Sock packing machine

A technology of packaging machine and socks, applied in the field of textile industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

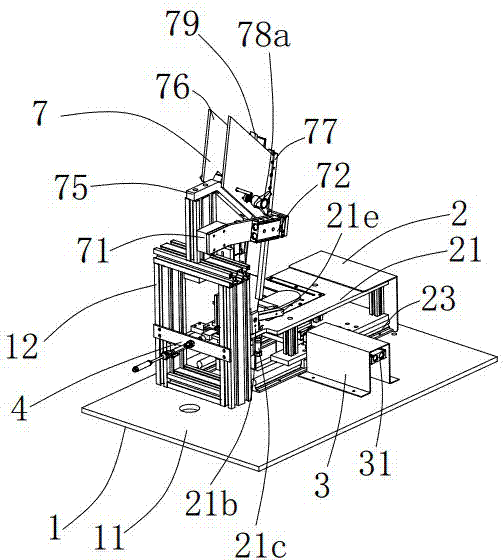

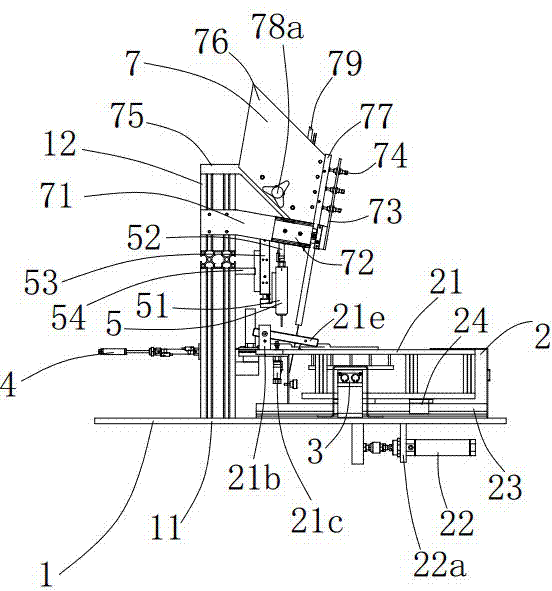

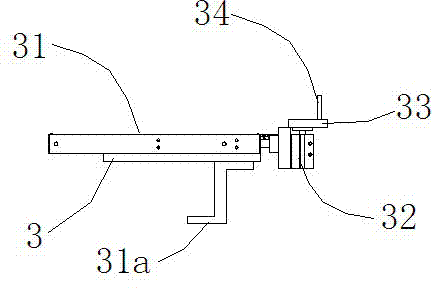

[0032] Figure 1 to Figure 10 Shown is the structural representation of the present invention.

[0033]The reference signs are: base 1, base bottom plate 11, support frame 12, loading platform 2, storage platform 21, screen row groove 21a, pressing plate base 21b, pressing plate cylinder 21c, pressing plate cylinder hole 21d, pressing plate 21e, pressing bar 21f, nail gun hole 21g of storage table, loading table cylinder 22, loading table cylinder fixing plate 22a, slideway 23, slider 24, sieve discharge mechanism 3, sieve discharge horizontal cylinder 31, sieve discharge fixing plate 31a, sieve discharge Vertical cylinder 32, sieve row push plate 33, sieve row rod 34, hook installation mechanism 4, hook installation cylinder 41, hook installation mechanism fixing plate 41a, hook storage part 42, hook through hole 42a, hook Storage tank 42b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com