Linear motor

A technology of linear motors and coils, which is applied in the direction of electric components, linear motion bearings, electrical components, etc., and can solve the problems of linear motor size increase and rod stroke limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

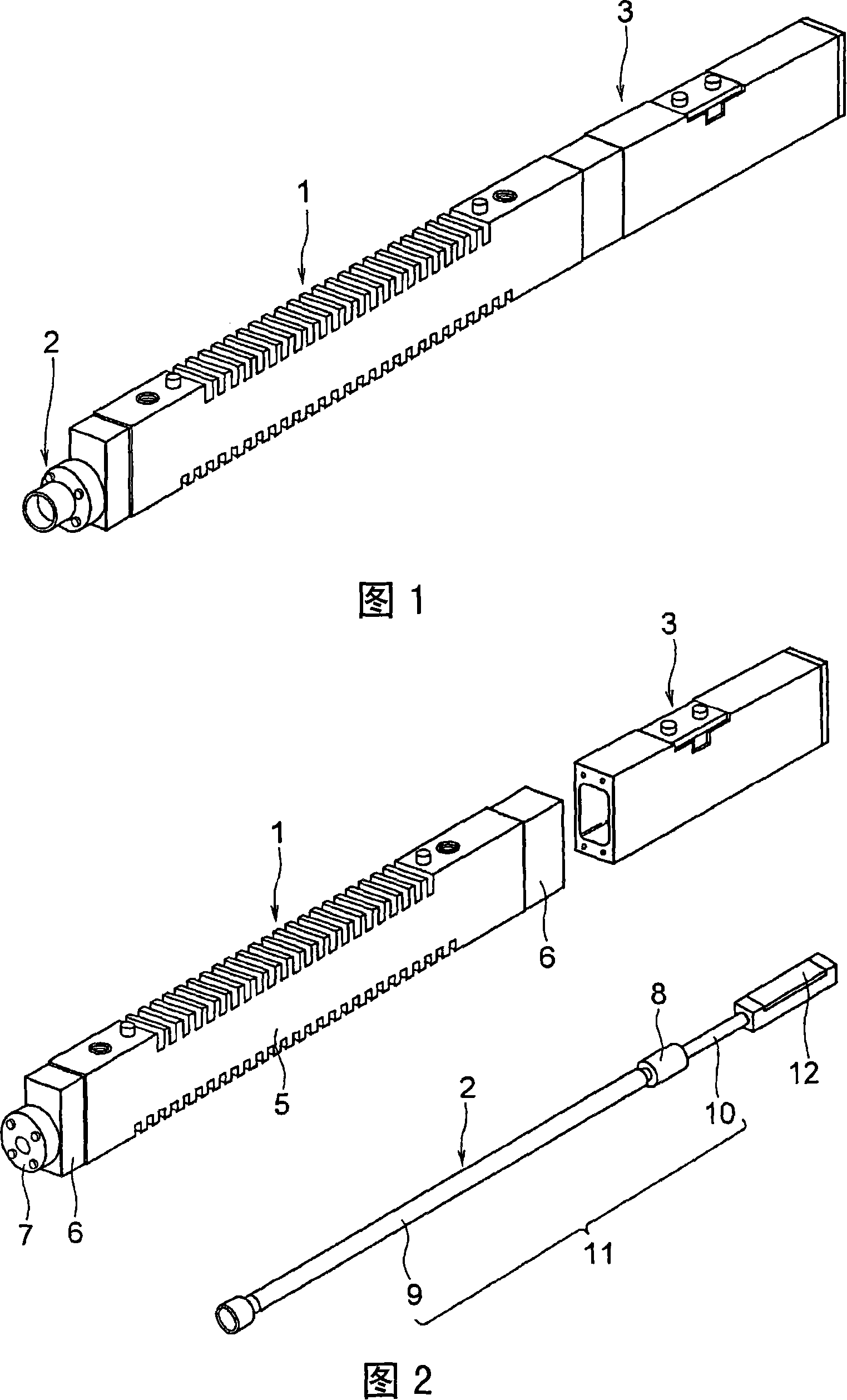

[0043] Embodiments of the present invention will be described in detail based on the drawings. FIG. 1 is an external perspective view showing a linear motor according to one embodiment of the present invention. The linear motor of this embodiment is a one-axis actuator, and is used to convey a moving body such as an electronic component in one axis direction. More specifically, for example, it is used to mount a chip-shaped electronic component on a drive shaft of a chip mount at a predetermined position. A rod part 2 capable of advancing and retreating is incorporated into a long and thin rectangular parallelepiped motor body part 1 . The speed and moving distance of the rod part 2 are detected by the detection part 3 installed at the rear end of the motor body part 1 .

[0044] FIG. 2 shows a state in which the linear motor is disassembled into a motor body 1 , a rod body 2 , and a detection unit 3 . First, the schematic configuration of these parts will be described.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com