Supramolecular material, preparation method and application thereof

A supramolecular and reactive technology, applied in the field of materials, can solve the problems of structural flexibility, poor stability, limited application scope, weakened fluorescence, etc., and achieve the effects of being conducive to large-scale industrial production, simple preparation method, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

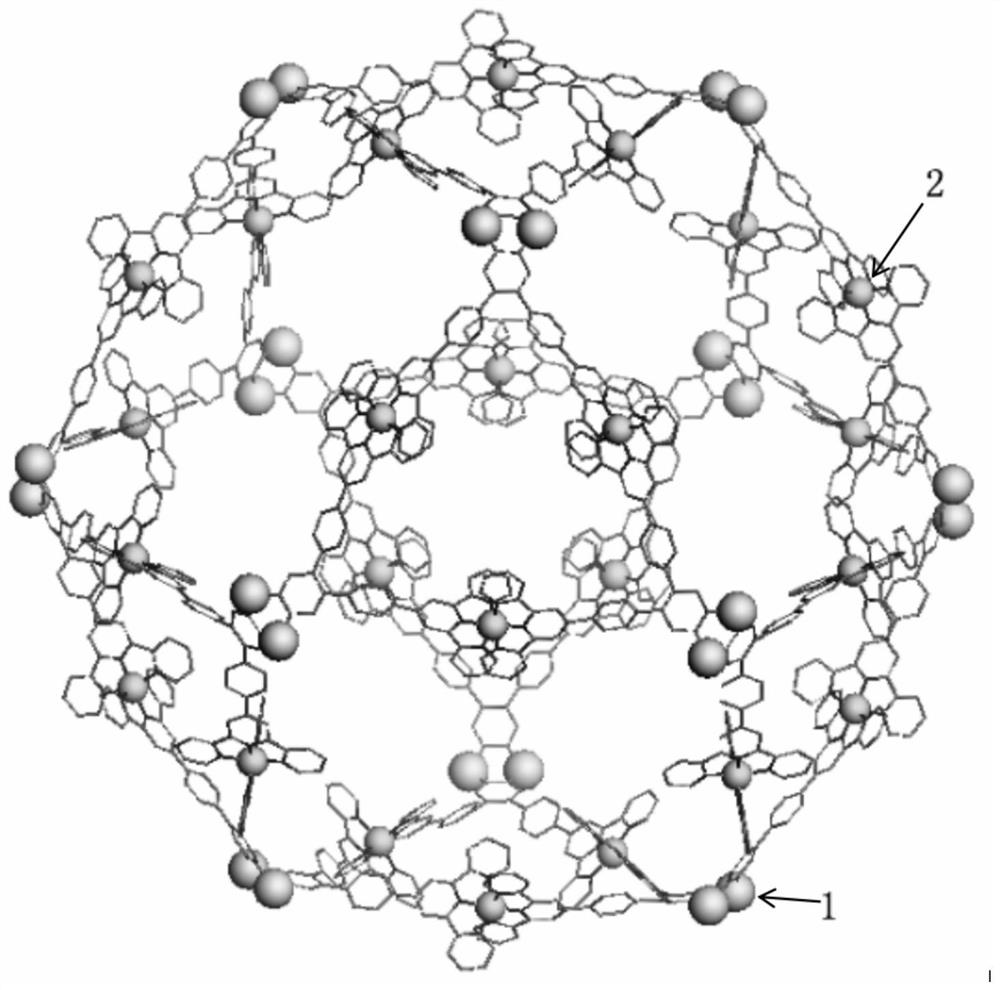

[0058] A kind of supramolecular material, is made of the unit structure shown in formula (V), and described supramolecular material is cage shape;

[0059]

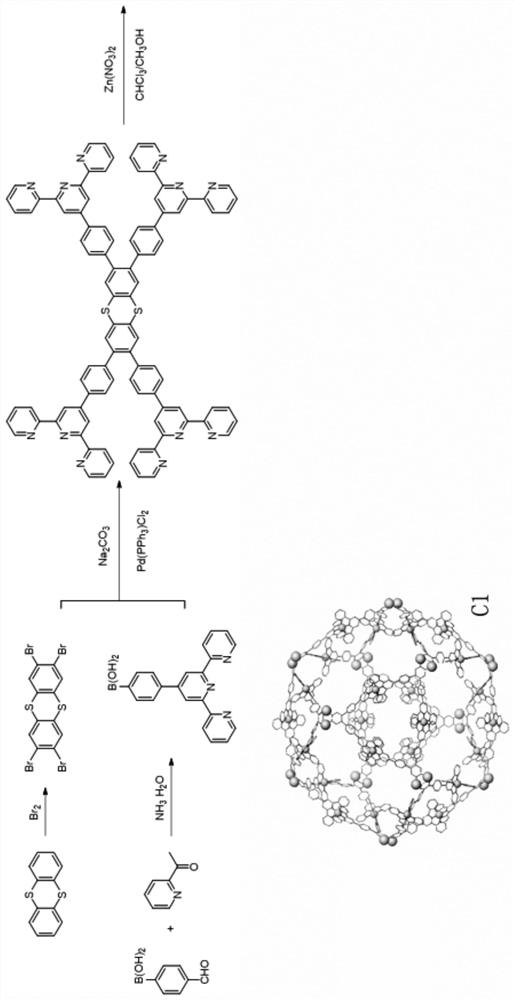

[0060] The preparation method of above-mentioned supramolecular material, comprises the following steps:

[0061] (1) Preparation of 2,3,6,7-tetrabromothianthrene

[0062]

[0063] Add thianthrene (3.24g, 15mmol) and 20mL glacial acetic acid into a three-necked flask, slowly add liquid bromine (19.2g, 120mmol) under nitrogen protection, react at a constant temperature of 100°C for 24h, and add 100mL of sodium bisulfite solution after cooling the solution Excess liquid bromine was quenched with CH 2 Cl 2 The extraction was washed with water, and the organic phase was washed with anhydrous MgSO 4 After drying, the solvent was rotary evaporated to obtain a crude product, which was recrystallized from n-hexane to obtain a white solid (3.21 g, 46%). 1 H NMR (500MHz, CDCl 3 ,300K,ppm):δ7.63(s,4H,Ph...

Embodiment 2

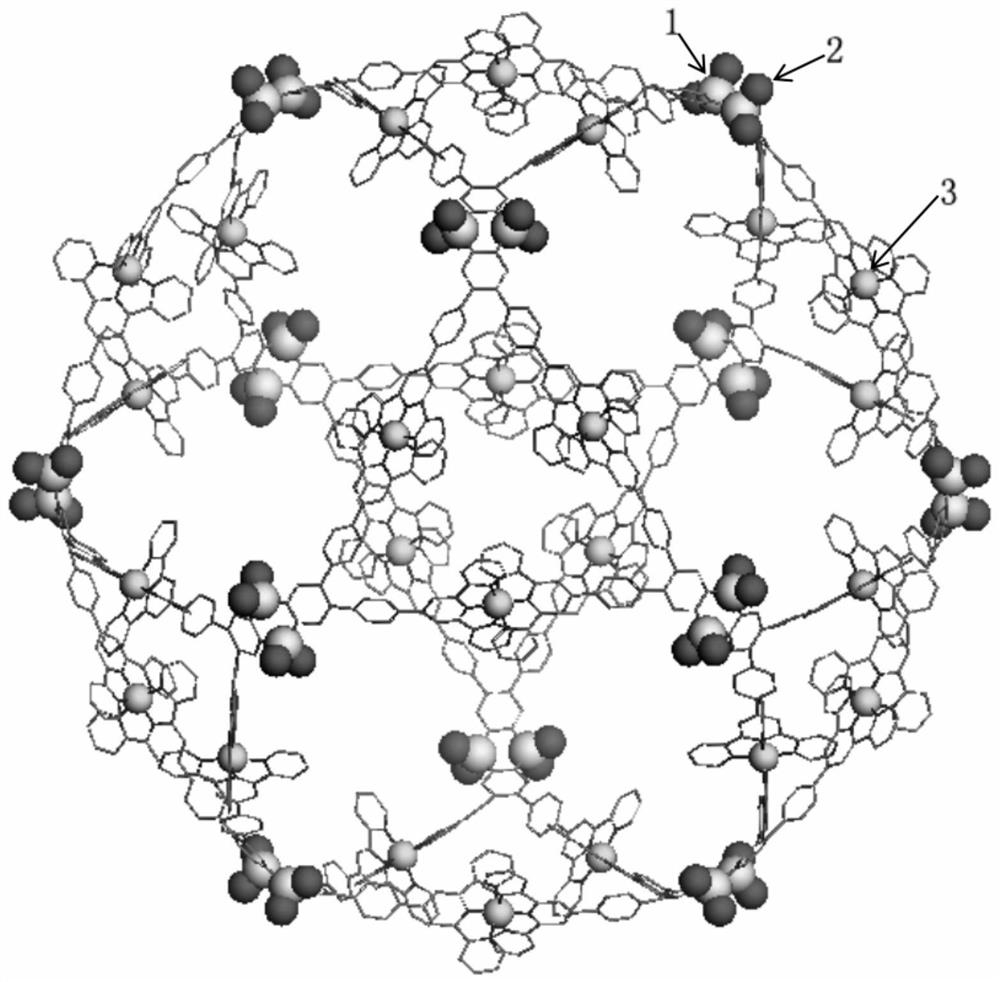

[0076] A supramolecular material consisting of a unit structure shown in formula (VI), the supramolecular material being cage-like;

[0077]

[0078] The preparation method of above-mentioned supramolecular material, comprises the following steps:

[0079] (1) Preparation of 2,3,6,7-tetrabromothianthrene

[0080]

[0081] Add thianthrene (3.24g, 15mmol) and 20mL glacial acetic acid into a three-necked flask, slowly add liquid bromine (19.2g, 120mmol) under nitrogen protection, react at a constant temperature of 100°C for 24h, and add 100mL of sodium bisulfite solution after cooling the solution Excess liquid bromine was quenched with CH 2 Cl 2 The extraction was washed with water, and the organic phase was washed with anhydrous MgSO 4 After drying, the solvent was rotary evaporated to obtain a crude product, which was recrystallized from n-hexane to obtain a white solid (3.21 g, 46%). 1 H NMR (500MHz, CDCl3, 300K, ppm): δ7.63 (s, 4H, PhH). 13 C NM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com