Patents

Literature

38results about How to "Consistent placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

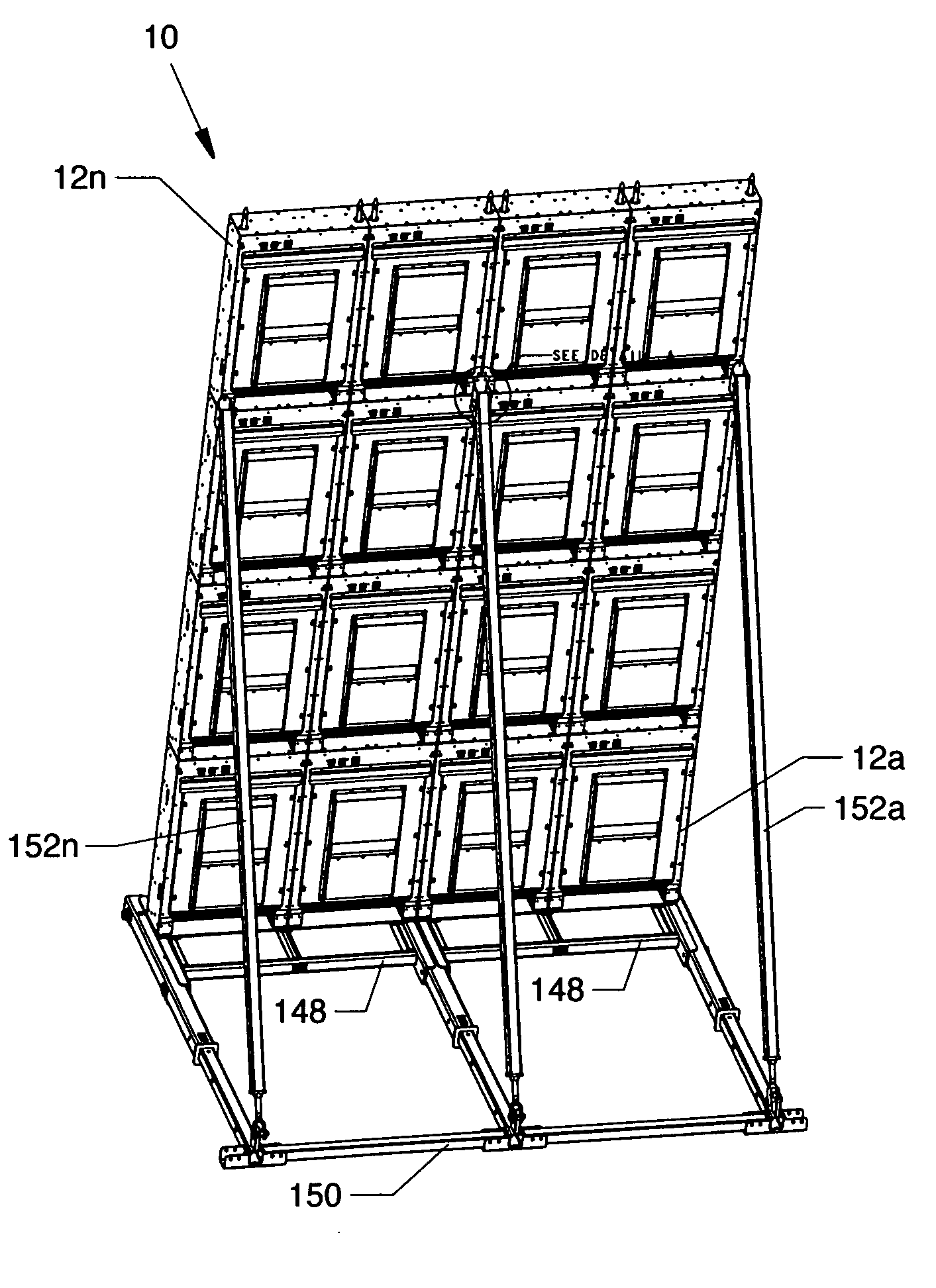

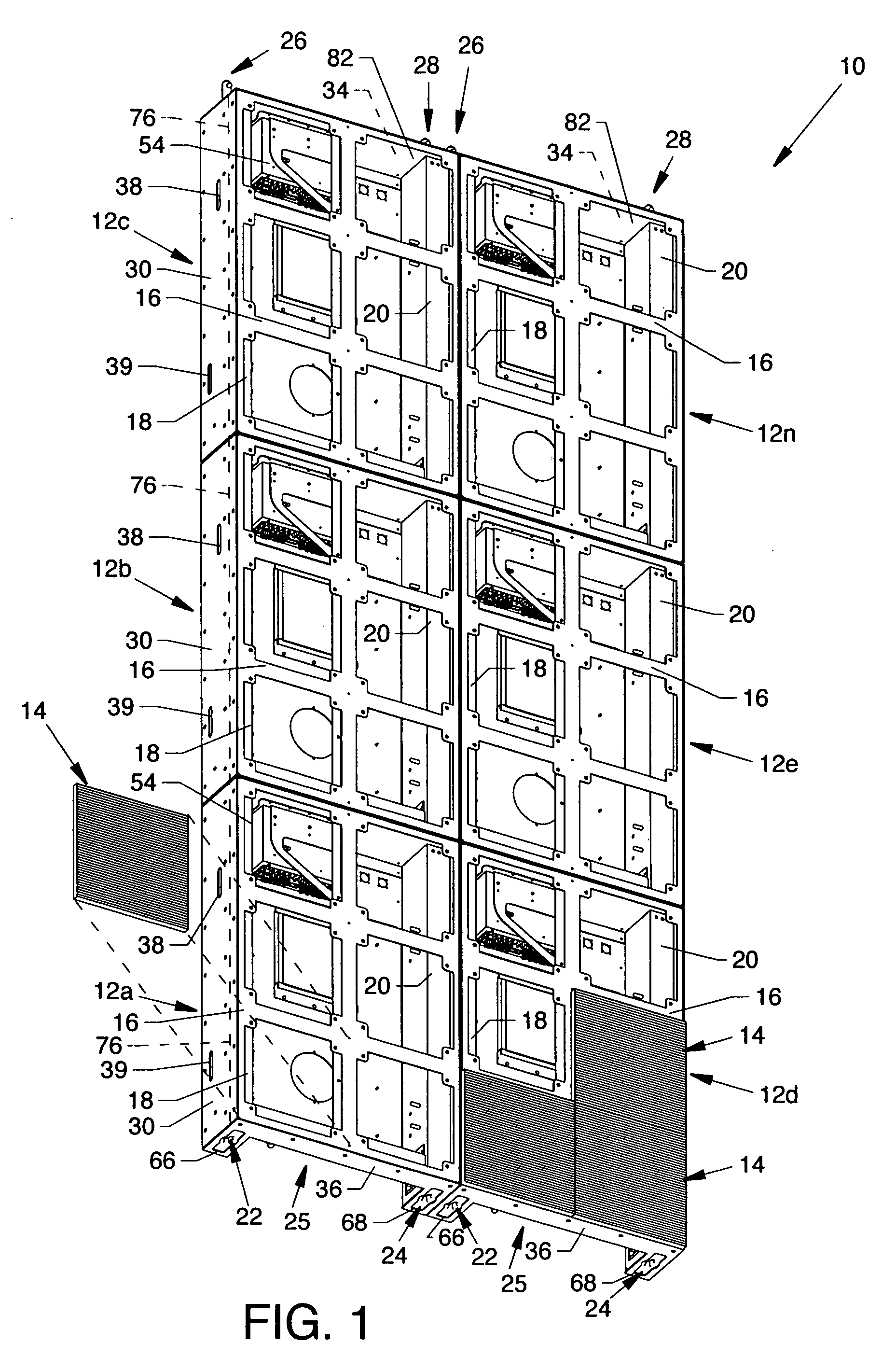

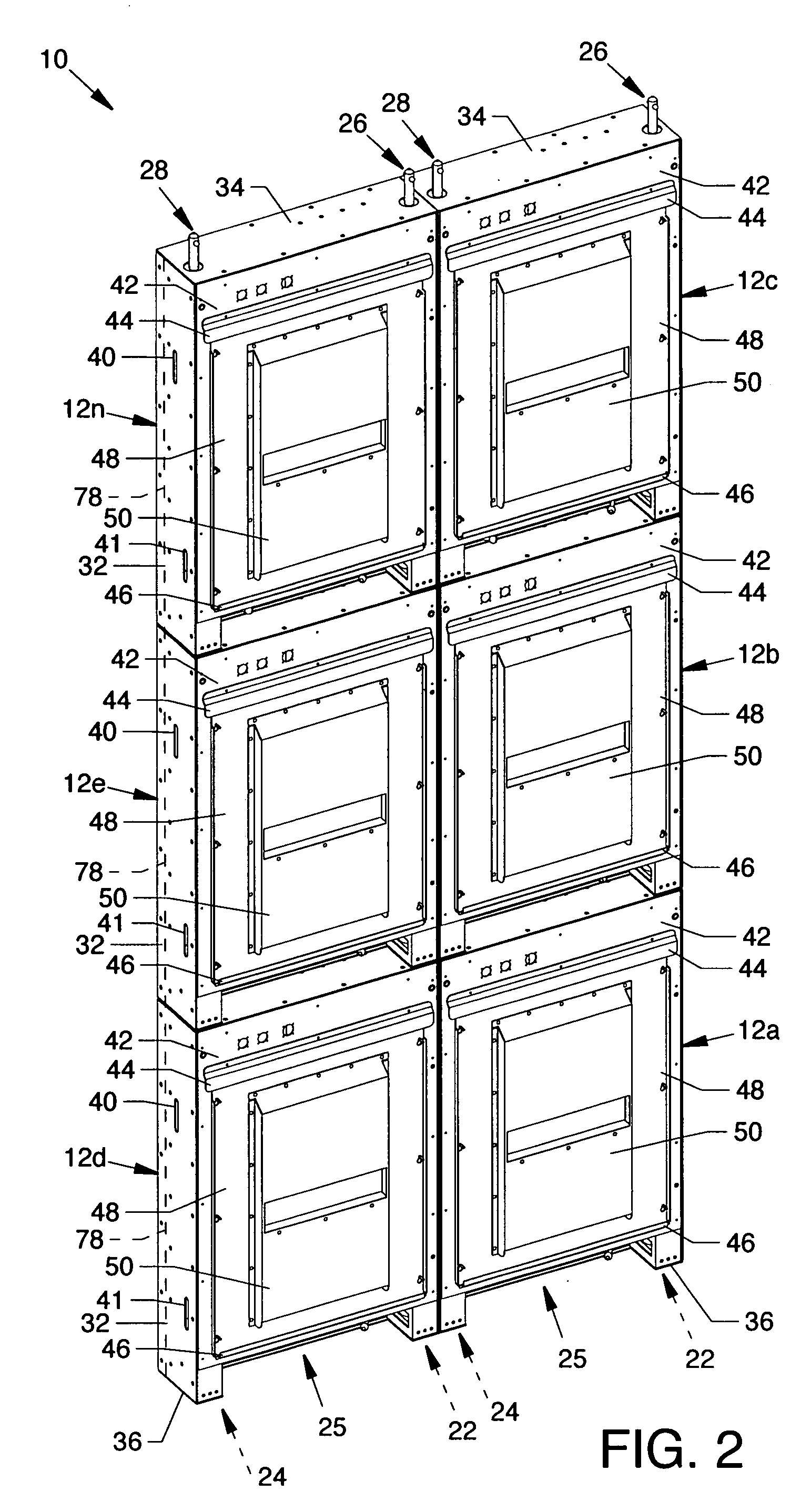

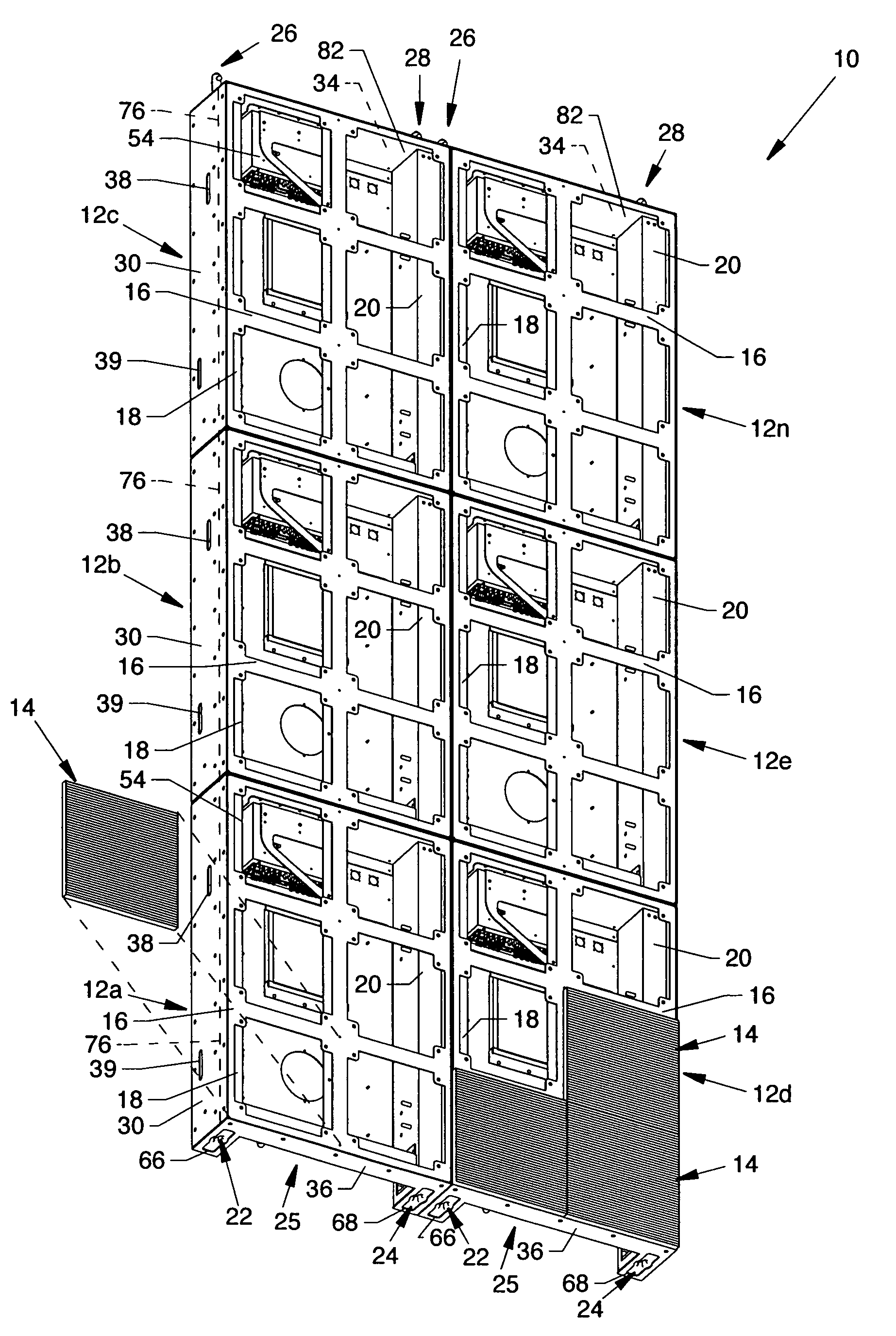

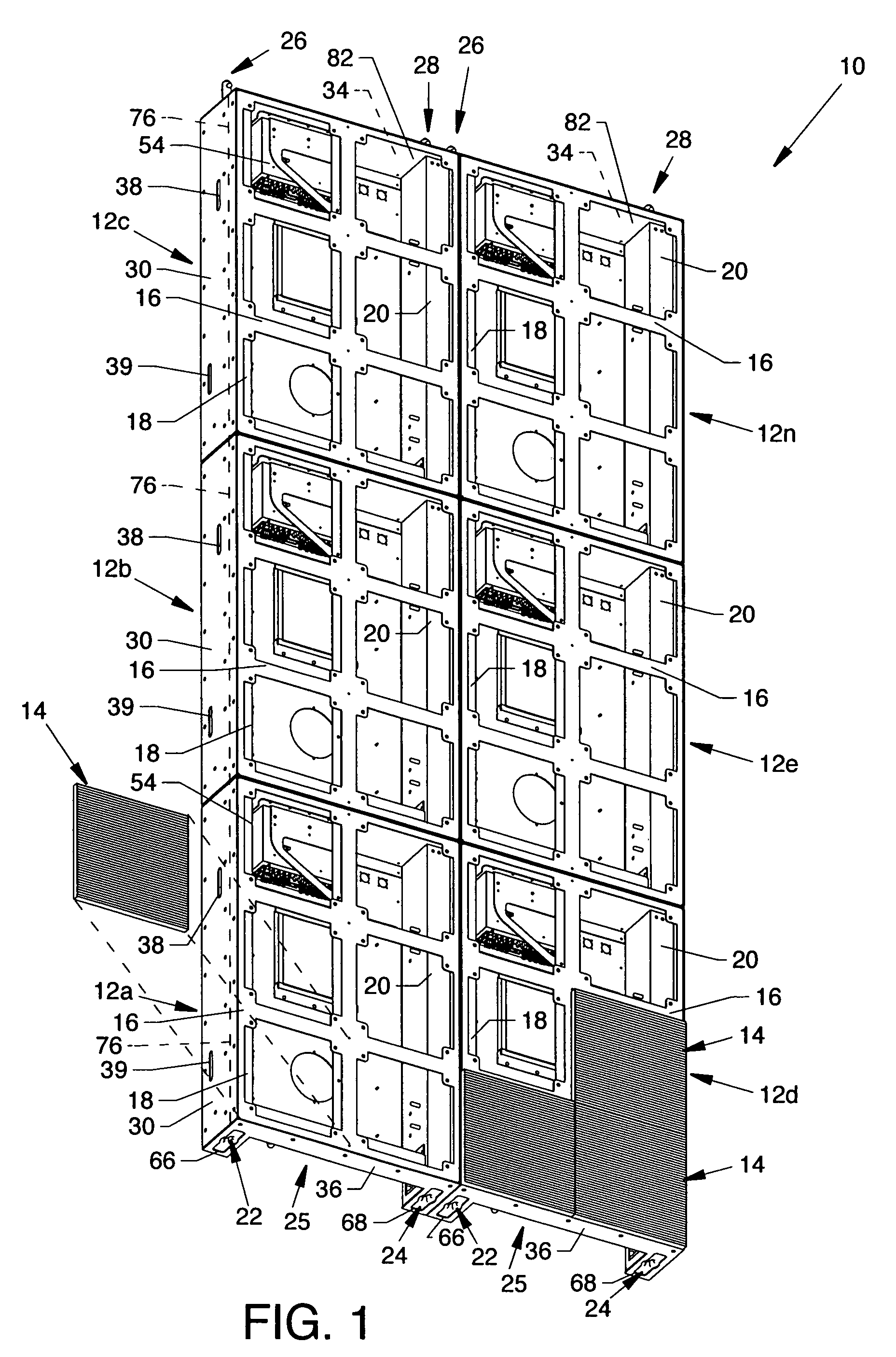

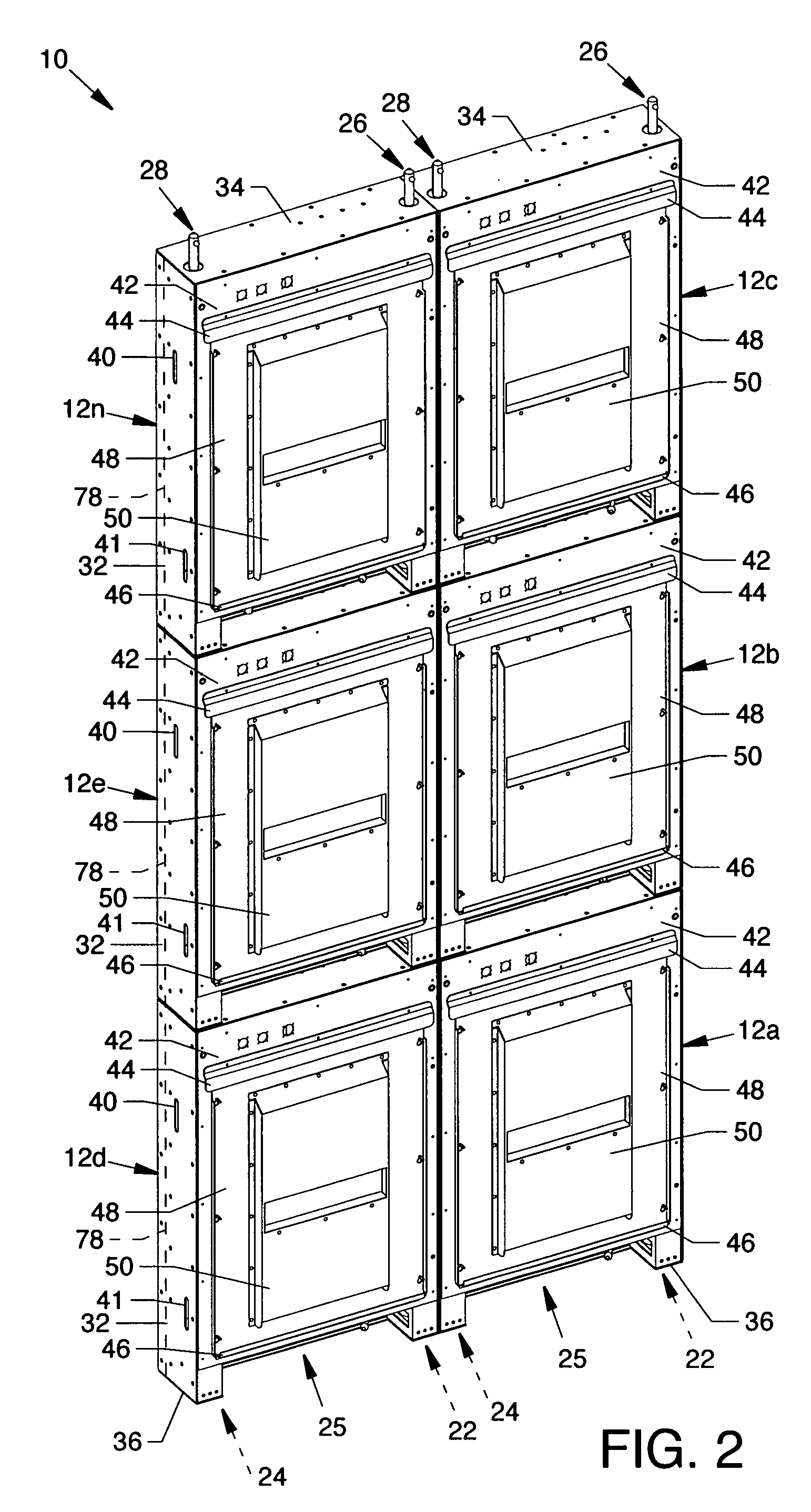

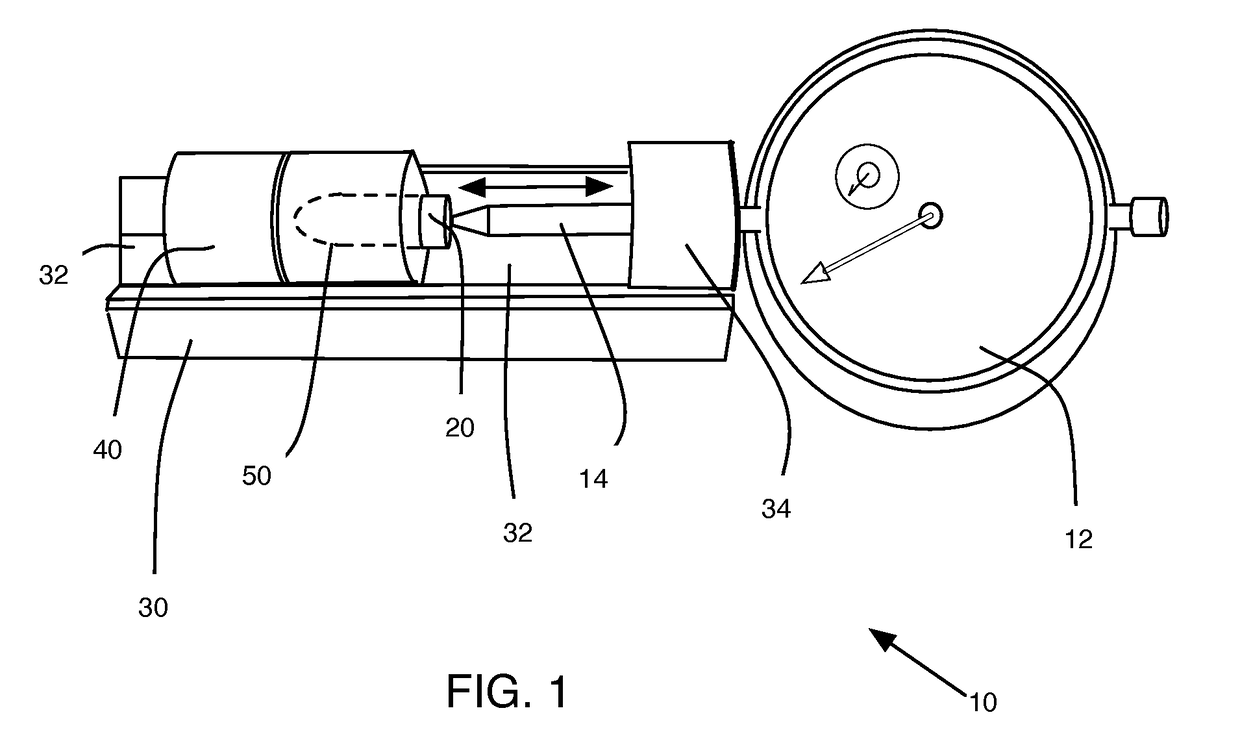

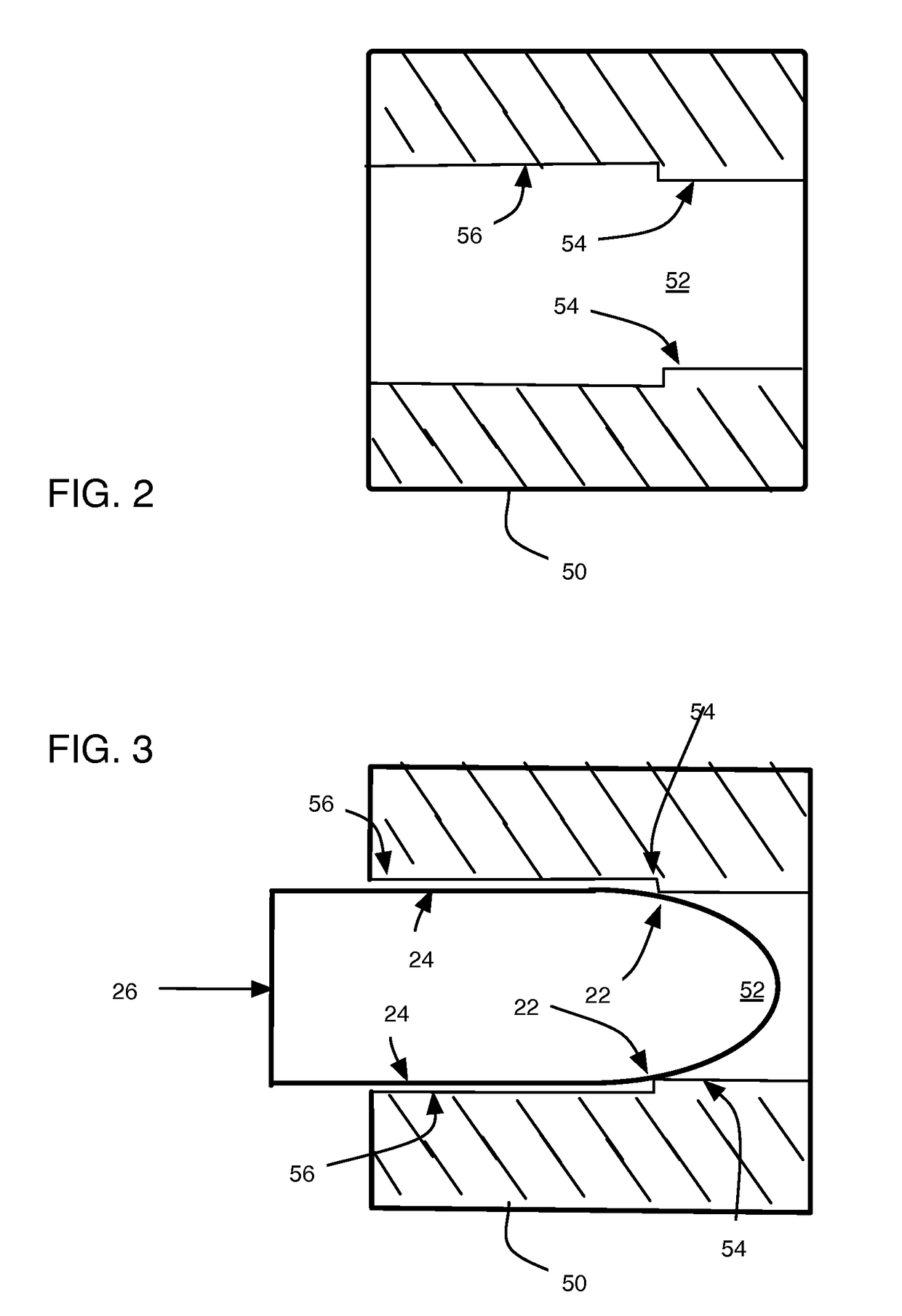

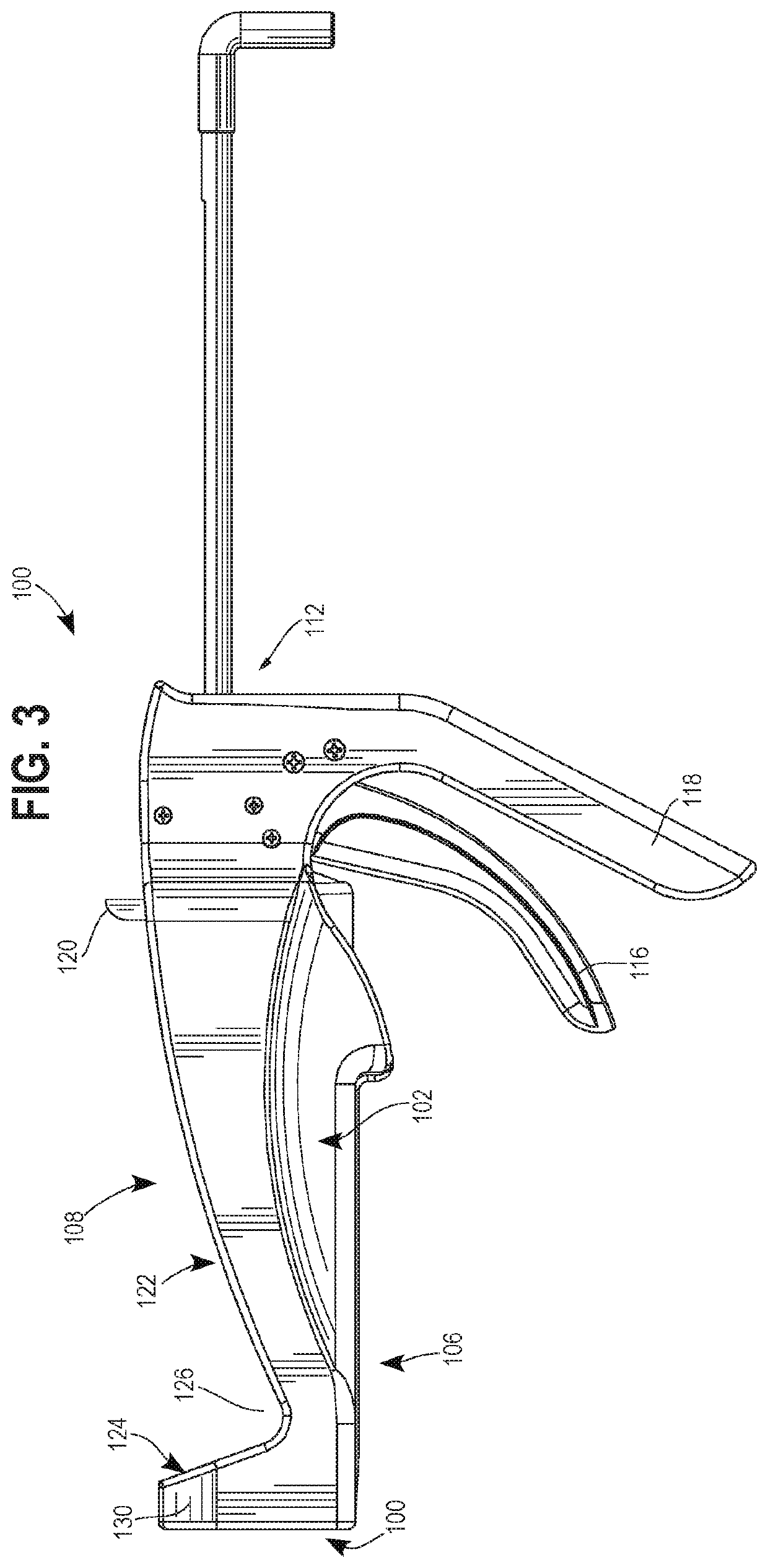

Transportable electronic sign display system

ActiveUS20080263924A1Lengthy set-up timeDown time minimizedRod connectionsCouplings for rigid shaftsModularityComputer module

A transportable electronic sign display system having modular cabinets which support electronic display modules and electronics having male and female latching assemblies connecting adjacent electronic display modules. Robust male and female latching assemblies at the top and bottom of electronic display modules provide for forcible positive action latching between vertically situated electronic display modules to provide a minimally visible horizontally oriented seam therebetween. Side latches between horizontally situated electronic display modules assemblies provide for latching to provide a minimally visible vertically oriented seam therebetween.

Owner:DAKTRONICS

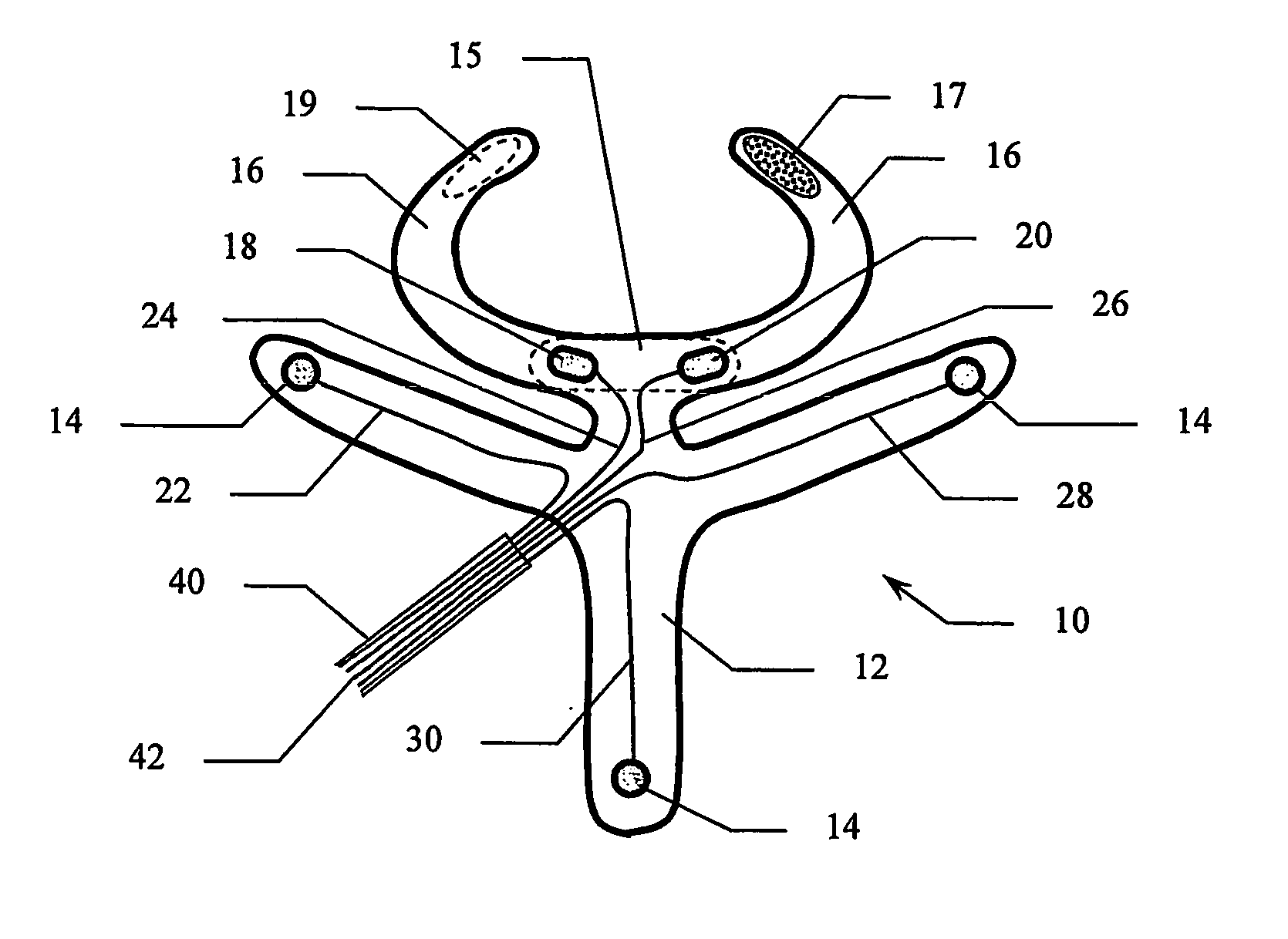

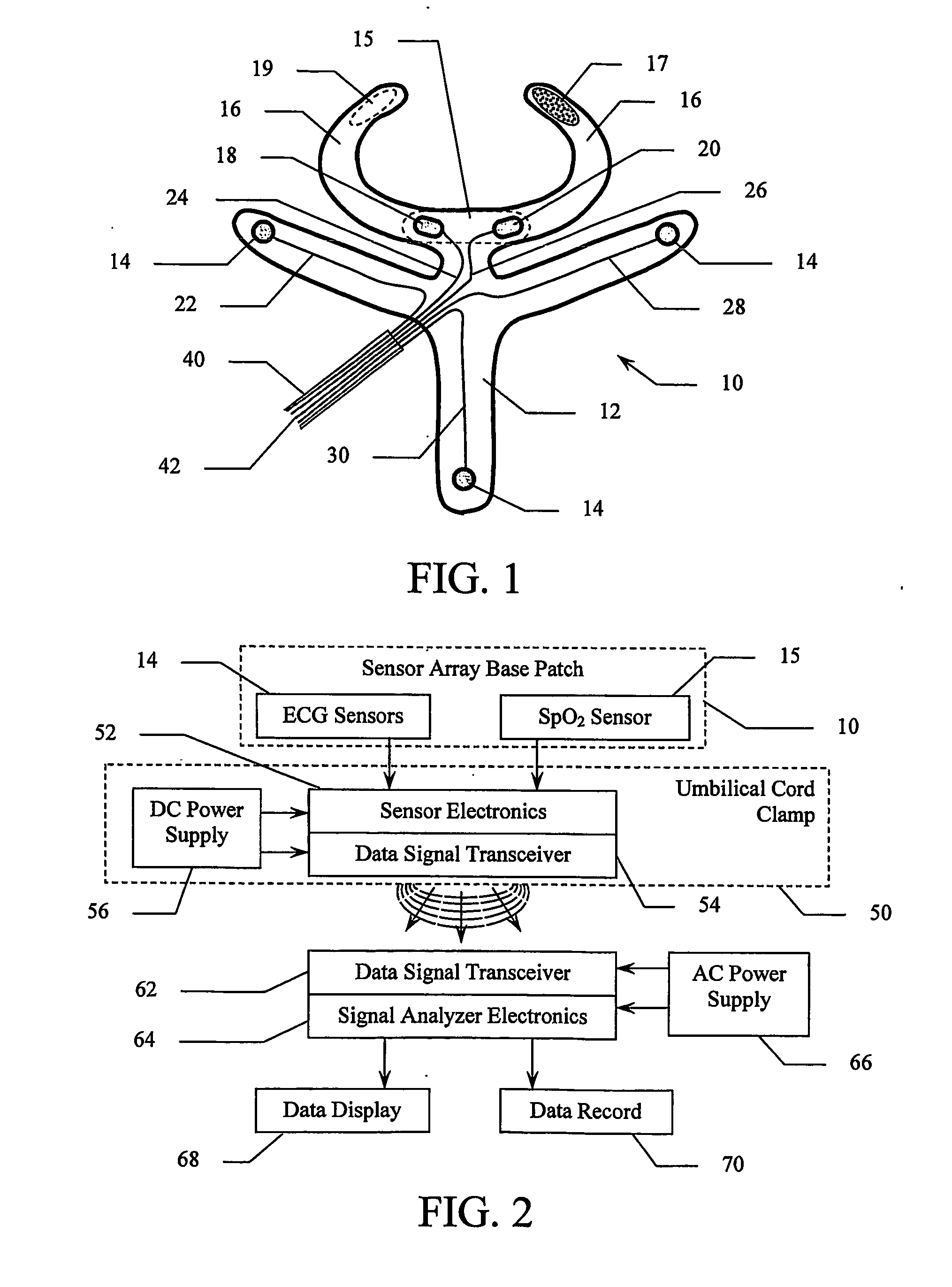

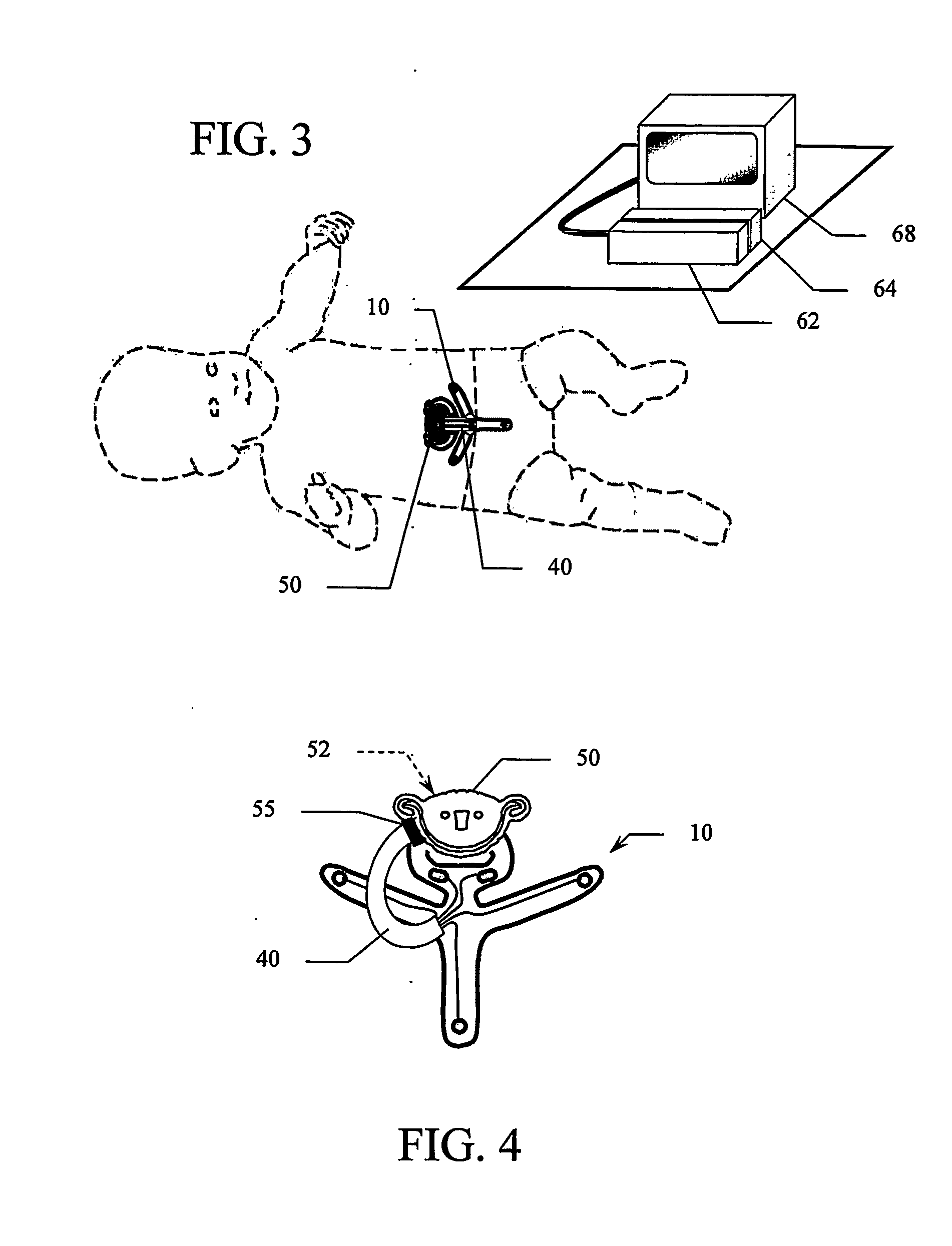

Periumbilical Infant Ecg Sensor and Monitoring System

InactiveUS20070276273A1Low costEliminate needElectrotherapyElectrocardiographyTransceiverMonitoring system

A periumbilical infant ECG sensor for measuring the heartbeat of a newborn infant. The ECG sensor also preferably includes an SAO2 sensor for measuring the oxygen saturation level of the infant's haemoglobin. The ECG sensor is fastenable about the stub of the infant's umbilical cord. The ECG sensor is preferably connected to an electronics module housed in a cavity of an umbilical cord clamp. The electronics module has a power source for supplying power to the ECG sensor and the SAO2 sensor and a transceiver for wirelessly transmitting the ECG and SAO2 signals to a monitoring station.

Owner:WATSON JR RICHARD L

Transportable electronic sign display system

ActiveUS7774968B2Lengthy set-up timeLarge tolerance of initial cabinet placementRod connectionsCouplings for rigid shaftsMobile electronicsElectronics

A transportable electronic sign display system having modular cabinets which support electronic display modules and electronics having male and female latching assemblies connecting adjacent electronic display modules. Robust male and female latching assemblies at the top and bottom of electronic display modules provide for forcible positive action latching between vertically situated electronic display modules to provide a minimally visible horizontally oriented seam therebetween. Side latches between horizontally situated electronic display modules assemblies provide for latching to provide a minimally visible vertically oriented seam therebetween.

Owner:DAKTRONICS

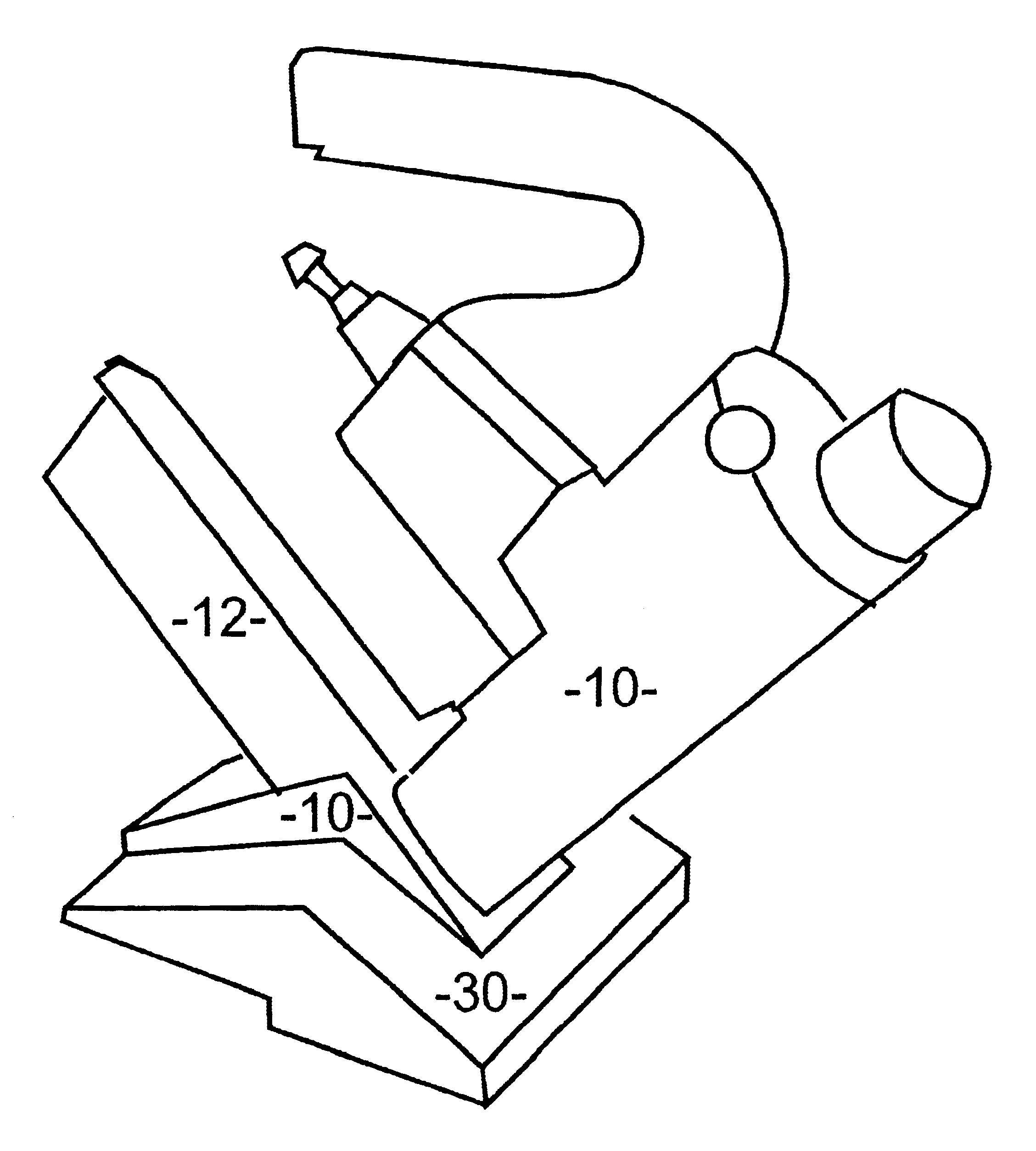

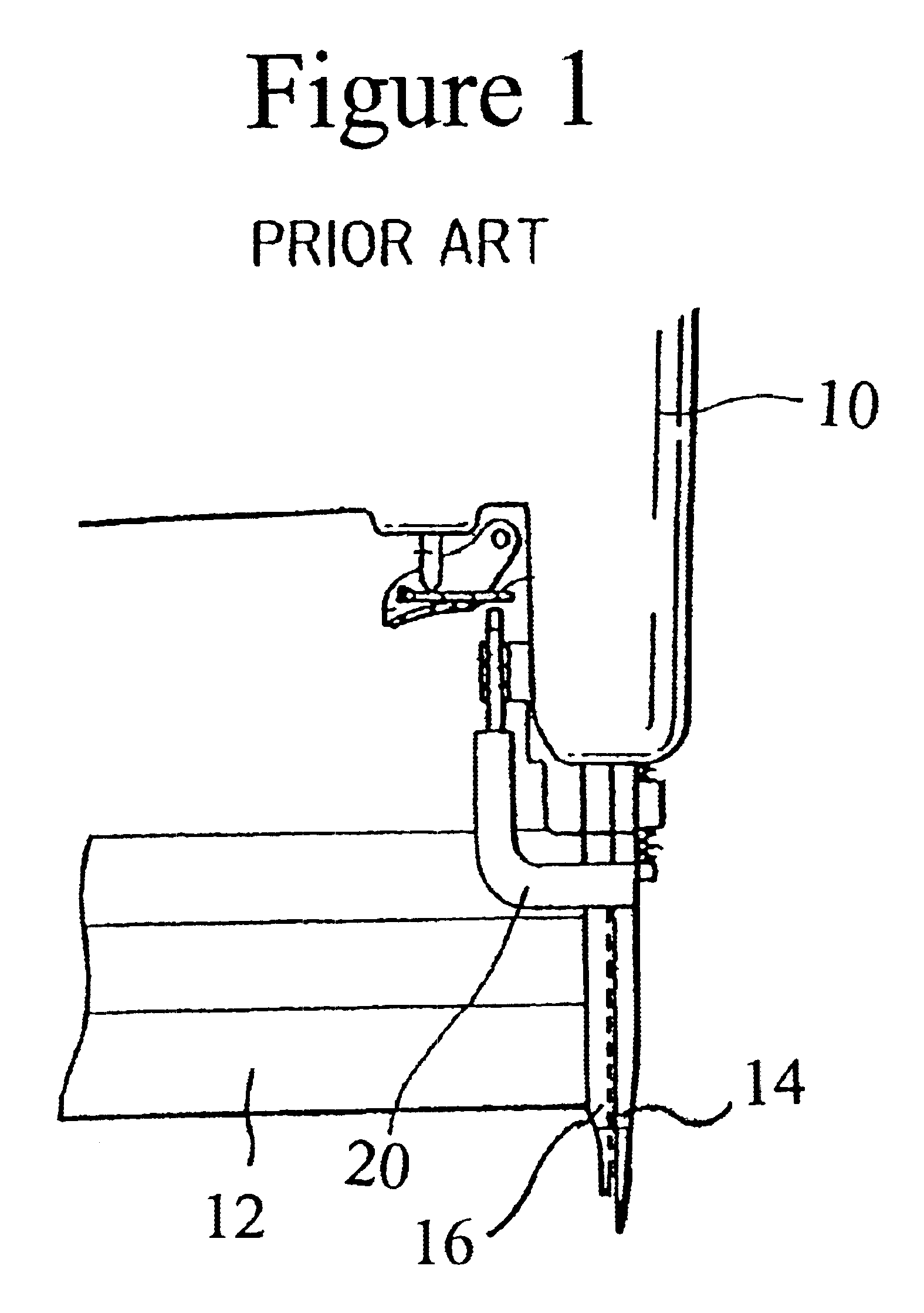

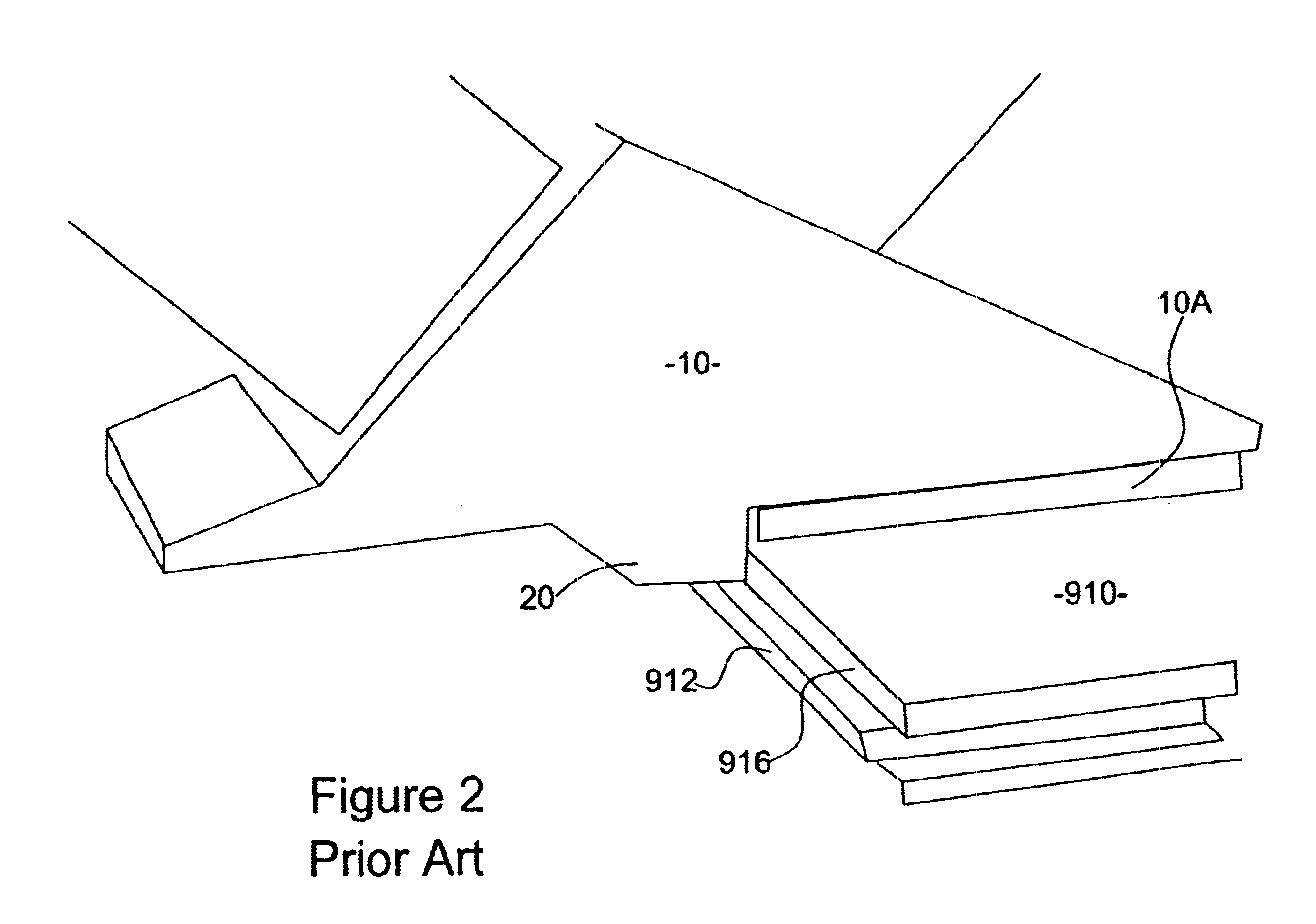

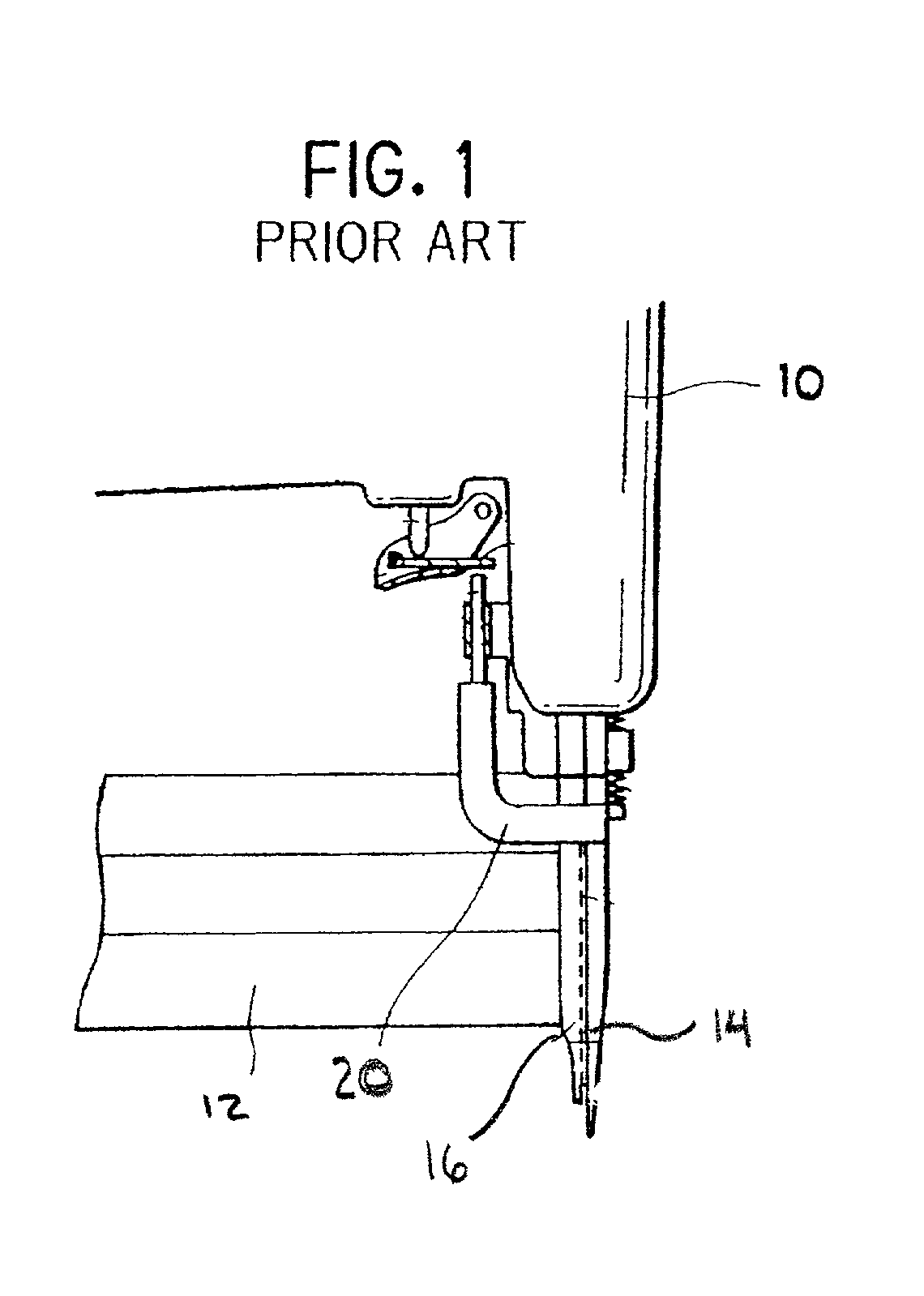

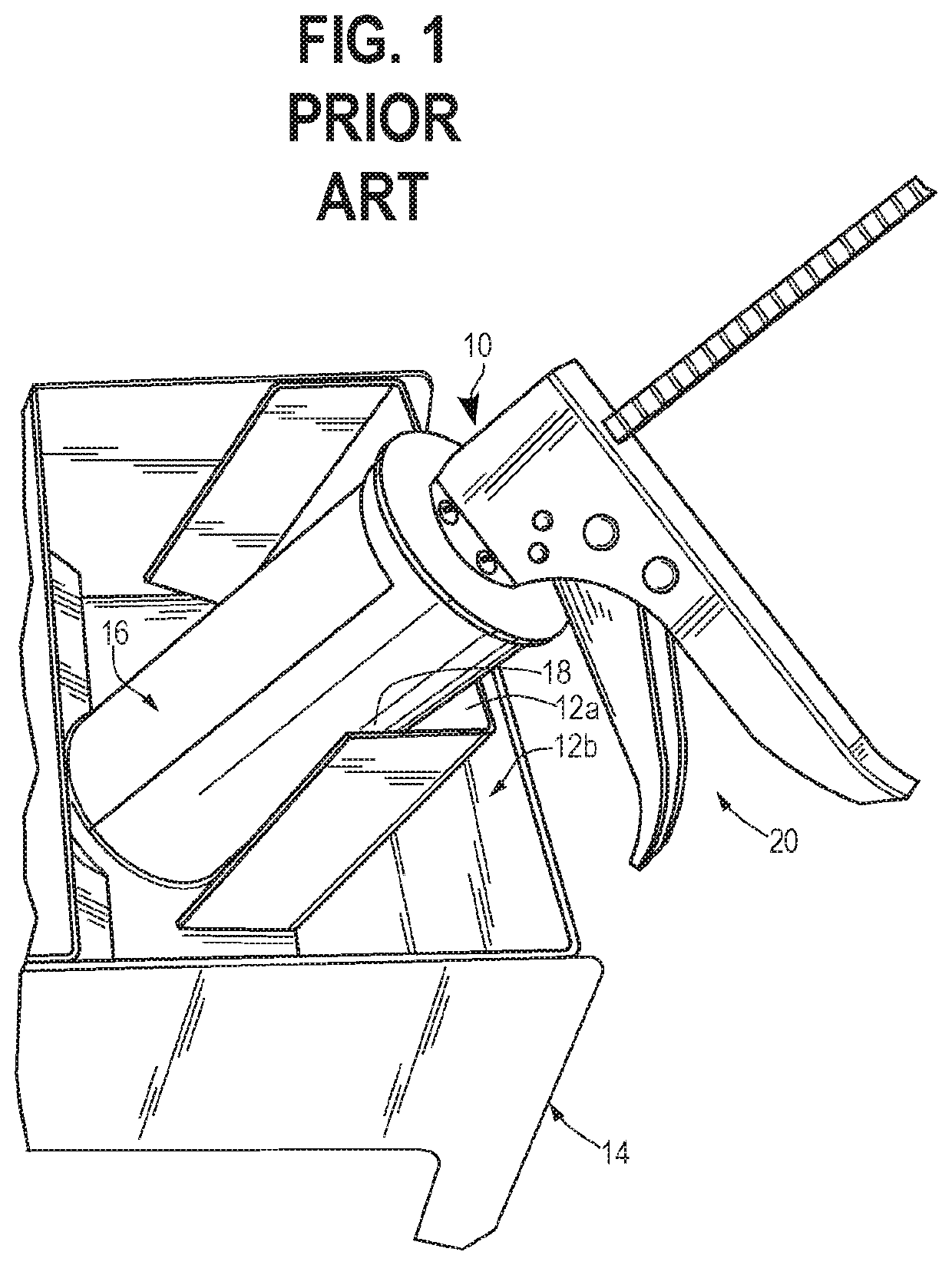

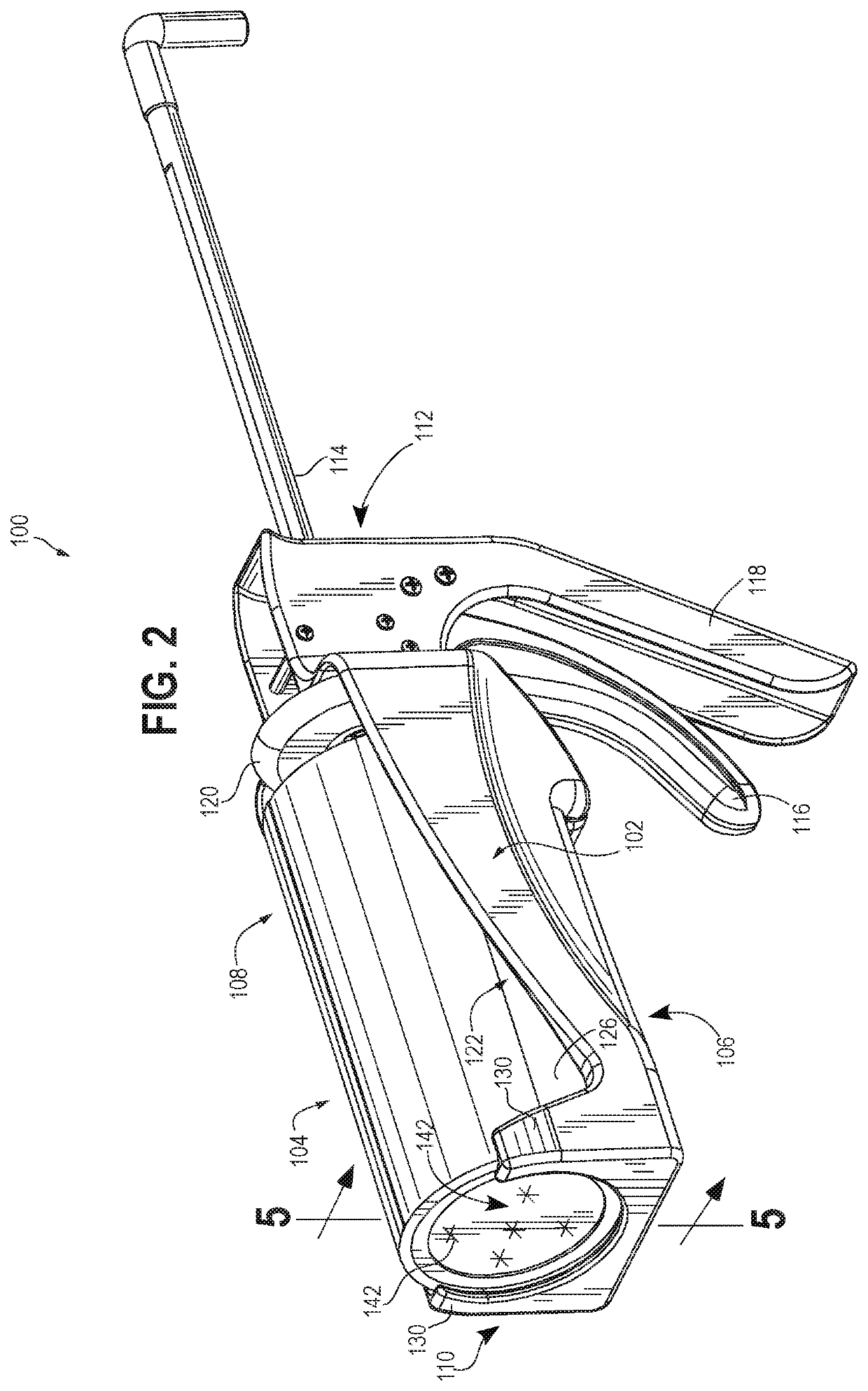

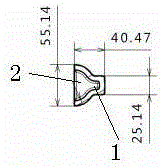

Accessory device for nail and staple guns

InactiveUS6631836B2Eliminate impact damageEasy to useStapling toolsNailing toolsStaple gunTongue and groove

An accessory device for fastener-driving tools such as nail and staple guns is provided. The device serves as a positioning guide for the tool and is designed to provide sufficient spacing and orientation between the fastener-driving tool and the target construction material. The device can be integrated into the body of the fastener-driving tool, manufactured as an attachment or manufactured as a separate tool. It prevents impact marring at the visible surface of the construction material by redirecting the force of the blow to a non-visible surface on the assembled construction material. Furthermore it increases speed and ease of movement for the user by serving as a guide for stability and ease of alignment. The device changes the impact point between the driving tool and the construction material, broadens the area of impact and protects the top edge of a tongue and groove construction material from impact damage.< / PTEXT>

Owner:DICKHAUT JOHN

Accessory device for nail and staple guns

An accessory device for fastener-driving tools such as nail and staple guns is provided. The device serves as a positioning guide for the tool and is designed to provide sufficient spacing and orientation between the fastener-driving tool and the target construction material. The device can be integrated into the body of the fastener-driving tool, manufactured as an attachment or manufactured as a separate tool. It prevents impact marring at the visible surface of the construction material by redirecting the force of the blow to a non-visible surface on the assembled construction material. Furthermore it increases speed and ease of movement for the user by serving as a guide for stability and ease of alignment. The device changes the impact point between the driving tool and the construction material, broadens the area of impact and protects the top edge of a tongue and groove construction material from impact damage.

Owner:DICKHAUT JOHN

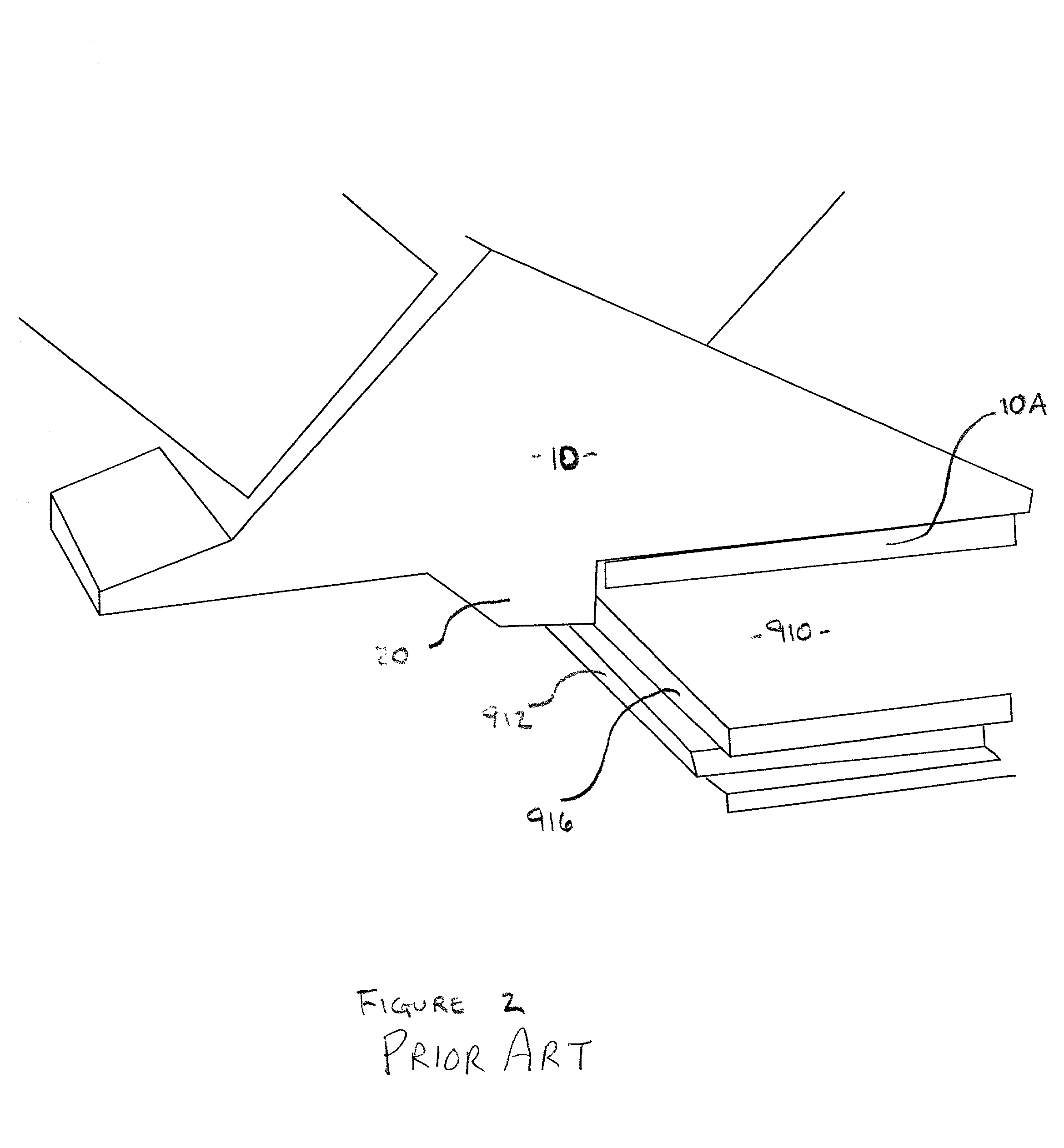

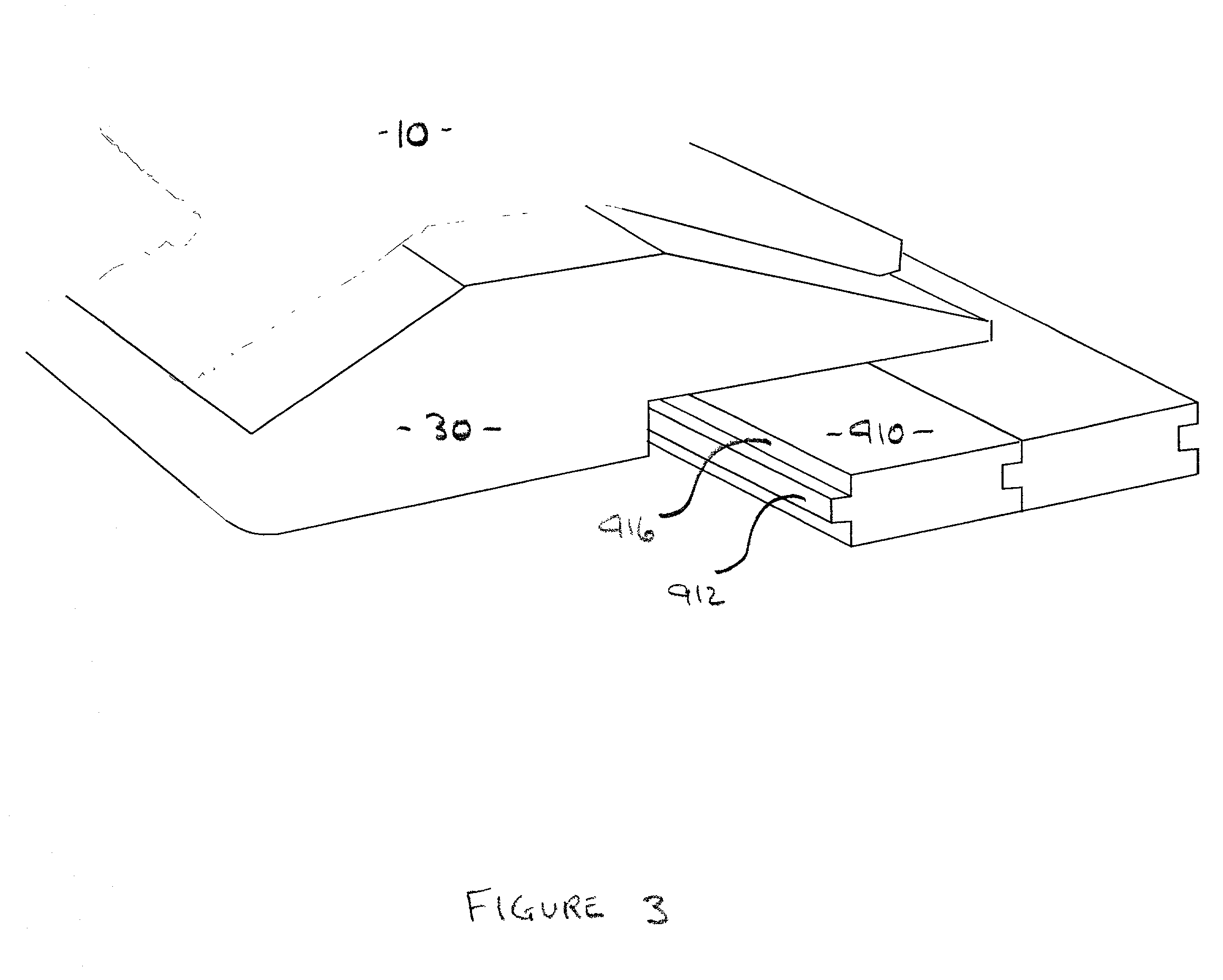

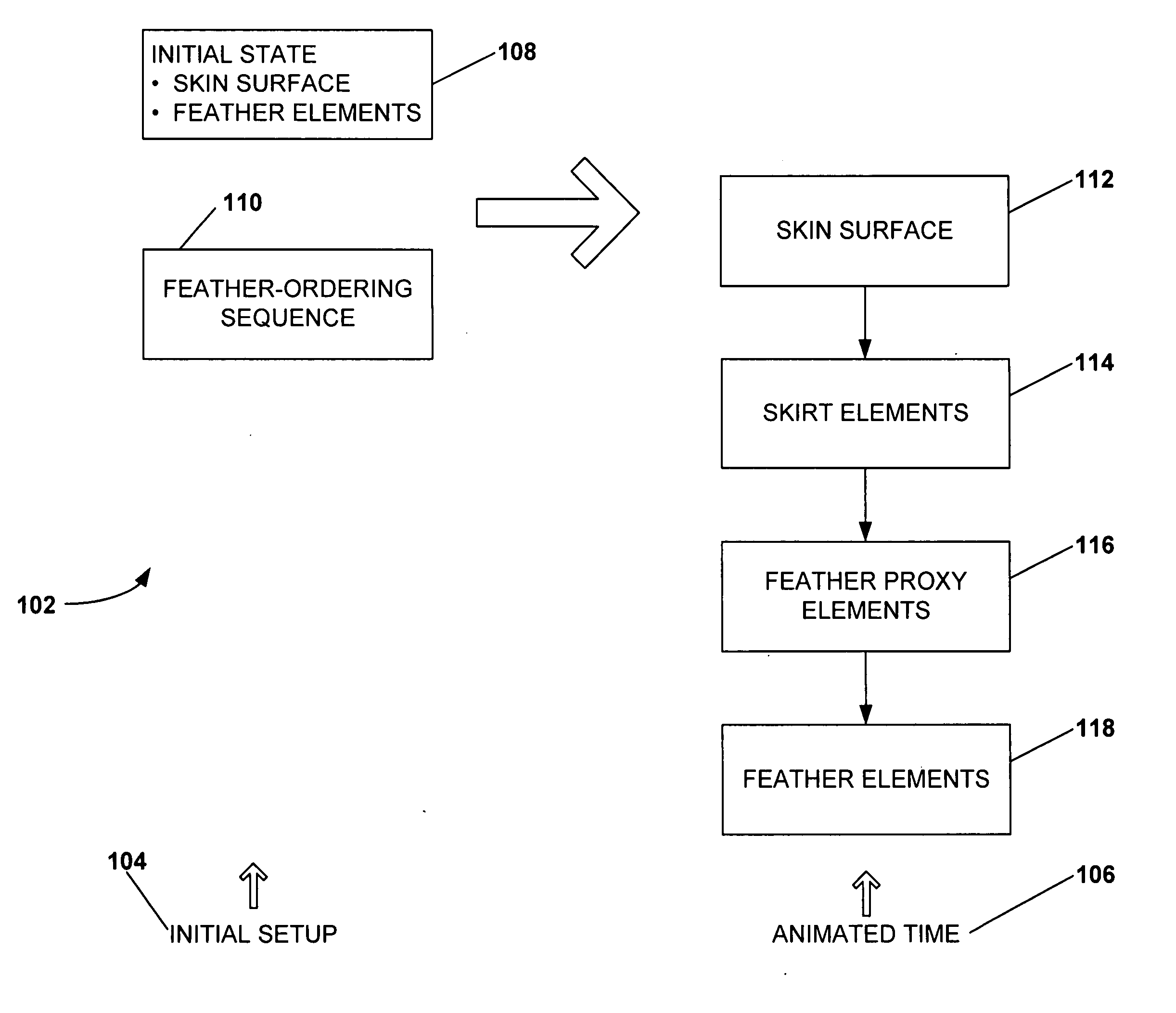

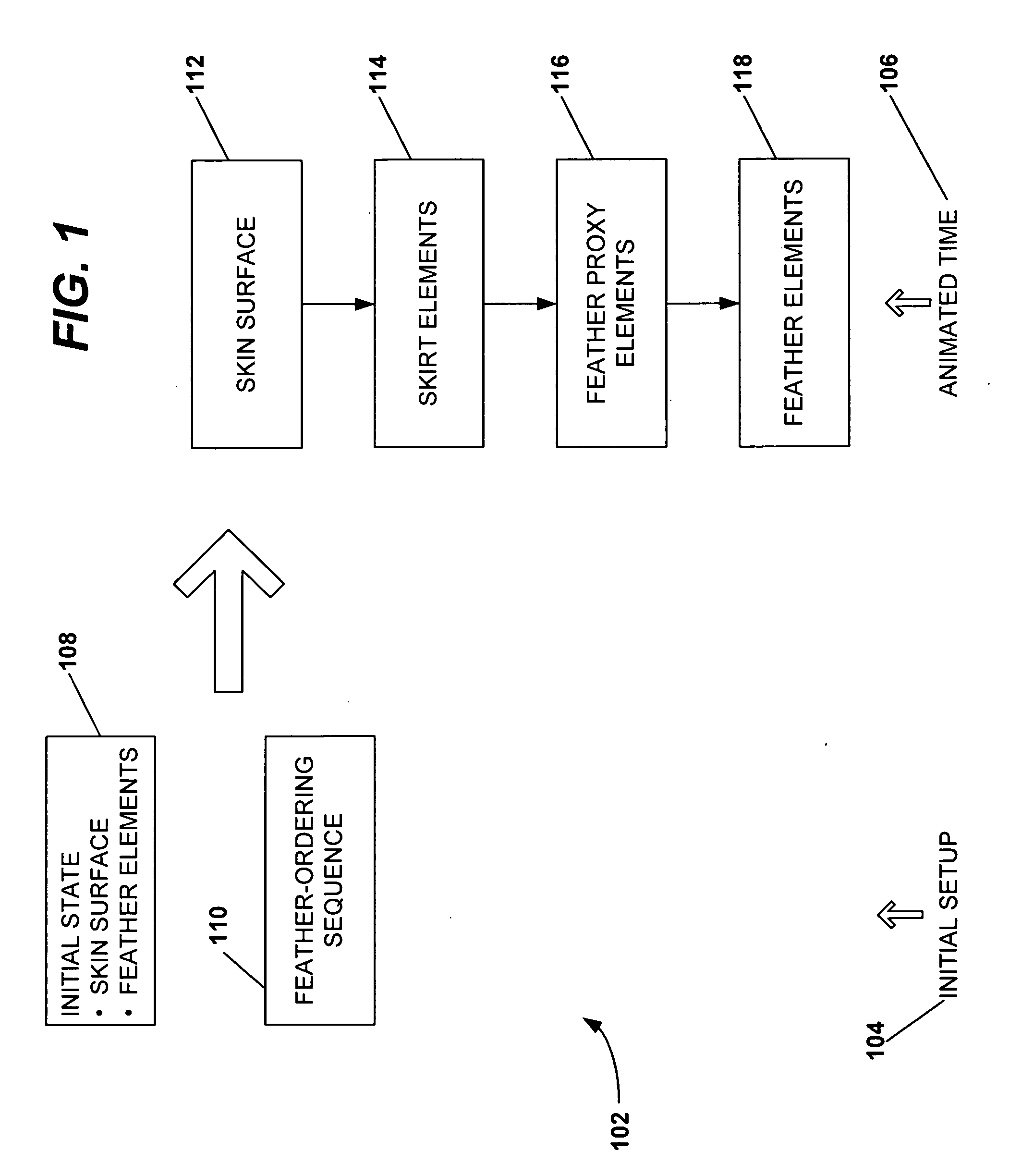

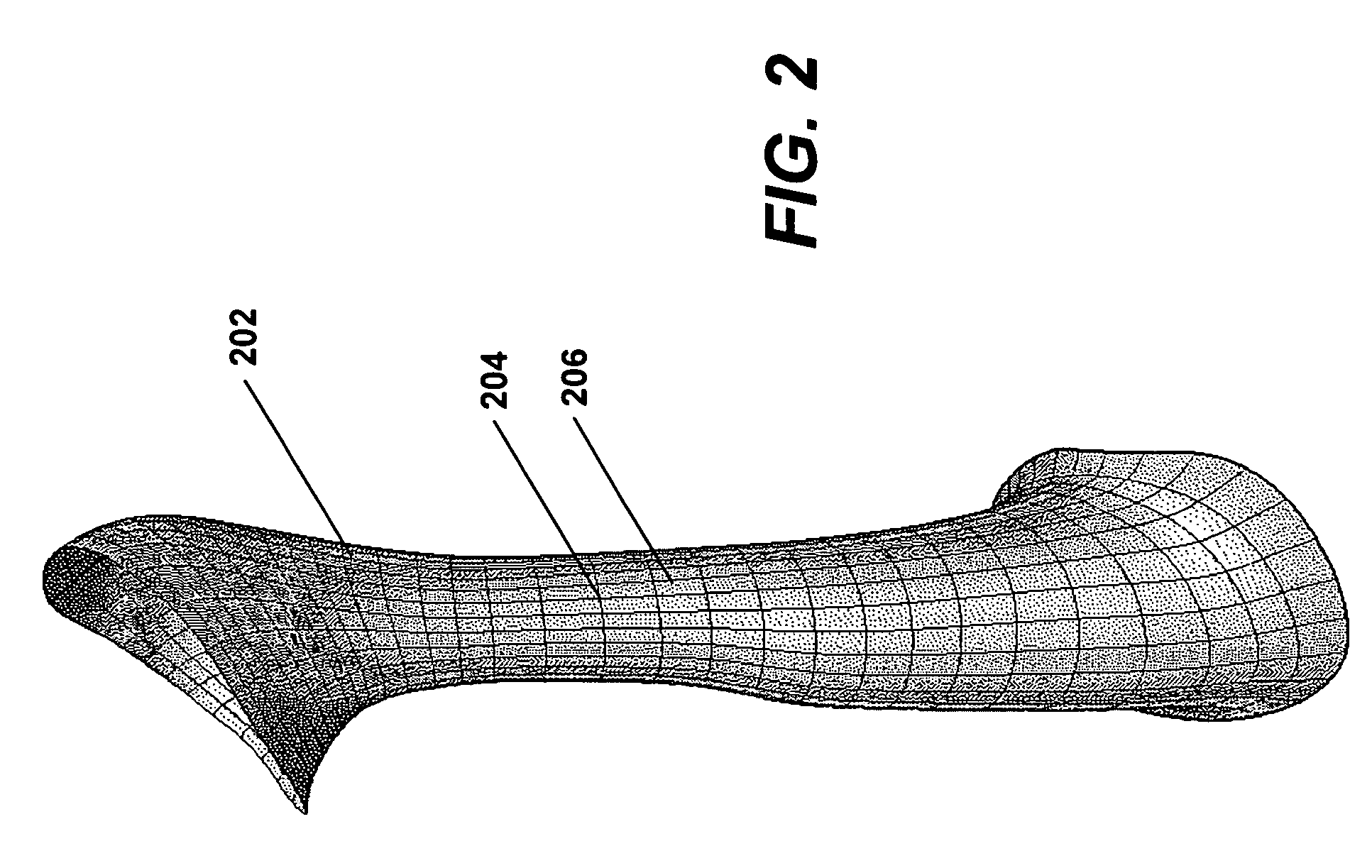

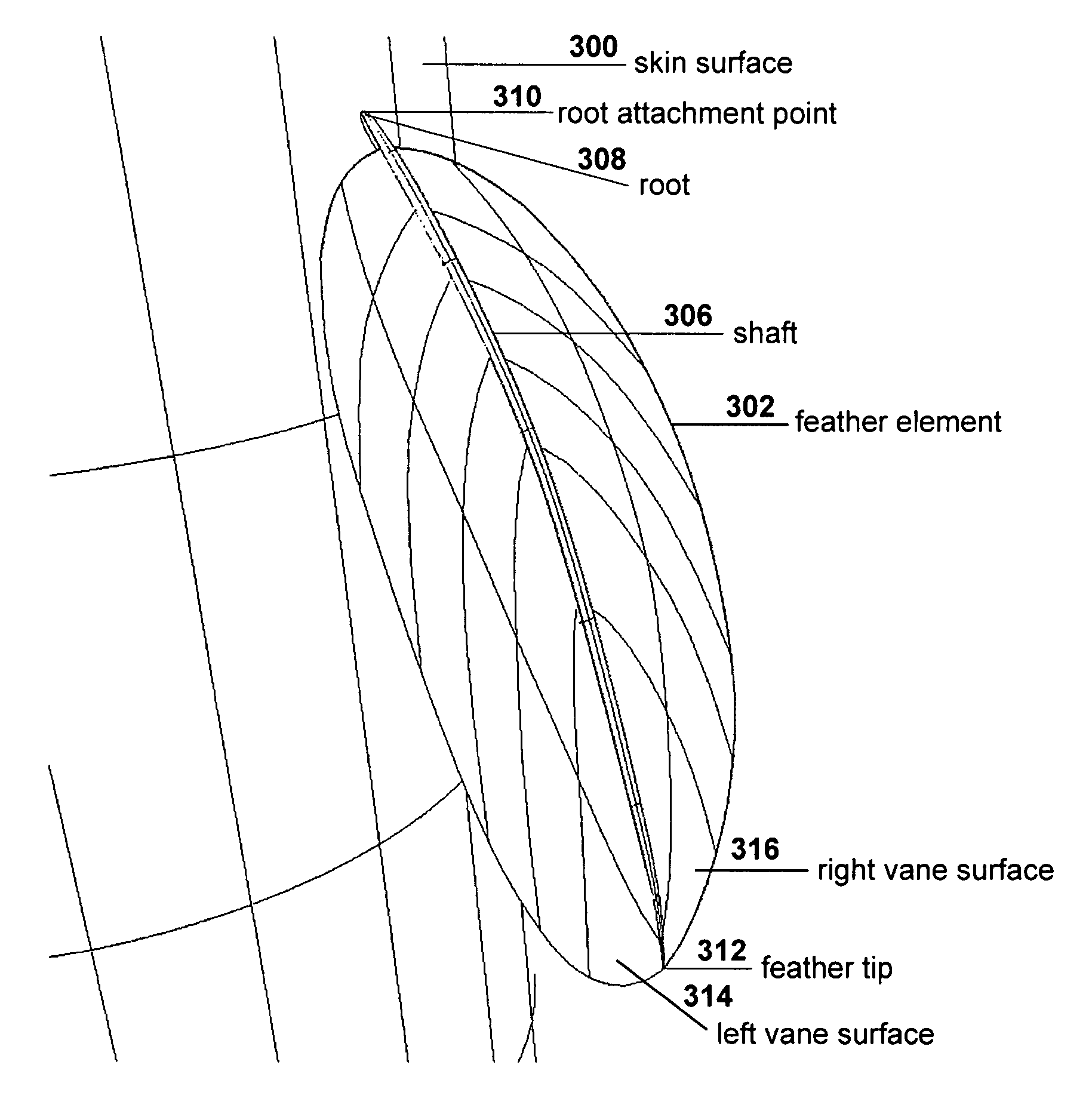

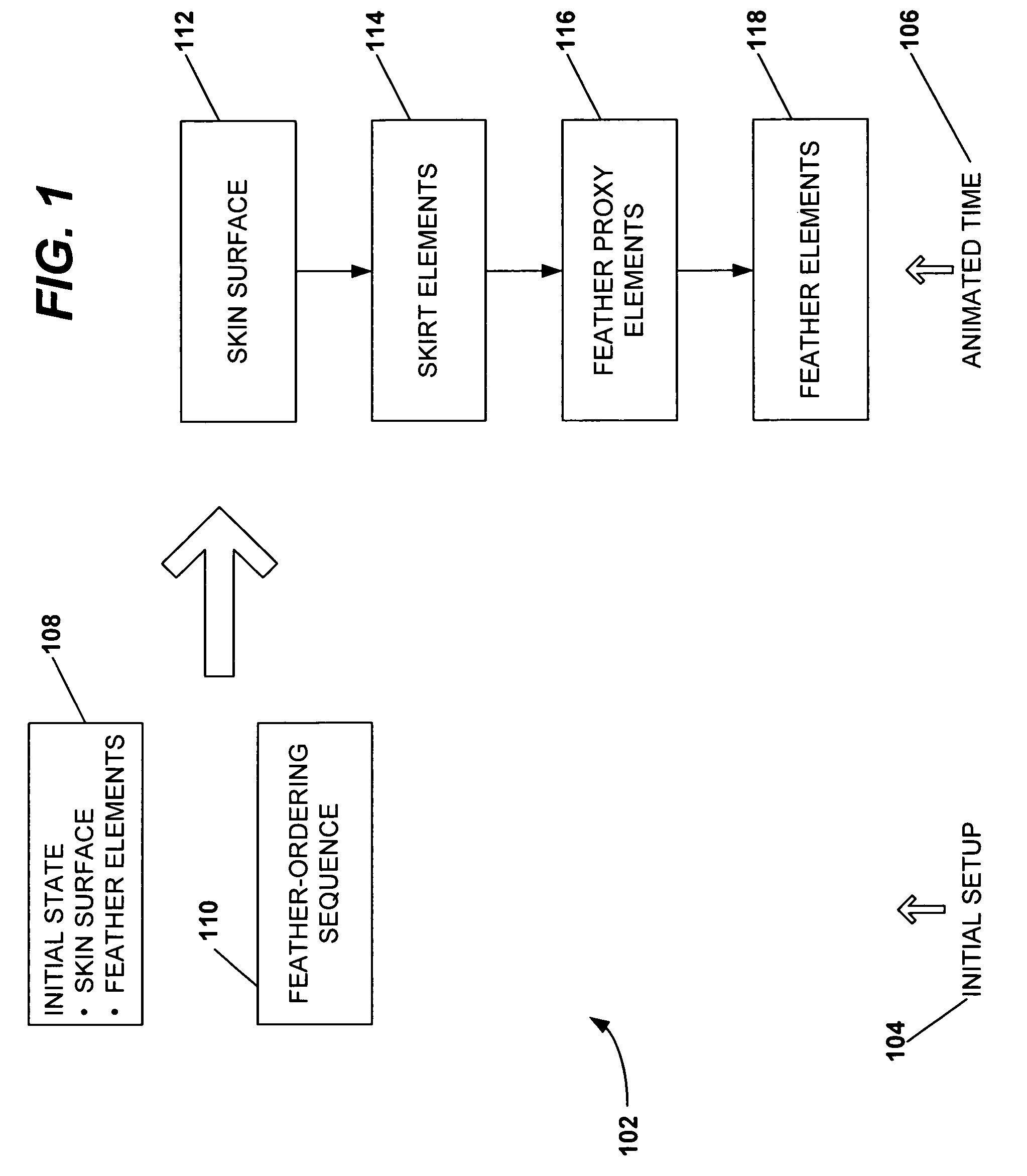

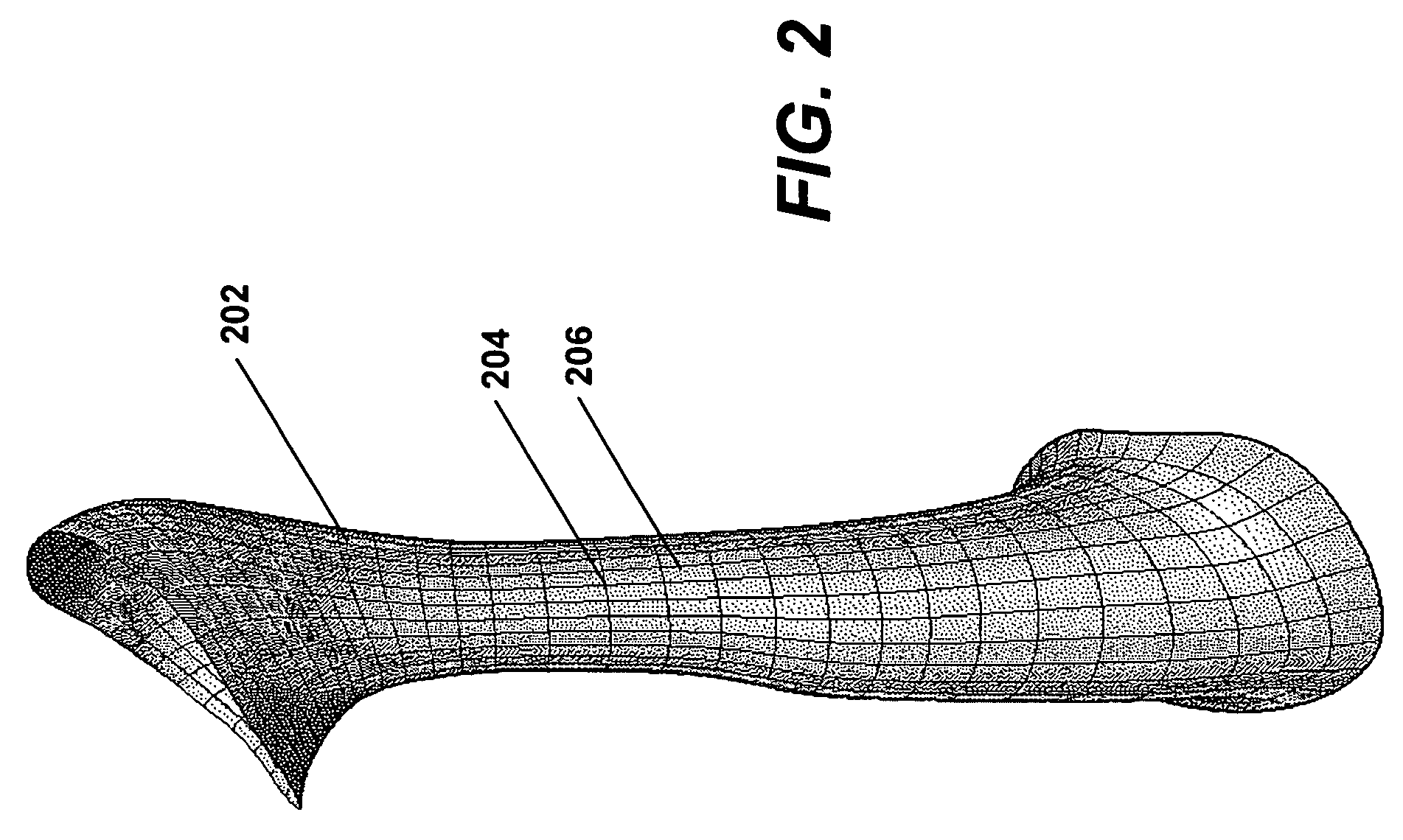

Layering method for feather animation

ActiveUS20070270092A1Avoid intersectionConsistent placementSkinning instrumentsDrawing from basic elementsAnimationSkin surfaces

A method of animating feather elements includes: specifying initial positions for a skin surface and for feather elements; specifying positions for the skin surface at an animated time; determining a feather-ordering sequence for placing the feather elements on the skin surface; determining positions for skirt elements that provide spatial extensions for the skin surface at the animated time; determining positions for feather-proxy elements that provide spatial extensions for the feather elements at the animated time; and determining positions for the feather elements at the animated time by extracting the feather elements from the feather-proxy elements. The feather-proxy elements are determined from the skirt elements according to the feather-ordering sequence, and the feather-proxy elements satisfy a separation criterion for avoiding intersections between the feather-proxy elements.

Owner:DREAMWORKS ANIMATION LLC

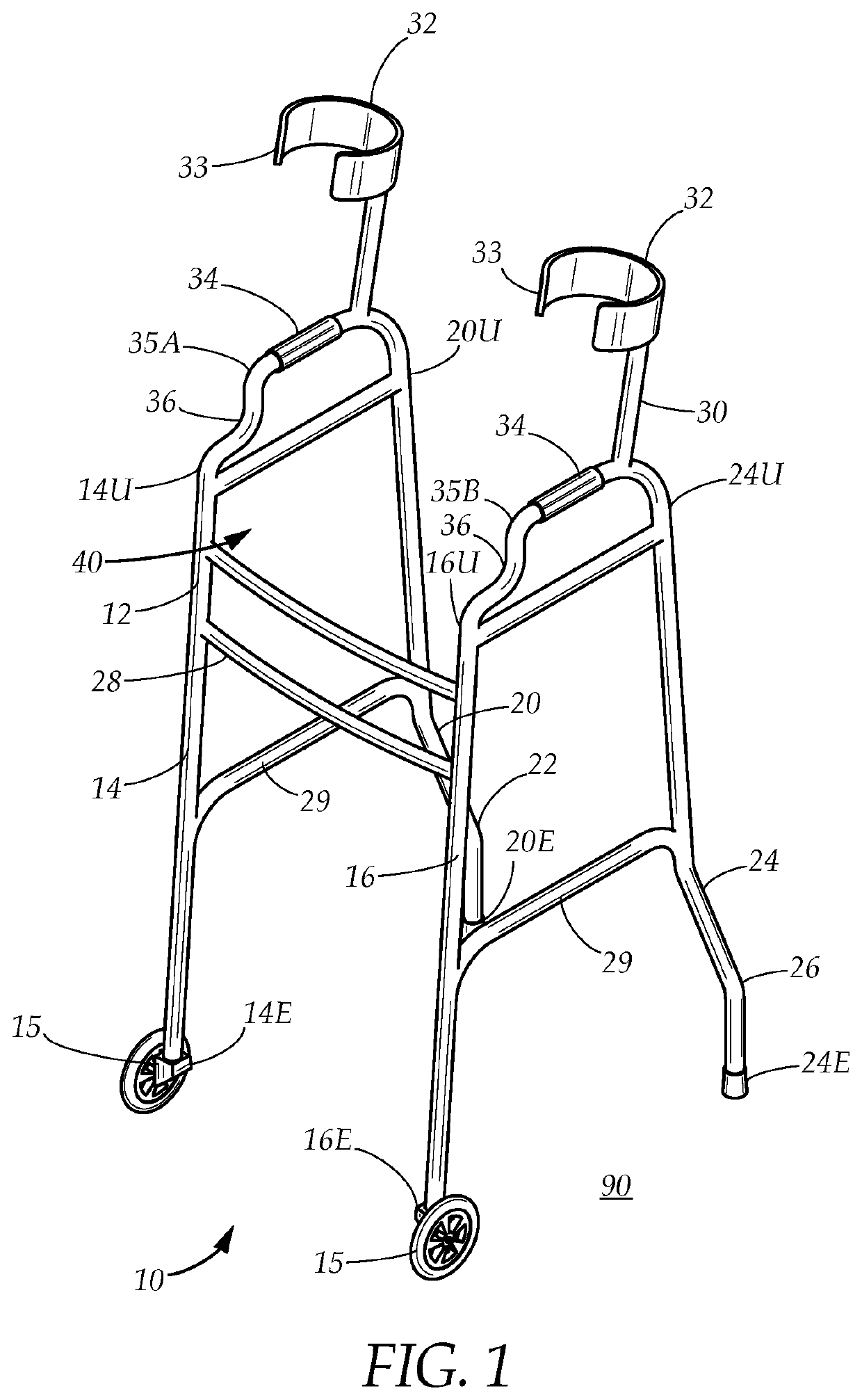

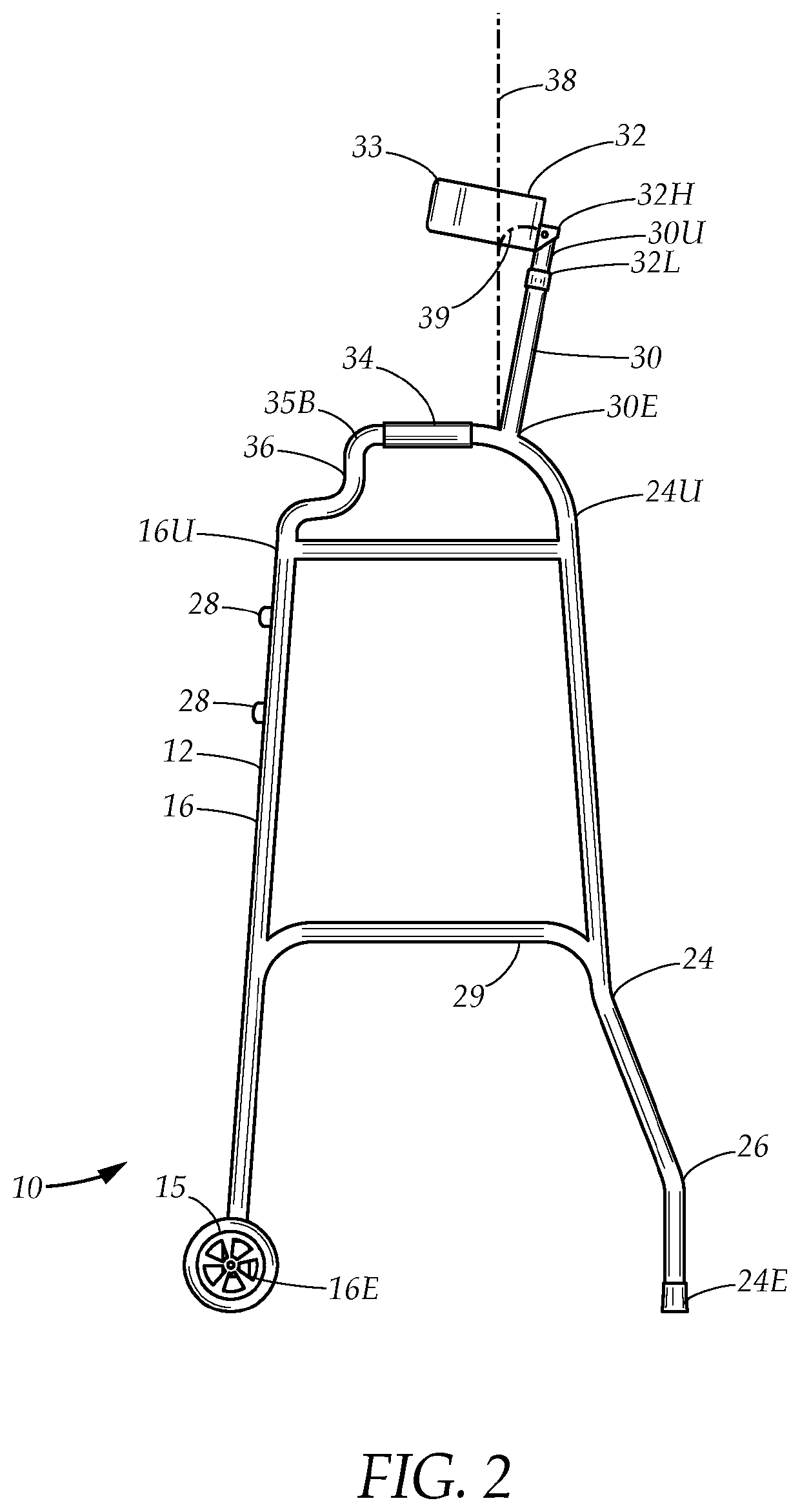

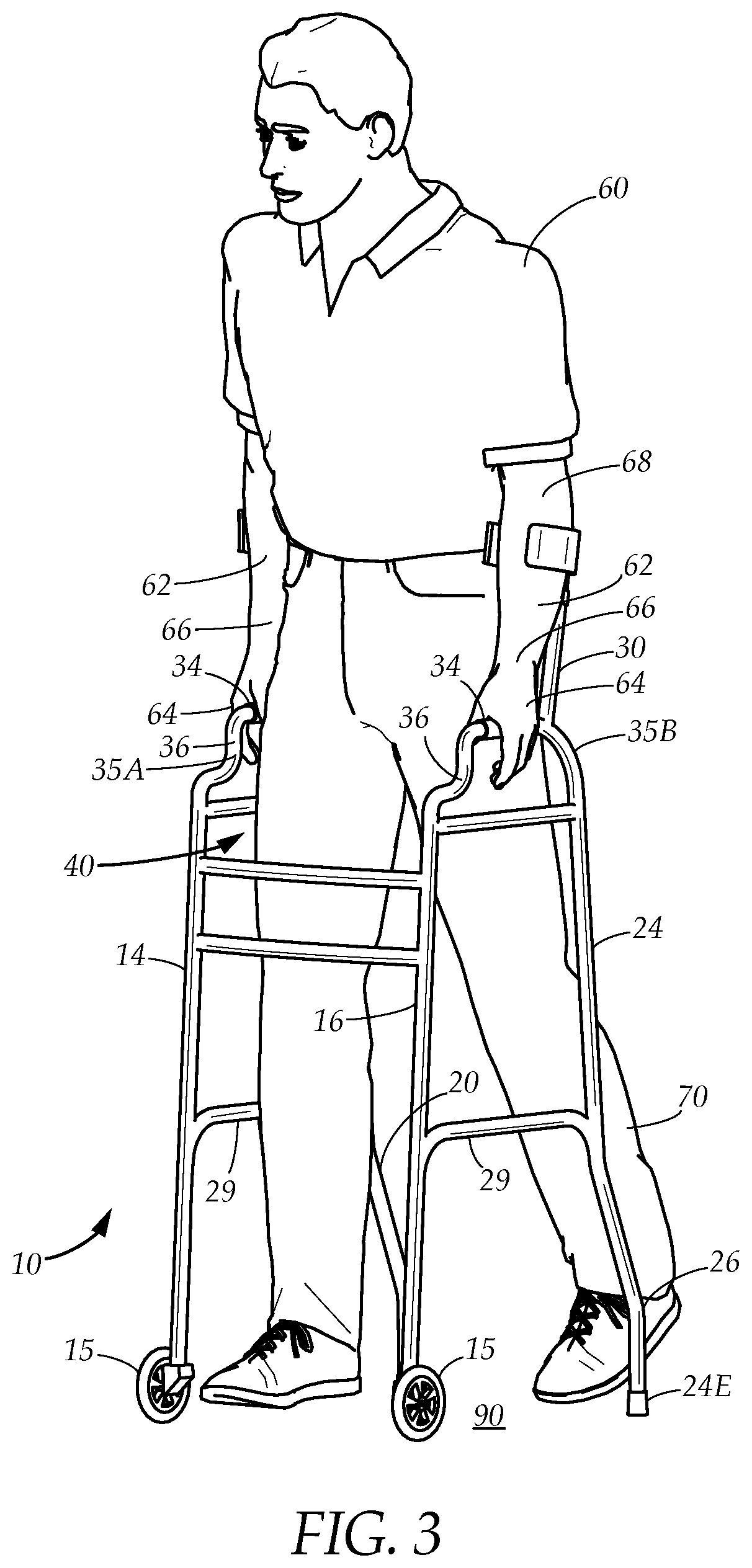

Posture-correcting walker

ActiveUS10583065B1Safe transferAccurate transferChiropractic devicesWalking aidsPhysical medicine and rehabilitationEngineering

A posture-correcting walker for assisting a user in performing safe ambulation, comprising a frame having a pair of front legs and a pair of rear legs joined together by a pair of horizontal supports, a pair of handgrips positioned on the horizontal supports, and a pair of forearm guiding supports which project upwardly at a rearward angle which are adapted to maintain the user's elbows and forearms at a guided posture angle during ambulation to ensure correct walking posture with the user's legs maintained within the frame. The forearm guiding supports each have a retaining cradle which supports the forearms and restricts rearward and sideways motion. The walker further has a descending segment ahead of each handgrip to ensure correct placement of the hands, as well as a pair of stabilizing segments which cause the rear legs to project rearwardly which stabilize the walker.

Owner:MEJIA MELANIE

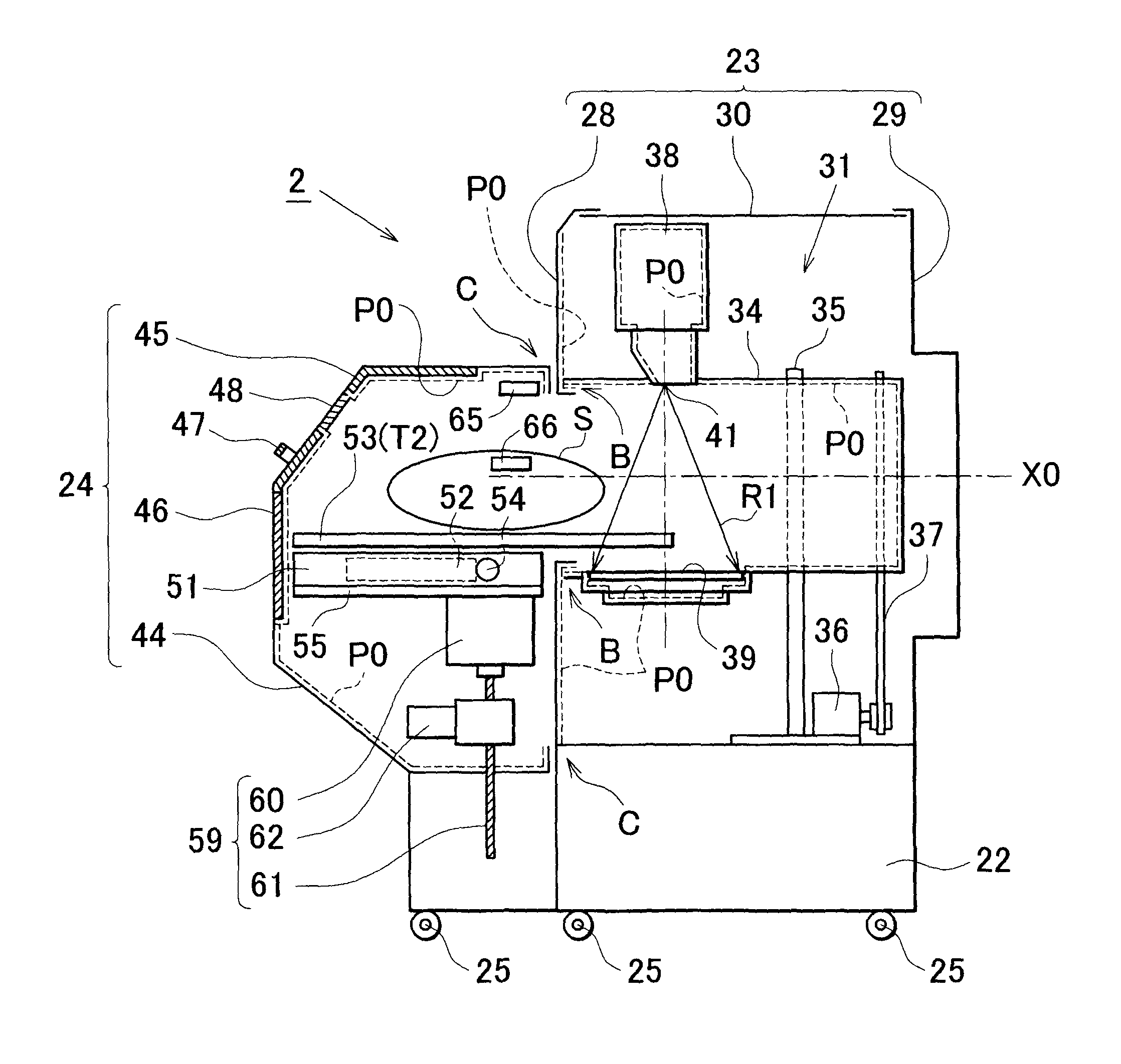

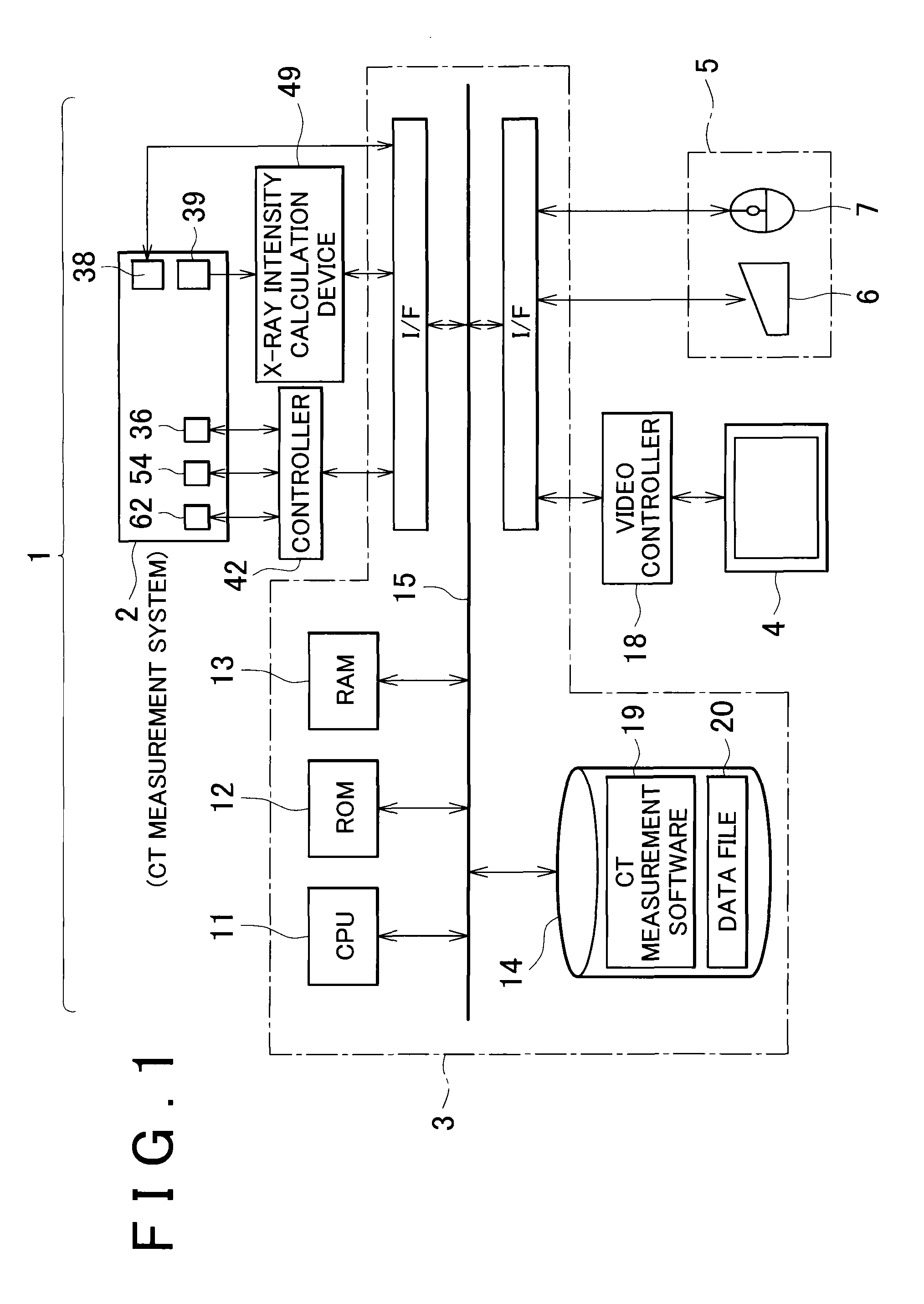

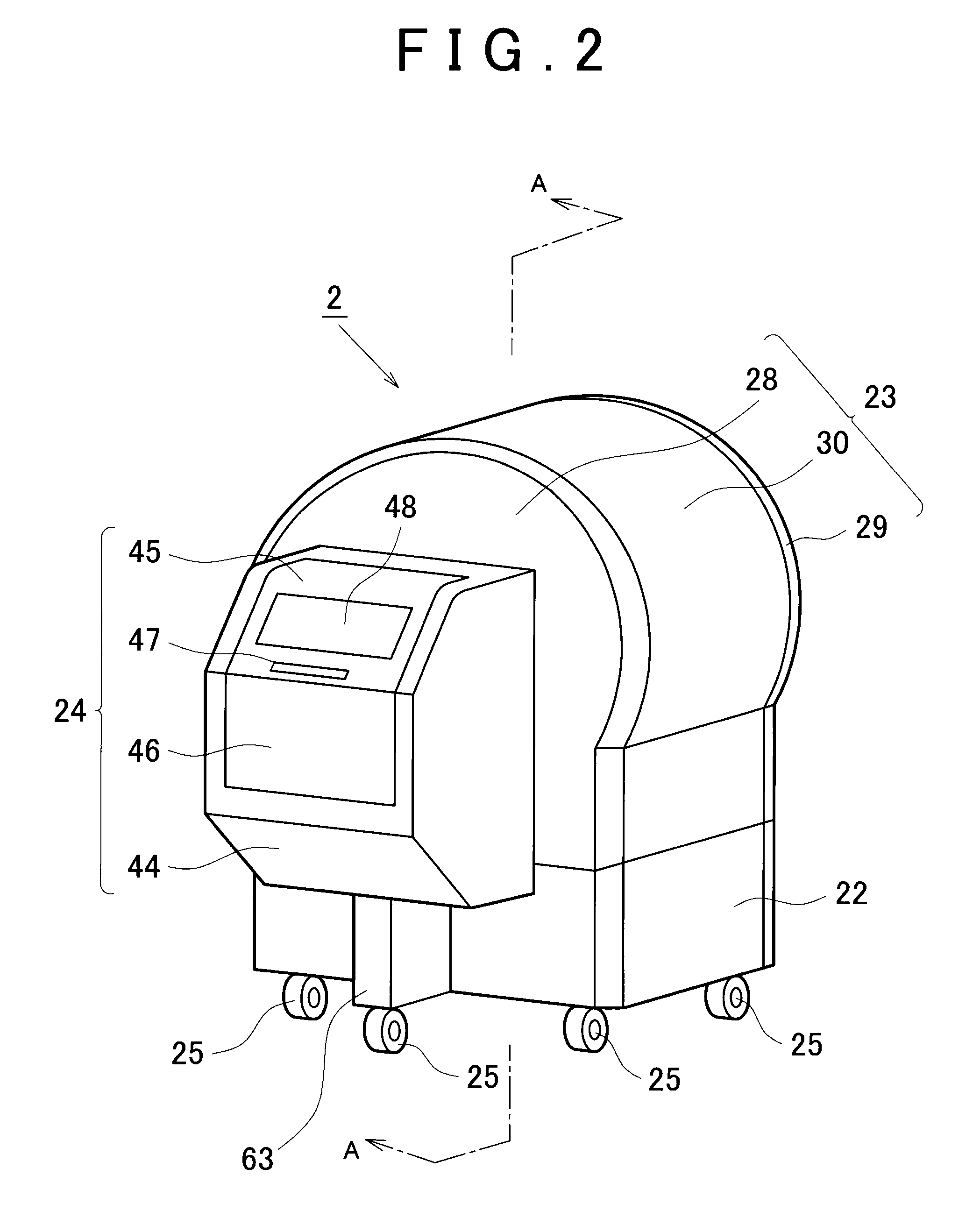

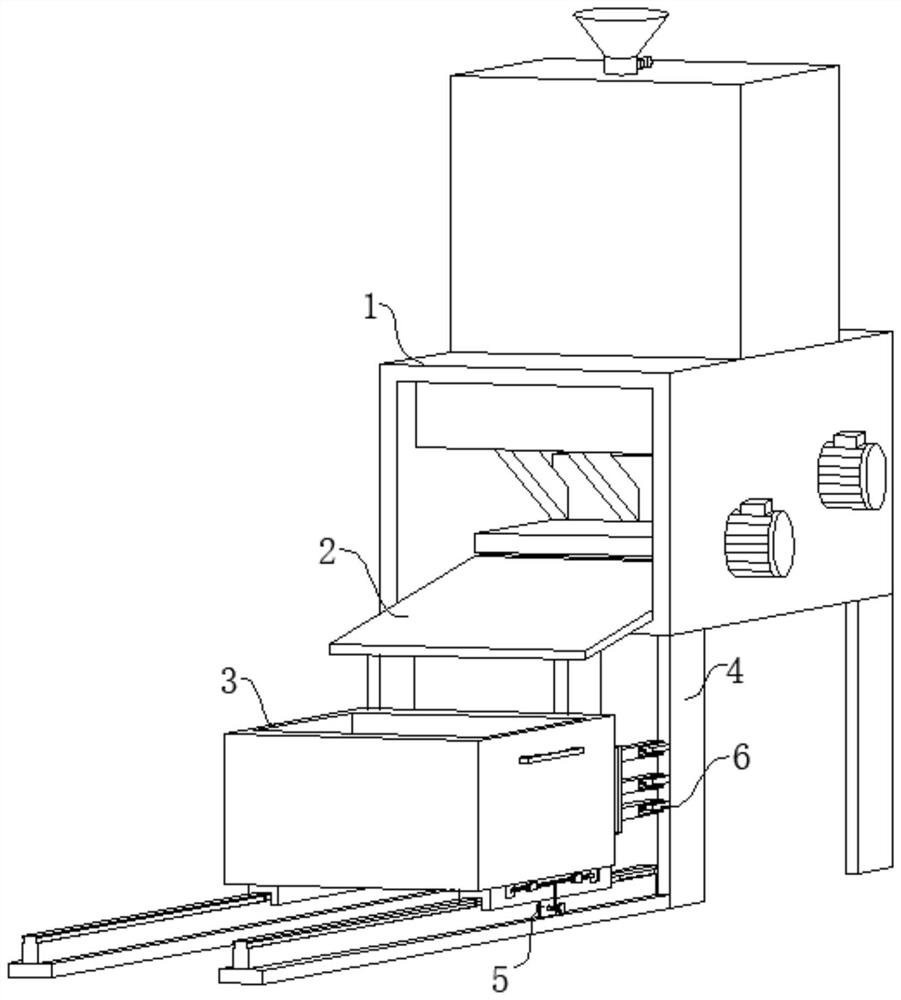

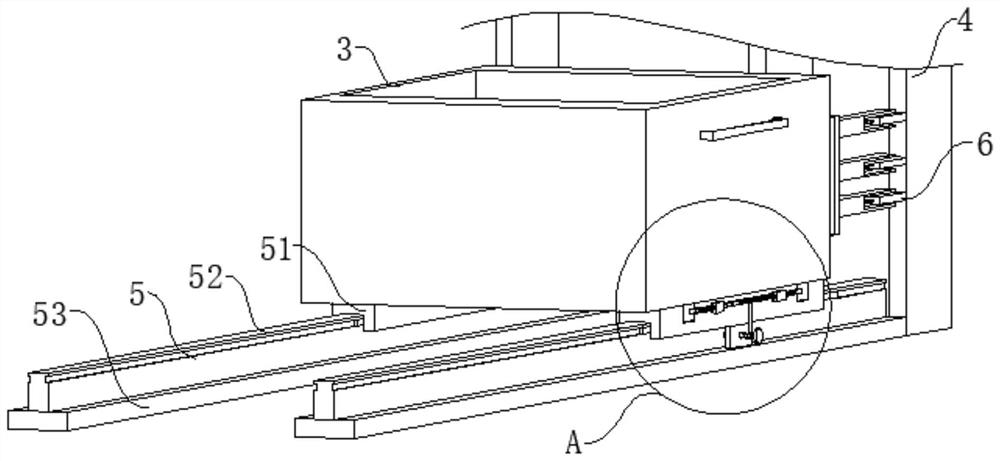

X-ray CT apparatus

ActiveUS9277895B2Consistent placementPatient positioning for diagnosticsComputerised tomographsSoft x rayX-ray generator

An X-ray CT apparatus for obtaining an internal image of a test subject by using X-rays. The X-ray CT apparatus has: an X-ray generator; an X-ray detector; a first casing for enclosing the X-ray generator and the X-ray detector; a test-subject table; a first table transporting mechanism for transporting the test-subject table between a first table position and a second table position, the first table position being a position where the main portion of the test-subject table receives X-rays from the X-ray generator, and the second table position being a position where the main portion of the test-subject table is on the outside of the first casing; and a second table transporting mechanism capable of vertically transporting the test-subject table. The first table transporting mechanism and the second table transporting mechanism operate in association with each other.

Owner:RIGAKU CORP

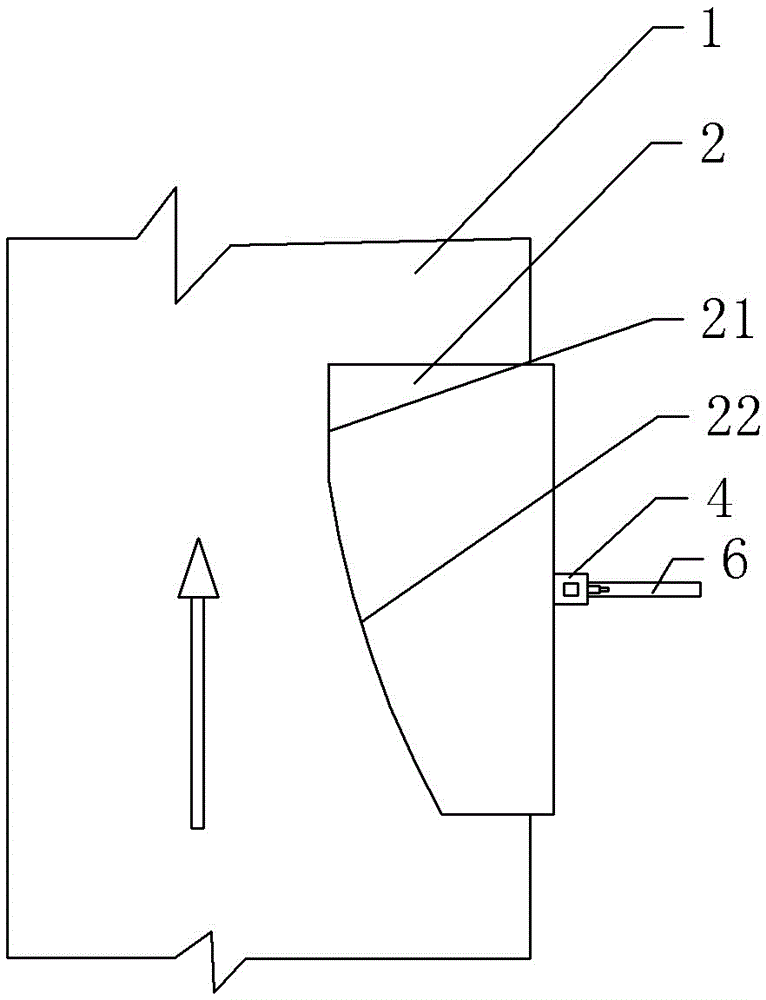

Oriented glass bottle transmission device

The invention discloses an oriented glass bottle transmission device. The oriented glass bottle transmission device comprises a bracket; a conveying belt is arranged on the bracket; a guide plate is arranged at the upper edge of the conveying belt, and is transversely placed; one end, near the middle part of the conveying belt, of the guide plate has an arc section and a straight section; the arc section and the straight section are integrally molded; the straight section is parallel to a conveying direction of the conveying belt; the arc section is positioned on one side, near feeding of the conveying belt, of the straight section; and one end, far from the conveying belt, of the guide plate is fixedly connected with the bracket. The oriented glass bottle transmission device improves the glass bottle production efficiency.

Owner:重庆兆峰玻璃晶品有限公司

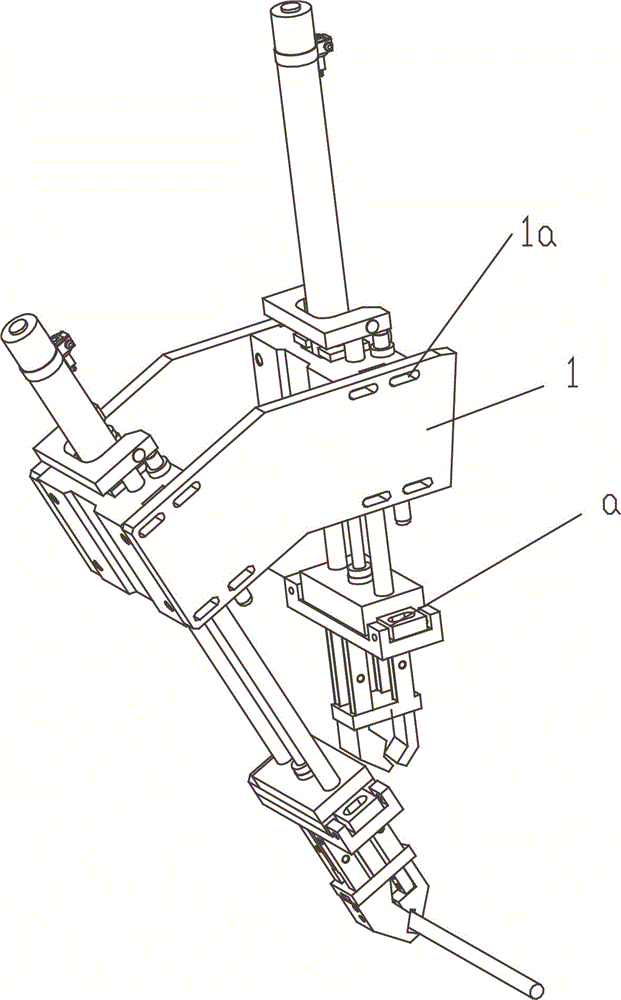

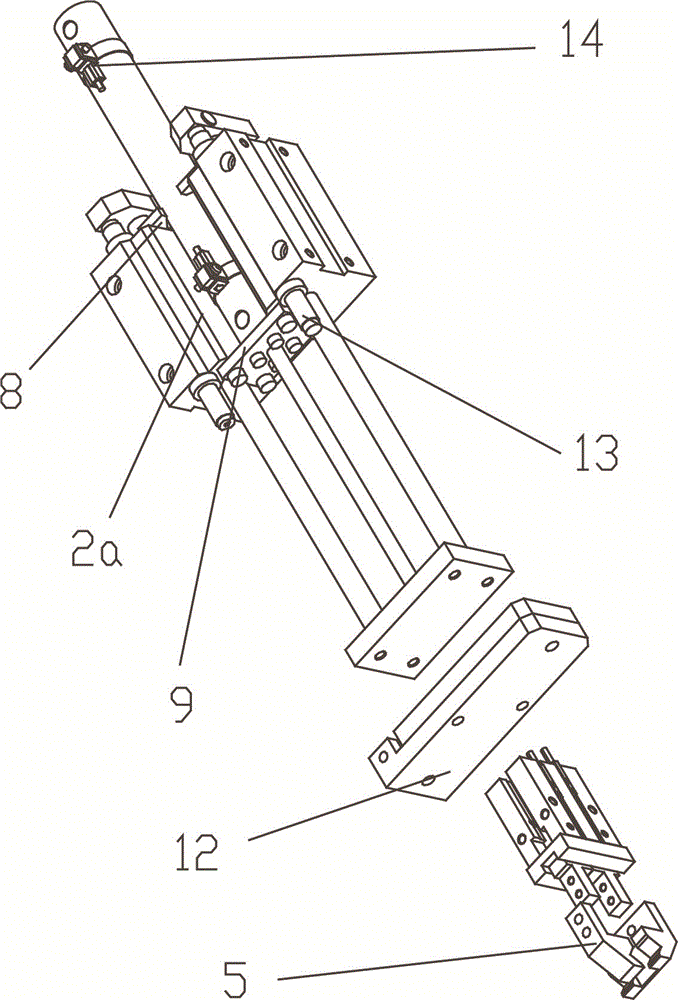

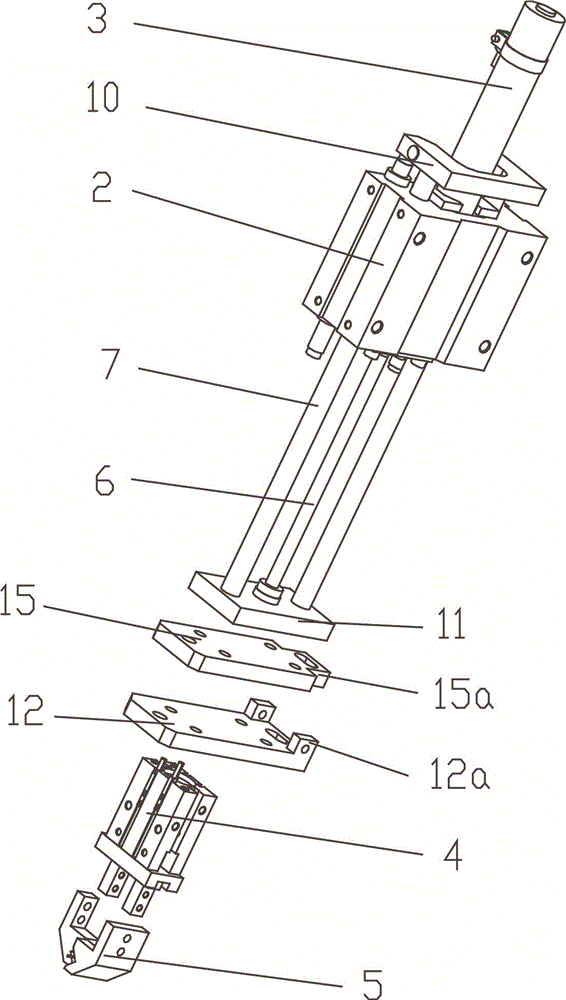

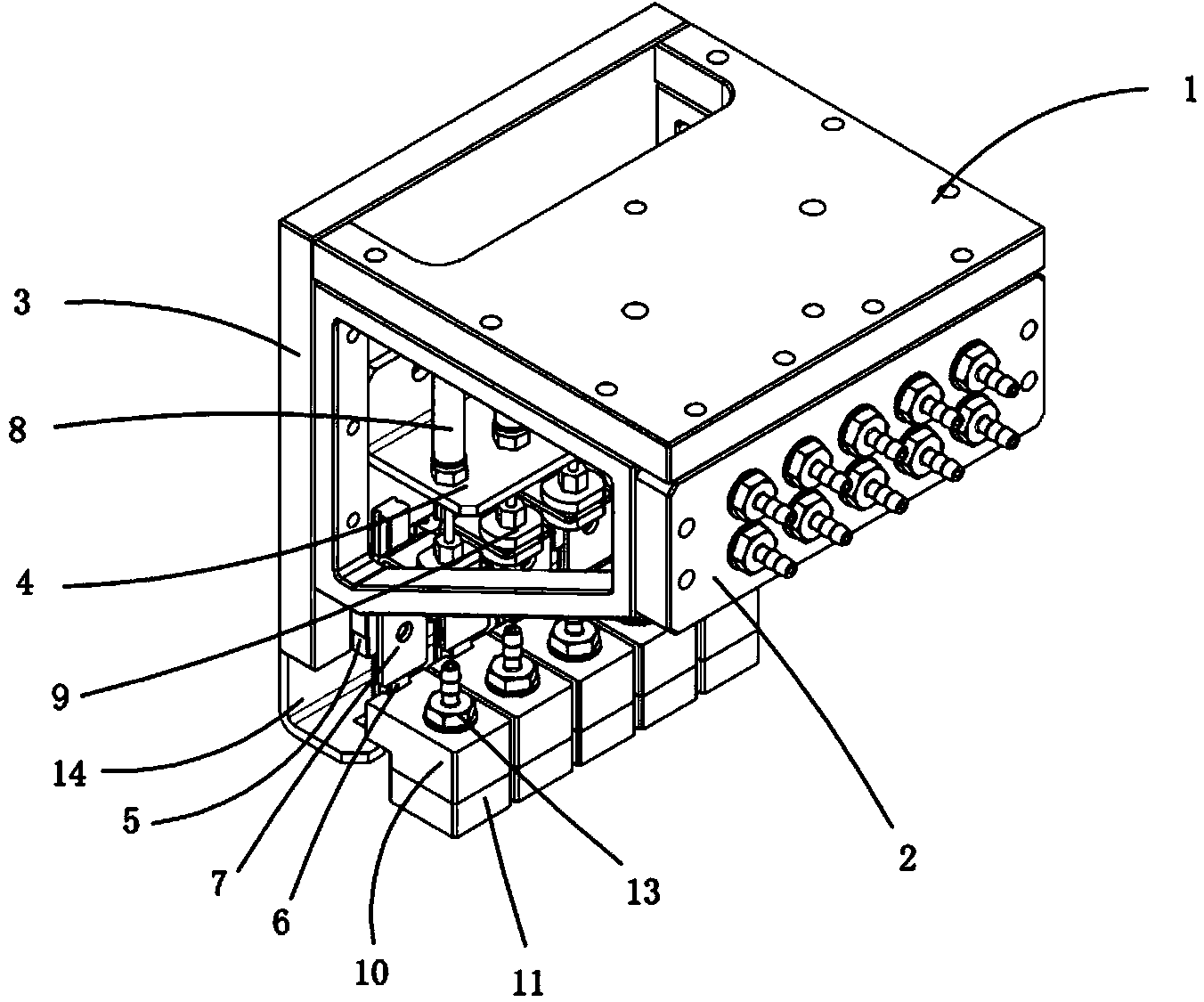

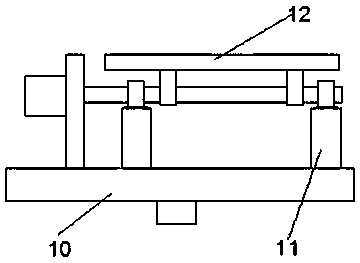

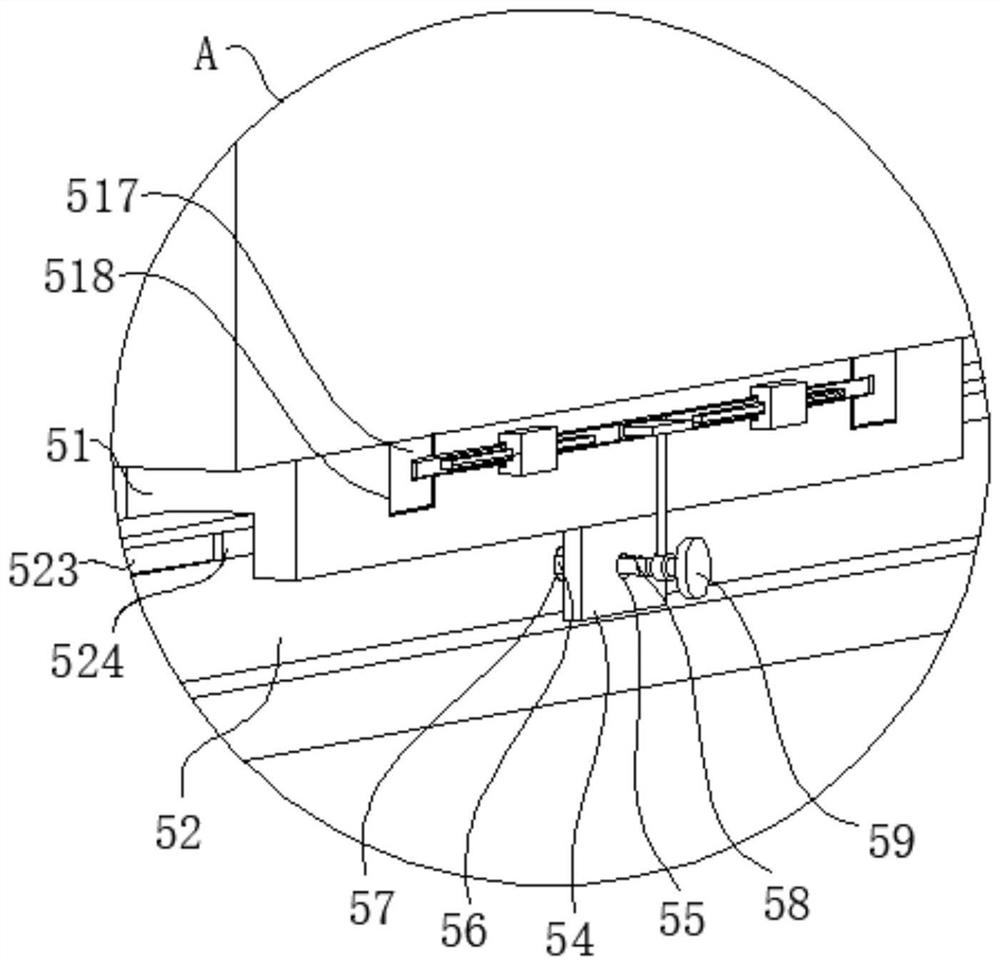

Clamping manipulator with two concentric rods

InactiveCN104526711AQuick pickPlace shortcutProgramme-controlled manipulatorRevolution surface grinding machinesPulp and paper industryManipulator

The invention discloses a clamping manipulator with two concentric rods. The clamping manipulator comprises two clamping plates and two mechanical arms. Each mechanical arm comprises a fixed block, a telescopic air cylinder, a pneumatic jaw air cylinder and pneumatic jaws, the two fixed blocks are installed between the two clamping plates at a certain included angle, each telescopic air cylinder is installed on the corresponding fixed block, each pneumatic jaw air cylinder is arranged below the telescopic rod of the corresponding telescopic air cylinder, and the pneumatic jaws in two pairs have the same extension end point. The clamping manipulator has the advantages that the two mechanical arms have the same extension end point, so workpieces are clamped and placed rapidly and conveniently, and the former workpiece and the latter rear workpiece are placed at the same position; air cylinder clamping plates can be used for finely adjusting the telescopic air cylinders; pneumatic jaw air cylinder mounting plates can be used for finely adjusting the positions of the pneumatic jaws.

Owner:宁波沃特美逊机器人科技有限公司

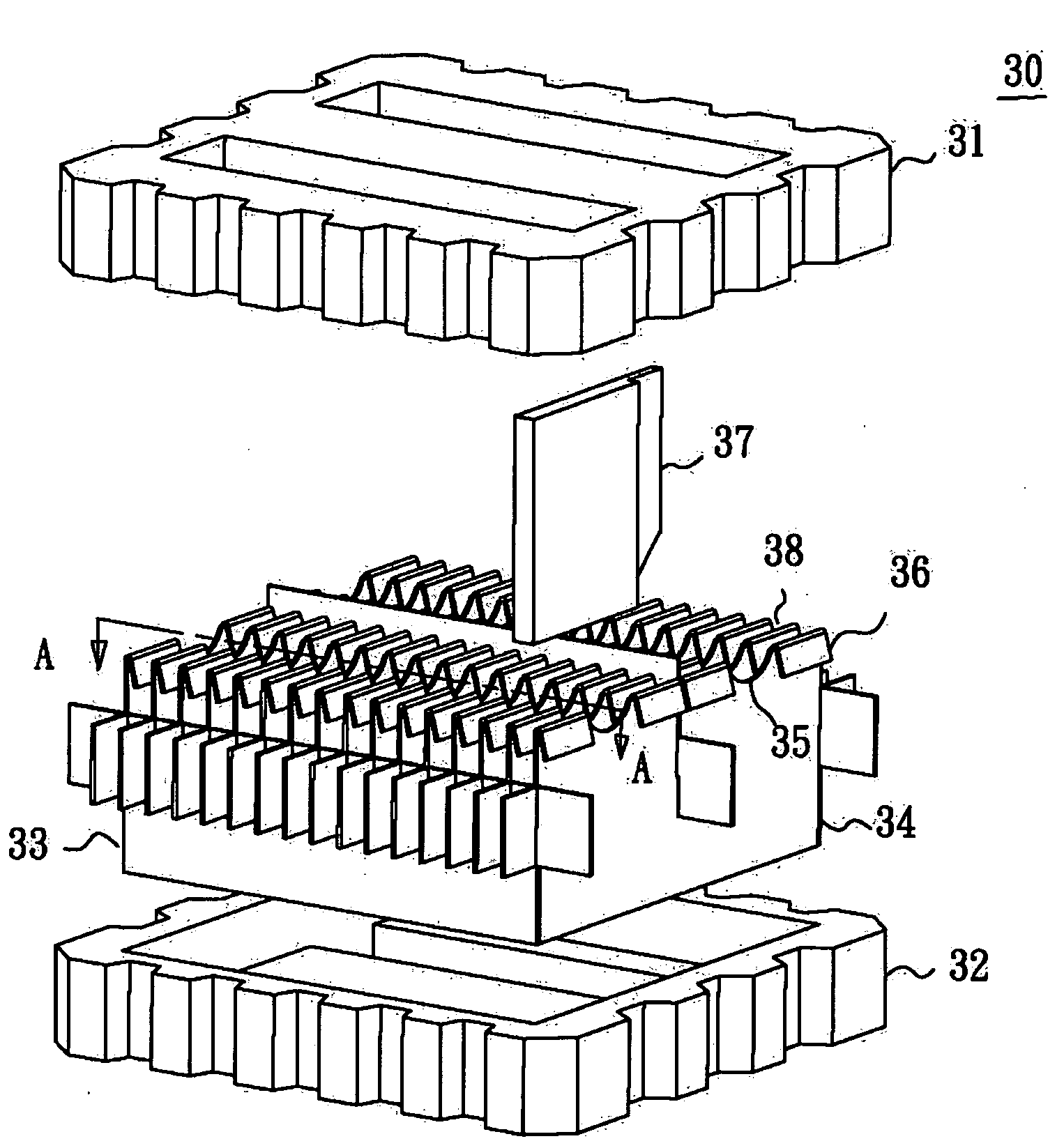

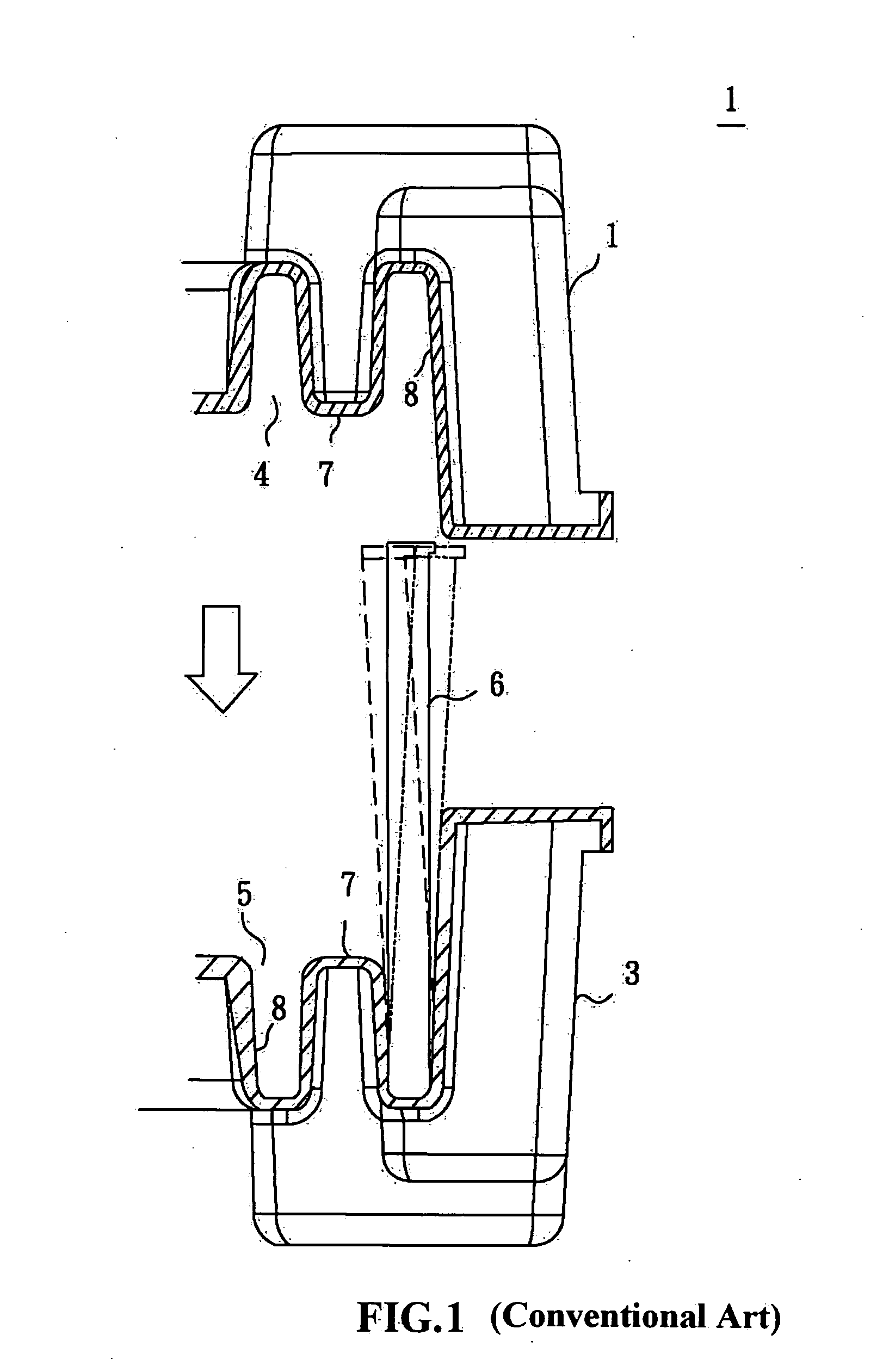

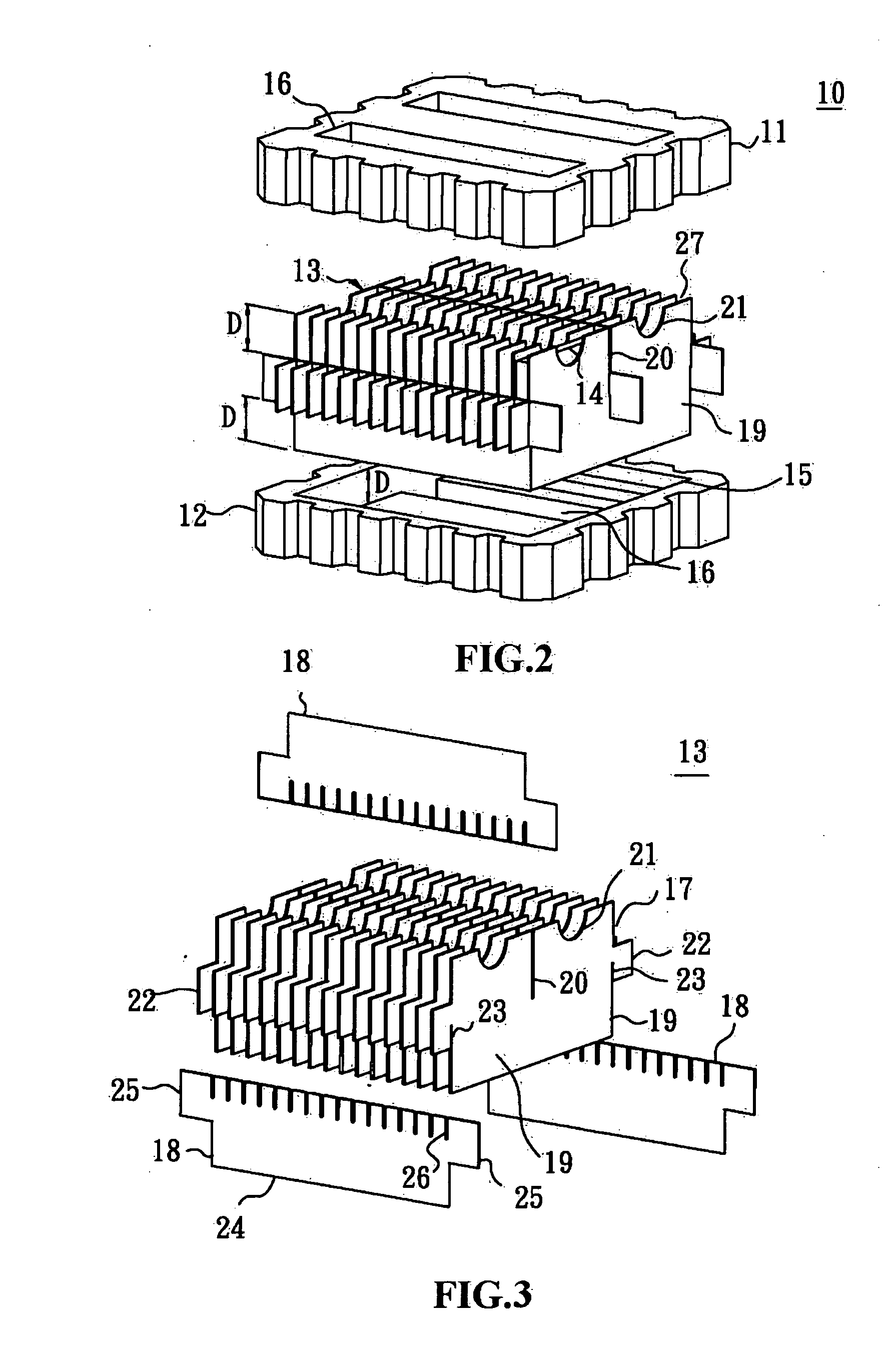

Container for disk drivers

InactiveUS20090078601A1Increase the number ofLow costPackaging eggsRecord information storageEngineeringMechanical engineering

Owner:QUANTA STORAGE INC

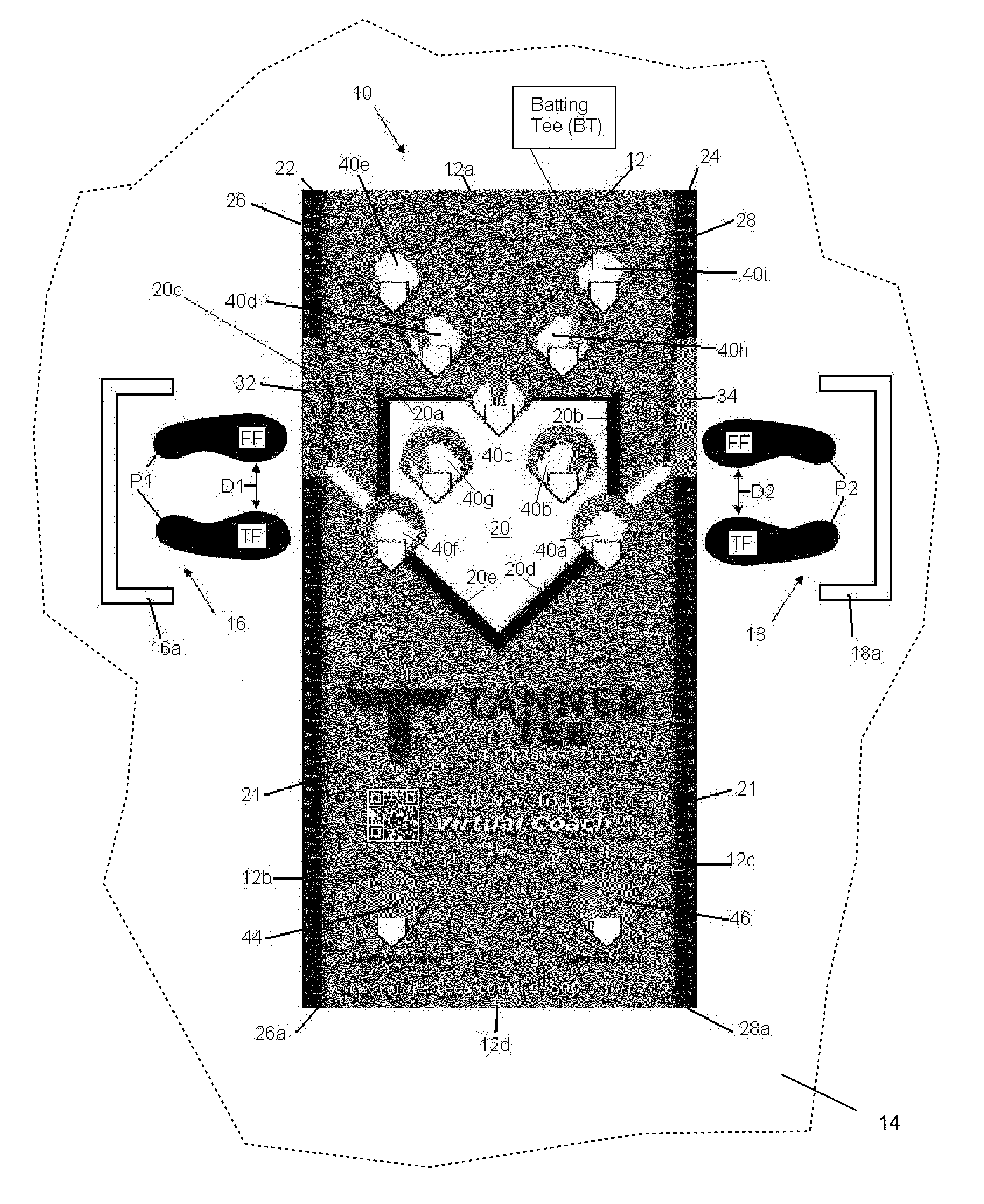

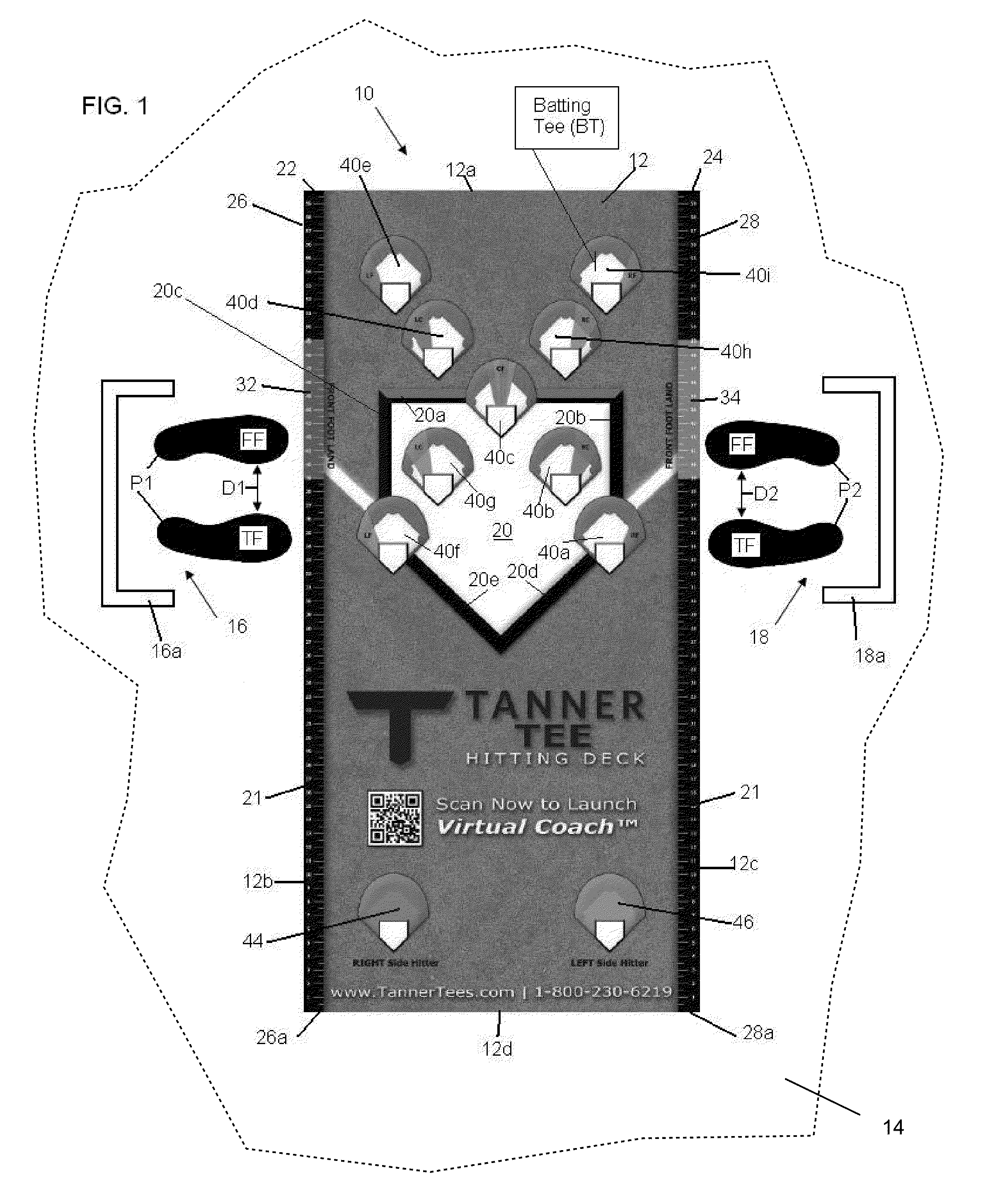

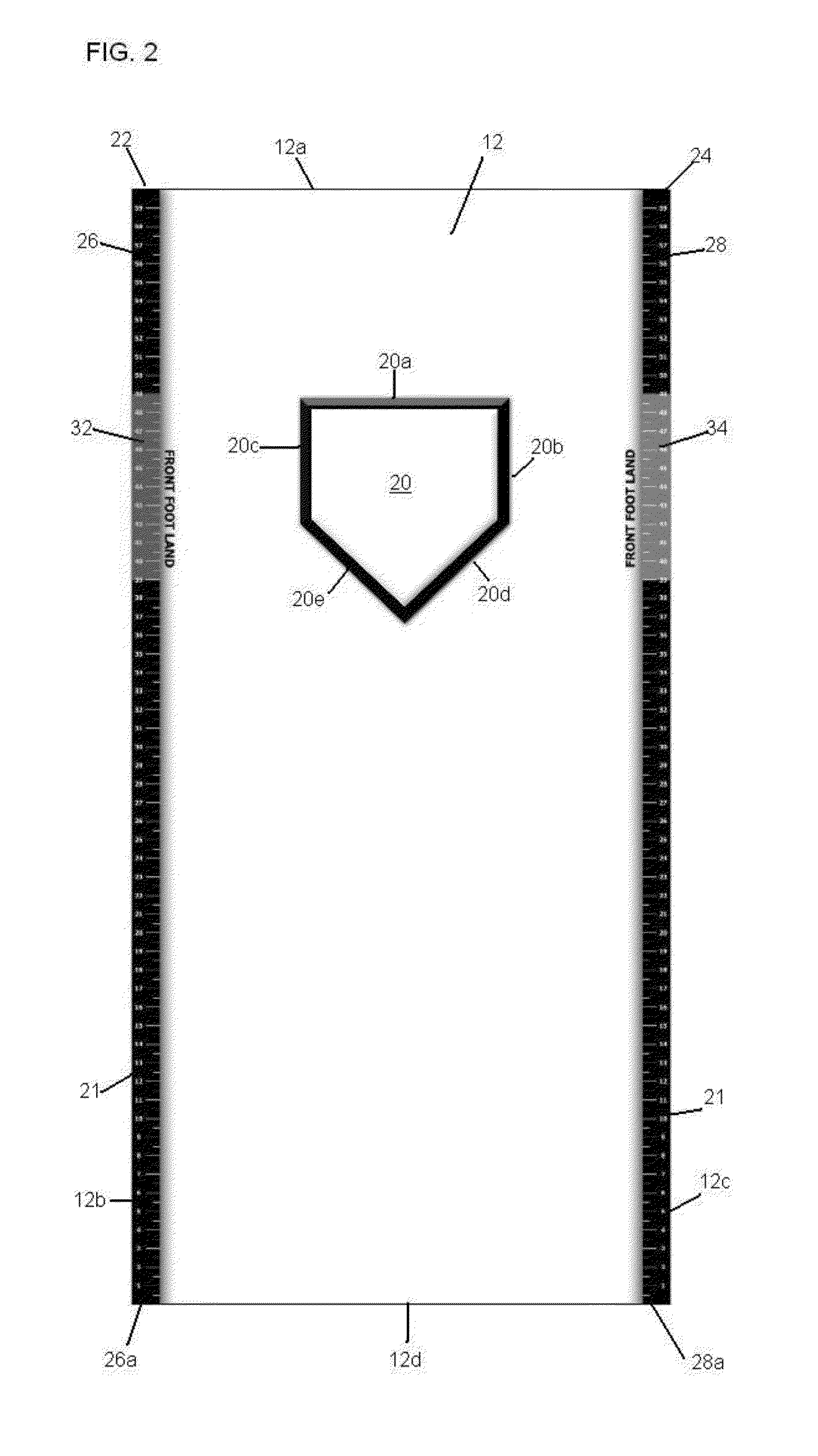

Hitting deck, hitting mat or training system, device or method

A baseball mat that in one embodiment has a plurality of indicia formed in a pattern that enables at least one or both a left-handed and a right-handed batter to know where to place a batting tee. In another embodiment, the batting mat comprises an interval system that enables a player to measure an interval or distance between a player's feet when the player is situated in a batting area associated with the batting mat. The interval system may have foot landing zones to assist the player in placing his or her feet. In another embodiment, a hitting deck graphic is used to define the plurality of indicia either alone or with direction indicia that enable a user to know or understand a direction in which a ball will be hit.

Owner:JOE H TANNER BASEBALL PROD

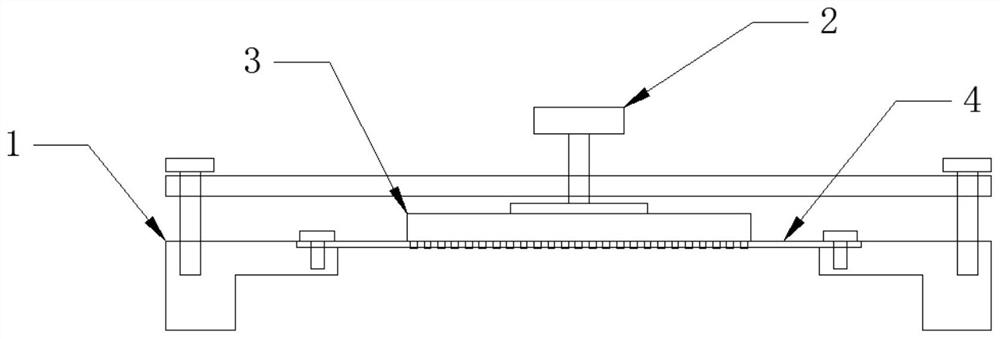

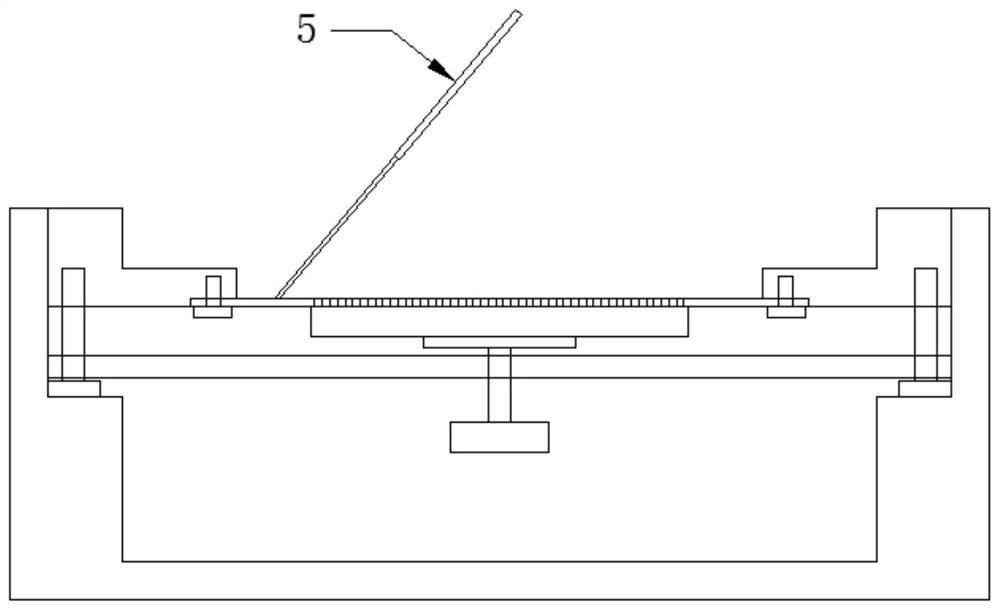

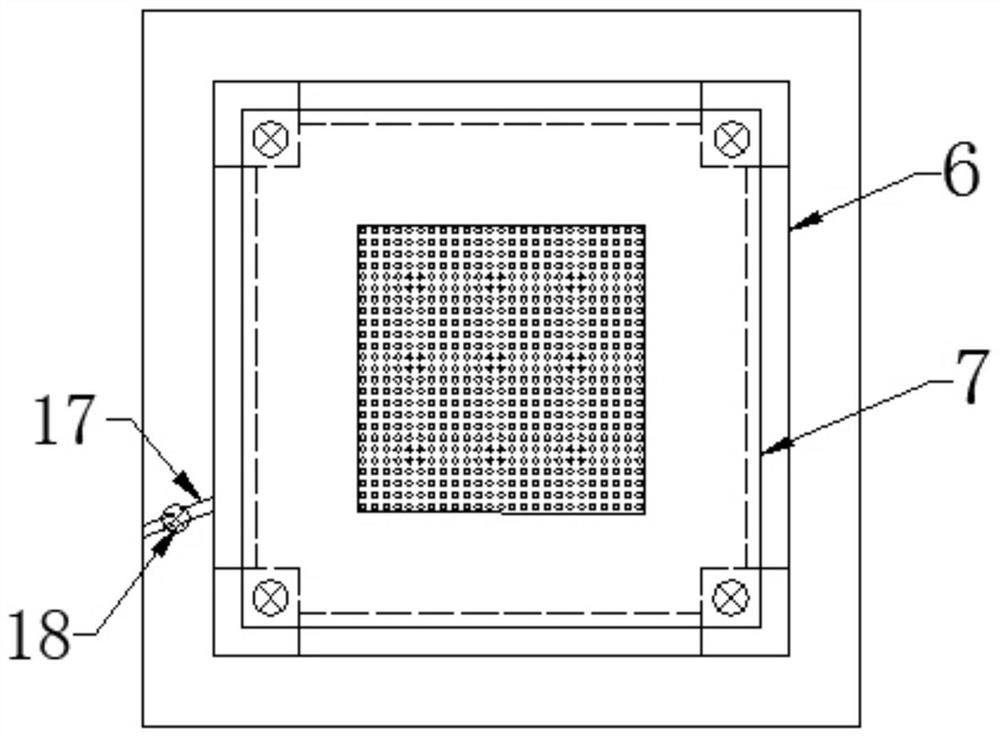

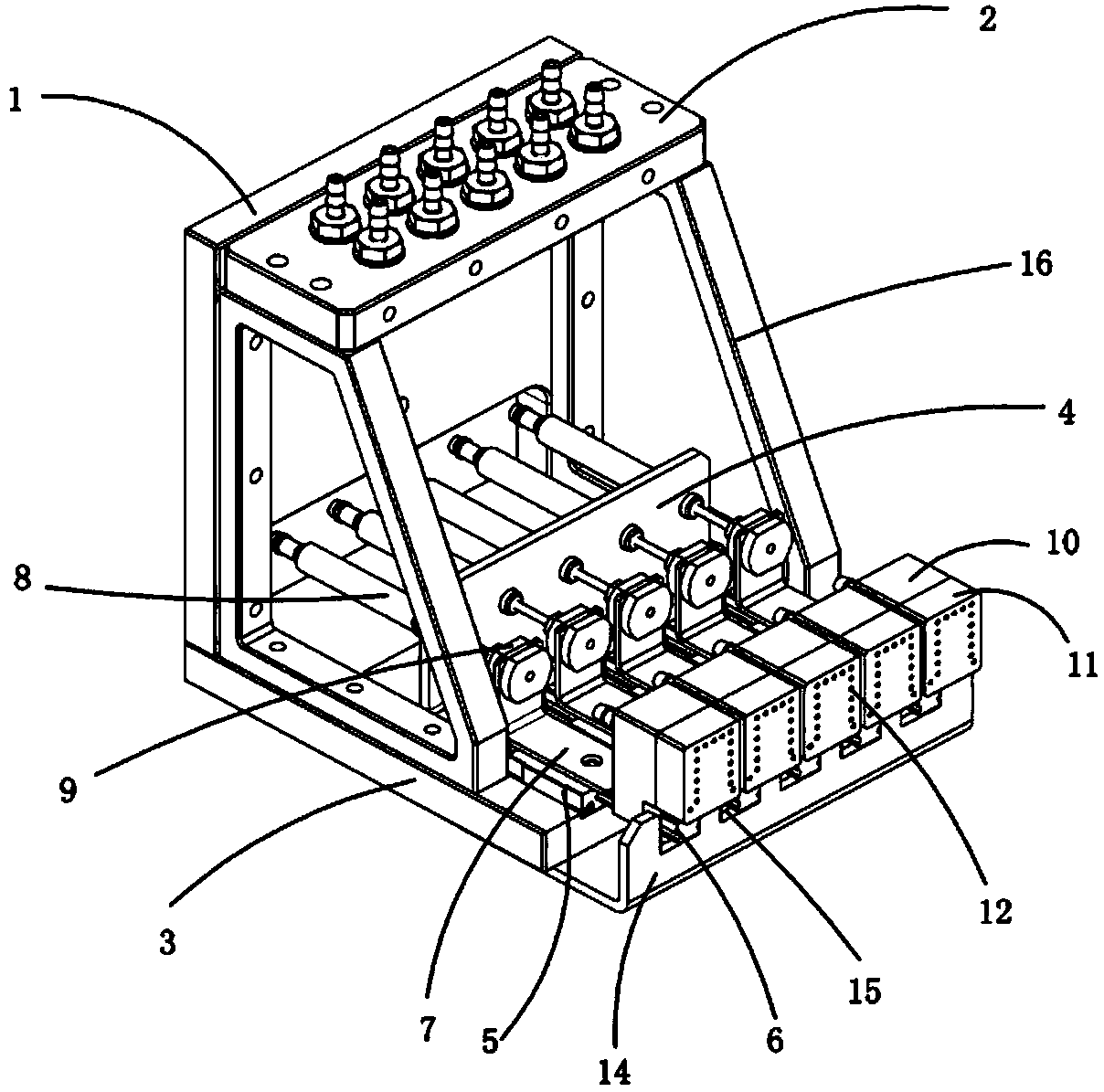

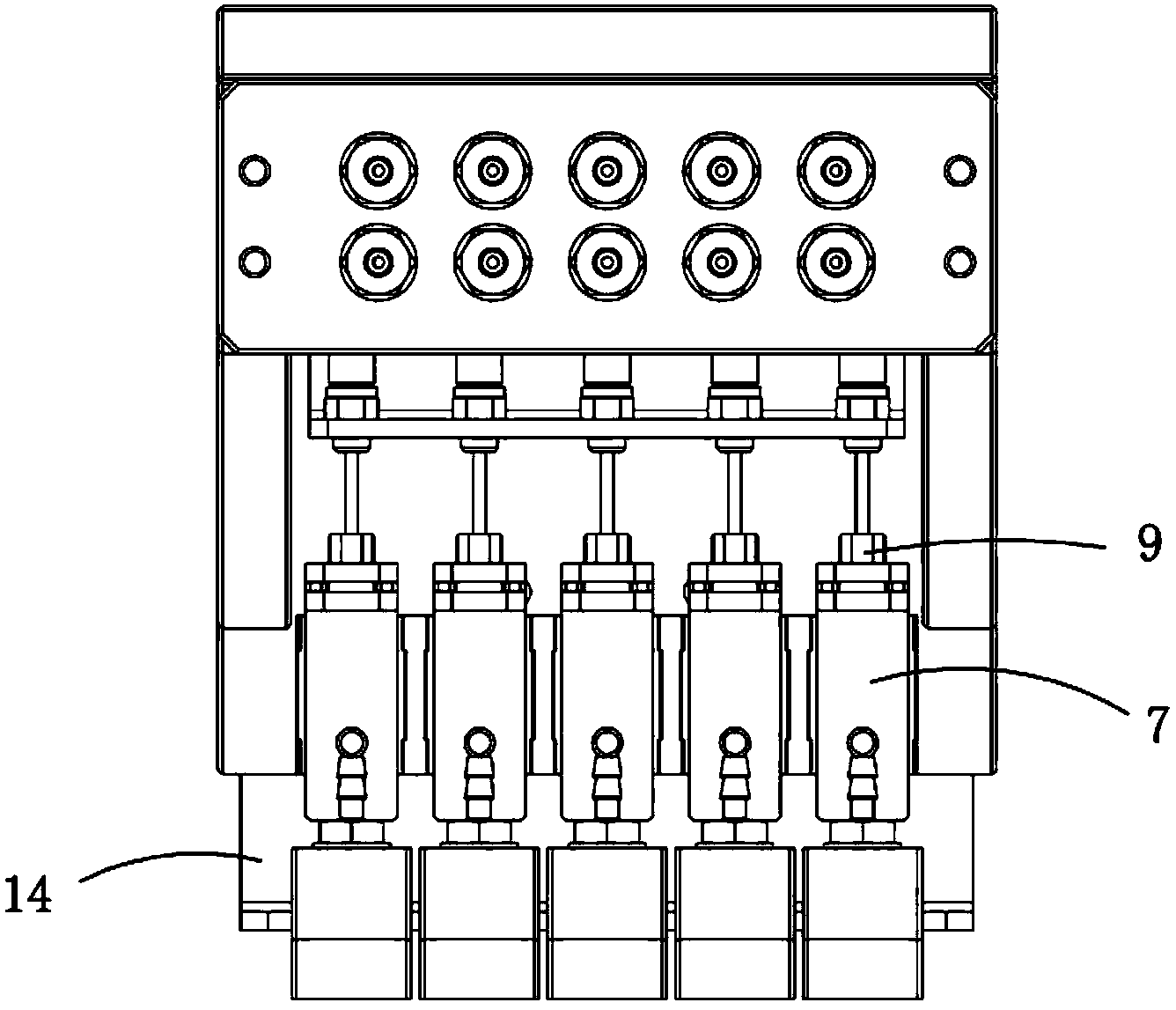

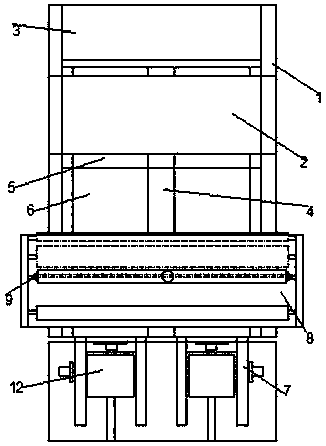

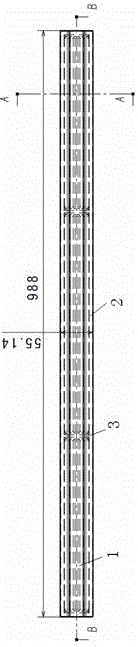

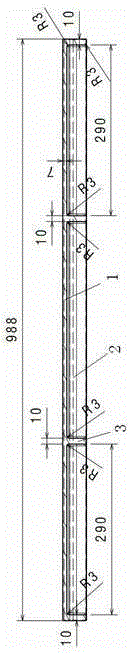

BGA ball mounting device and method based on SMT reworking table

ActiveCN113766823AEfficient placementConsistent placementPrinted circuit assemblingFinal product manufactureSolder ballEngineering

The invention provides a BGA ball mounting device based on an SMT (surface mount technology) reworking table, which comprises a soldering paste printing tool, used for printing a soldering paste array on a bonding pad of a BGA device; a ball mounting tool, used for placing solder balls and comprising a ball leakage steel sheet, holes being formed in the ball leakage steel sheet in an array mode, and the positions of the holes corresponding to solder paste printed on a BGA device bonding pad; a limiting frame, used for fixing the ball leaking steel sheet; a ball carrying main body, nested in the limiting frame, positioned below the ball leaking steel sheet and used for receiving the solder balls falling from the holes of the ball leaking steel sheet; and a SMT reworking table, used for pasting the to-be-reballed BGA devices printed with the soldering paste to the solder balls placed by the reballing tool in a one-to-one correspondence manner through visual alignment. The BGA ball mounting method comprises the steps of solder paste printing, solder ball placement, solder ball and solder paste positioning and reflow soldering. The device has the advantages of high accuracy, high universality and high stability.

Owner:SHANGHAI RADIO EQUIP RES INST

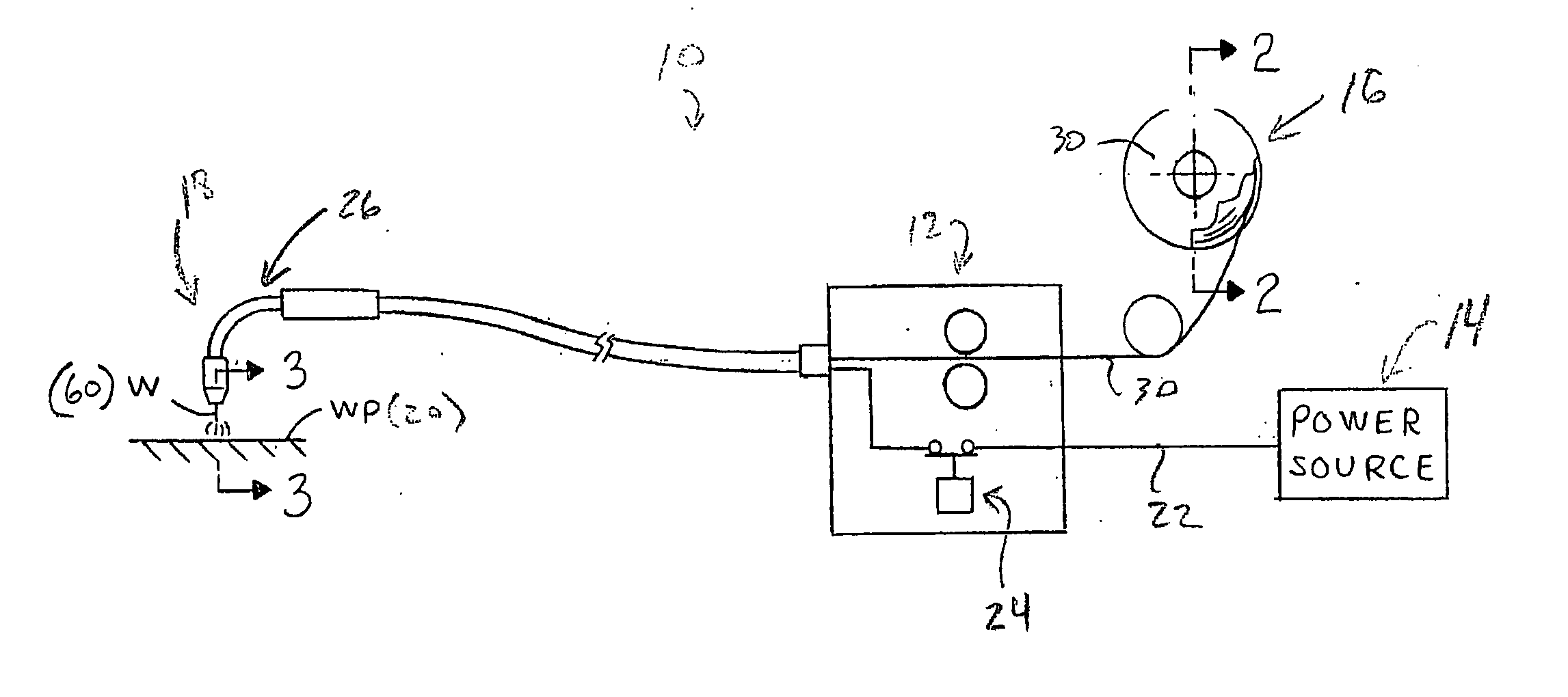

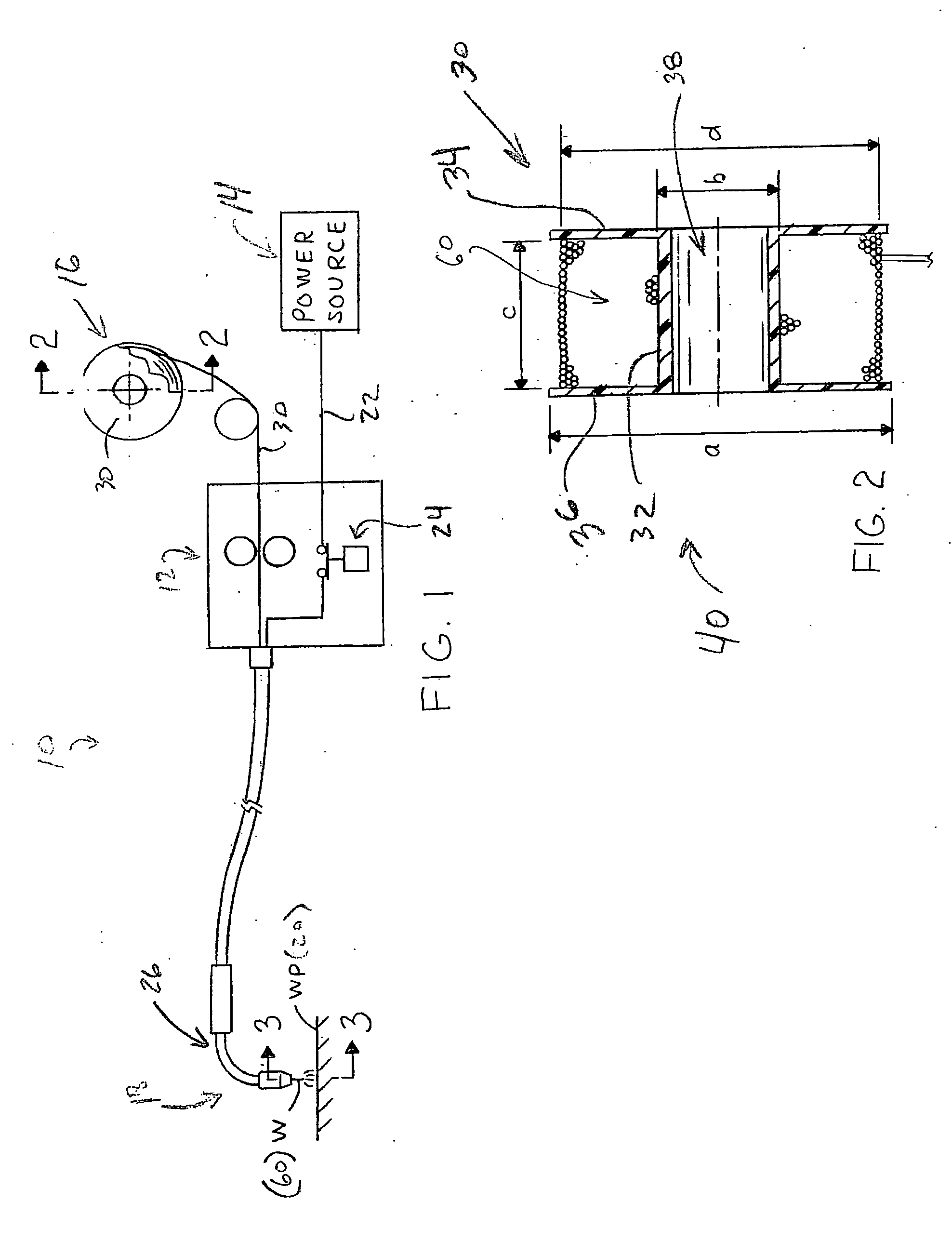

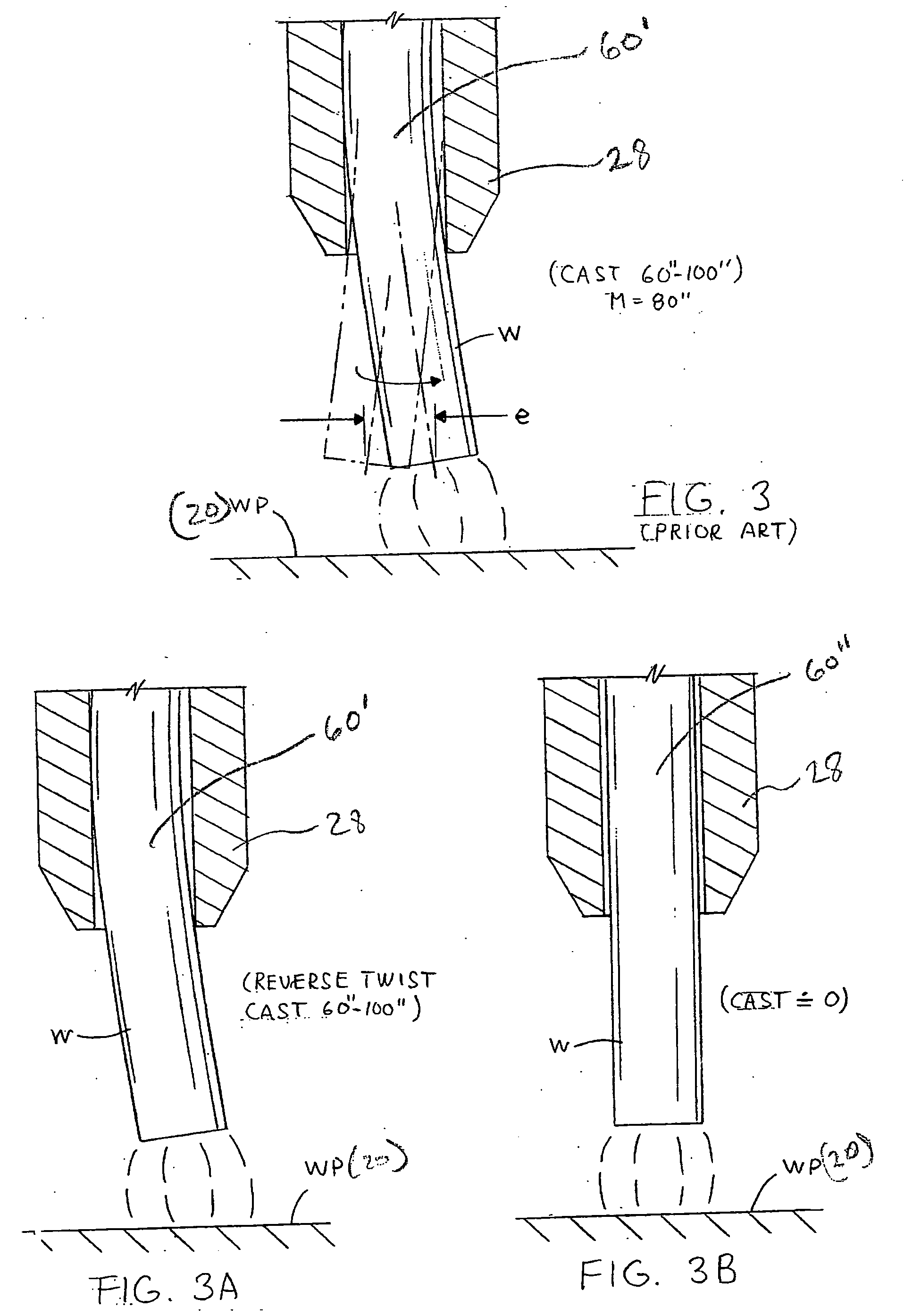

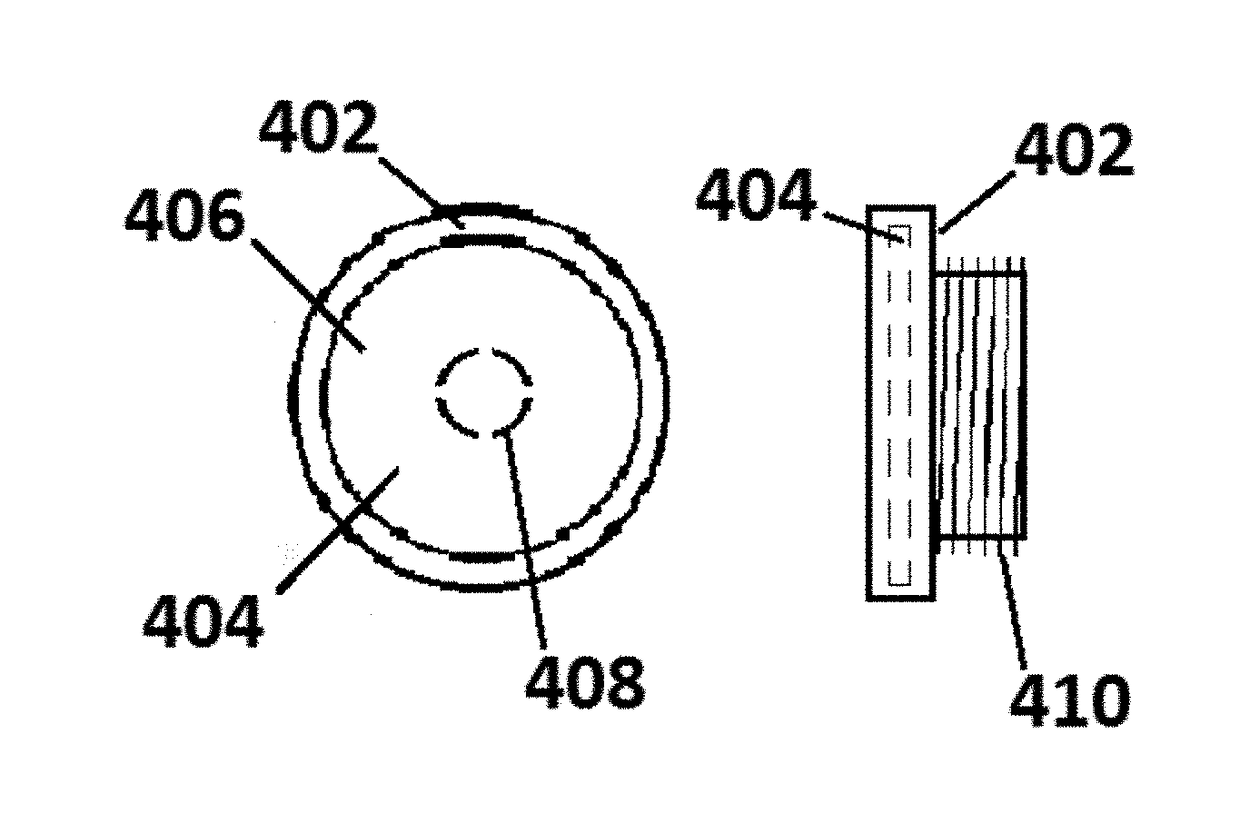

Weld wire with large cast, method of making same, and loaded spool article of manufacture

InactiveUS20070175877A1Reduce inconsistencySuccessful useWelding/cutting media/materialsSoldering mediaCircular sectionMaterials science

A weld wire for storage on a spool of weld wire, a method for making same, and an article of manufacture including a weld wire carried on a spool. The weld wire has a substantially linear cast in the form of an undulating curve including a succession of generally semi-circular sections having a generally fixed mean average radius of curvature of about 200 inches but not less than 80 inches. In one form, the cast has a radius of curvature in the range of about 100-300 inches. The linear cast is formed on the weld wire prior to the weld wire being wound onto the spool of weld wire. The linear cast is at least partially retained on the weld wire after the weld wire is unwound from the spool and during the feeding of the weld wire through a welding machine. The spool includes a hub portion having a diameter in the range of about 18-20 inches for carrying weld wire having a diameter in the range of about 0.035-0.062 inches. The present application pertains to the art of welding, and more particularly to welding wires used in welding machines.

Owner:LINCOLN GLOBAL INC

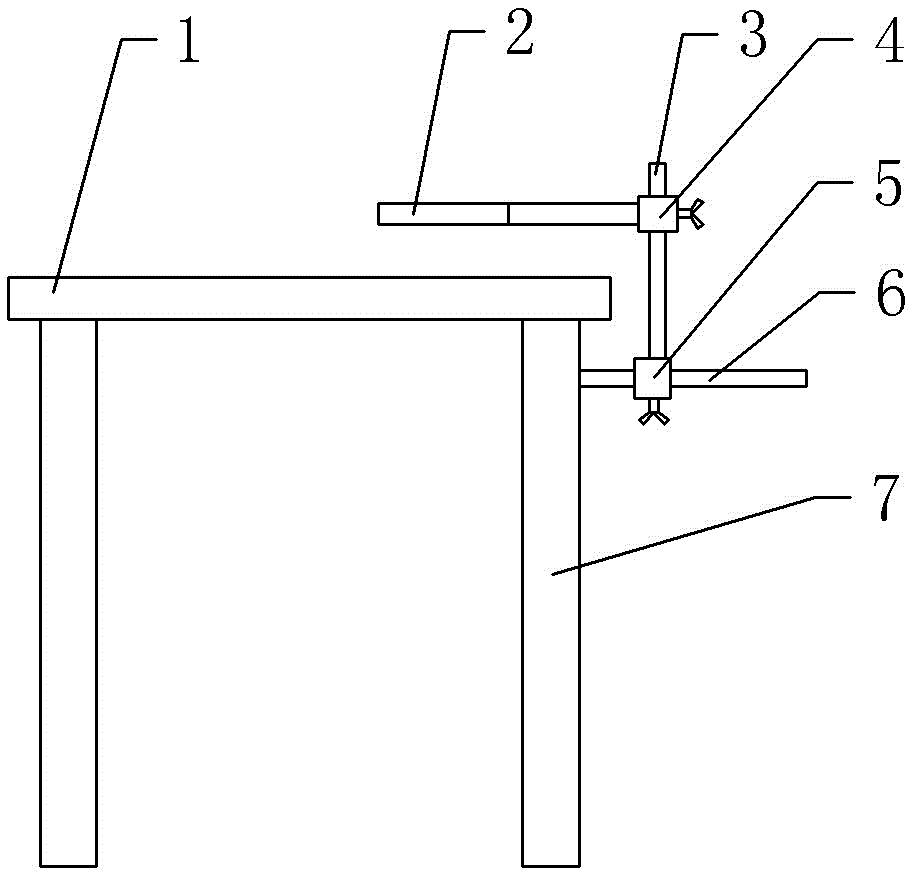

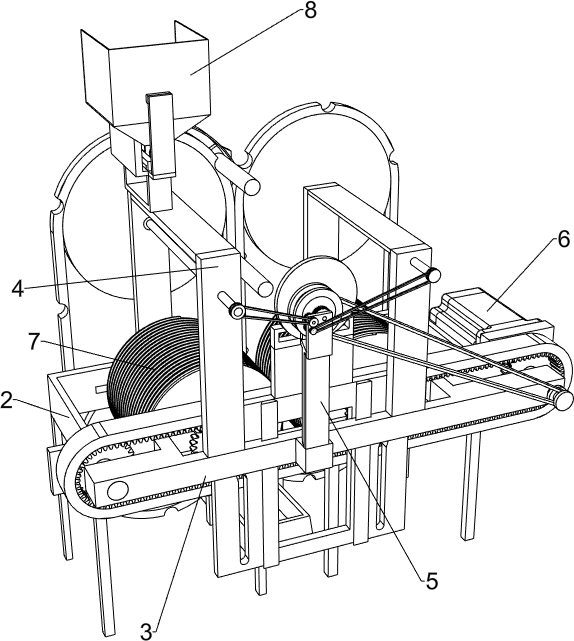

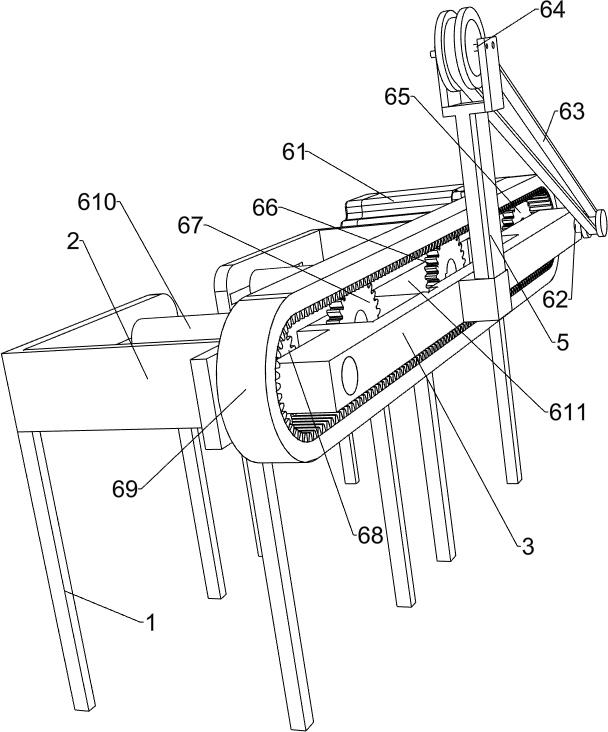

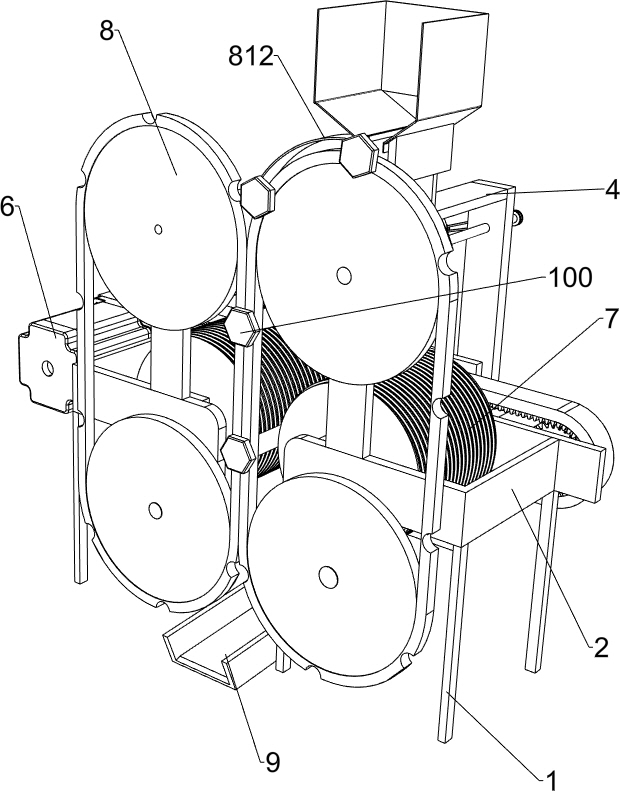

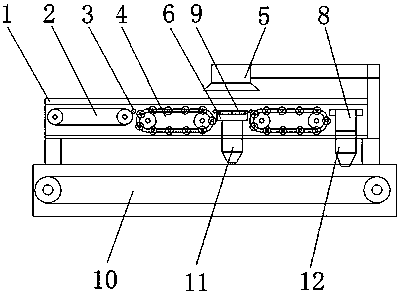

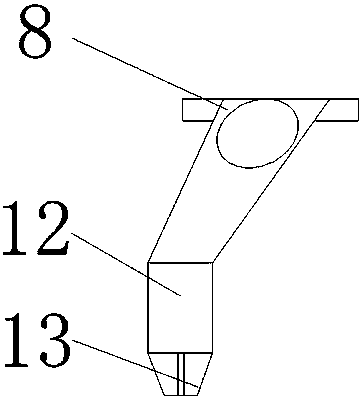

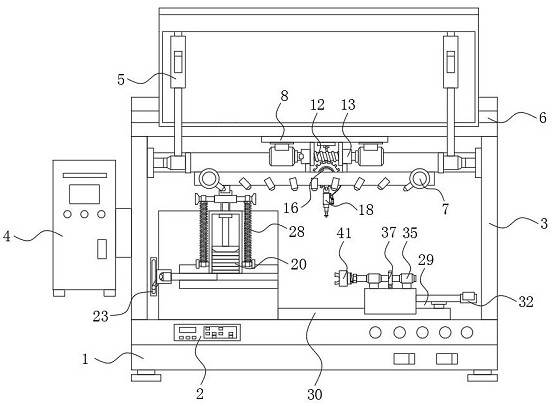

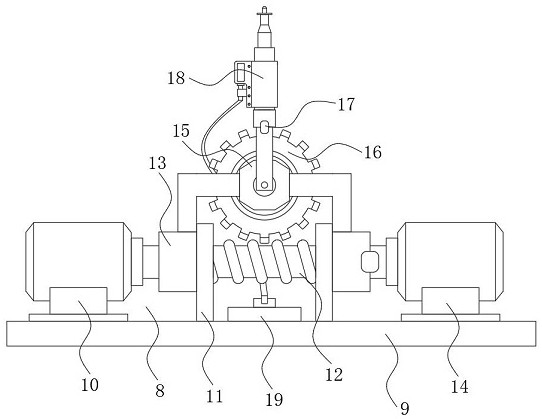

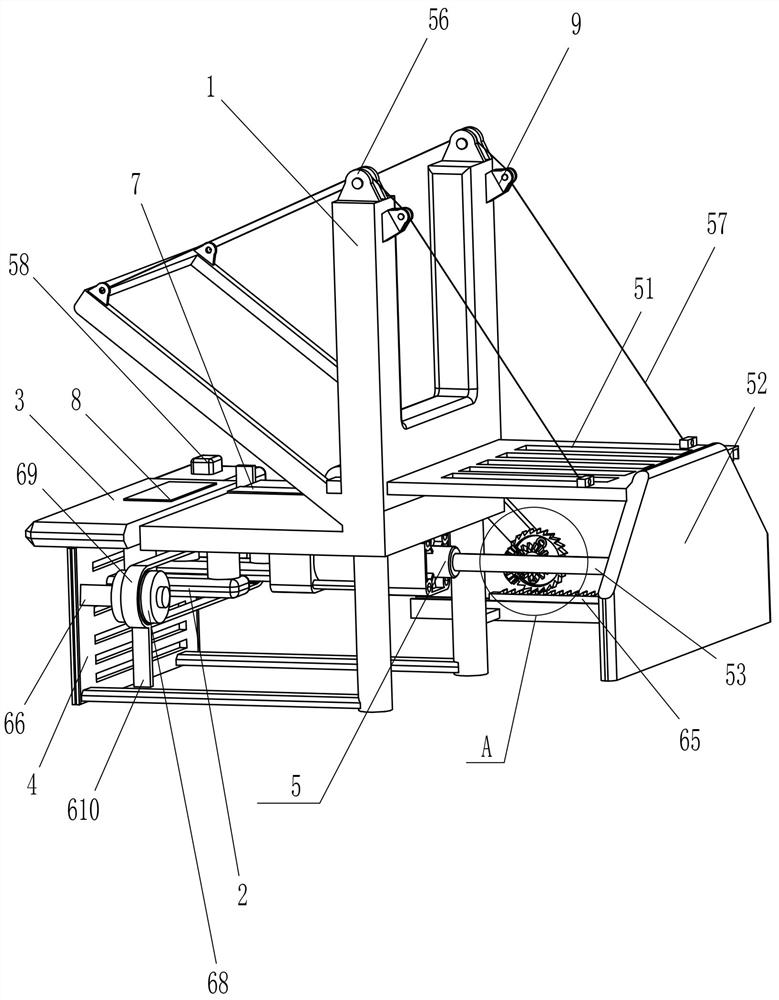

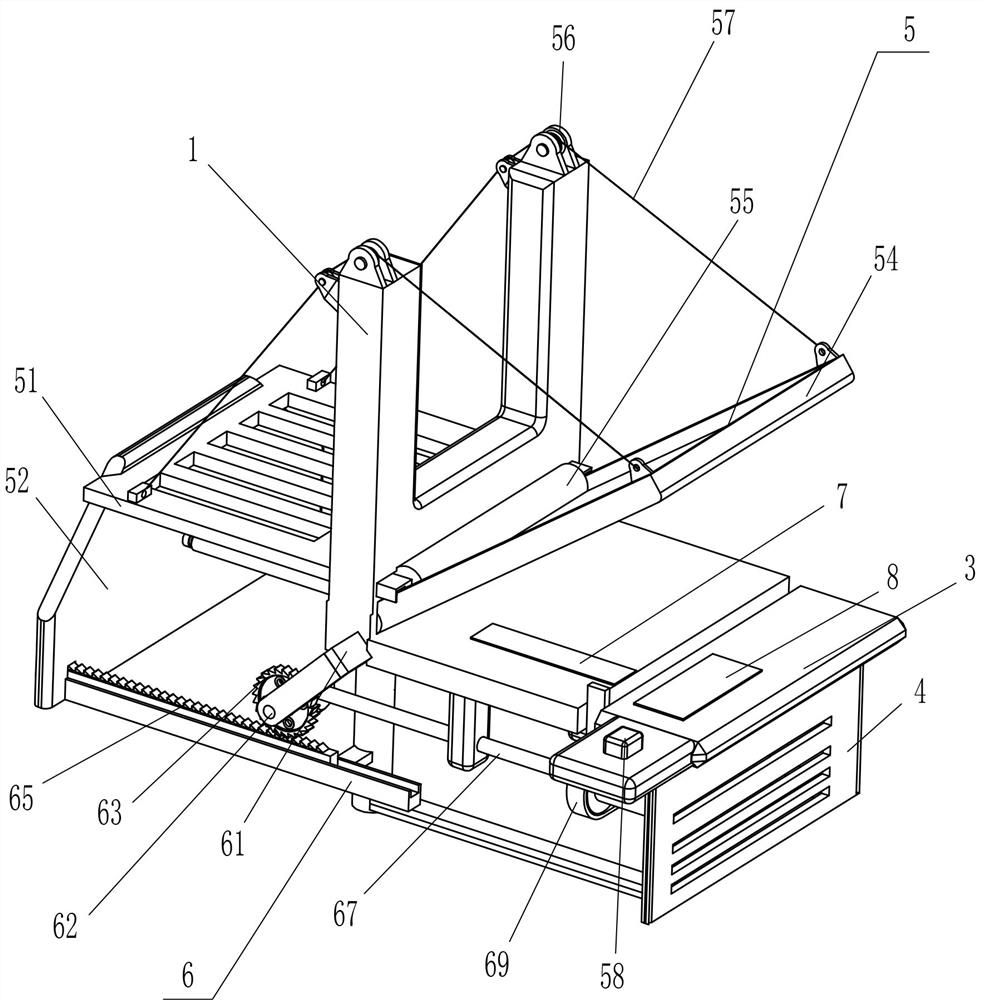

Screw thread forming equipment

ActiveCN111974918AConsistent placementConsistent positionMetal-working feeding devicesScrew-threads articlesEngineeringScrew thread

The invention relates to screw forming equipment, and particularly relates to screw thread forming equipment. The technical problem to be solved is how to provide the screw thread forming equipment that does not require manual placement and removal of a screw. In order to solve the technical problem, the screw thread forming equipment comprises a frame, a supporting plate, brackets, a supporting column, a driving assembly and a working assembly, wherein a plurality of supporting legs are connected to the end of the frame; the supporting plate is connected to one side of the frame; the end of the supporting plate is connected with the two brackets, and the brackets penetrate through the frame; one side of the supporting plate is connected with the supporting column; the driving assembly ismounted between the frame and the supporting plate; and the working assembly is mounted on the frame. According to the screw thread forming equipment, the working assembly and a feeding assembly can be driven by the driving assembly to work, the feeding assembly operates to convey the screw intermittently, the unthreaded screw is firstly conveyed into the working assembly, and the working assemblyoperates to thread the screw therein.

Owner:南京力迅螺杆有限公司

Vacuum suction sucker

The invention relates to a vacuum suction sucker. A connector fixing plate and a sliding block fixing plate ate installed on a top plate of the vacuum suction sucker; a pen-type air cylinder fixing metal plate and four sliding blocks are fixedly connected to the sliding block fixing plate, and sliding rails are installed on each sliding block; an air cylinder connecting metal plate is connected to each sliding rail, four pen-type air cylinders are connected to the pen-type air cylinder fixing metal plate, and the lower ends of the pen-type air cylinders are connected with the air cylinder connecting metal plates respectively through floating connectors; a sucker fixing block is installed below each sliding rail, suckers are installed below each sucker fixing block, and mini connectors are installed on each sucker fixing block; a limiting metal plate is connected to the lower portion of the sliding block fixing plate; a mechanical arm is installed on the top plate and driven to the position above products in a supplying area; the pen-type air cylinders are ventilated, the sucker is extended out to the limiting metal plate, it is guaranteed that the bottom faces of the four suckers are flush, the suckers suck air to suck the products, and then the pen-type air cylinders are retracted; the mechanical arm is then driven to move to an attachment area or an assembly area, and the suckers are extended out one by one to enable the products to be attached or assembled to the specific positions.

Owner:BOZHON PRECISION IND TECH CO LTD

Egg packaging device

InactiveCN108248923AImprove detection and recognition speedImprove packaging efficiencyPackaging eggsPackaging automatic controlInductorElectric control

The invention relates to an egg packaging device, and belongs to the technical field of packaging machines. According to the egg packaging device, eggs are put on a conveying belt, the conveying beltconveys the eggs to a conveying chain A, an auxiliary roller enables the eggs to enter the conveying chain A one by one, and the conveying chain A conveys the eggs to a screening device one by one; alaser inductor recognizes the passing eggs, and if the large ends of the eggs are upward and the small ends of the eggs are downward, the screening device does not work; the eggs are conveyed to egg inlets through a conveying chain B to enter packaging pipelines B and fall into a packaging box from the packaging pipelines B; and if the laser inductor detects that the small ends of the eggs are upward and the large ends of the eggs are downward, an electric control baffle in the screening device is opened, and the eggs fall into packaging pipelines A below the screening device and fall into thepackaging box through the packaging pipelines A. In the egg packaging device, the laser inductor is adopted for recognizing the eggs, and therefore the eggs are screened, it is guaranteed that the eggs in the packaging box are placed consistently during packaging, the laser inductor can effectively screen the eggs, and the work efficiency of the device can be improved.

Owner:吴迪

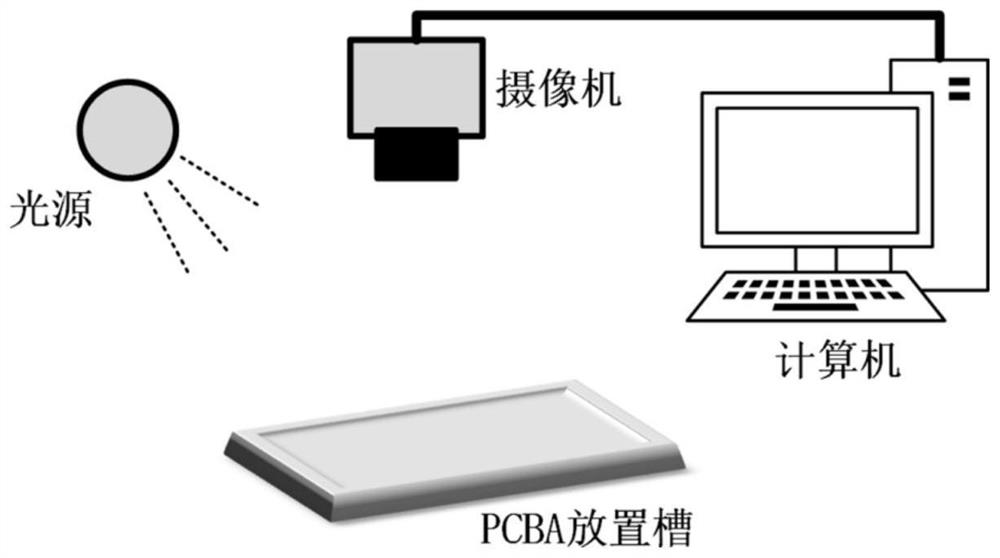

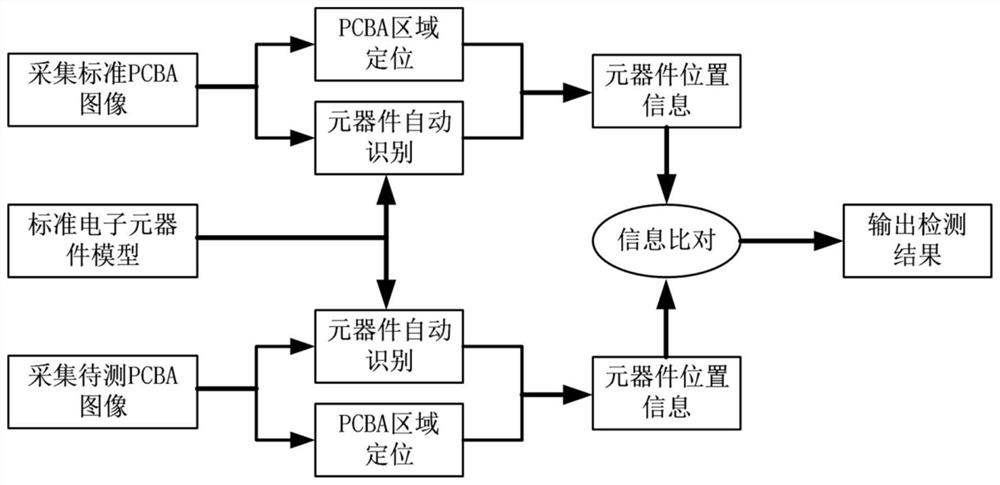

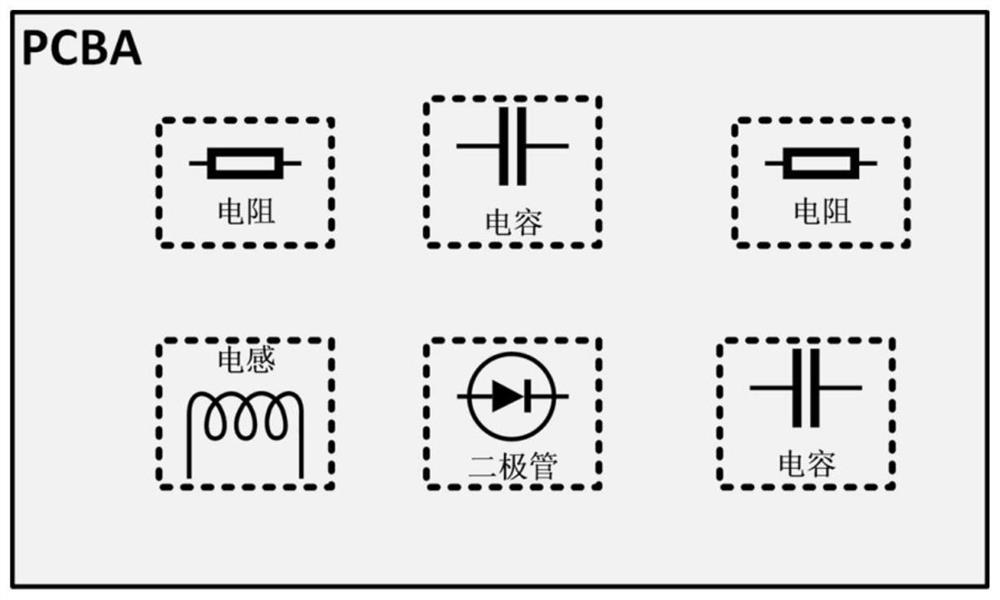

PCBA appearance detection method and device

PendingCN114004815AReduce labor costsImprove detection efficiencyImage enhancementImage analysisMachine visionEngineering

The invention discloses a PCBA appearance detection method and device, belongs to the technical field of industrial visual detection, and solves the problem of how to improve the detection efficiency of a PCBA of which the surface is provided with complex three-dimensional electronic components by adopting a machine visual detection method. The method comprises the following steps of: applying a component model obtained by deep learning training to a standard PCBA image, and extracting and identifying each component in the standard PCBA image; comparing the position information of the components of the to-be-detected PCBA board with the position information of the components of a standard PCBA board one by one, calculating the area cross ratio IOU of each corresponding marking frame to judge whether wrong welding and missing welding exist in electronic components or not, and the problems that due to the fact that a manual visual mode is mainly adopted in traditional PCBA appearance detection, the labor intensity is high, workers are prone to fatigue, and the detection efficiency is low are solved, the labor cost is reduced, and the detection efficiency is improved; the device is simple in structure and low in cost.

Owner:HRG INT INST FOR RES & INNOVATION

Chemical fiber mat cutting device

The invention discloses a chemical fiber mat cutting device which comprises a rack. A cutting frame provided with a plurality of laser cutting devices is arranged on the rack, and a feeding conveyingarea, a plurality of chemical fiber mat conveying areas and a plurality of waste material conveying areas are arranged on the rack. Each chemical fiber mat conveying area comprises a conveying grooveand a lifting conveying seat, the conveying groove is formed in the inner part of the corresponding waste material conveying area, and the lifting conveying seat is arranged below the cutting frame. The conveying groove is formed in the rack on the rear side of the lifting conveying seat, and an infrared sensor is arranged on the lifting conveying seat. Conveying mechanisms are arranged on the twosides of the end part of the conveying groove, and a discharging device is arranged on the rack of the lower end between the two conveying mechanisms. A winding frame is arranged on the rack, and a first backup roller, a group of conveying rollers, a second backup roller and a winding roller are arranged on the winding frame. The chemical fiber mat cutting device is simple in structure and reasonable in design, can convey a cut chemical fiber mat separately, can automatically discharge the chemical fiber mat, and meanwhile can collect waste materials produced after cutting. Therefore, the production efficiency is improved, and the cost is reduced.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

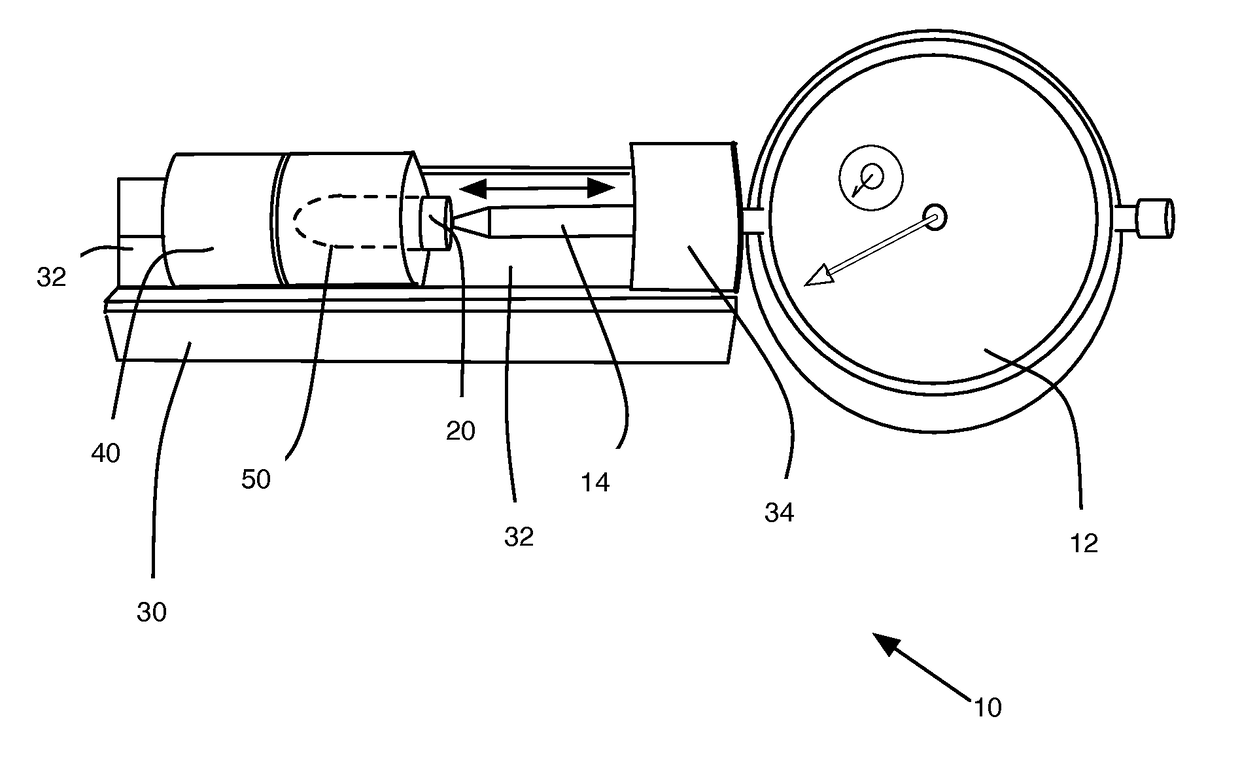

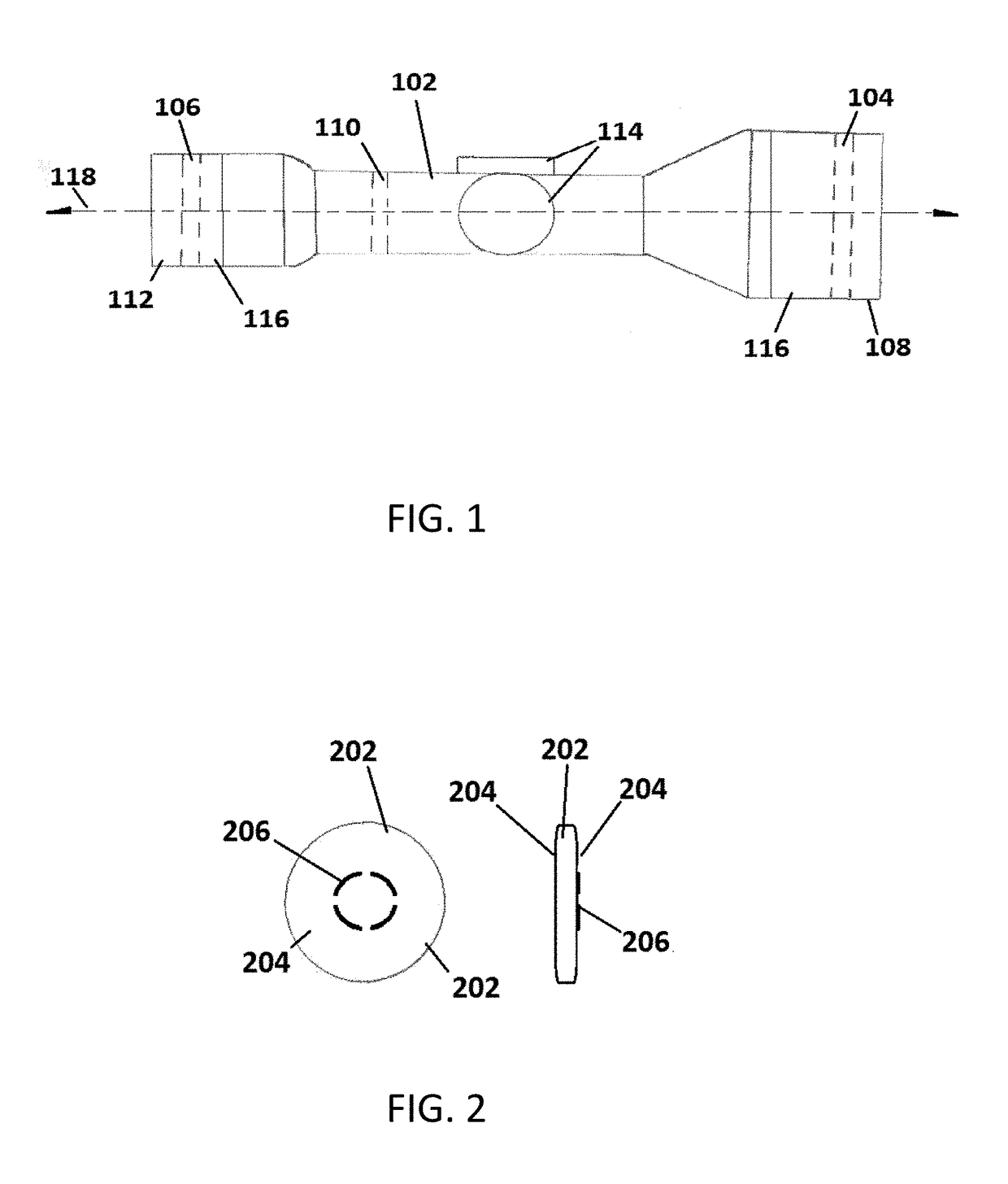

Bullet comparator

The present invention provides a device and method for improved, repeatable, consistent, rapid, and accurate measurements of a bullet using a dial indicator. The bullet comparator of the present invention consists of a fixture block having a V-shaped groove running along a long axis of the block and a dial indicator coupled to one end of the fixture, configured so its probe operably moves toward the center of the fixture. A stop block adjustably positions in the V-shaped grove of the fixture. And, at least one floating chamber selectively positions in the V-shaped grove of the fixture. The floating chamber is a cylindrical body defining an interior chamber; the interior chamber has a first ring-contact and at least a second ring-contact on an interior portion of the chamber.

Owner:HOLLAND DARRELL

Stirring device for food processing

PendingCN112371051APrevent tippingAchieve positioningTransportation and packagingMixer accessoriesProcess engineeringMechanical engineering

The invention relates to a stirring device for food processing. The stirring device comprises a food stirring tank and supporting columns, the four supporting columns are arranged on a bottom plate ofthe food stirring tank and distributed in a matrix mode, a discharging guide plate is obliquely arranged at a discharging port of the food stirring tank, a finished product collecting box is arrangedunder the oblique lower end of the discharging guide plate, and a movable locking mechanism is arranged at the lower end of the finished product collecting box. The supporting structure is arranged below an existing finished product collecting box, and through the supporting structure, the effect of convenient movement can be achieved, when the finished product collecting box is carried, the defects of traditional manual carrying can be overcome, sliding pushing type carrying is adopted, and therefore the effect of saving time and labor is achieved. The locking structure is arranged on the supporting structure, the position of the finished product collecting box can be locked through the locking structure, so that the finished product collecting box can be prevented from turning over in the collecting process, and the finished product collecting box can be positioned through the locking structure.

Owner:蔡磊磊

Layering method for feather animation

ActiveUS7649535B2Avoid intersectionConsistent placementSkinning instrumentsDrawing from basic elementsSkin surfaceAnimation

A method of animating feather elements includes: specifying initial positions for a skin surface and for feather elements; specifying positions for the skin surface at an animated time; determining a feather-ordering sequence for placing the feather elements on the skin surface; determining positions for skirt elements that provide spatial extensions for the skin surface at the animated time; determining positions for feather-proxy elements that provide spatial extensions for the feather elements at the animated time; and determining positions for the feather elements at the animated time by extracting the feather elements from the feather-proxy elements. The feather-proxy elements are determined from the skirt elements according to the feather-ordering sequence, and the feather-proxy elements satisfy a separation criterion for avoiding intersections between the feather-proxy elements.

Owner:DREAMWORKS ANIMATION LLC

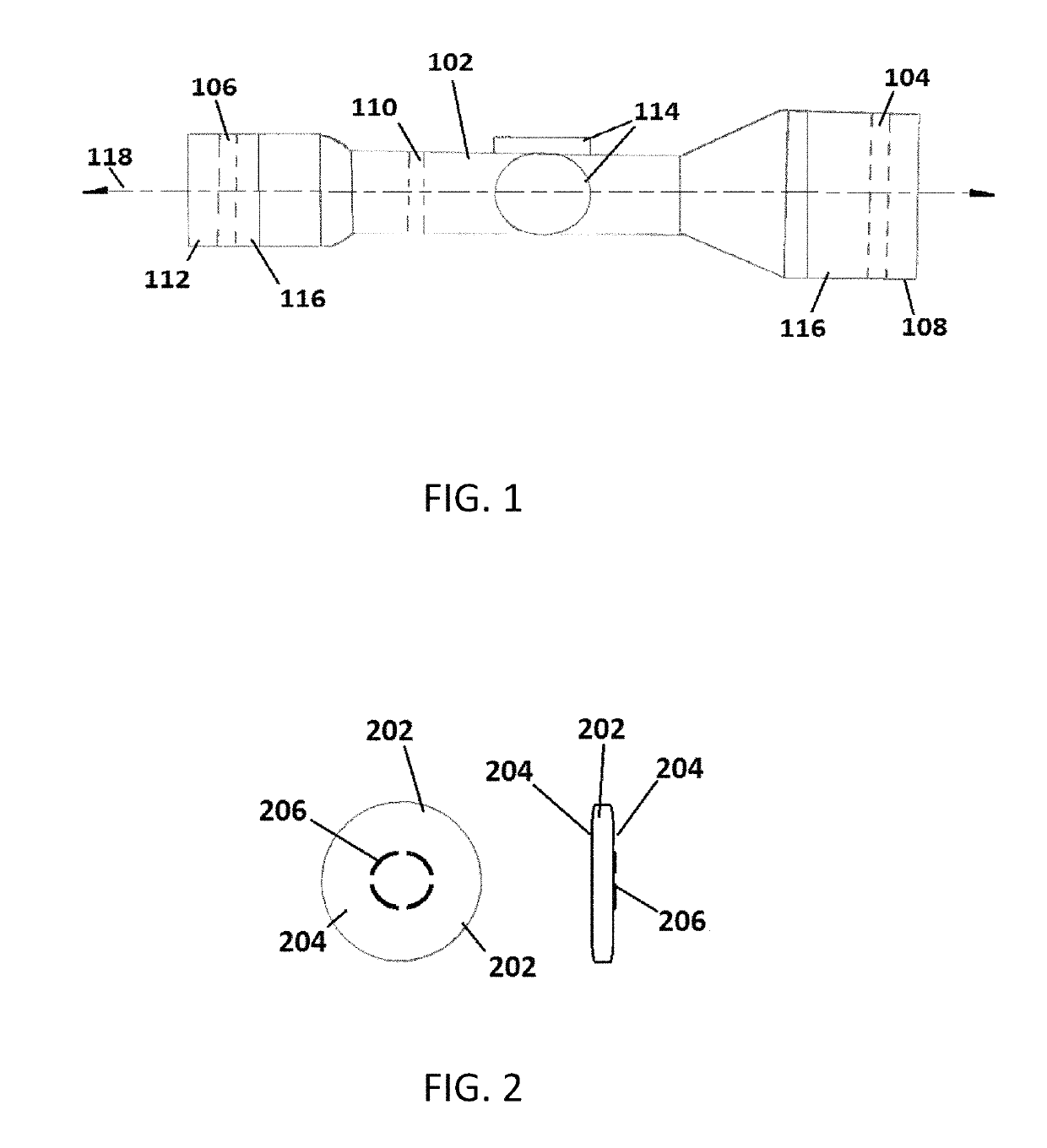

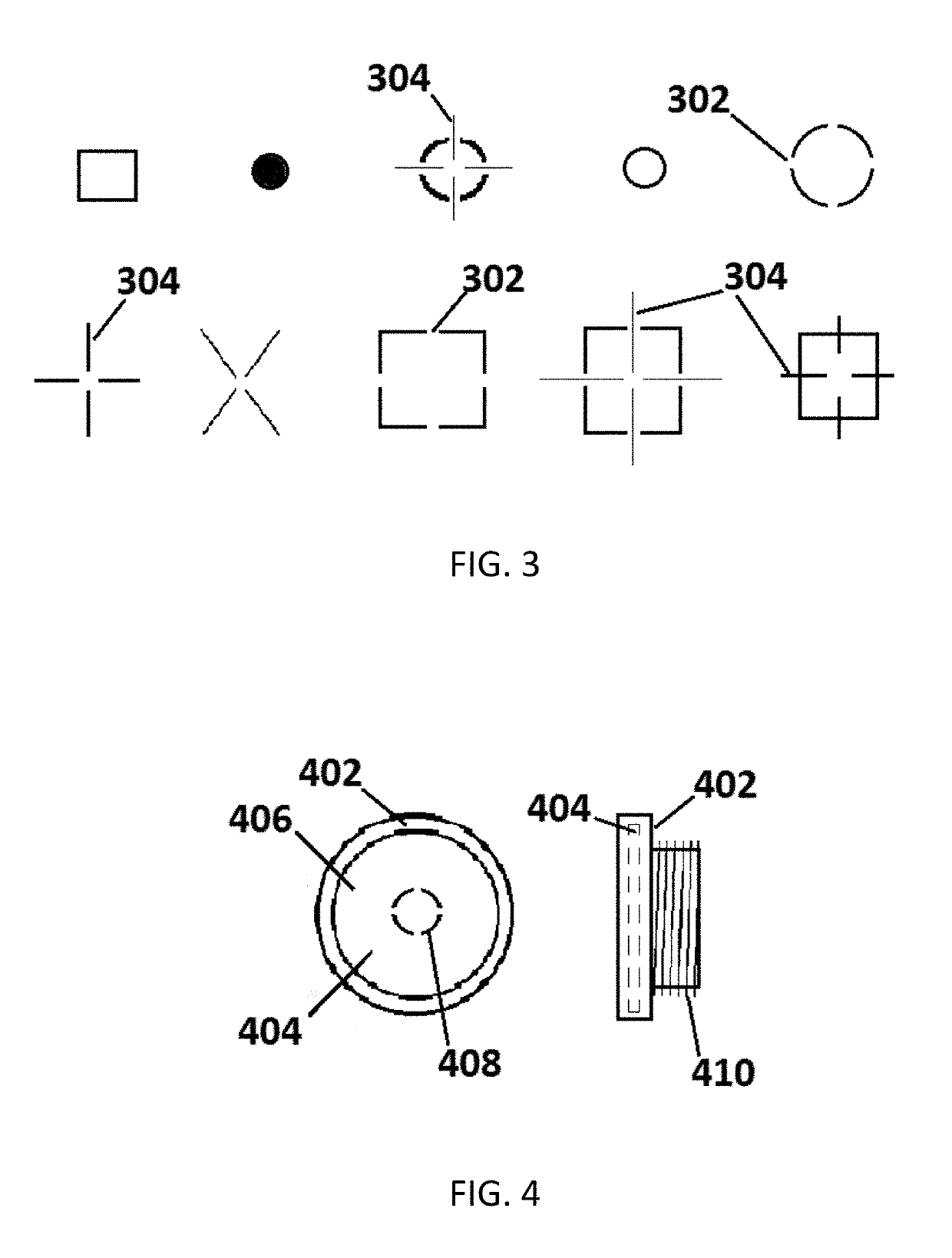

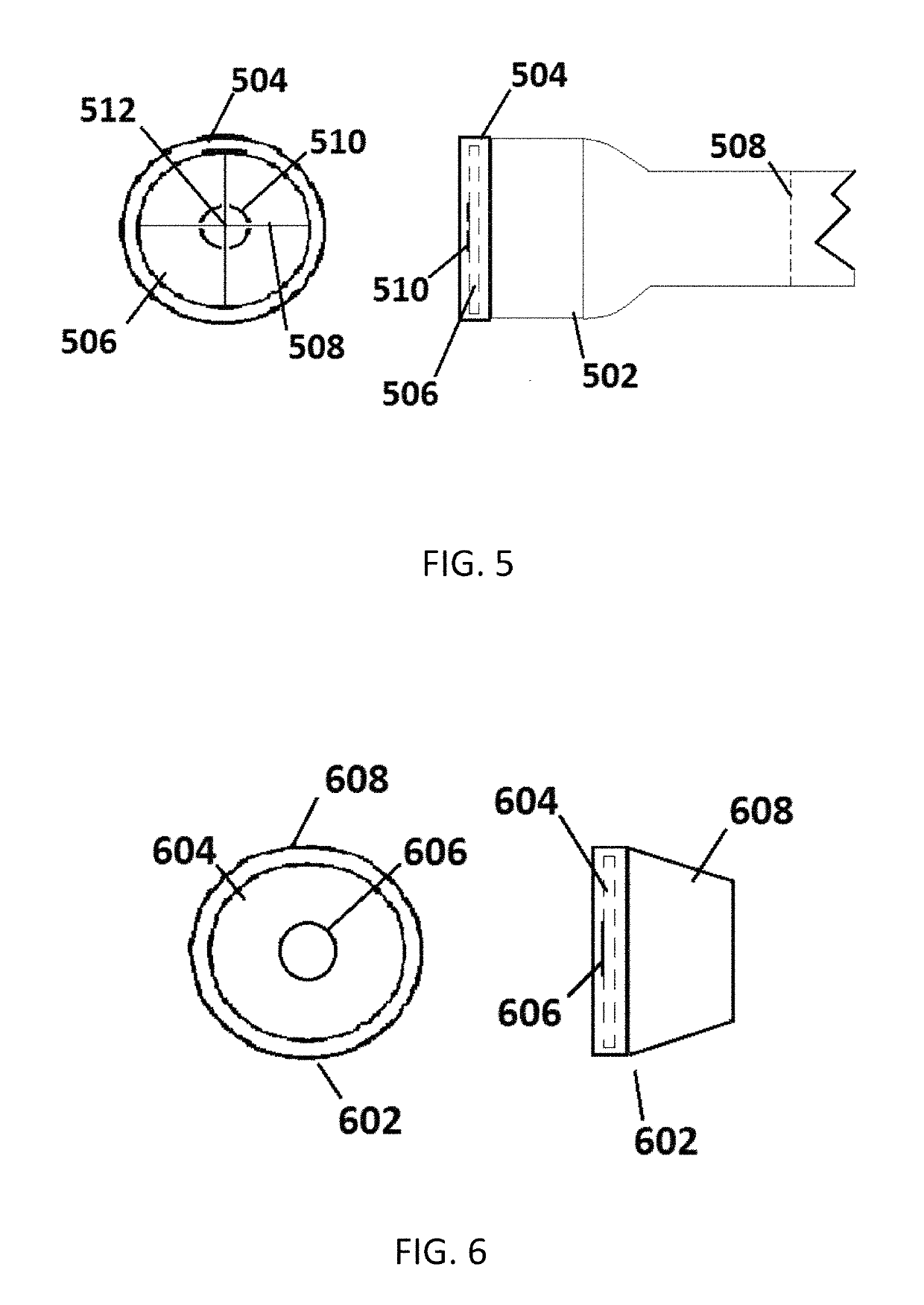

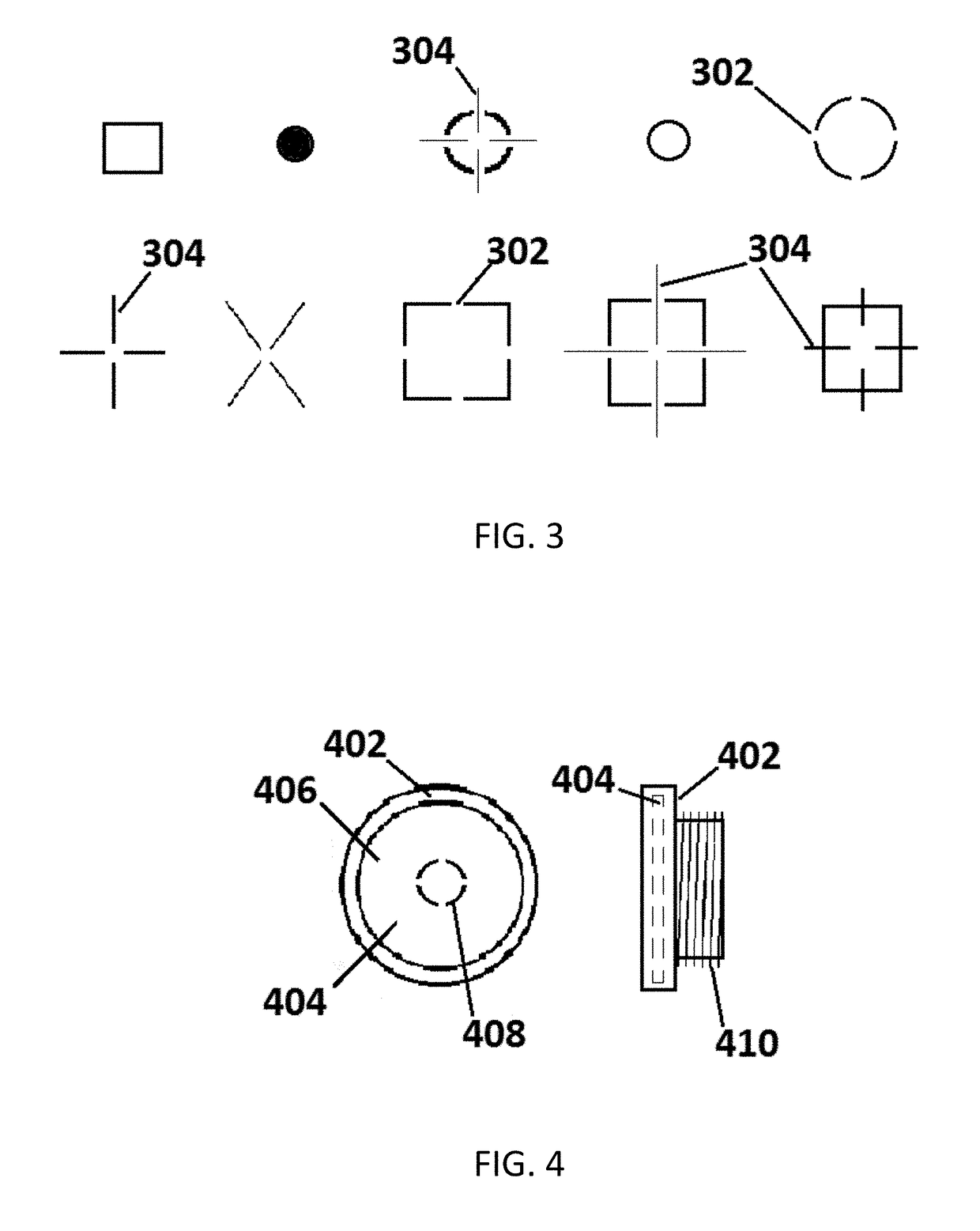

Marksman positioning device

Device and related methods for improving the accuracy and precision of firearms fitted with optical sights. The device comprises a small alignment pattern for indexing against a small, central region of a target picture aimpoint or reticle. The alignment pattern is applied to an auxiliary lens fixed in position externally behind an ocular lens. The auxiliary lens is supported by a frame secured to the optical sight or the auxiliary lens is made to adhere to the outside surface of the ocular lens. Some embodiments refract or condition light to improve target pictures. Alternatively, an alignment pattern, without an auxiliary lens, is applied directly to or made integral with an ocular lens during the manufacture of an optical sight. In general, referencing the alignment pattern with the reticle, by adjusting eye placement until a desired alignment is observed, provides consistent shooter positioning and reduced parallax.

Owner:ROCQUE WILLIAM

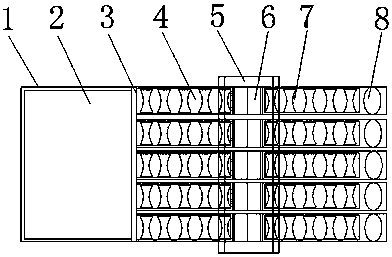

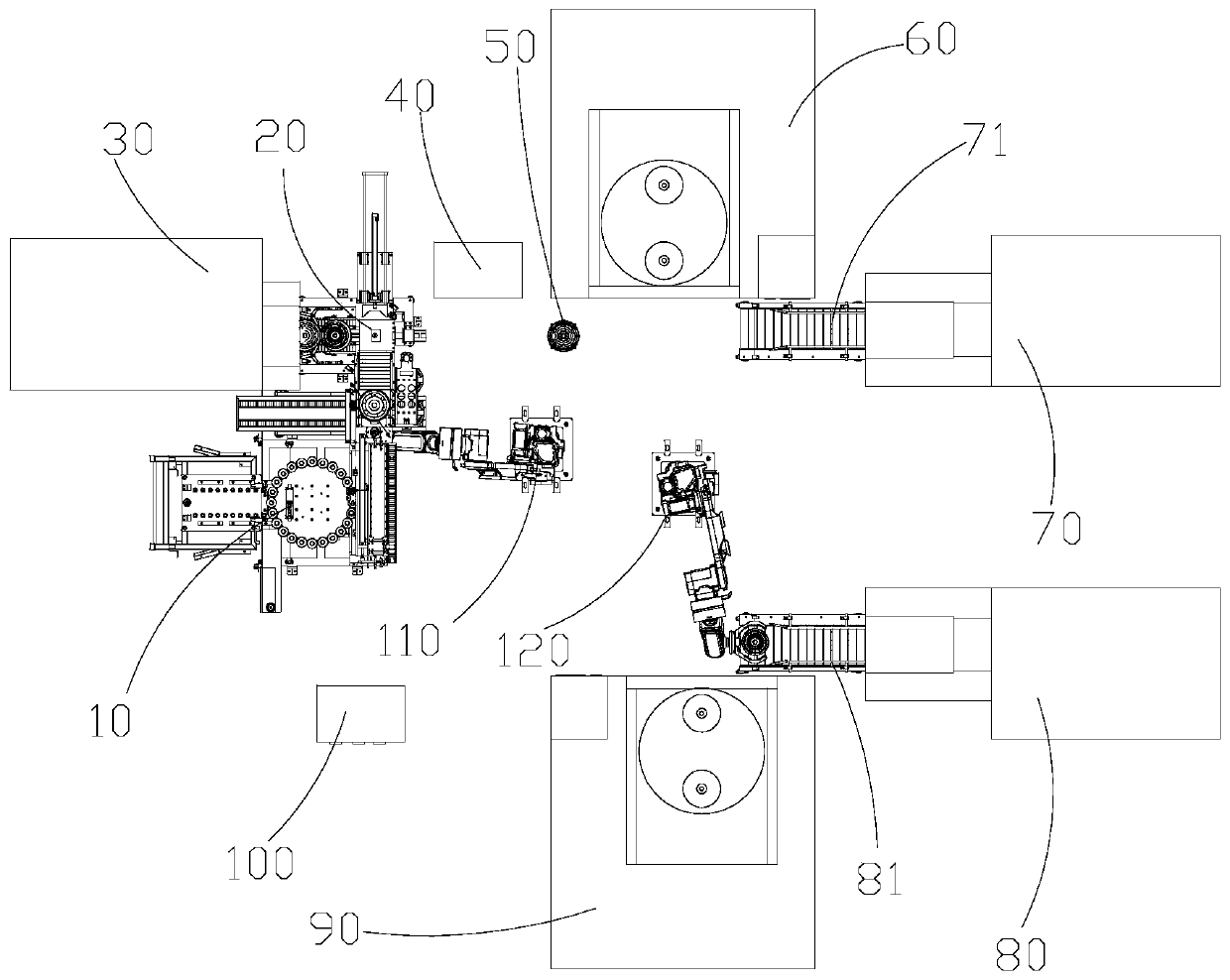

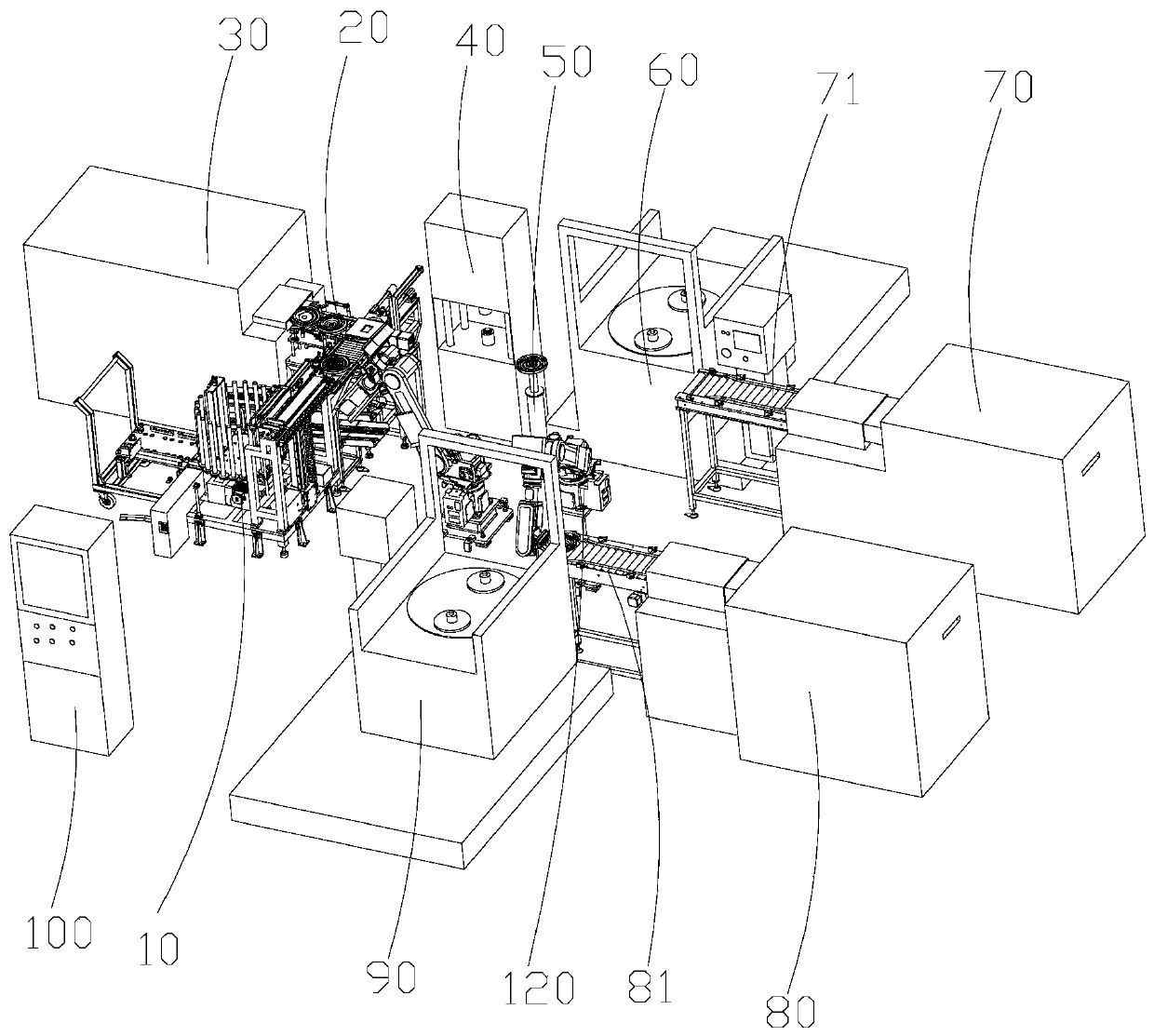

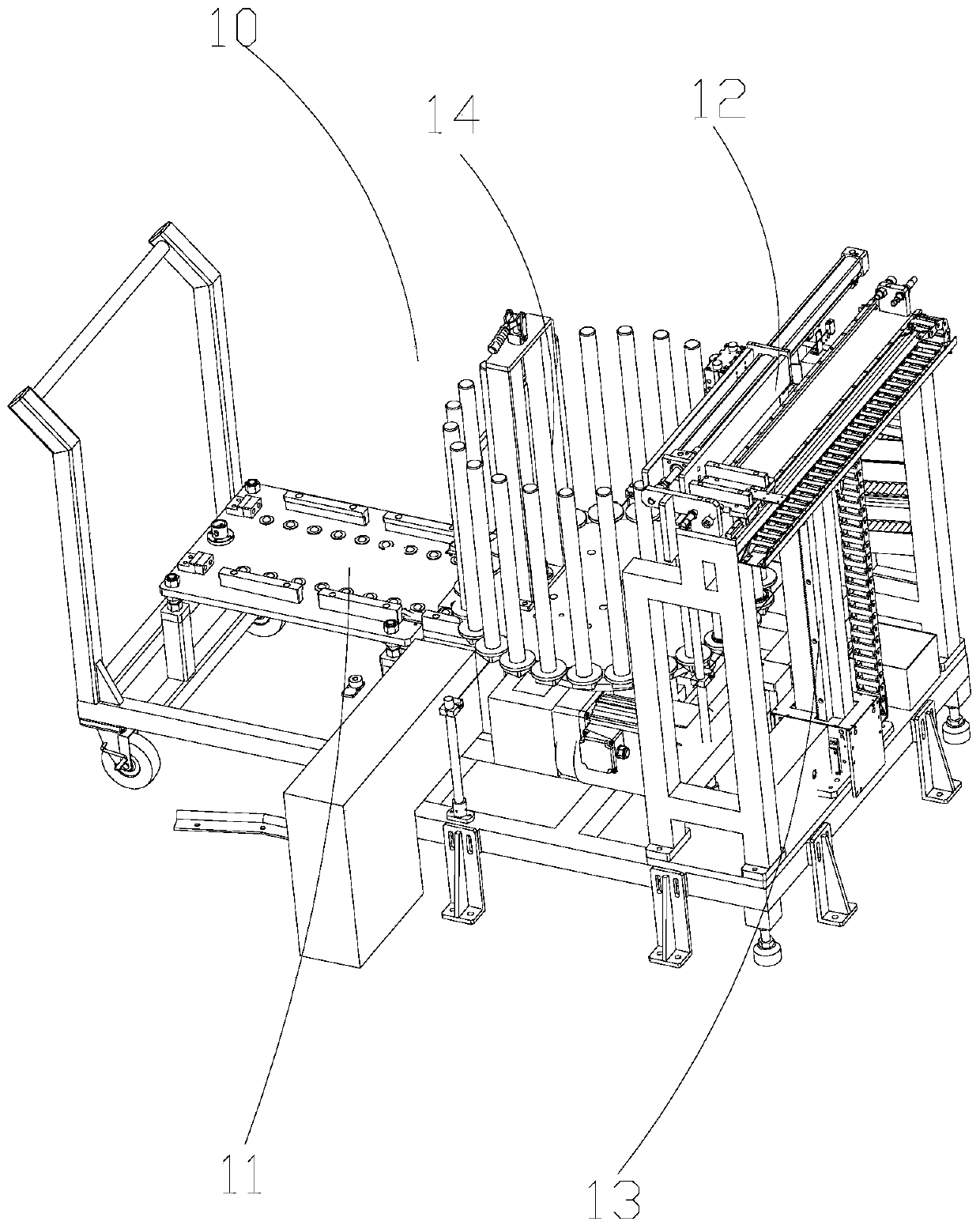

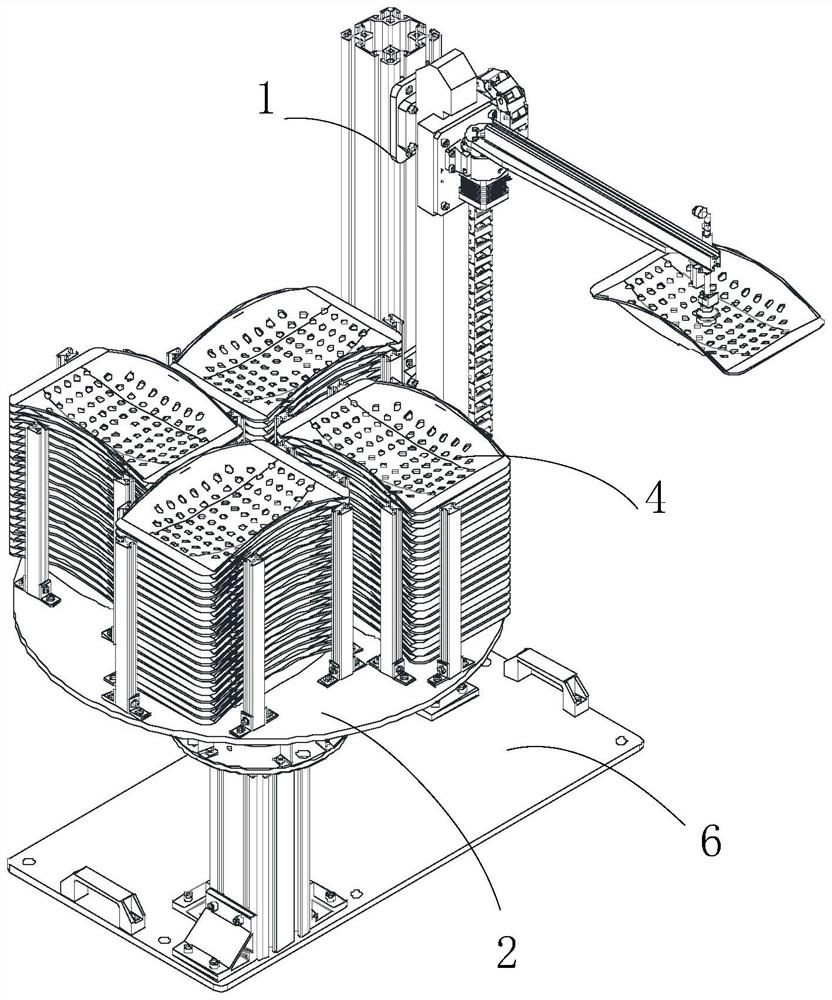

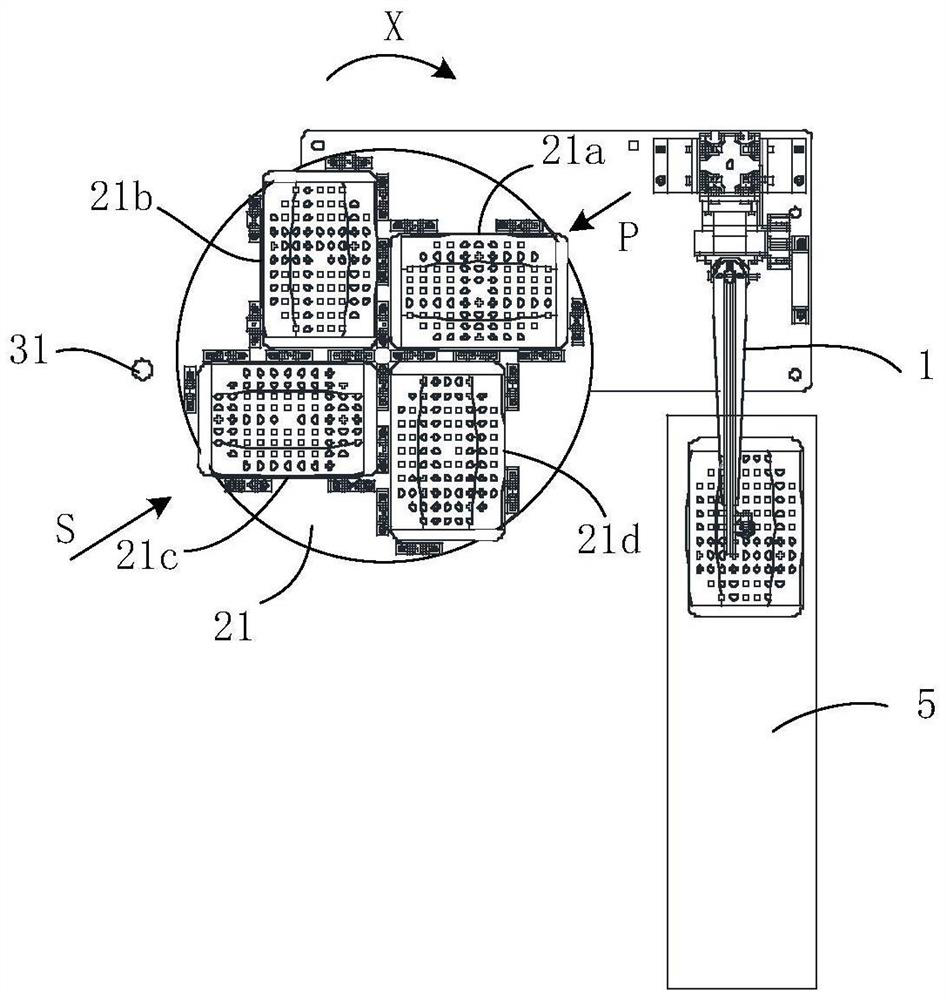

Wheel hub assembly line

InactiveCN110977453ASave human effortImprove work efficiencyGripping headsAssembly machinesTemperingRobot hand

The invention provides a wheel hub assembly line. According to the wheel hub assembly line of the invention, a feeding device, a turnover device, a cleaning device, a press-in device, a transfer table, a first welding machine, a first high-frequency tempering furnace, a second high-frequency tempering furnace, a second welding machine and a controller are annularly arranged; a first mechanical armand a second mechanical arm are arranged in the middle; wheel hub accessories are grabbed through the first mechanical arm and the second mechanical arm which are arranged in the middle; and the turnover, pressing, welding, tempering, cleaning and other procedures of the wheel hub accessories are achieved; the assembly of the wheel hub accessories is automatically completed and does not need manual participation. With the wheel hub assembly line adopted, labor is greatly saved; working efficiency is improved; the placement positions of products are consistent; the quality of the products is stable; and labor cost is reduced.

Owner:佛山市铭柯智能设备科技有限公司

Marksman Positioning Device

Devices and methods for improving the accuracy and precision of firearm shooting are disclosed. Devices comprise an alignment pattern for enhancing optical sights. The enhanced sights provide consistent shooter positioning, reduced parallax errors, and improved target pictures.

Owner:ROCQUE WILLIAM

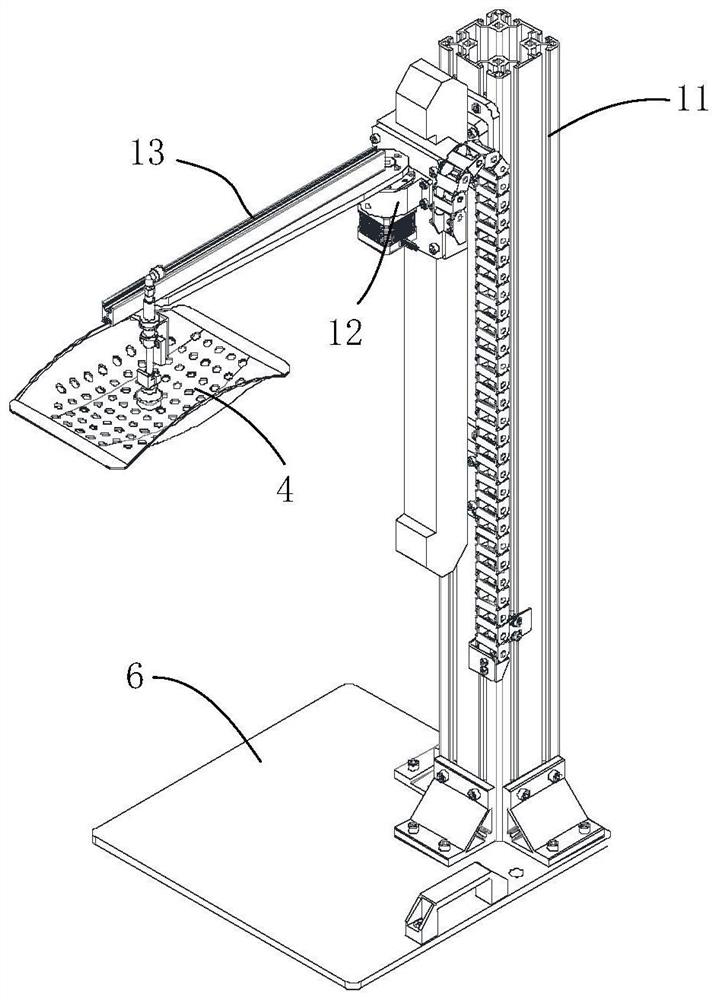

Food container transfer device and transfer method

ActiveCN113998460ARealize automatic transferConsistent placementControl devices for conveyorsDe-stacking articlesEngineeringMechanical engineering

The invention relates to a food container transfer device and a transfer method. The food container transfer device comprises: a temporary storage unit used for temporary storage of food containers to be transferred; and a transfer unit, wherein the transfer unit comprises a lifting mechanism, a rotating mechanism and a picking arm. The lifting mechanism is configured to drive the picking arm to ascend and descend in the way, the rotating mechanism is configured to drive the picking arm to rotate in the way, and the picking arm is rotated to the position above the temporary storage unit so as to pick up the food containers stored by the temporary storage unit, and then the picking arm is rotated to the target position so as to release the picked food containers to the target position.

Owner:SHENGDOUSHI SHANGHAI SCI & TECH DEV CO LTD

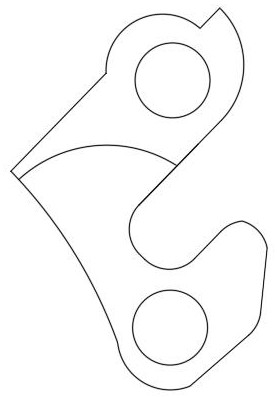

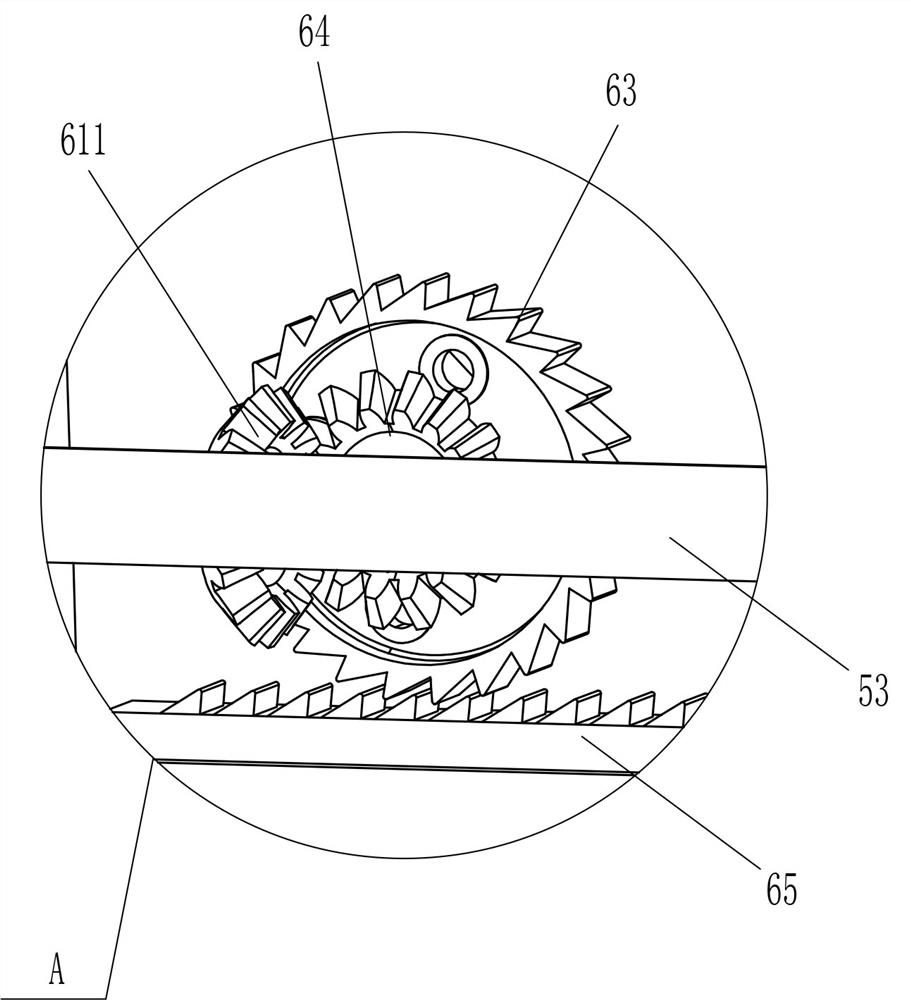

Variable-speed tail hook machining equipment with automatic sand blasting and ash removing functions

PendingCN112809564AFully contactedThe effect of uniform sandblastingBlast gunsAbrasive machine appurtenancesSand blastingReciprocating motion

The invention discloses a variable-speed tail hook machining equipment with automatic sand blasting and ash removing functions and relates to the technical field of special-shaped component machining and detection. The variable-speed tail hook machining equipment specifically comprises a workbench, a controllable variable-direction sand blasting mechanism, a reset intermittent feeding mechanism, a rotary telescopic mechanism and a tenon-and-mortise clamping mechanism. A control end is arranged on one side of the workbench. According to the variable-speed tail hook machining equipment with the automatic sand blasting and dust removing functions, a rotary telescopic mechanism is arranged, a power source is connected with a grooving rack through a transmission crank to form a transmission structure, and a sliding base on one side of the output end of the grooving rack is driven to be located in a rail to do transverse reciprocating motion; and ,meanwhile, a rotating shaft with a gear at the middle end is connected with a rack through shaft sleeves penetrating through two sides of the top end of a sliding seat, and the rack is driven by a sliding sleeve at the surface end of a guide rod to drive the tenon-and-mortise clamping mechanism at the output end of the rotating shaft to rotate, so that full contact between a sand blasting material and each end face of a tail hook component is realized in the rotary telescopic movement process of the mechanism, and the effect of uniform sand blasting is achieved.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Automatic discharging printing machine for environment-friendly bag processing

ActiveCN112140704AFast printEasy to operateRotary pressesConveyor partsProcess engineeringPrinting press

The invention relates to a printing machine, and particularly relates to an automatic discharging printing machine for environment-friendly bag processing. The automatic discharging printing machine for environment-friendly bag processing can replace people to print environment-friendly bags, and is convenient to operate, high in working efficiency and consistent in printed pattern position. The automatic discharging printing machine for environment-friendly bag processing comprises an L-shaped plate and an operation plate, wherein u-shaped fixing blocks are symmetrically installed on one sideoutside the L-shaped plate, and the operation plate is fixedly connected between the ends of the two u-shaped fixing blocks close to the L-shaped plate. According to the automatic discharging printing machine for environment-friendly bag processing, the environment-friendly bags are placed on the L-shaped plate, a button is pressed, an air cylinder is started, a printing plate swings downwards tomake contact with the environment-friendly bags, a roller moves rightwards to print patterns on the environment-friendly bags, after pattern printing is completed, the printing plate swings upwards to reset, and therefore the environment-friendly bags can be rapidly printed, operation is convenient, and the working efficiency is high.

Owner:日照坤钰包装科技有限公司

Condiment dispensing device

ActiveUS10618076B2Reduce impactReduce noiseLiquid surface applicatorsSpraying apparatusShock absorberPhysics

A condiment dispensing device is provided that, when activated by a user, may expel a condiment from a condiment cartridge secured within the condiment dispensing device. The condiment dispensing device includes a recess at its bottom portion in which a dampener member may be secured. When the dampener member is secured in the recess, the bottom portion of the dispensing device is flat, which results in the device being orientation within a holder in a consistent and predictable fashion. Because the dampener member may be made of a rubber or soft plastic, when the condiment dispensing device is placed in the holder, substantially less impact and noise are created than if the dispensing device were construed entirely made of metal.

Owner:HUHTAMAKI INC

Electrolyzed suspension rod for special-shaped sealing rings

Owner:苏州井上橡塑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com