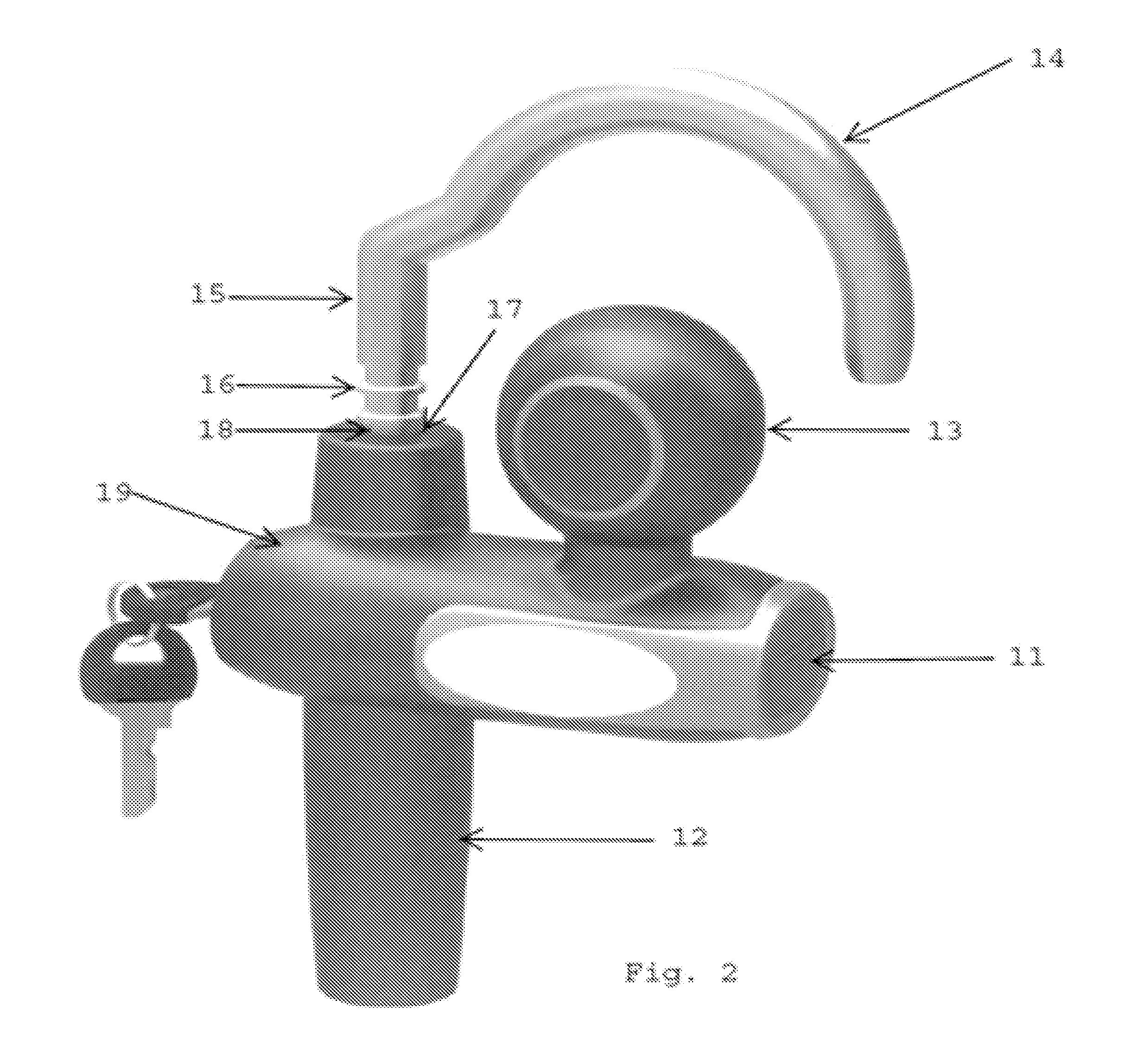

Single armed trailer coupler locking device

A locking device for obstructing towing of an unattached trailer has a lock base and a single-armed curved interlock bracket. The lock base has a cylindrical leg. The single-armed interlock bracket has an grooved arm sliding along an aperture on the cylindrical leg and may be permanently attached to the lock base. Grooves on the arm allows a locking means to be engaged with the lock bracket at different height. When engaged, the locking means may restrict the interlock bracket from swirling. The open end of the interlock bracket provides flexibility to accommodate trailer couplers with different cap / rim sizes. The cylindrical leg may have a sealed bottom end and may function as a handle. The locking device may also feature a push-in locking mechanism to lock the interlock bracket in a position without using a key.

Owner:YUAN GUOJI

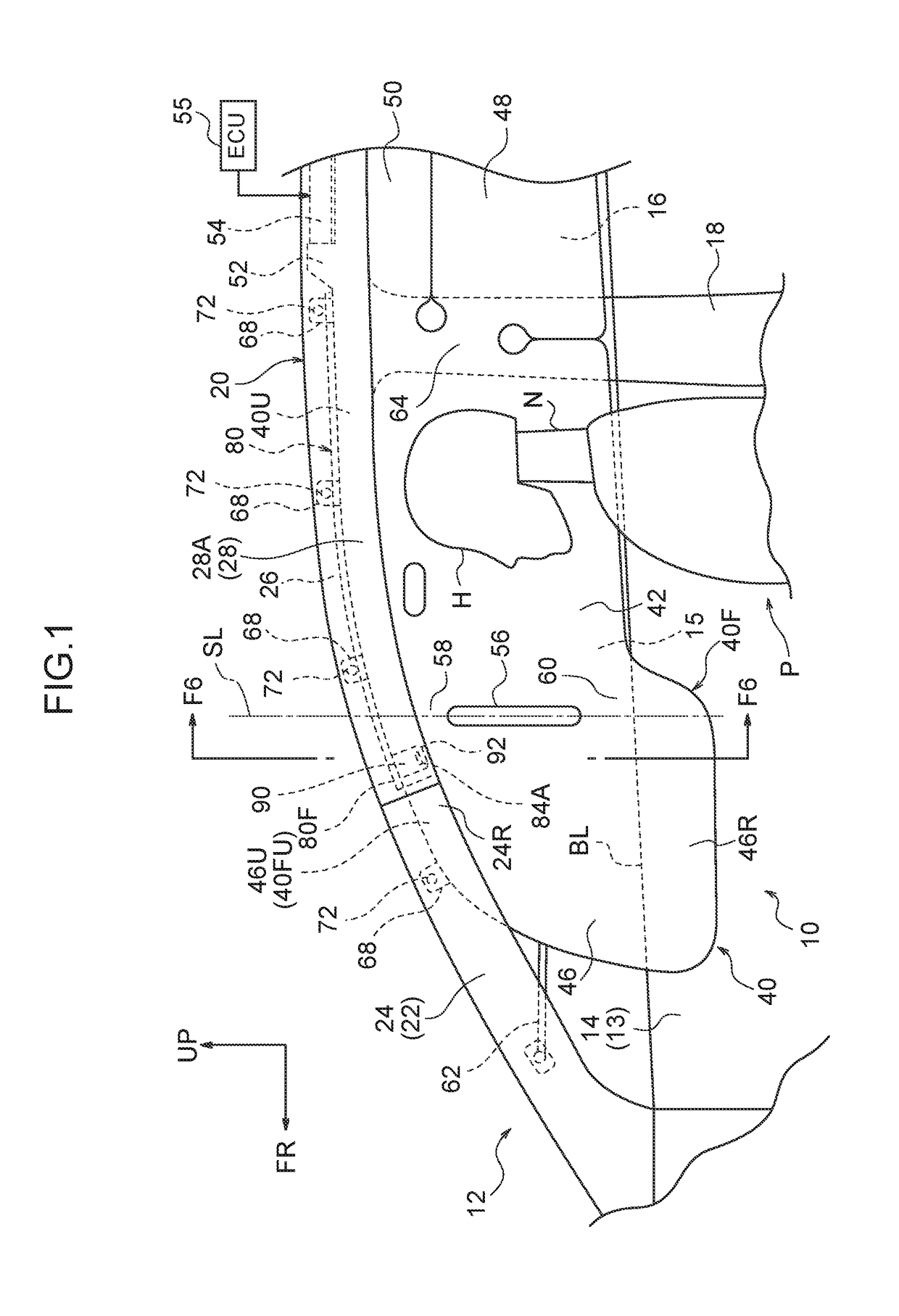

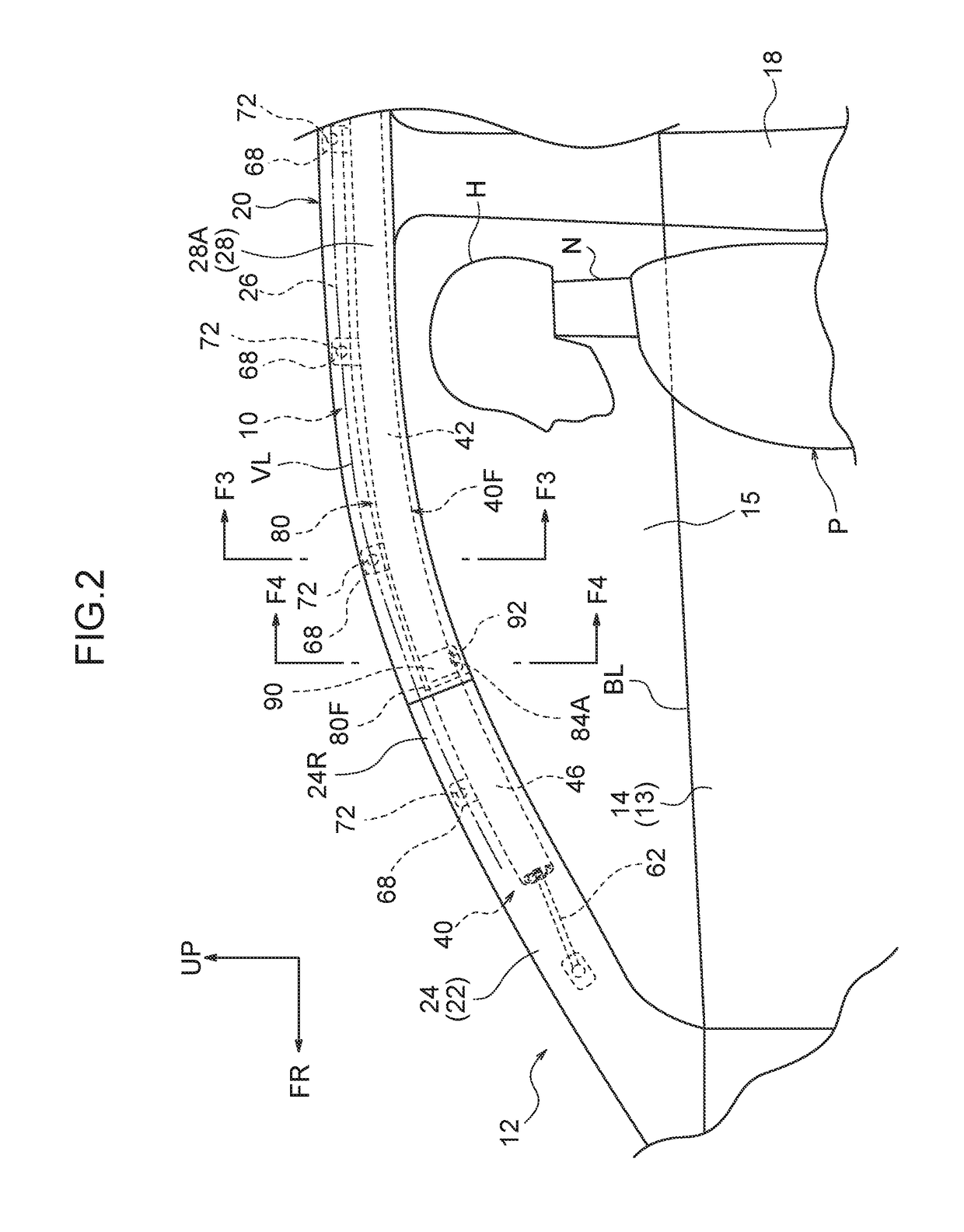

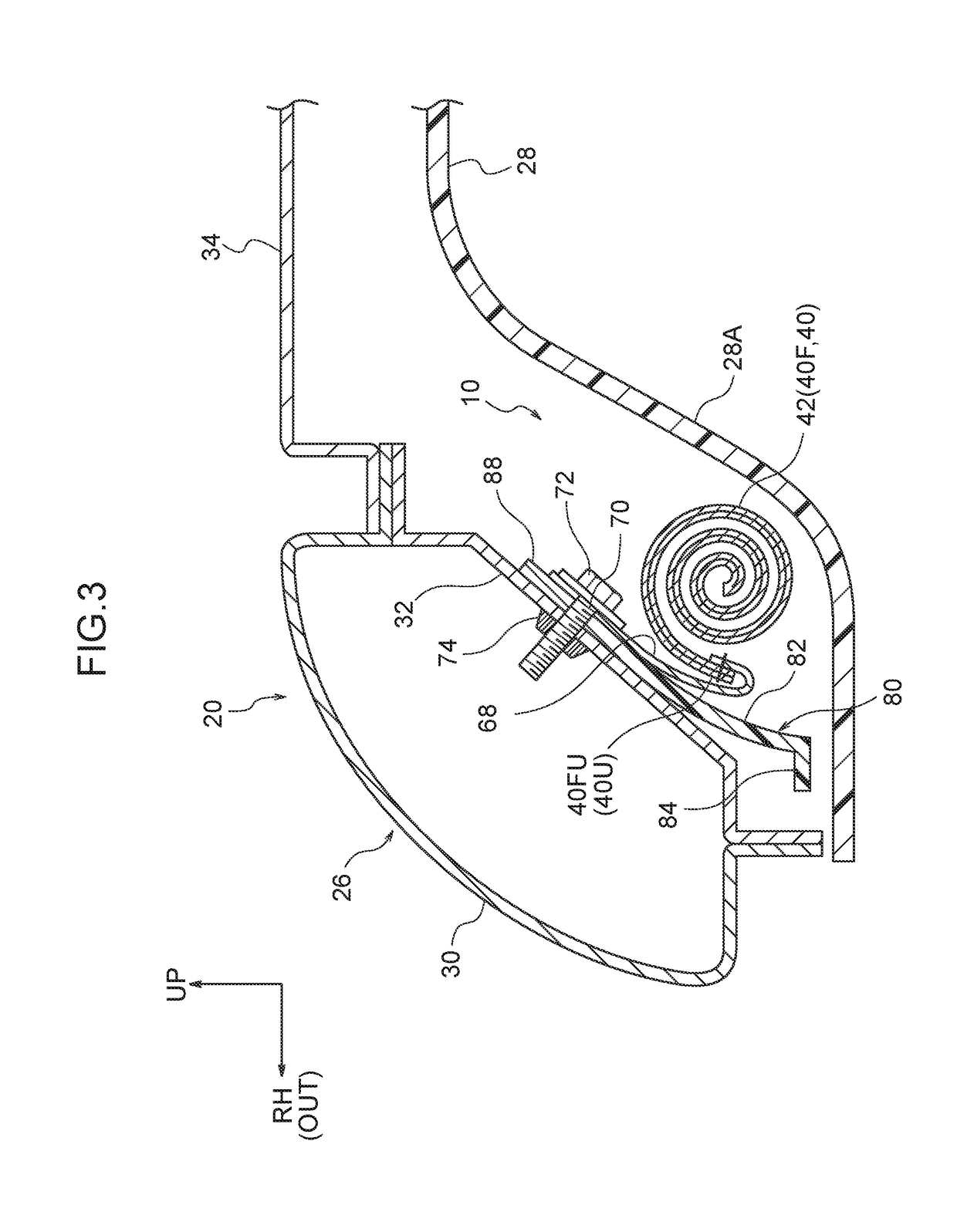

Curtain airbag device for vehicle

ActiveUS20190047505A1Control swingImprove vehicle occupant protection performancePedestrian/occupant safety arrangementEngineeringAirbag

A curtain airbag device for a vehicle including; a curtain airbag that includes tabs that are anchored at a roof side portion, stowed in the roof side portion in folded state, inflates and expands toward the vehicle lower side, and includes, at a front portion, a front seat oblique collision chamber that inflates to the vehicle lower side relative to a door beltline and is superposed in the vehicle width direction with a door trim; and a swing restriction tab projecting from upper edge portion of front portion of the curtain airbag, anchored at the roof side portion at the vehicle lower side with respect to an imaginary line that runs along the curtain airbag in folded state and passes through anchoring points of the tabs, and restricts upward swinging with respect to the vehicle by the front portion of the inflated and expanded curtain airbag.

Owner:TOYOTA JIDOSHA KK

Cantilever structure of operation stable

The invention discloses a cantilever structure of an operation stable. The cantilever structure comprises a rotating arm and a bracket, wherein a cable penetrates through the rotating arm, and the bracket is located above the rotating arm. The cantilever structure is characterized in that a complete cycle rotation limiting structure is arranged between the rotating arm and the bracket and comprises a central spindle, a sleeve and a bearing, wherein the central axis of the central spindle is vertically arranged, the central spindle is sleeved with the sleeve in a spaced mode, and the bearing is located between the sleeve and the central spindle. The lower end of the central spindle is connected to the rotating arm in a bolted mode, the central spindle penetrates through the sleeve, and the upper end of the sleeve is fixed to the operation stable. The bearing is arranged between the central spindle and the sleeve. It is guaranteed that the upper end of the central spindle does not abut against the operation stable, and a rotation bearing abuts against a preset shoulder on the central spindle to axially fix the lower end of the sleeve. In order to achieve complete cycle rotation limiting, limiting blocks are arranged at the lower end of the sleeve and just abut against fastening bolts for connecting the central spindle and the rotating arm when the sleeve rotates to a certain position, and therefore complete cycle rotation, relative to the rotating arm, of the operation table is achieved.

Owner:JIANGSU YONGJIN METAL TECHNOLOGY CO LTD

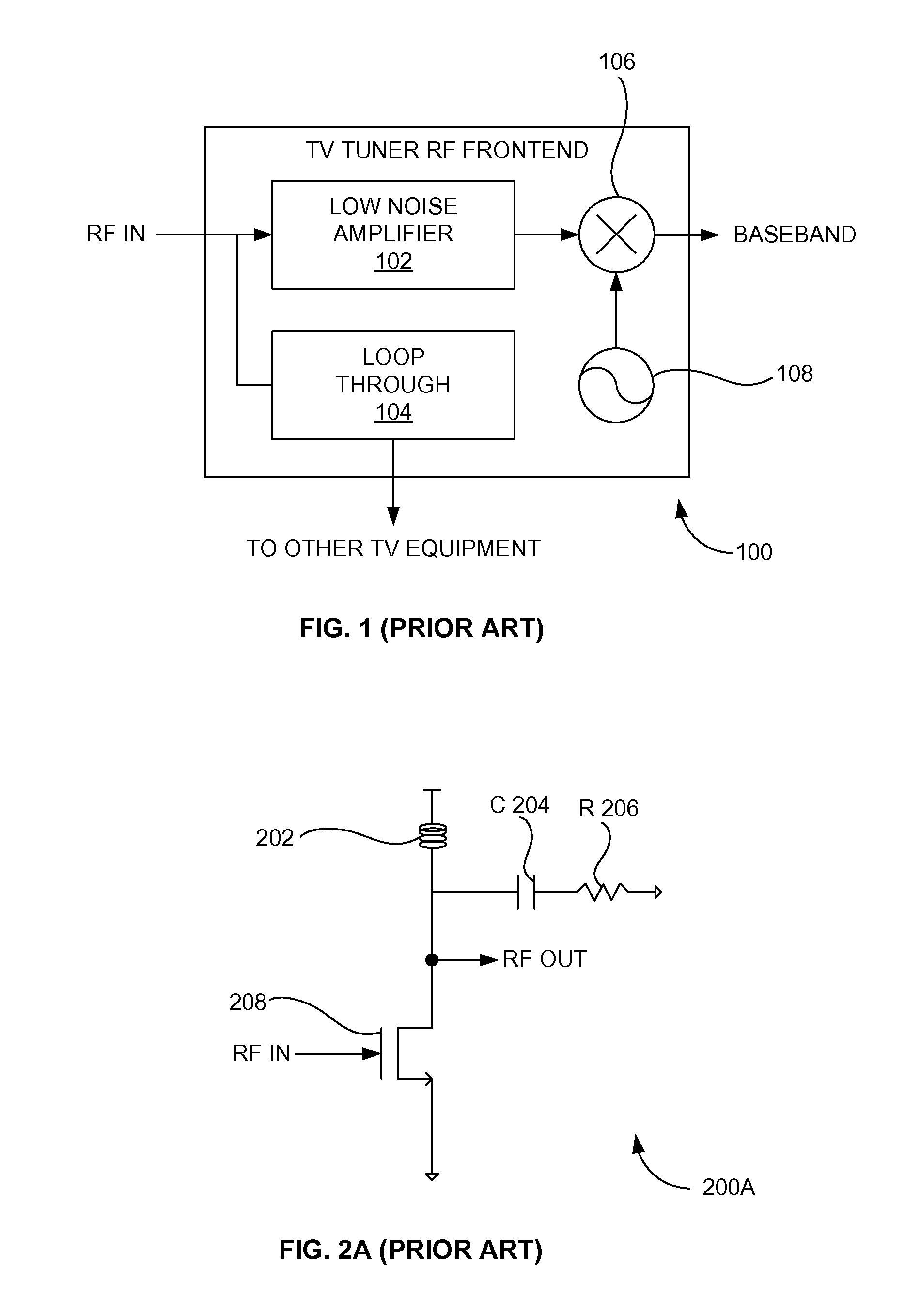

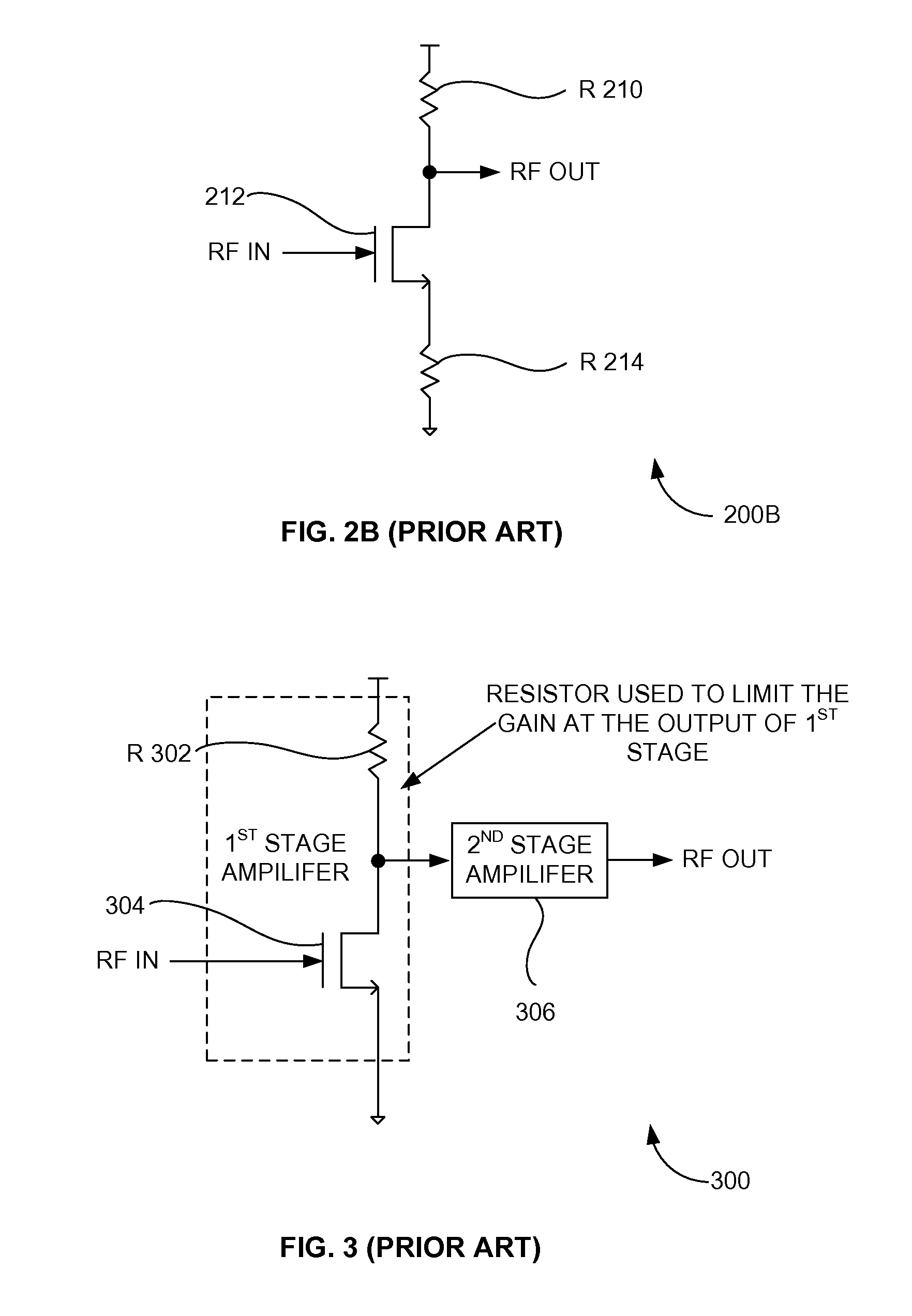

High linearity, low noise, wide bandwidth amplifier/buffer

ActiveUS8115553B1Little noiseLower impedancePush-pull amplifiersPhase-splittersLow noiseAudio power amplifier

A radio frequency wide band amplifier having a noise that does not exceed a threshold value, and a linearity better than a threshold value. The radio frequency wide band amplifier architecture includes a first stage amplifier and a second stage amplifier. The second stage amplifier includes an input source resistor (Rin) that receives an input voltage signal, a feedback resistor (Rfb) directly connected to the input source resistor, a p-type metal-oxide-semiconductor (PMOS) transistor directly connected to the input source resistor. The PMOS transistor receives an output from the input source resistor. A n-type metal-oxide-semiconductor (NMOS) transistor directly connected to the input source resistor. The NMOS transistor receives an output from the input source resistor. A lumped output resistor (Rout) that receives an output from the feedback resistor, the PMOS transistor, and the NMOS transistor. A terminal of the lumped output impedance is connected to ground.

Owner:ATMEL CORP

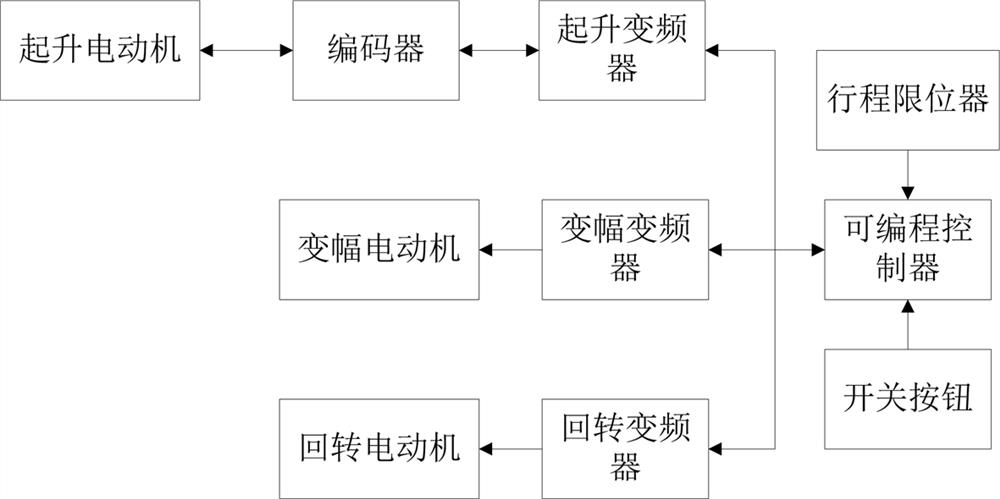

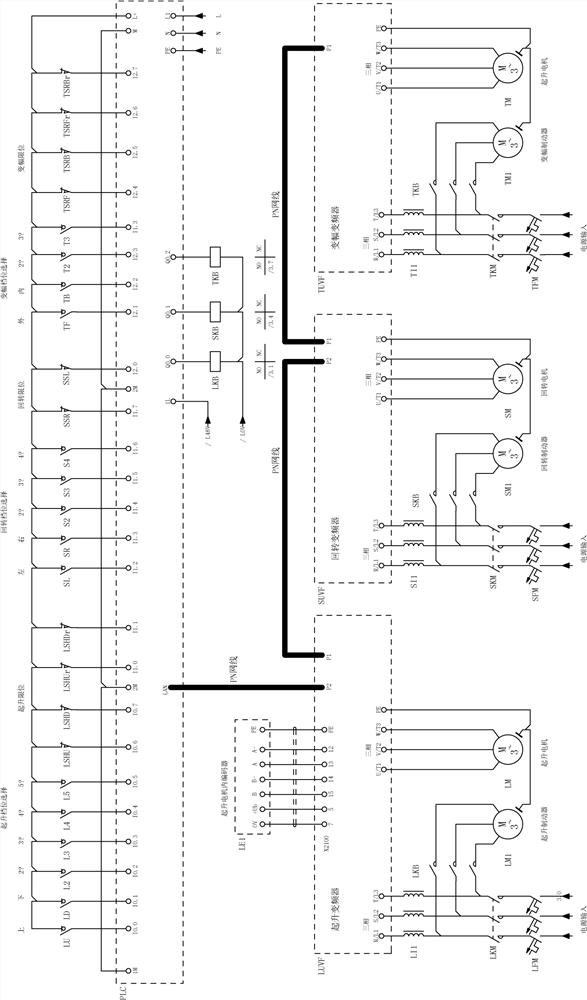

Amplitude variation and rotation linkage anti-swing system and method for tower crane

PendingCN113060662AEasy to operateFlexible operationCranesLoad-engaging elementsFrequency changerDriver/operator

The invention relates to an amplitude variation and rotation linkage anti-swing system and method for a tower crane. After an anti-swing function is initialized and activated, a lifting motor, an encoder, a lifting frequency converter, an amplitude variation motor, an amplitude variation frequency converter, a rotation motor, a rotation frequency converter and a programmable controller are matched to obtain the current height of a hoisted heavy object of the crane; after an operation handle gives amplitude variation and rotation speed signals, the programmable controller calculates and obtains speed curves of the amplitude variation motor and the rotation motor which enable the heavy object not to swing in operation according to a simple pendulum period principle in combination with the current heavy object height and a received speed signal instruction, and the amplitude variation frequency converter and the rotation frequency converter drive the amplitude variation motor and the rotation motor according to the received speed curves to control stable start and stop of the hoisted heavy object and reduce the swing amplitude of the heavy object. The system is reliable in performance, and solves the problem that safety accidents are easily caused due to the fact that the heavy object swings greatly in the air due to unskilled operation of a driver and needs to be held stably by personnel.

Owner:ZHEJIANG HUBA CONSTR MACHINERY

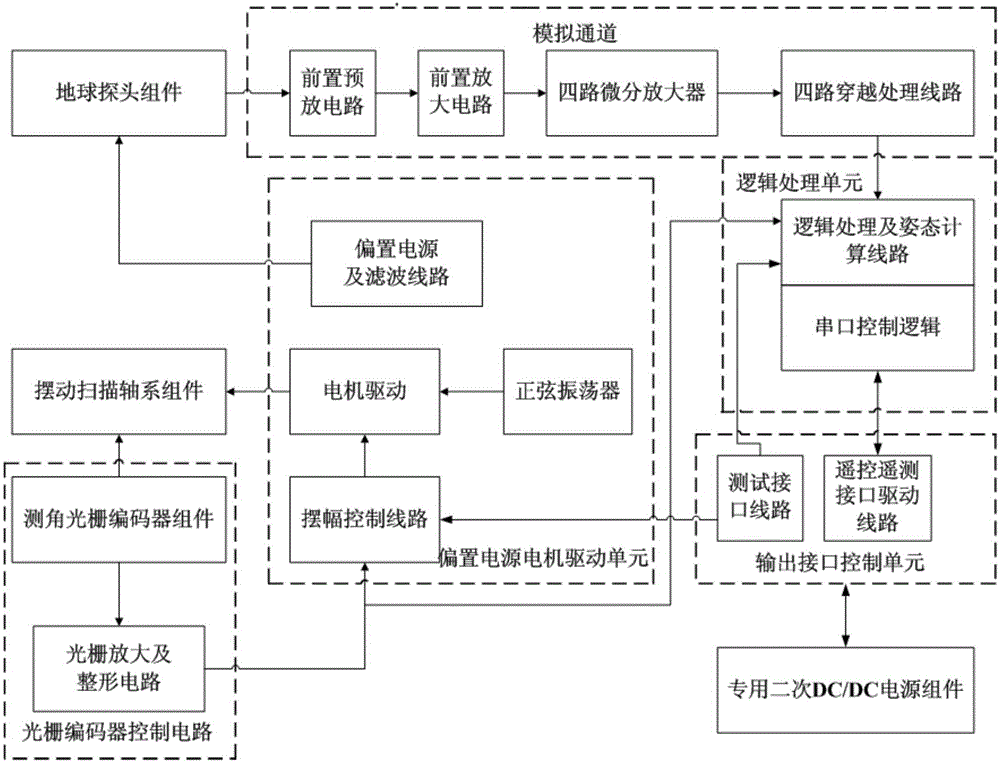

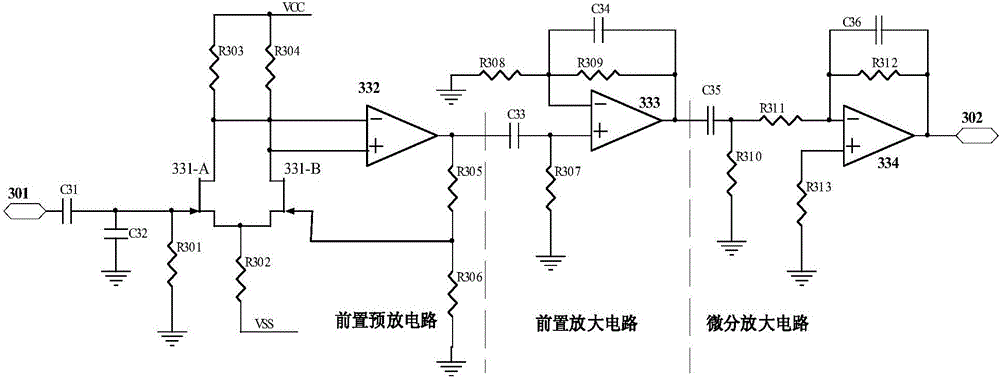

Miniaturized swing infrared circuit system

ActiveCN106441561AControl swingEffective calculationRadiation pyrometryInstruments for comonautical navigationMotor Drive UnitEngineering

The invention provides a miniaturized swing infrared circuit system. The miniaturized swing infrared circuit system includes an earth probe assembly, a swing scanning shafting assembly, an analog channel assembly, a bias power supply and motor driving unit, an output interface control unit, a logical processing unit, a grating encoder control circuit, and a special secondary DC / DC power assembly, wherein the bias power supply and motor driving unit includes a bias power supply and filtering line, a motor driving module, a sinusoidal oscillation device and an amplitude control line; and the output interface control unit includes a test interface line and a remote control remote measurement interface driving line. By means of cooperative control of the logical processing unit and the grating encoder control circuit, the miniaturized swing infrared circuit system realizes control of the swing amplitude of a swing mirror. And compared with the prior art, the miniaturized swing infrared circuit system can fully and effectively utilize the swing signal of the swing mirror and the output signal of the earth probe assembly to calculate the attitude information, and is relatively high in applicability.

Owner:BEIJING INST OF CONTROL ENG

Self-adjusting supporting head

ActiveUS20160280521A1Control swingSafety devices for lifting equipmentsLifting framesEngineeringSelf adjusting

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Bending tester for network optical fiber cable

ActiveCN105865959ACompact structureEasy to operateMaterial strength using repeated/pulsating forcesElectric machineryEngineering

The invention discloses a bending tester for a network optical fiber cable. The bending tester comprises a base, a control panel, a motor assembly, a connecting rod assembly, a fixture and a fixture seat. The base is located at the bottommost of the tester. The motor assembly comprises a motor and a motor seat. The connecting rod assembly comprises five connecting rods and an optical fiber cable clamping plate, wherein the first connecting rod is connected with the motor, the optical fiber cable is installed in the optical fiber cable clamping plate, the bottom of the optical fiber cable is installed on the fixture, and the fixture is fixed to the fixture seat. The bending tester is compact in structure, easy to operate, and capable of effectively controlling the swing amplitude of the connecting rod assembly, the fixing height of the optical fiber cable can be flexibly adjusted, and thus the working efficiency can be greatly improved.

Owner:上海朋邦实业有限公司

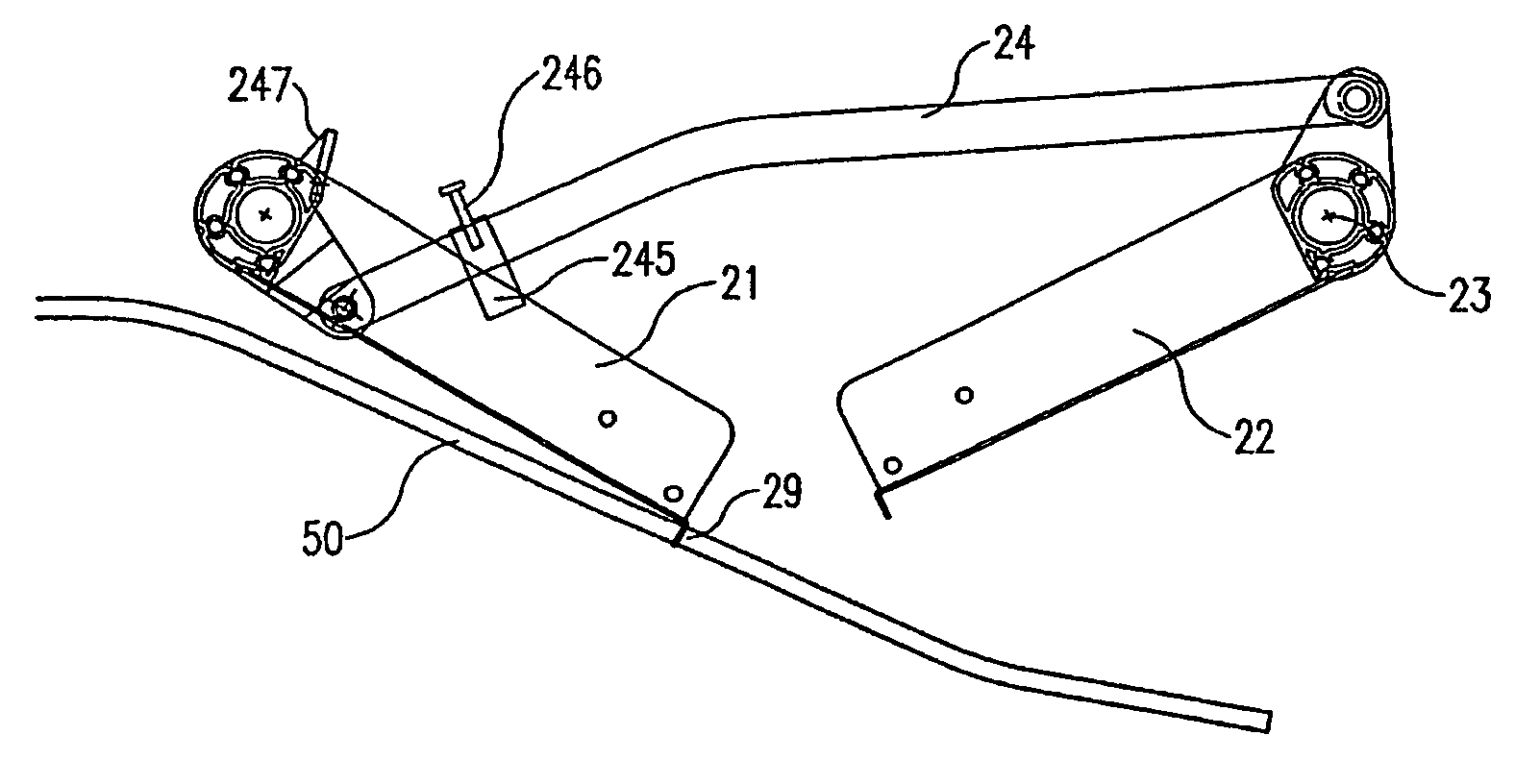

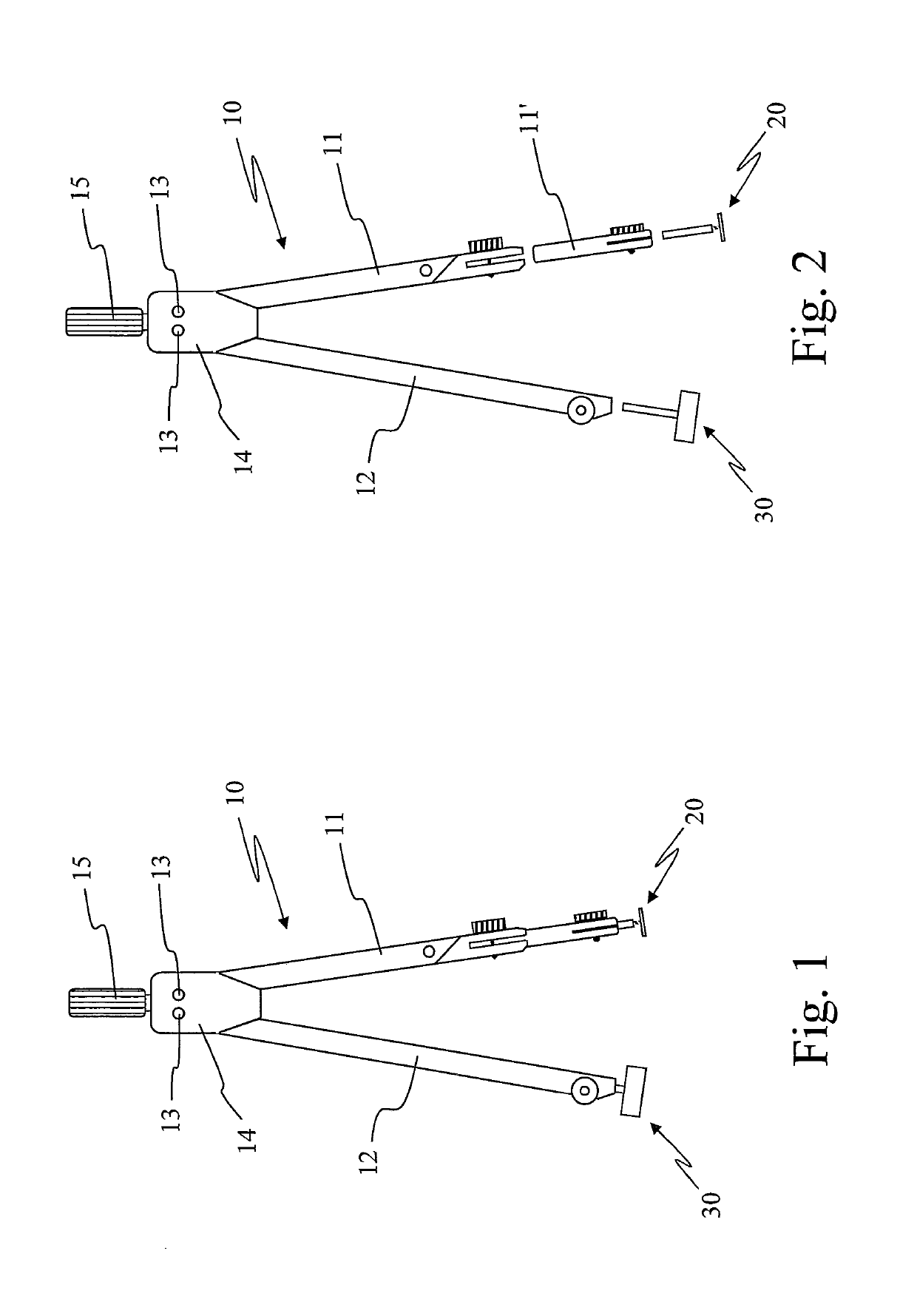

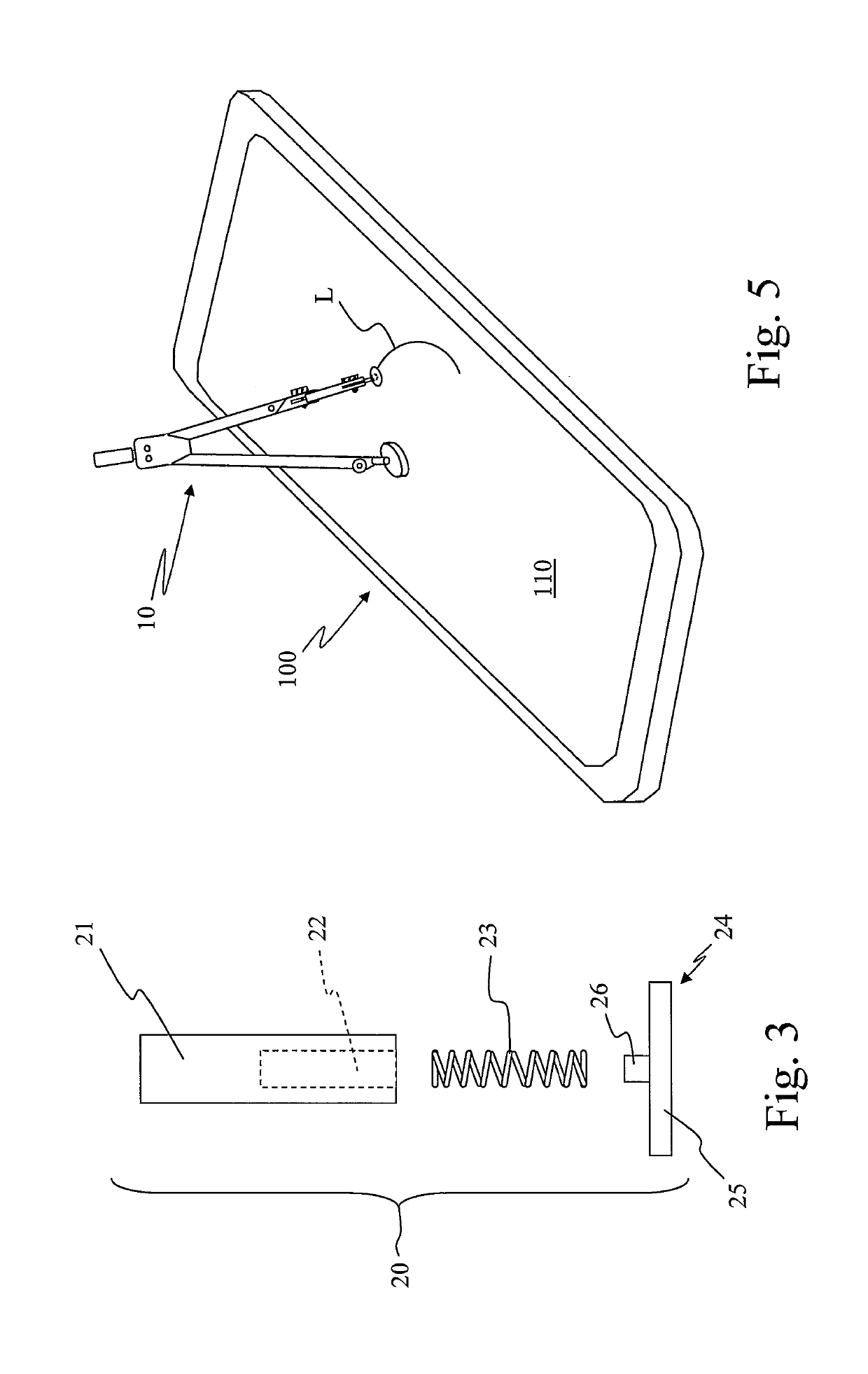

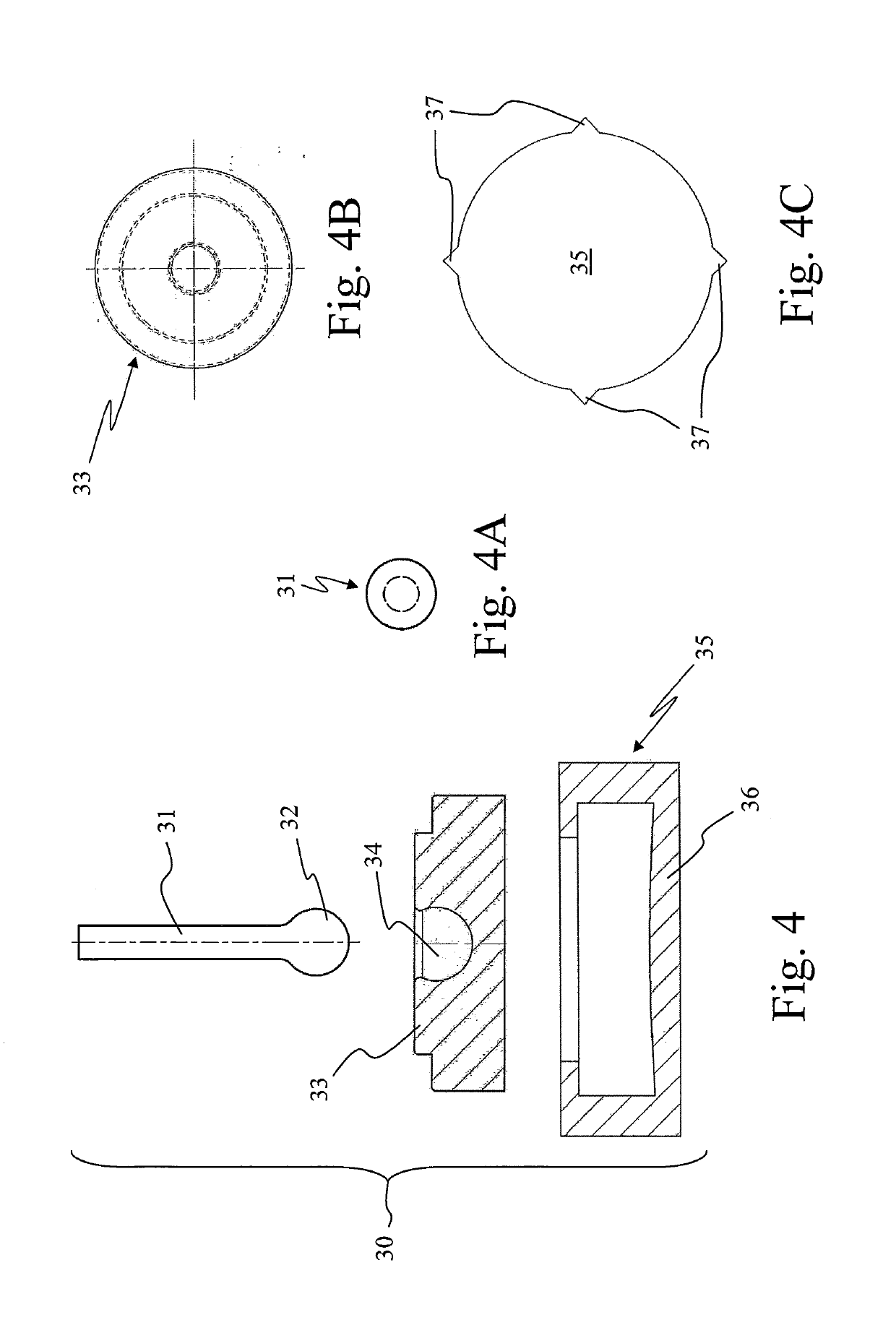

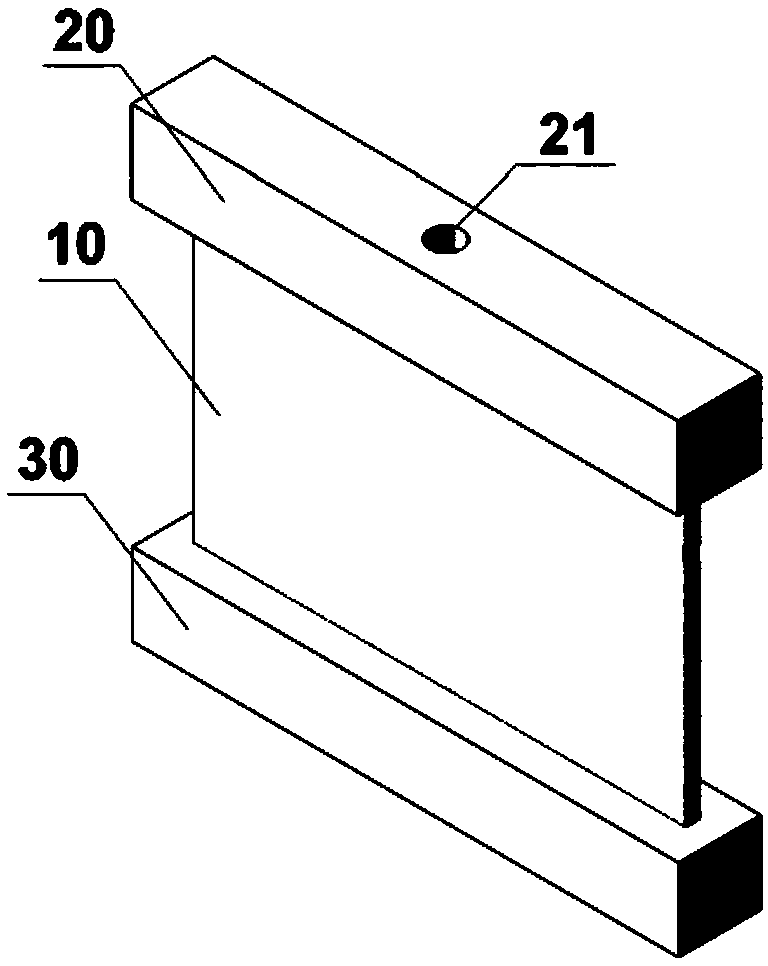

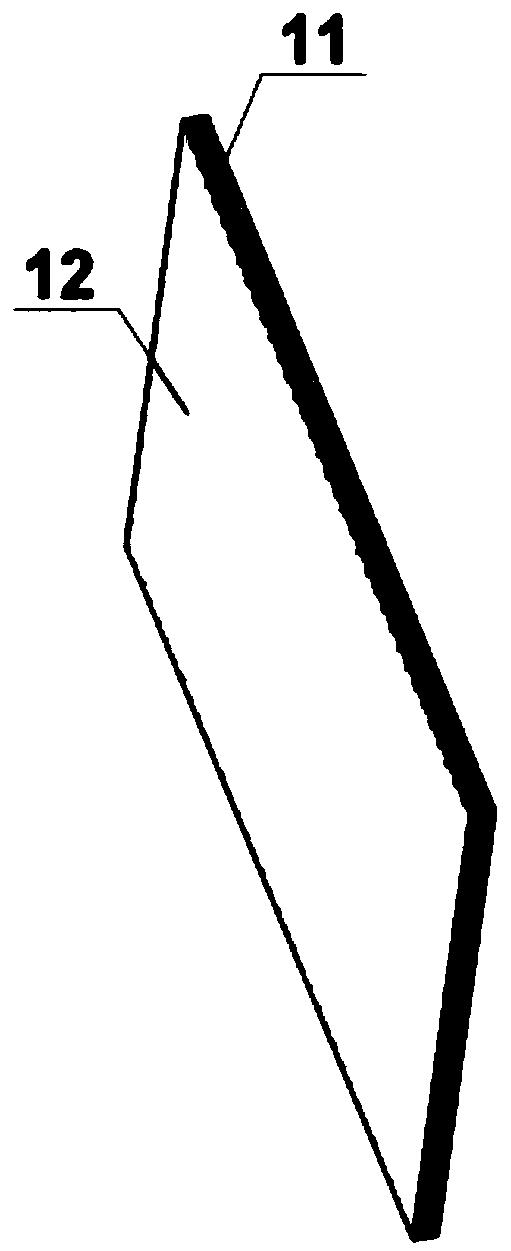

Apparatus and process for drawing lines

InactiveUS20190204936A1Control swingEnsure stabilityCircular curve drawing instrumentsInput/output processes for data processingEngineeringTouchscreen

An apparatus and a process for drawing lines on a sensitive medium are disclosed. The apparatus comprises at least one tool for drawing lines and a programmable device equipped with a touchscreen, the latter being the sensitive medium. The tool for drawing lines includes a compass comprising a first leg having a drawing means installed thereon, the drawing means being able to interact with the touchscreen of the programmable device.

Owner:KRONOS SRL

New energy power battery cooling box laser powder filling swing welding method

ActiveCN108747022AMeet performance requirementsPromote absorptionLaser beam welding apparatusNew energyEnergy absorption

The invention relates to a new energy power battery cooling box laser powder filling swing welding method, and belongs to the technical field of material engineering. The problem about connection of anew energy automobile power battery cooling box is solved. The new energy power battery cooling box laser powder filling swing welding method is characterized in that at the connecting part of a battery cooling box, a laser device provided with a galvanometer scanning system generates swing laser beams to conduct powder filling welding. By controlling the galvanometer scanning system, the swing amplitude and the swing frequency of the laser beams are controlled, energy of the laser beams is weakened when the laser beams swing to a thin wall on one side of a welding seam, and welding penetration is prevented. When the laser beams swing to the other side of the welding seam, the energy of the laser beams is strengthened, and the welding seam is formed. In the welding process, synchronous powder feeding is carried out, the laser beams directly act on the metal powder, absorption of lasers is promoted, and the energy absorbing efficiency is increased; and the metal powder has the effectsof buffering the laser beams and protecting a connector, and the problem about welding penetration, caused by disturbance during welding, of abdomen structural member thin walls is avoided. The new energy power battery cooling box laser powder filling swing welding method provides a new thought for welding complex structural members.

Owner:宁波众远新材料科技有限公司

Multifunctional electric cleaning device for robot lens

The invention relates to a multifunctional electric cleaning device for a robot lens. The multifunctional electric cleaning device comprises a mounting plate, a visible light imaging instrument and an infrared imaging instrument are respectively mounted on the two sides at the upper part of the mounting plate, and a lens mounting plate for lenses of the visible light imaging instrument and the infrared imaging instrument to be placed on is arranged at one end of the mounting plate; an outer brush is arranged in a position, between the lens of the visible light imaging instrument and the infrared imaging instrument, of the lens mounting plate; a drive device arranged on the mounting plate consists of a motor and a control circuit board, and is connected to the lower part of the outer brush through a transmission shaft; the motor is fixed on the control circuit board and is connected with the transmission shaft through a coupler, the coupler is provided with a shifting sheet, and a left limit switch and a right limit switch matched with the shifting sheet during use are arranged in positions, on the two sides of the coupler, of the control circuit board; the swinging frequency and the swinging amplitude of the outer brush can be controlled, the working state of the outer brush can be adjusted according to the imaging interference degree, and the outer brush has the multiplex function of cleaning raindrops, frost fog and dust.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO XUZHOU POWER SUPPLY CO +1

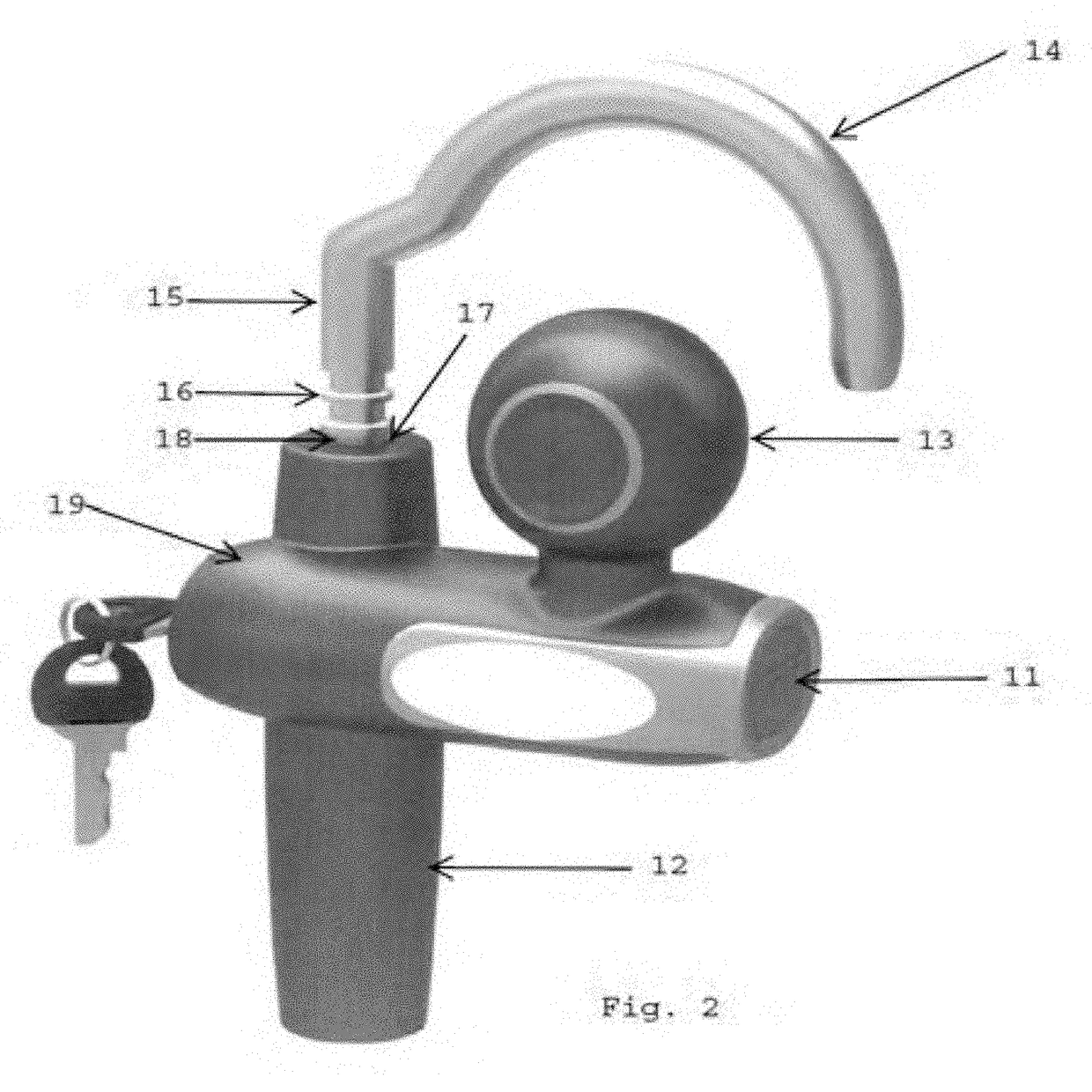

Single-armed trailer coupler locking device

A locking device for obstructing towing of an unattached trailer has a lock base and a single-armed curved interlock bracket. The lock base has a cylindrical leg. The single-armed interlock bracket has an grooved arm sliding along an aperture on the cylindrical leg and may be permanently attached to the lock base. Grooves on the arm allows a locking means to be engaged with the lock bracket at different height. When engaged, the locking means may restrict the interlock bracket from swirling. The open end of the interlock bracket provides flexibility to accommodate trailer couplers with different cap / rim sizes. The cylindrical leg may have a sealed bottom end and may function as a handle. The locking device may also feature a push-in locking mechanism to lock the interlock bracket in a position without using a key.

Owner:YUAN GUOJI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com