New energy power battery cooling box laser powder filling swing welding method

A power battery and welding method technology, applied in the field of material engineering, can solve problems such as reducing the stability of the welding process, welding through, and affecting the performance of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

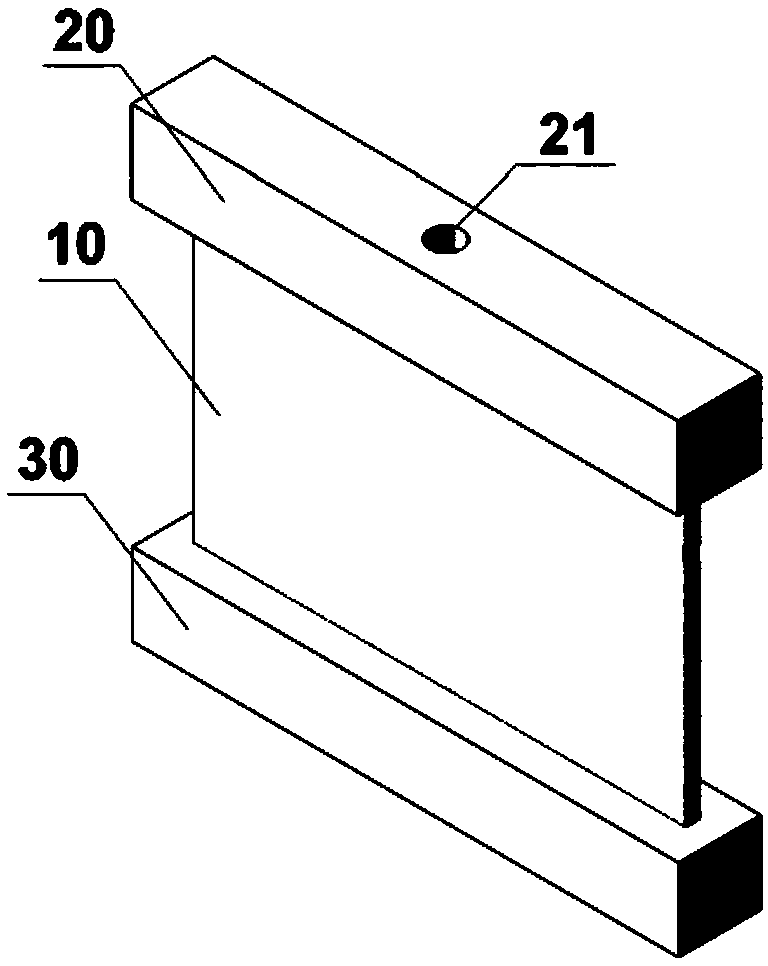

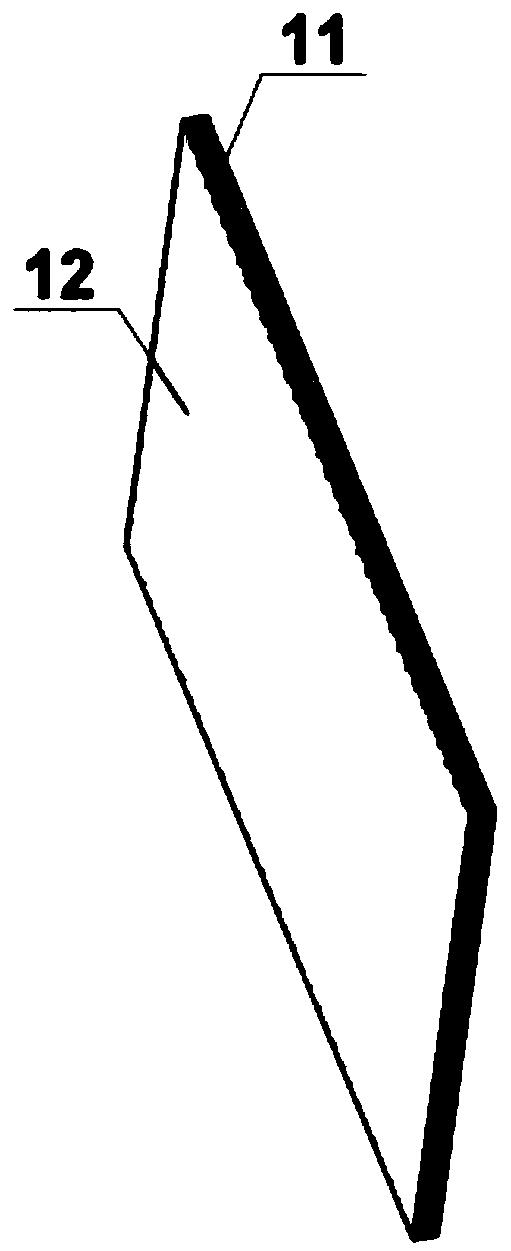

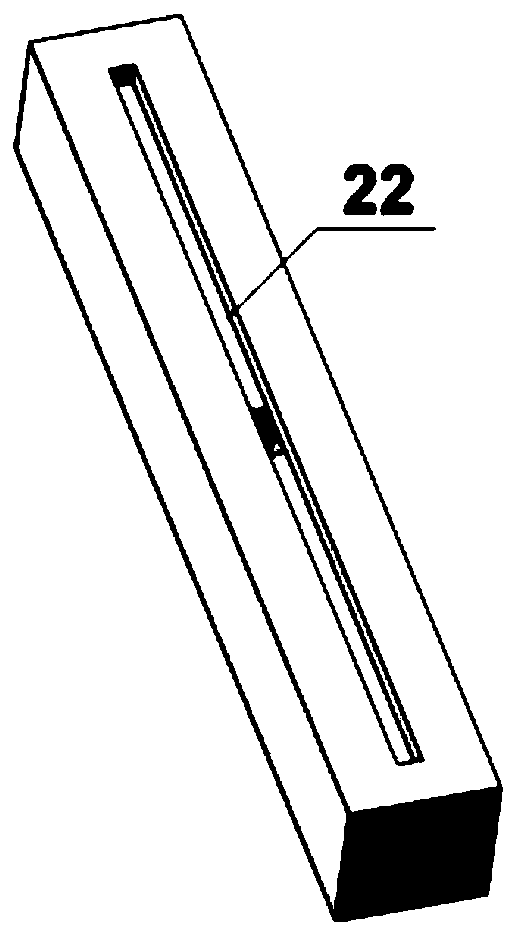

[0032] figure 1 It is a schematic diagram of the structure of the new energy battery cooling box. The mark 10 in the figure is the abdominal structural part of the battery cooling box, which is generally made of aluminum alloy. Such as figure 2 As shown, the abdominal structure is composed of a plurality of parallel vertical plates 11 plus double wall plates 12 . In order to facilitate heat dissipation, the vertical plate and wall plate are thinner, only 0.4mm. figure 1 The marks 20 and 30 in the middle are the upper and lower structural parts of the battery cooling box respectively, which are also made of aluminum alloy. figure 1 The mark 21 in the middle is a liquid hole, image 3 The middle mark 22 is a groove structure, which plays a role in matching the abdominal structure with the bottom structure. Only when the bottom structural member and the abdominal structural member are combined into a closed cooling box can it be used for cooling liquid. Therefore, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com