Stirring device for food processing

A stirring device and food processing technology, which is applied in the direction of mixer accessories, transportation and packaging, dissolution, etc., and can solve the problems of static placement of the storage box, time-consuming and labor-consuming, and movement of the collection box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

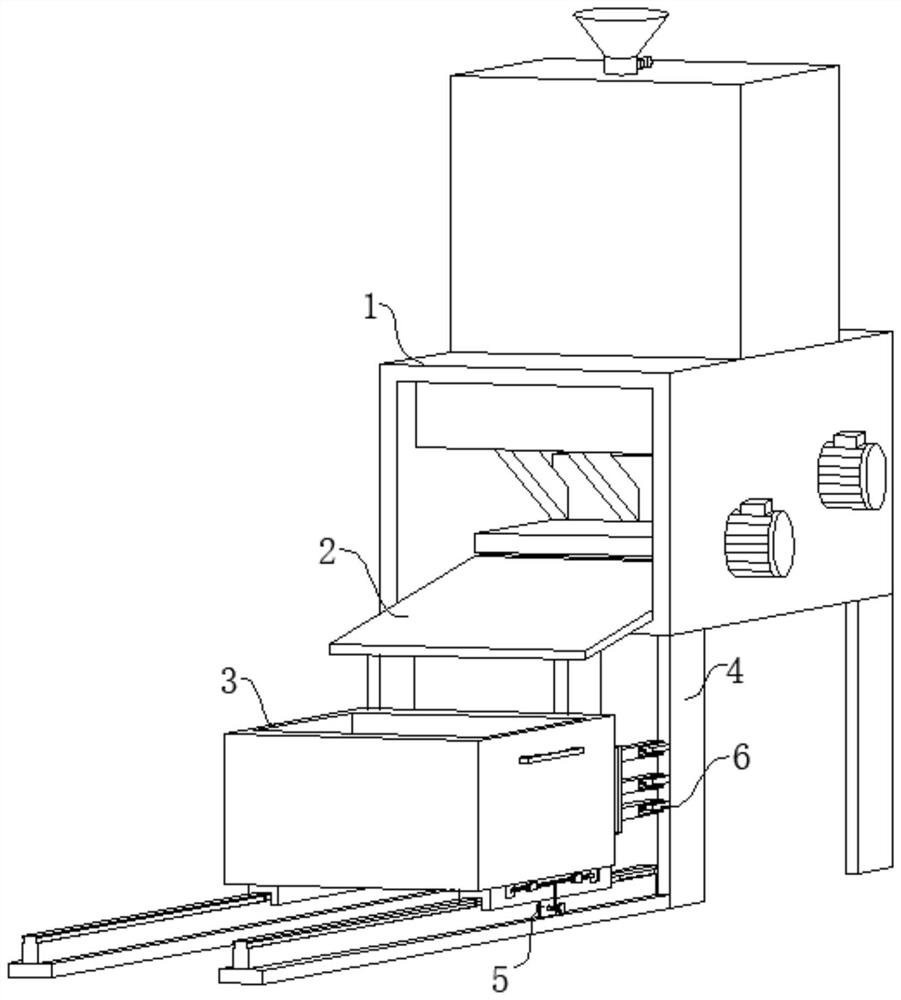

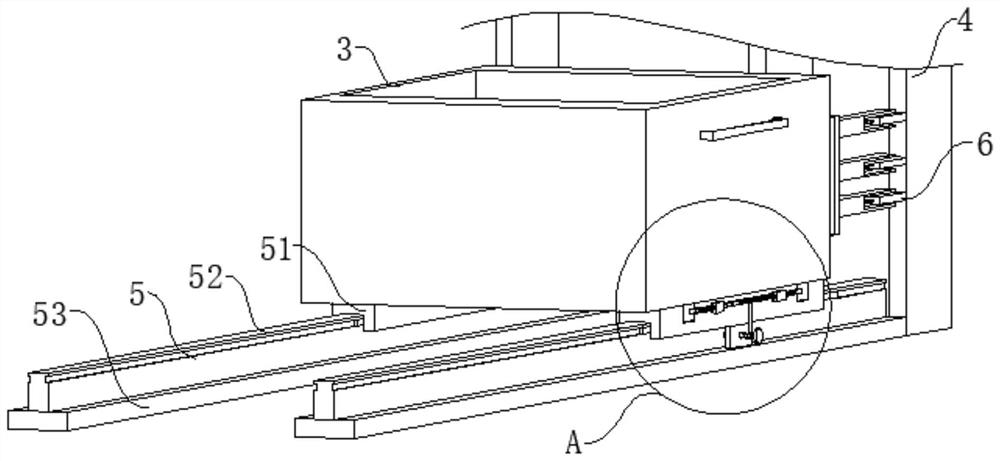

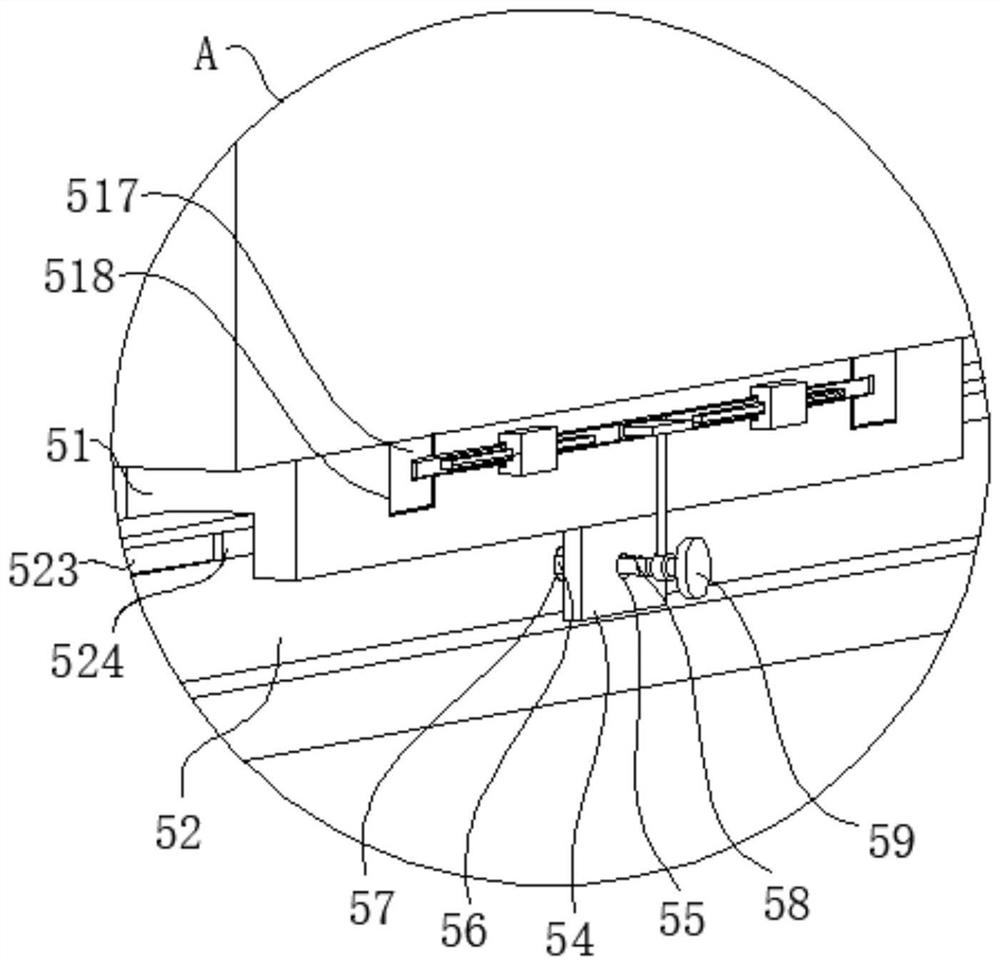

[0035] Attached below Figure 1-6 The present invention is further described with embodiment:

[0036] A stirring device for food processing, comprising a food mixing tank 1 and a supporting column 4, four supporting columns 4 are arranged on the bottom plate of the food mixing tank 1, and the four supporting columns 4 are distributed in a matrix, the output of the food mixing tank 1 A discharge guide plate 2 is installed obliquely at the mouth, and a finished product collection box 3 is provided directly below the inclined lower end of the discharge guide plate 2. The lower end of the finished product collection box 3 is provided with a mobile locking mechanism 5. The mobile locking mechanism 5 is set for finished product collection. For the convenient movement and locking of the box 3, the rear end of the finished product collection box 3 is provided with two buffer collision mechanisms 6, and the free ends of the buffer collision mechanisms 6 are connected to the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com