Cantilever structure of operation stable

A technology of operating table and cantilever, which is applied in the direction of machine table/support, supporting machine, mechanical equipment, etc., and can solve the problems of cable entanglement, cable damage, operating table disconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

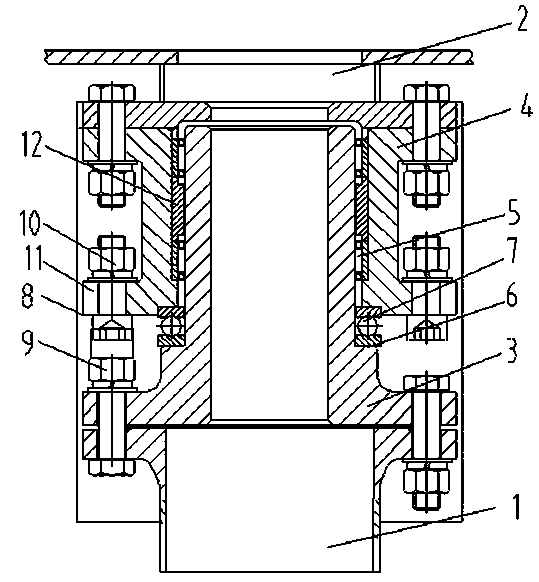

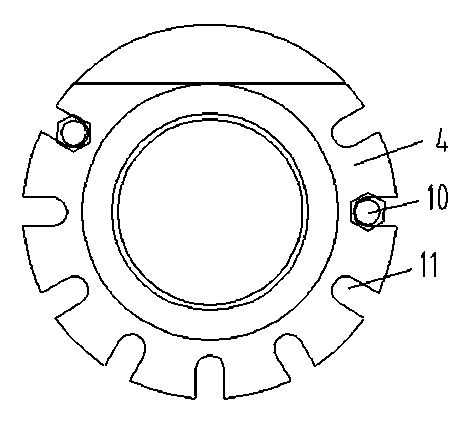

[0015] The cantilever structure of the operating table of the present invention includes a rotating arm 1 through which cables are threaded and a bracket 2 located above the rotating arm 1 . In order to limit the full circle rotation of the pivoting arm 1 relative to the bracket 2, a limited full circle rotation structure is arranged between the pivot arm 1 and the bracket 2. The sleeve on the shaft 3, the bearing 5 between the sleeve and the mandrel 3, the fastening bolt 9 at the lower end of the mandrel is bolted to the rotating arm 1, there is a gap between the upper end of the mandrel and the bracket 2, the sleeve The upper end of the sleeve is bolted to the bracket 2, and the lower end of the sleeve and the lower end of the mandrel is provided with a slewing bearing 7 that is against the lower end of the sleeve and the preset shoulder 6 on the mandrel 3, and the lower end of the sleeve is provided with a An integral flange 8 is provided with a limit block 10 against the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com