Joint brick for building block

a technology of building blocks and joints, applied in the field of joints for building blocks, can solve the problems of not being able to achieve the effect of substantially swinging, extending or bending relative to each other, and the interlocking structure of conventional building blocks still has some disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

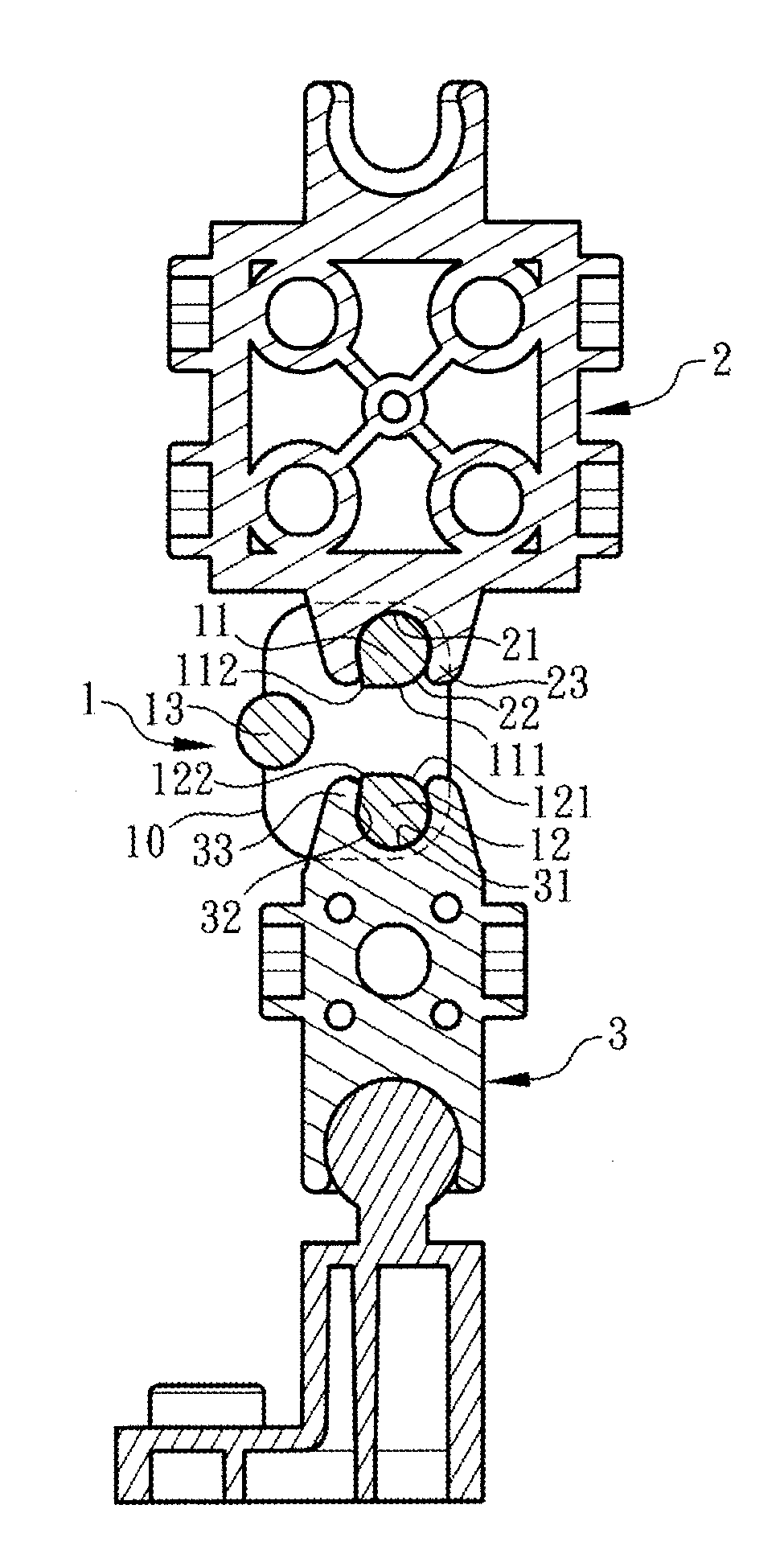

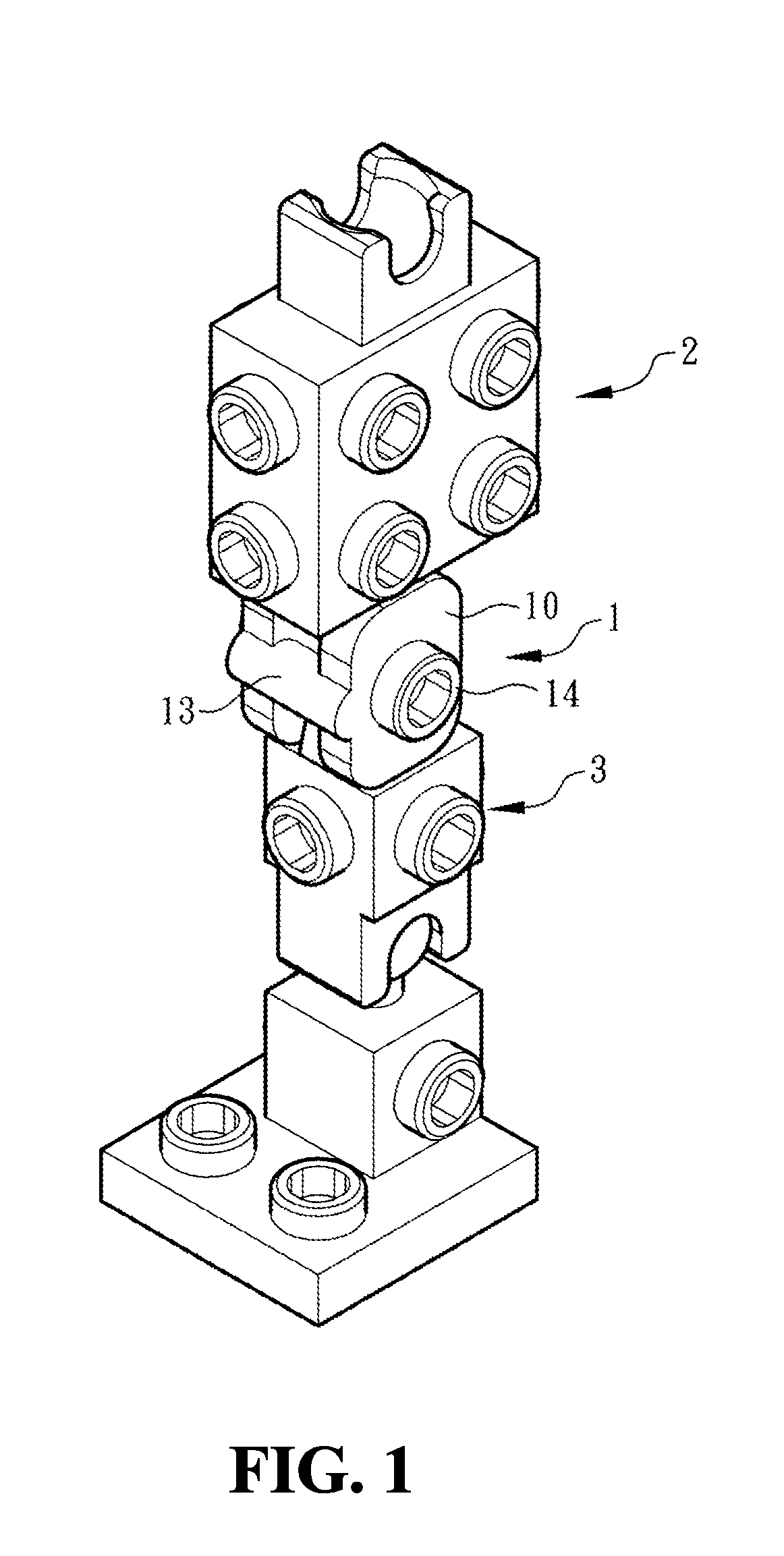

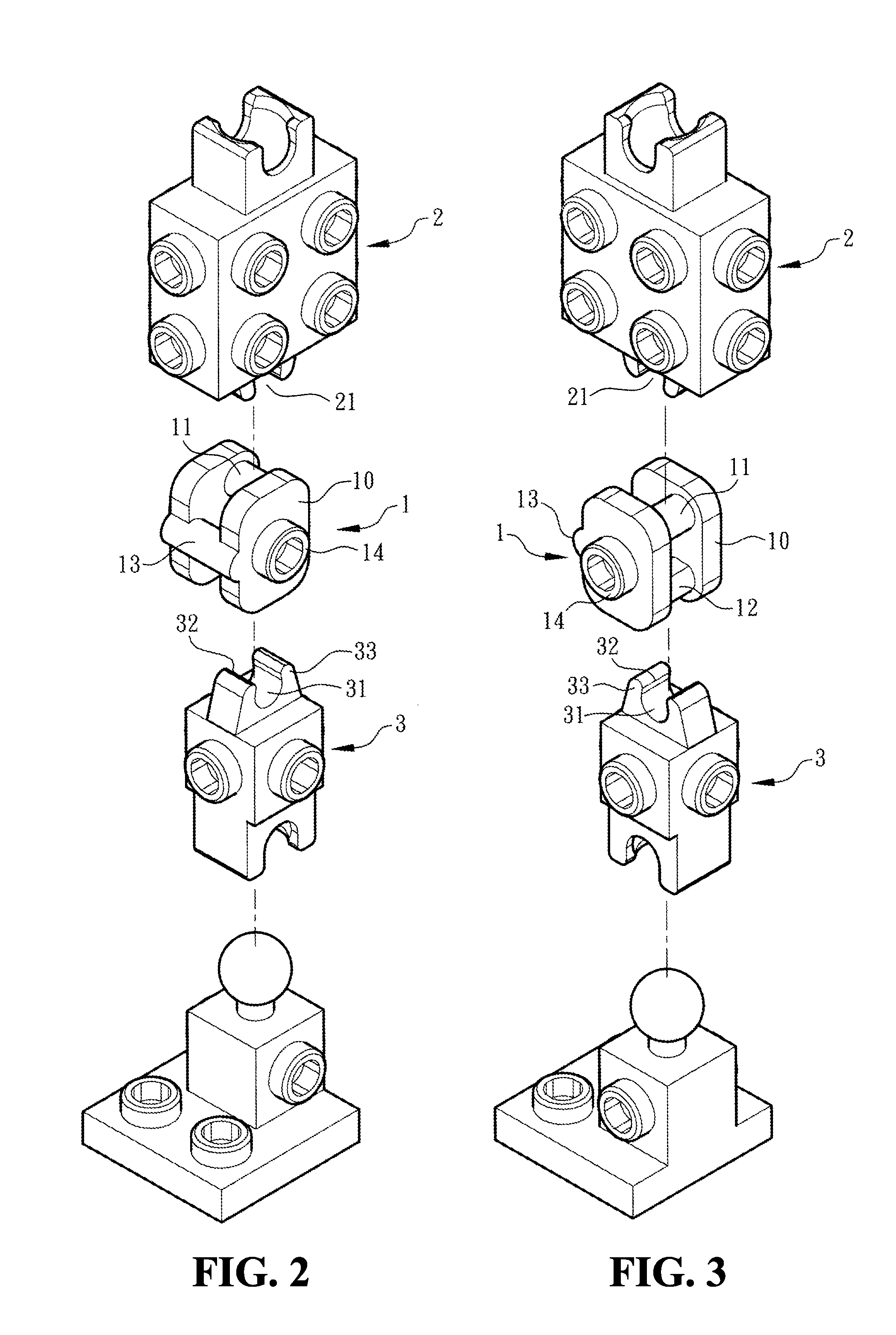

[0027]When connecting the building blocks to form robots having movable limbs (hands or legs), insects or animals, etc, both ends of the joint brick 1 are respectively acted as a top end and a bottom end due to the first axial post 11 and the second axial post 12 respectively located at the top end and the bottom ends of the joint brick 1. the present invention gives an example that the building blocks are assembled to form a limb (a movable lower or upper limb) of a robot. A thigh brick 2 having engaging recesses 21 is provided at the top end of the joint brick 1, and the engaging recess 21 disposed at the bottom end of the thigh brick 2 is engaged with the first axial post 11 disposed at the top end of the joint brick 1. The engaging recess 21 of the thigh brick 2 can be a conventional engaging recess. The engaging recess 21 is shaped in a groove and provided with a recess opening 22 and two outer edge portions 23 disposed at two sides of the recess opening 22, so that the thigh b...

second embodiment

[0032]Referring to FIGS. 6 and 7, according to the present invention, the joint brick 1 is further engaged with a front knee brick 4 having a conventional engaging recess 41. The engaging recess 41 of the front knee brick 4 is engaged with the engaging shaft 13 of the joint brick 1 and outer edge portions 43 disposed at two sides of the engaging recess 41 are inserted into the space between the two side plates 10, thereby connecting the front knee brick 4 with the joint brick 1. The front knee brick 4 also provides an encasing function for the front of the joint brick 1. The front knee brick 4 may further include a decoration portion 40 disposed at a side opposite to the engaging recess 41 to work as an exterior structure of the robot, the insect, the animal, and the like. Therefore, the appearance of the connected building blocks can be changed according to the designs of the decoration portion 40. It makes connecting the building blocks easier, more convenient and more interesting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com