Amplitude variation and rotation linkage anti-swing system and method for tower crane

A tower crane and crane technology, applied in cranes, transportation and packaging, load hoisting components, etc., can solve the problems of casualties, ignorance of tower crane performance, increase alignment time, etc., to reduce safety accidents, improve Safety, flexible operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

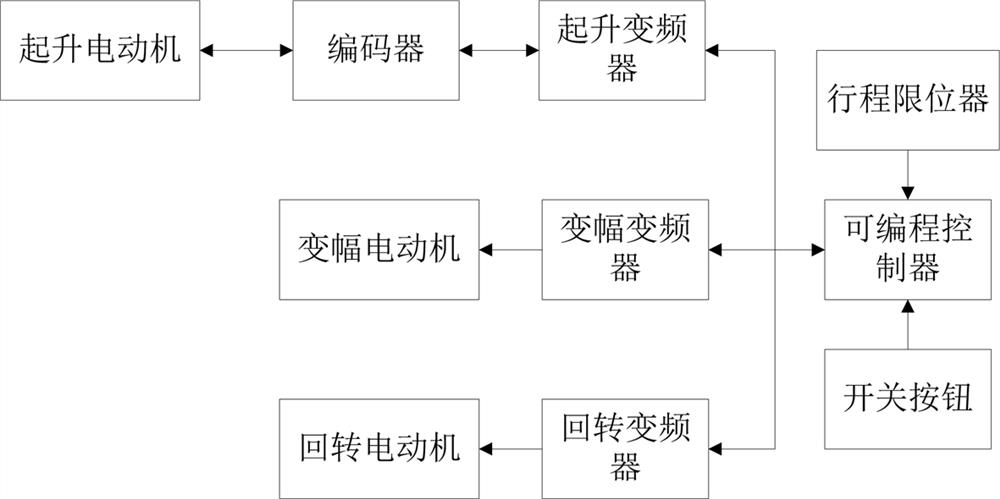

[0041] The invention relates to a luffing and slewing linkage anti-sway method of a tower crane. The method includes the following steps.

[0042] Step 1: Initialize and activate the anti-shake function; for example, press the anti-shake button on the linkage table to trigger.

[0043] Step 2: Obtain the current height of the crane lifting the load.

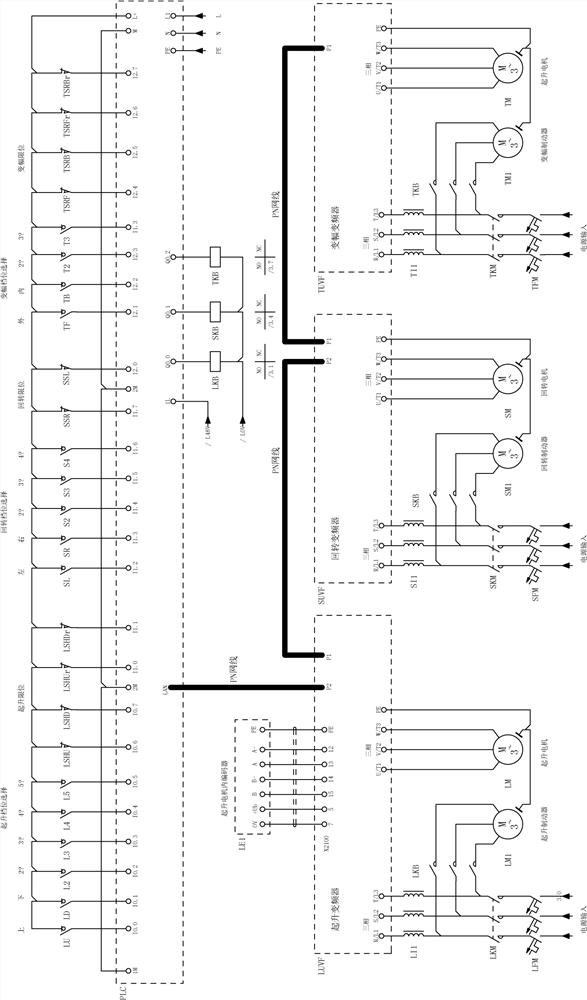

[0044] In the step 2, the current speed of the coordinated encoder is collected by the lifting frequency converter, and transmitted to the programmable controller through the PN bus communication, and the programmable controller calculates the current height of the heavy object hoisted by the crane after receiving the speed signal .

[0045] The current speed V s =V d ÷i×π×D÷a÷60, the current height of the crane hoisting heavy objects H=H 0 +H 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com