Patents

Literature

116 results about "Staple gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A staple gun or powered stapler is a hand-held machine used to drive heavy metal staples into wood, plastic, or masonry. Staple guns are used for many different applications and to affix a variety of materials, including insulation, house wrap, roofing, wiring, carpeting, upholstery, and hobby and craft materials.

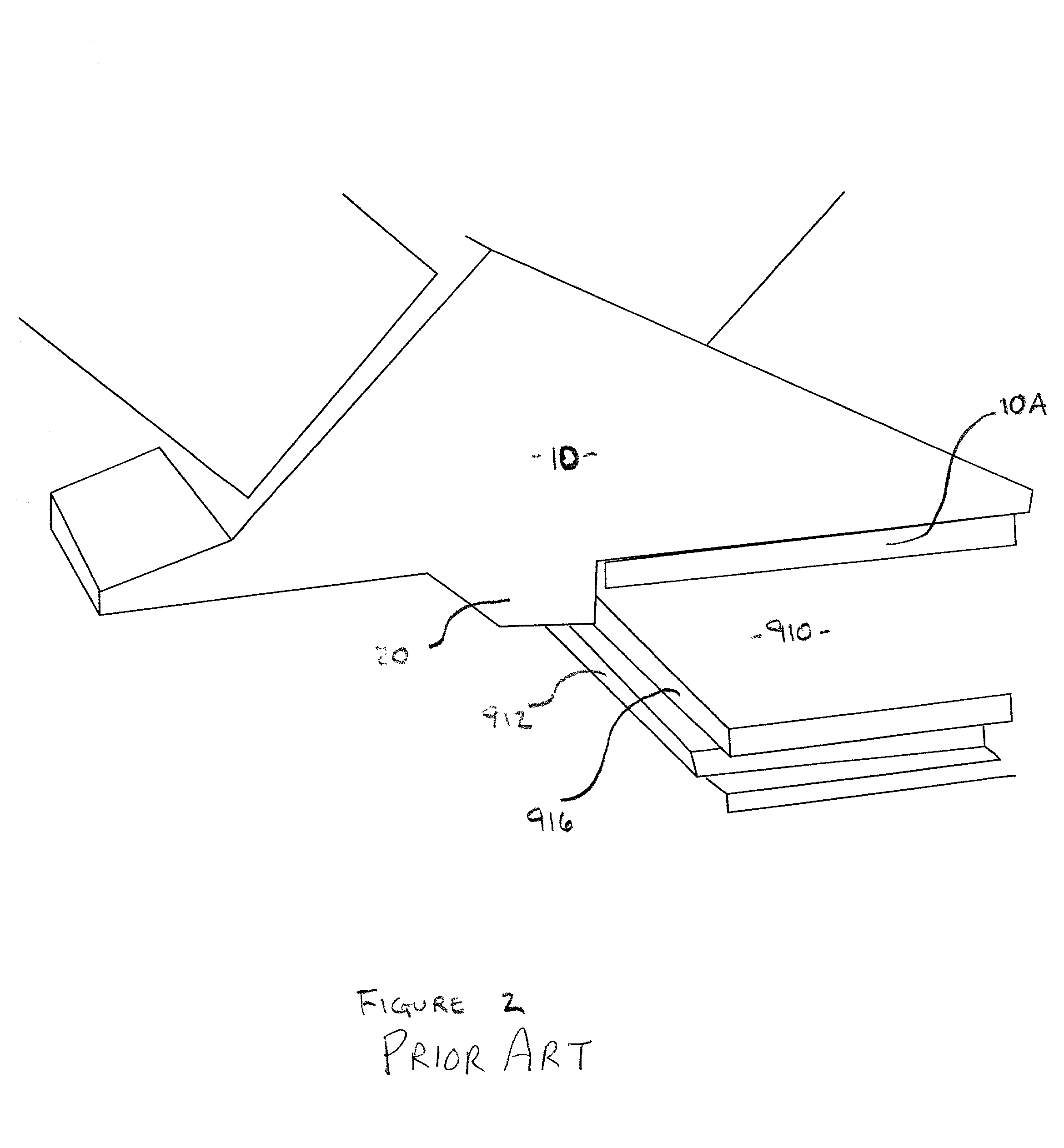

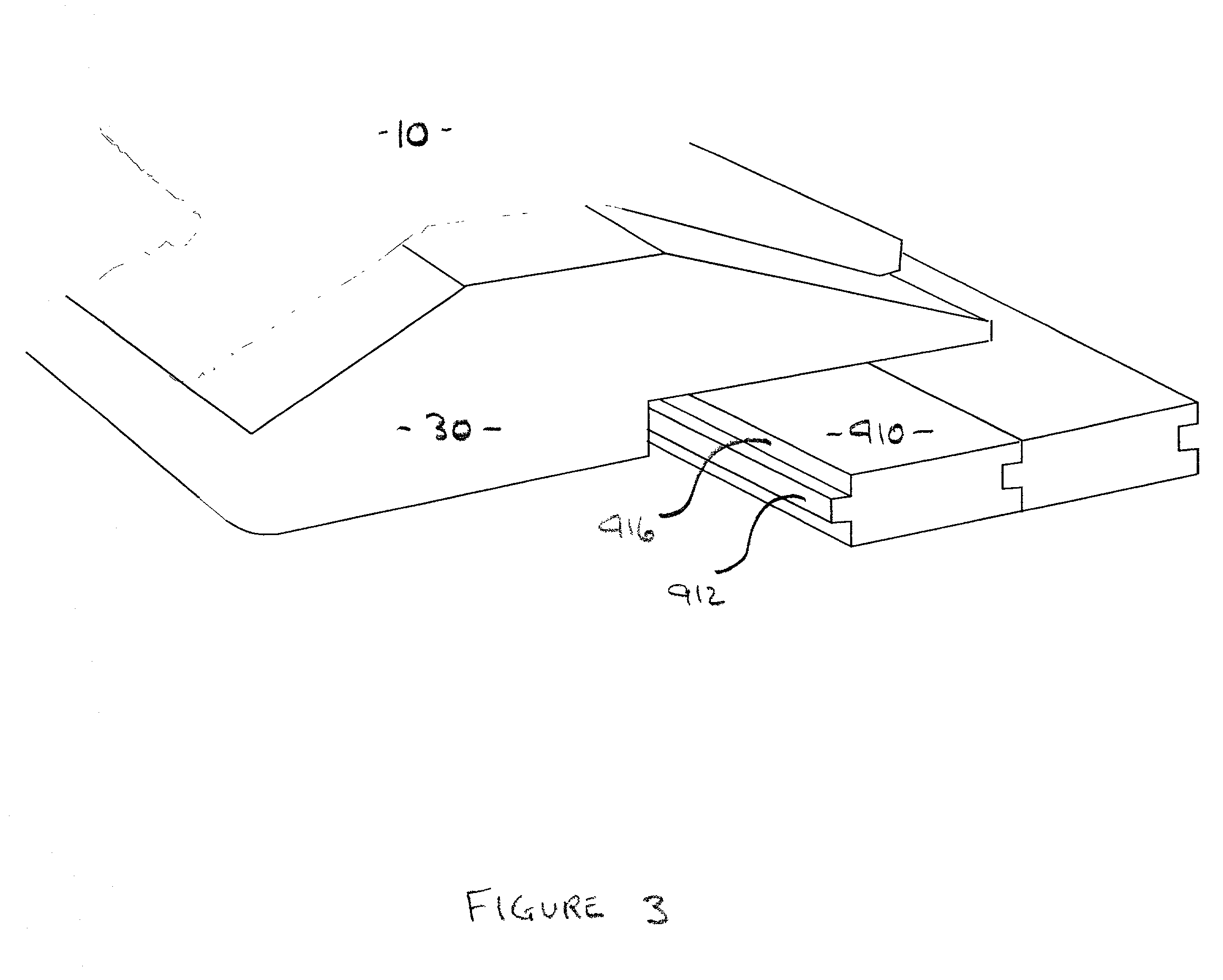

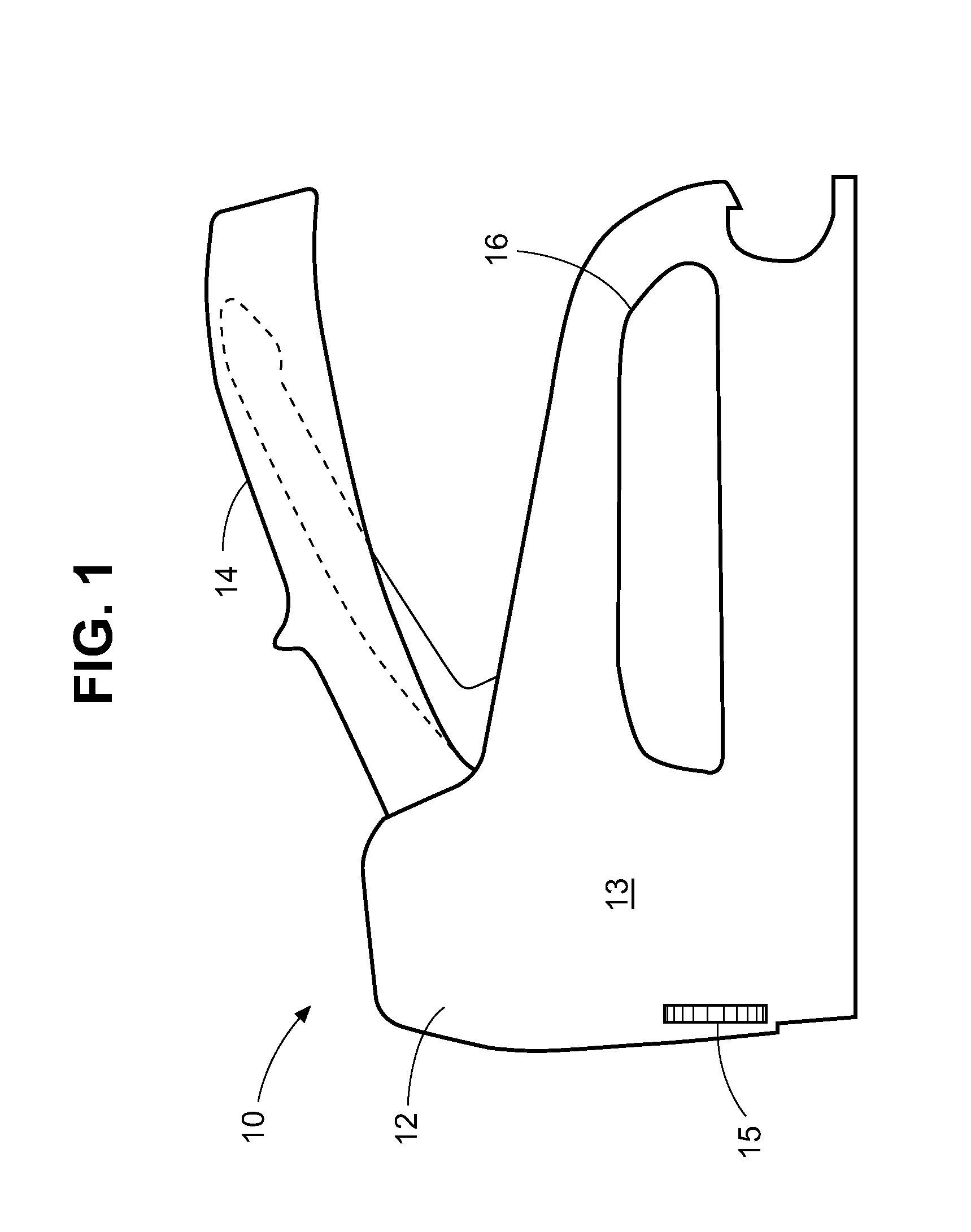

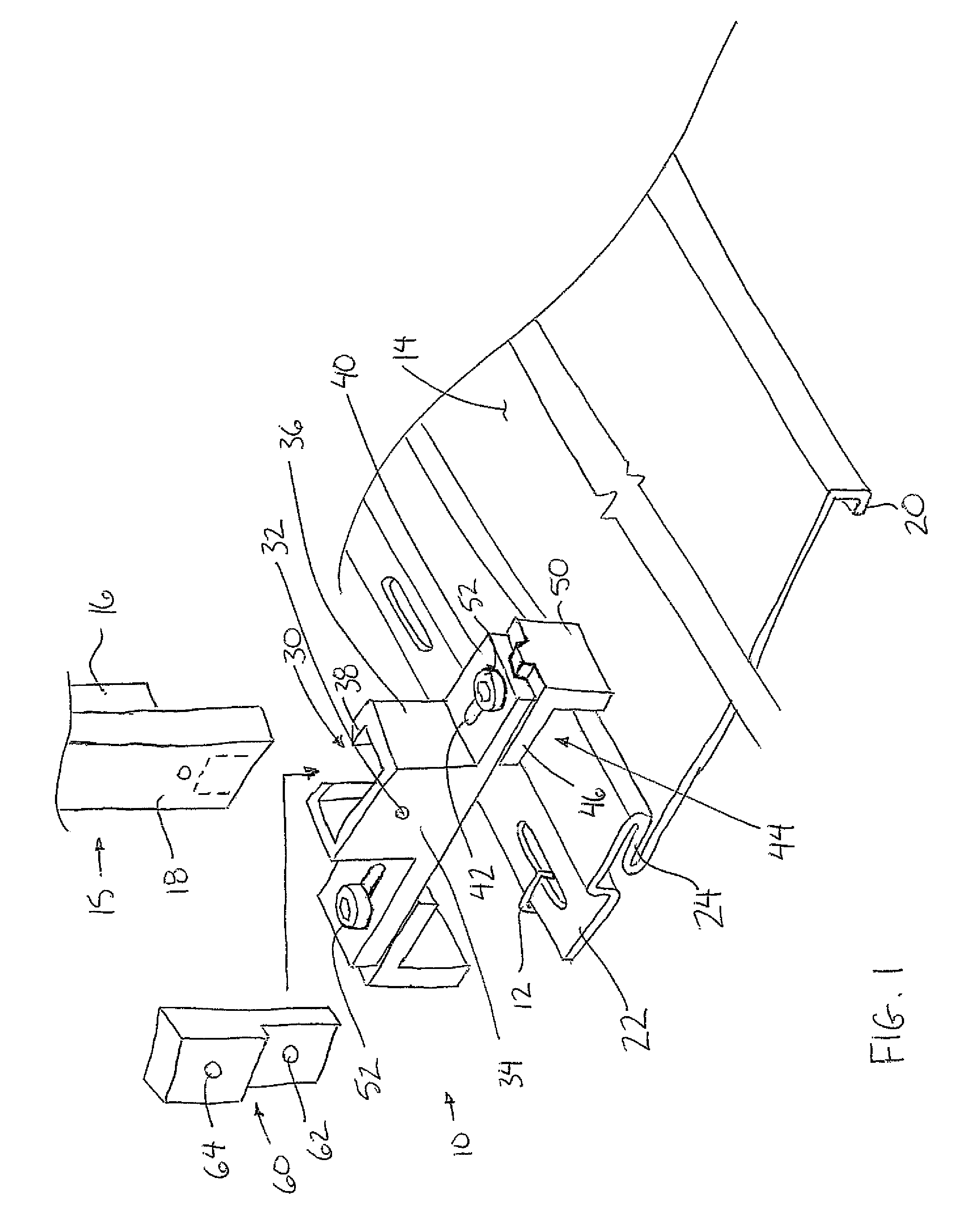

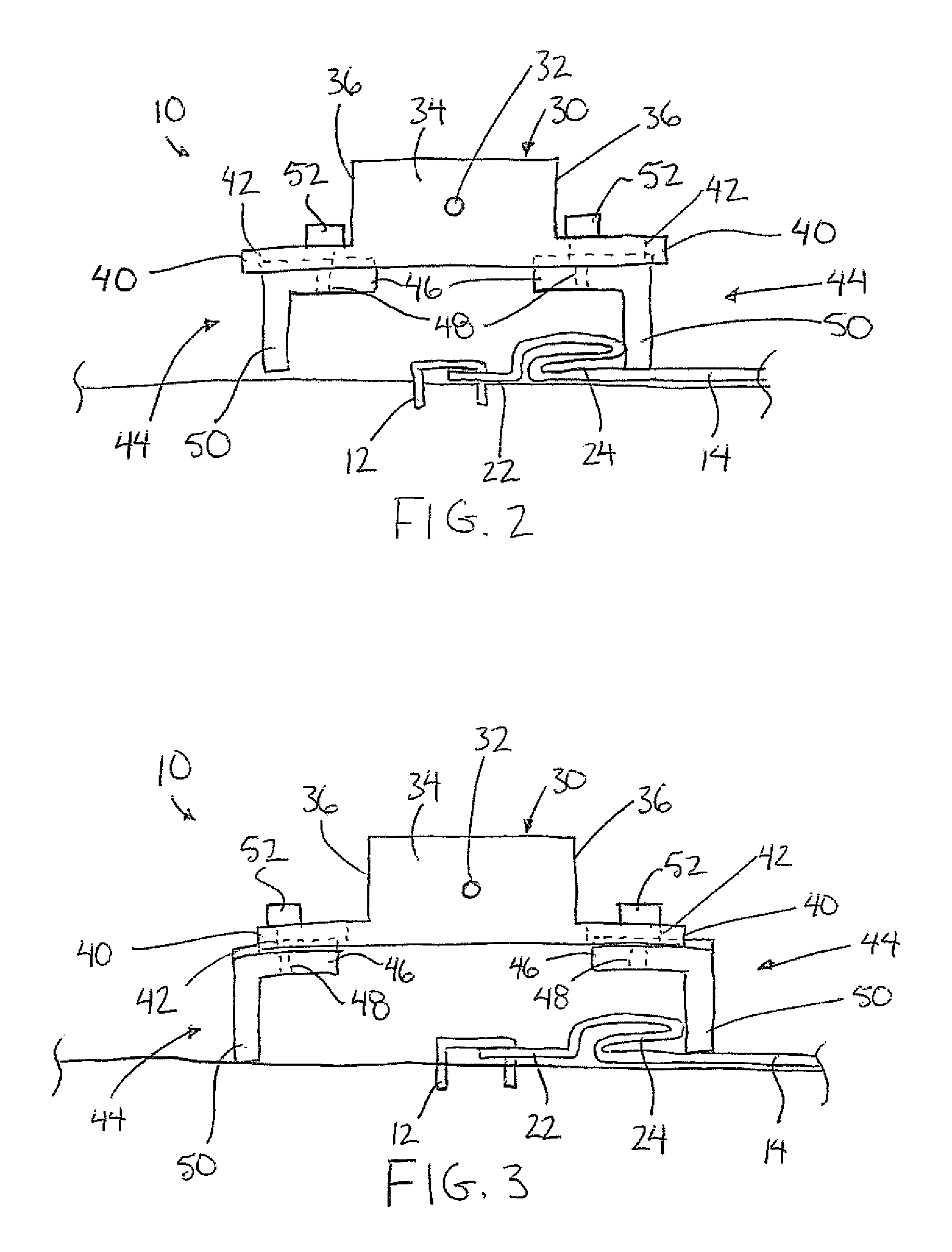

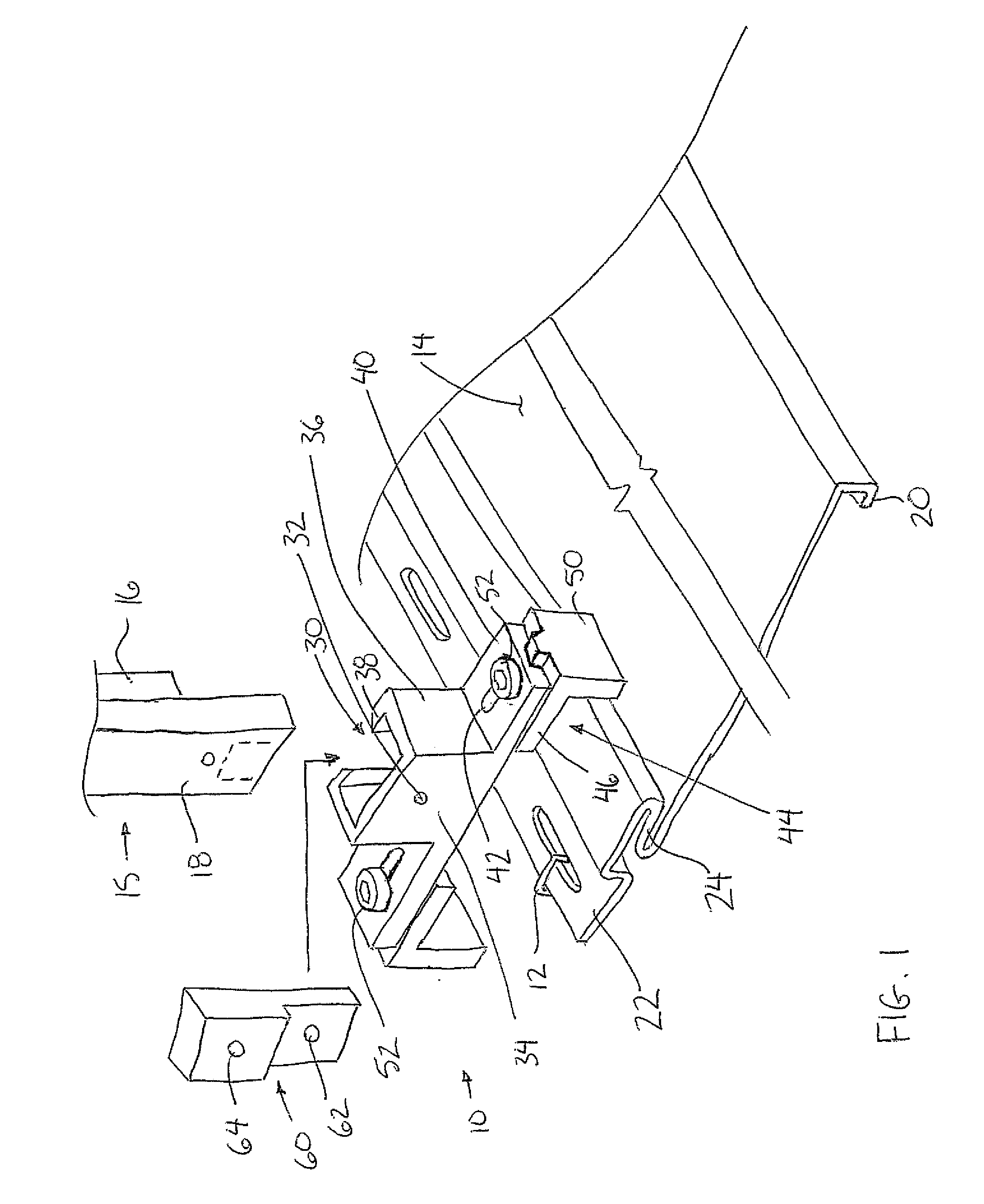

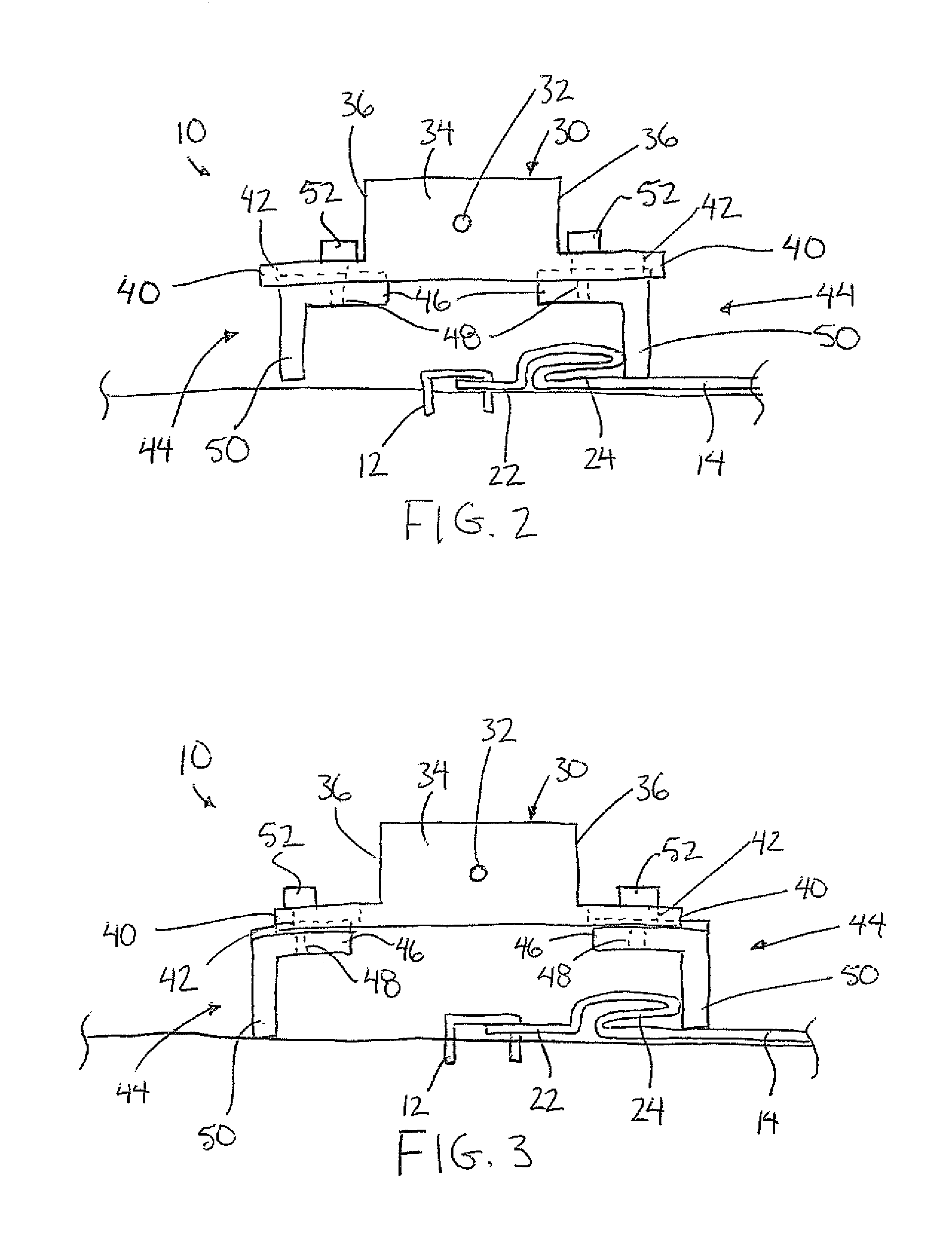

Accessory device for nail and staple guns

InactiveUS6631836B2Eliminate impact damageEasy to useStapling toolsNailing toolsStaple gunTongue and groove

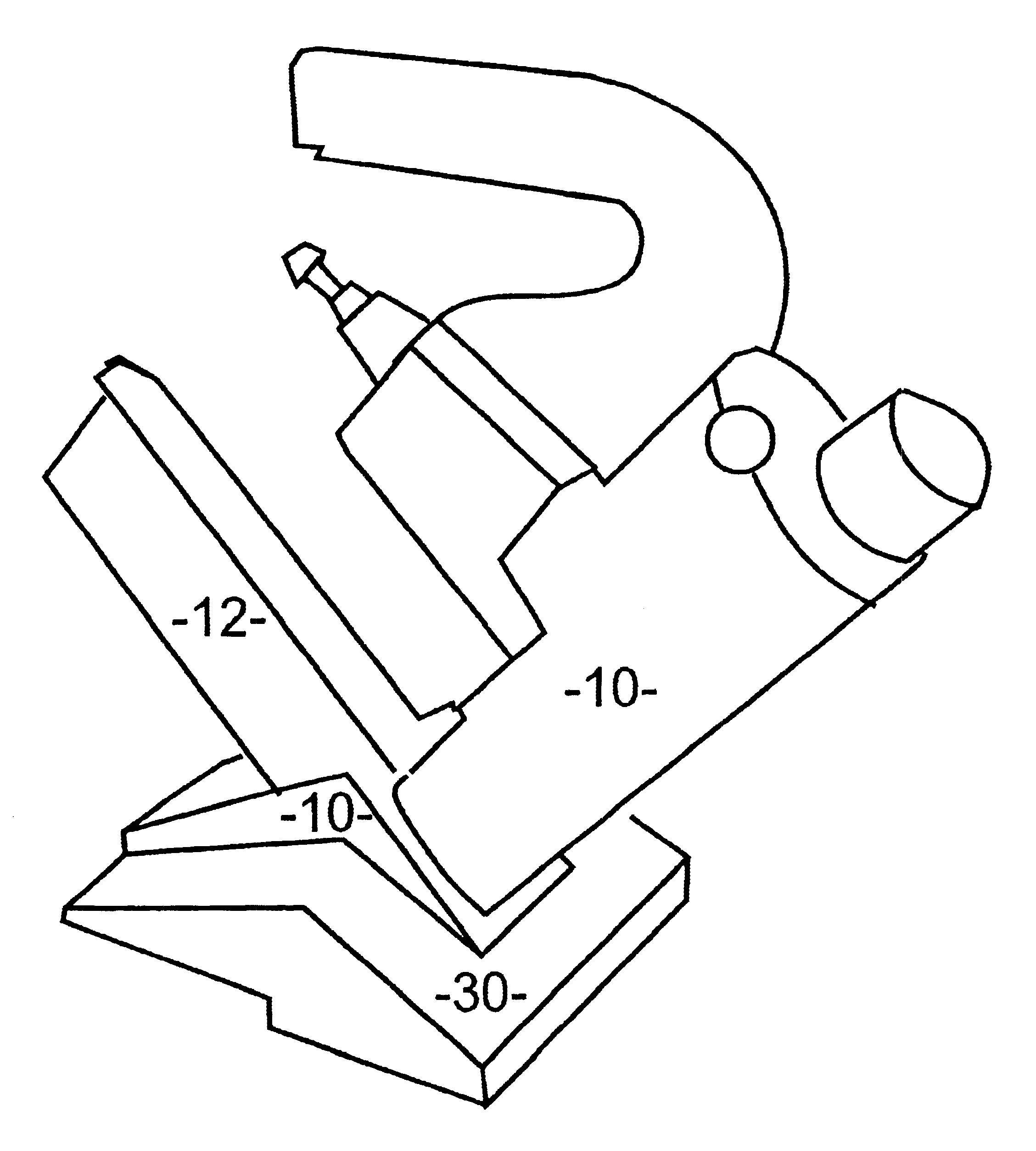

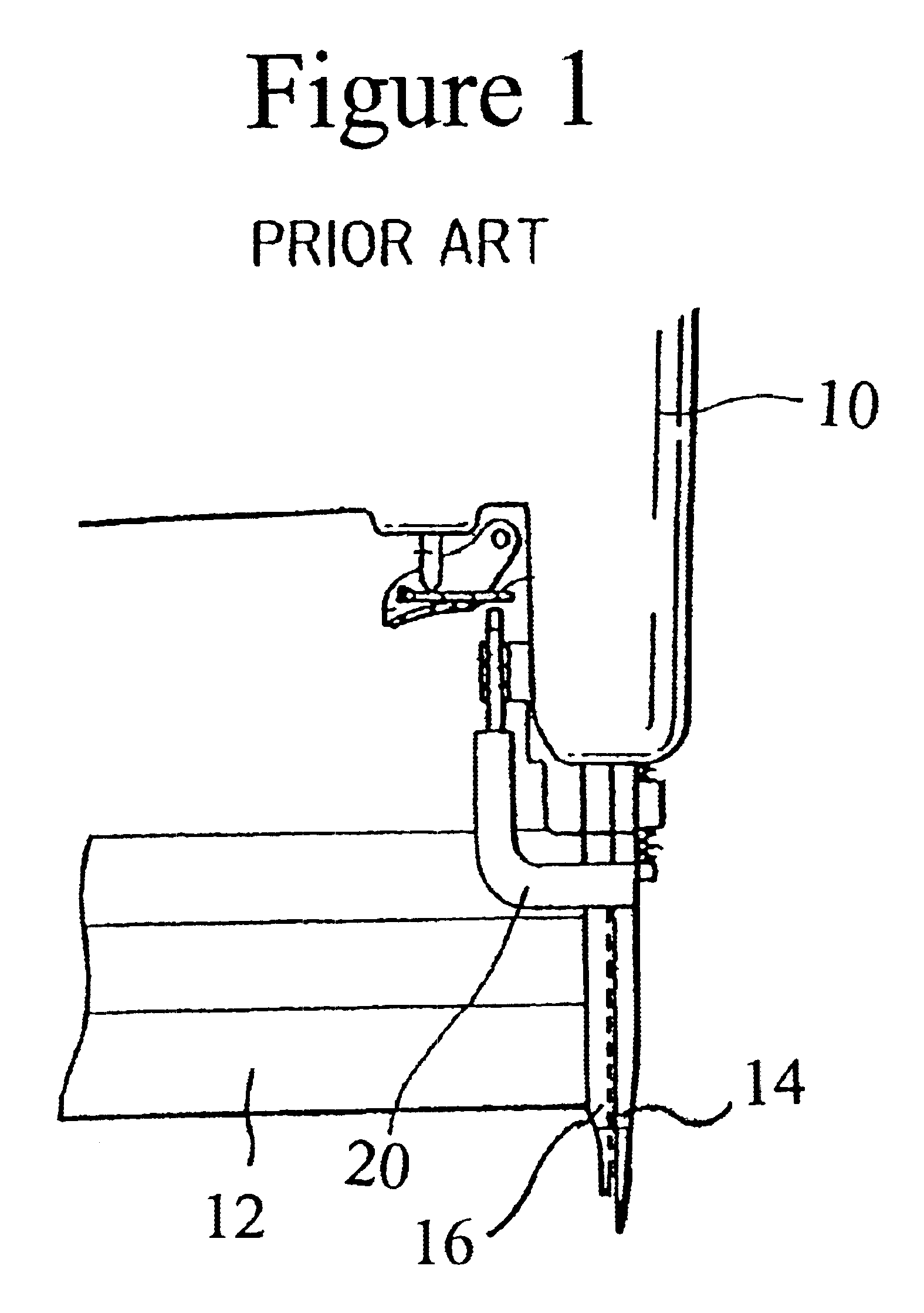

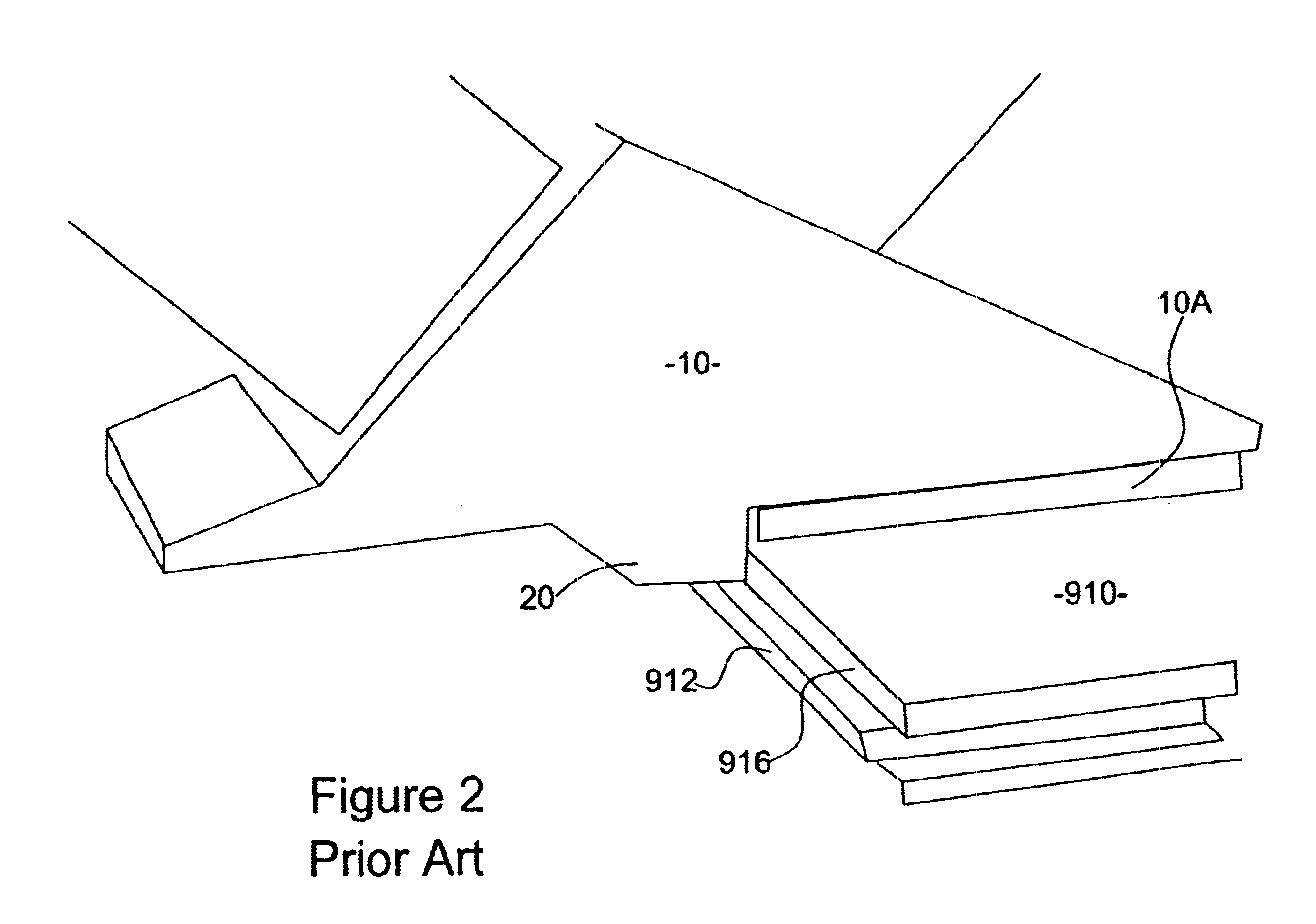

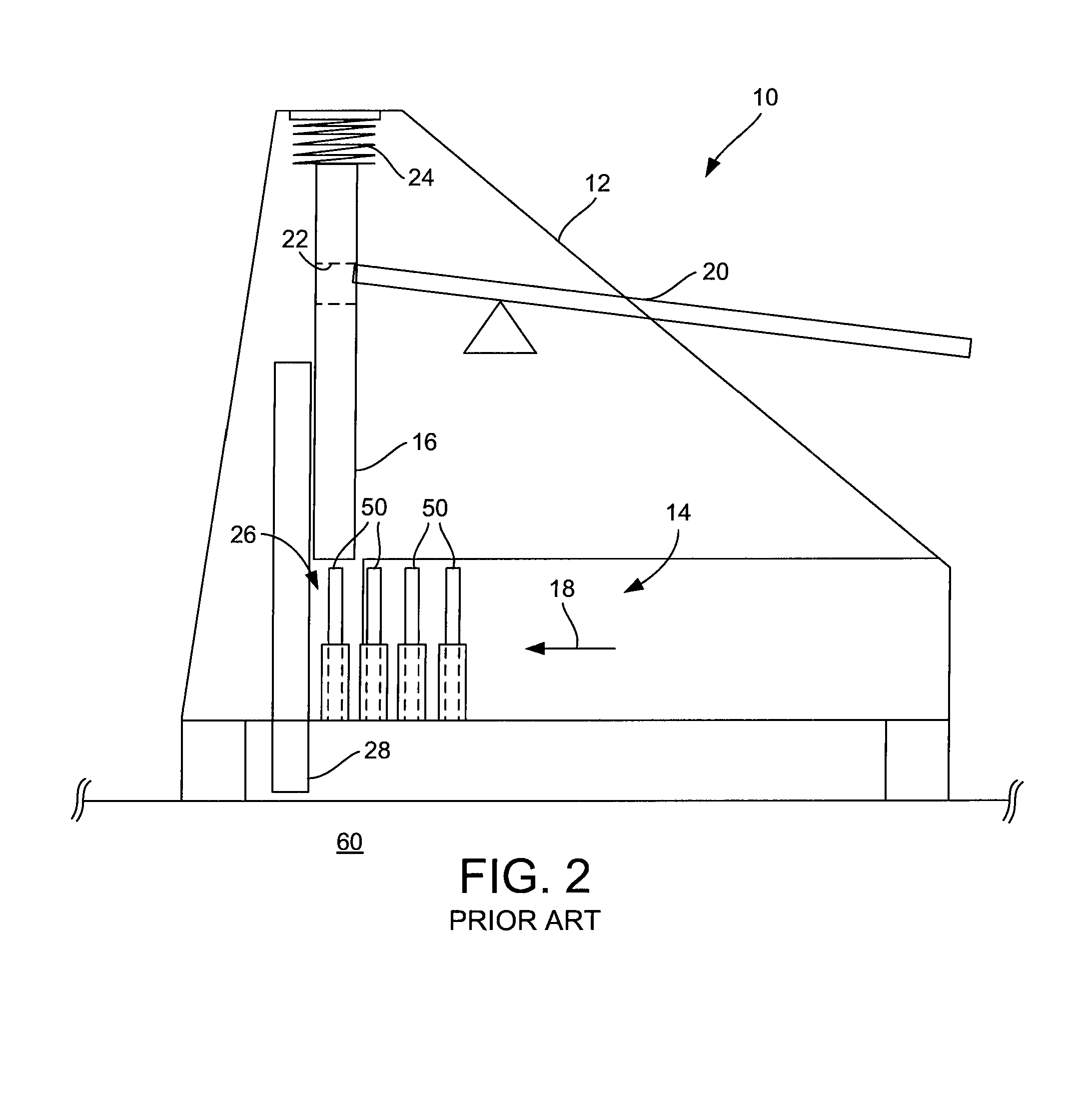

An accessory device for fastener-driving tools such as nail and staple guns is provided. The device serves as a positioning guide for the tool and is designed to provide sufficient spacing and orientation between the fastener-driving tool and the target construction material. The device can be integrated into the body of the fastener-driving tool, manufactured as an attachment or manufactured as a separate tool. It prevents impact marring at the visible surface of the construction material by redirecting the force of the blow to a non-visible surface on the assembled construction material. Furthermore it increases speed and ease of movement for the user by serving as a guide for stability and ease of alignment. The device changes the impact point between the driving tool and the construction material, broadens the area of impact and protects the top edge of a tongue and groove construction material from impact damage.< / PTEXT>

Owner:DICKHAUT JOHN

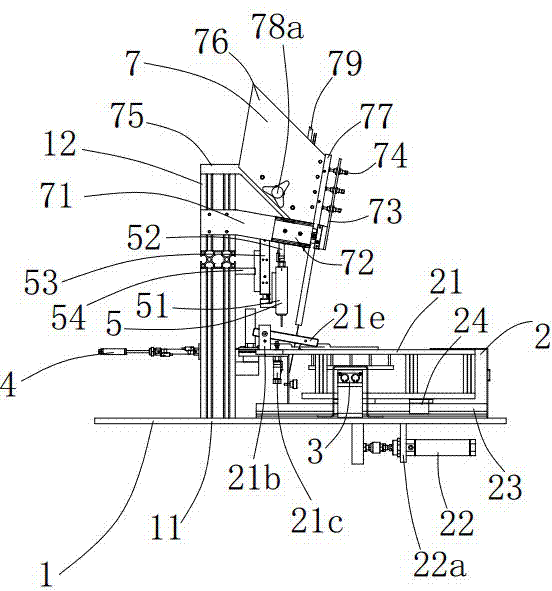

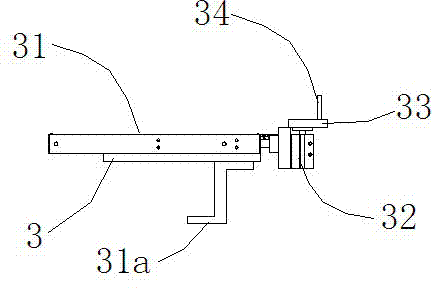

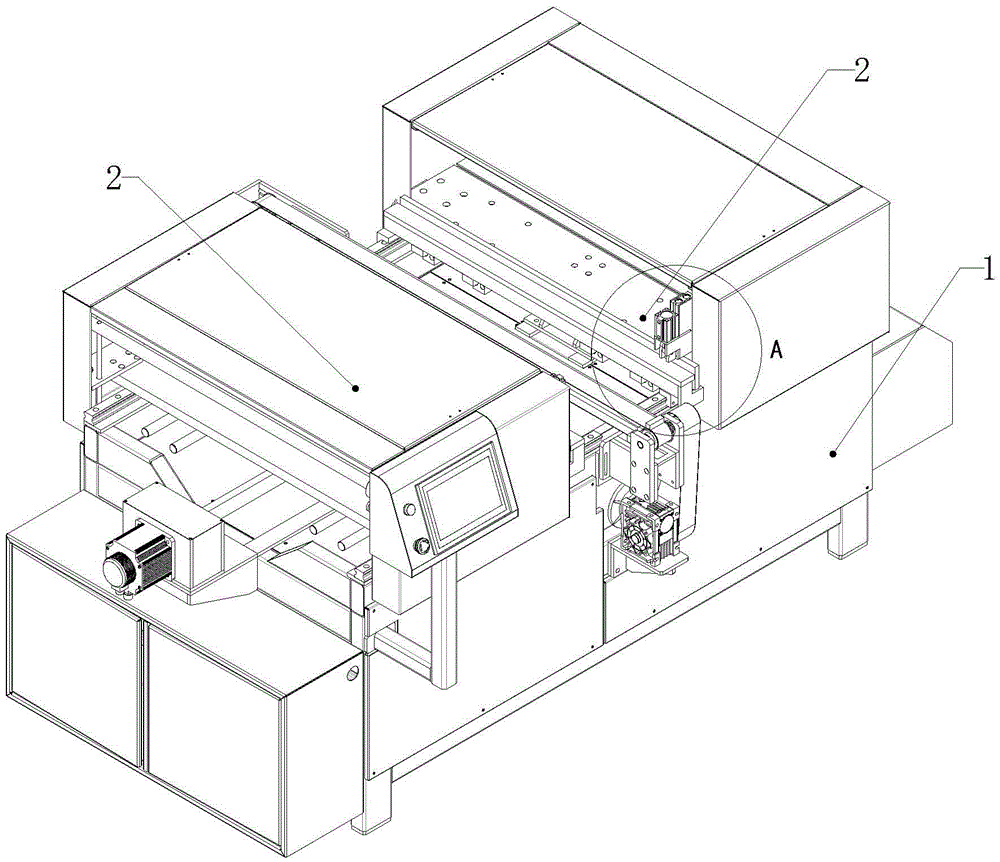

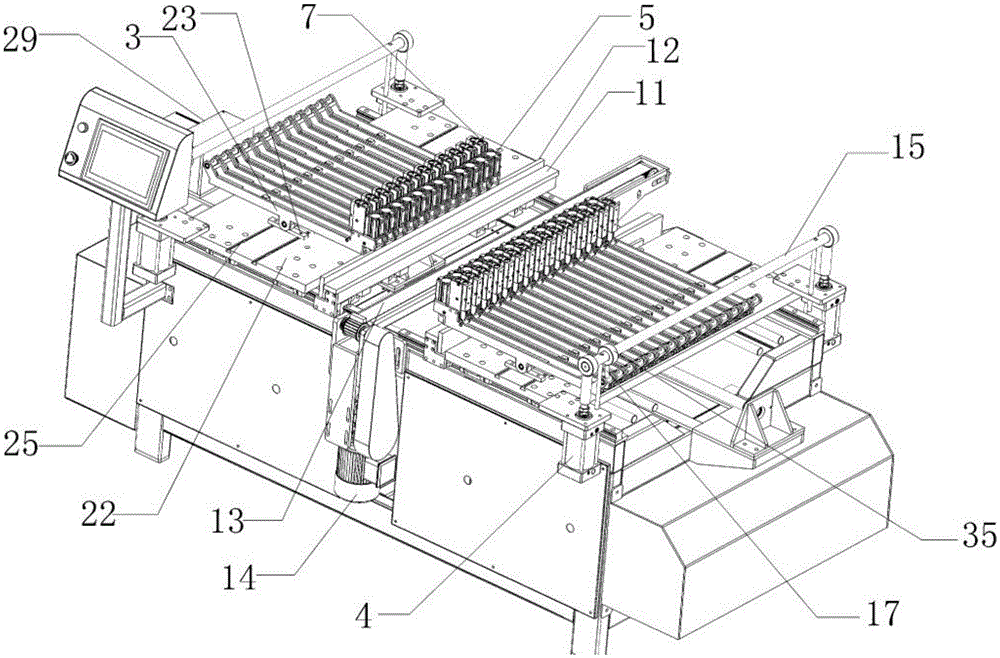

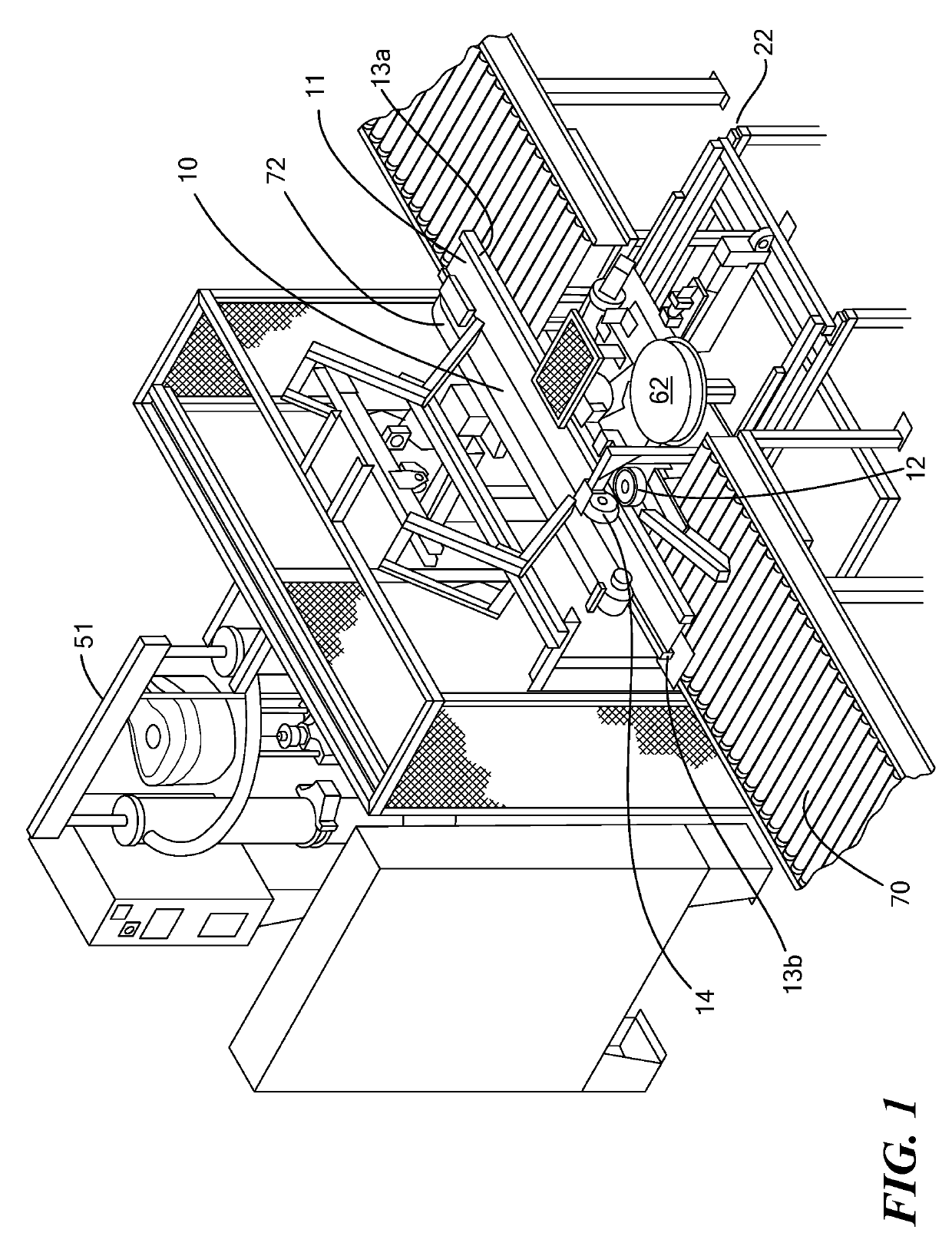

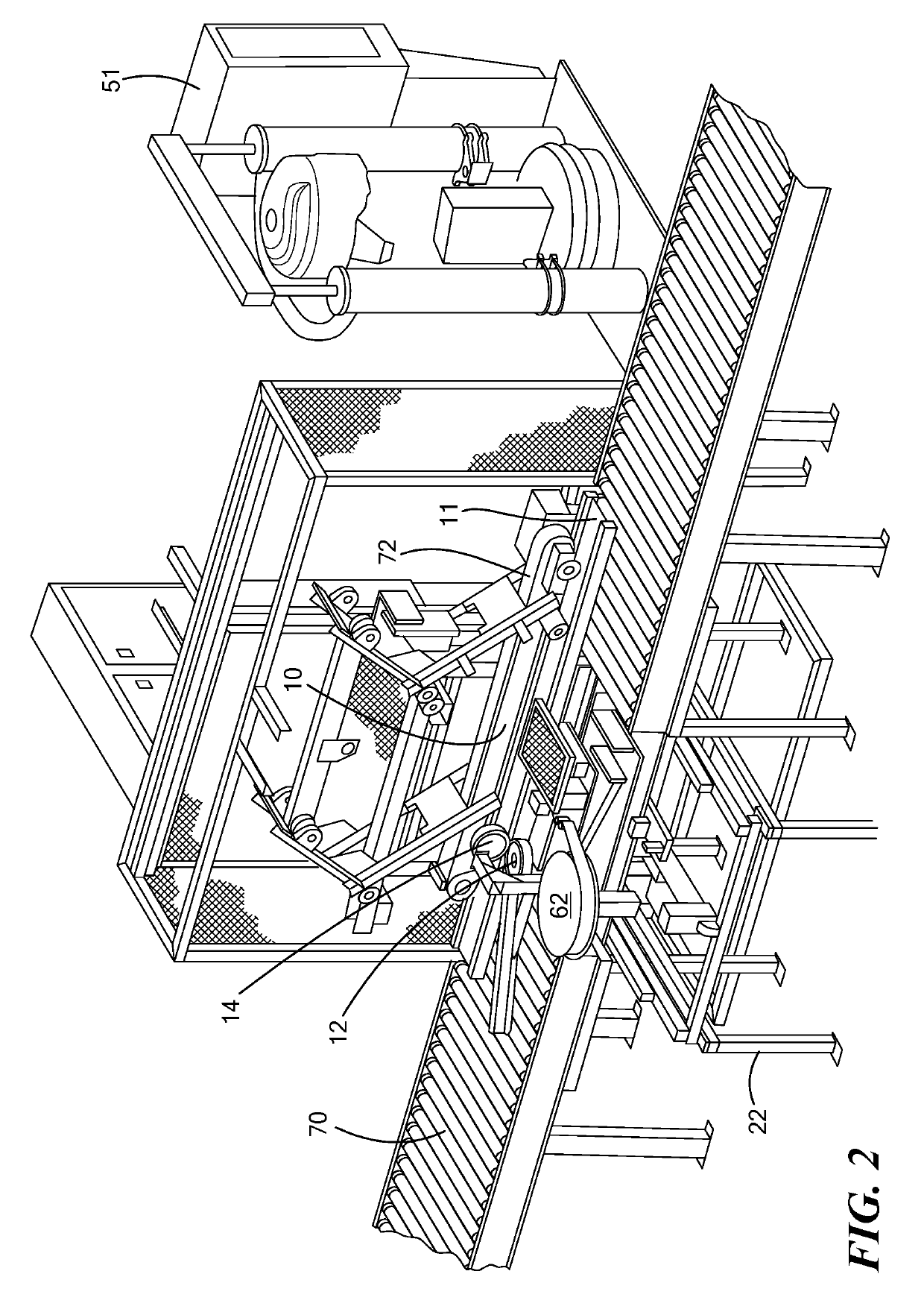

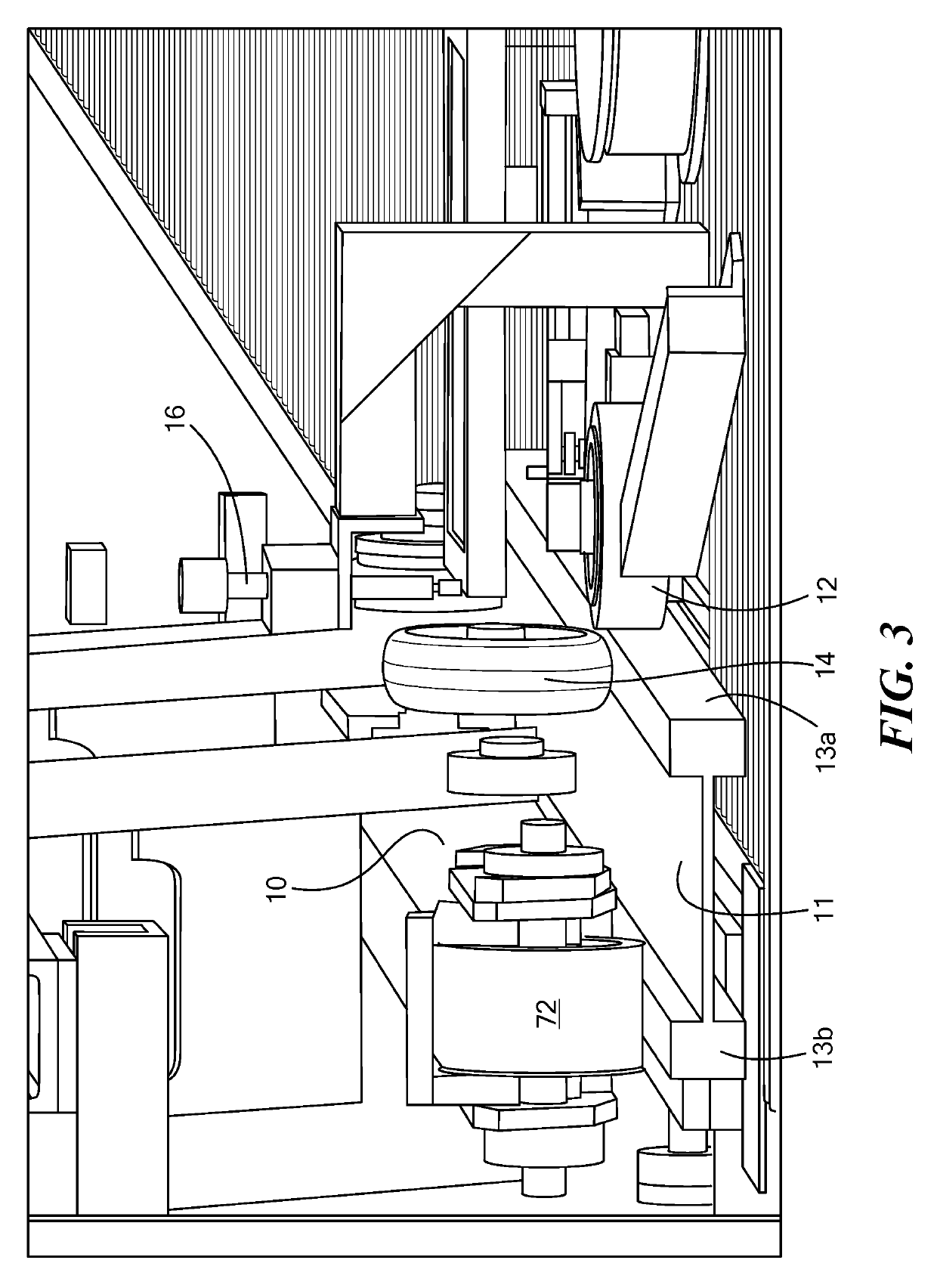

Sock packing machine

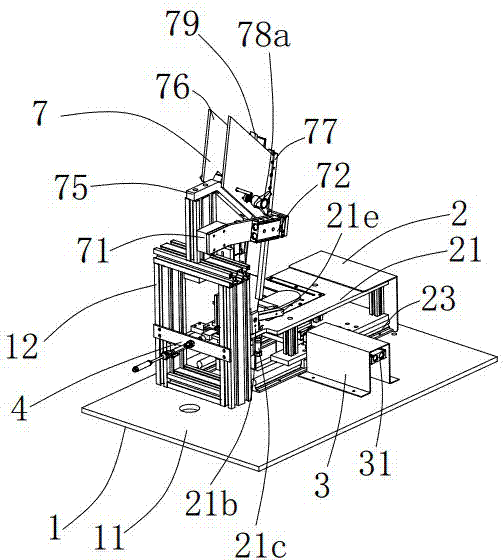

The invention discloses a sock packing machine. The sock packing machine comprises a base, an object loading table, a screen mechanism, a lifting hook install mechanism capable of installing a lifting hook for scraps of papers, a staple gun for installing plastic nails, a scrap of paper die and scrap of paper feeding mechanisms for storing and conveying the scraps of papers, wherein the lifting hook install mechanism is arranged before the object loading table, the scrap of paper die is arranged between the lifting hook install mechanism and the object loading table, the screen mechanism is arranged below the object loading table side, the staple gun is arranged above the scrap of paper die, the scrap of paper feeding mechanisms are all arranged above the staple gun, the object loading table, the lifting hook install mechanism, the staple gun, the scrap of paper die and the scrap of paper feeding mechanisms are all arranged on the base, the object loading table is provided with an object placing table, an object loading table cylinder, a sliding rail and a slide block, the front end of the object loading table cylinder is fixedly connected with the object placing table, the object placing table is fixedly connected with the slide block, the slide block is matched with the sliding rail in an embedded mode, the object placing table is provided with a screen slot and an object placing table staple gun hole, the scrap of paper die is C-shaped and provided with a lifting hook hole and a scrap of paper die staple gun hole.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

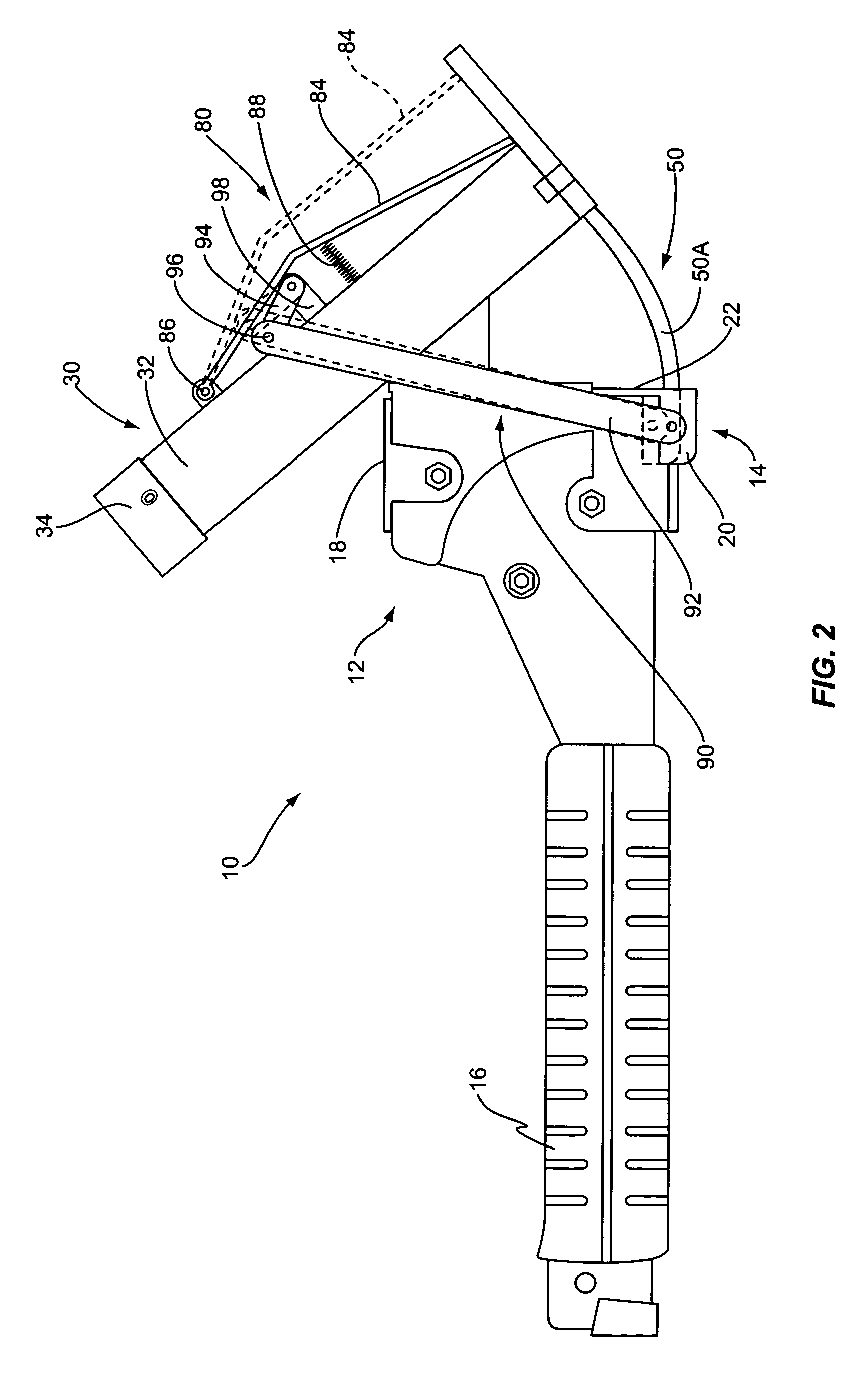

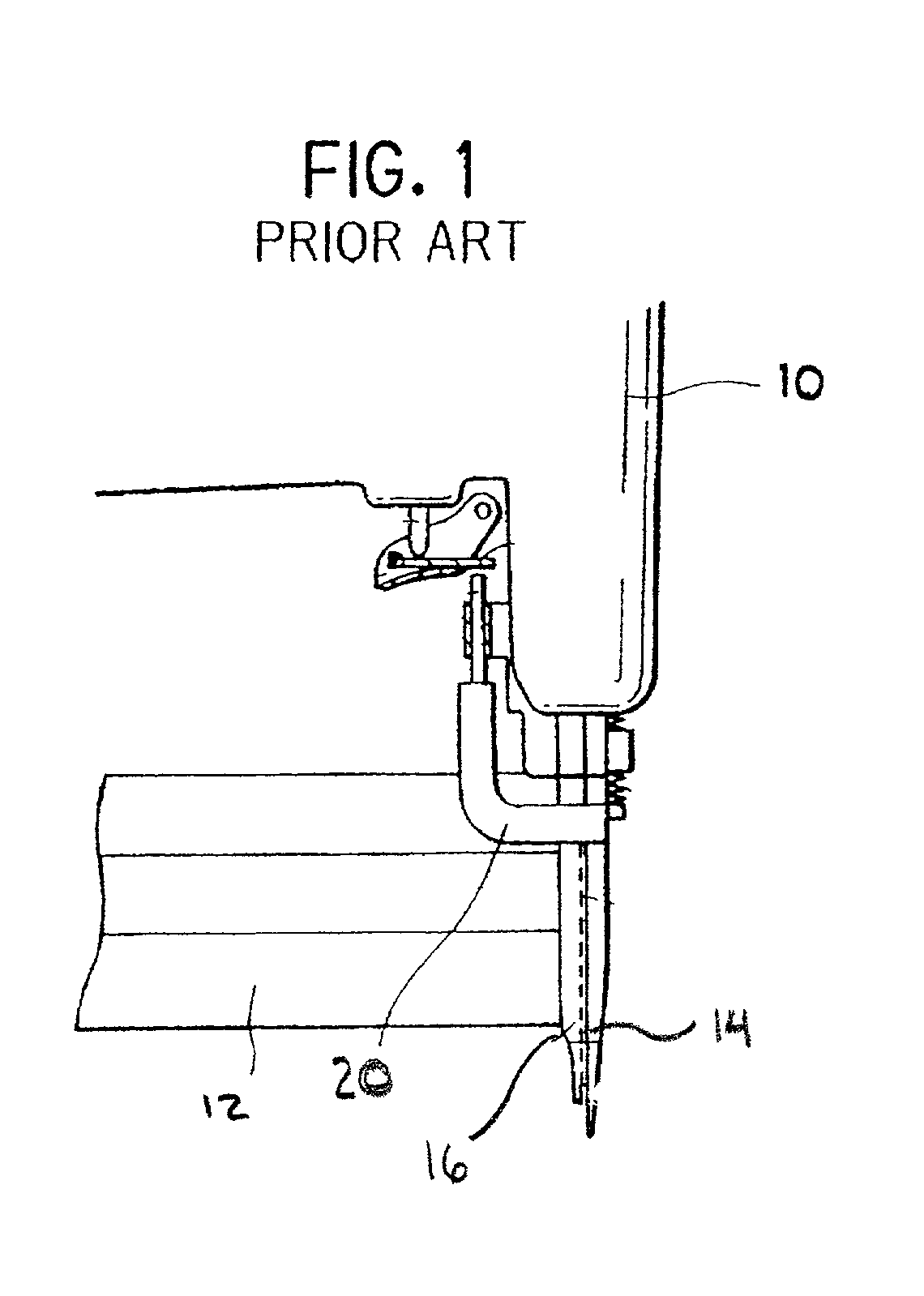

Combination staple gun and cap feeding device

A combination manual staple gun and a cap feeding device comprises a staple gun having a cap feeding device attached thereto. Interconnected between the staple gun and the cap feeding device is an actuating linkage. The actuating linkage is connected to a movable member of the staple gun and is driven in response to the actuation of the staple gun or in response to the staple gun being pressed against a surface for the purpose of shooting a staple into the surface. More particularly, the cap feeder device includes a container for containing a stack of caps and a cap feeder or feeding mechanism for engaging one cap at a time and directing the cap towards a cap ejection area associated with a staple gun in response to the connecting or actuating linkage being actuated.

Owner:SDGI HLDG

Accessory device for nail and staple guns

An accessory device for fastener-driving tools such as nail and staple guns is provided. The device serves as a positioning guide for the tool and is designed to provide sufficient spacing and orientation between the fastener-driving tool and the target construction material. The device can be integrated into the body of the fastener-driving tool, manufactured as an attachment or manufactured as a separate tool. It prevents impact marring at the visible surface of the construction material by redirecting the force of the blow to a non-visible surface on the assembled construction material. Furthermore it increases speed and ease of movement for the user by serving as a guide for stability and ease of alignment. The device changes the impact point between the driving tool and the construction material, broadens the area of impact and protects the top edge of a tongue and groove construction material from impact damage.

Owner:DICKHAUT JOHN

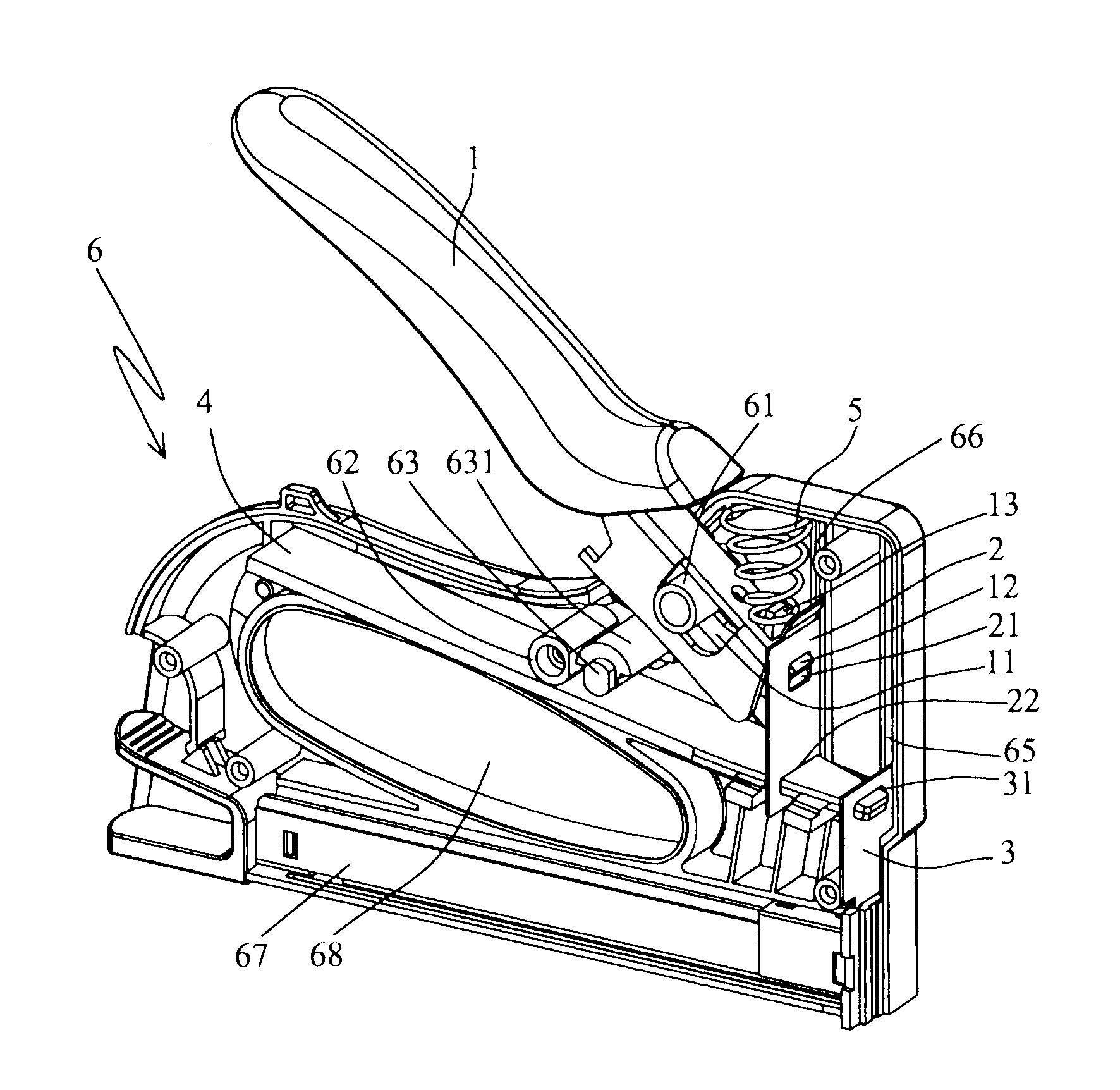

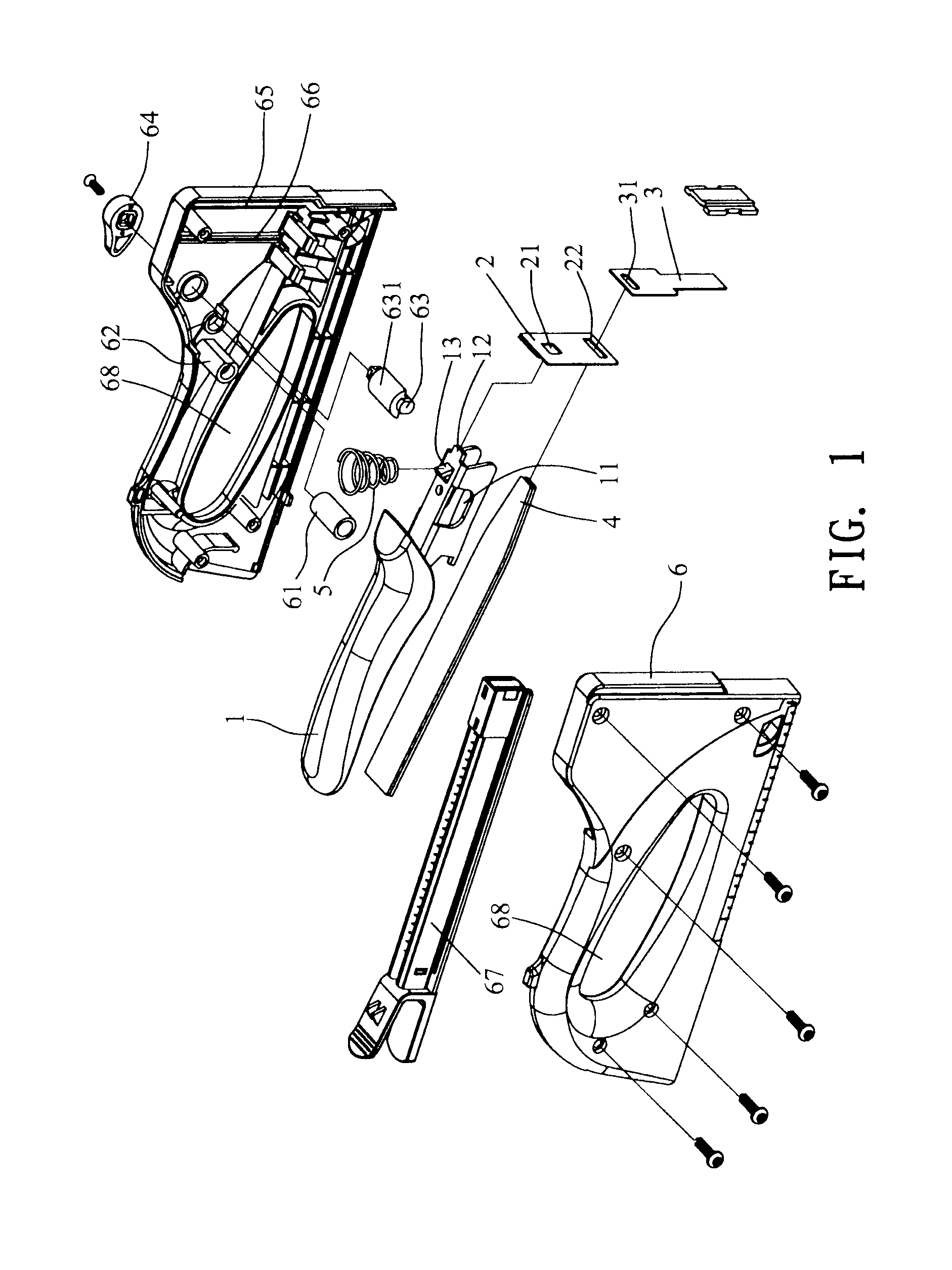

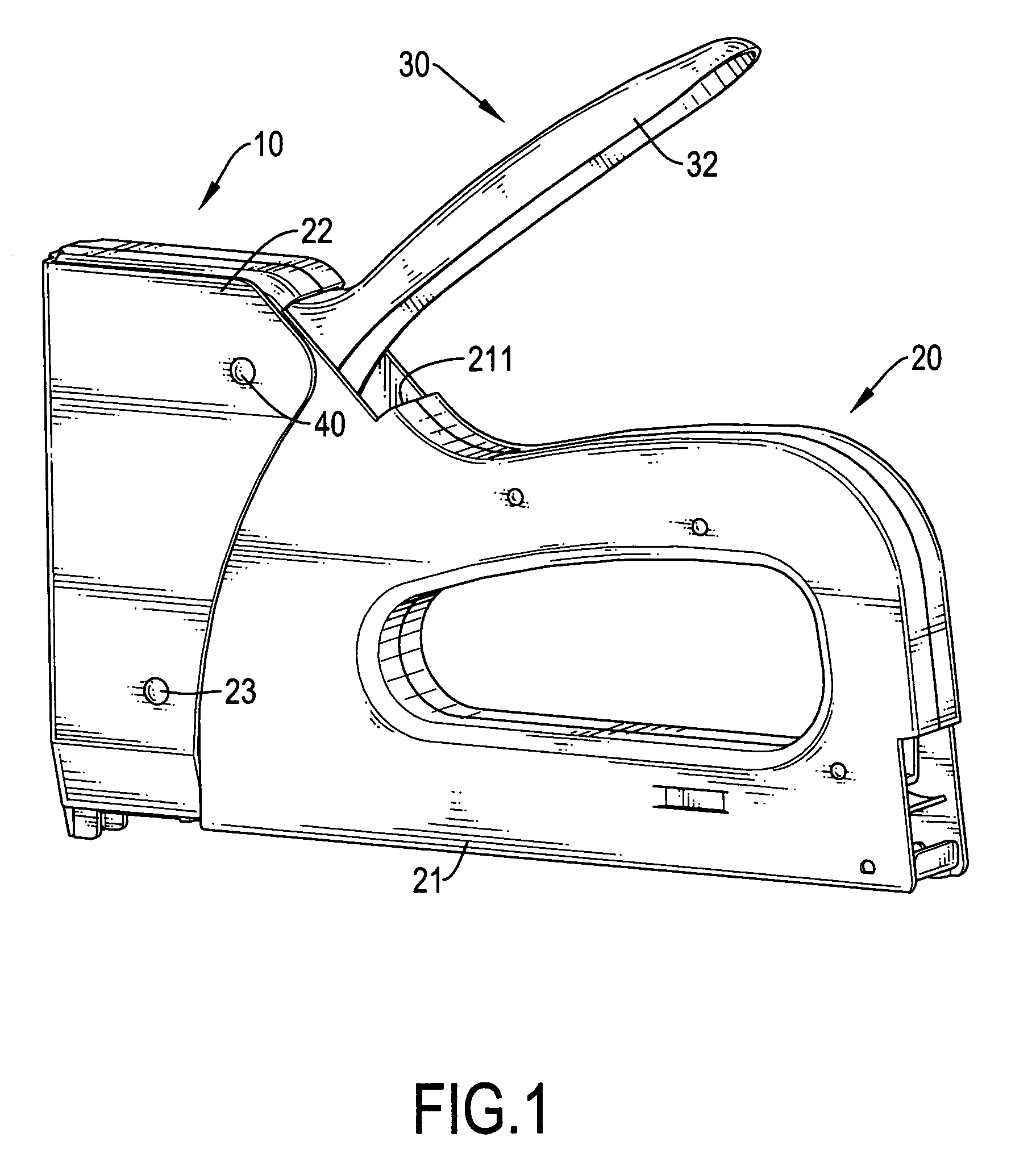

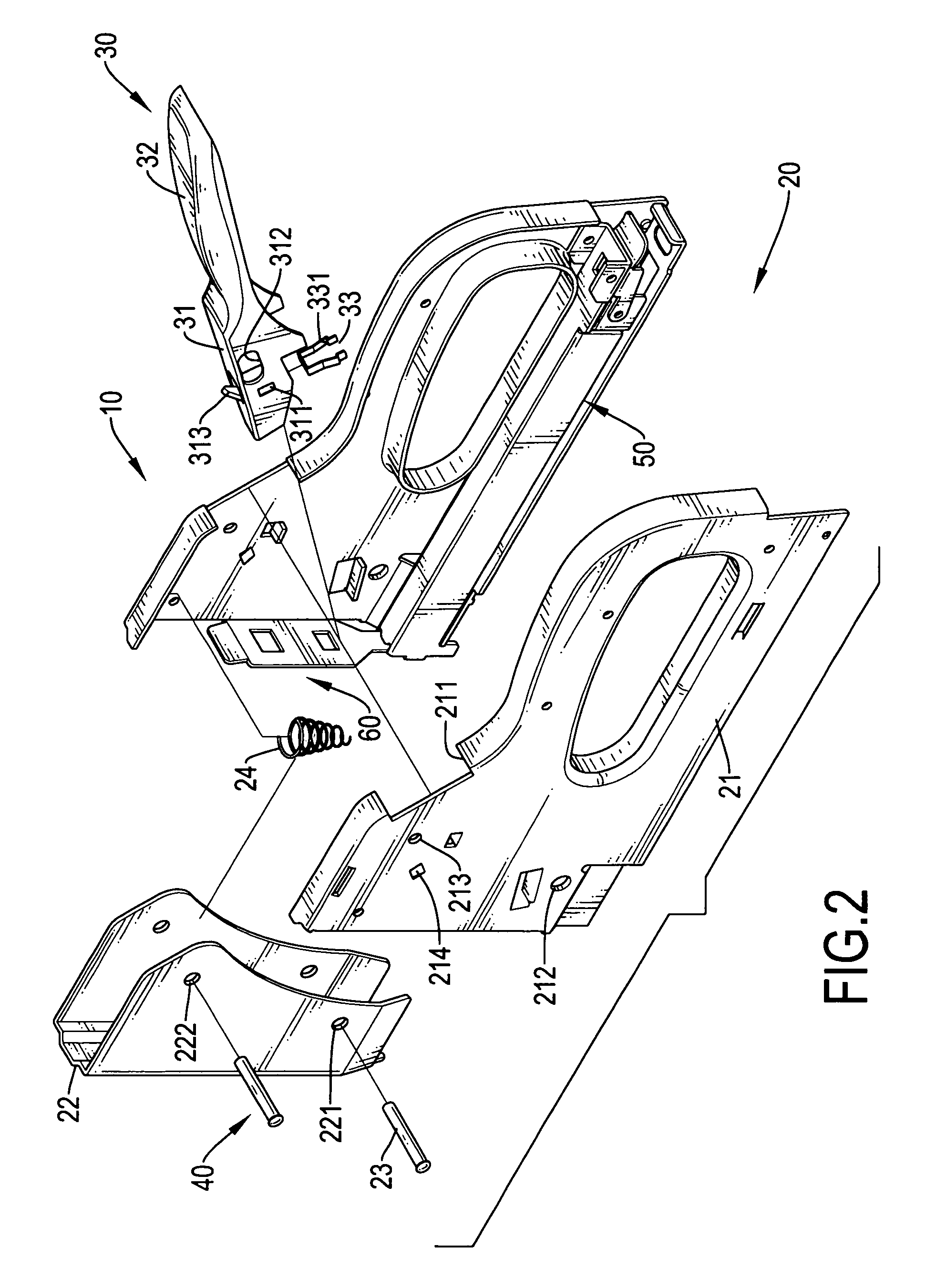

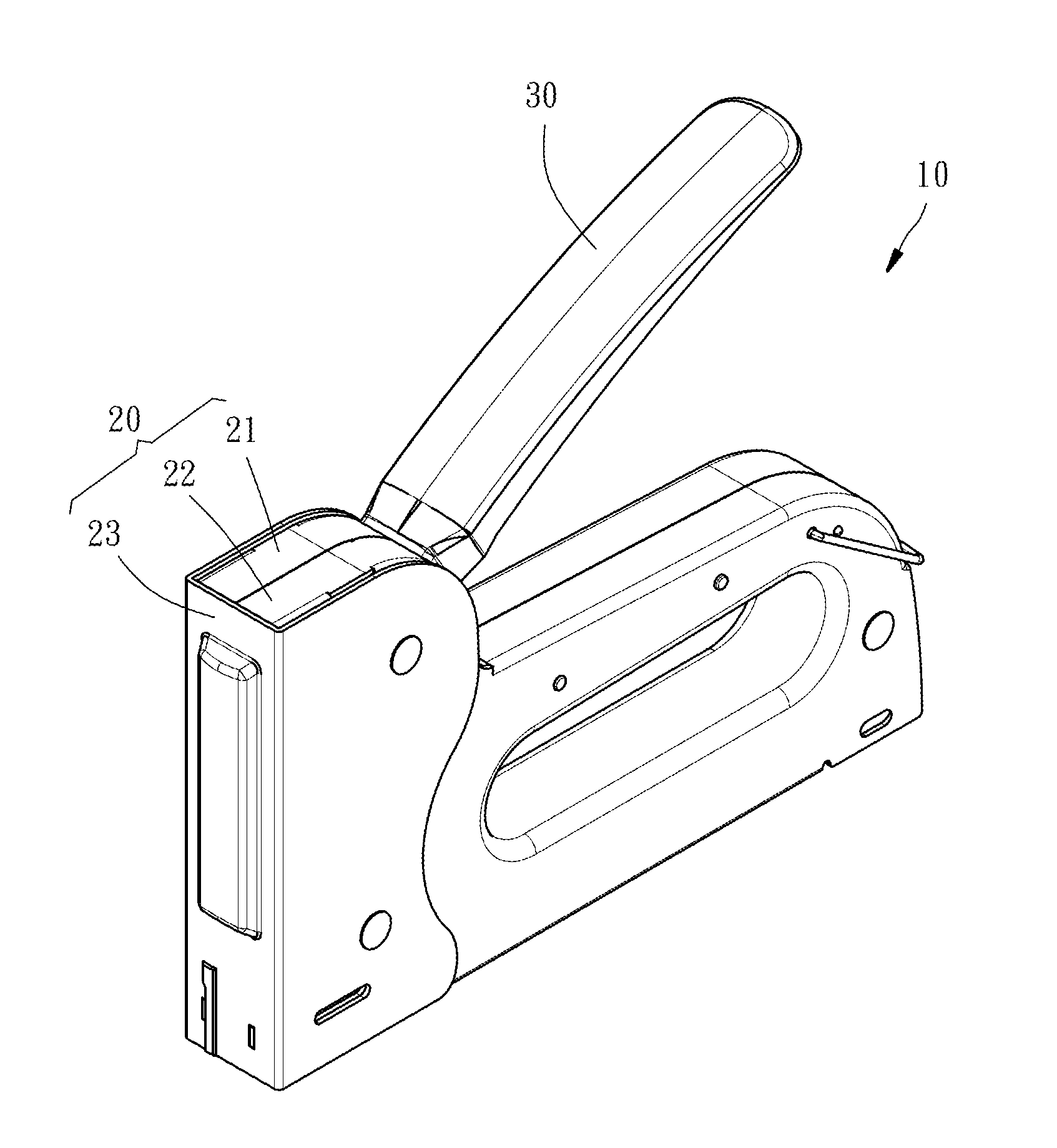

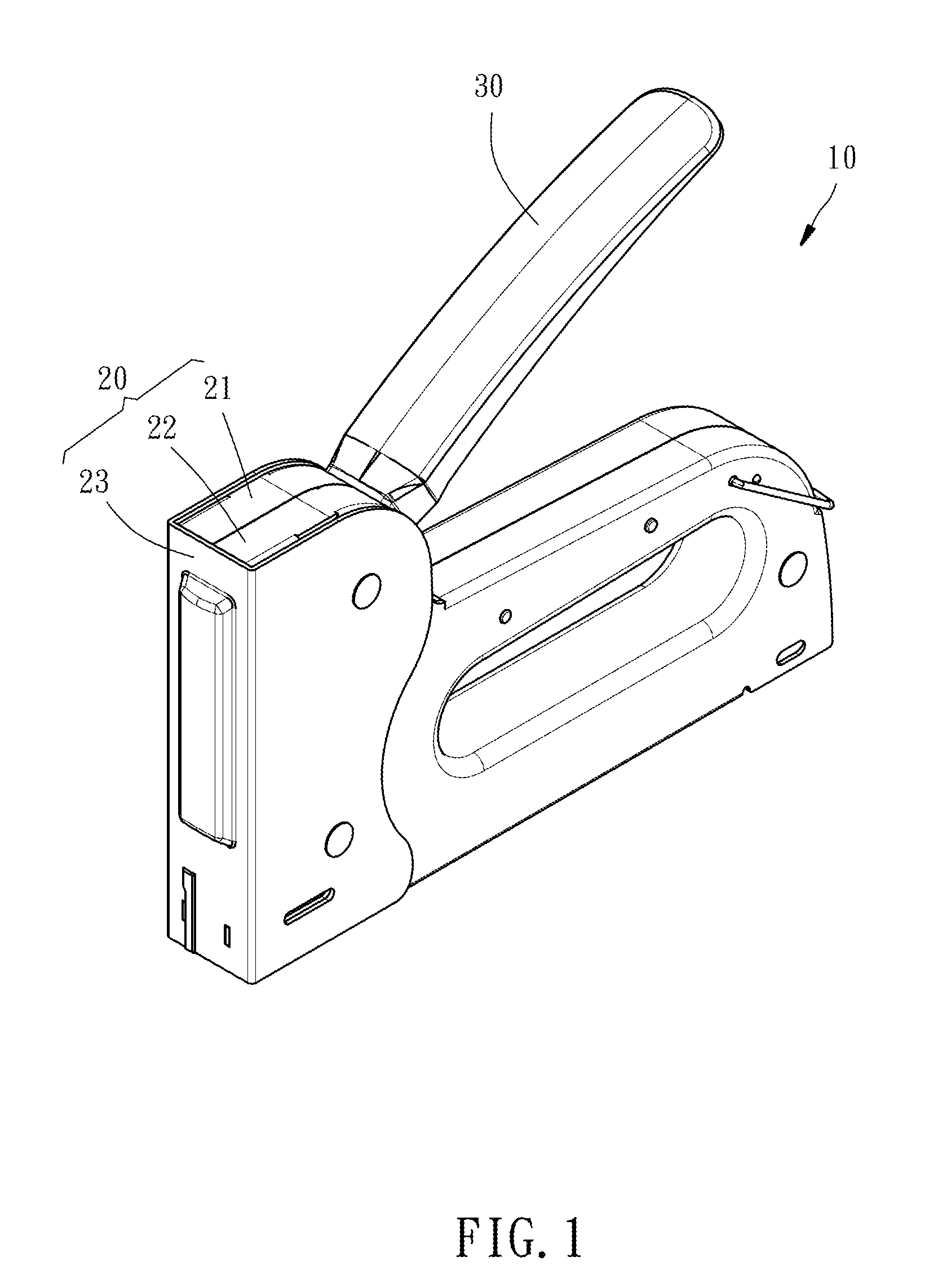

Staple gun

A staple gun includes an arm having an elongate hole and a protrusion extends from the first end of the arm. A driving plate has a first hole and a second hole. The protrusion is inserted into the first hole. A strike plate is located beside the driving plate and has a third hole. A resilient plate has a first end extending through the second hole and the third hole. A spring is rested on a top of the first end of the arm. A case includes a fulcrum axle and a fixed axle. The fulcrum axle extends through the elongate hole of the arm and is located behind the driving plate. The fixed axle contacts a top surface of the resilient plate. The effort arm from the fulcrum axle to the front end of the arm is shortened so as to save effort when pivoting the arm.

Owner:HUANG CHIEN CHUAN

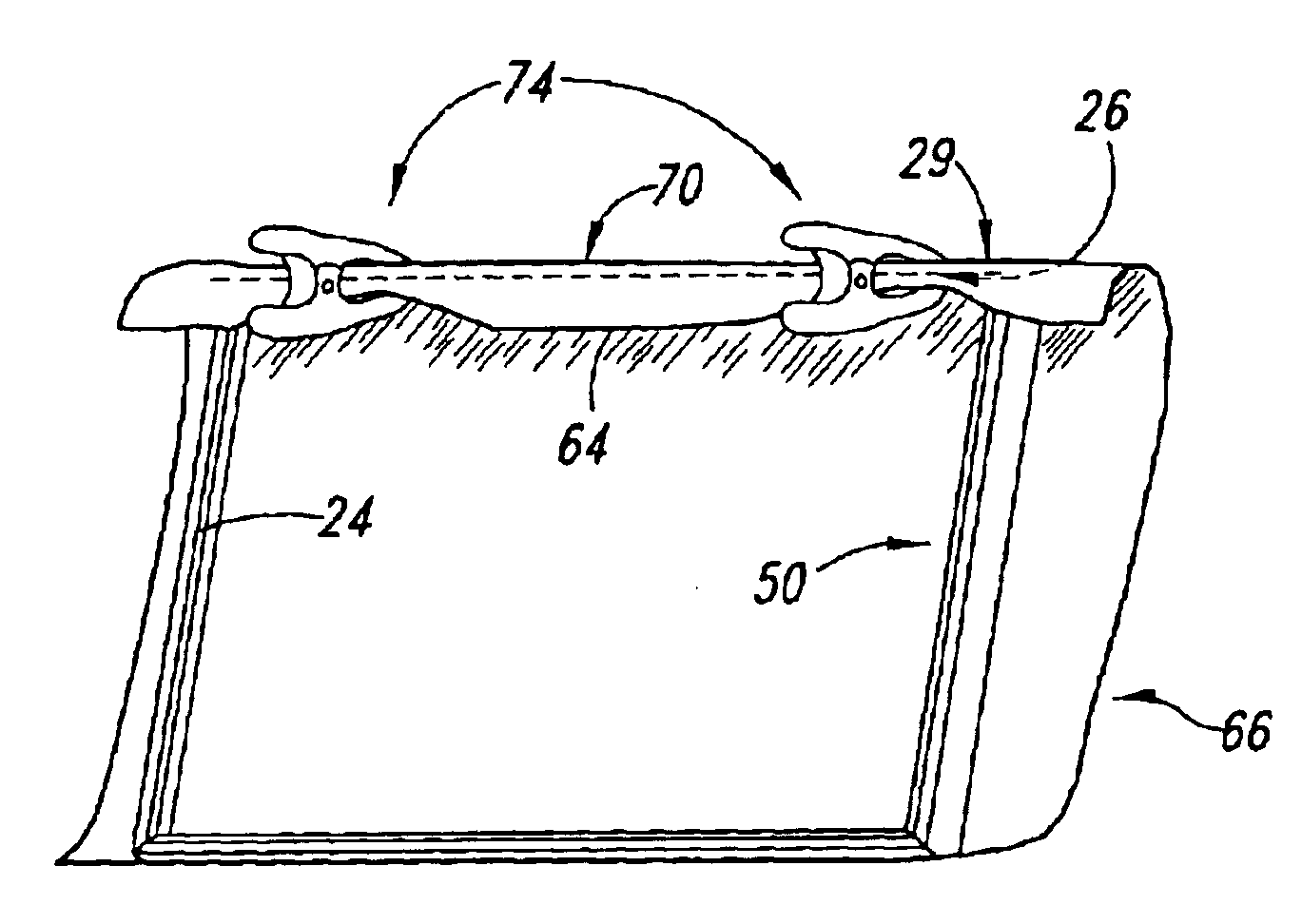

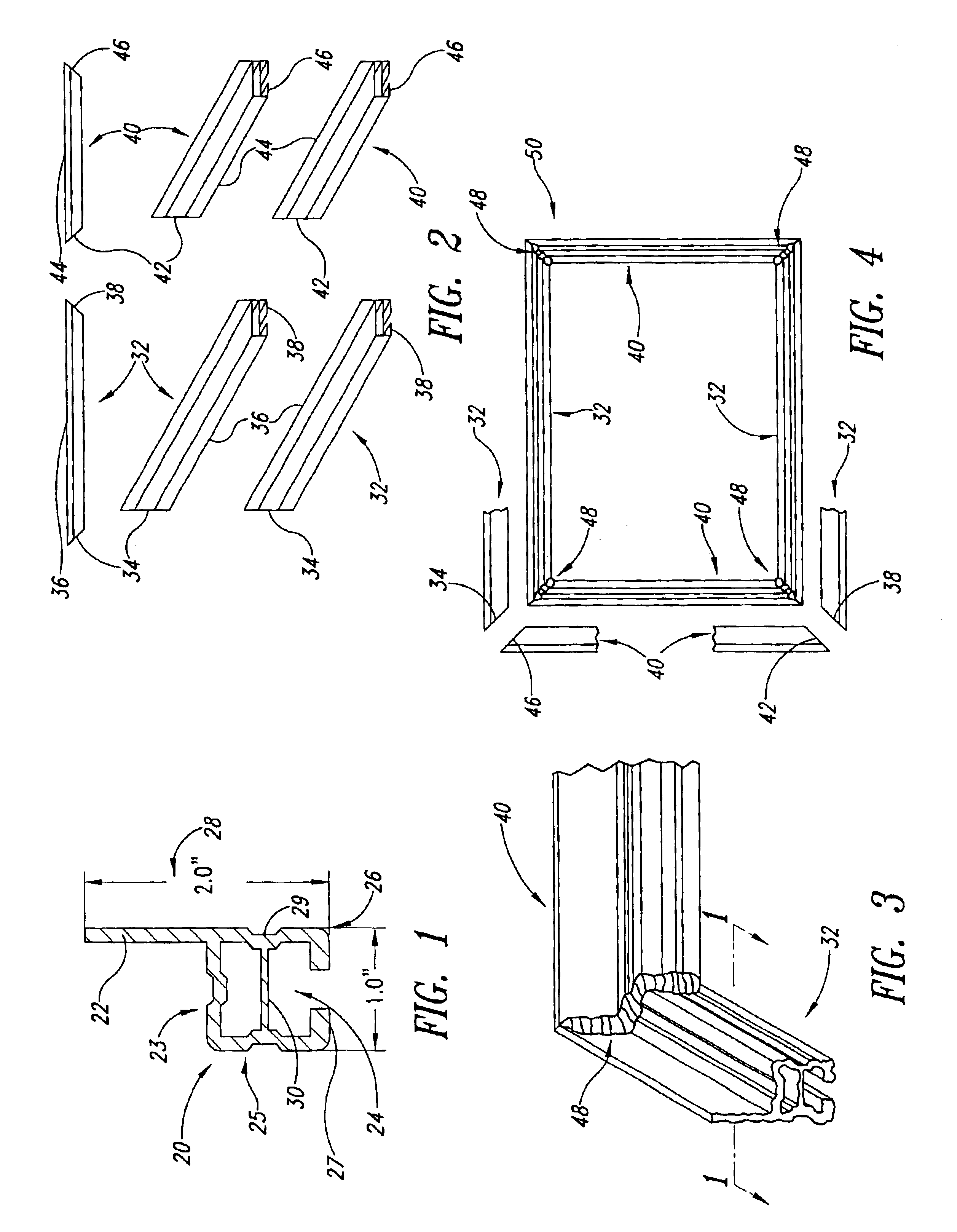

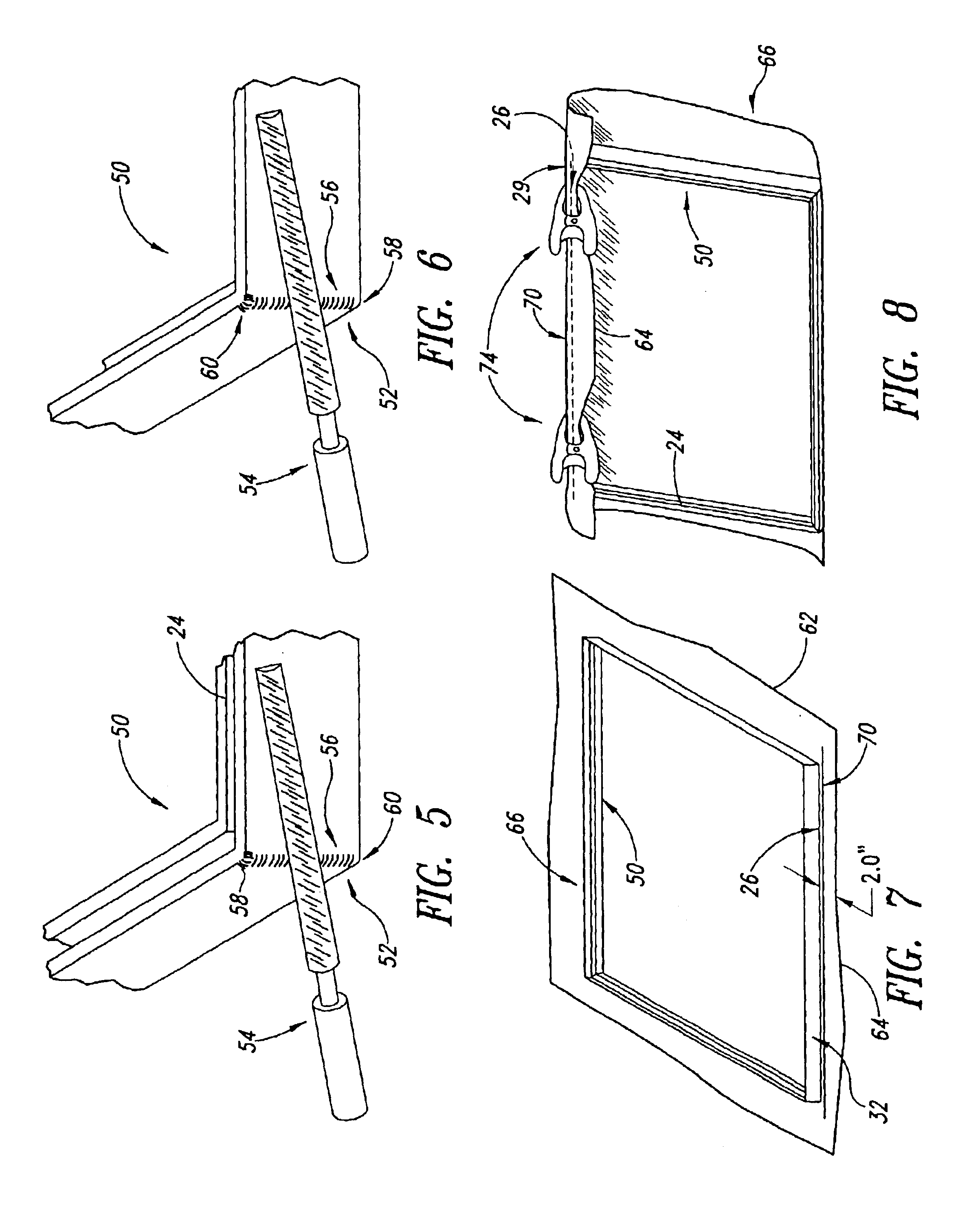

Method of attaching canvas to a frame

InactiveUS6983524B2Easy to stretchPrevent tearing of the canvasShaping toolsPicture framesStaple gunEngineering

A canvas framing system and method for attaching canvas to an extruded aluminum frame to achieve a taut mount painting surface, including forming the frame of aluminum material, rounding selected corners and edges of the frame, temporarily securing a first portion of the canvas to the frame and attaching the canvas to the frame, preferably with staples using a modified staple gun, stretching the canvas on the frame and temporarily securing an opposing portion of the canvas to an opposing side of the frame, which is then stapled thereto, and stretching and attaching remaining portions of the canvas to the frame with the staple gun. Cross bracing can be installed on the frame to prevent bending when the canvas is stretched taut thereon.

Owner:EASTWOOD MARK T

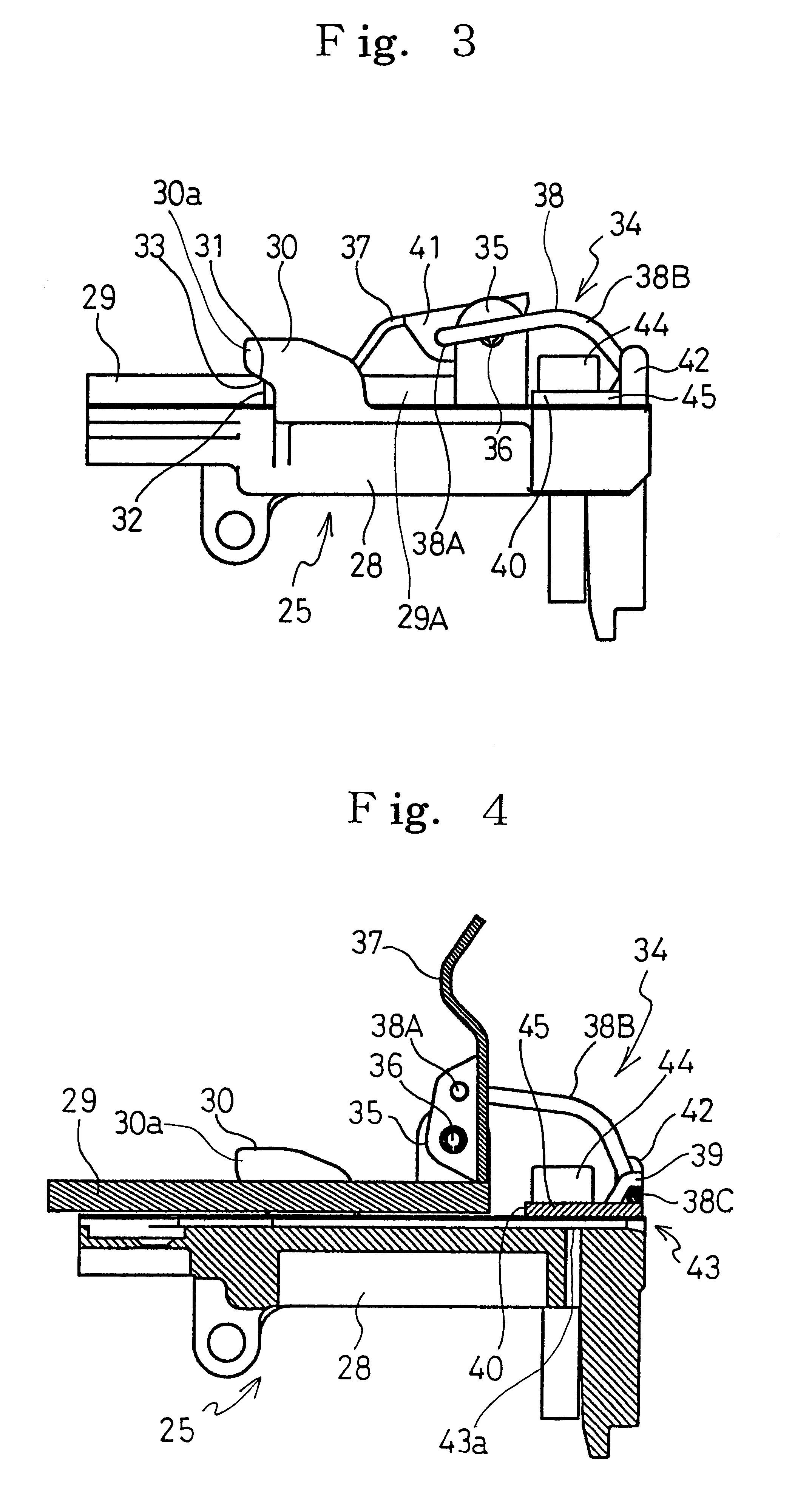

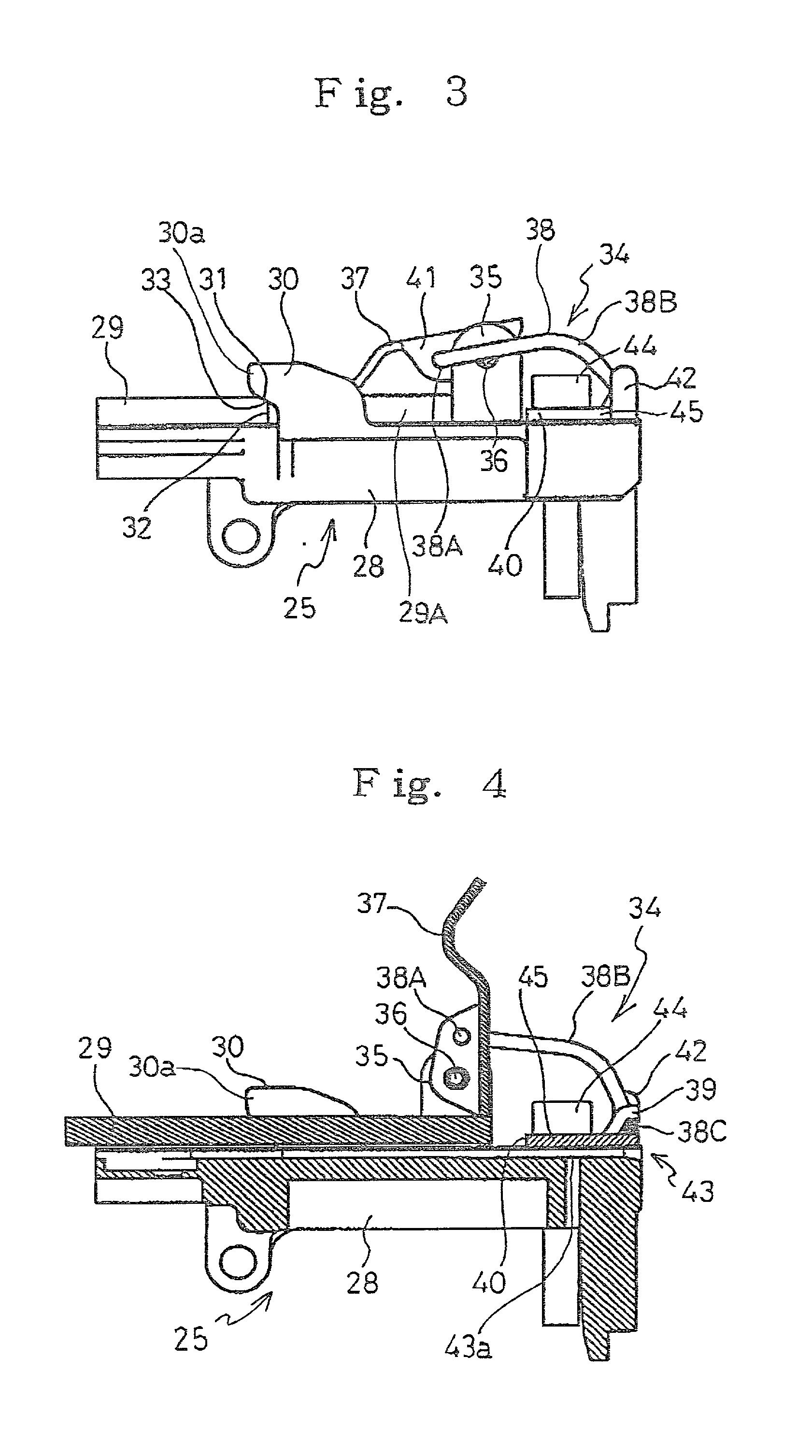

Staple gun

A staple gun comprising a main body and a staple injection nozzle for injecting a staple into a target object, the staple injection nozzle including a nozzle body mounted on a staple striking body and a cover plate for removably closing an upper portion of a staple injection path of the nozzle body so as to guide the staple. The nozzle body has protrusions to receive an end portion of the cover plate and press this cover plate from upward, and an urging member is provided to urge the cover plate in a direction that the end portion of the cover plate intrudes into the protrusions.

Owner:MAX CO LTD

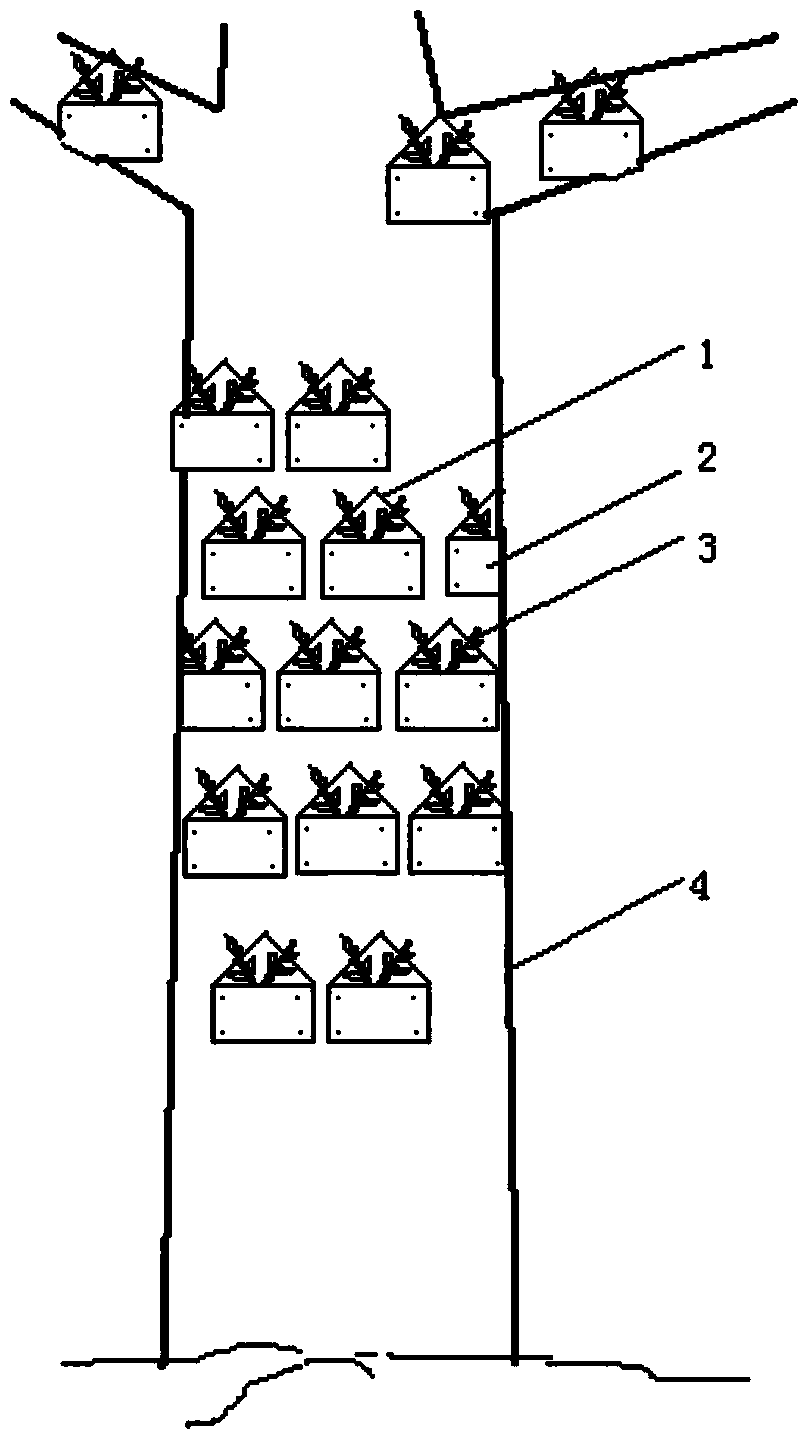

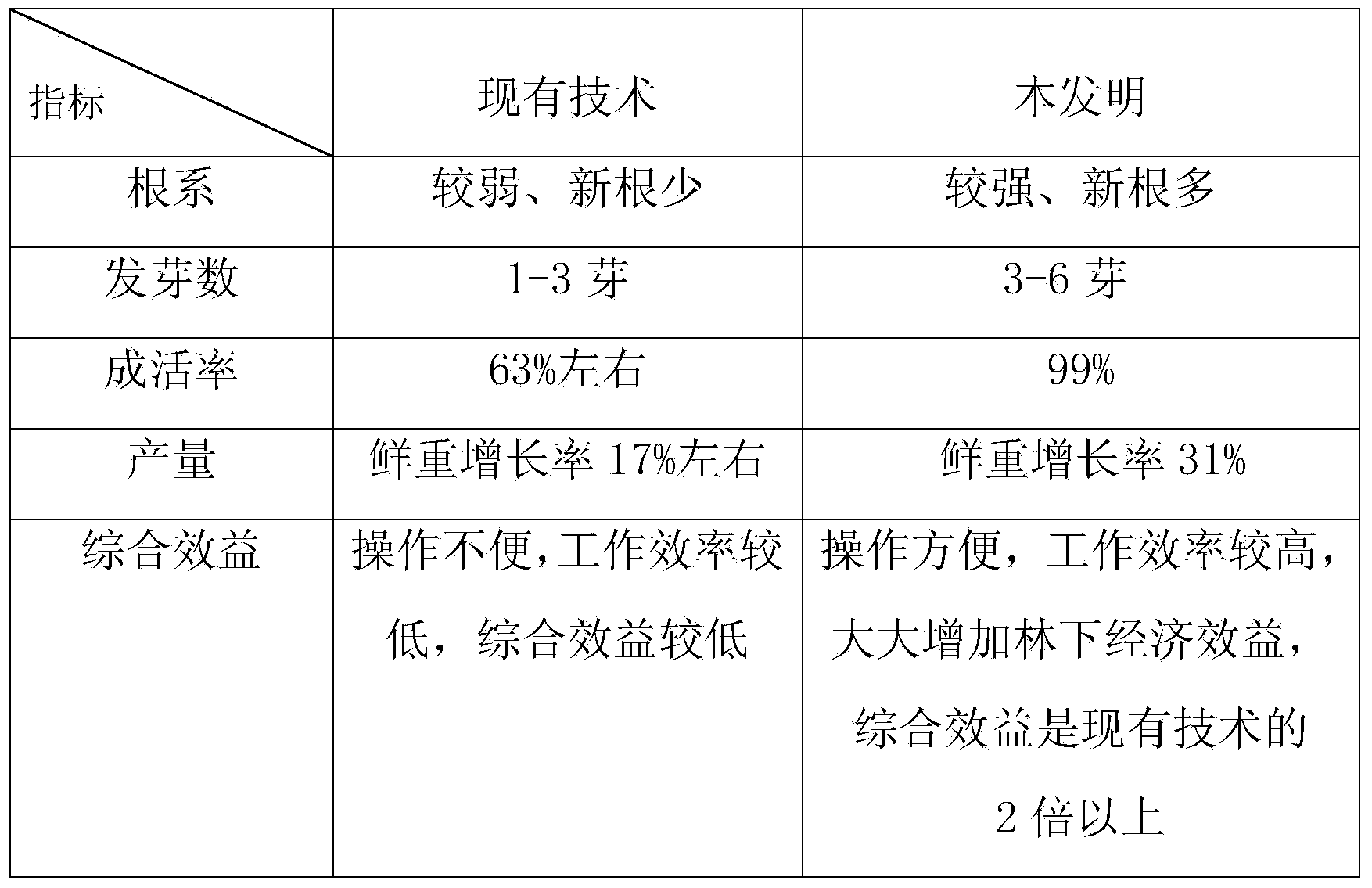

Planting method for pasting dendrobium officinale hood pocket to tree

InactiveCN103858738AEffective protectionPromote rootingCultivating equipmentsSoilless cultivationPlanting seedEngineering

The invention discloses a planting method for pasting a dendrobium officinale hood pocket to a tree. The method includes the following steps that a degradable non-woven fabric material is processed to be the mask-shaped hood pocket, fixing ropes are arranged on the long edges, the fixing ropes and three corners of the hood pocket are stapled to a truck or a branch of a planting seed tree through a U-shaped staple gun, dendrobium officinale seedlings, lichen, humus media and the like are placed into the hood pocket in a planting mode, the fourth corner at the upper end of the hood pocket is well fixed, and the seedlings which are well planted are watered. Compared with the prior art, the method has the advantages that the root system of plants is effectively protected, rooting is promoted, the natural environment is adapted to more rapidly, supervenience and stress resistance are high, the rate of survival reaches more than 95%, the germination rate is improved, the number of the plants is increased, the yield is increased by more than 70%, operation is convenient, working efficiency is high, and economic benefits are more than twice of economic benefits in the prior art.

Owner:FUJIAN JIUYITANG PHARMA

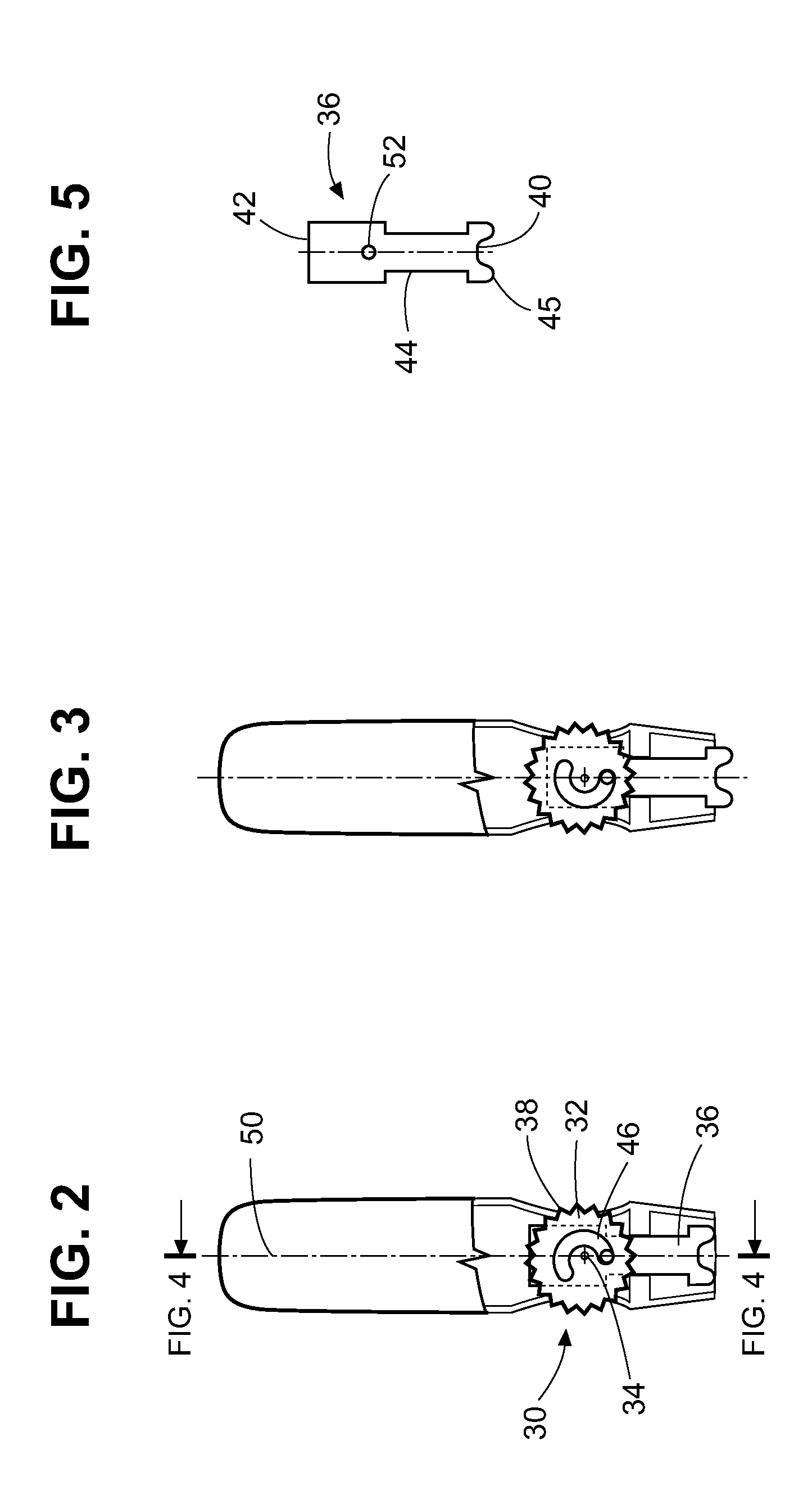

Staple gun wire guide

Owner:ARROW FASTENER CO INC

Wire guide for an automatic staple gun

Owner:ARROW FASTENER CO INC

Wire guide for an automatic staple gun

A wire guide apparatus for a powered staple gun is adapted to be housed in a low-profile housing at the front end of the staple gun, forward of the safety and staple driver.

Owner:ARROW FASTENER CO INC

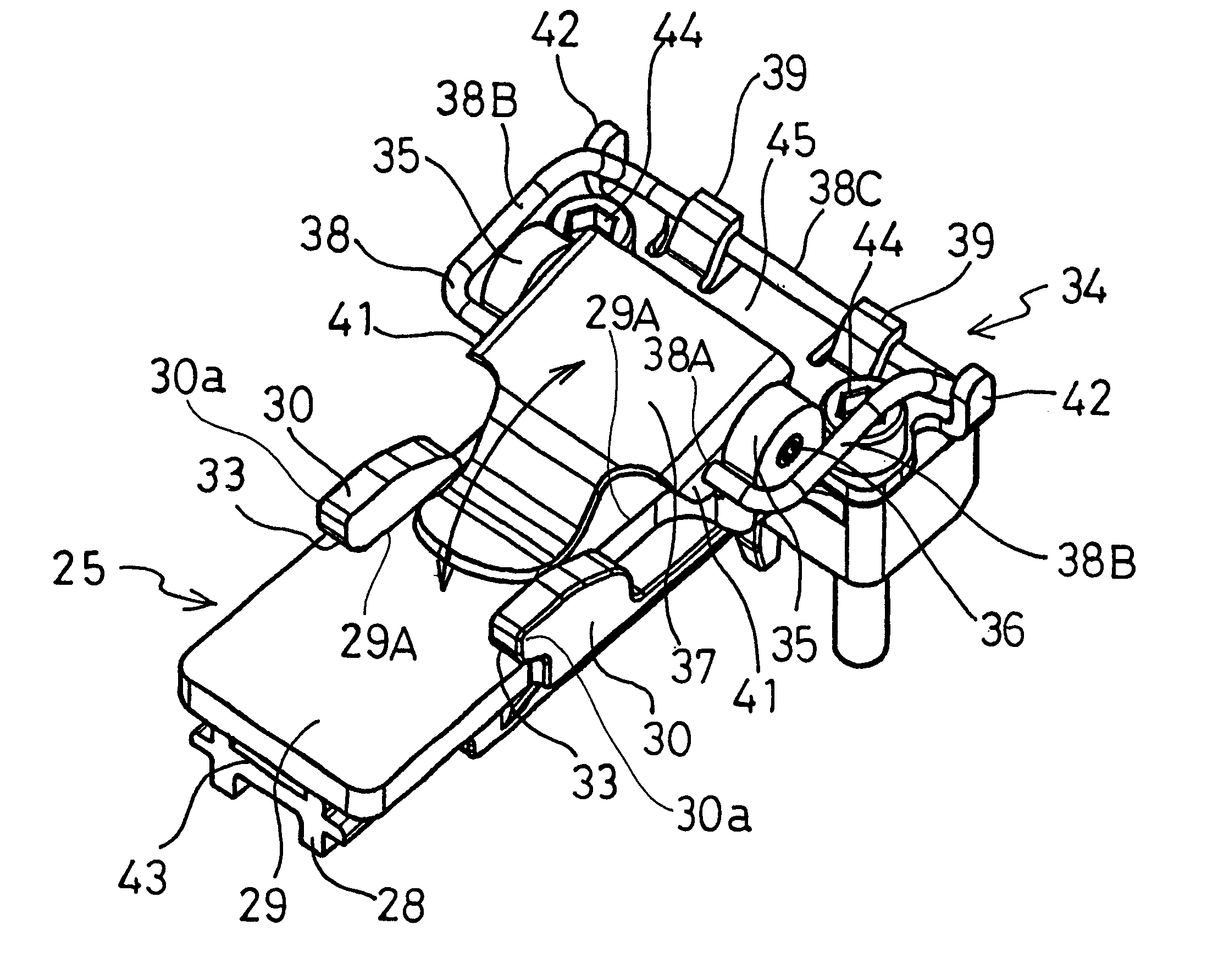

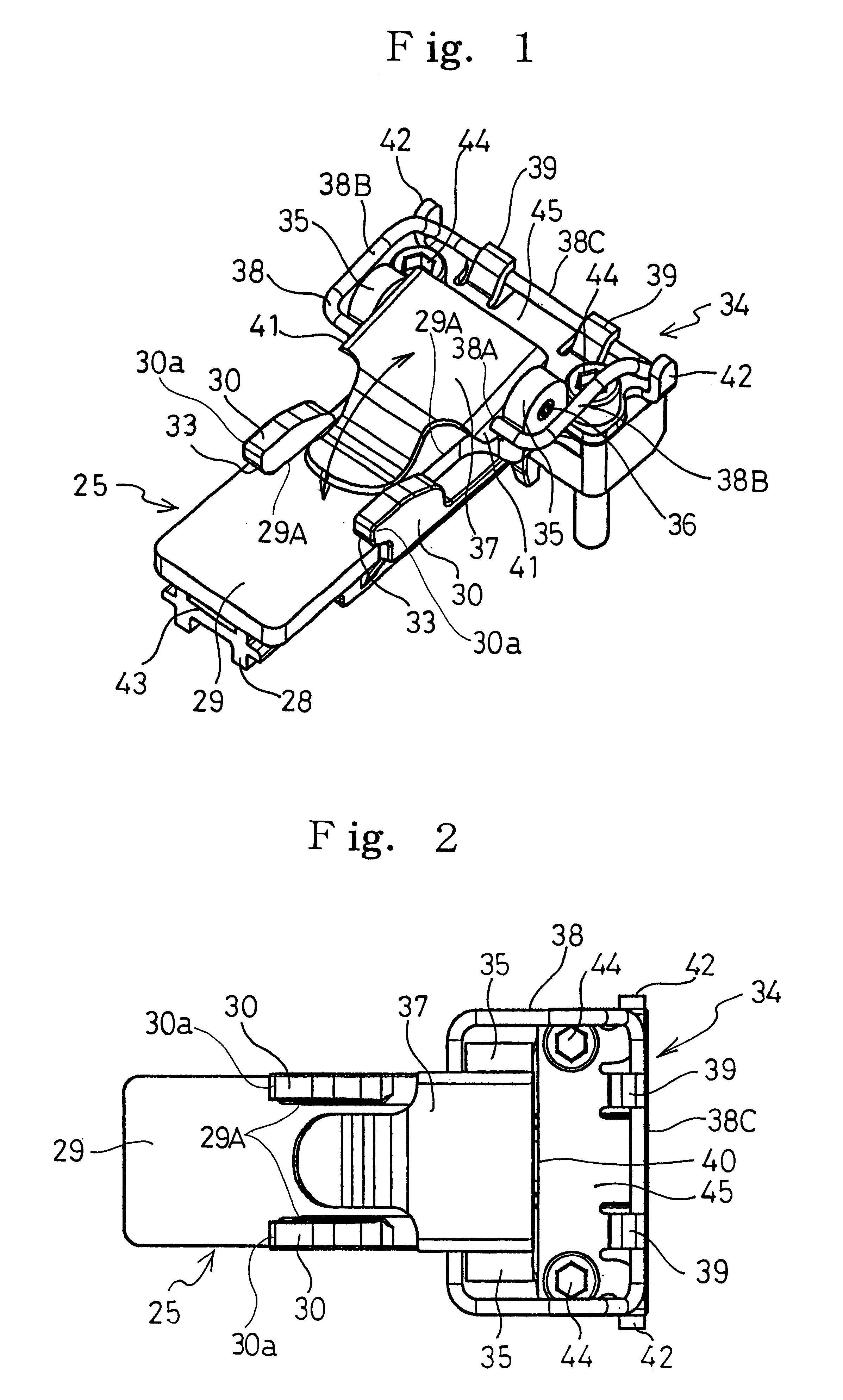

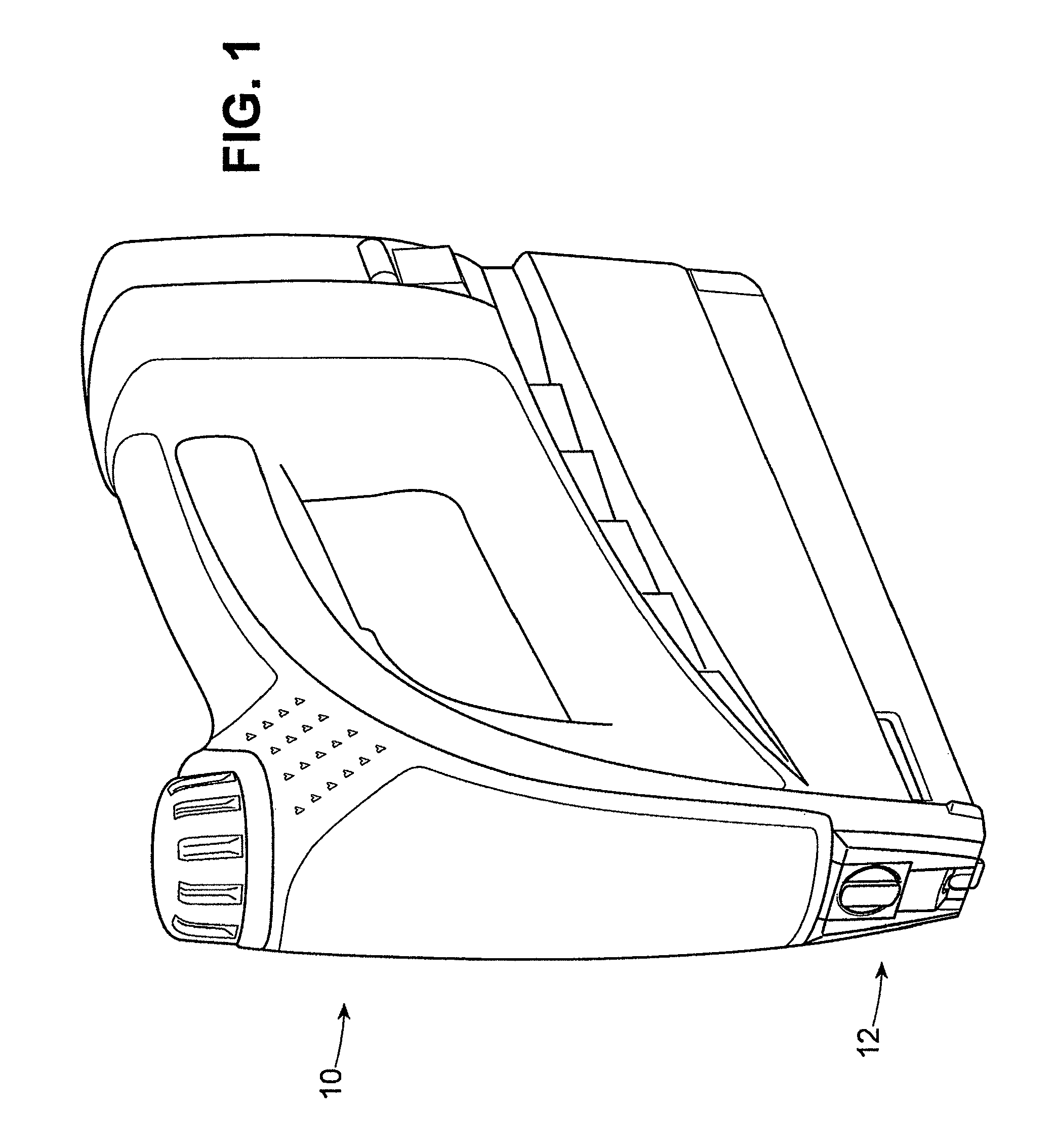

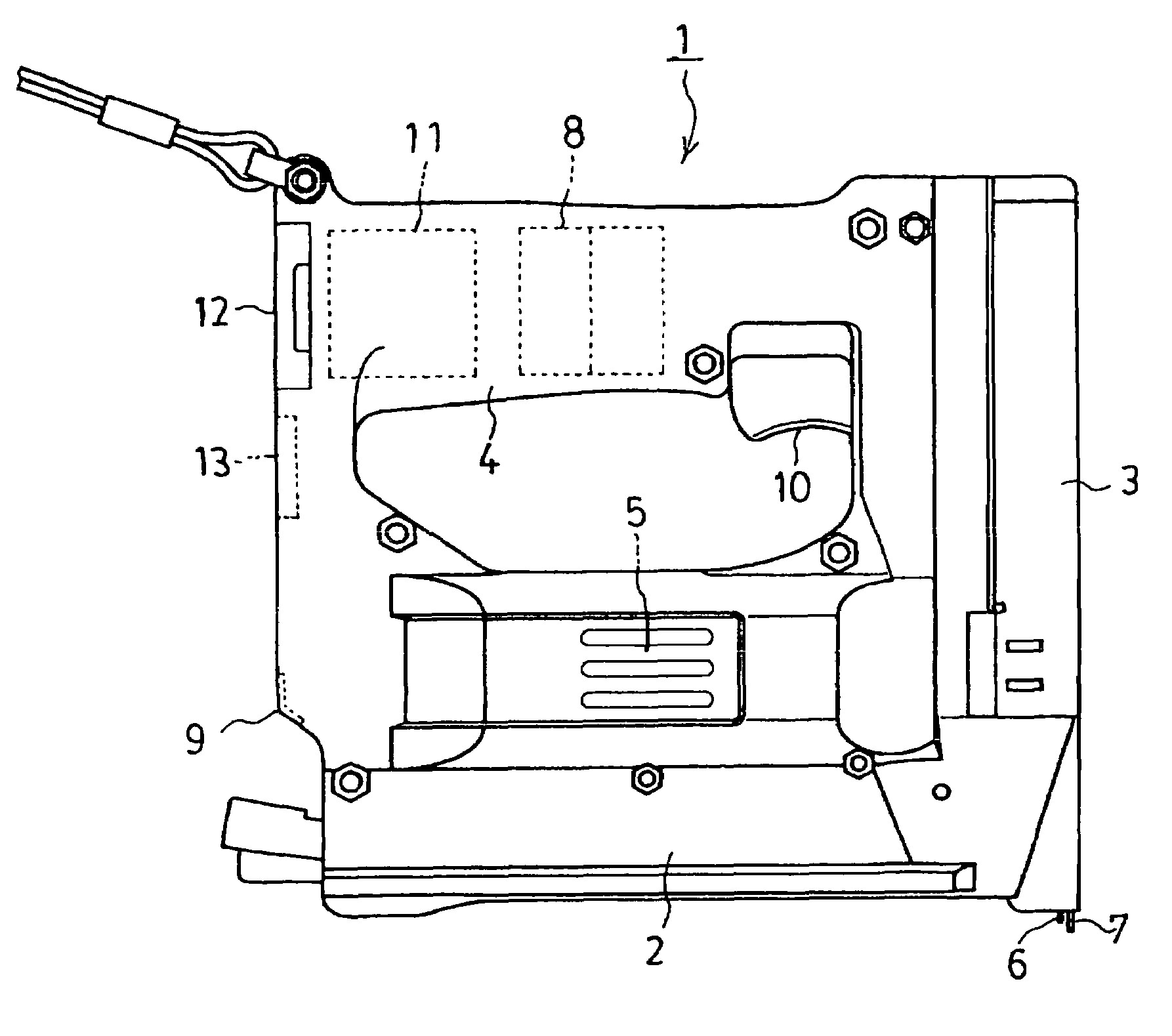

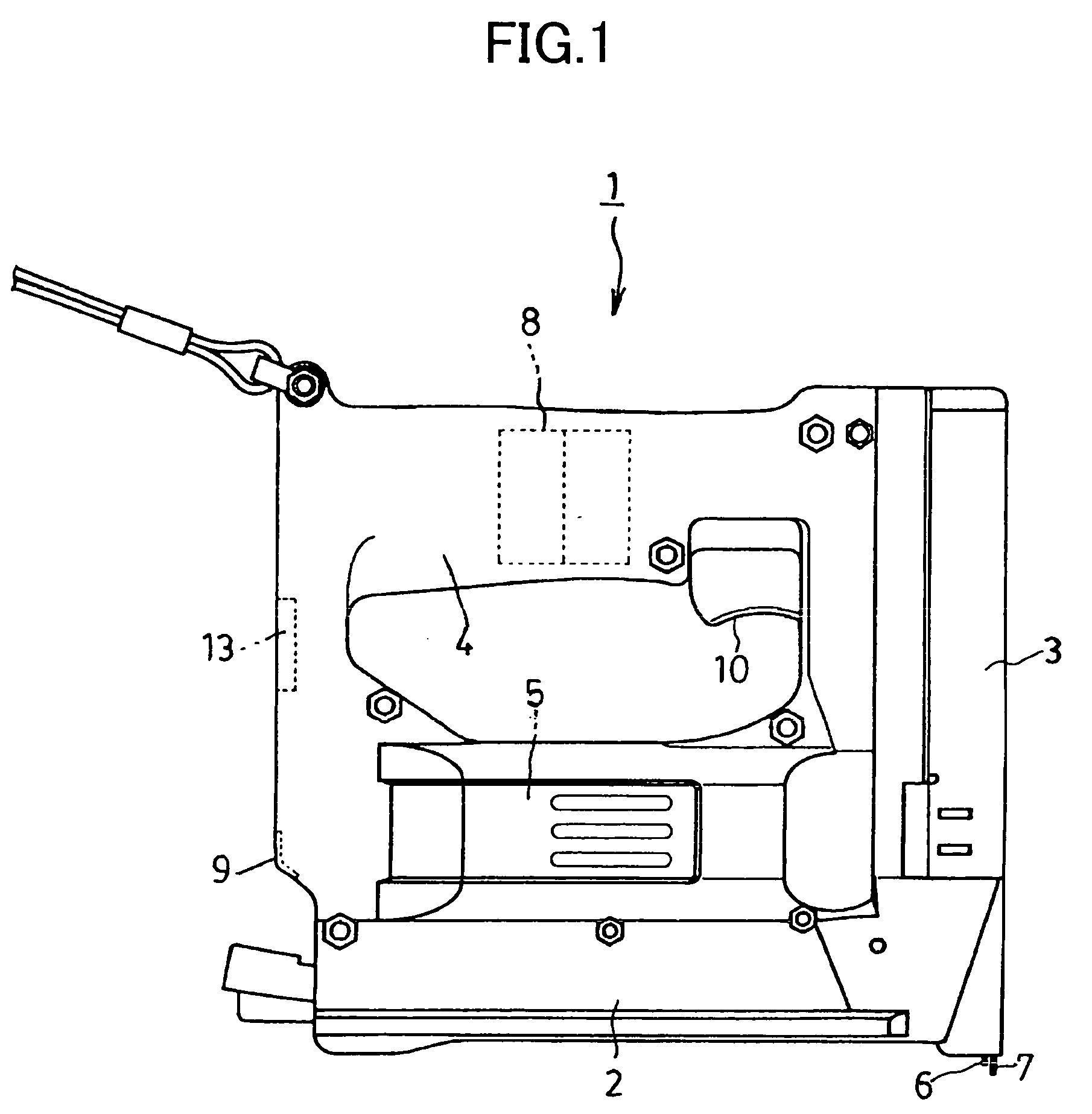

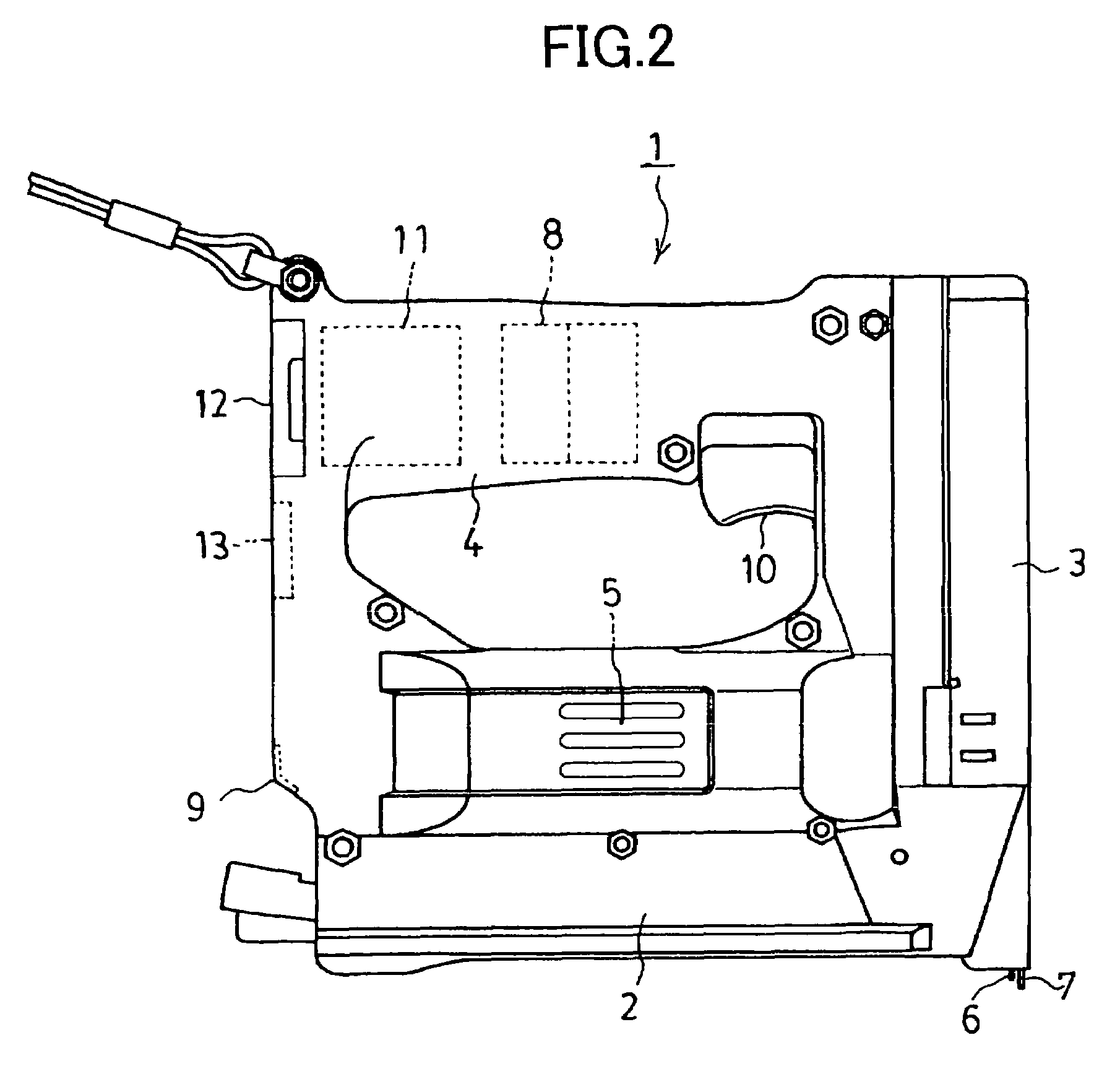

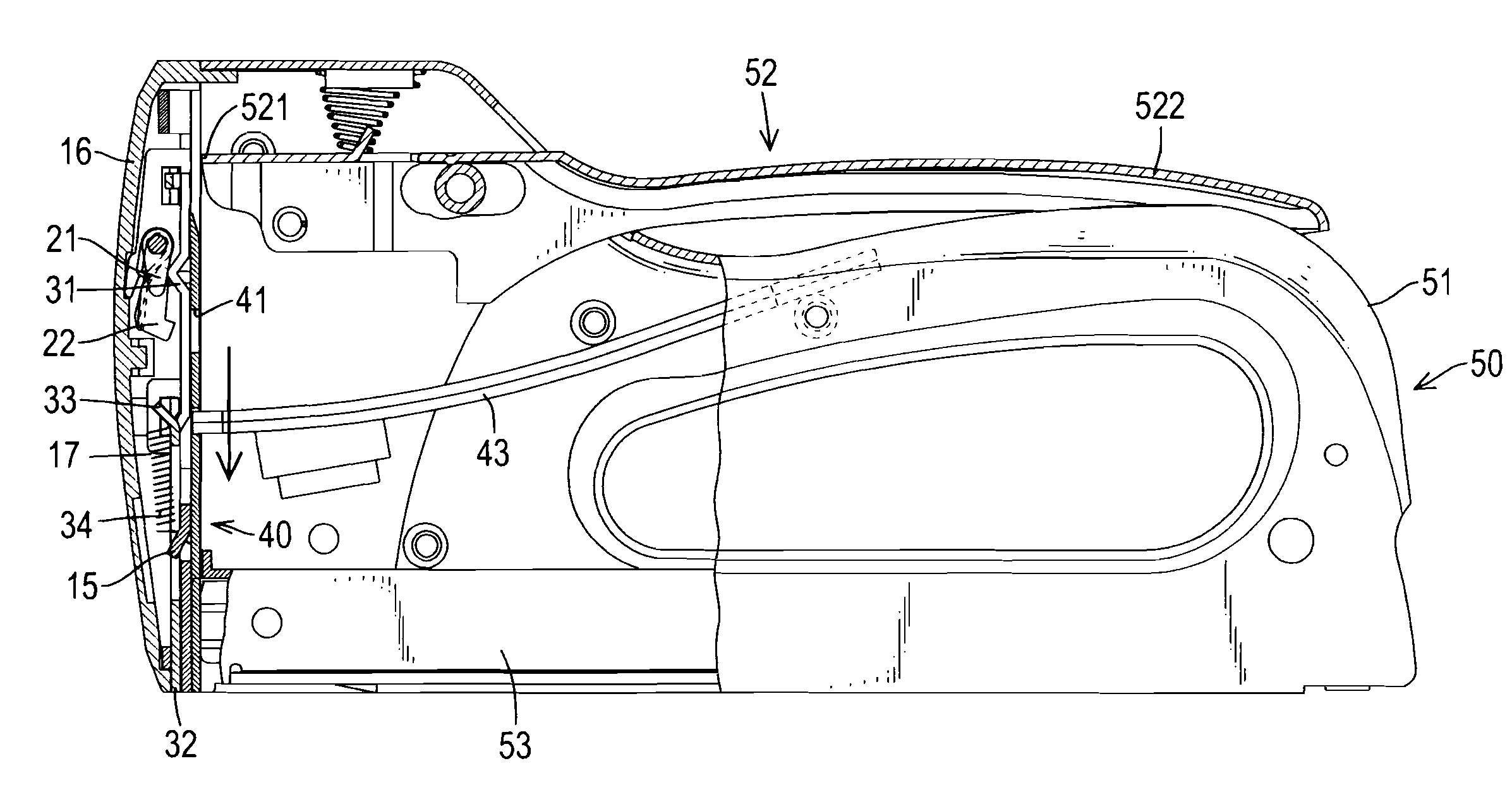

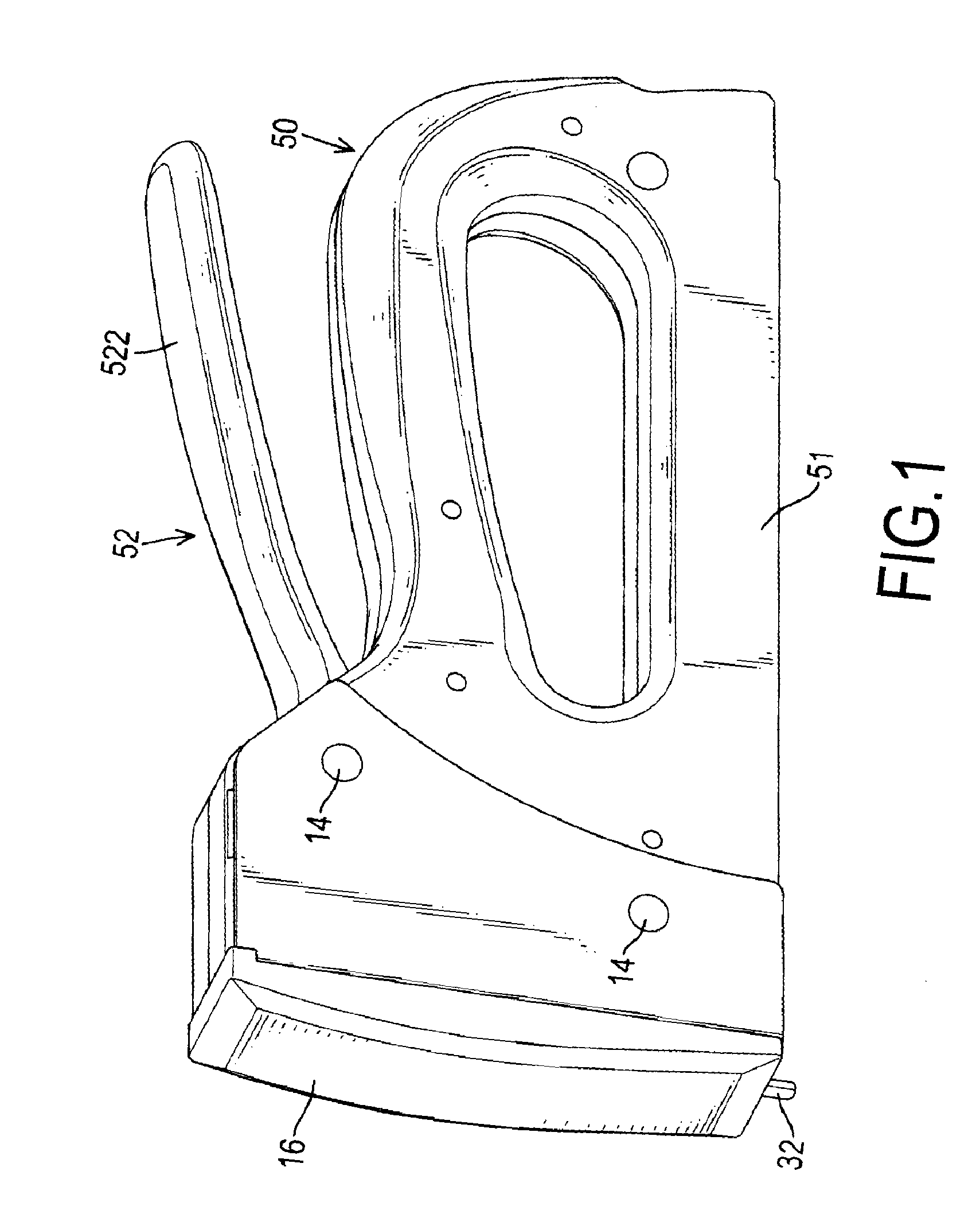

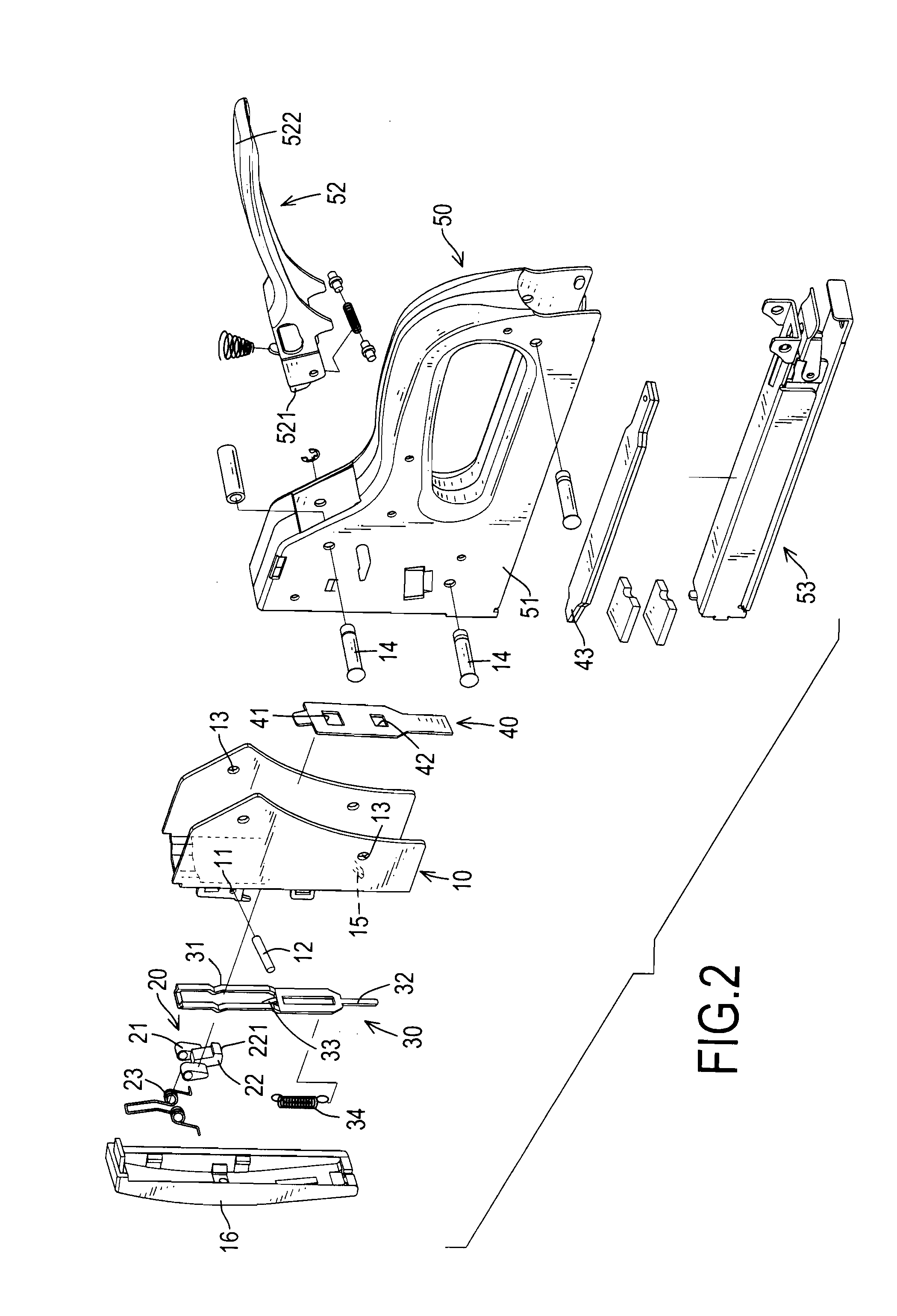

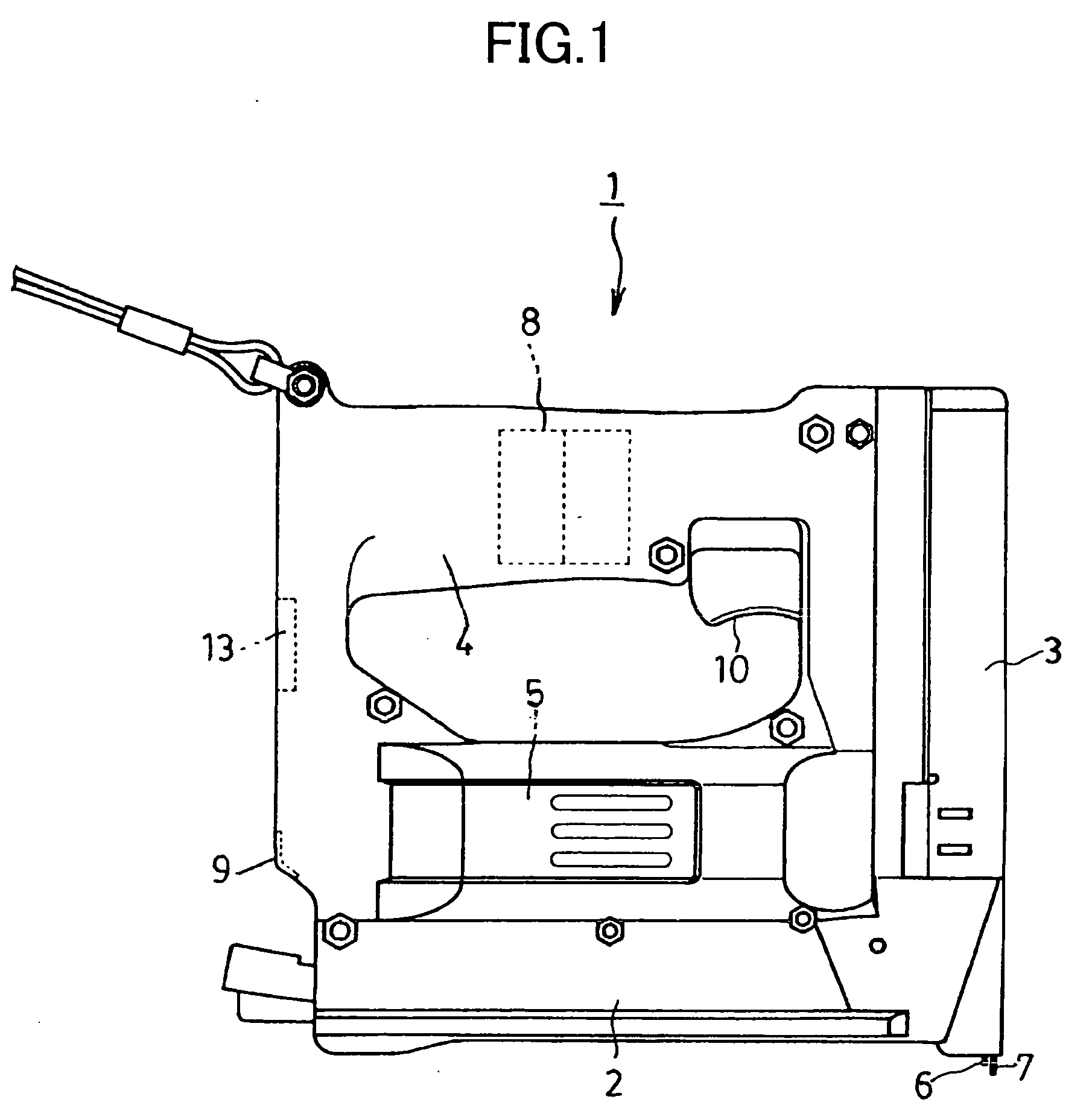

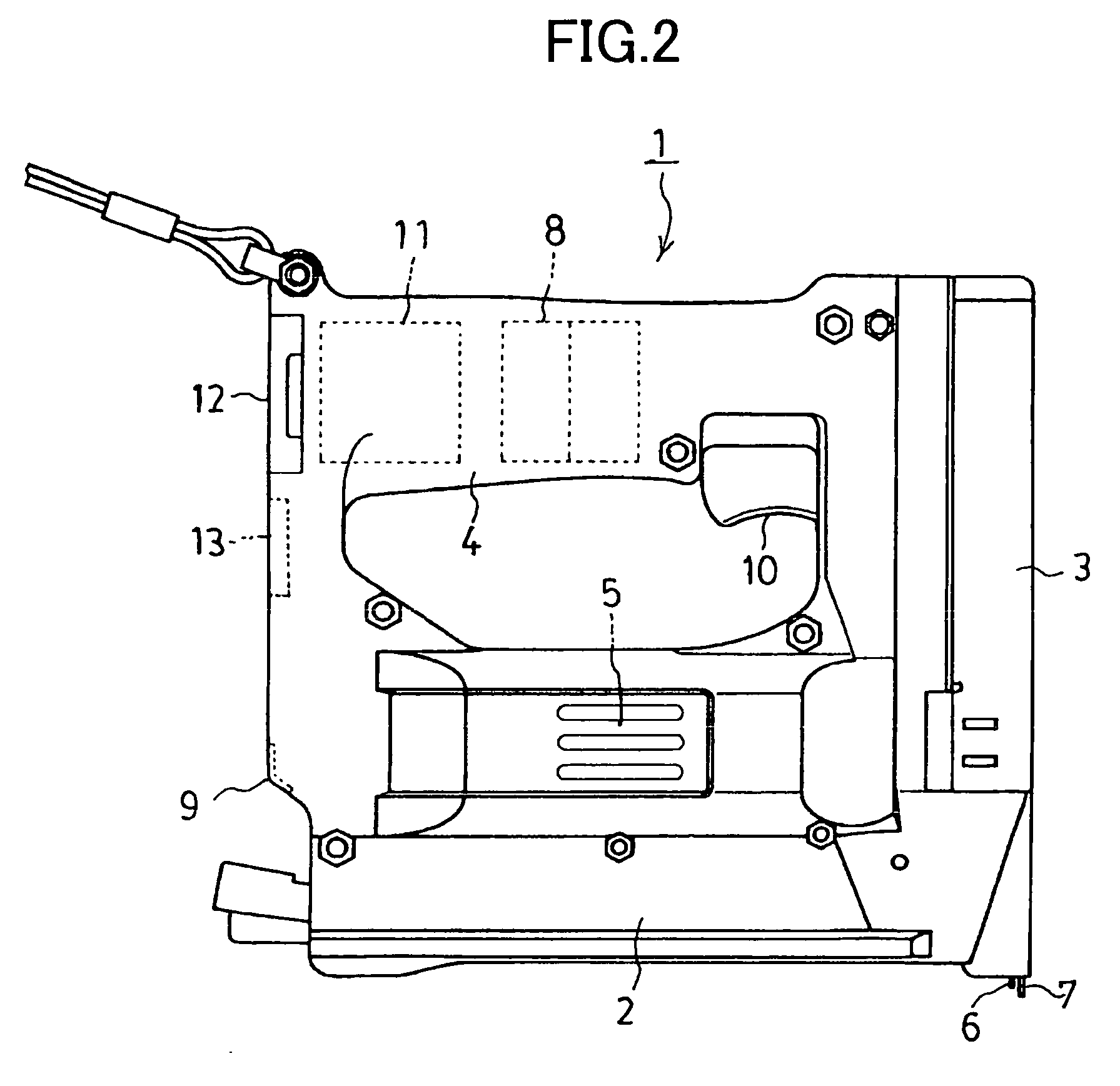

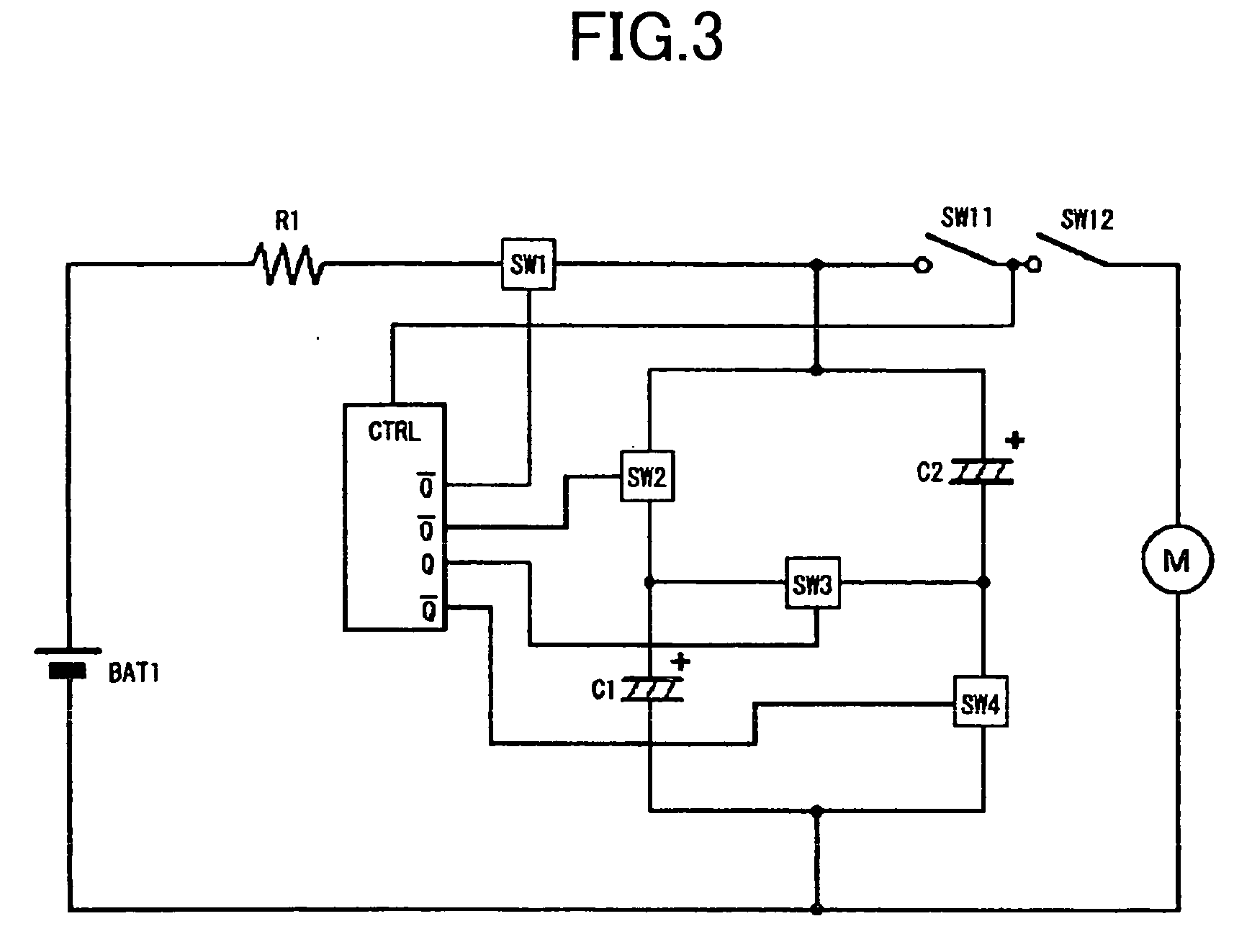

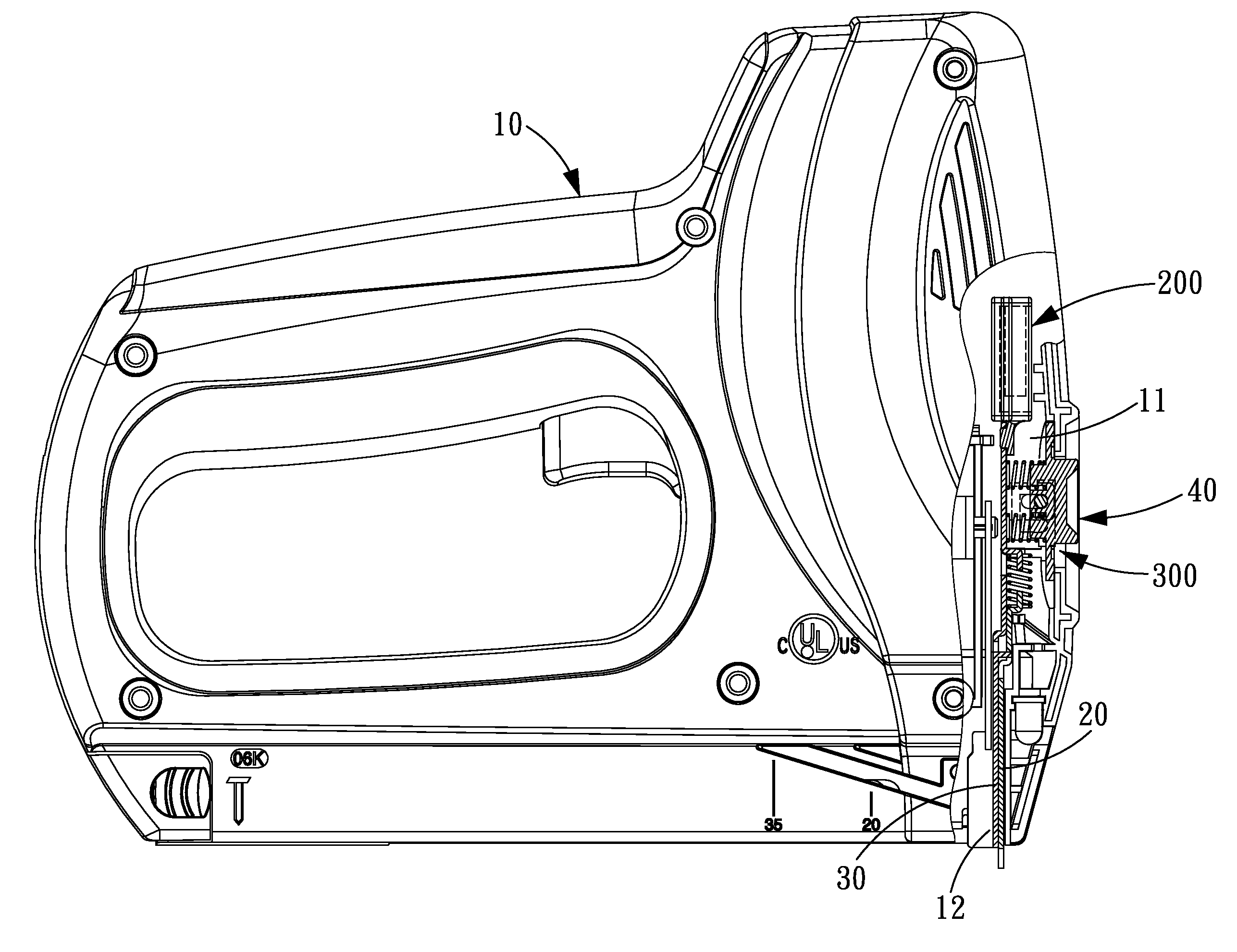

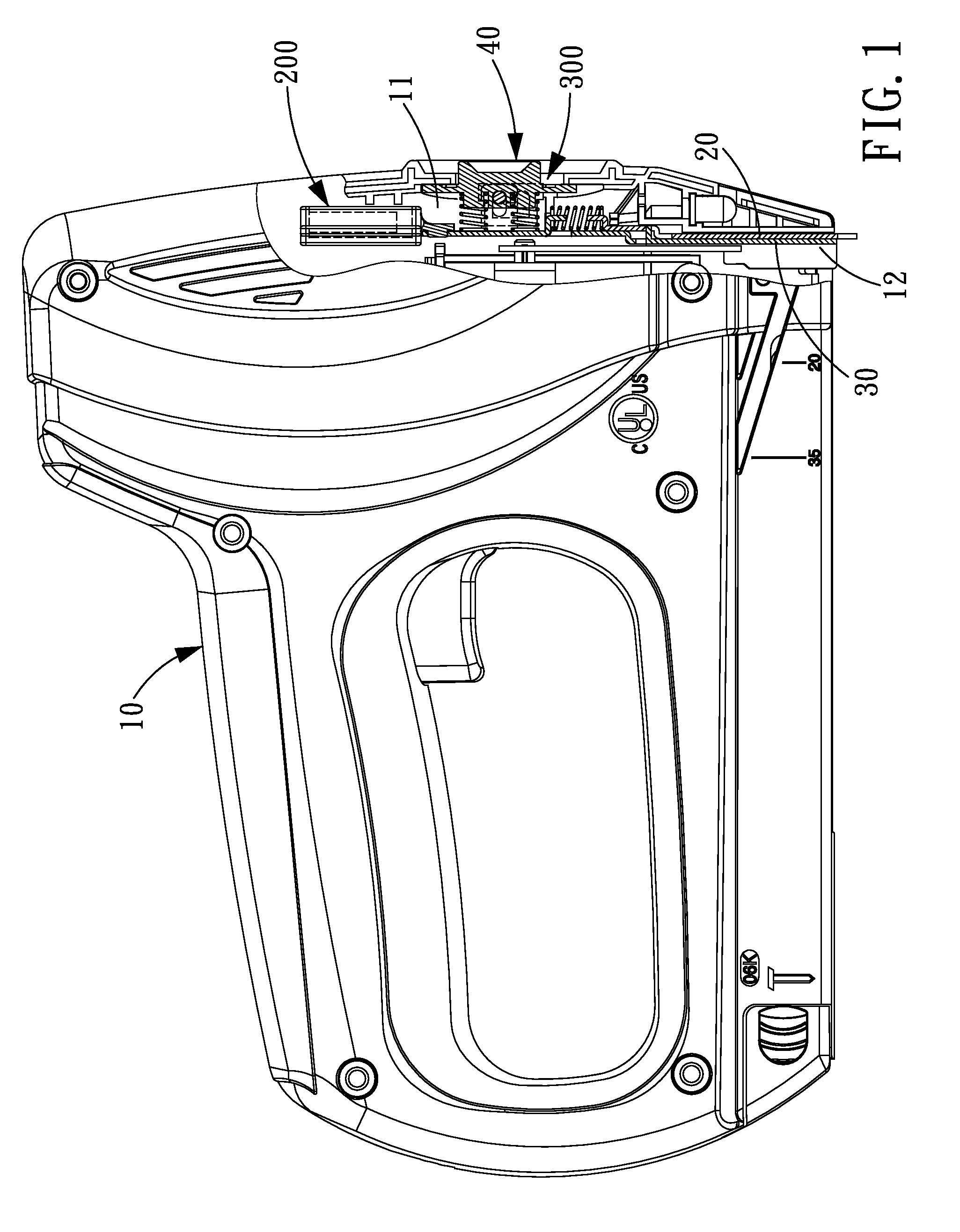

Cordless power tool

InactiveUS7248019B2Small sizeReduce weightStapling toolsBatteries circuit arrangementsHigh energyElectrical battery

A cordless power tool such as a power staple gun 1 includes a power supply circuit of an electric double layer capacitor 8 and a lithium-ion battery 11. In a standby state, the lithium-ion battery charges the electric double layer capacitor, and at a switch on time, the electric double layer capacitor supplies large current to the motor 5. By combining the lithium-ion battery with high energy density and the electric double layer capacitor capable of discharging large current, it is possible to greatly reduce the size and weight as compared with a case where a nickel-cadmium battery or a nickel-hydrogen battery is used. Besides, since the electric double layer capacitor has a very long lifetime, the running cost can also be reduced.

Owner:MAX CO LTD

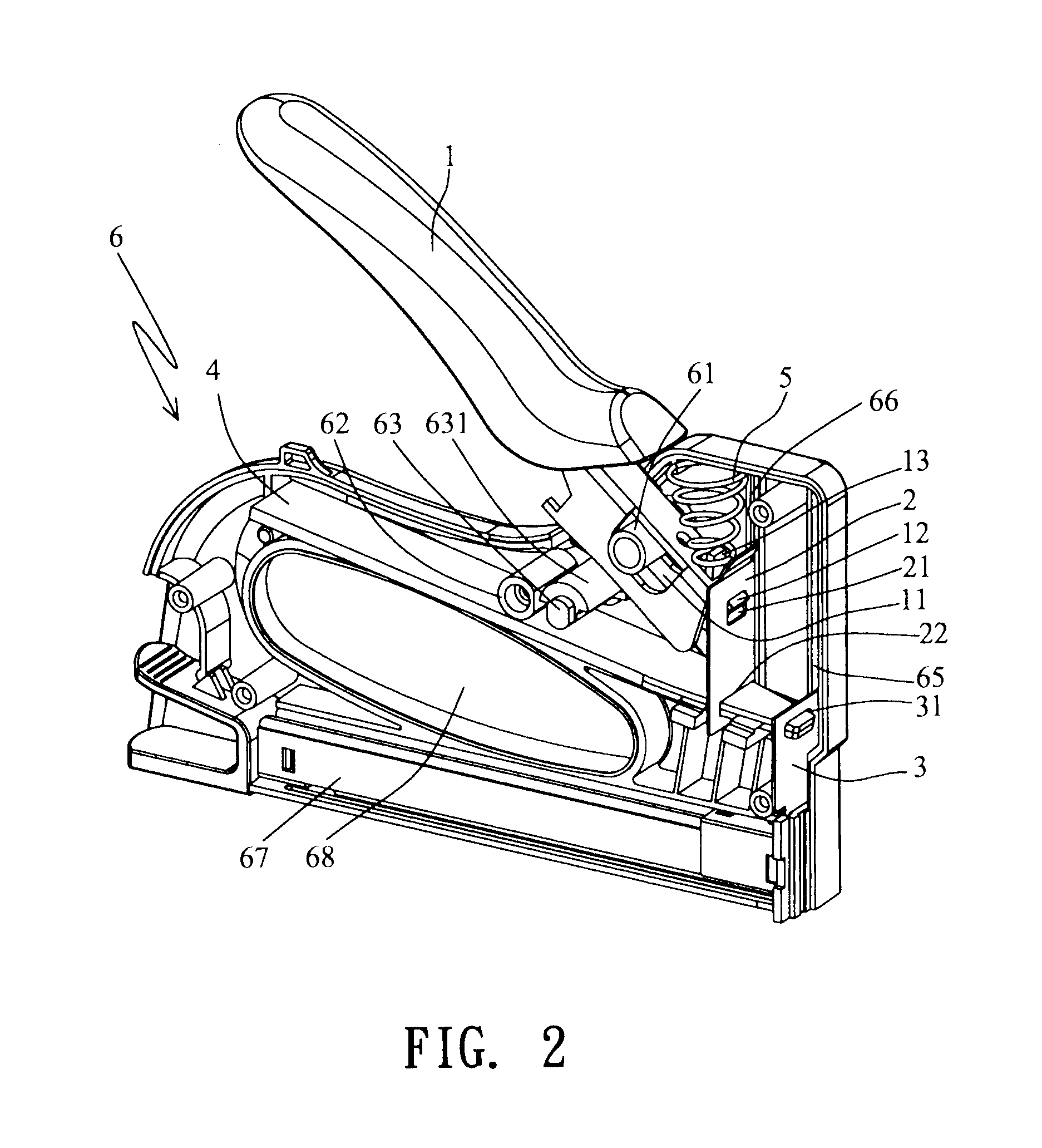

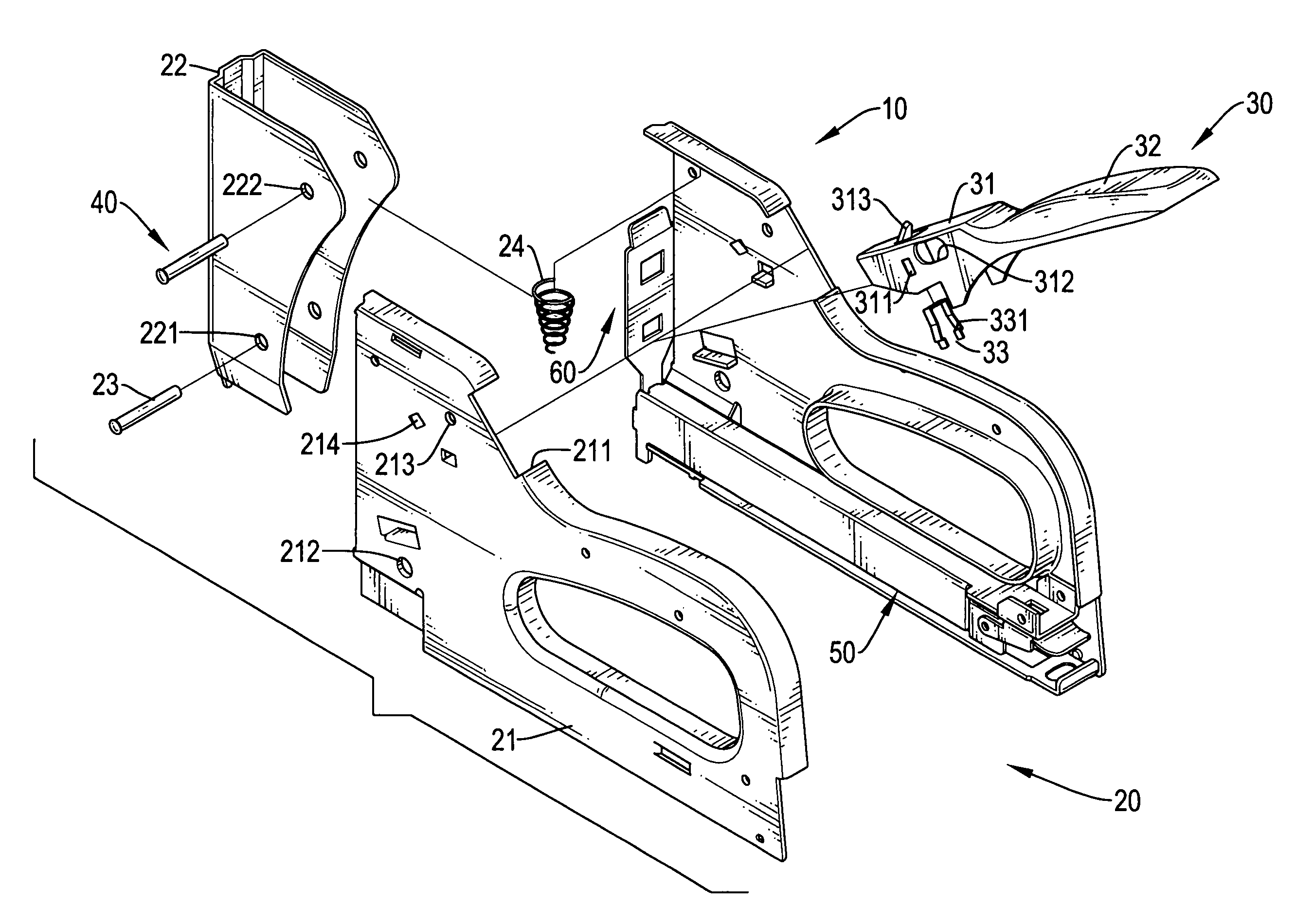

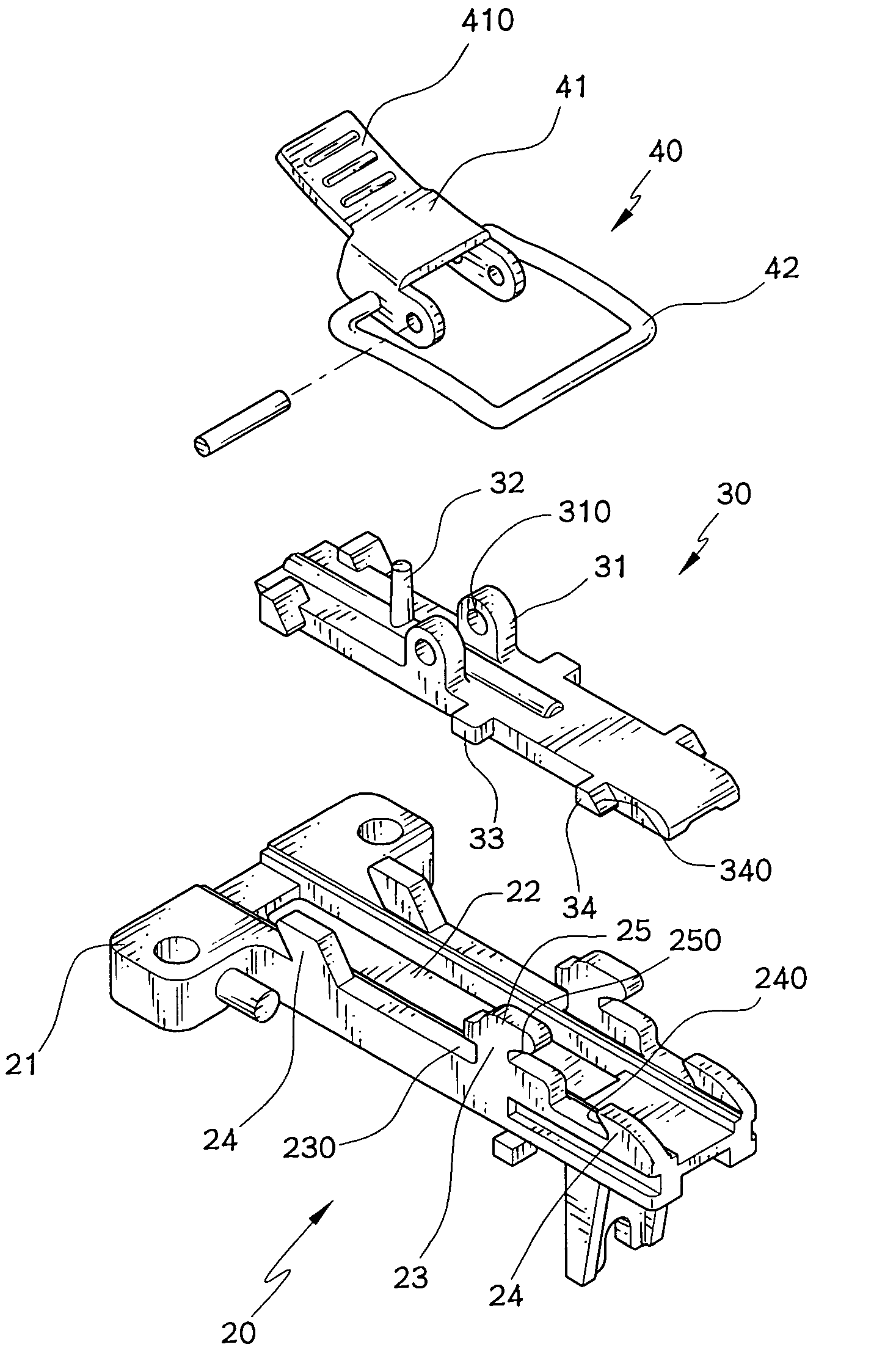

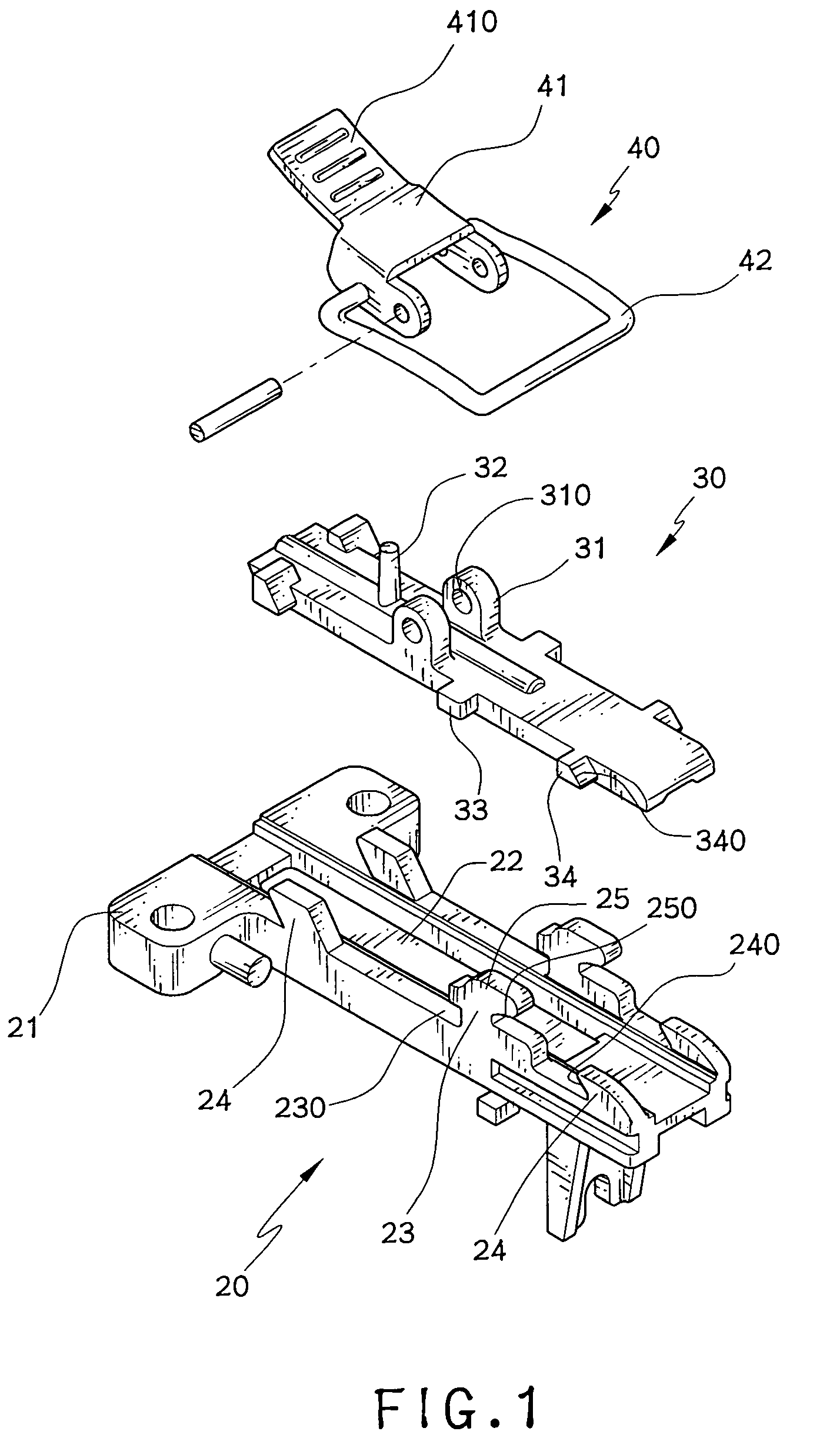

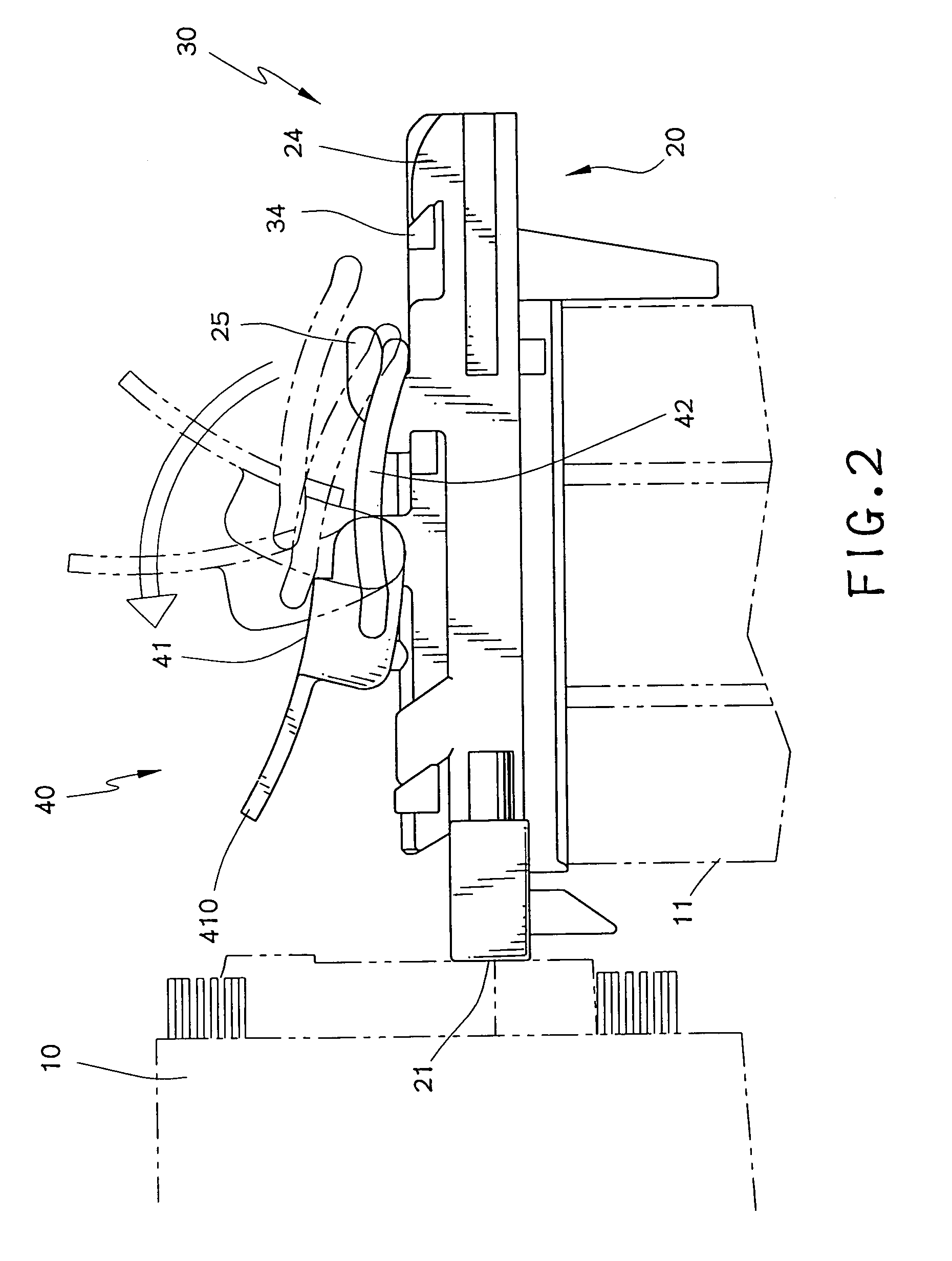

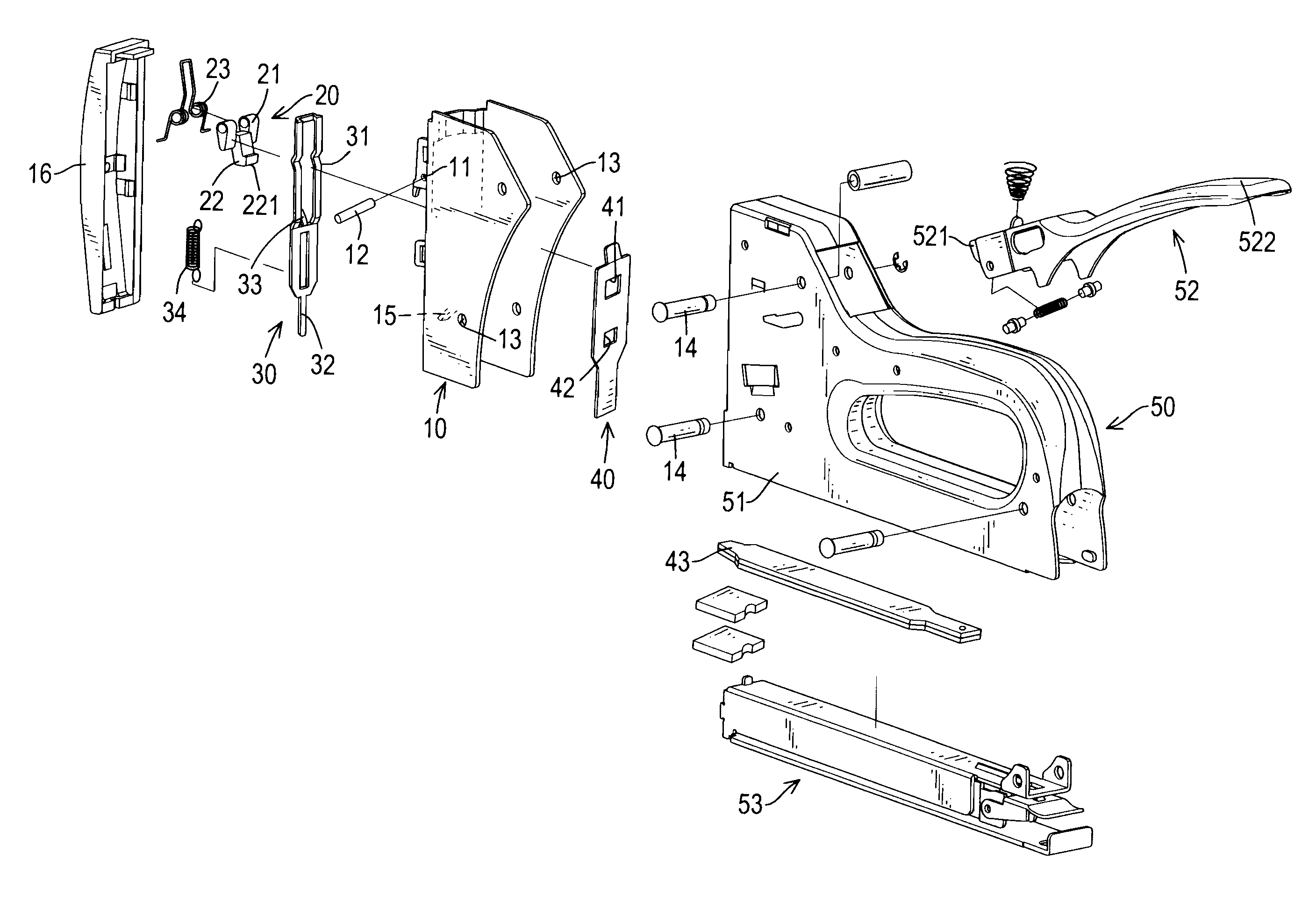

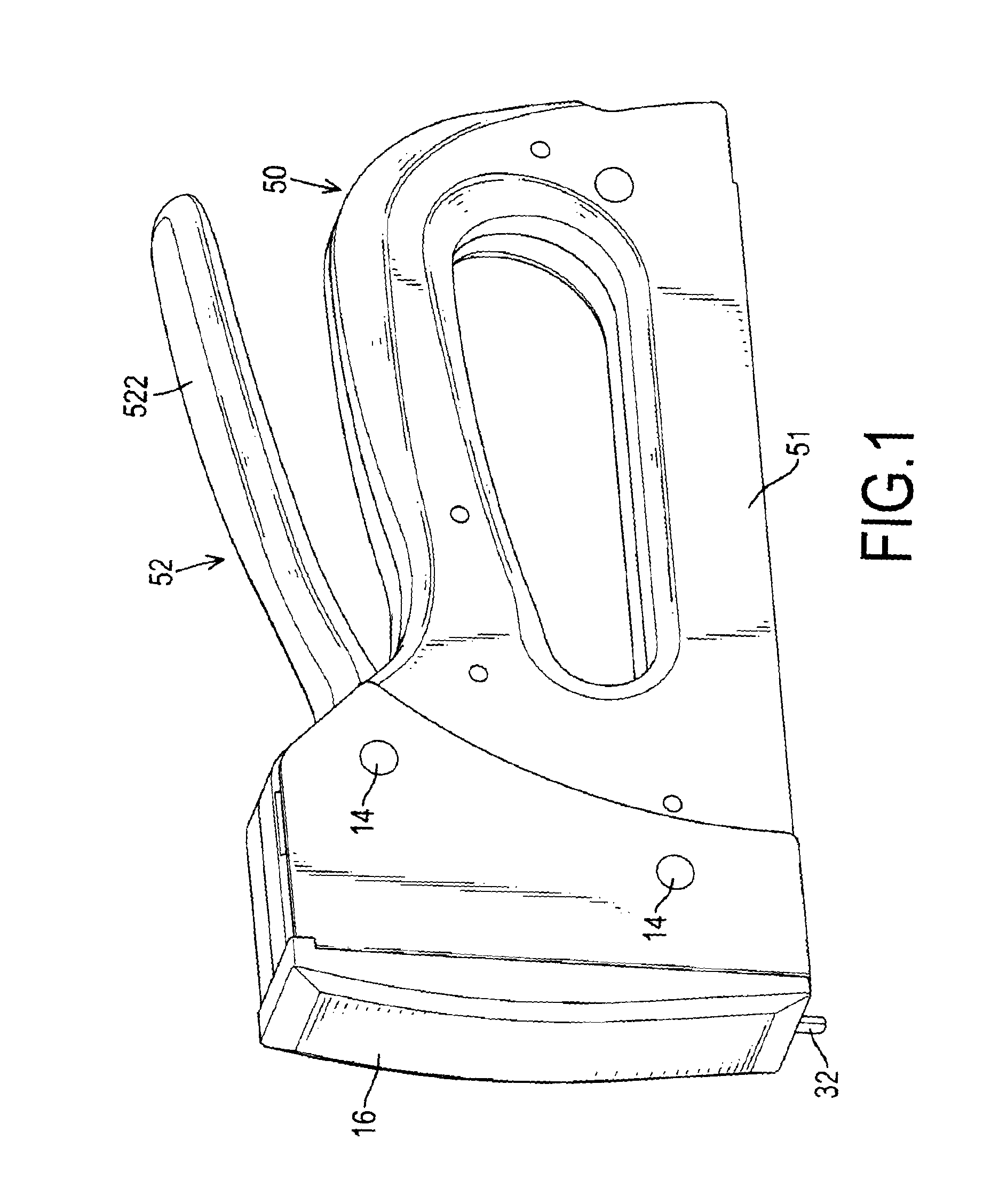

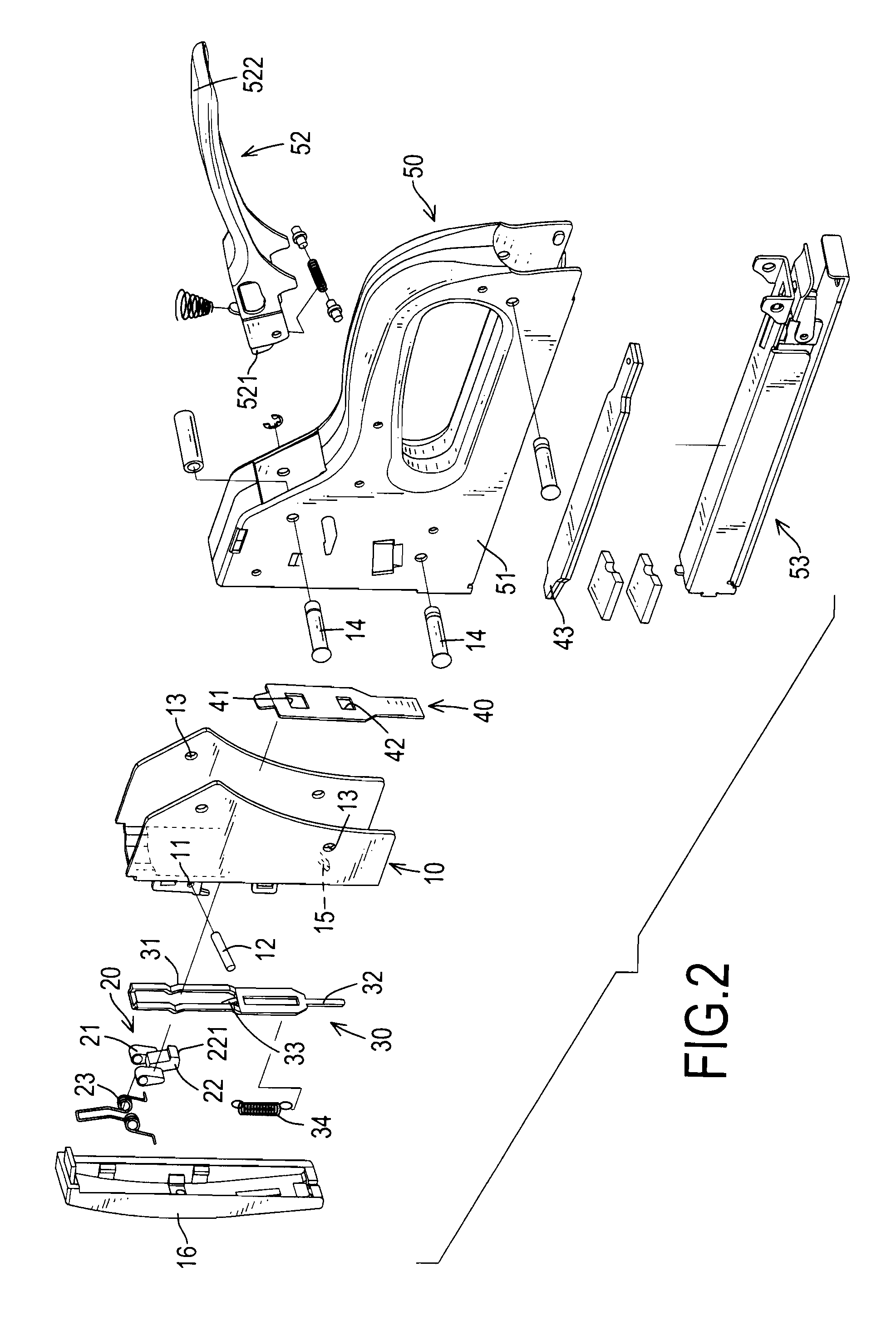

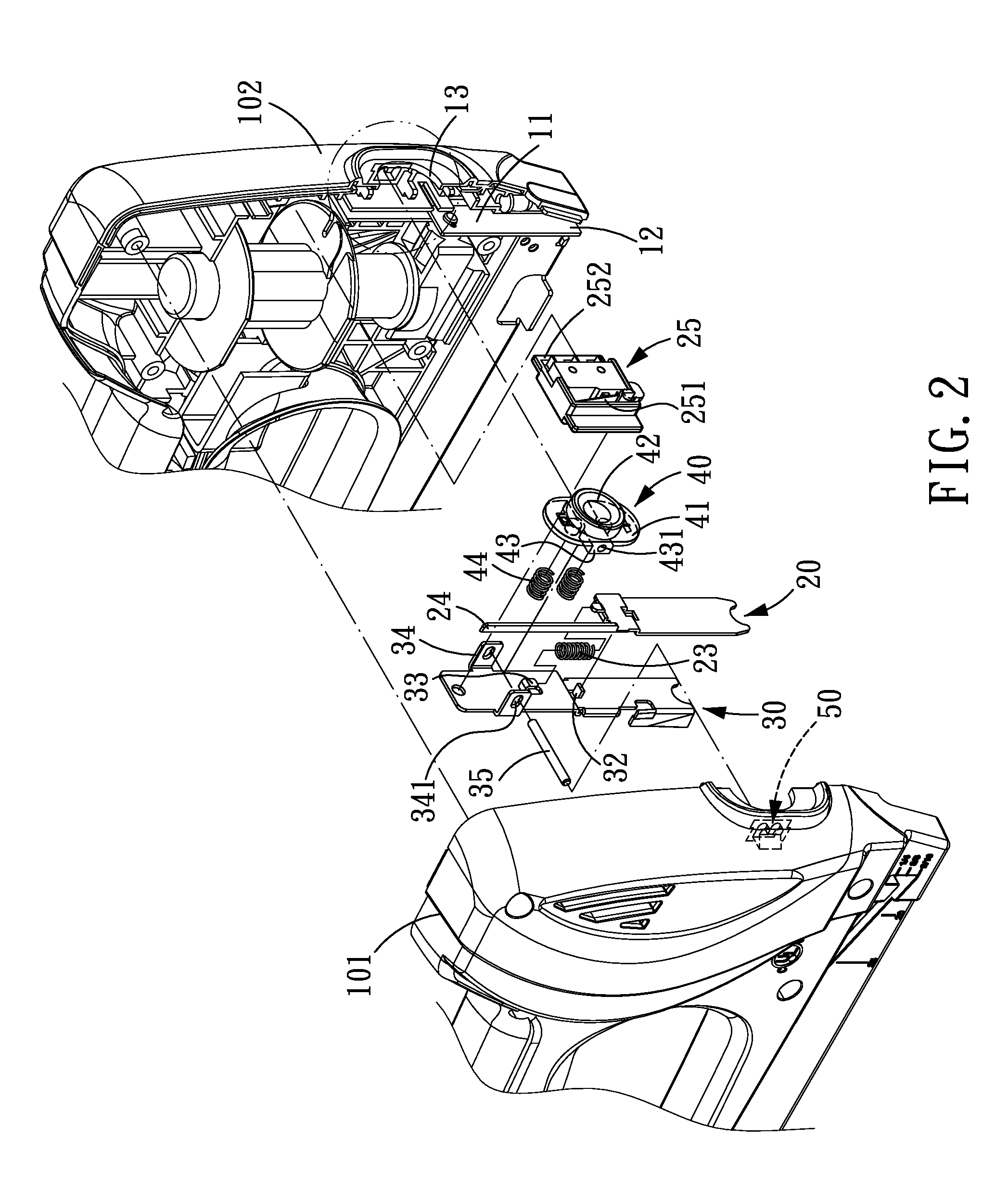

Staple gun with a latch assembly

InactiveUS7252217B1The process is simple and convenientStapling toolsNailing toolsStaple gunEngineering

A staple gun with a latch assembly has a housing, a handle, a pivot pin, a spring, a staple driver and a staple magazine. The housing has two half-casings and a handle opening. The half-casings are symmetrical and connected to each other, and each half-casing has a latch tab. The latch tab is formed on and protrudes in from the half-casing. The handle is connected pivotally to the housing through the handle opening and has an inner end and a latch clip. The inner end extends into the housing between the half-casings and has two sides and two mounting slots formed respectively in the sides of the inner end and aligning with each other. The latch clip is mounted in and protrudes through the mounting slots to selectively engage the latch tabs and hold the handle in place.

Owner:LIN JUI YUAN

Automobile handrail manufacturing technology

ActiveCN103802703ASimple preparation processThe preparation process is matureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesManufacturing technologyStaple gun

The invention relates to the field of automobile part manufacturing technologies, in particular to an automobile handrail manufacturing technology. The technology comprising the following processing steps: (1) selectively purchasing a leather material and a sponge, (2) tailoring the leather material and the sponge according to the shape of an outer cover of an automobile handrail, (3) spraying glue on and baking one surface of the sponge so as to enable the sponge to wrap the surface of the upper cover of the automobile handrail smoothly, (4) prebaking the leather material, and then spraying glue and baking, for the second time, one surface of the material so as to enable the leather material to wrap the upper surface of the sponge smoothly, (5) stretching the leather material and the sponge along the edge of the leather material and the edge of the sponge so as to enable the leather material and the sponge to be smooth, using a staple gun to nail for fixation, and shearing off the surplus leather material and the surplus sponge, (6) assembling the upper cover, of the automobile handrail, processed in the last step to a handrail seat so as to obtain the automobile handrail. The automobile handrail manufacturing technology is simple and mature and has the advantages of being high in processing efficiency and low in manufacturing cost.

Owner:DONGGUAN HIROSAWA AUTOMOTIVE TRIM

Staple gun

A staple gun comprising a main body and a staple injection nozzle for injecting a staple into a target object, the staple injection nozzle including a nozzle body mounted on a staple striking body and a cover plate for removably closing an upper portion of a staple injection path of the nozzle body so as to guide the staple. The nozzle body has protrusions to receive an end portion of the cover plate and press this cover plate from upward, and an urging member is provided to urge the cover plate in a direction that the end portion of the cover plate intrudes into the protrusions.

Owner:MAX CO LTD

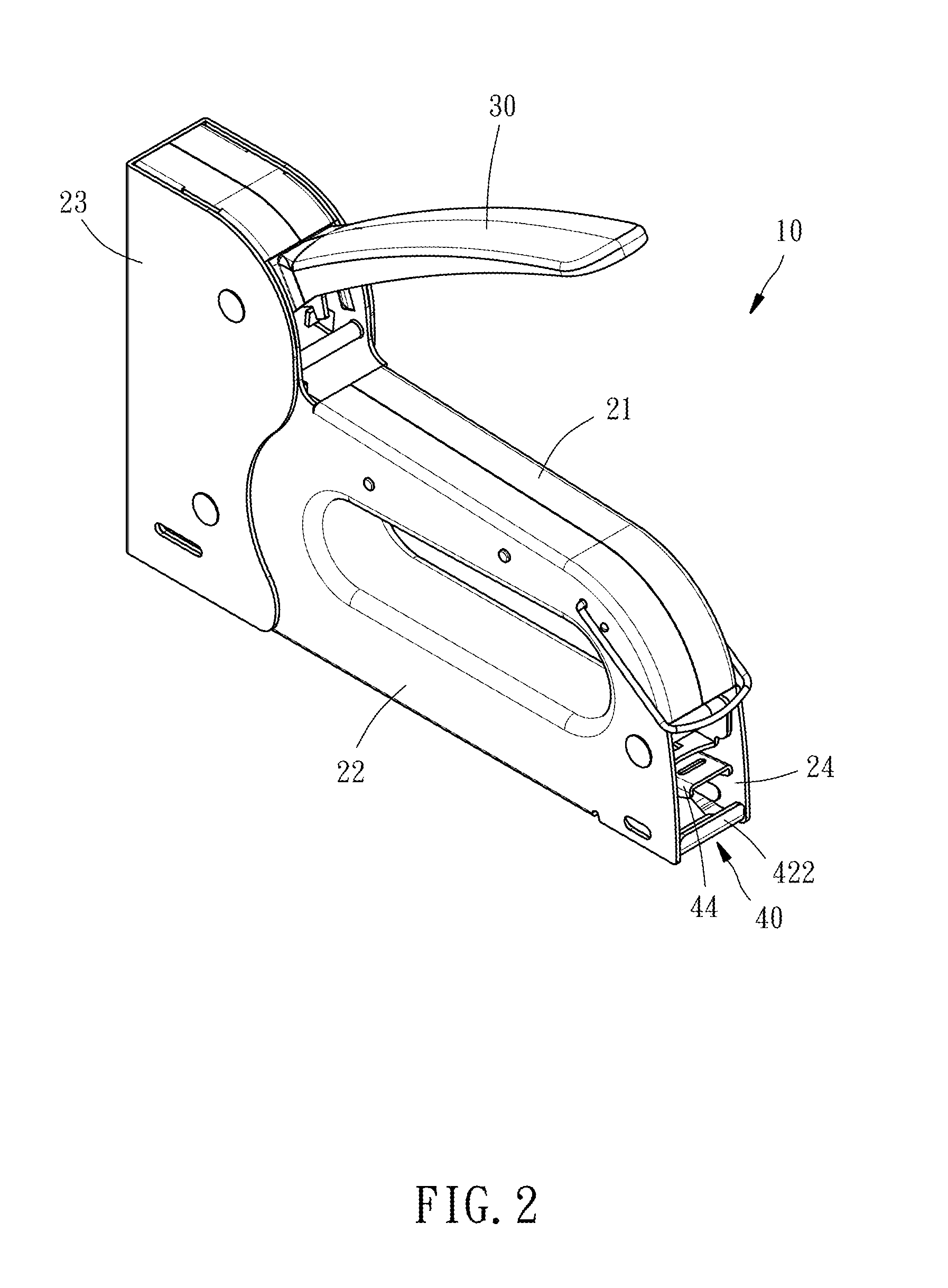

Staple gun automatically applicable to staples of multiple sorts

A staple gun includes: a casing having a front blocking surface; a magazine disposed in the casing; and a staple delivery element and a resilient element disposed at the magazine. The magazine includes at least a staple cutting portion each having a top surface, a front end surface, and a guiding surface connected between the top surface and the front end surface. The front end surface and the guiding surface face the front blocking surface. A clearance for passing staples is disposed between the front end surface and the front blocking surface. The staple delivery element pushes staples in the magazine in a staple delivering direction. The resilient element enables staples to push the front end surface and the guiding surface of the staple cutting portion of the magazine, such that the magazine moves relative to the casing in a clearance adjustment direction opposite to the staple delivering direction.

Owner:SAME YONG INDAL

Latch assembly for a staple gun

A latch assembly for a staple gun has a front cover, a locking element, a pushing element and a staple driver. The front cover has a connecting bolt. The locking element is mounted on the front cover and has two cams, a torsion spring and a locking block. The cams and the torsion spring are mounted around the connecting bolt. The pushing element is mounted in the front cover and has a pushing lever and a pressing pin. The pushing lever abuts the cams. The pressing pin extends out of the front cover. The staple driver is mounted in the front cover and has a locking hole, a through hole and an elastic panel. The locking hole is formed through the staple driver and engages the locking block. The latch assembly can hold a handle of the staple gun conveniently and safely when the staple gun is not being used.

Owner:LIN JUI YUAN

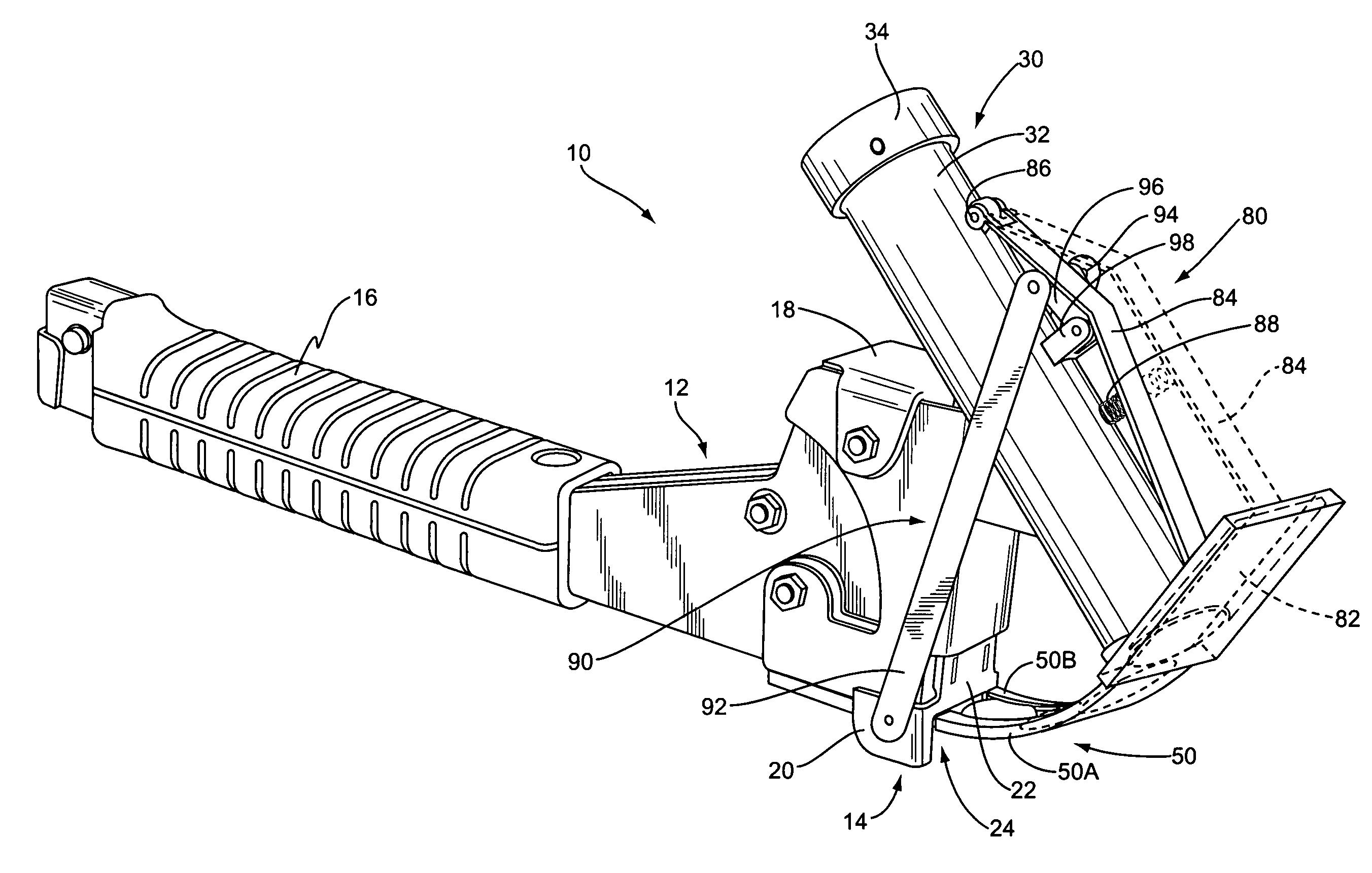

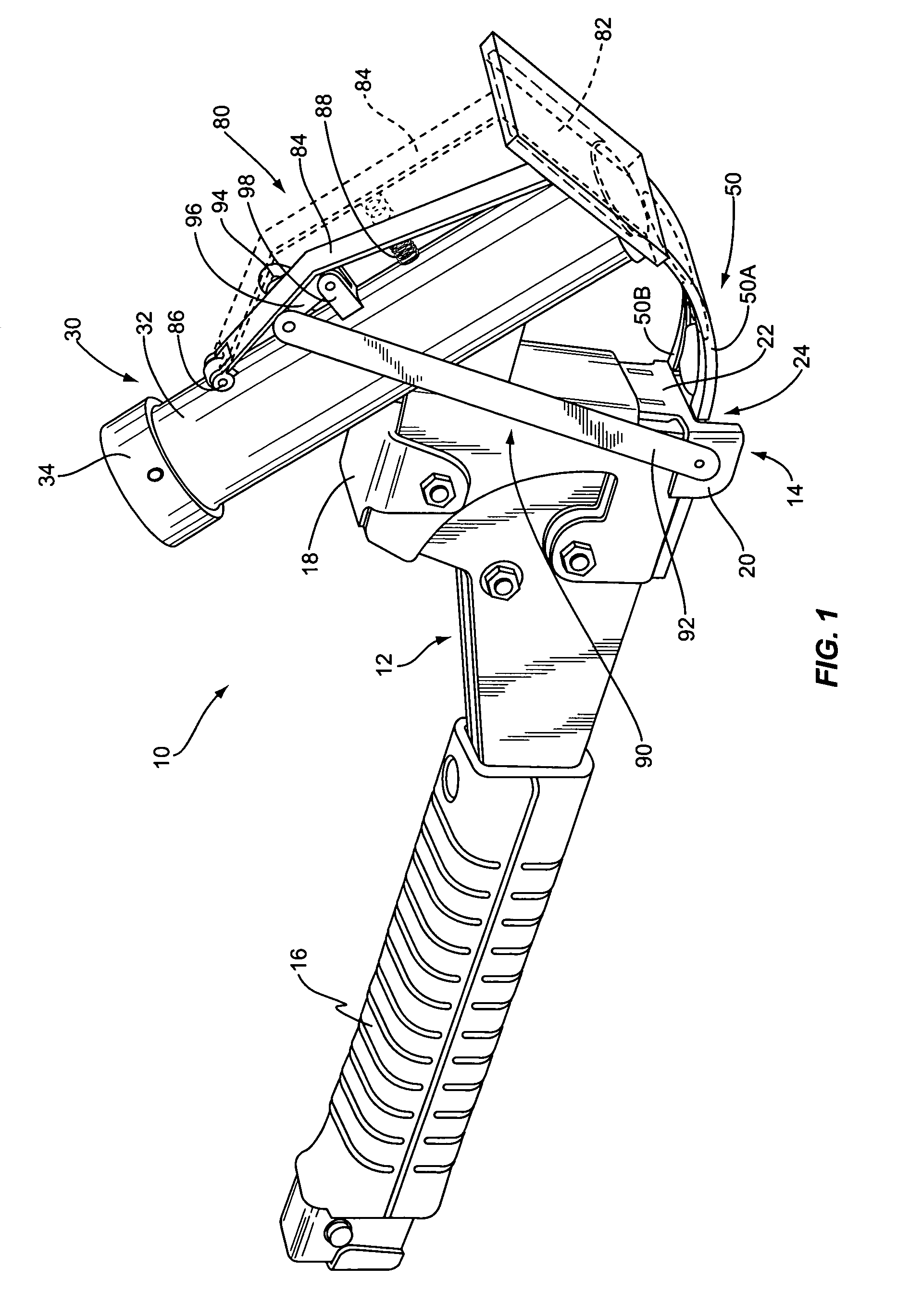

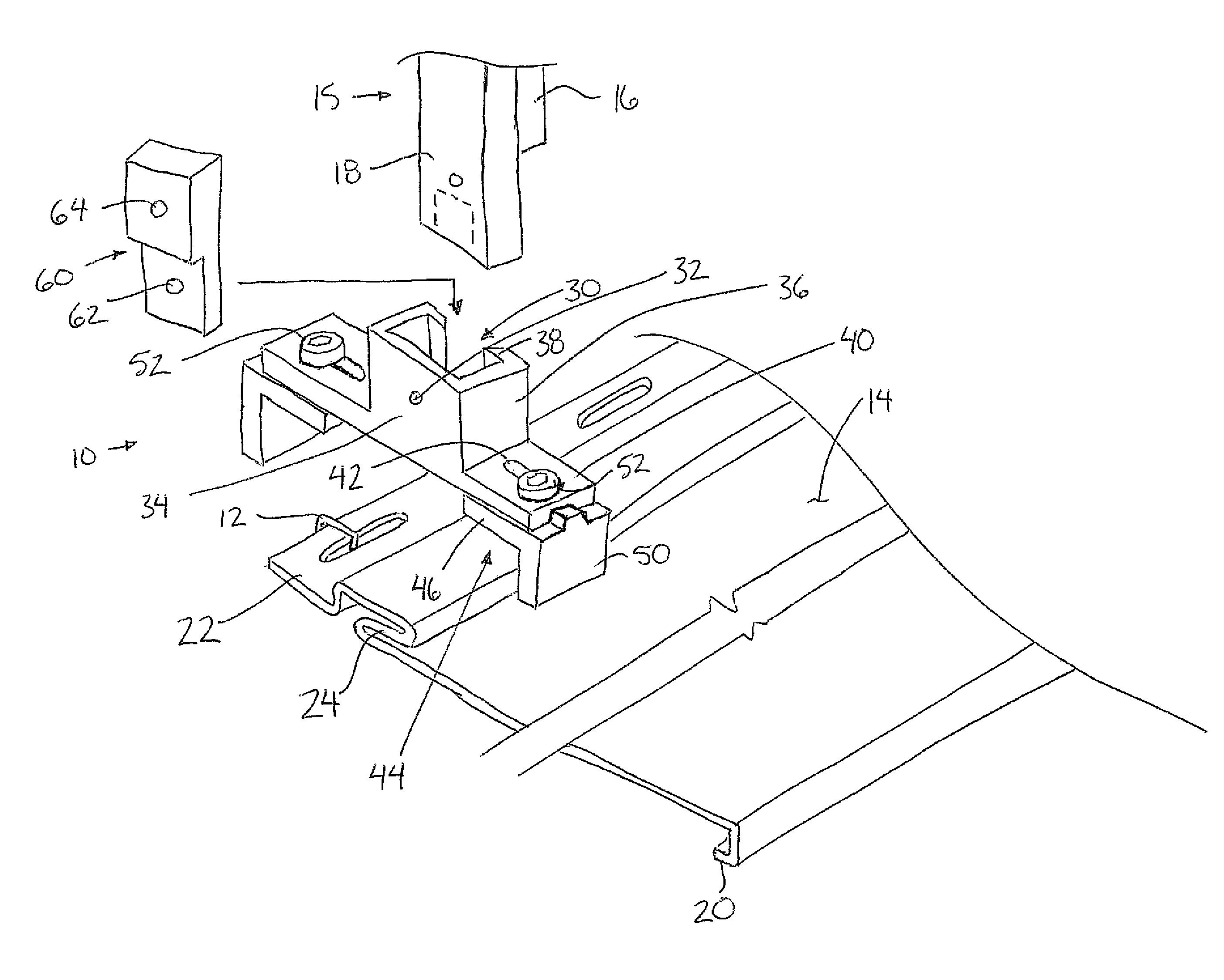

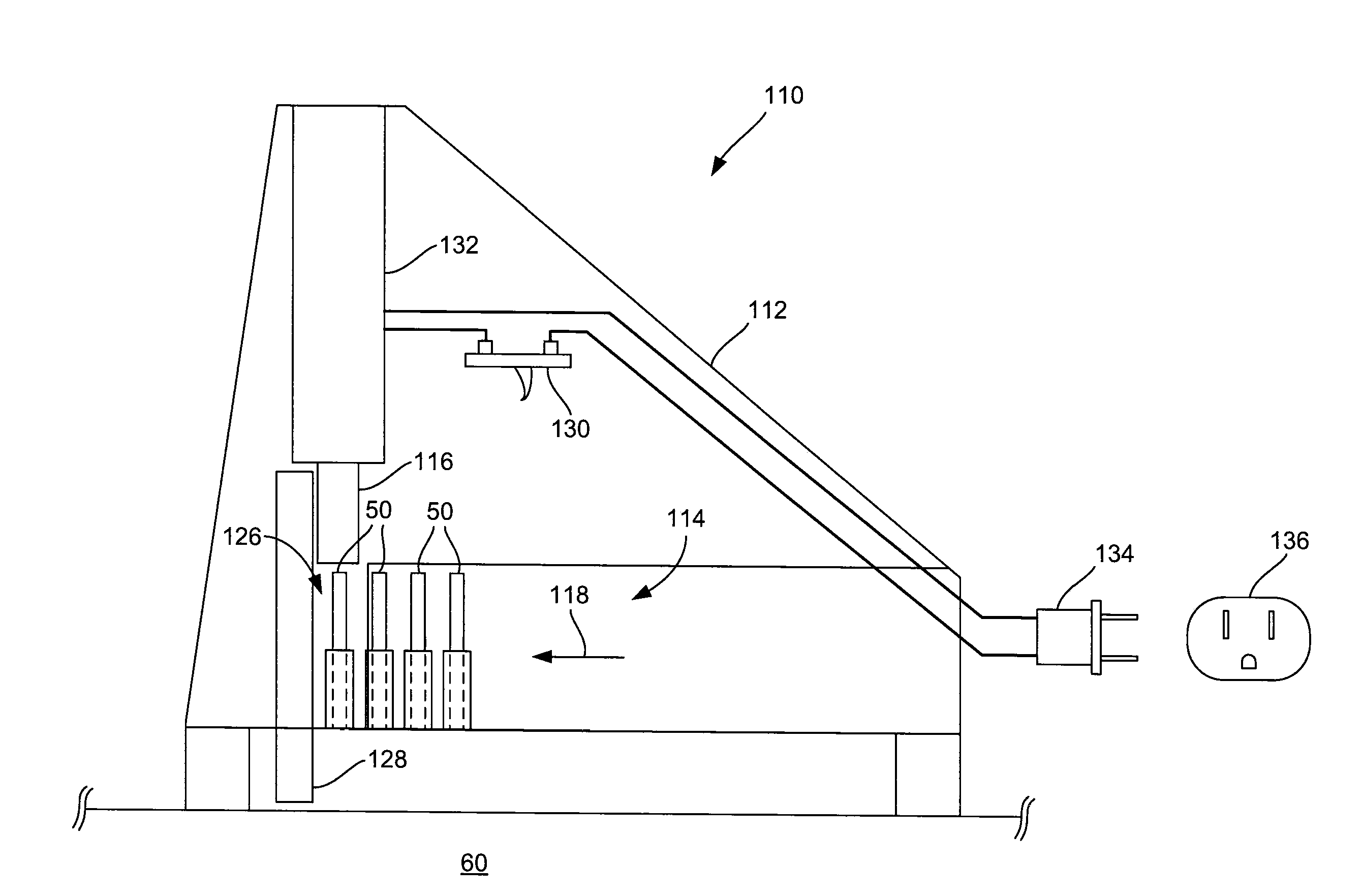

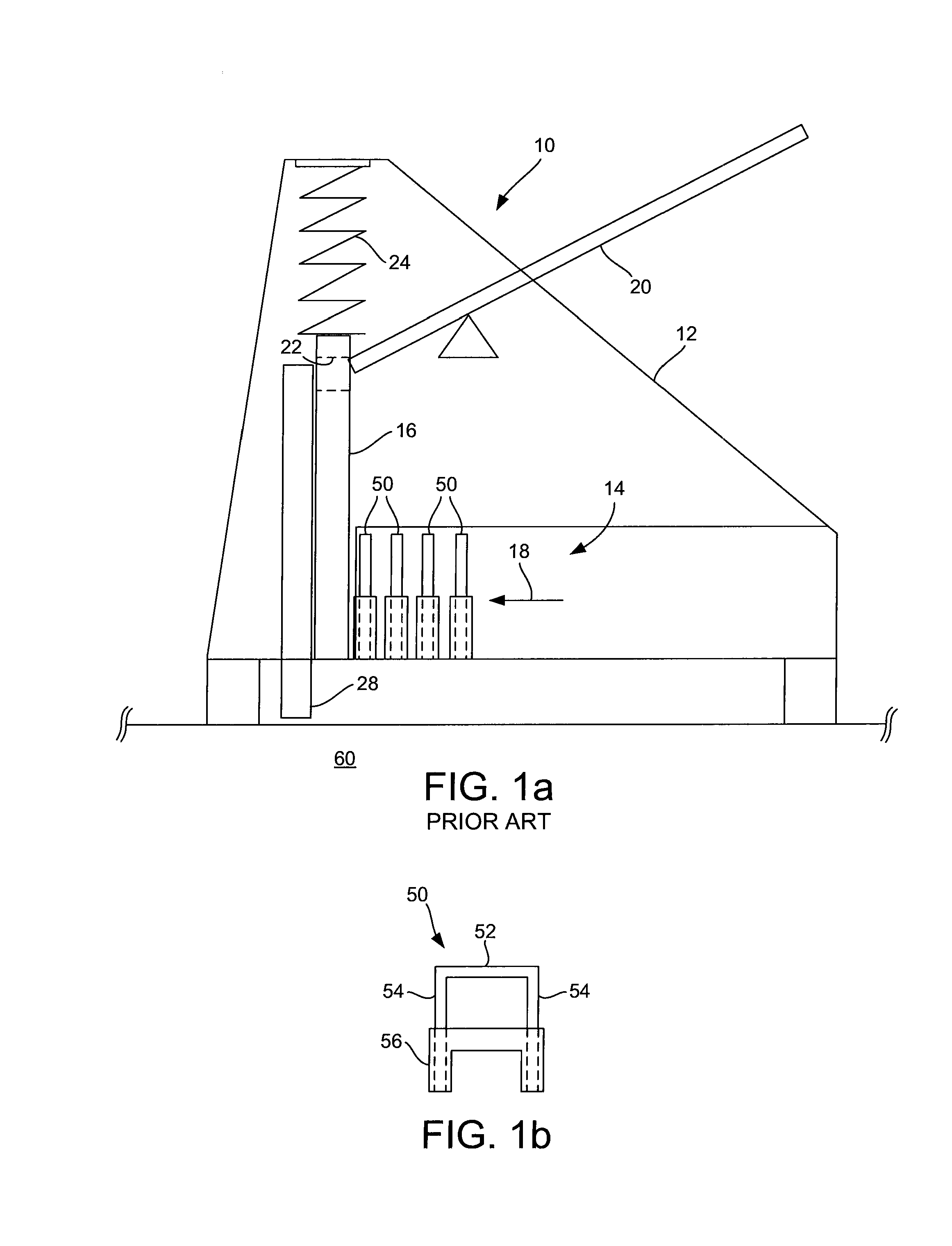

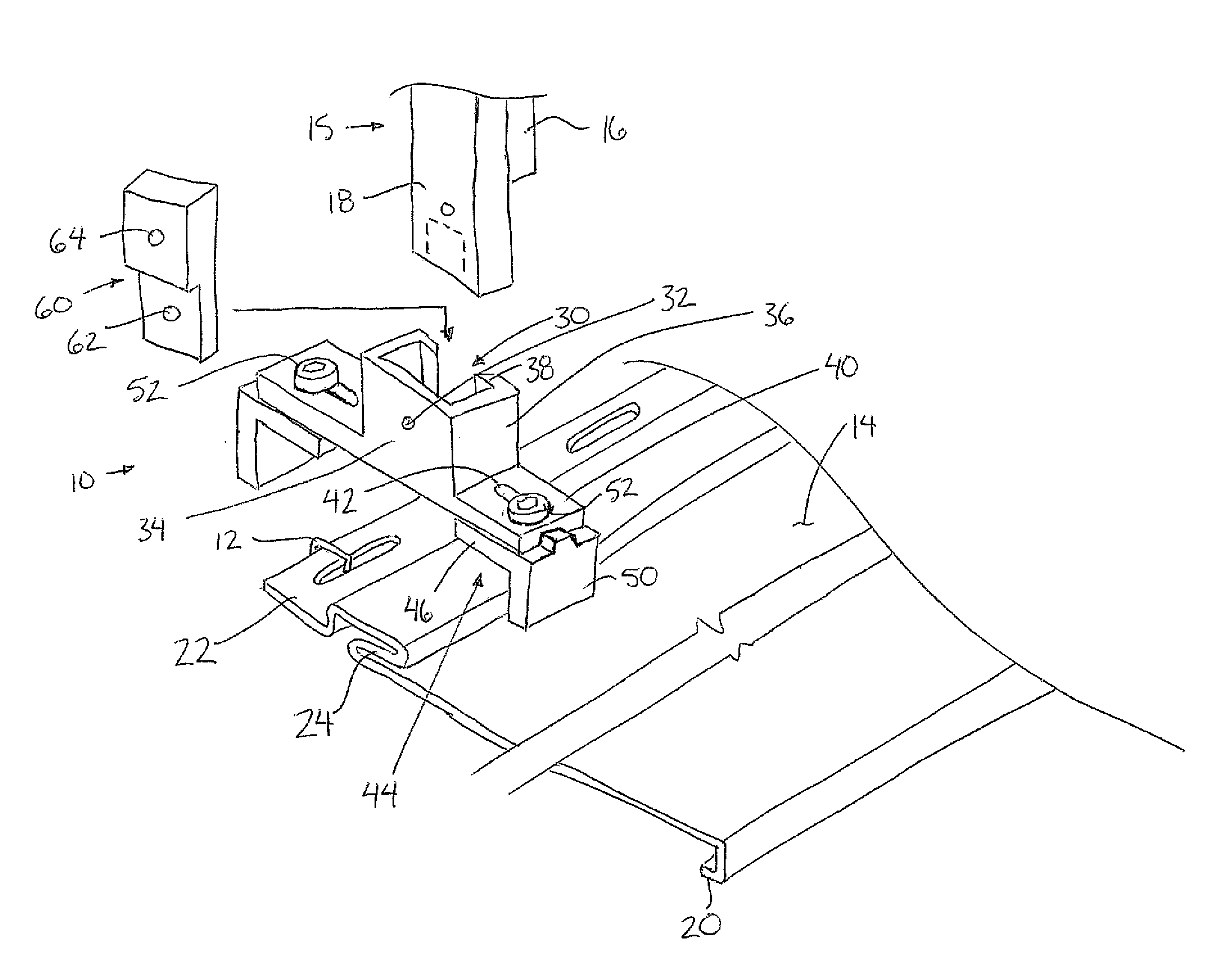

Siding gauge device for staple gun

ActiveUS7739807B2Improve securityShorten the timeStapling toolsDrilling/boring measurement devicesStaple gunClassical mechanics

A gauge device for use with a staple gun serves to align the staple gun relative to building siding to dispense a two prong staple from a head of the staple gun into one of a plurality of fastener apertures in siding members of the building siding. The gauge device comprises a pair of flanges arranged to depend from laterally opposed sides of the head of the staple gun at a location such that abutment of one of the flanges below a lock edge channel of a siding member locates one prong of the two prong staple to be in alignment with one of the fastener apertures and locates the other prong of the two prong staple above the top free edge of a nailing flange of the siding member.

Owner:GRANT KEVIN ANTHONY

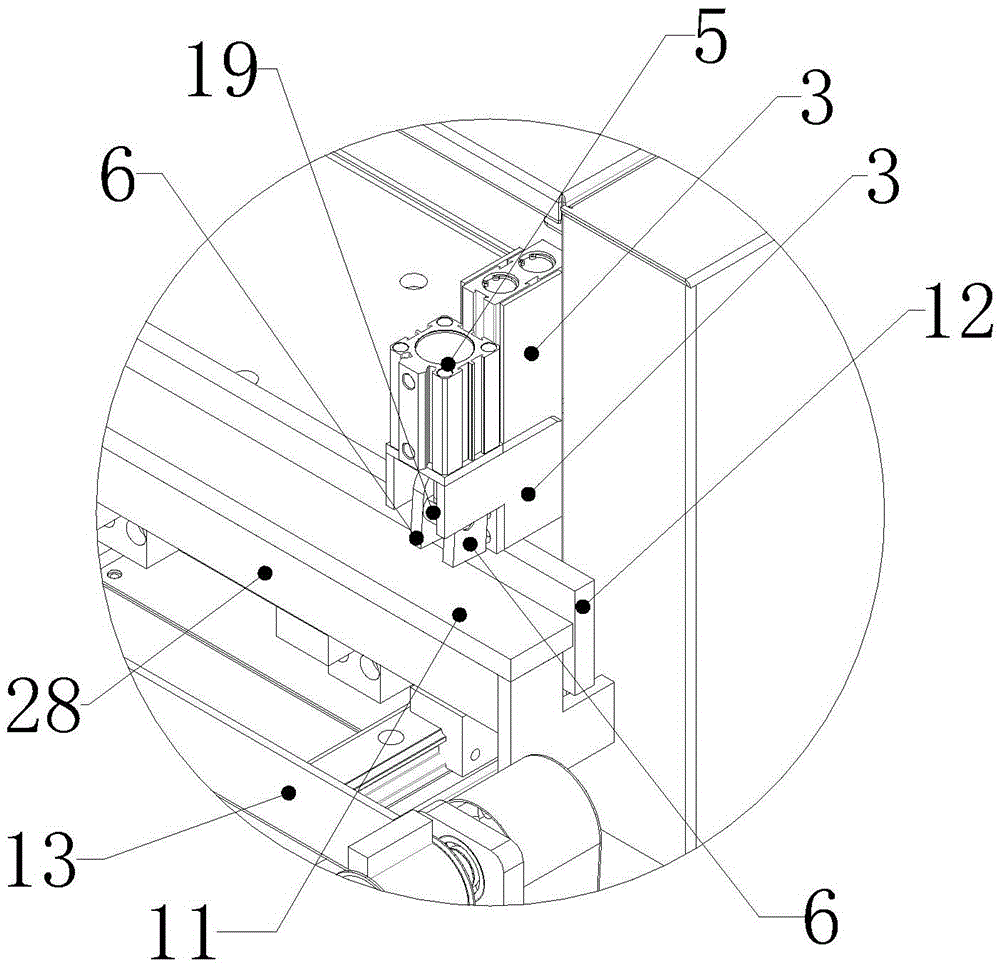

Canvas nailing method of cloth nailing machine

InactiveCN105538988ANo human intervention requiredFast bindingSpecial ornamental structuresStaple gunEngineering

The invention relates to a canvas nailing method of a cloth nailing machine, wherein the nailing speed is high and the nailing effect is good. The canvas nailing method includes the following steps that 1, a conveyor belt conveys a frame to the nailing position; 2, a piston rod of a pressing air cylinder moves downwards and drives a cloth pressing plate to rotate till the bottom end of the cloth pressing plate is opposite to the canvas; 3, a piston rod of a lifting air cylinder moves upwards and drives one end of a staple gun body to move upwards till the cloth pressing plate tightly presses the canvas to the frame; 4, a piston rod of a nailing air cylinder moves downwards so as to drive a nailing head to move downwards, and the nailing head drives a nail to move downwards after being in contact with the nail arranged in a nail storage groove till the nail penetrates through a nail penetrating hole and is knocked into the frame.

Owner:WUXI CITY YINYING STATIONERY & SPORTS CO LTD

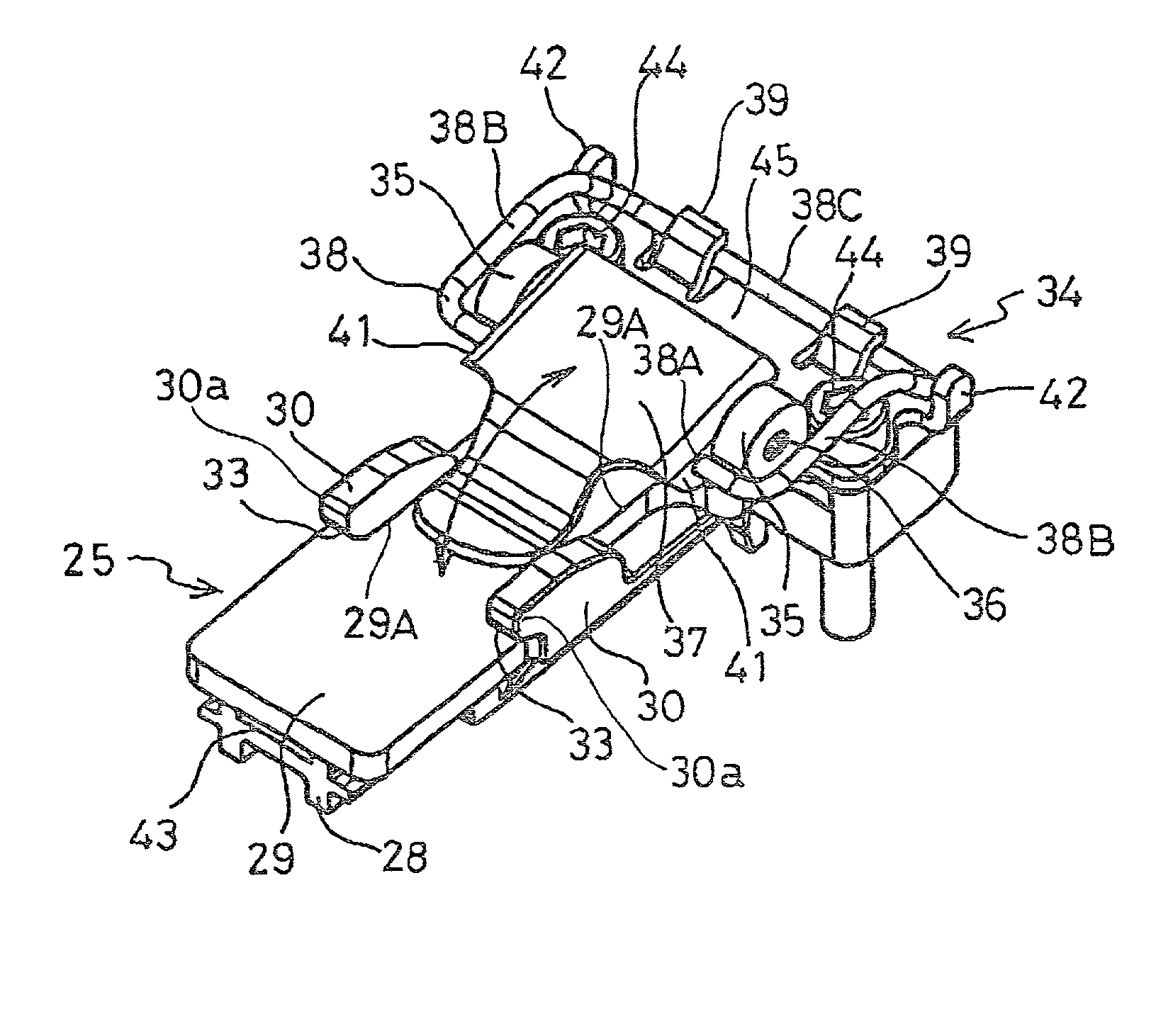

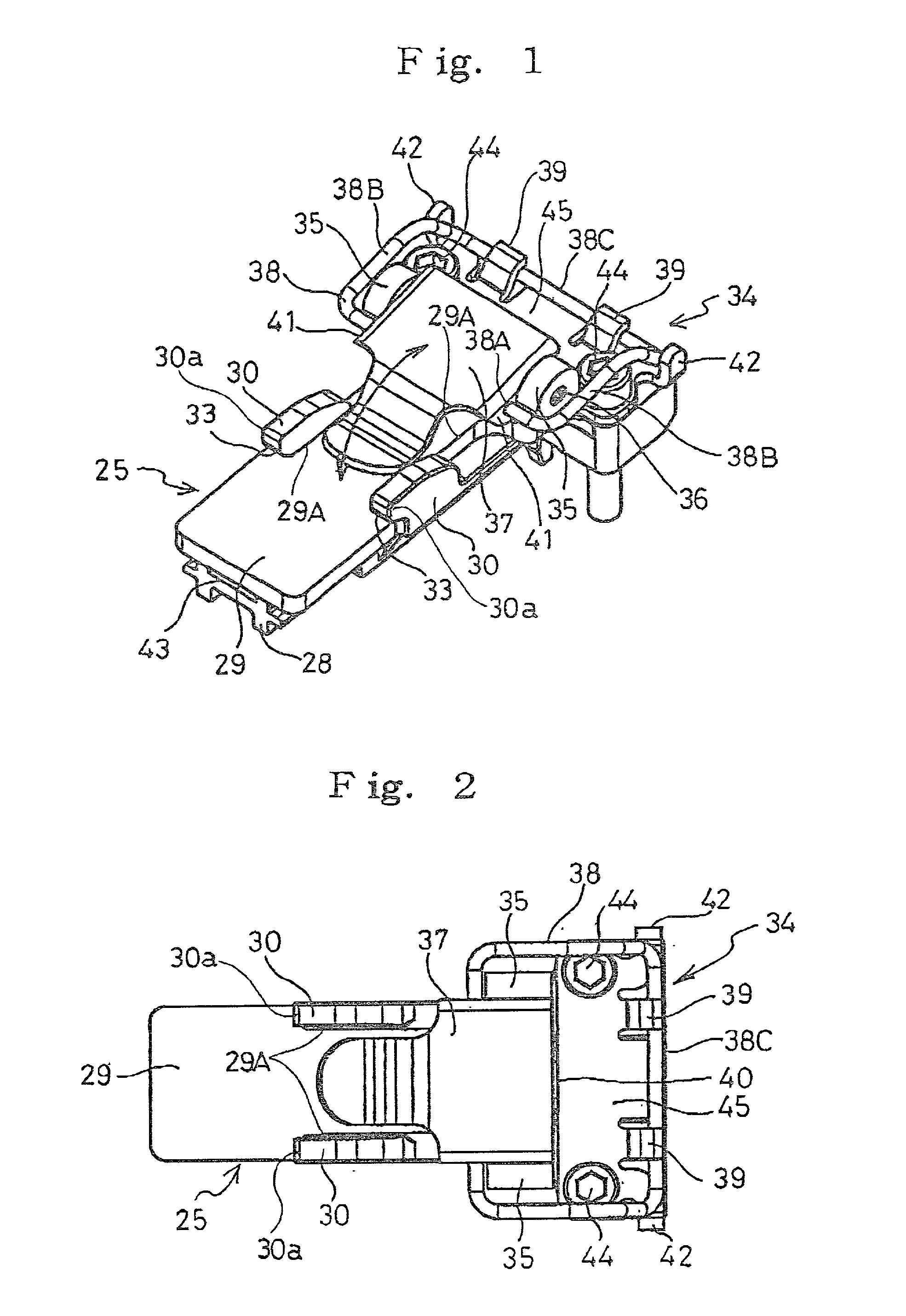

Fastening structure for cover and top seat of magazine of stapling gun nose

A stapling comprises a nose having a top seat, a nose cover, and a fastening latch. The top seat is mounted on the top of a magazine and is provided with a plurality of retaining portions. A top cover is provided with a plurality of retaining portions and is mounted on the top seat such that the retaining portions of the top cover are retained by the retaining portions of the top seat. The fastening latch is pivoted to the top cover such that a retaining ring of the fastening latch is retained by a holding slot of the retaining portions of the top seat. The top seat and the top cover are securely held together in such a way that they work together to confine a staple which is discharged by the stapling gun, thereby ensuring the accuracy and precision of driving staples.

Owner:APACH IND CO LTD

Cordless power tool

InactiveUS20060108980A1Small sizeReduce weightStapling toolsBatteries circuit arrangementsElectrical batteryHigh energy

A cordless power tool such as a power staple gun 1 includes a power supply circuit of an electric double layer capacitor 8 and a lithium-ion battery 11. In a standby state, the lithium-ion battery charges the electric double layer capacitor, and at a switch on time, the electric double layer capacitor supplies large current to the motor 5. By combining the lithium-ion battery with high energy density and the electric double layer capacitor capable of discharging large current, it is possible to greatly reduce the size and weight as compared with a case where a nickel-cadmium battery or a nickel-hydrogen battery is used. Besides, since the electric double layer capacitor has a very long lifetime, the running cost can also be reduced.

Owner:MAX CO LTD

Latch assembly for a staple gun

A latch assembly for a staple gun has a front cover, a locking element, a pushing element and a staple driver. The front cover has a connecting bolt. The locking element is mounted on the front cover and has two cams, a torsion spring and a locking block. The cams and the torsion spring are mounted around the connecting bolt. The pushing element is mounted in the front cover and has a pushing lever and a pressing pin. The pushing lever abuts the cams. The pressing pin extends out of the front cover. The staple driver is mounted in the front cover and has a locking hole, a through hole and an elastic panel. The locking hole is formed through the staple driver and engages the locking block. The latch assembly can hold a handle of the staple gun conveniently and safely when the staple gun is not being used.

Owner:LIN JUI YUAN

Powered insulated staple gun

A device for applying insulated fasteners to a substrate is disclosed. The device comprises a housing that includes a fastener recess and an ejection recess, and the fastener recess is configured to accommodate insulated fasteners. The device further comprises a powered actuator that includes an ejection member that moves over a range of positions. The ejection member permits one of the insulated fasteners to enter the ejection recess in a retracted position, and the ejection member forces the one of the insulated fasteners to leave the ejection recess in an extended position. A power connector operatively connects the powered actuator to a power source to provide power to move the ejection member. A manual actuator is operatively disposed between the power source and the powered actuator to selectively provide power from the power source to the powered actuator.

Owner:ACTUANT CORP

Staple gun

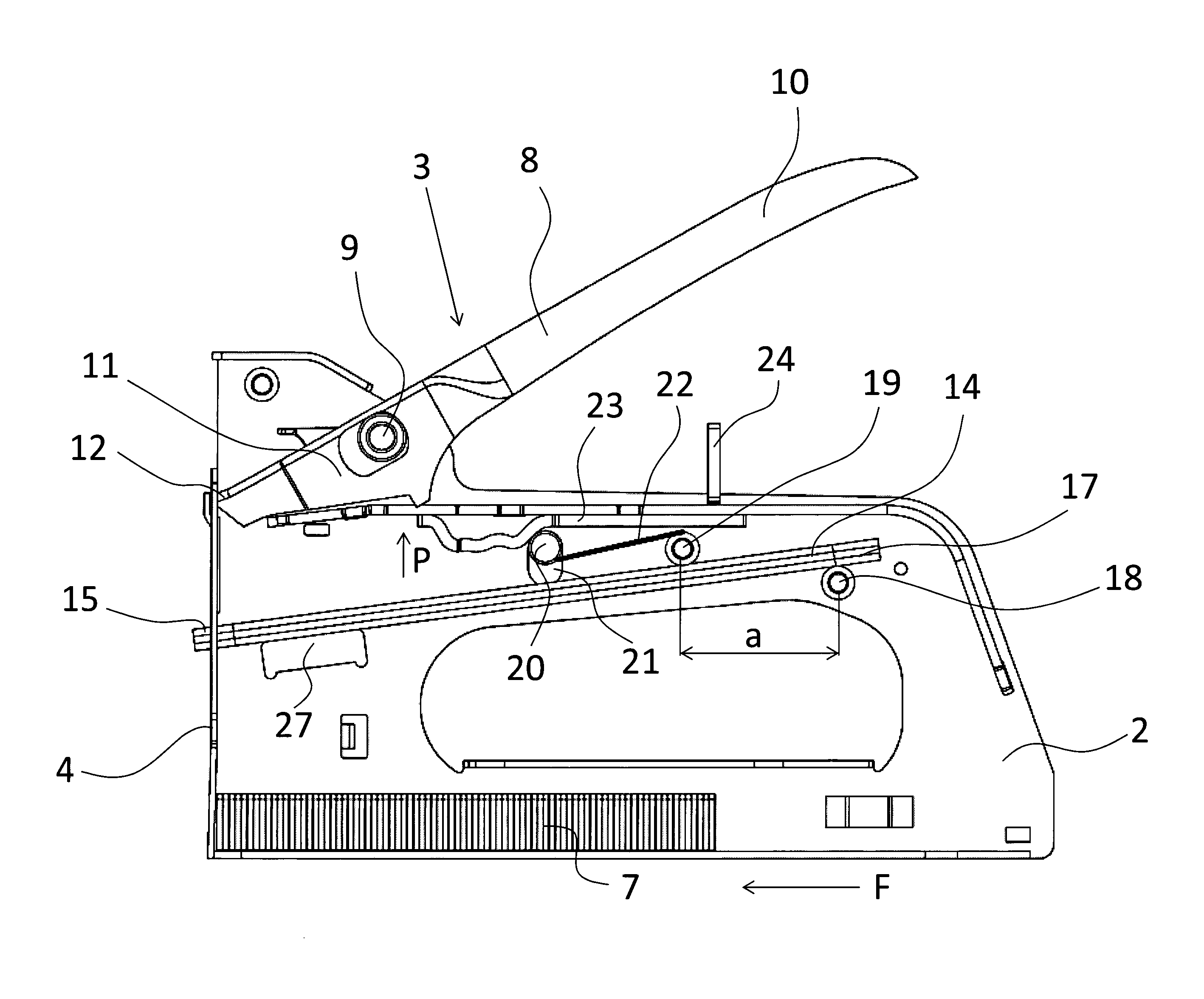

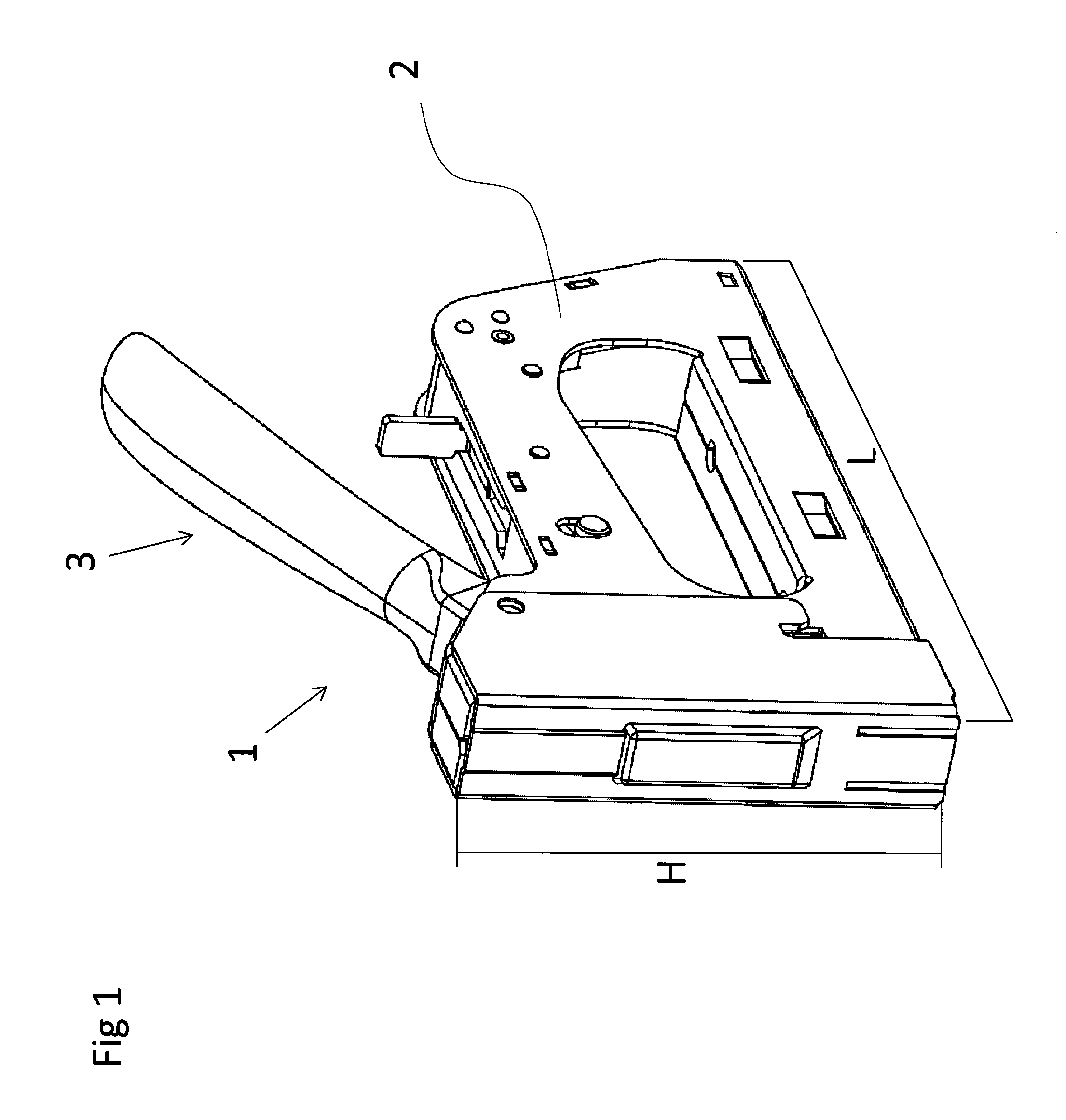

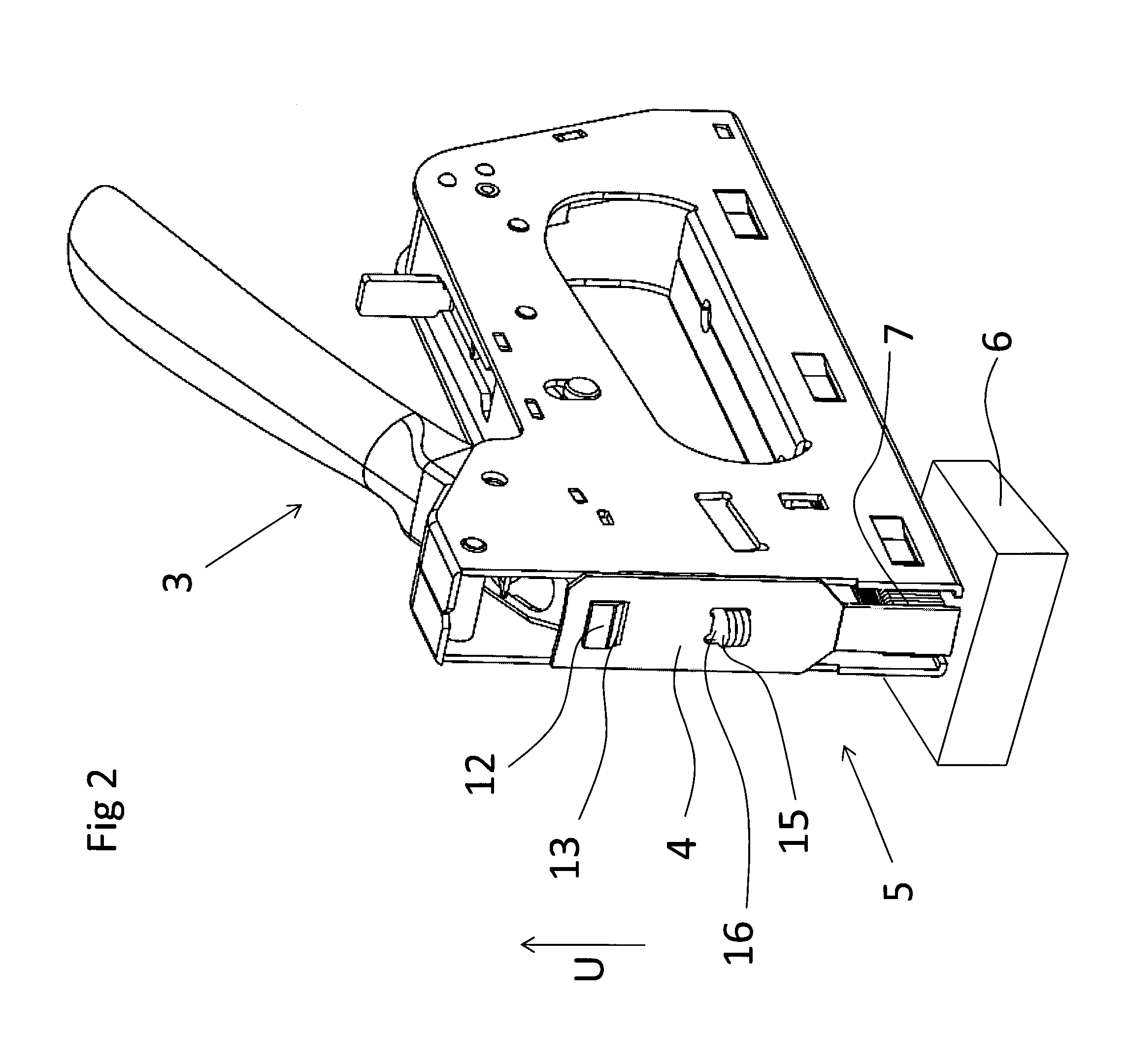

Staple gun for driving staples into a workpiece, which gun includes a frame, arranged in which is a driver, which can be conveyed in an up and downward movement and which in the downward movement (N) executes a drive stroke in which the staple is driven and which can be conveyed by an activation member in the upward movement (U) to a highest height h, in which the activation member releases the driver for the execution of the drive stroke, and which driver is coupled to a first end of an elongated elastic member, which is tensioned when the driver is conveyed in the upward movement for execution of the drive stroke, and which is connected at a second end to a bearing pin assigned to the frame as well as a first breakpoint pin placed between the bearing pin and the driver at a first distance (a) from the bearing pin and around which the elastic member is bent and tensioned when the driver is moved in the upward movement, and a second breakpoint pin placed between the driver and the first breakpoint pin at a second distance (b) from the bearing pin and arranged so that it can be moved between a first position, in which it does not engage with the elastic member when this is moved by the driver in the upward movement, and a second position, in which it engages with the elastic member when the driver is moved in the upward movement and tensions the member, wherein the first distance (a) at which the first breakpoint pin is placed from the bearing pin is related to (h) as 1.6-2.0:1.

Owner:ISABERG RAPID

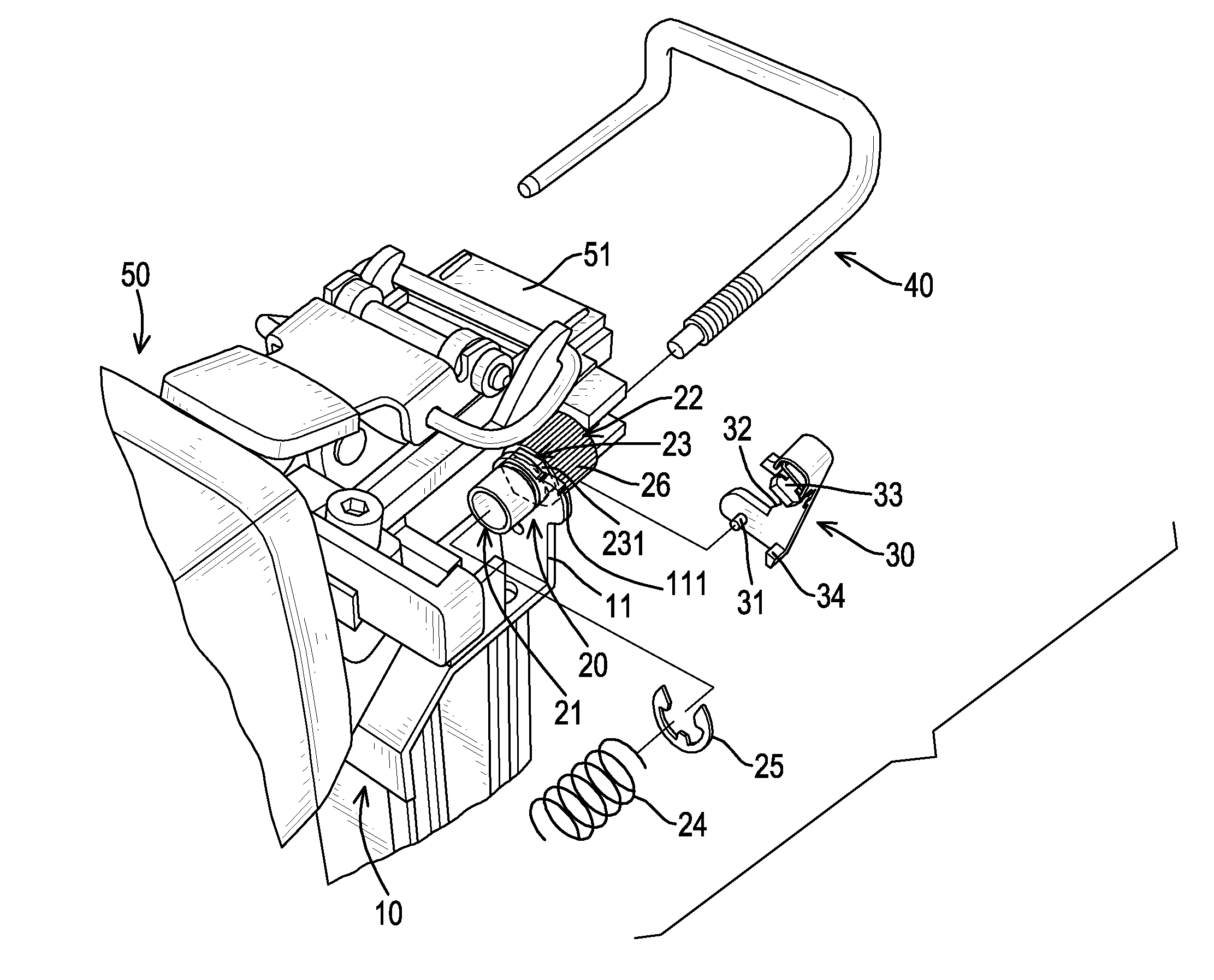

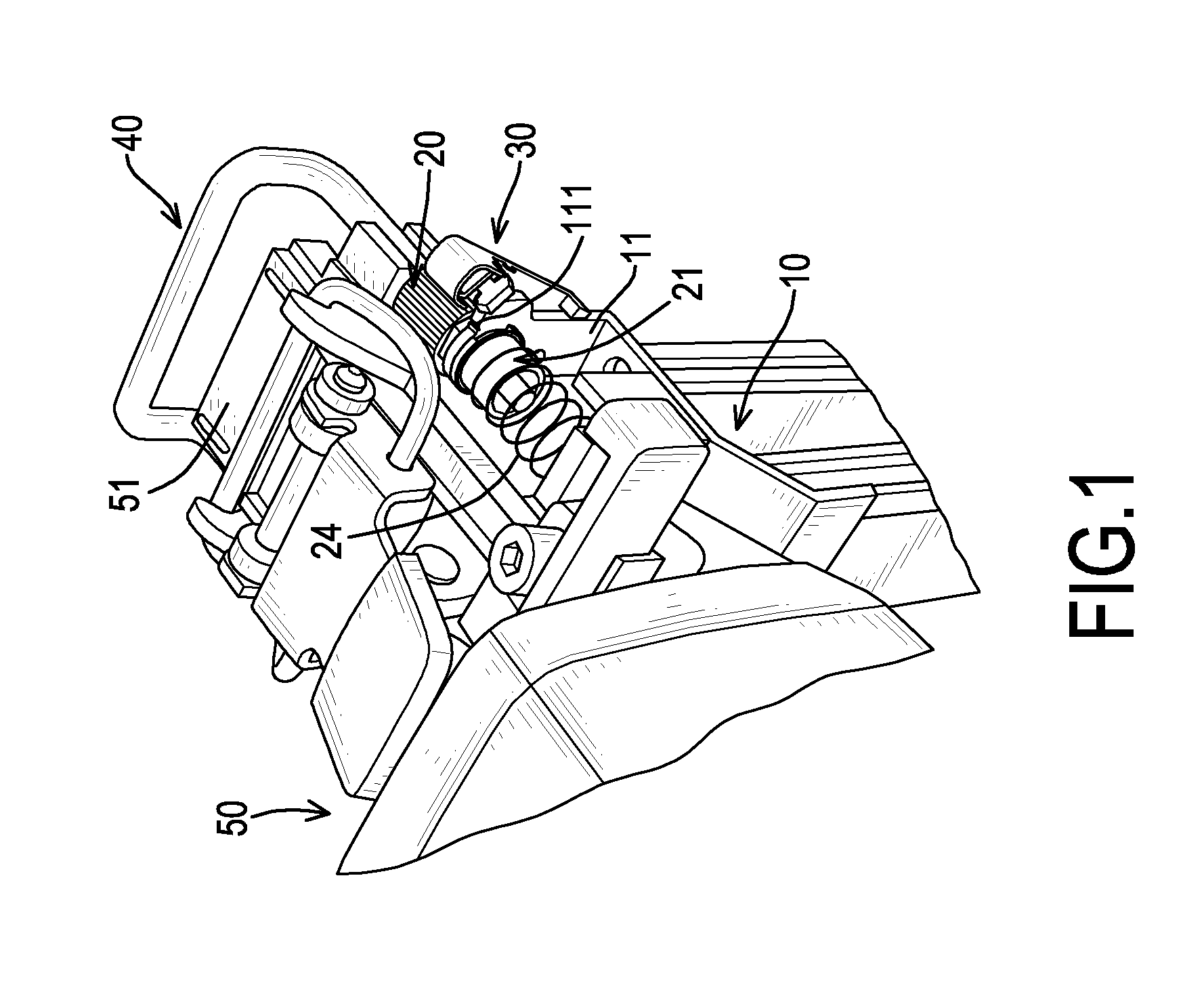

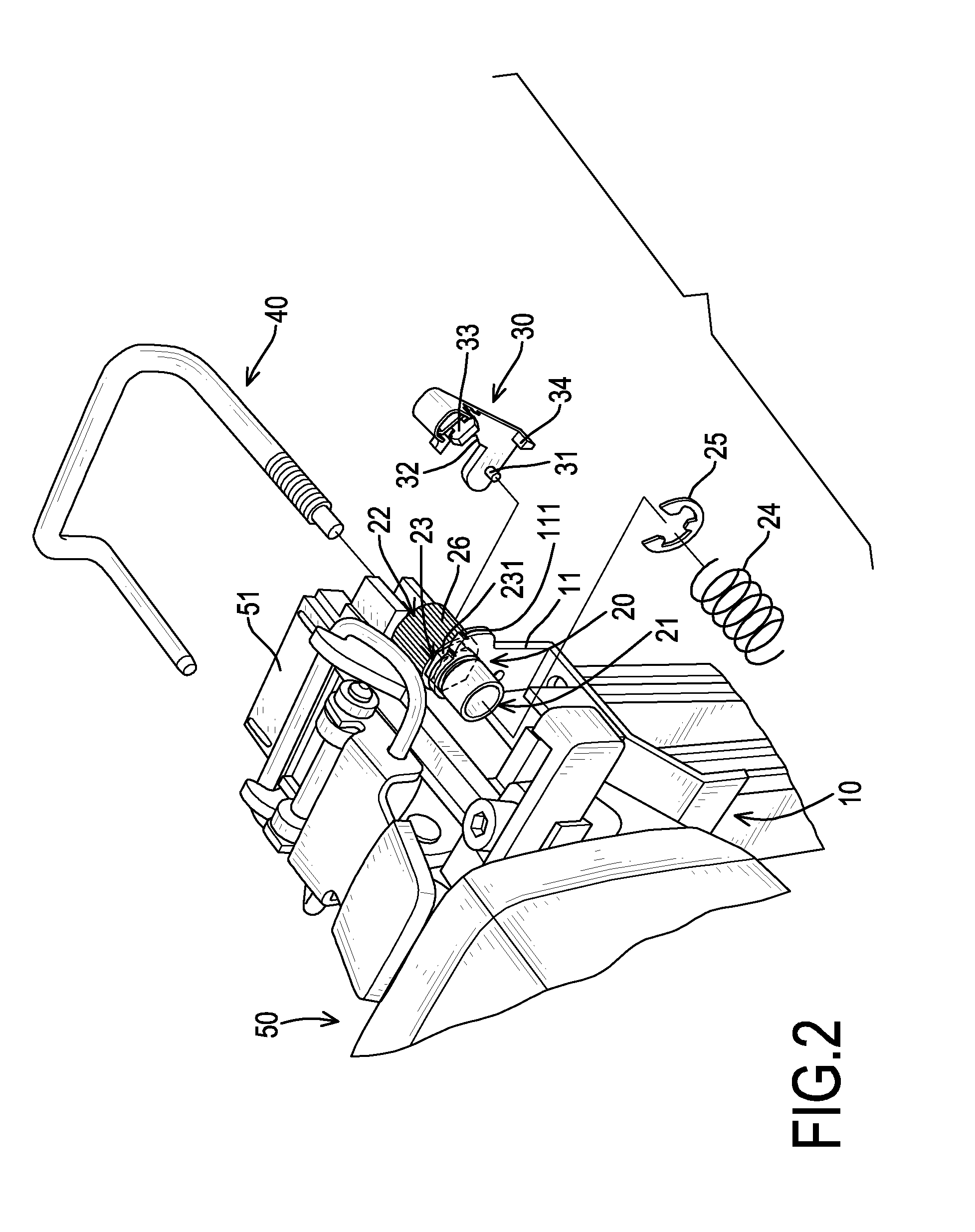

Adjusting-fixing assembly for a staple gun

ActiveUS20120305624A1Preferred quality of constructionSecurely holdStapling toolsNailing toolsStaple gunEngineering

An adjusting-fixing assembly for a staple gun has a sliding frame, an adjusting nut, a fixing arm and an abutting shaft. The sliding frame is movably connected to the staple gun and has a connecting board with two positioning recesses. The adjusting nut is rotatably mounted on the sliding frame and has an engaging segment. The engaging segment is formed on the adjusting nut between the threaded end and the connecting board and has multiple engaging faces. The fixing arm is rotatably connected to the sliding frame, engages with the adjusting nut and has a connecting rod, an engaging recess and a positioning element. The engaging recess is formed in an inner side of the fixing nut and engages with two adjacent engaging faces of the engaging segment. The abutting shaft is connected to the adjusting nut and is movably connected to the staple gun.

Owner:TESTO IND

Siding Gauge Device for Staple Gun

ActiveUS20090277032A1Improve securityTime for alignment is reducedStapling toolsDrilling/boring measurement devicesStaple gunFree edge

A gauge device for use with a staple gun serves to align the staple gun relative to building siding to dispense a two prong staple from a head of the staple gun into one of a plurality of fastener apertures in siding members of the building siding. The gauge device comprises a pair of flanges arranged to depend from laterally opposed sides of the head of the staple gun at a location such that abutment of one of the flanges below a lock edge channel of a siding member locates one prong of the two prong staple to be in alignment with one of the fastener apertures and locates the other prong of the two prong staple above the top free edge of a nailing flange of the siding member.

Owner:GRANT KEVIN ANTHONY

Staple Gun with a Safety Device and Its Safety Device

A staple gun with a safety device and its safety device are disclosed. The staple gun with a safety device comprises a safety device and a staple-floating unit that are installed in a housing of the staple gun. The safety device includes a safety push sheet and a switch. In a middle portion of the safety push sheet is defined an engaging slot along a staple-discharging direction, and the safety push sheet is further provided with a triggering sheet extending from an upper end thereof. The staple-floating unit is movably connected to the safety device and includes a guide sheet, a control knob, and a positioning pin. The positioning pin can be used to drive the safety push sheet and the guide sheet to move downwards to make the safety push sheet and the guide sheet to protrude out of the staple exit synchronously for facilitating exerting the staple-floating function.

Owner:NAILERMATE ENTERPRISE +1

Plastic nail

InactiveCN101298516AImprove corrosion resistanceHigh strength corrosion resistanceStaplesNailsGlass fiberStaple gun

The invention relates to a plastic chain riveting, the raw materials of which are calculated by weight: 40-60 portions of nylon, 40-60 portions of glass fiber, 0-10 portions of mineral powder, 0.1-0.5 portion of coupling agent, 0.1-0.5 portion of antioxidant, and 0.3-2 portions of lubricant. The plastic chain riveting made by the invention is characterized by long service life without treatment and comparatively long-term high strength and high rigidity maintenance, which is applicable to common electrical or air staple guns, with good comprehensive mechanical property, strong corrosion resistance, light mass and simple forming of products, and grinding and shaving can be done during usage, thus various components with complex shapes can be easily machined.

Owner:NANJING HONGRUI PLASTIC PROD

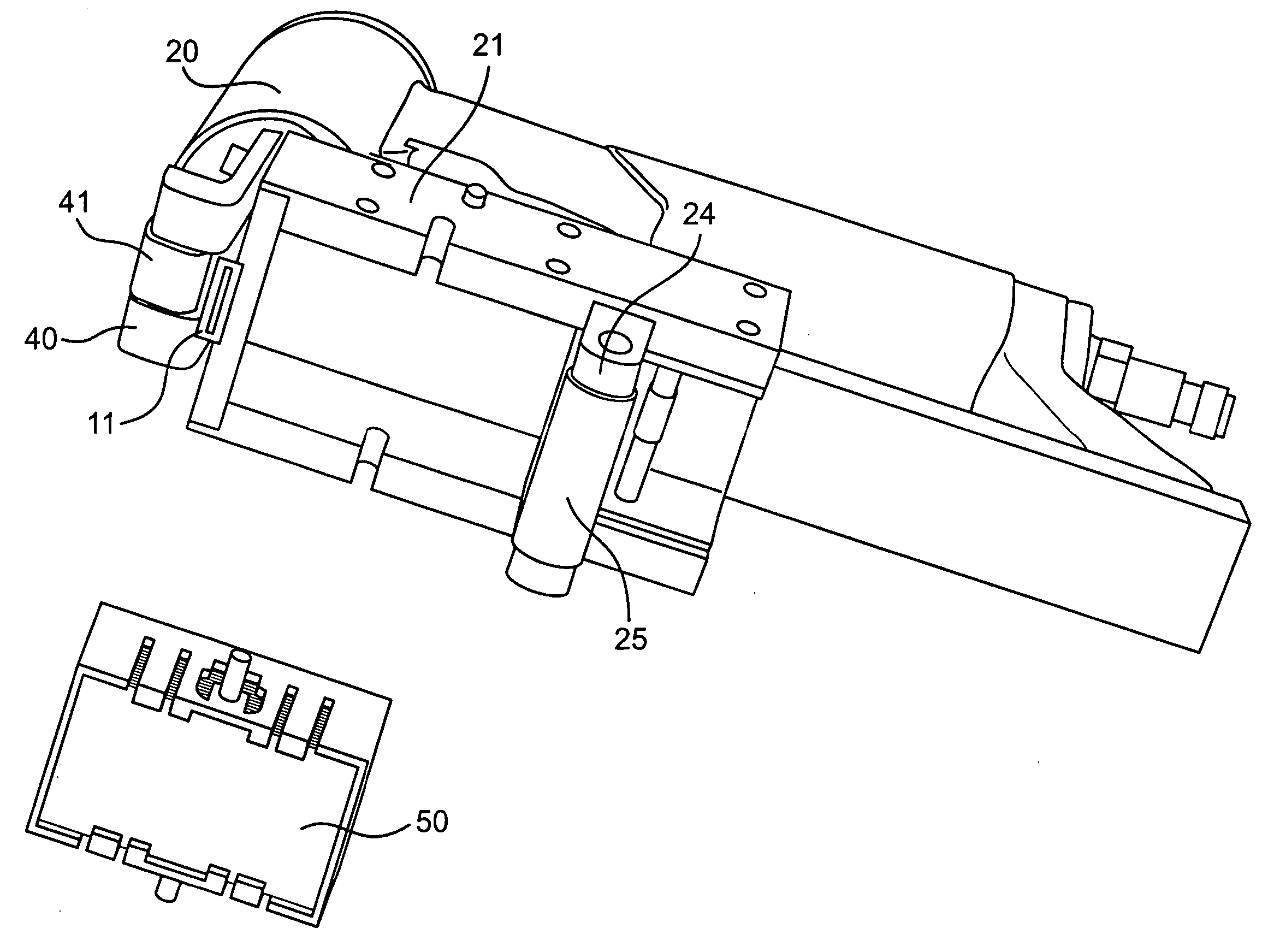

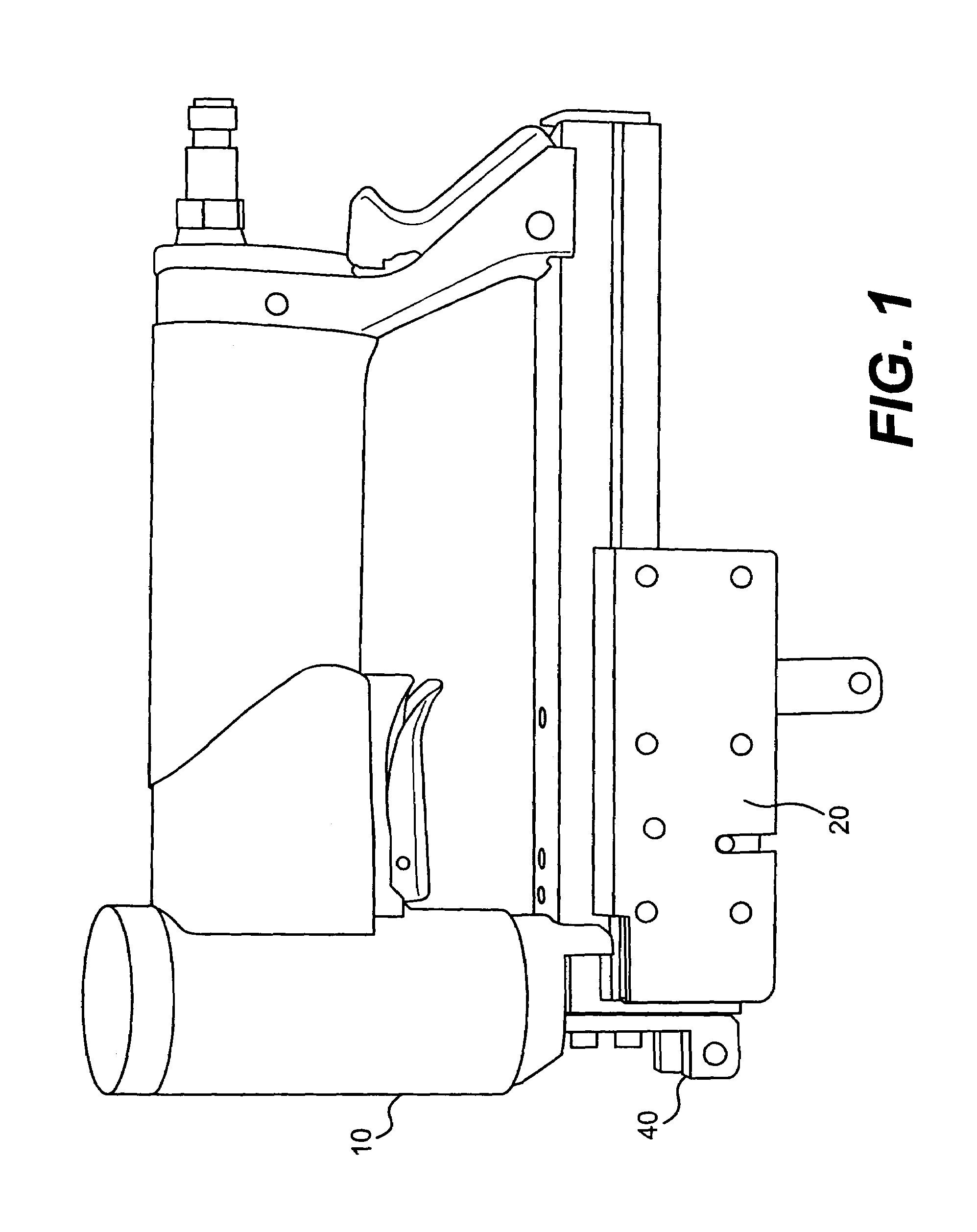

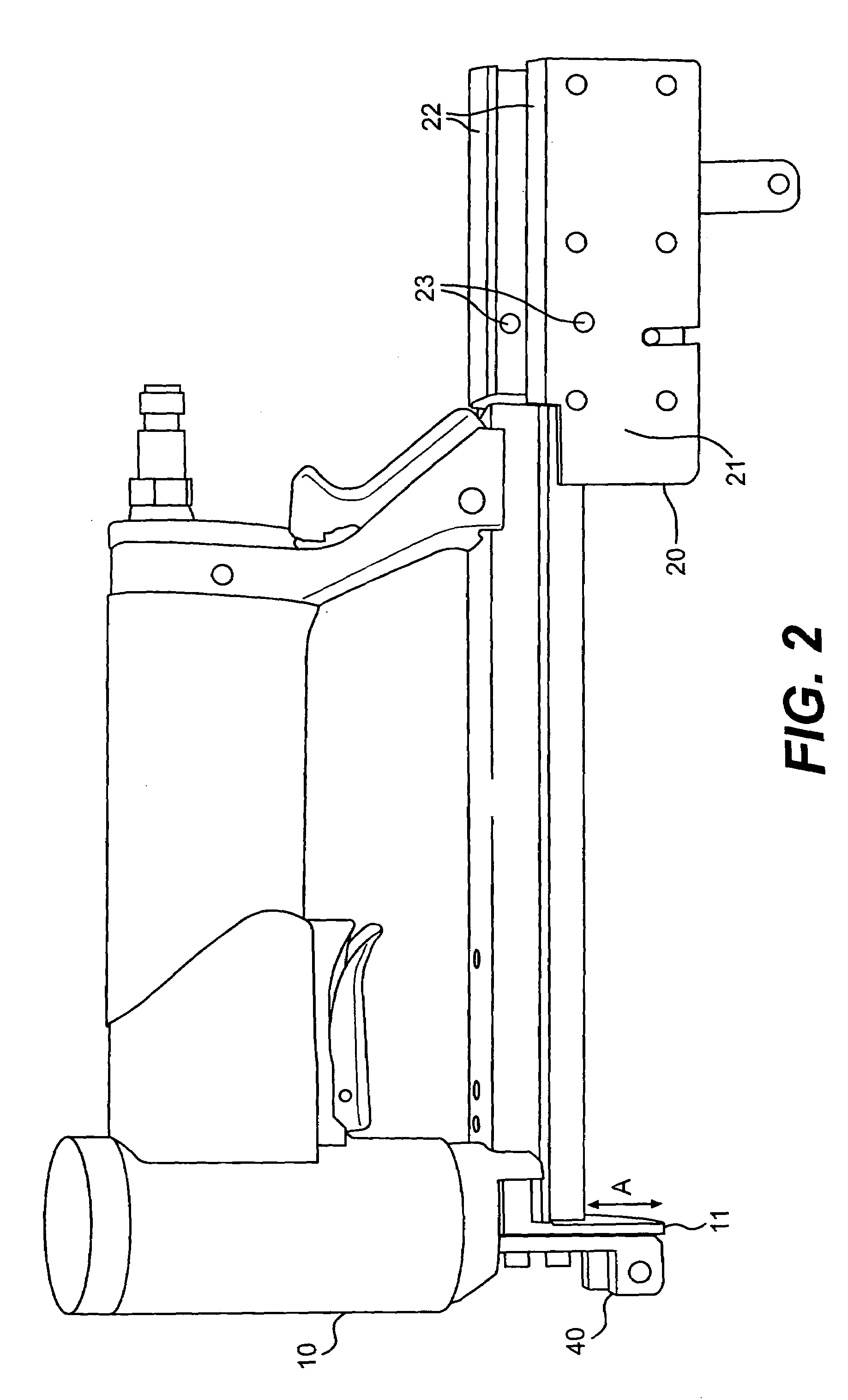

Adhesive and release liner application system

An adhesive and release liner application system and method. A bottom table is slidable with respect to a frame and a middle table is slidable with respect to the bottom table. An elevator drive subsystem between a top table and the middle table is configured to adjust the elevation of the top table relative to the middle table. An adhesive head, connected to an adhesive supply subsystem, a release liner applicator, a release liner cutter, and a staple gun are mounted to the top table for applying the adhesive to a surface of a structural member positioned adjacent the top table, for applying a release liner over the adhesive on the surface, for inserting at least one staple through the release liner and into the surface, and for cutting the release liner.

Owner:NAT LUMBER CO

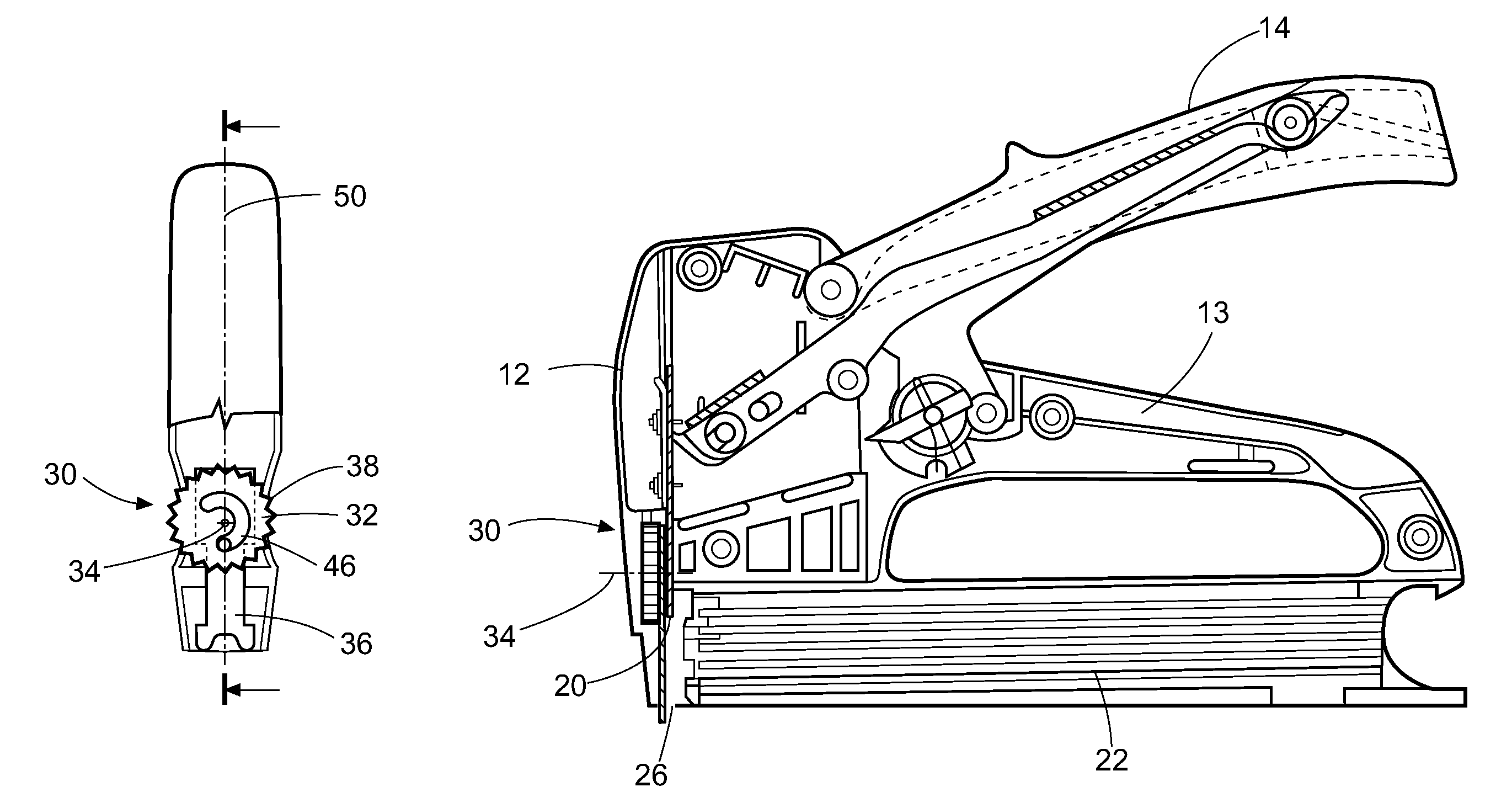

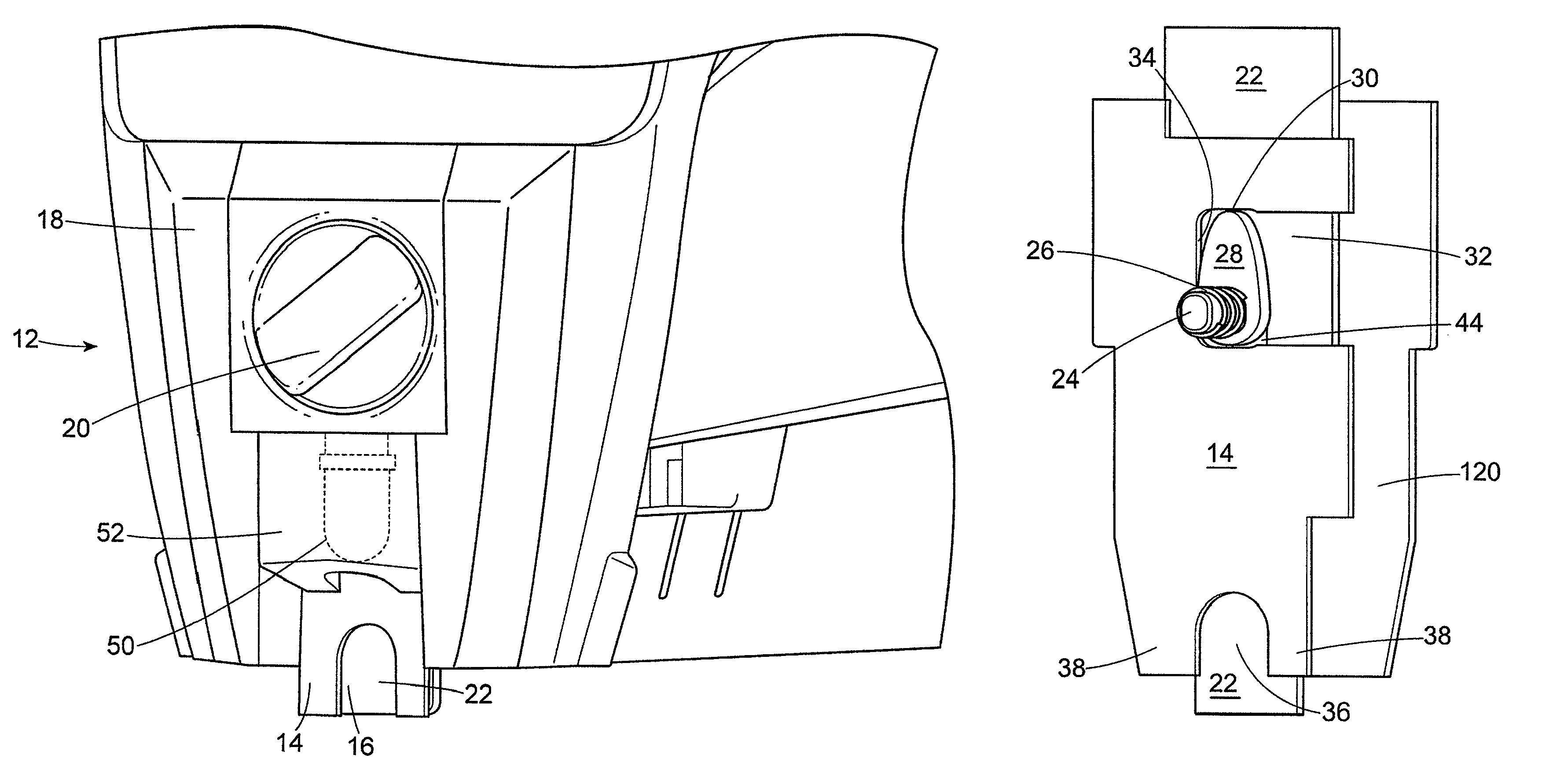

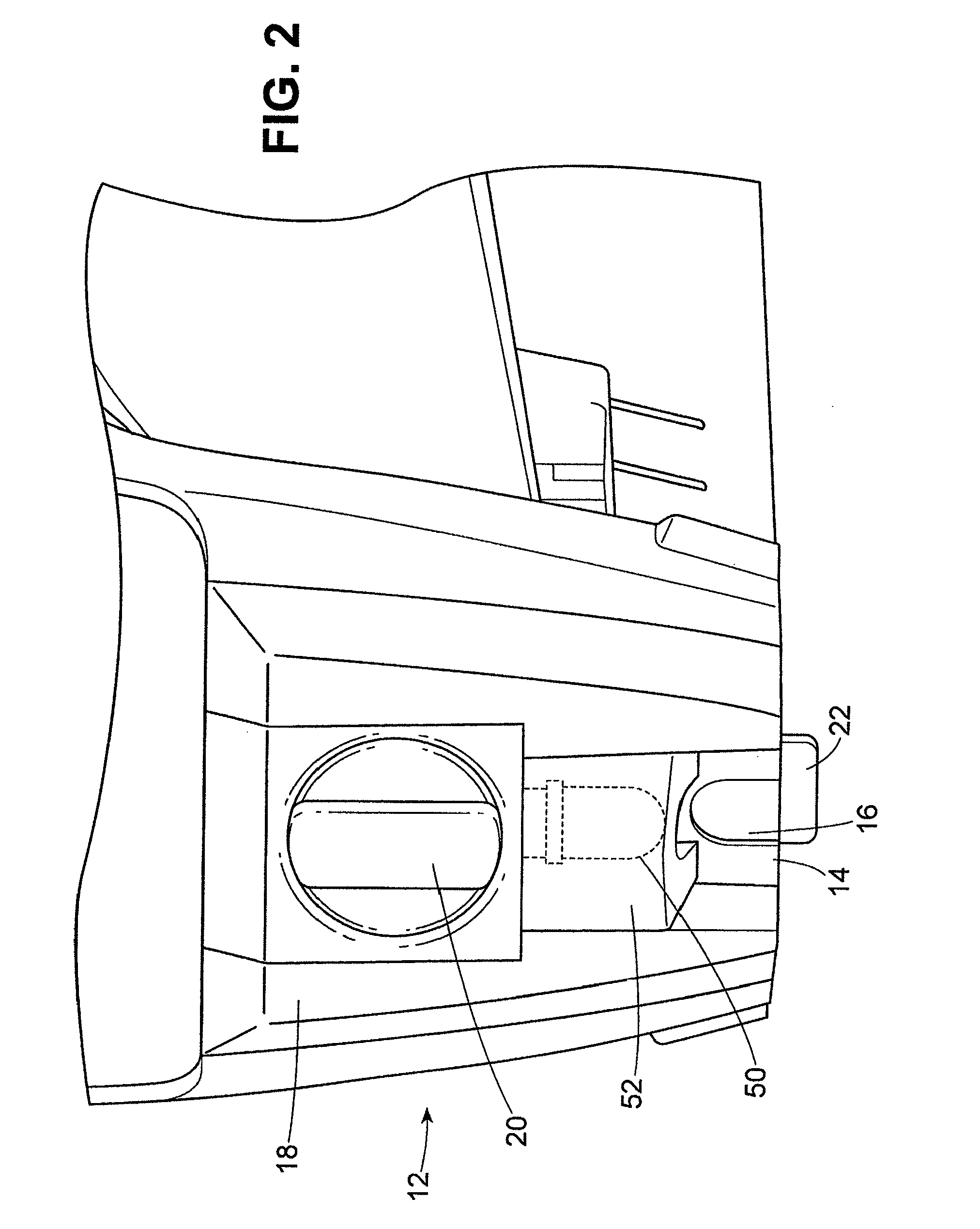

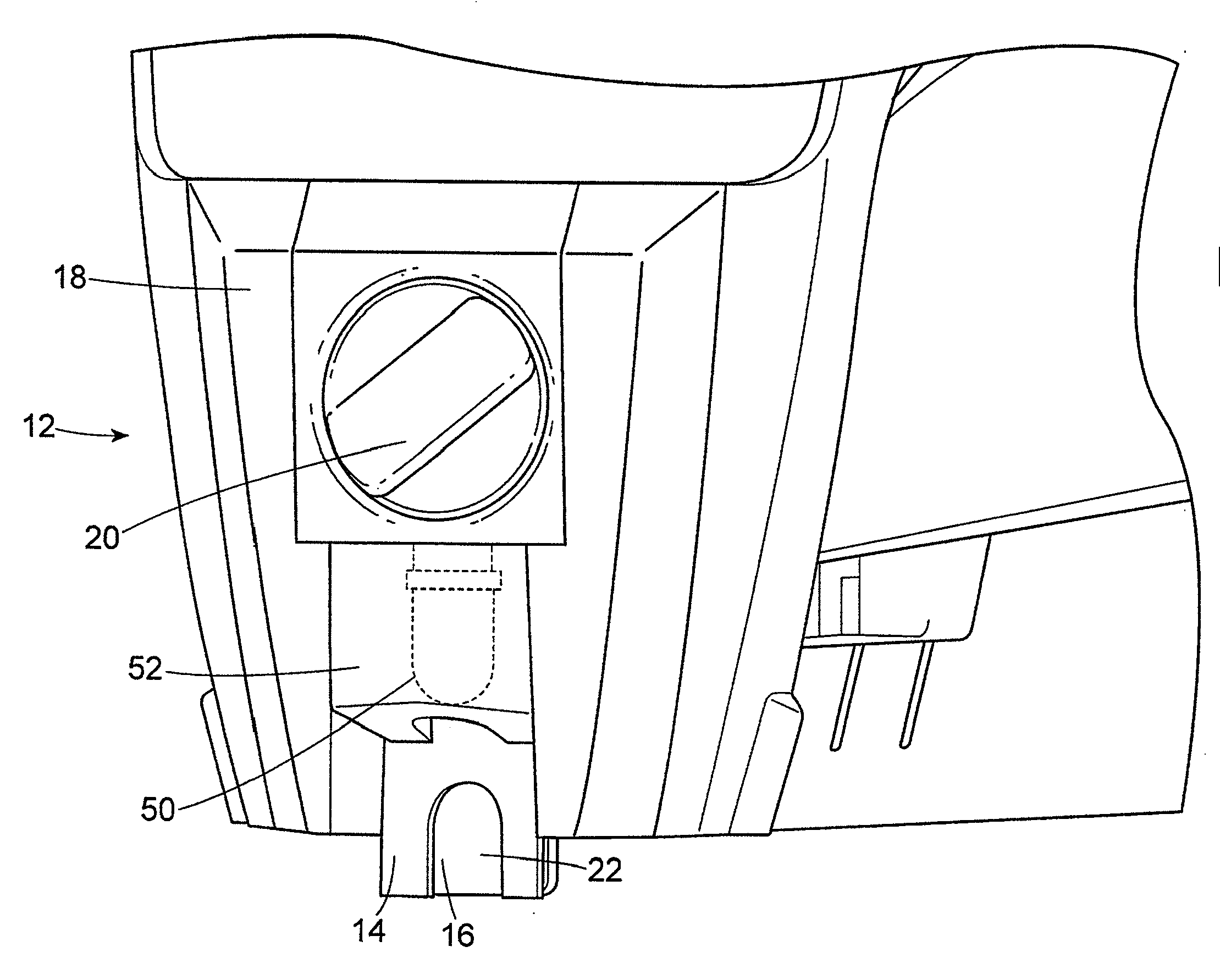

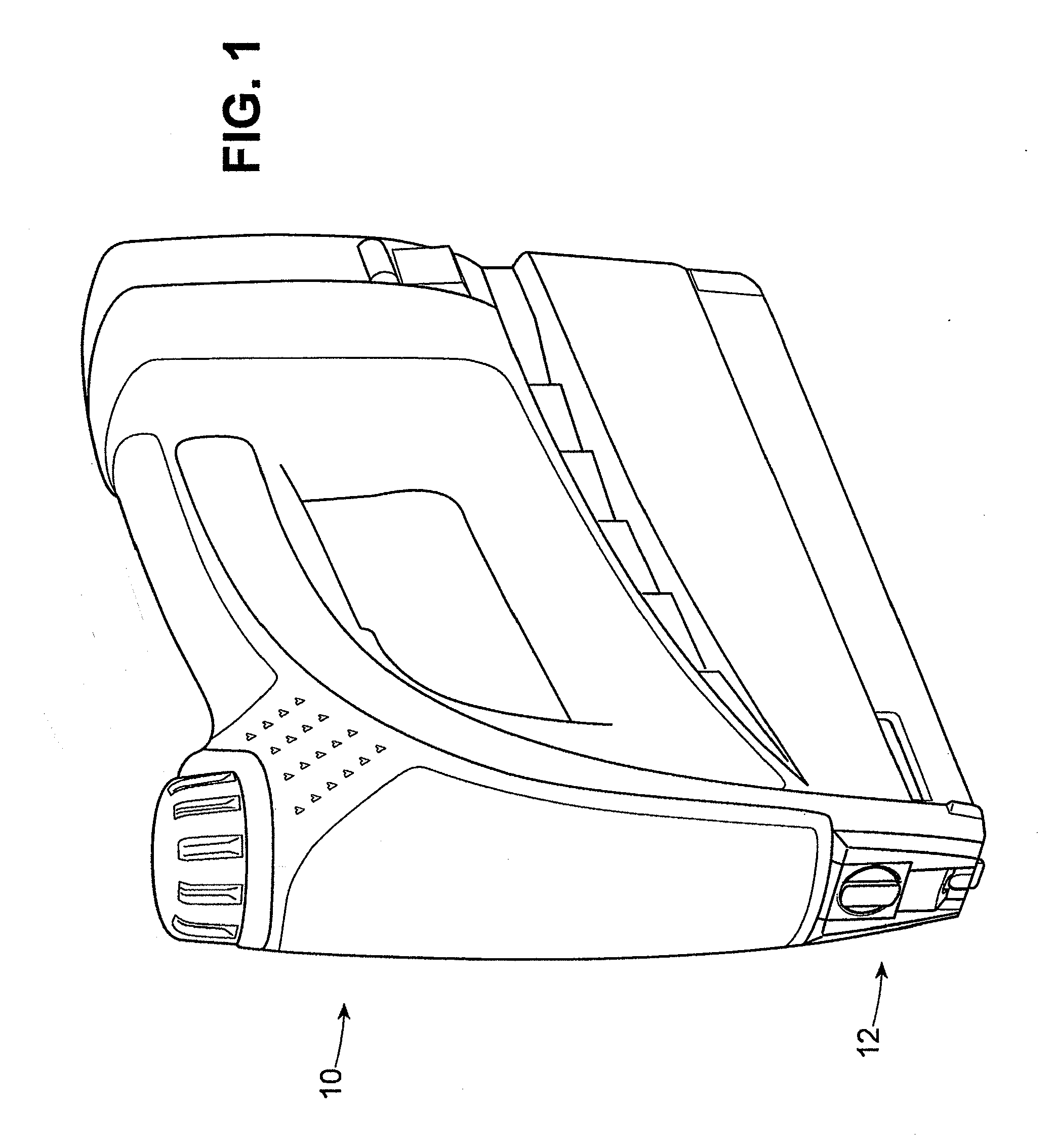

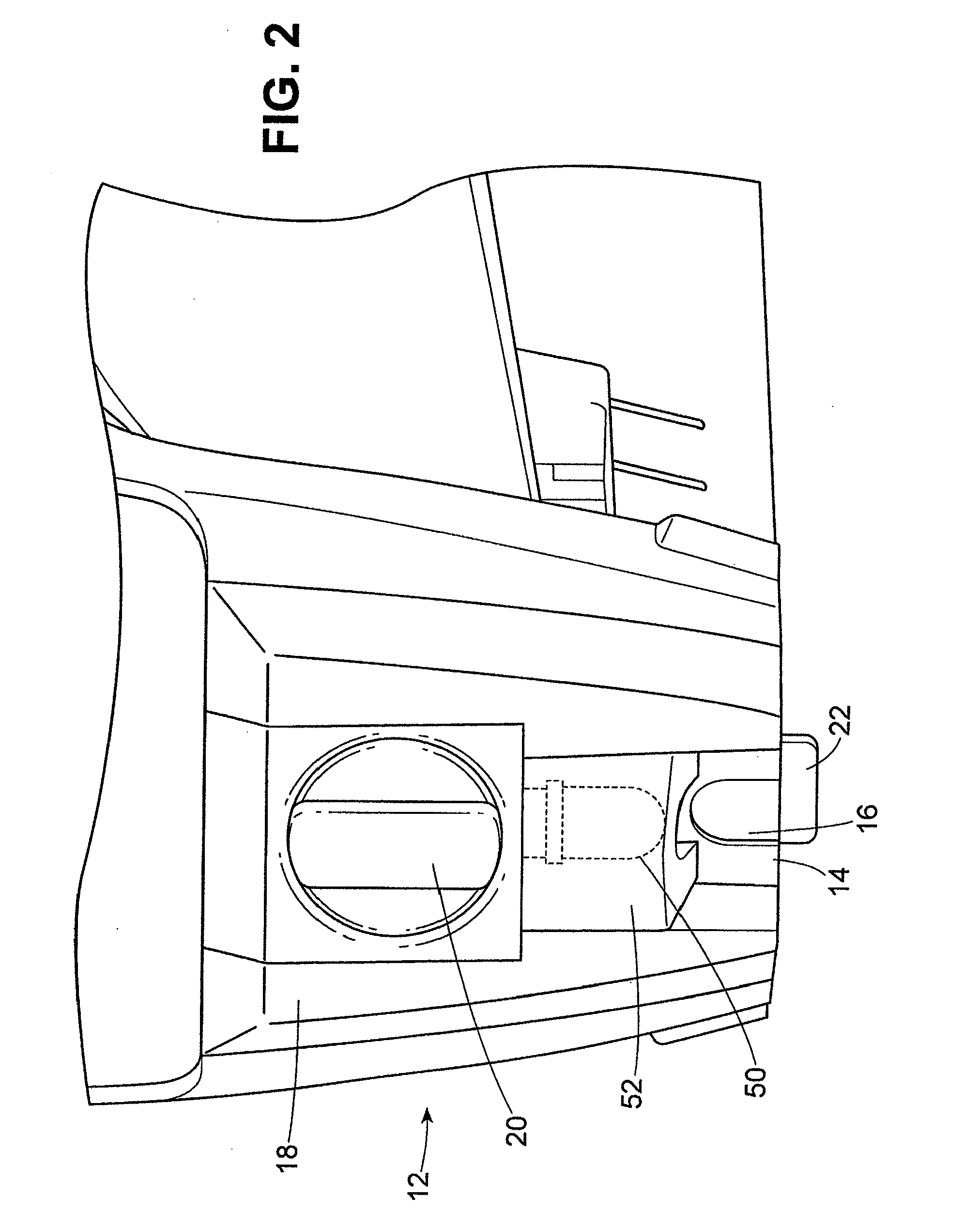

Staple gun apparatus for attaching tab

InactiveUS7090109B2Reducing user fatigueImprove compactnessStapling toolsCoin-freed apparatus detailsPolyolefinStaple gun

The invention comprises a staple gun with highly compact accessory apparatus for attaching a planar tab or label to a fixing surface. The accessory has a housing and a positioning and indexing assembly associated with the housing which is operable to feed and hold a tab or label between the staple gun head and fixing surface, thereby allowing single-handed fixing of a label or tab to a fixing surface. The apparatus can include a roller assembly, staple gun and accessory apparatus or have all components integrated into the construction of a staple gun apparatus. Preferably, the apparatus is mated with a tab or label holding magazine. Some exemplary embodiments of the invention are suitable for securing protective covering to lumber product and may be configured for rectangular polyolefin tabs measuring approximately 0.035 inch thick and 1.0 inches by 2.0 inches.

Owner:COLUMBIA RIVER STAPLE & LUMBER WRAP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com