Vacuum suction sucker

A technology of vacuum suction and fixing plate, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of low work efficiency, low equipment utilization, increase production costs, etc., and achieve convenient replacement, high precision, and interchangeability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

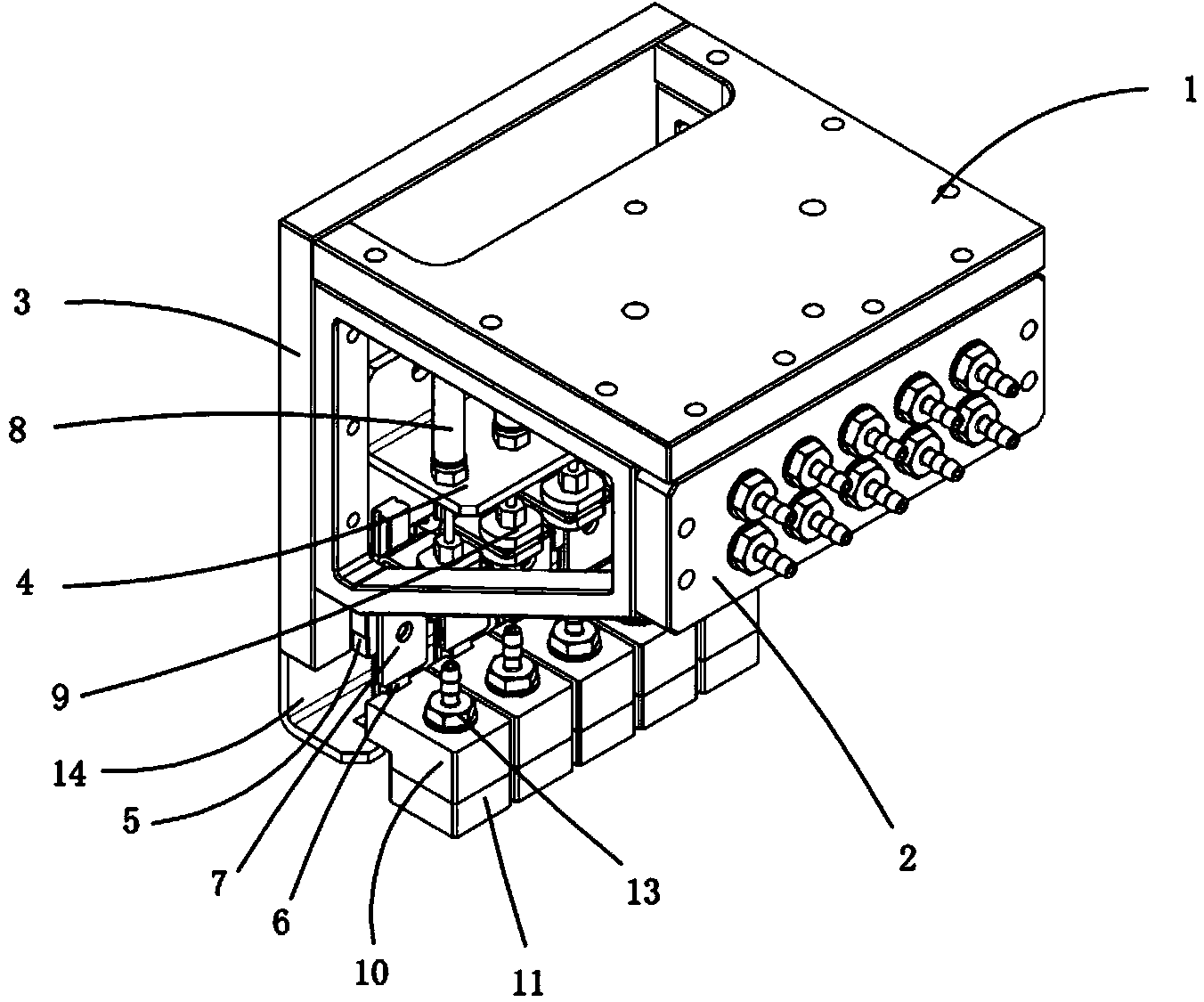

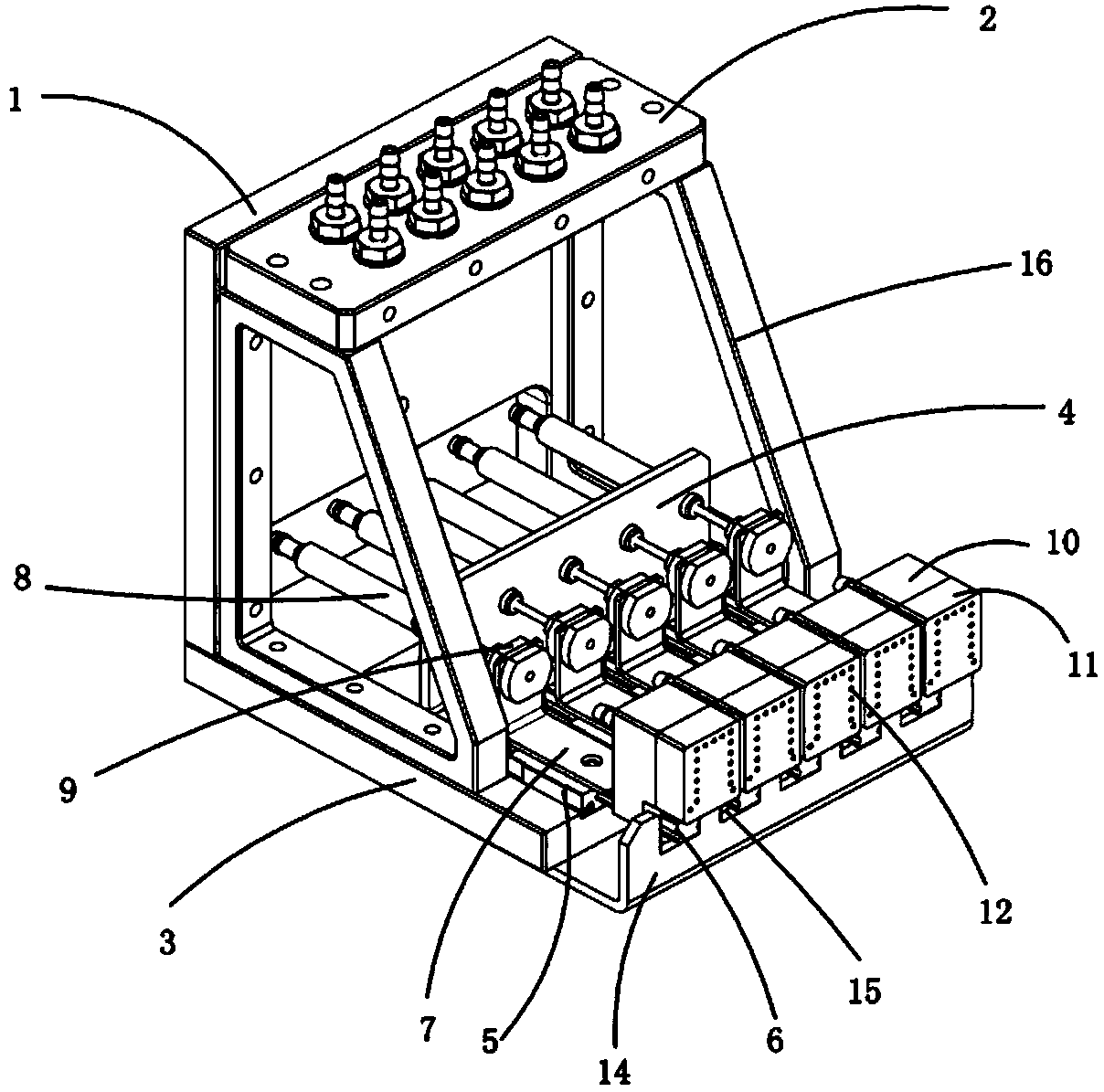

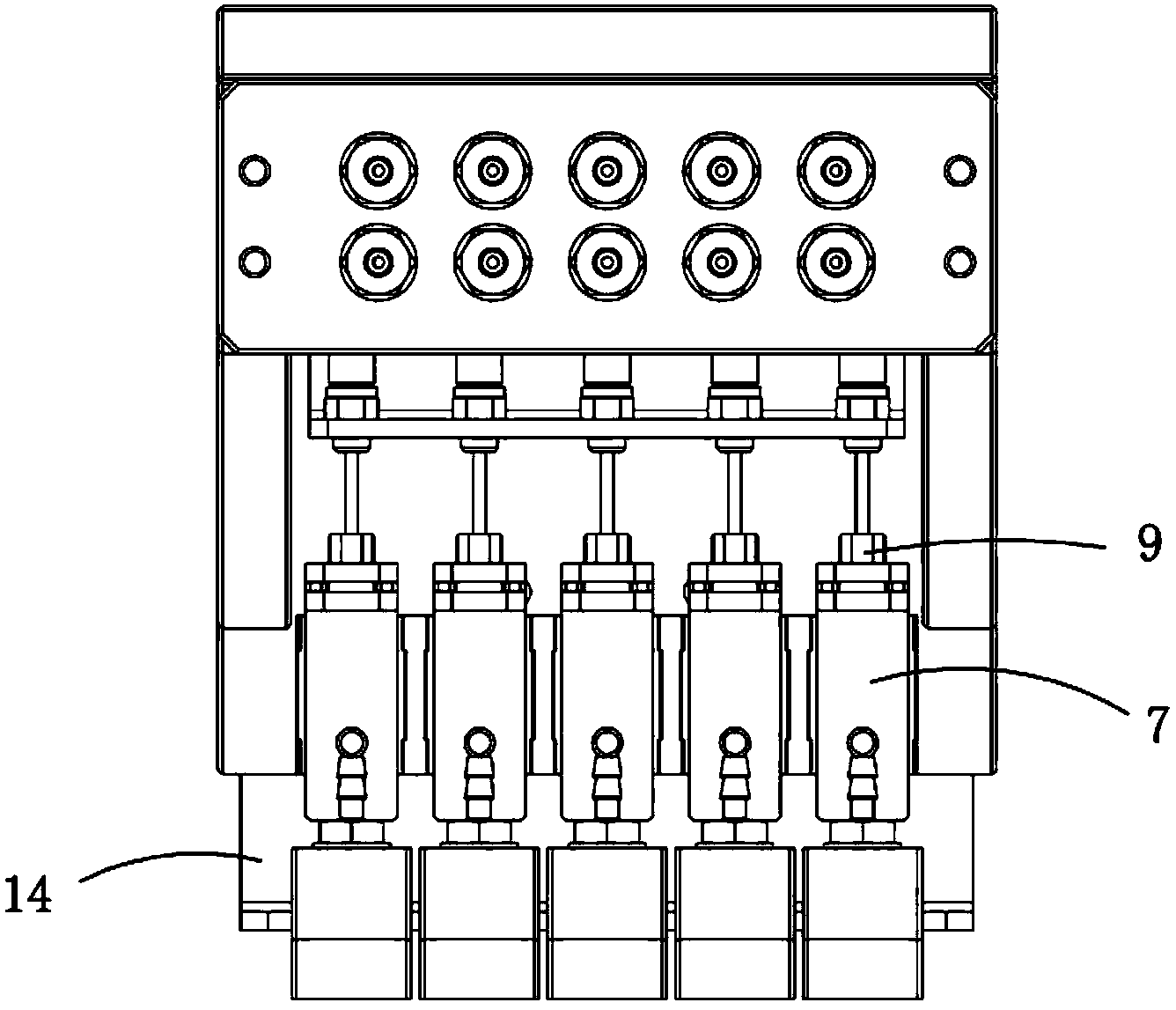

[0021] Examples, see attached Figure 1~4 , a vacuum suction head, which includes a top plate 1, a joint fixing plate 2 is vertically installed on the front side of the top plate, a mini joint is placed on the joint fixing plate, and a slider fixing plate 3 is vertically installed on the rear side of the top plate; The fixed plate of the slider is fixedly connected with a pen-type cylinder fixed sheet metal 4 and four groups of sliders 5, and each group of sliders is equipped with slide rails 6; each group of slide rails is connected with a cylinder connected with sheet metal 7 , four sets of pen-shaped cylinders 8 are connected to the fixed sheet metal of the pen-shaped cylinder, and the lower ends of each set of pen-shaped cylinders are connected with each group of cylinder connecting sheet metal through floating joints 9 respectively; There is a suction head fixing block 10, and the bottom of each group of suction head fixing blocks is equipped with a suction head 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com