Screw thread forming equipment

A technology for forming equipment and threads, applied in the field of screw thread forming equipment, can solve the problems of manual and repeated placement, and achieve the effect of reducing workload, reducing errors and consistent positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

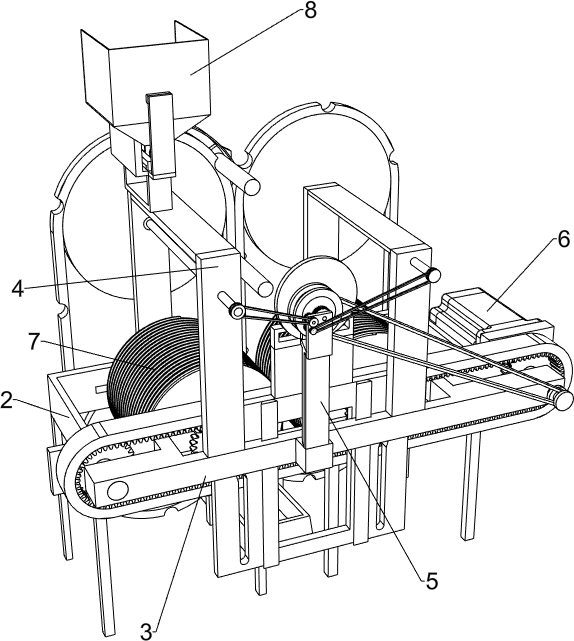

[0025] A kind of screw thread forming equipment, such as Figure 1-6 with Figure 8 As shown, it includes a support leg 1, a frame 2, a support plate 3, a support 4, a pillar 5, a drive assembly 6 and a working assembly 7, a plurality of support legs 1 are connected to the bottom of the frame 2, and a support plate 3 is connected to the rear side of the frame 2 , two brackets 4 are connected to the top of the support plate 3, and the two brackets 4 are left and right symmetrical. As for the component 6, the working component 7 is installed on the frame 2, and the driving component 6 is connected with the working component 7 in transmission.

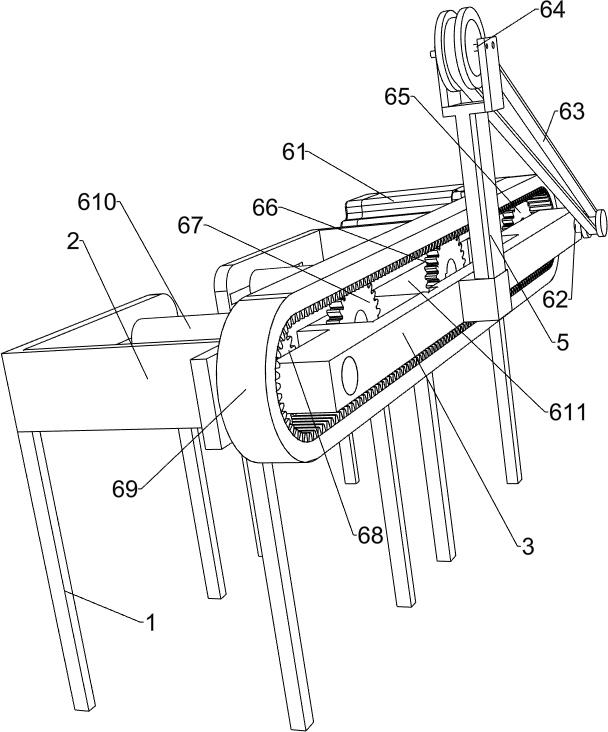

[0026] The driving assembly 6 includes a servo motor 61, a first rotating shaft 62, a first belt 63, a second rotating shaft 64, a first gear 65, a second gear 66, a third gear 67, a fourth gear 68, a timing belt 69, a Three rotating shafts 610 and the fourth rotating shaft 611, a servo motor 61 is installed on the left part of the fram...

Embodiment 2

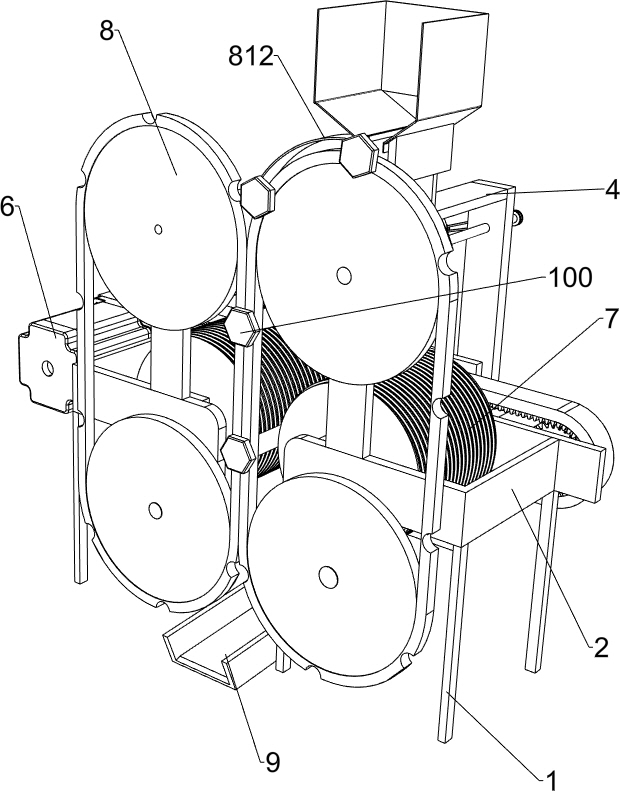

[0030] On the basis of Example 1, such as figure 1 , figure 2 , Image 6 with Figure 7 As shown, it also includes a feeding assembly 8, and the feeding assembly 8 includes a material box 81, a first rotating disk 82, a grooved belt 83, a sixth rotating shaft 84, a seventh rotating shaft 85, a second rotating disk 86, and a second incomplete gear 87, the sixth gear 88, the seventh gear 89, the second belt 810, the third belt 811 and the block 812, the front side of the top of the right side support 4 is connected with the material box 81, and the top of the right side support 4 is connected with the sixth rotating shaft in a rotational manner 84, the lower part of the front side of the right support 4 is rotatably connected with the first turntable 82, the front end of the sixth rotating shaft 84 is also connected with the first turntable 82, and the upper part of the left support 4 is rotatably connected with the seventh rotating shaft 85, the left support 4 The lower par...

Embodiment 3

[0033] On the basis of Example 2, such as figure 1 As shown, a collection tank 9 is also included, and a collection tank 9 is connected between the inner surfaces of the two legs 1 between the lower first turntable 82 and the lower second turntable 86, and the collection groove 9 is located on the lower side of the first turntable. 82 and below the second turntable 86 on the lower side, the collecting tank 9 is inclined to be set with the front low and the rear high.

[0034] The threaded screw rod 100 then falls into the collection tank 9, and then slides down into the collection frame through the collection tank 9, so that the screw rod 100 can be concentrated into the collection frame and prevent the screw rod 100 from scattering around.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com