PCBA appearance detection method and device

A technology of appearance inspection and inspection method, applied in the field of PCBA appearance inspection method and device, can solve the problem of incompatibility of PCB inspection method, and achieve the effects of low cost, improved inspection efficiency, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

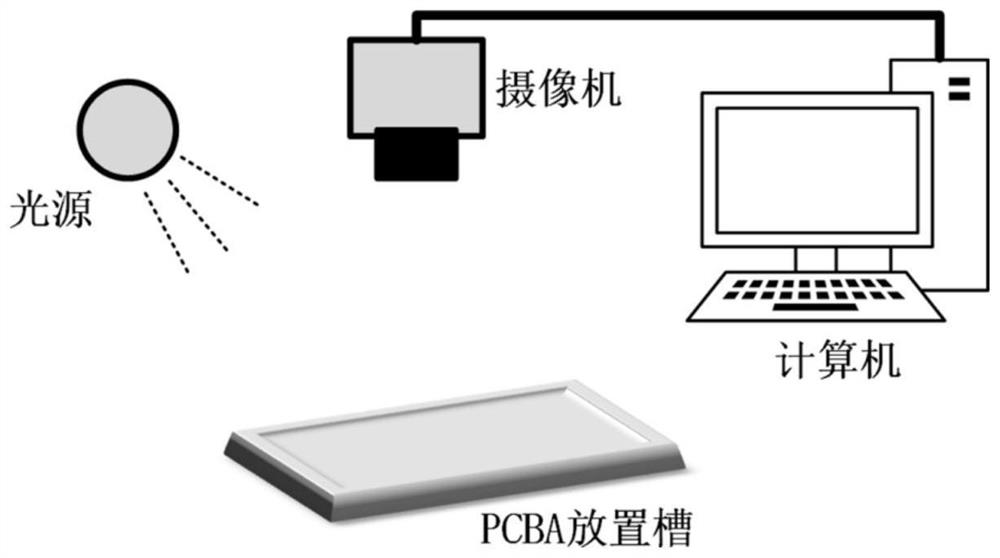

[0035] Such as figure 1 As shown, a PCBA board appearance detection device includes: a computer, a camera, a light source, and a PCBA placement groove, the camera is connected to the computer, the PCBA placement groove is used to place the PCBA board, and the light source is installed on the PCBA The top of the placement slot is used for system lighting; the field of view of the camera can cover the PCBA placement slot, and the light source irradiation area also needs to cover the PCBA placement slot, and the light intensity distribution is relatively uniform; the slot size of the PCBA placement slot and the appearance size of the PCBA Equal, the PCBA board can be placed in the PCBA placement slot just to ensure that the placement position and posture of the PCBA are consistent each time, so the area of interest in the image is less offset; at the same time, the appearance color of the PCBA placement slot is single, and There is a large color difference with the color of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com