Preparation method of high-magnetic-energy-product and high-coercivity sintered neodymium iron boron magnet

A technology with high coercive force and high magnetic energy product, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of limited grain growth inhibition effect, high vacuum and evaporation temperature requirements, and electron beam evaporation. Expensive equipment and other issues, to achieve the effect of reducing the tendency of grain growth, reducing the use of heavy rare earth elements, and improving the tendency of low-temperature sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a sintered NdFeB magnet with high energy product and high coercivity, specifically comprising the following steps:

[0025] Step 1: Distributing the ingredients according to the design, the ingredients are melted, and the quick-setting cast pieces are obtained to obtain the quick-setting cast pieces;

[0026] According to the following mass percentage ingredients: Pr-Nd: 28-32%; Co: 0-1.2%; Cu: 0-0.6%; Nb: 0-0.6%; Ga: 0-0.6%; B: 0.9-1.2% and the remaining content of Fe.

[0027] Step 2: NdFeB cast flakes undergo hydrogen crushing, disproportionation reaction, and jet milling to obtain 0.5-10 μm NdFeB fine powder;

[0028] Step 3: Deposit Dy / Tb particles and Pr / Nd particle element particles on the NdFeB fine powder step by step or simultaneously by using the thermal resistance evaporation deposition method;

[0029] The heavy rare earth thermal resistance wire in thermal resistance evaporation includes the first deposition element and the second ...

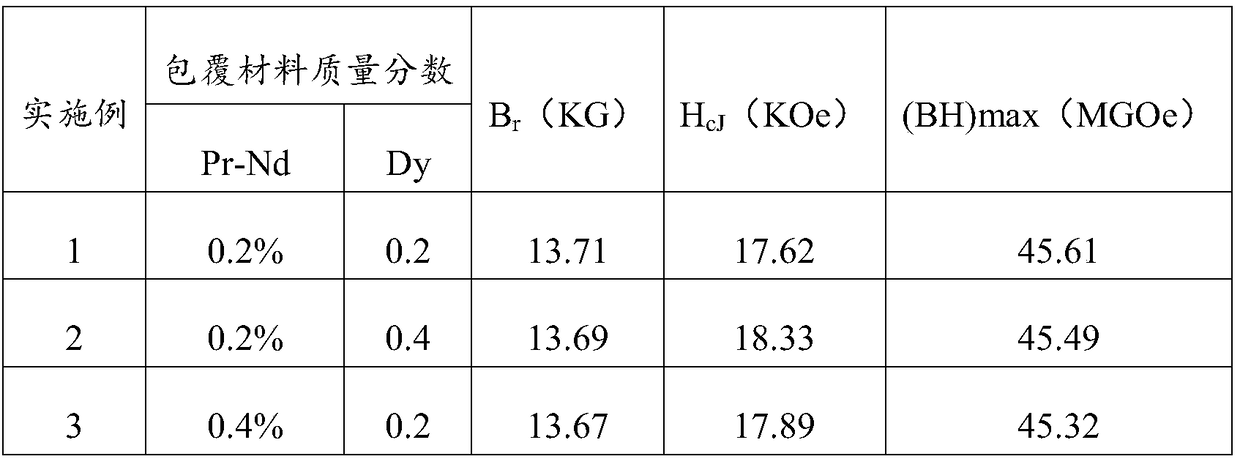

Embodiment 1

[0035] (1) According to the following mass percentage batching: Pr-Nd: 29.8%; Co: 0.8%; Cu: 0.2%; Al: 0.3%; Nb: 0.2%; Ga: 0.2%; Fe.

[0036] (2) The prepared raw materials are put into the vacuum quick-setting casting furnace, and under the condition of evacuating to 1Pa, they are filled with Ar gas protection for heating and melting. It is a 0.2-0.4mm alloy cast piece; then the magnetic powder with an average particle size of 2.9um is prepared by hydrogen crushing, disproportionation reaction, and jet milling; the Dy particles and Pr / Nd particle element particles are deposited on the neodymium simultaneously by thermal resistance evaporation deposition method On the iron boron fine powder, control the deposition process parameters, add the mass fractions of Dy and Pr / Nd in the magnetic powder prepared in the above steps by the method of thermal resistance deposition to be 0.2% and 0.2% respectively; when the magnetic field strength is greater than 1.5 Tess Orientation and pr...

Embodiment 2

[0038] (1) According to the following mass percentage batching: Pr-Nd: 29.8%; Co: 0.8%; Cu: 0.2%; Al: 0.3%; Nb: 0.2%; Ga: 0.2%; Fe.

[0039] (2) The prepared raw materials are put into the vacuum quick-setting casting furnace, and under the condition of evacuating to 1Pa, they are filled with Ar gas protection for heating and melting. It is a 0.2-0.4mm alloy cast piece; then the magnetic powder with an average particle size of 2.9um is prepared by hydrogen crushing, disproportionation reaction, and jet milling; the Dy particles and Pr / Nd particle element particles are deposited on the neodymium simultaneously by thermal resistance evaporation deposition method On the fine iron-boron powder, control the deposition process parameters, control the deposition process parameters, add the mass fractions of Dy and Pr / Nd in the magnetic powder prepared in the above steps by thermal resistance deposition to 0.4% and 0.2% respectively; Orient and press-form in a magnetic field with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com