Bending tester for network optical fiber cable

A technology of bending testing machine and optical fiber line, which is applied in the field of optical fiber line for network, can solve the problems of inflexible adjustment of the bending range of the test piece and inflexible adjustment of the fixed position of the test piece, and achieve a compact structure, improved work efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

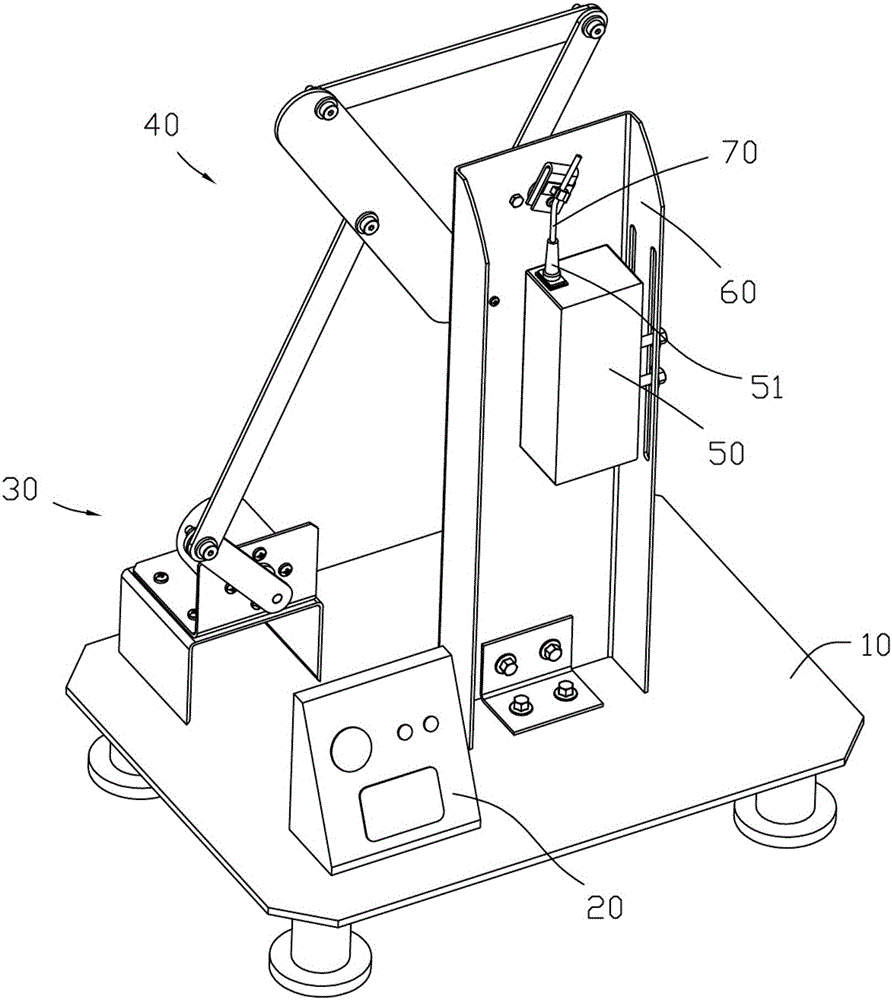

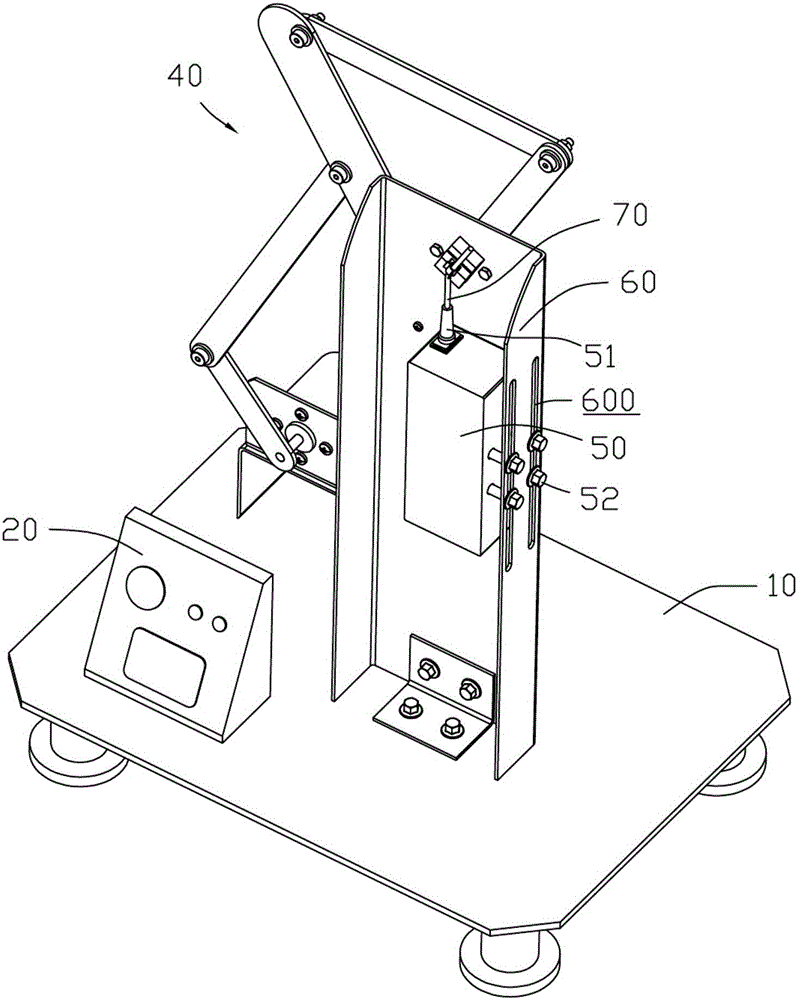

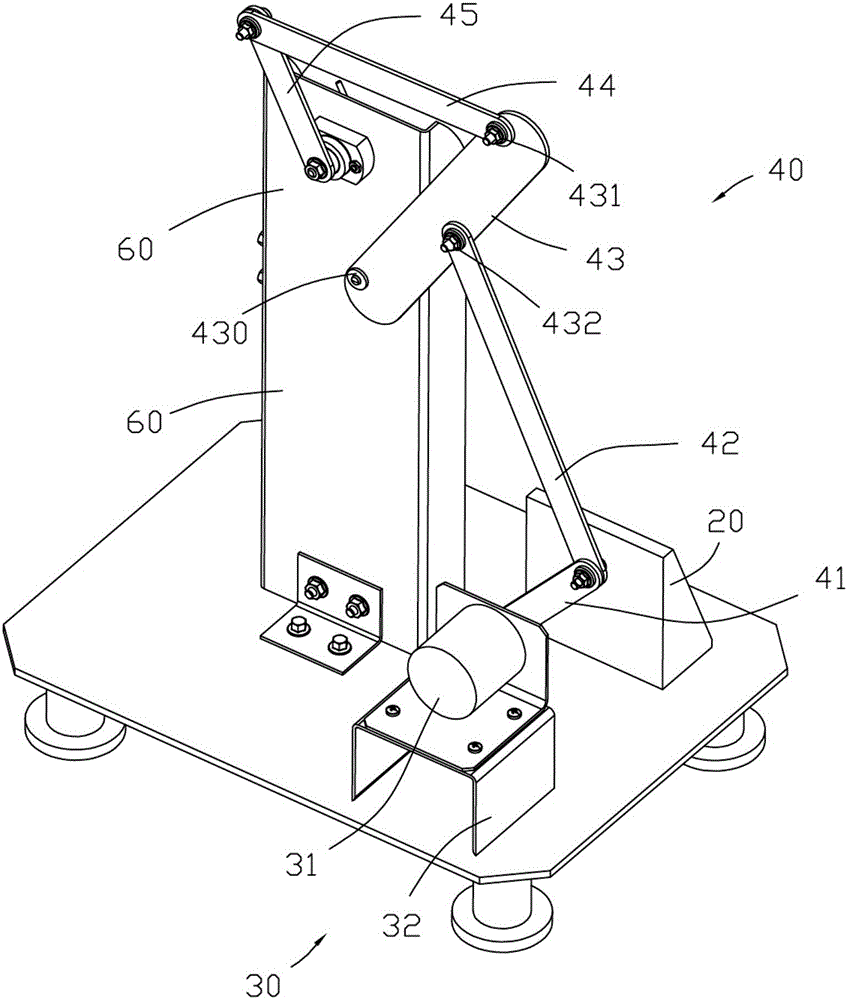

[0015] to combine Figure 1 to Figure 5 , a bending testing machine for network optical fiber lines, including a base 10, a control board 20, a motor assembly 30, a connecting rod assembly 40, a clamp 50 and a clamp seat 60; the base 10 is located at the bottom of the testing machine, and the motor assembly 30 includes The motor 31 and the motor seat 32, the connecting rod assembly 40 includes five connecting rods and an optical fiber clamping plate 47, wherein the first connecting rod 41 is connected to the motor 31, and the optical fiber 70 is installed in the optical fiber clamping plate 47, so The bottom of the fiber optic cable 70 is installed on the clamp 50 , and the clamp 50 is fixed on the clamp seat 60 .

[0016] to combine image 3 and Figure 5 , the connecting rod assembly 40 includes a first connecting rod 41, a second connecting rod 42, a third connecting rod 43, a fourth connecting rod 44, a fifth connecting rod 45, a connecting rod fixing block 46 and an opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com