Patents

Literature

34results about How to "Reduce vibration speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

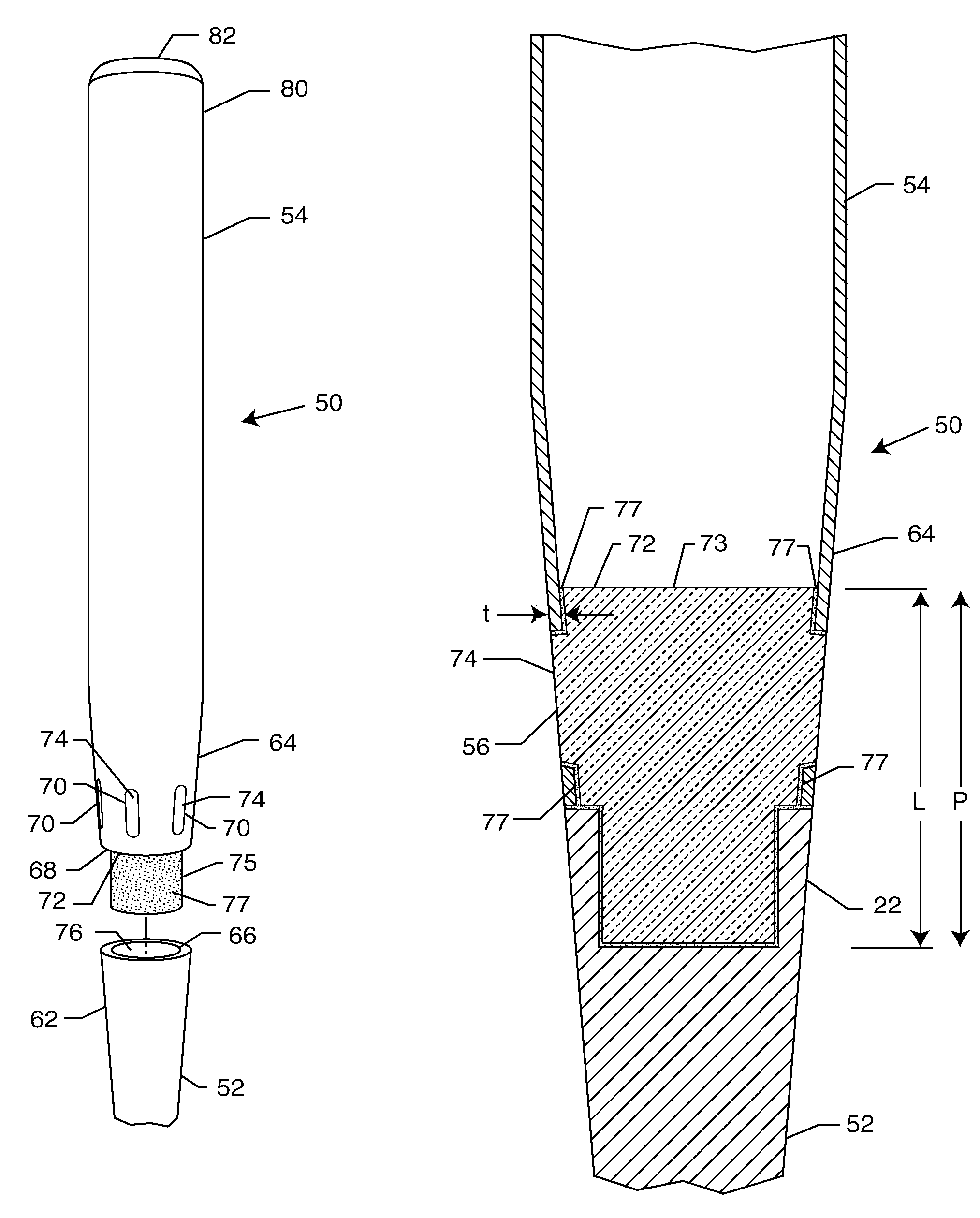

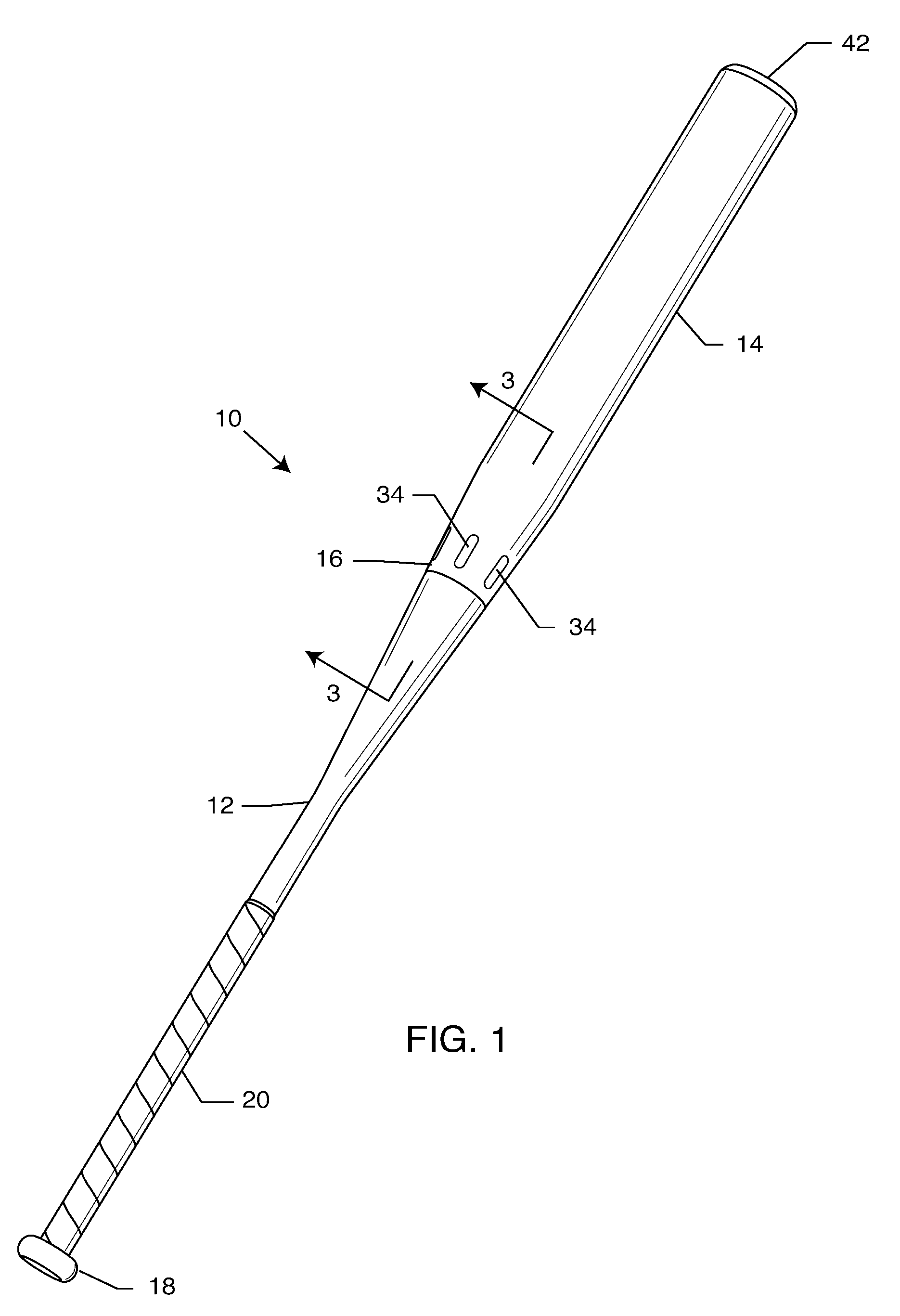

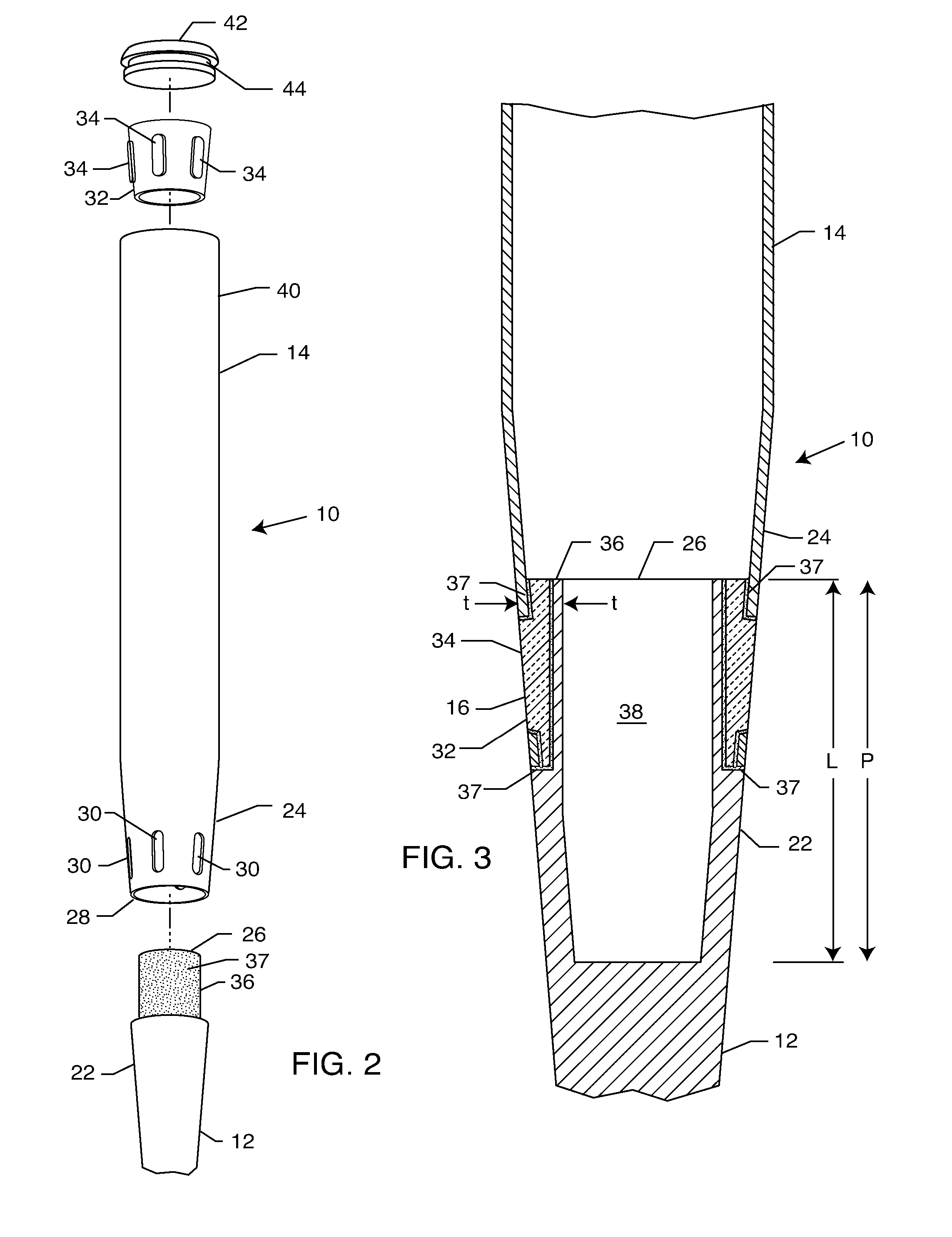

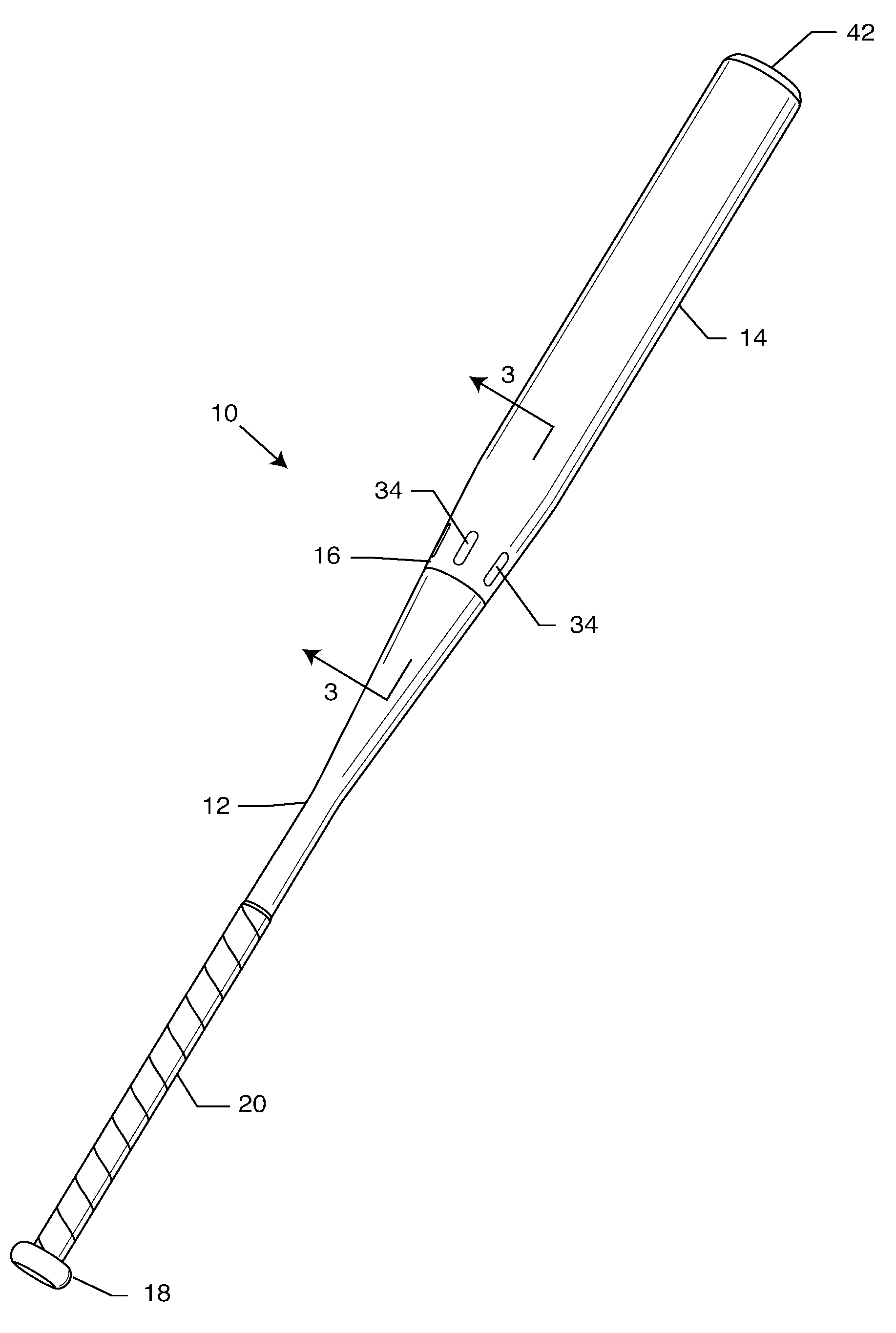

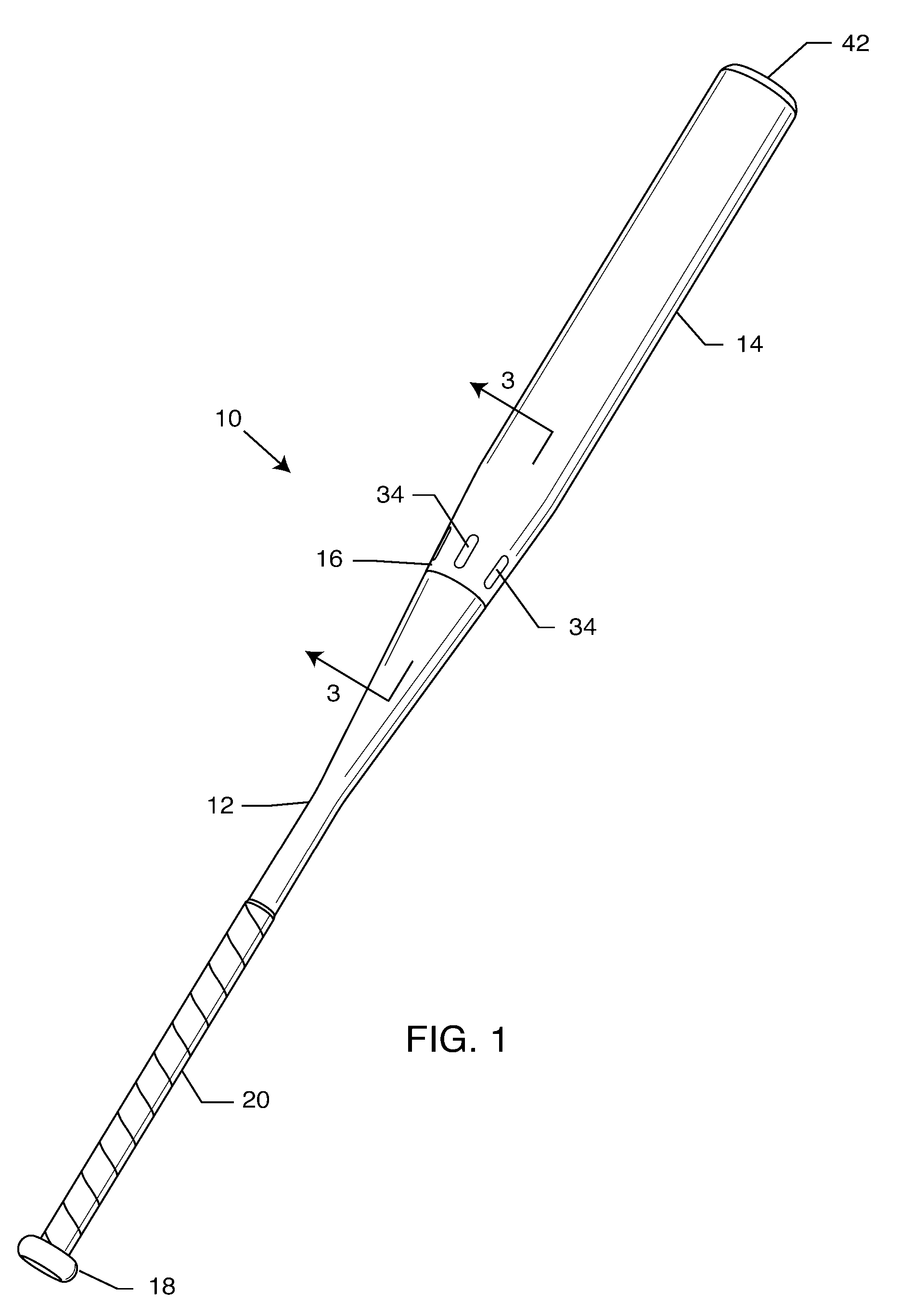

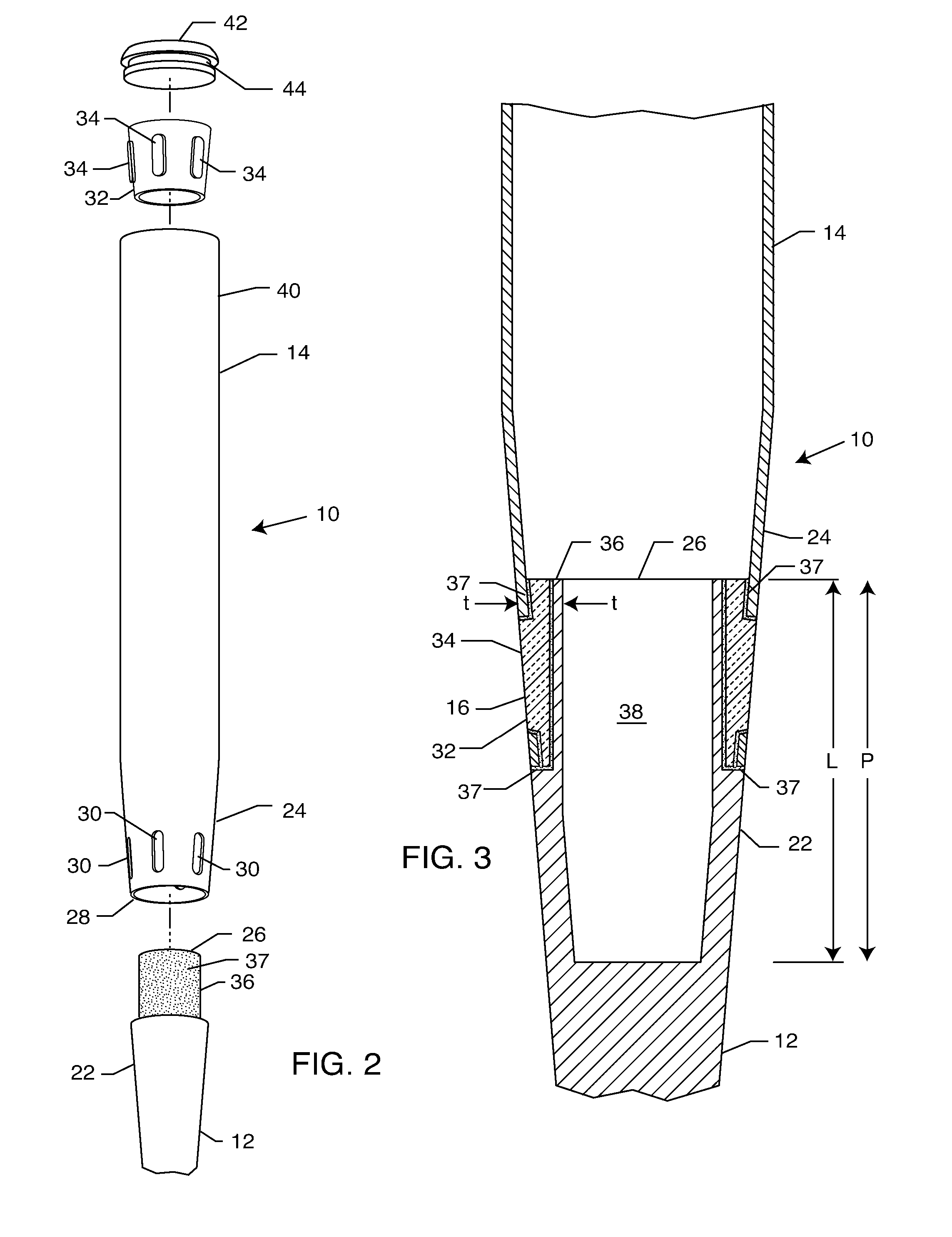

Multi-component bat and assembly process

ActiveUS7381141B2Reduce vibration speedIncrease spot sizeRacket sportsMechanical engineeringBaseball bat

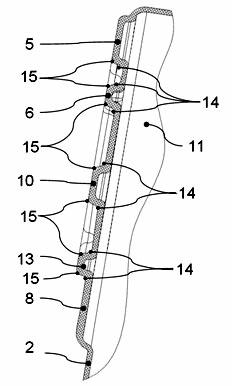

A process for assembling a multi-component baseball bat includes providing a bat barrel having an end with a plurality of slots and selecting a bat handle. A section of the handle is enveloped by the end of the barrel. The barrel and handle are interconnected in coaxial engagement to define an intermediate tapered section which returns energy and power to the barrel that emanates from the barrel due to an impact of a ball on the barrel. An example of a multi-component baseball bat formed by the process includes a bat barrel having a plurality of slots; a bat handle; and a connector attached to an end of the handle. The connector engages the slots of the barrel and is coaxially disposed between the barrel and the handle for interconnecting the barrel and handle in an aligned relation, to return energy and power to the barrel.

Owner:VAN NGUYEN THU

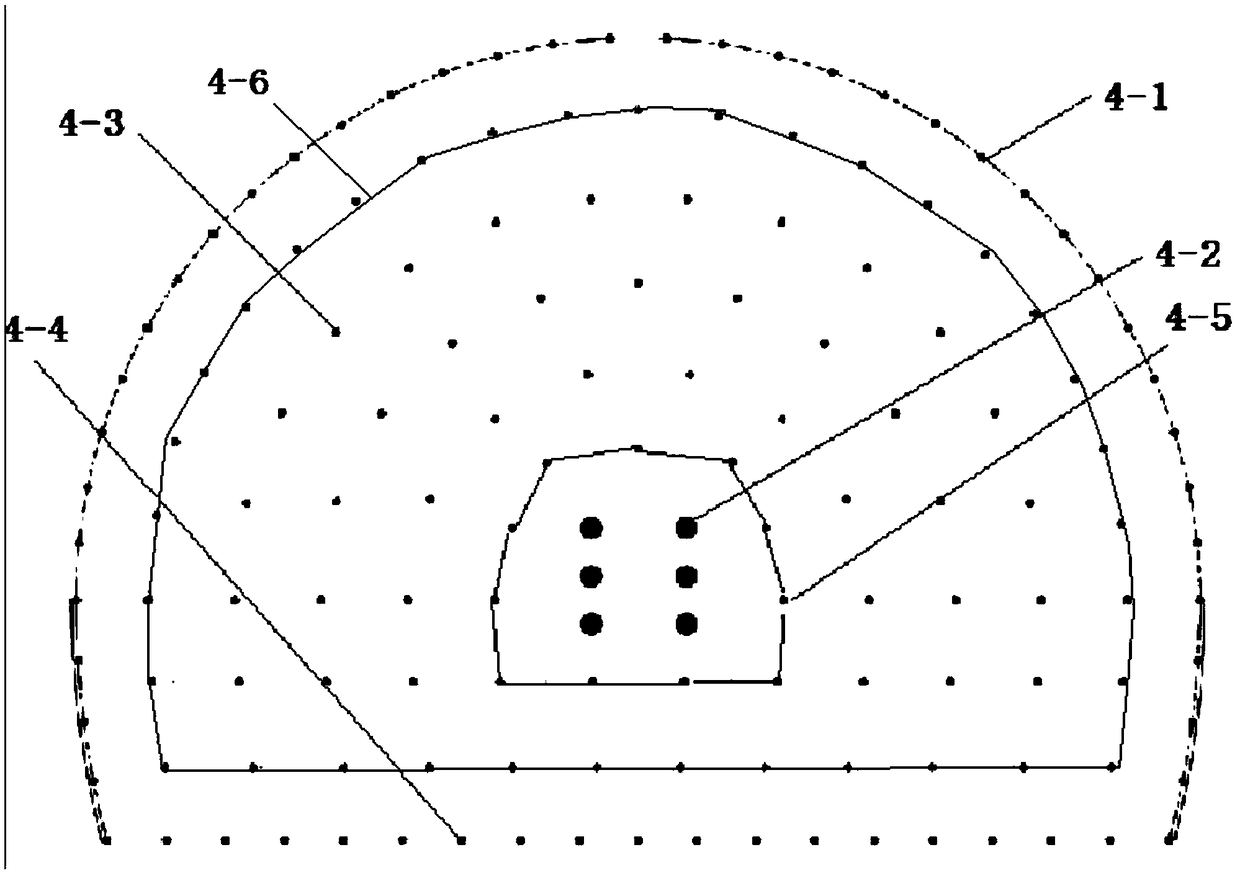

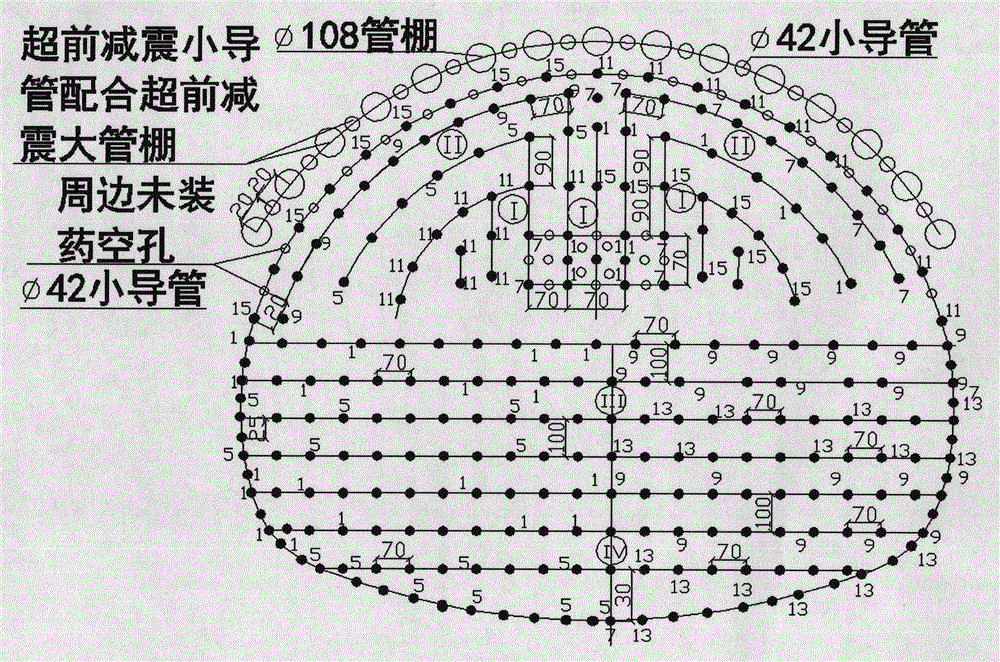

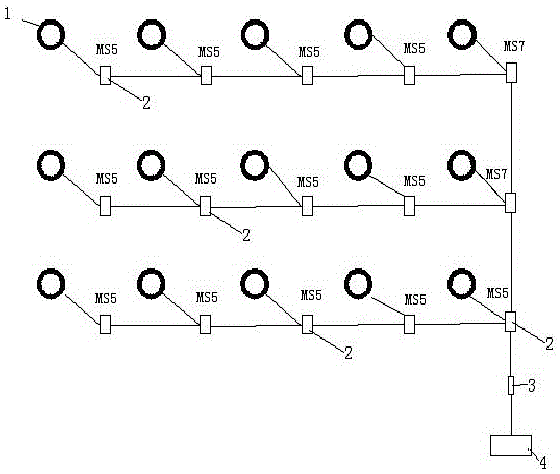

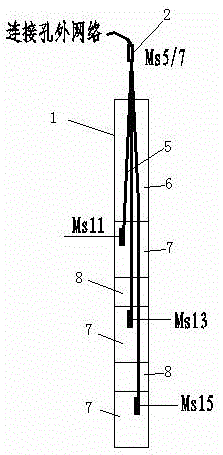

Tunnel millisecond blasting method

ActiveCN107764144AReduce the blast velocityReduced blasting noise and vibrationBlastingEngineeringStructural engineering

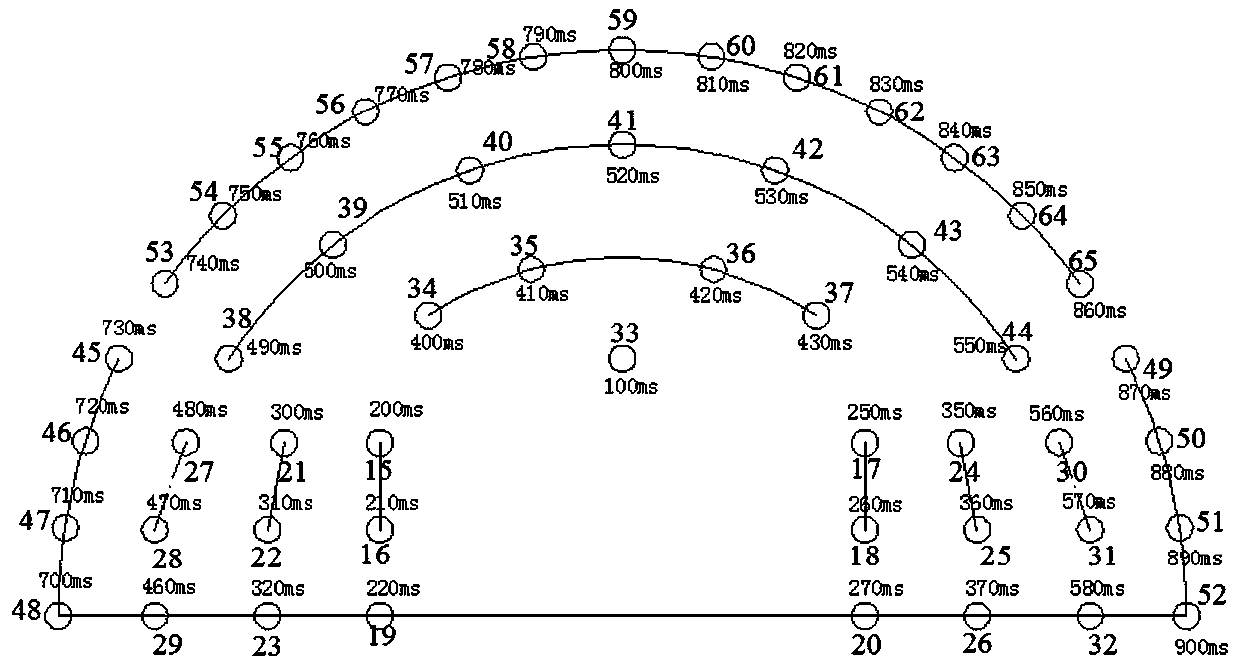

The invention discloses a tunnel millisecond blasting method. The method comprises the following steps of 1, distributing of blast holes, the number of the blast holes and the blasting parameters of the blast holes are designed, wherein the blasting parameters of the blast holes comprise hole diameters, hole distances, resistance lines and depth of a periphery hole, an reliever hole and a cut hole; 2, the blast holes are drilled in a tunnel boring face to be blasted; 3, explosive loading is carried out on the blast holes drilled in the tunnel boring face; 4, blocking and compacting is carriedout on the blast holes filled with explosive; 5, time delay setting is carried out on digital electronic detonators in all the blast holes; and 6, after the time delay setting is finished, wire connecting is carried out, and sequential detonation is conducted after determining that no errors exist. Compared with an existing millisecond blasting technology which is complex in blasting mechanism anddoes not have explicit theory and practice supports, the tunnel millisecond blasting method has the advantages that the different cut blasting methods are adopted for different surrounding rocks andfield conditions, so that the purposes of improving blasting efficiency, reducing the vibration speed and saving financial resources are achieved.

Owner:北京住总集团有限责任公司 +1

Tunnel excavation water pressure blasting construction method

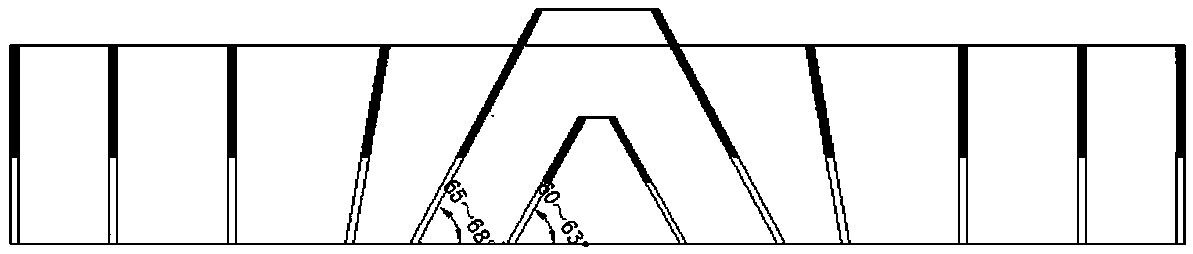

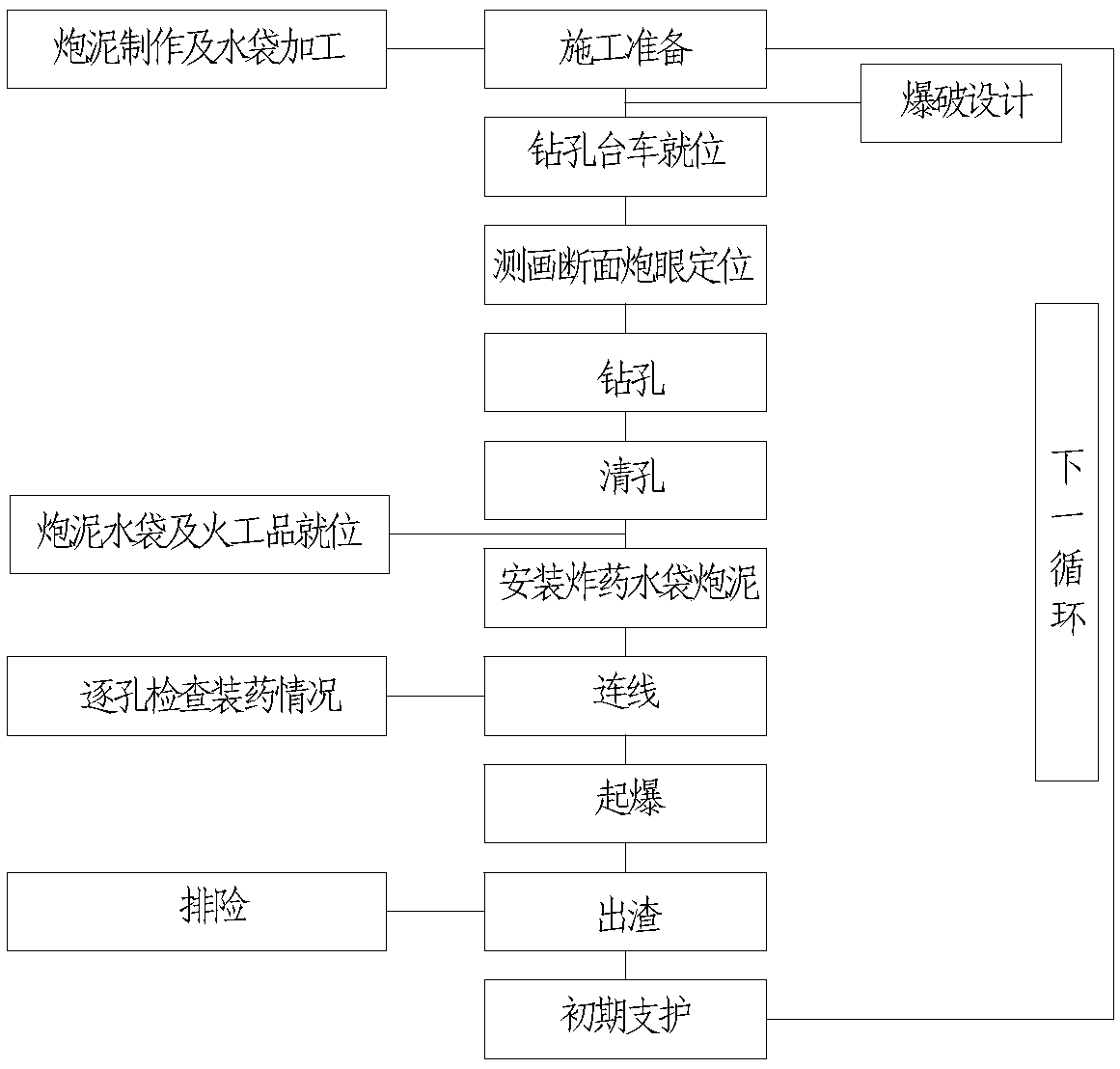

InactiveCN109373840AImprove the construction environmentIncrease profitBlastingTunnelsGeomorphologyDetonation

The invention discloses a tunnel excavation water pressure blasting construction method. The tunnel excavation water pressure blasting construction method comprises the following steps of (1) arranging a trolley in place and conducting danger elimination; (2) measuring, distributing and drilling holes; (3) installing explosives, water bags and stemming, wherein the peripheral holes are excavated on the arc edge of the tunnel face of a tunnel, and the explosives, the water bags and stemming are installed in the following manners of air spacing, decoupling charge and the explosive quantity at hole bottoms more than that of other parts; cut holes are drilled in an inclined mode, and the included angle between the cut holes and the excavation face is 65 degrees-75 degrees; the continuous coupling charge method is adopted for loosening holes, relief holes, inner ring holes and bottom plate holes, blasting caps are buried into hole bottom cartridges, and energy gathering holes face orifices;the water bags are arranged at the hole bottoms of shot holes, and the water bags are arranged again after completion of explosive charging, and the holes are blocked through the stemming; (4) detonating a detonating network; (5) conducting after-detonation check and misfire processing; and (6) withdrawing the explosives to the warehouse. Through the tunnel excavation water pressure blasting construction method, the energy of explosives can be made full use of, environmental pollution can be reduced, and the cost can be saved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

A multi-component bat and assembly process

A process for assembling a multi-component baseball bat includes providing a bat barrel having an end with a plurality of slots and selecting a bat handle. A section of the handle is enveloped by the end of the barrel. The barrel and handle are interconnected in coaxial engagement to define an intermediate tapered section which returns energy and power to the barrel that emanates from the barrel due to an impact of a ball on the barrel. An example of a multi-component baseball bat formed by the process includes a bat barrel having a plurality of slots; a bat handle; and a connector attached to an end of the handle. The connector engages the slots of the barrel and is coaxially disposed between the barrel and the handle for interconnecting the barrel and handle in an aligned relation, to return energy and power to the barrel.

Owner:VAN NGUYEN THU

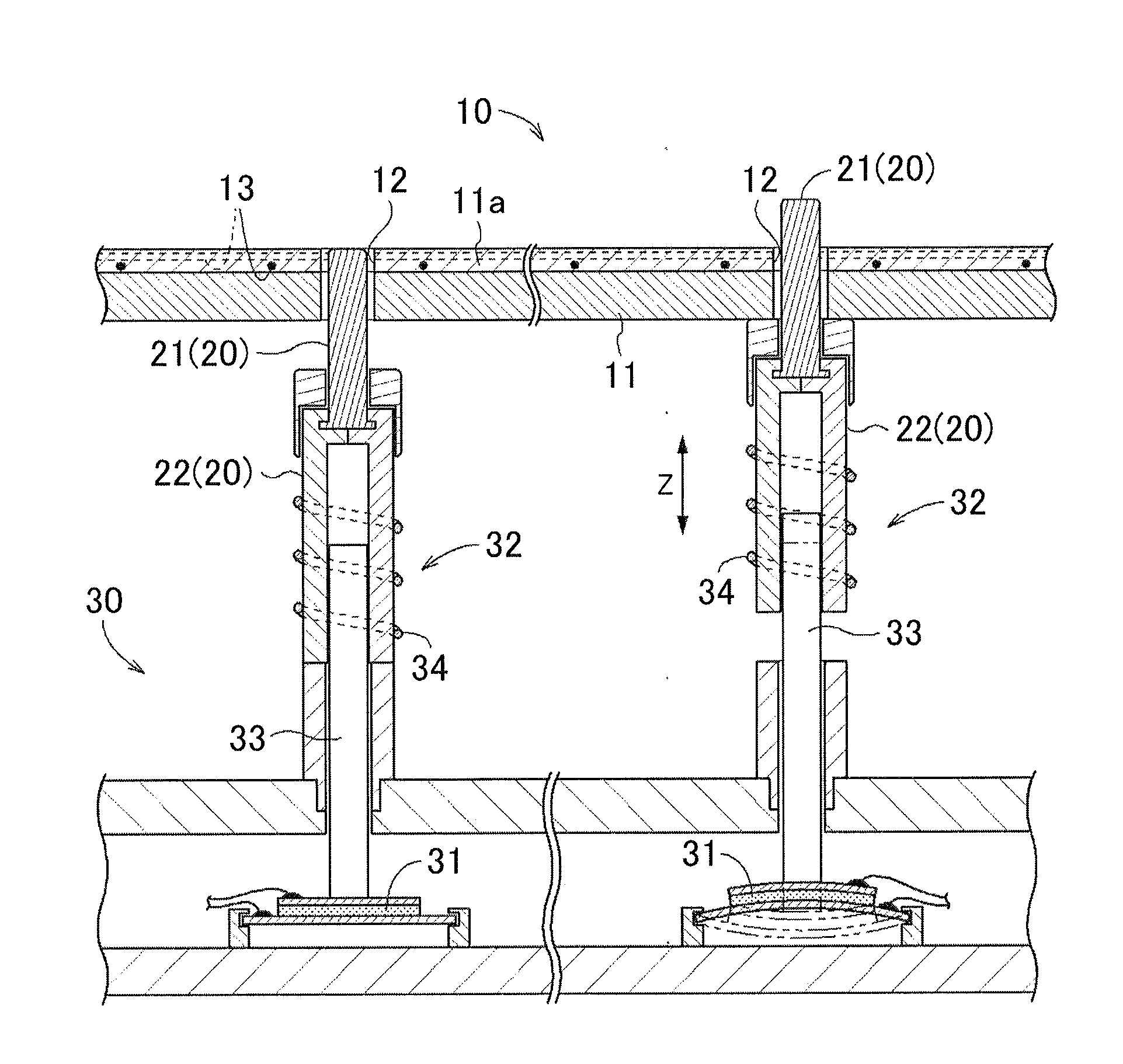

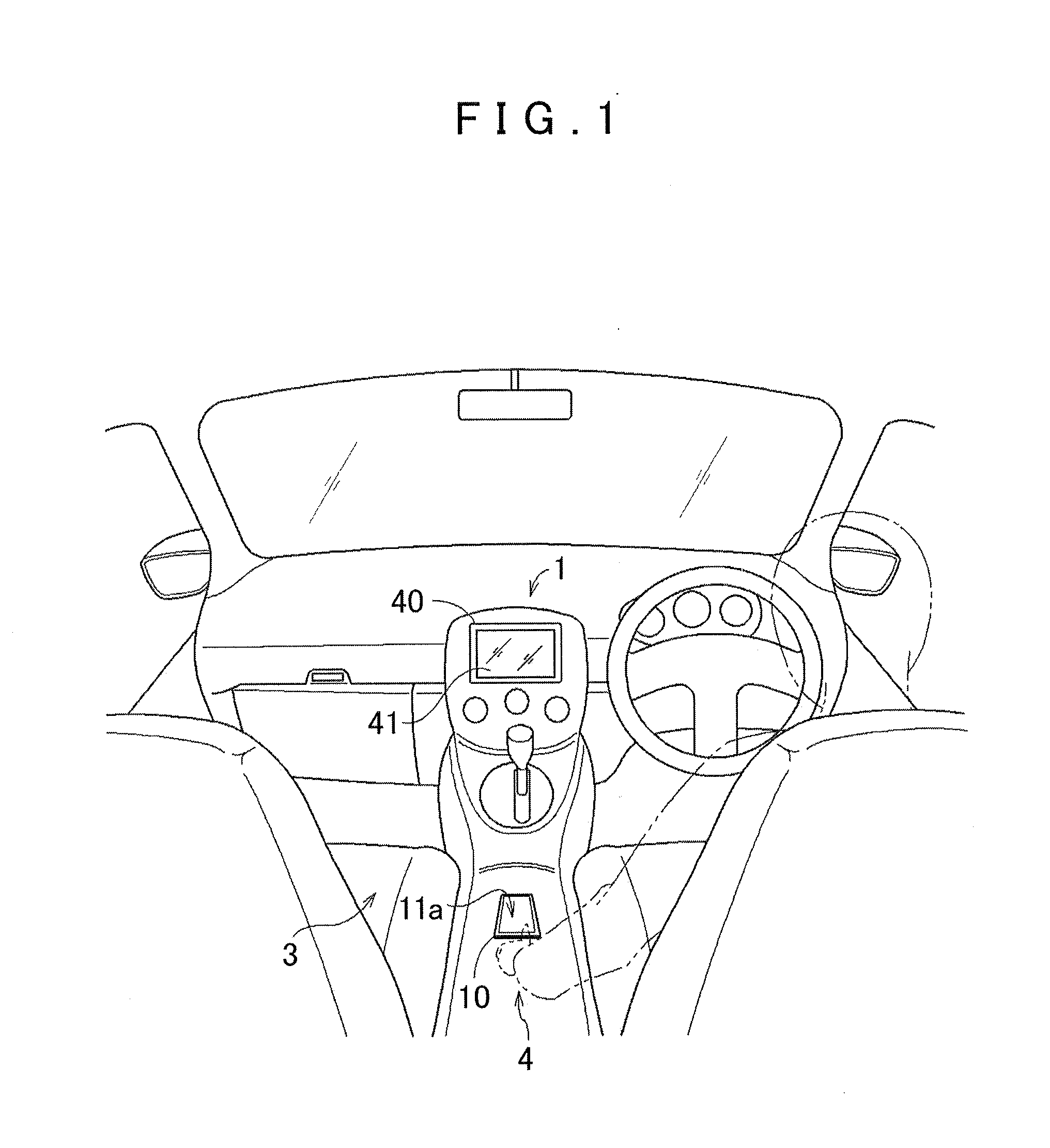

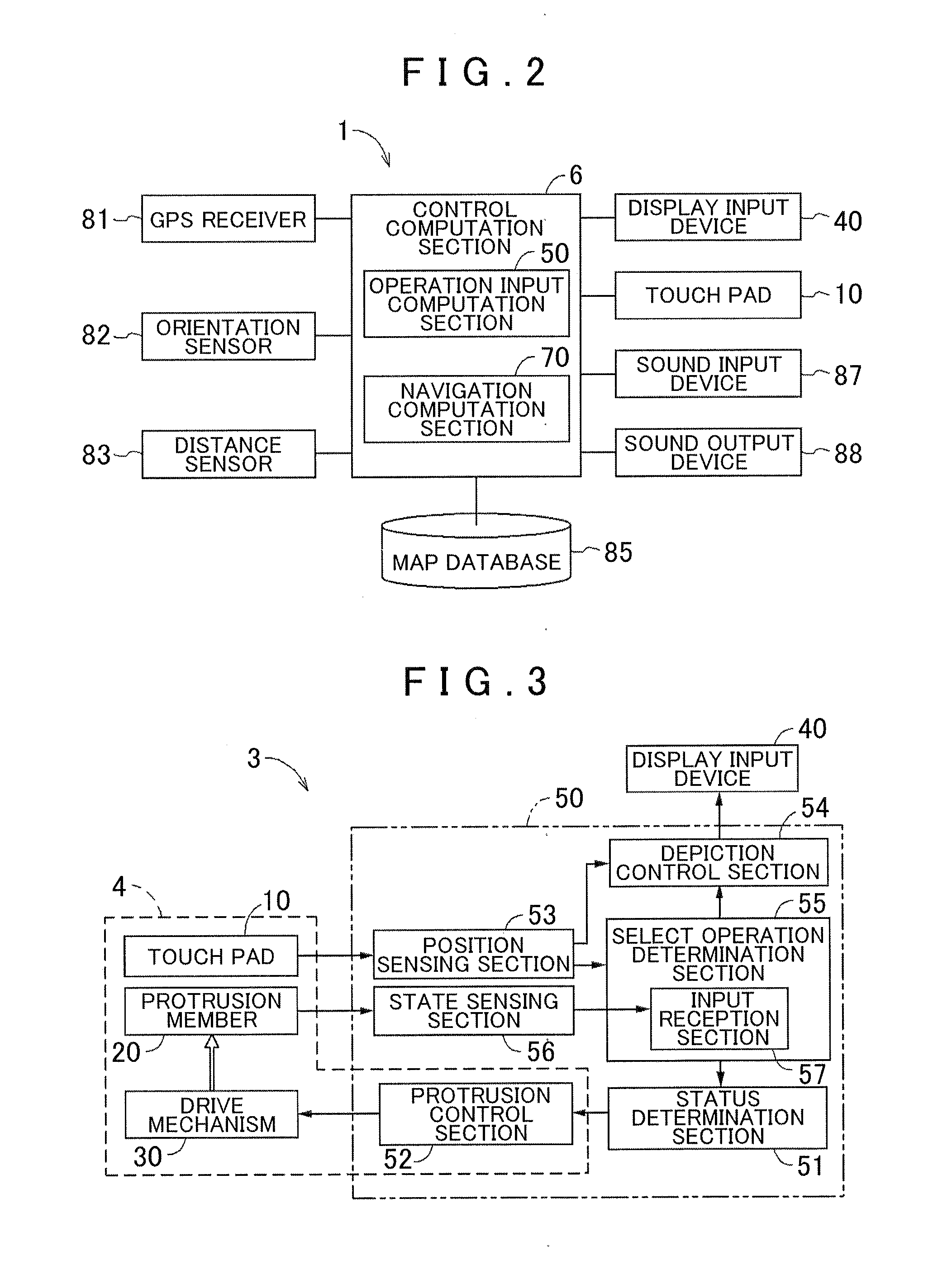

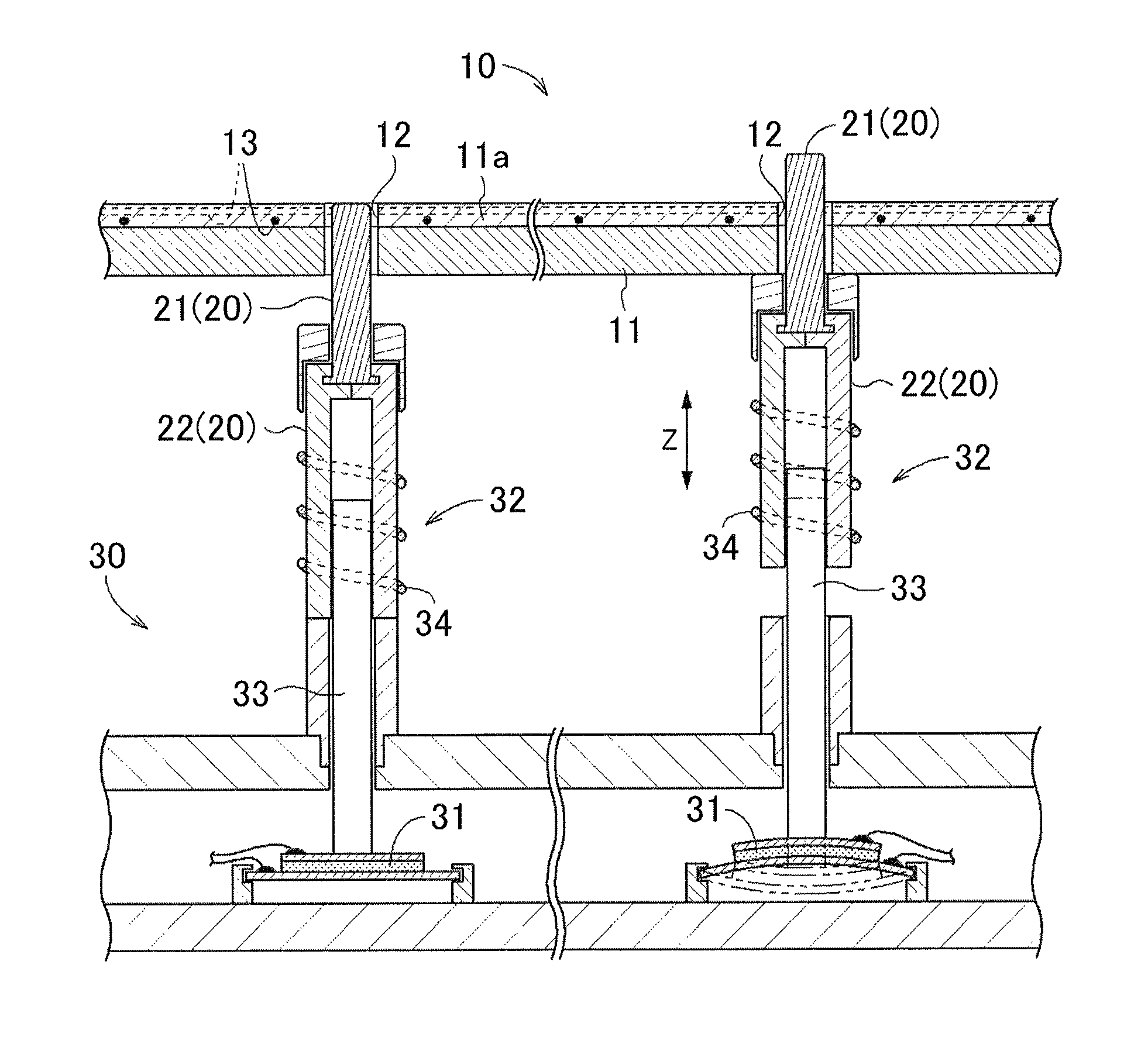

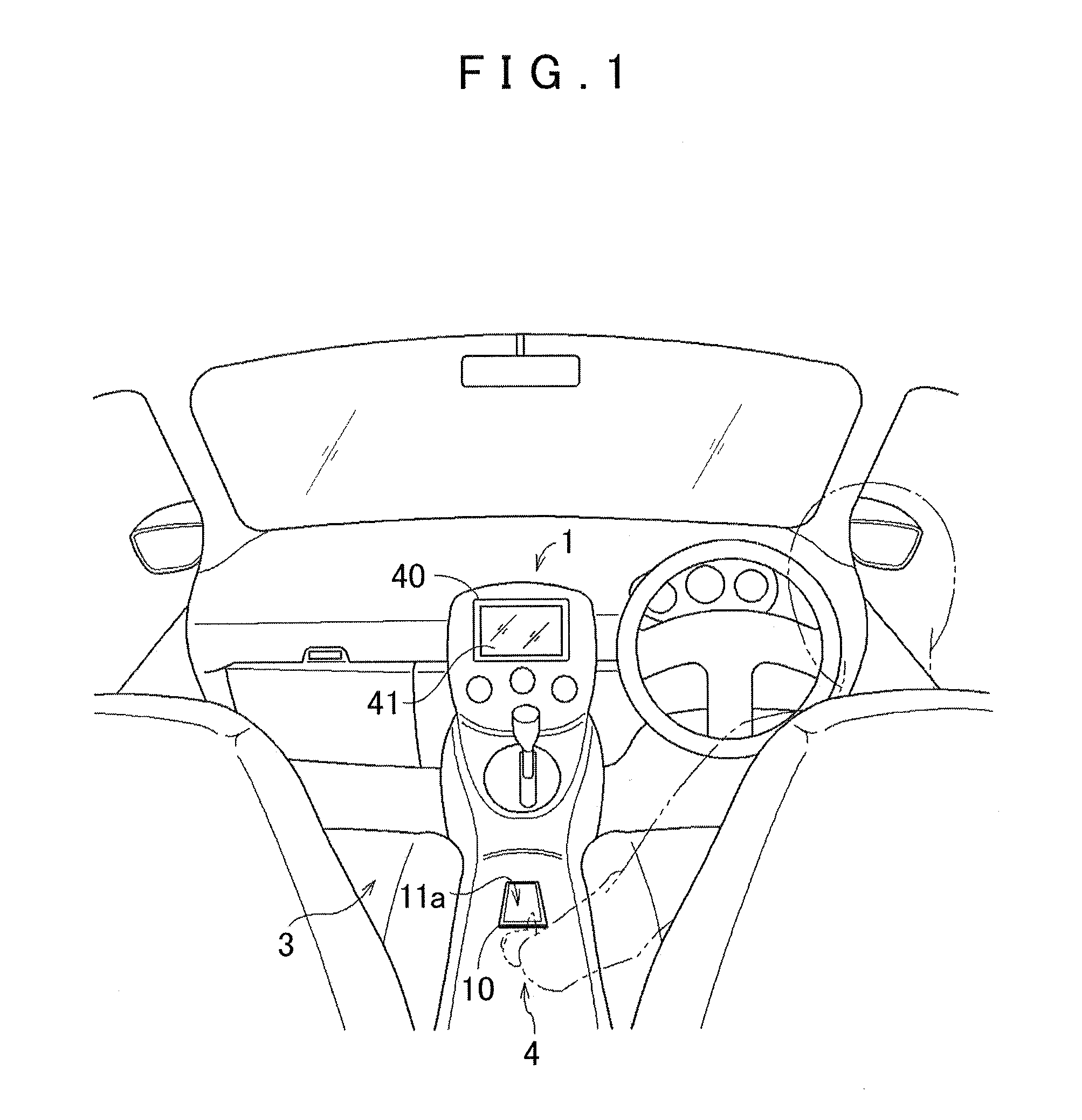

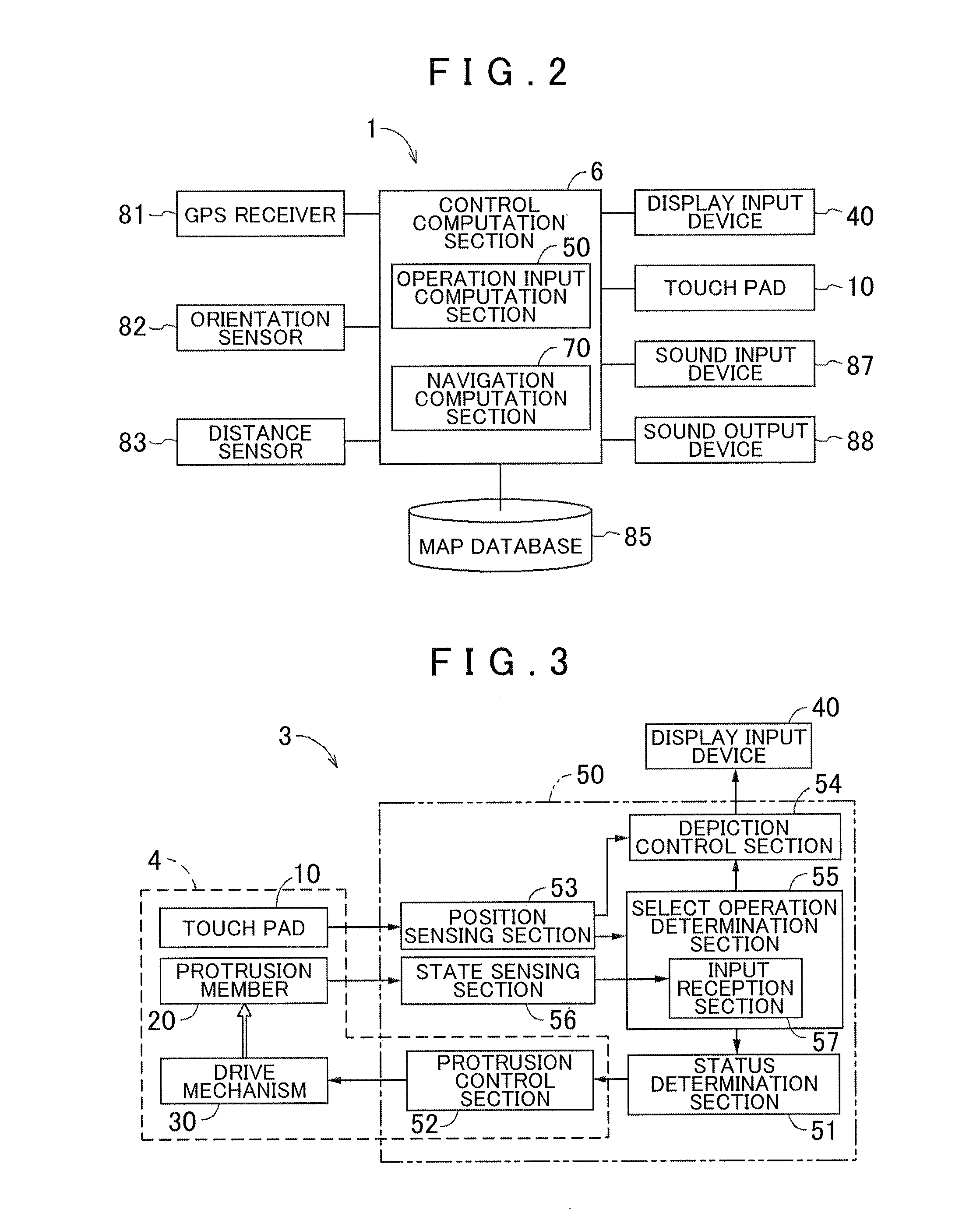

Operation input device

InactiveUS20130161164A1Provide such operationWithout impairing the operation feeling of the touch pad experiencedElectrostrictive/piezoelectric relaysInput/output processes for data processingEngineeringElectrical and Electronics engineering

An operation input device system and method are provided. The operation input device includes a touch pad having an operation plate on a surface of which an operation surface is formed. The touch pad is configured to sense an object in contact with or in proximity to the operation surface to receive input corresponding to a position of the sensed object. A hole portion provided to penetrate through the operation plate and a protrusion member inserted into the hole portion. The operation input device also includes a drive mechanism provided on a back surface side of the operation plate and configured to cause an advancing / retracting operation of the protrusion member along a direction intersecting the operation surface between a first state in which a distal end portion of the protrusion member is above the operation surface and a second state in which the distal end portion is not above the operation surface.

Owner:AISIN AW CO LTD

Operation input device

InactiveUS9064663B2Without impairing the operation feeling of the touch pad experiencedProcess stabilityPiezoelectric/electrostrictive devicesElectrostrictive/piezoelectric relaysElectrical and Electronics engineeringInput device

An operation input device system and method are provided. The operation input device includes a touch pad having an operation plate on a surface of which an operation surface is formed. The touch pad is configured to sense an object in contact with or in proximity to the operation surface to receive input corresponding to a position of the sensed object. A hole portion provided to penetrate through the operation plate and a protrusion member inserted into the hole portion. The operation input device also includes a drive mechanism provided on a back surface side of the operation plate and configured to cause an advancing / retracting operation of the protrusion member along a direction intersecting the operation surface between a first state in which a distal end portion of the protrusion member is above the operation surface and a second state in which the distal end portion is not above the operation surface.

Owner:AISIN AW CO LTD

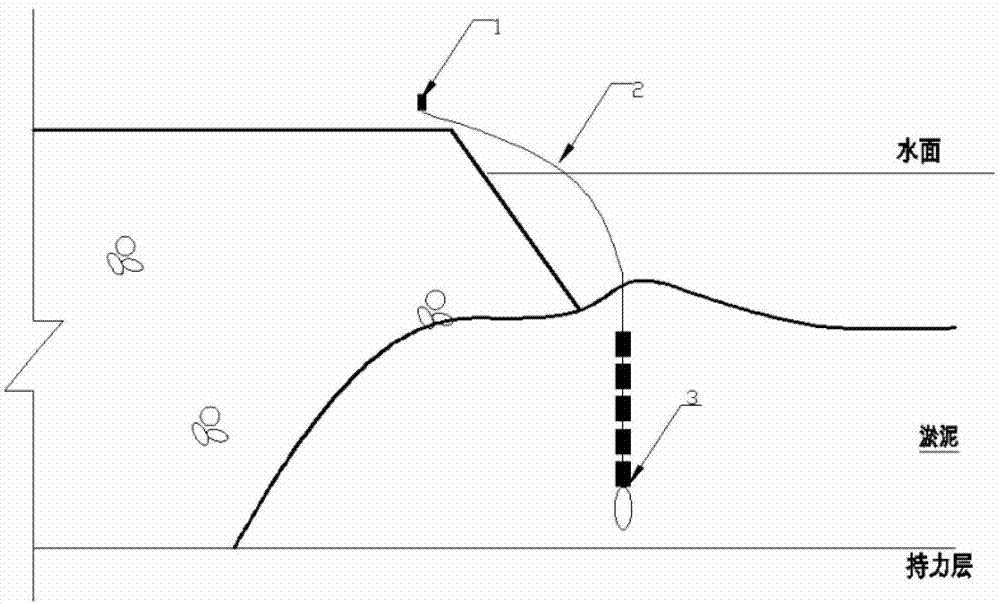

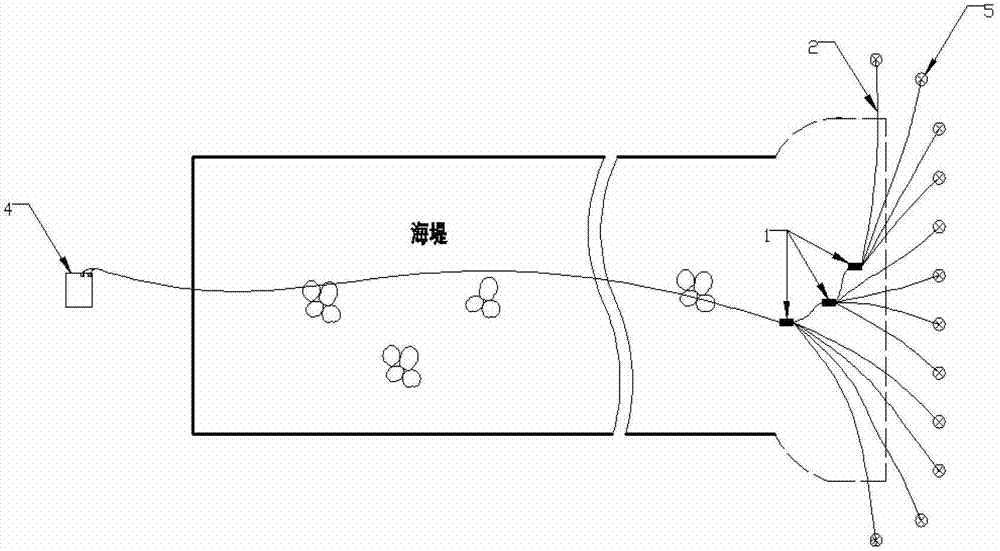

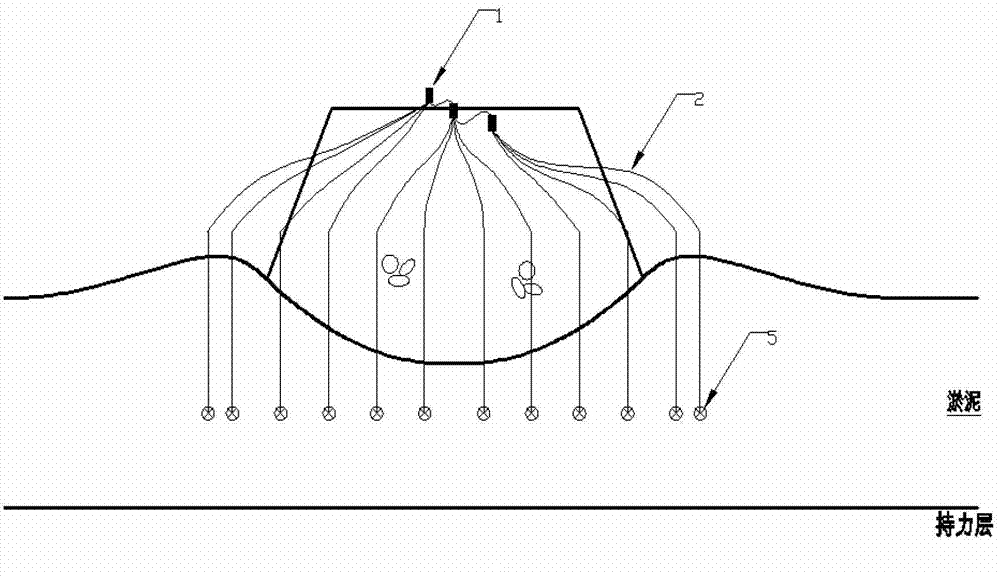

Environment protection explosion squeezing silting embanking method

ActiveCN103114597ADetonation shock speed reducedExtended propagation timeBlastingEmbankmentsShortest distanceEngineering

The invention discloses an environment protection explosion squeezing silting embanking method. Explosives inside each hole of explosive bags are divided into a plurality of evenly separated explosives in the order from top to bottom. An air cushion layer is fixedly arranged at the bottom of a section of explosives at the bottom layer, and the mode of blowing up the explosive bags sequentially in sections is adopted in a combination mode. The environment protection explosion squeezing embanking method has the advantages of being capable of buffering and wakening intense earthquake waves, high-pressure impact waves and high-decibel noises generated by the explosion in a short distances, being wider in application range, and capable of being used in areas with higher environment protection requirements like an cultivation area, an area near neighborhood and the like.

Owner:宁波高新区围海工程技术开发有限公司

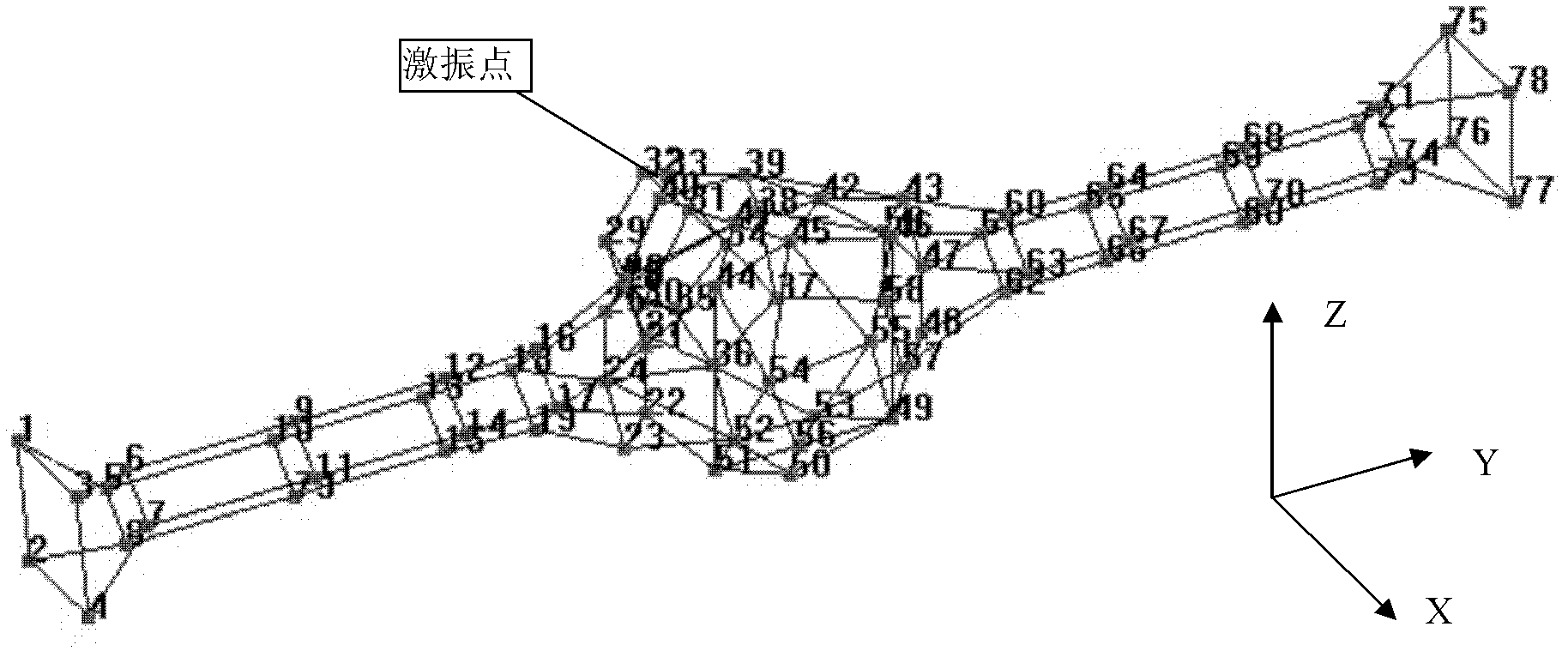

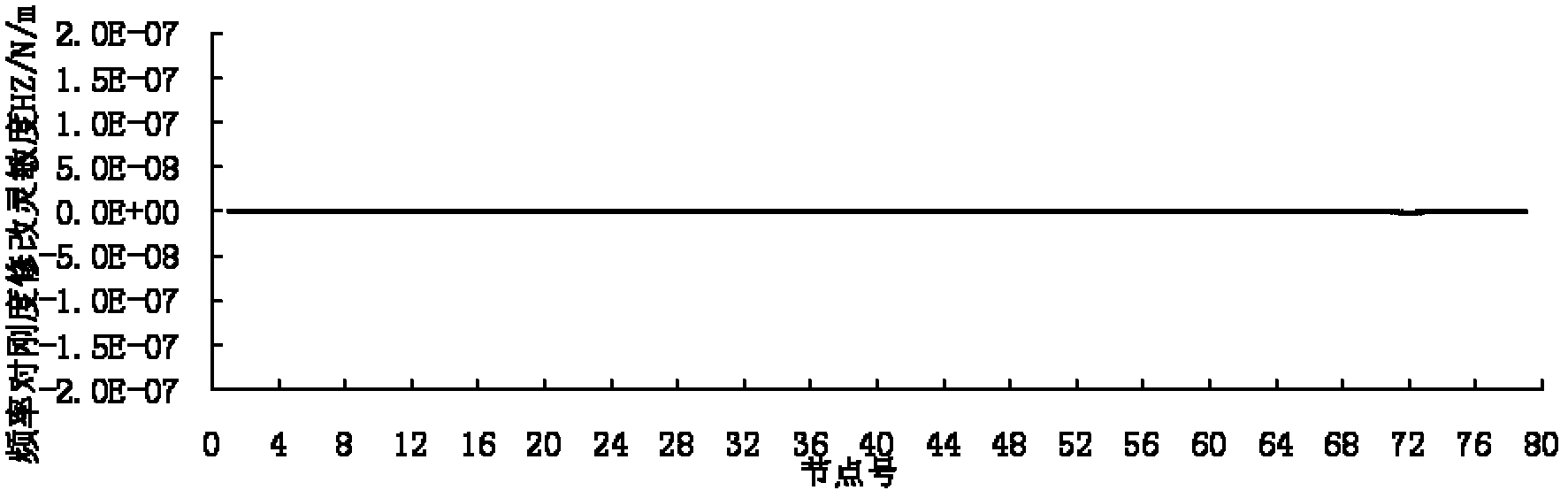

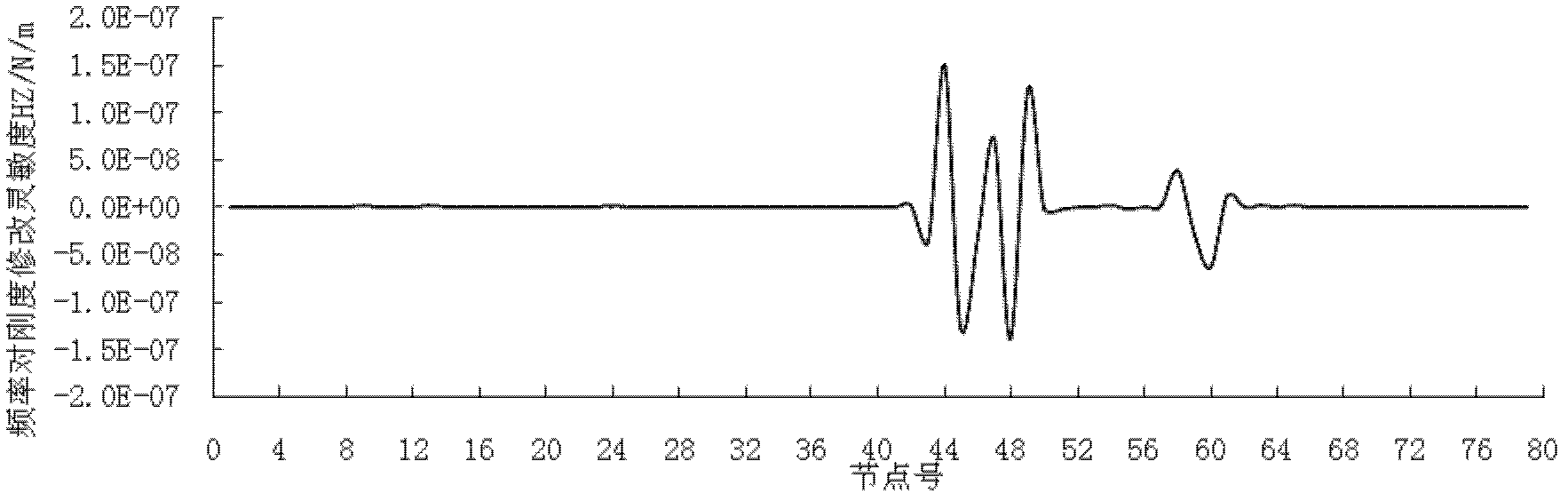

Design method for rear drive axle of micro-surface automobile with low noise

InactiveCN102221402AReduce vibration accelerationReduce noiseSubsonic/sonic/ultrasonic wave measurementVehicle suspension/damping testingLow noiseEngineering

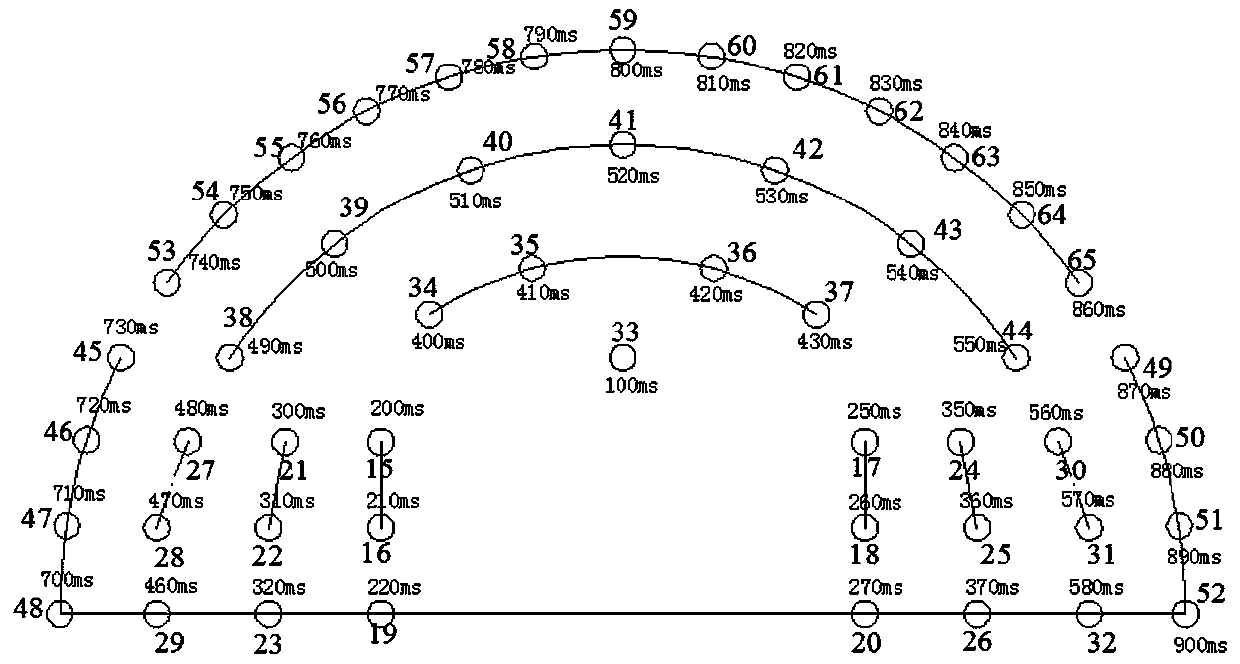

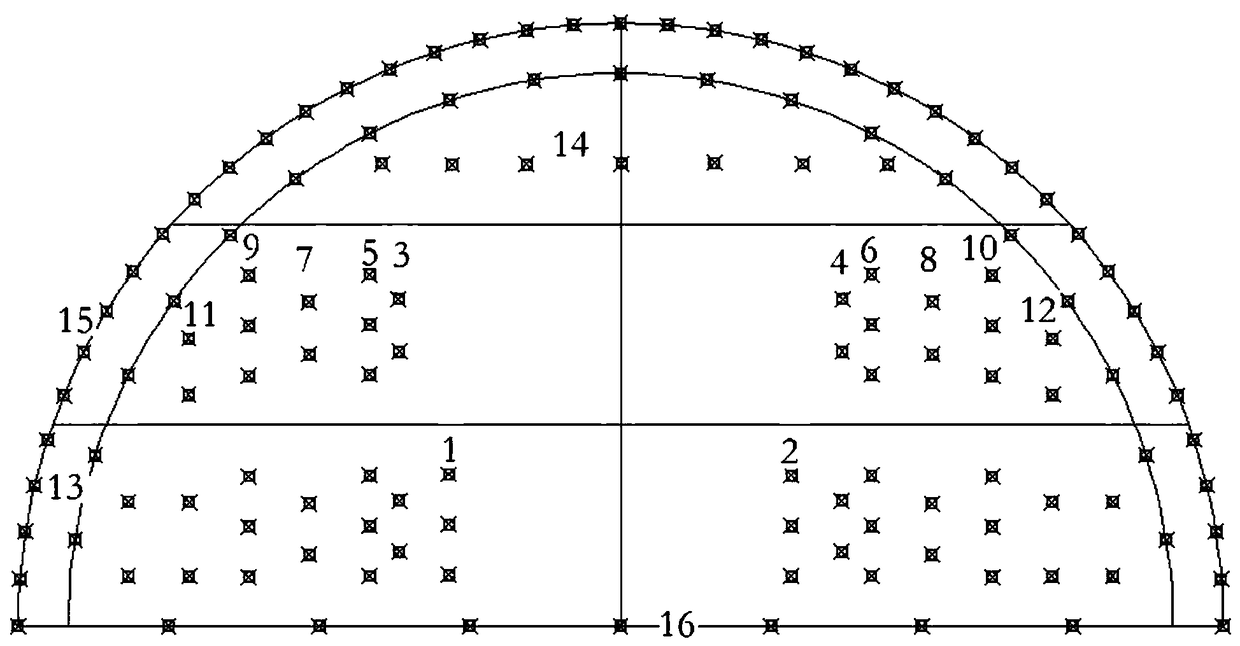

The invention discloses a design method for the rear drive axle of a micro-surface automobile with low noise, wherein 80 vibration measuring points are uniformly arranged on the shell of the rear axle; each vibration measuring point is provided with a vibration sensor which is forcefully beaten at the right upper part of the main reduction part of the rear axle to apply excitation; the vibration data of each vibration measuring point are obtained by utilizing the vibration sensors; the transfer functions between the vibration response and knocking force signals of each vibration measuring point are solved, thereby obtaining the total transfer functions of the rear drive axle; the modal fitting and the mass unification are carried out by utilizing the total transfer functions and combiningthe structural model of the rear drive axle, thereby identifying the modal parameters of the rear drive axle; the sensitivity data of the natural frequency of each vibration measuring point on rigidness corresponding to the selected order are drawn by utilizing a test modal analysis technique; and a welding metal block with the multiple vibration measuring points is selected according to the sensitivity curve, thereby finishing the noise reduction optimization of the rear drive axle. The design method disclosed by the invention can solve the problem that the vibration noise of the rear drive axle of the micro-surface automobile is overlarge to influence the NVH (noise, vibration and harshness) of the automobile.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

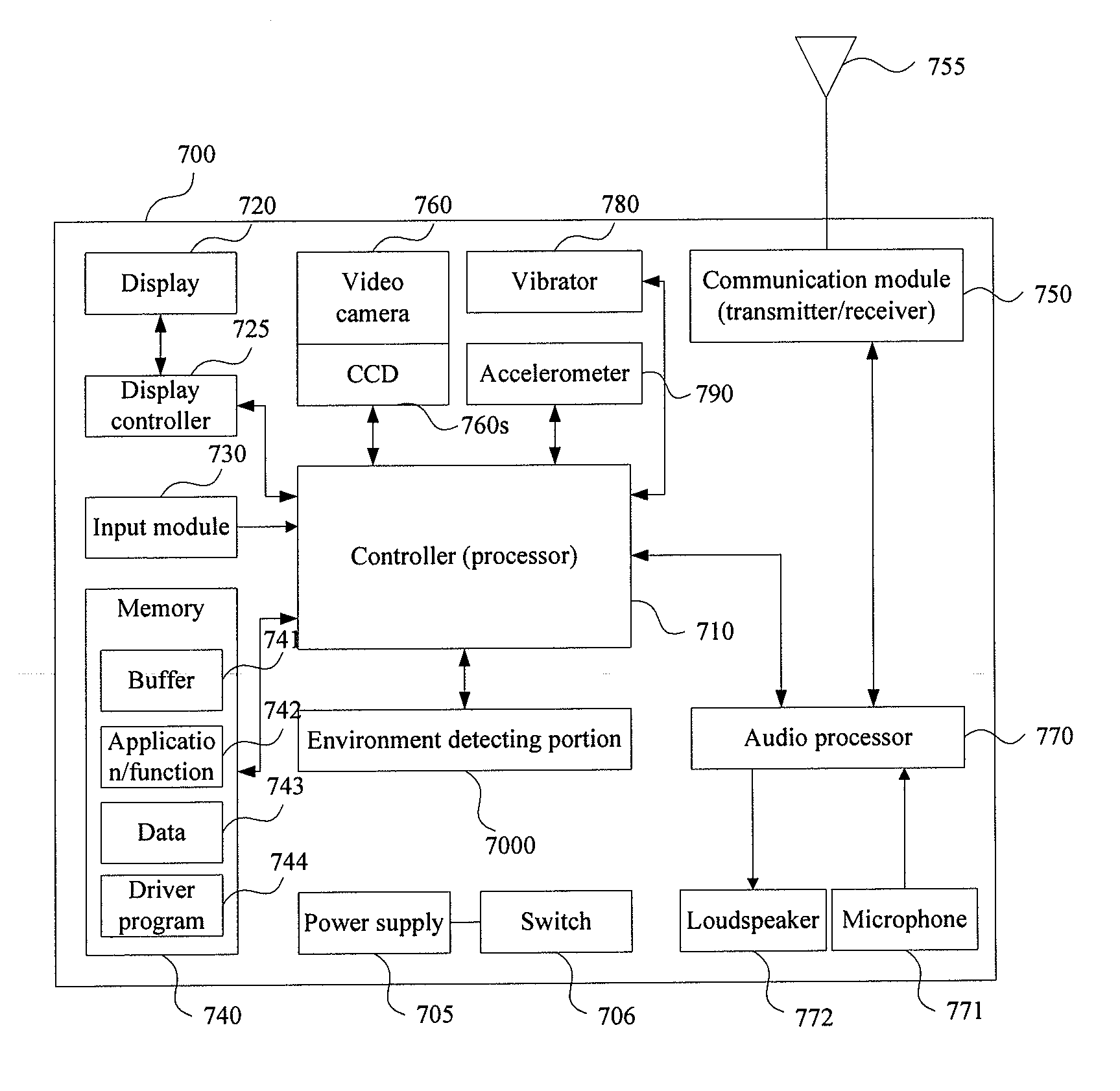

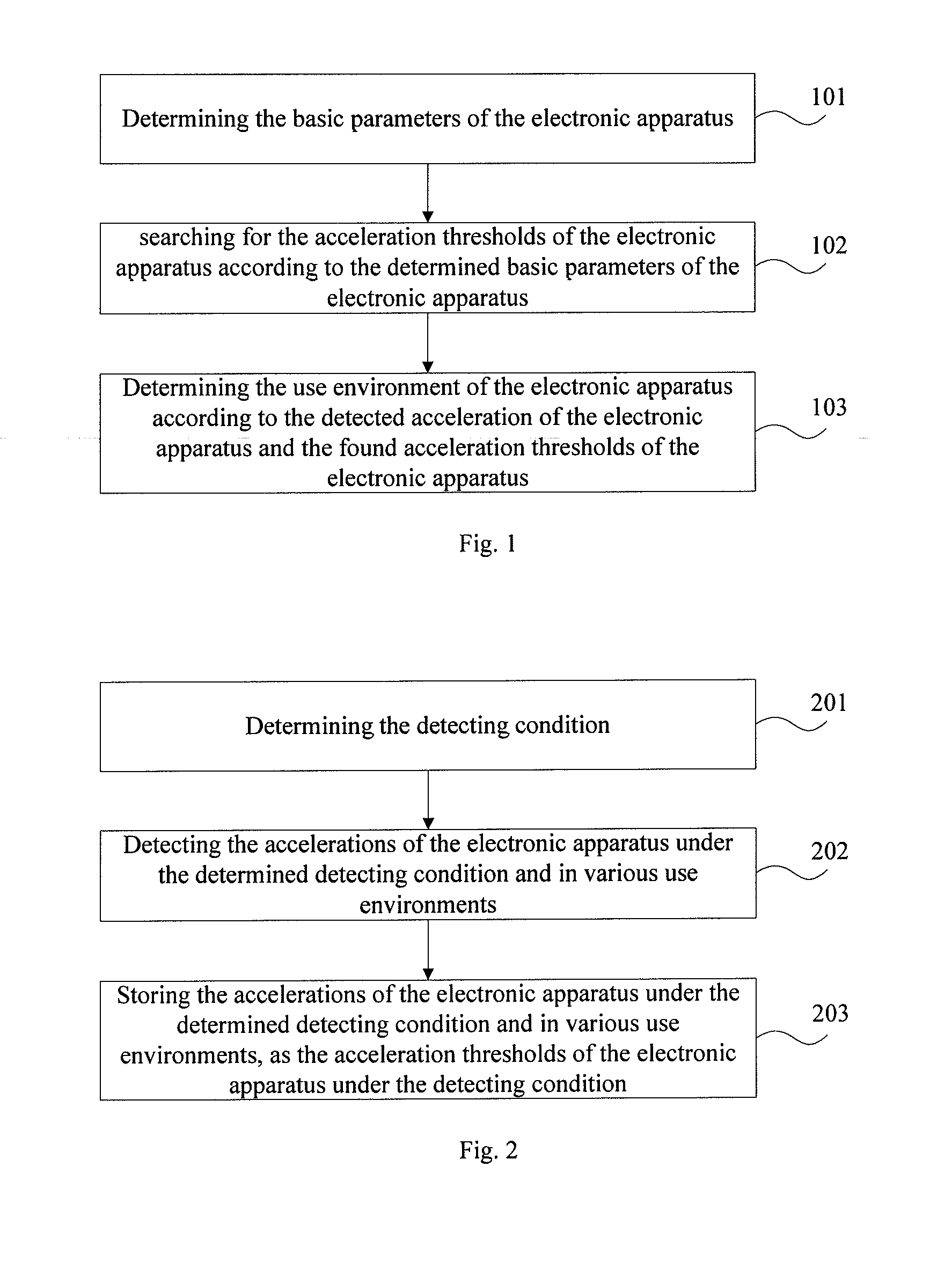

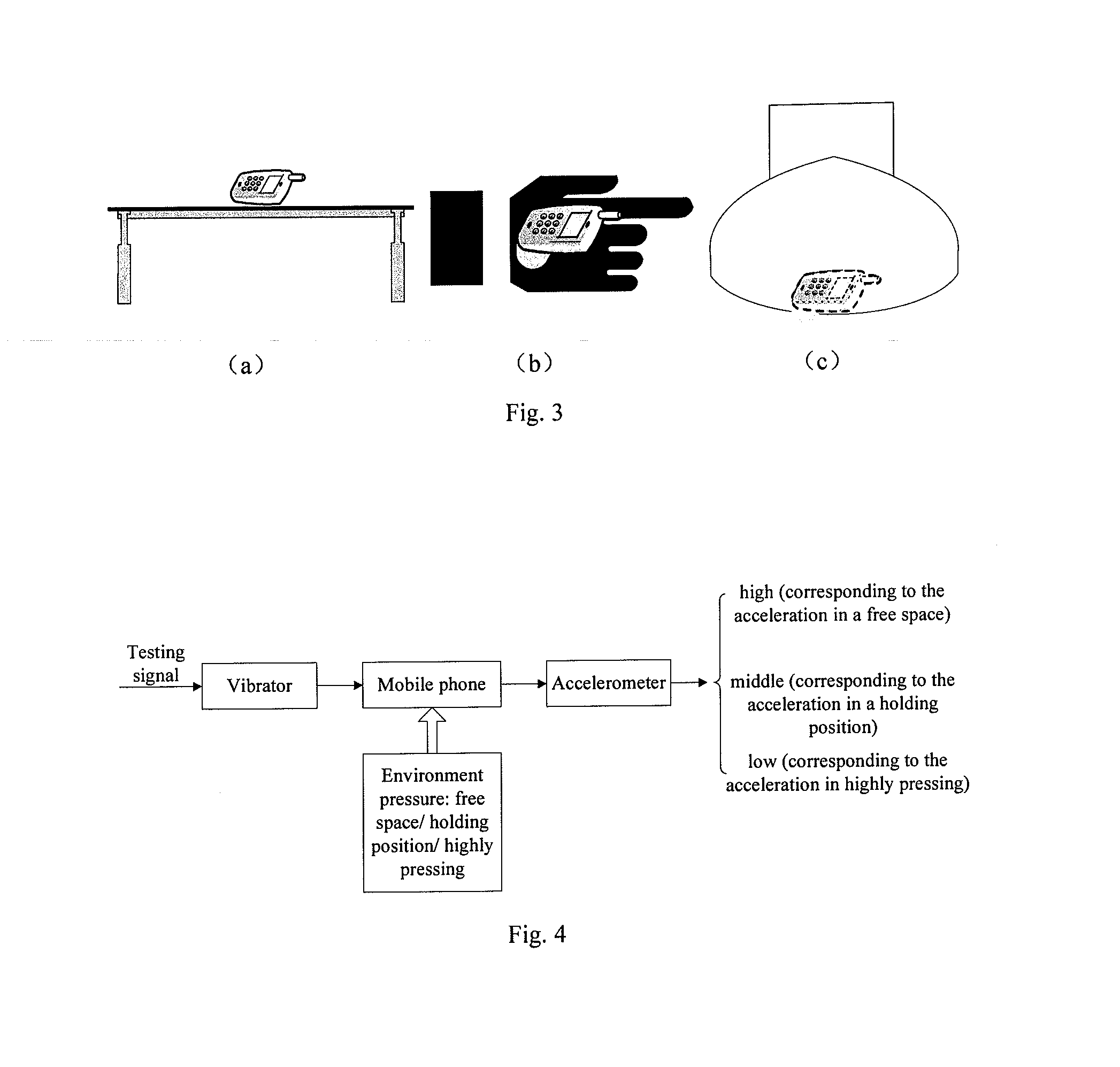

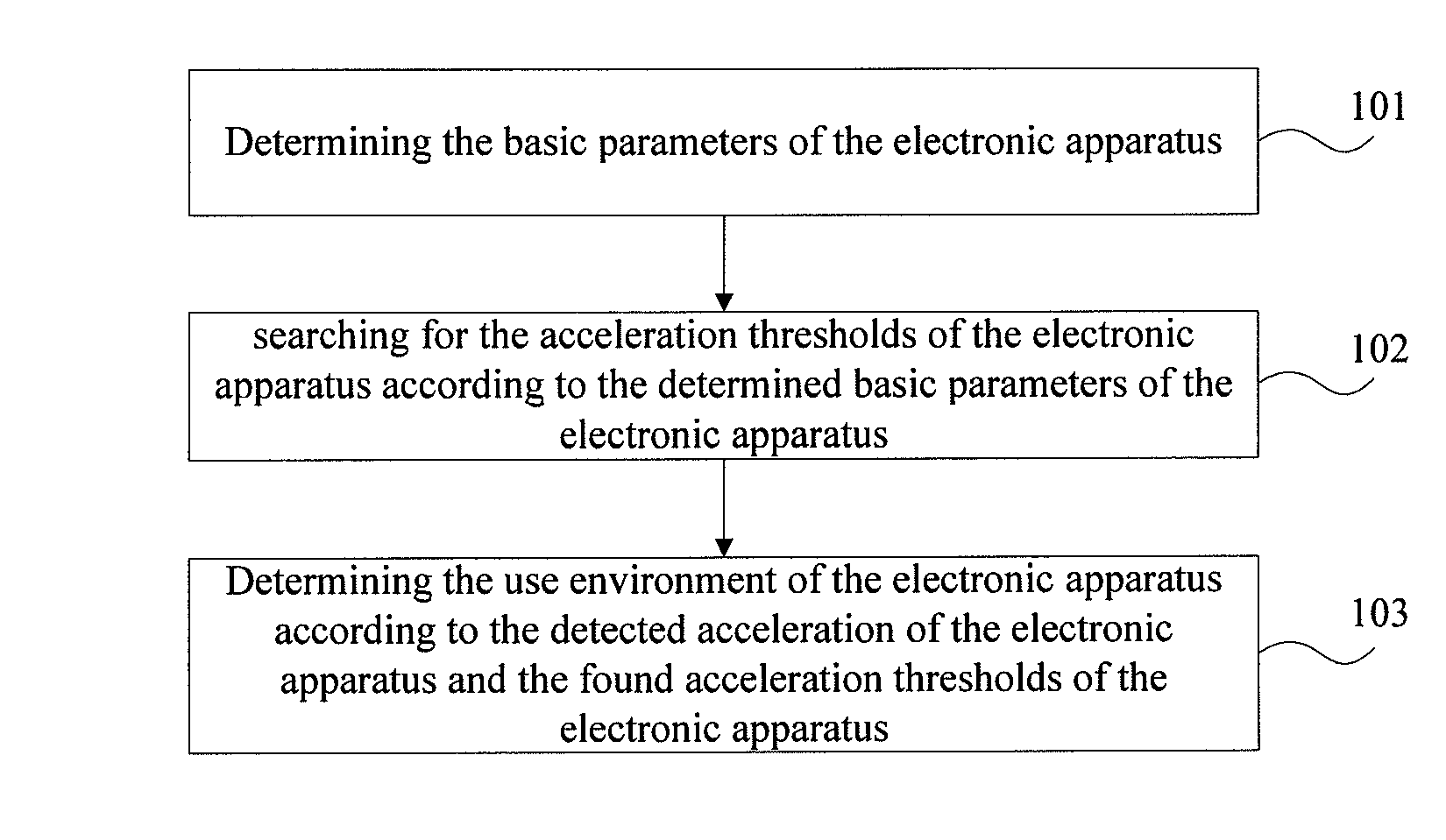

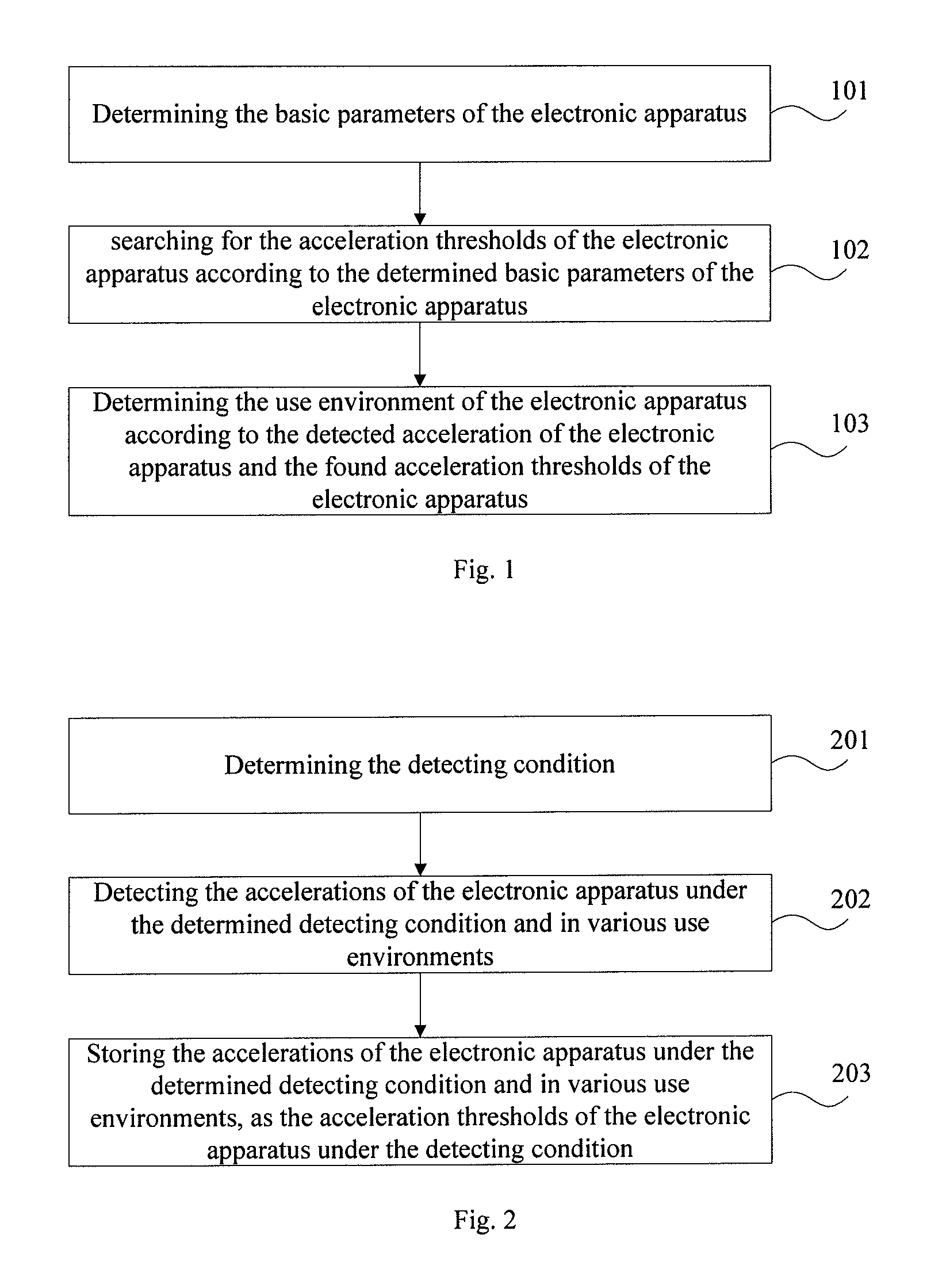

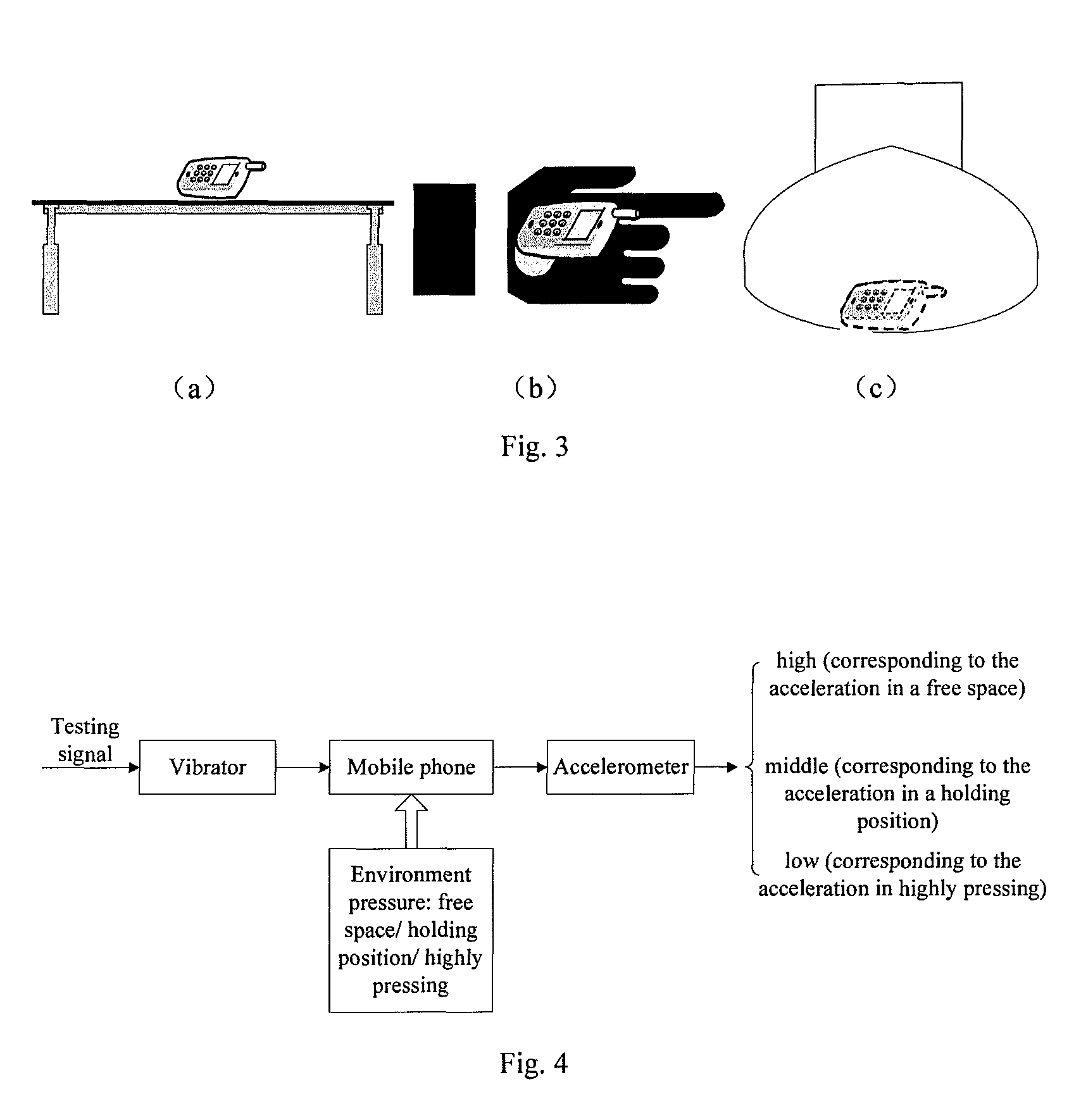

Electronic apparatus use environment detecting method, electronic apparatus performance optimizing method and electronic apparatus

ActiveUS20120227486A1Shorten speedReduce volumeDevices with sensorAcceleration measurementAccelerometerElectric equipment

Apparatus and method use a vibrator and an accelerometer of electronic apparatus for detecting the use environment of the electronic apparatus, and according to the use environment a method and electronic apparatus are provided for optimizing the performance of the electronic apparatus according to the use environment of the electronic apparatus. The method for detecting use environment comprises: determining the basic parameters of the electronic apparatus; searching for the acceleration thresholds of the electronic apparatus according to the determined basic parameters of the electronic apparatus; and determining the use environment according to the detected acceleration of the electronic apparatus and the found acceleration thresholds of the electronic apparatus. The use environment of the electronic apparatus may be detected by the vibrator and accelerometer of the electronic apparatus, thereby optimizing the performance of the electronic apparatus according to the use environment.

Owner:SONY CORP

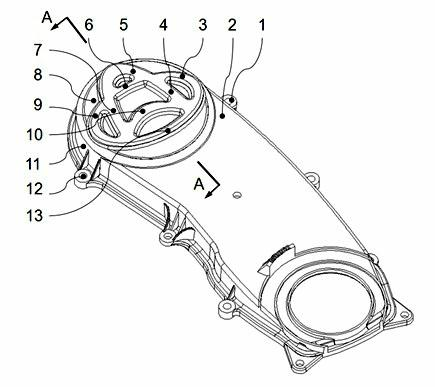

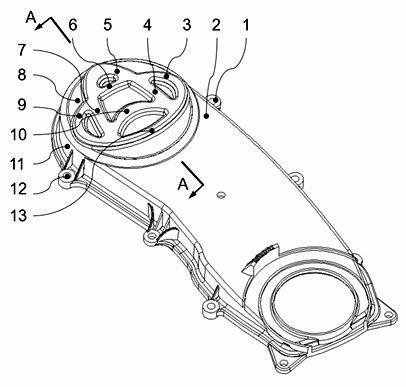

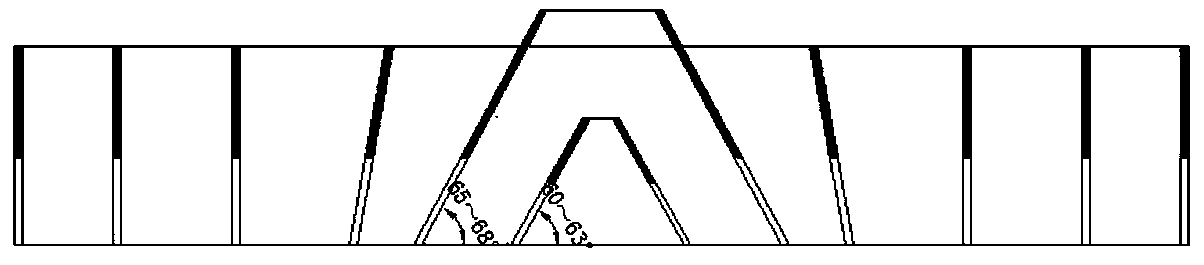

Front shell of vehicle engine

InactiveCN102121429AReduce sound pressure levelIncrease stiffnessCasingsMachines/enginesResonanceEngineering

The invention provides a front shell of a vehicle engine. A circular table board is additionally arranged on the top of the front shell and is provided with reinforcing ribs to form region segmentation, so that the rigidity of the circular table board is enhanced and noise radiation of the surface structure of the front shell is lowered. The reinforcing ribs consist of outer ring reinforcing ribs and inner ring reinforcing ribs, wherein the outer ring reinforcing ribs are connected with the side wall of the front shell; the outer ends of a part of reinforcing ribs are connected with a front shell installation point; and all reinforcing ribs are arranged in an elliptical shape and a letter 'A' shape which are mutually staggered. Due to reasonable arrangement of the reinforcing ribs, a small quantity of materials can be used, the stiffness of the front shell of the engine is enhanced, local modal frequency is improved, the local resonance and surface radiation noise are lowered, and appearance is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

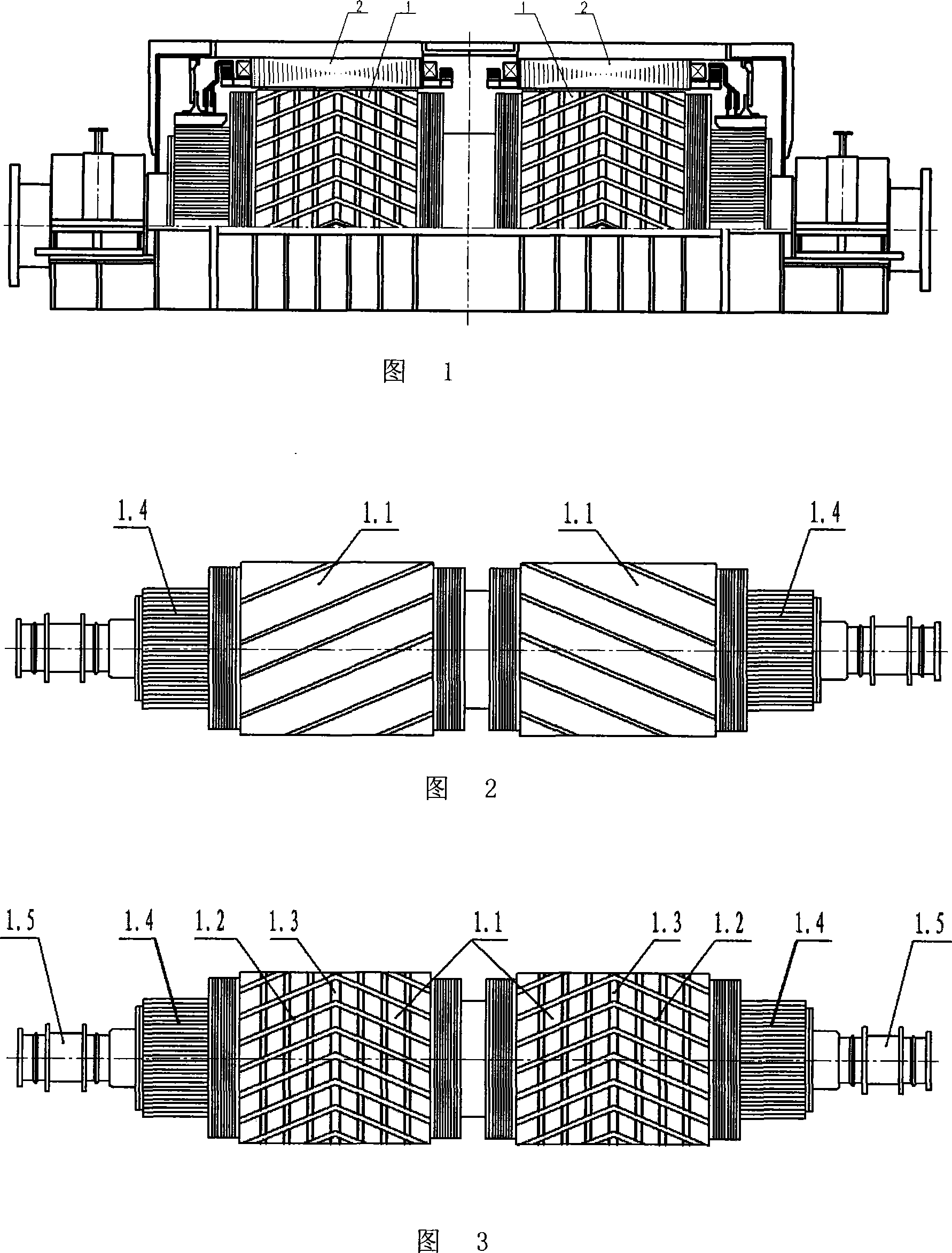

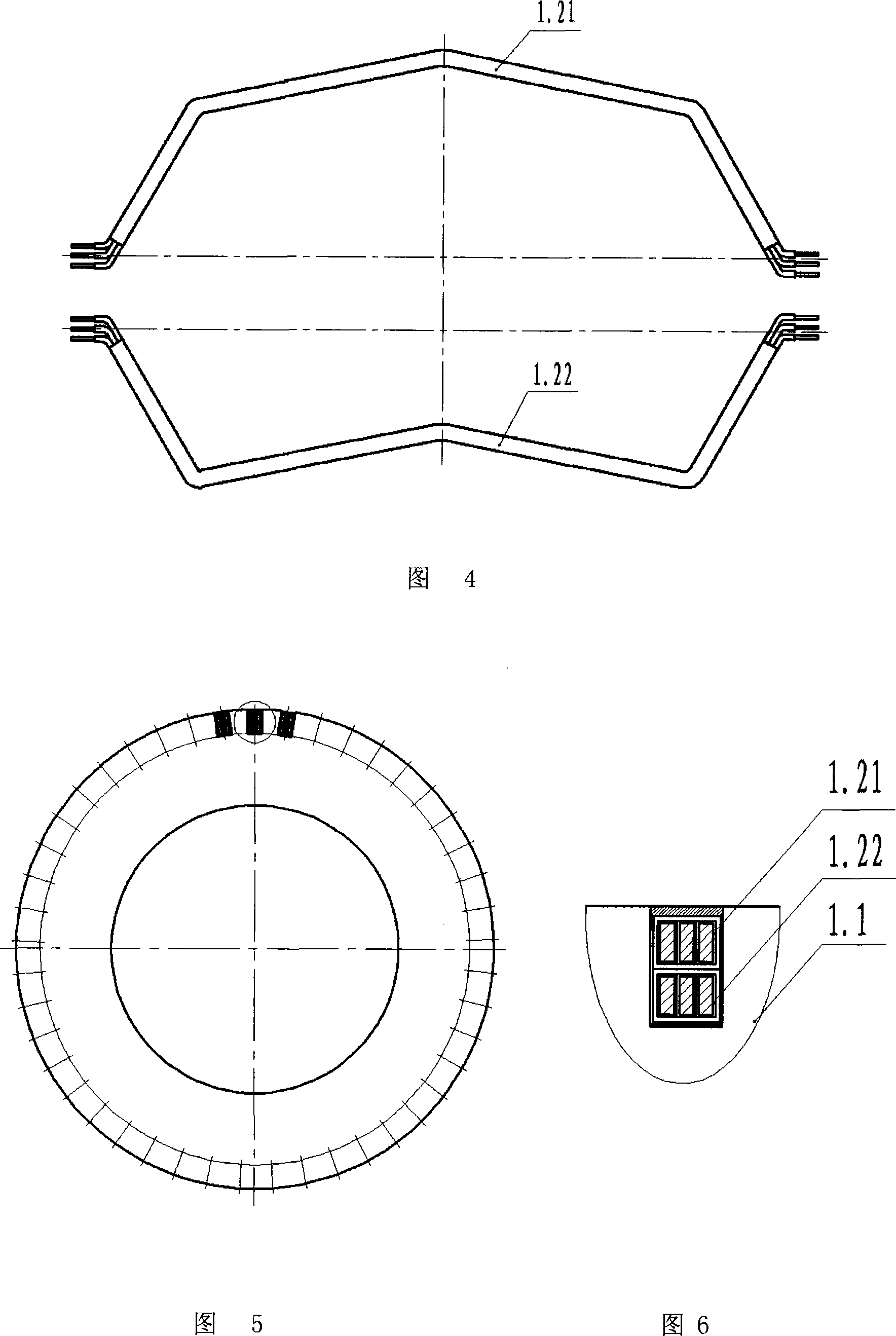

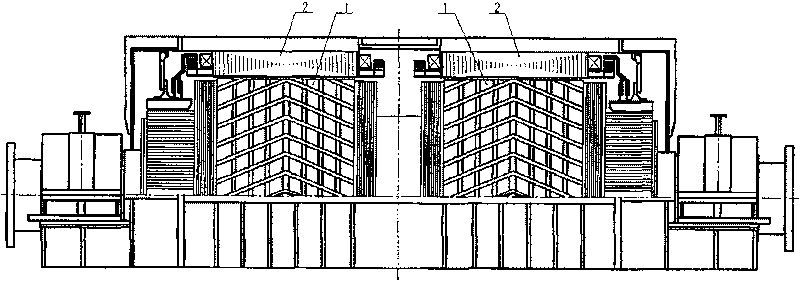

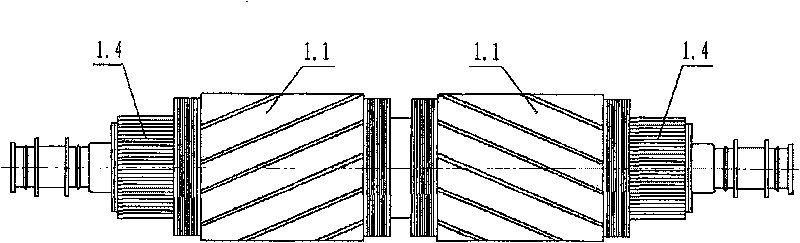

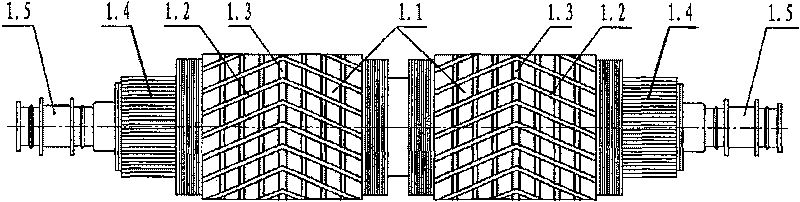

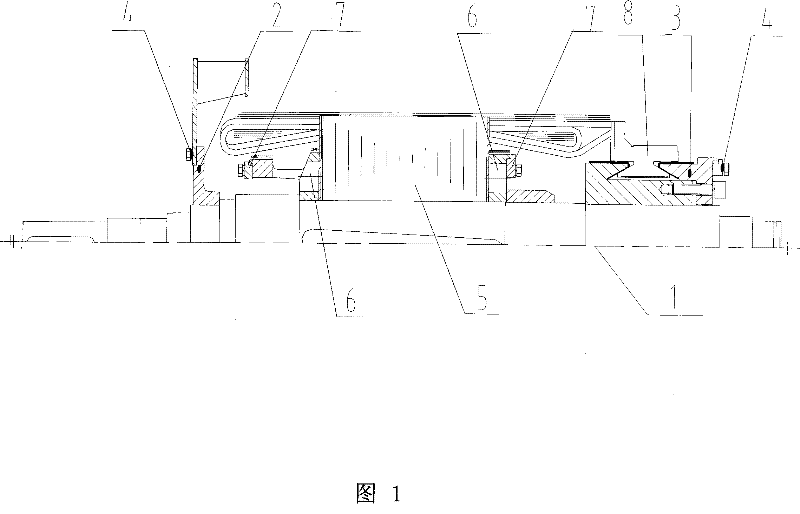

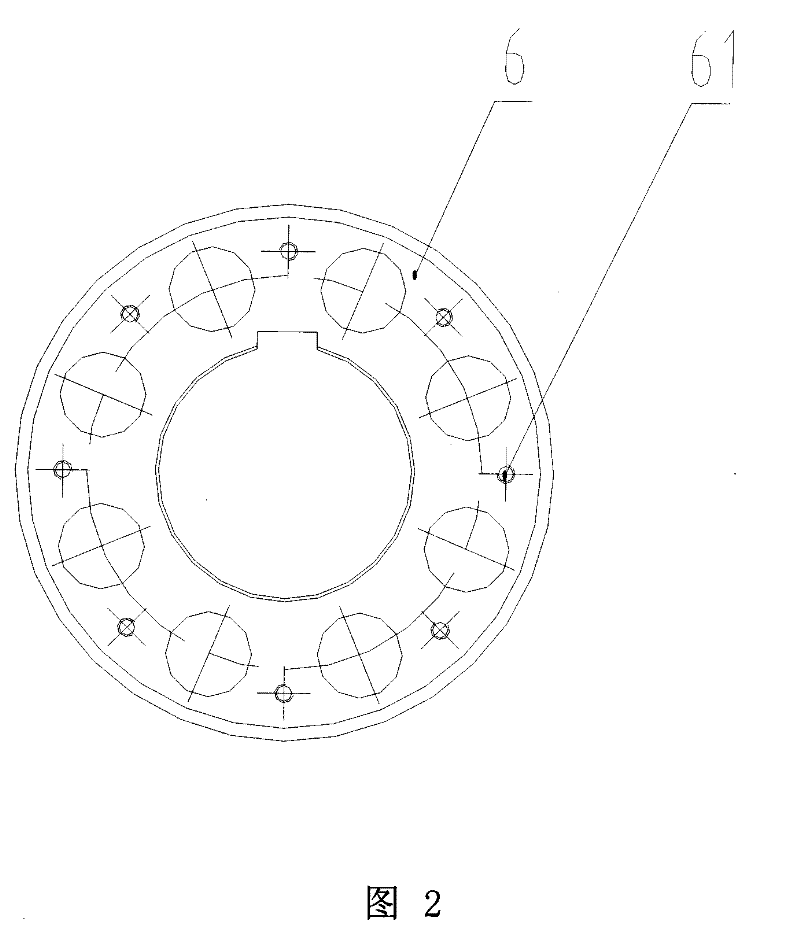

DC propulsion motor

InactiveCN101114790AGood technical effectNormal functioningDC commutatorWorking environmentEngineering

The invention relates to a direct current propulsion motor which belongs to the field of motor technology, which is particularly suitable for the direct current propulsion motor which is used for medium vessel and large vessel. The invention comprises a rotor and a stator, wherein the rotor comprises an armature core, an armature winding, a radical ventilation duct, a commutator and a rotating shaft; the armature winding which is distributed on the external circumference surface of the armature core is inverted 'V'-shaped; the inverted 'V'-shaped armature winding consists of an inverted 'V'-shaped upper coil of winding insulation and an inverted 'V'-shaped lower coil of winding insulation which are both of half-style structure and are embedded into an inverted 'V'-shaped skewed slot of the armature core. The invention has the advantages that: the radial electromagnetic force of the motor is reduced; the amplitude and the vibration noise are reduced; the working environment is improved; the electromagnetic vibration of a whole motor base is reduced; the electromagnetic vibration in the whole speed range of the motor is assuredly promoted to be restricted to the greatest degree; the operation effect is better; and the function is much better exerted.

Owner:中国船舶重工集团公司第七一二研究所

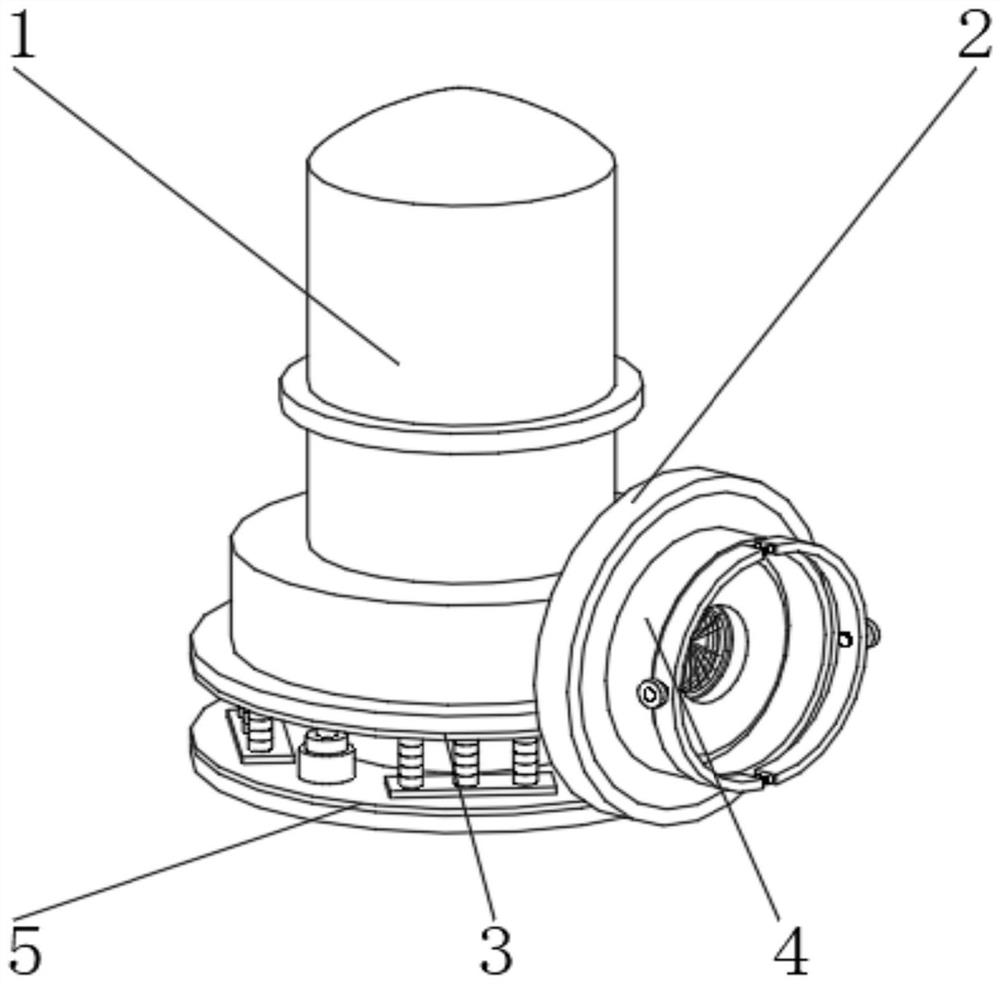

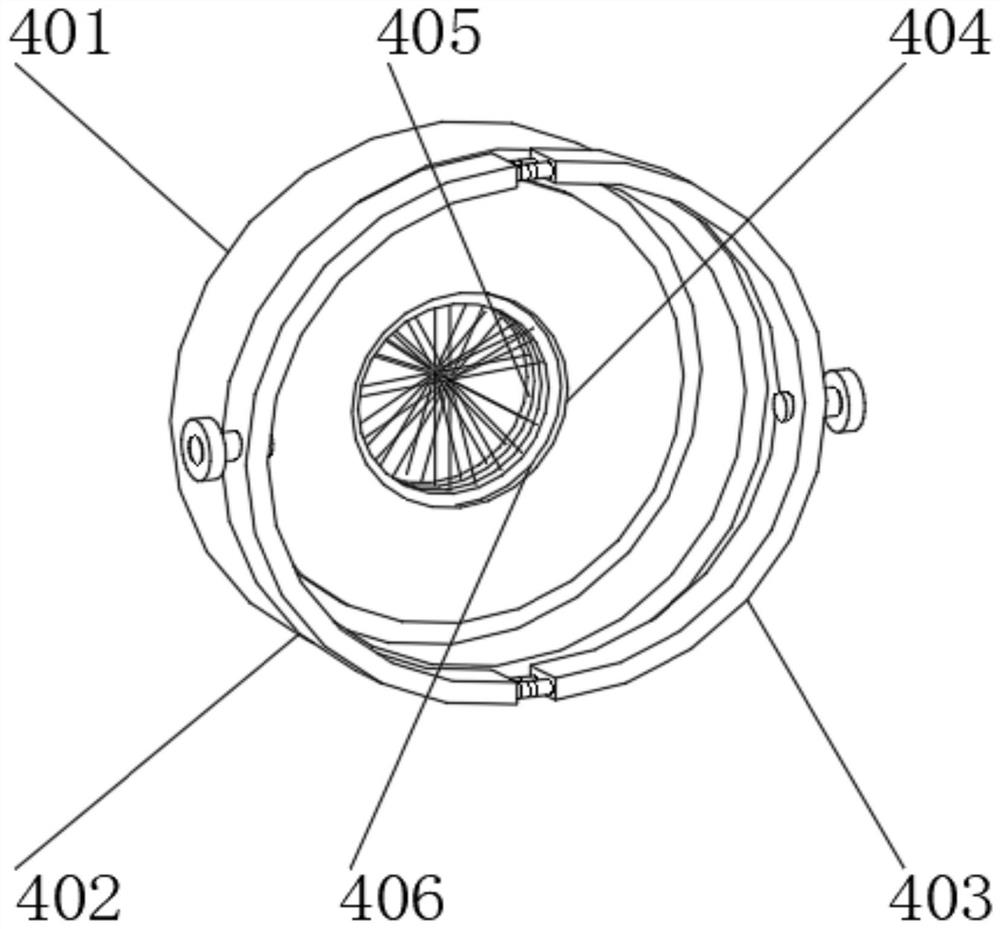

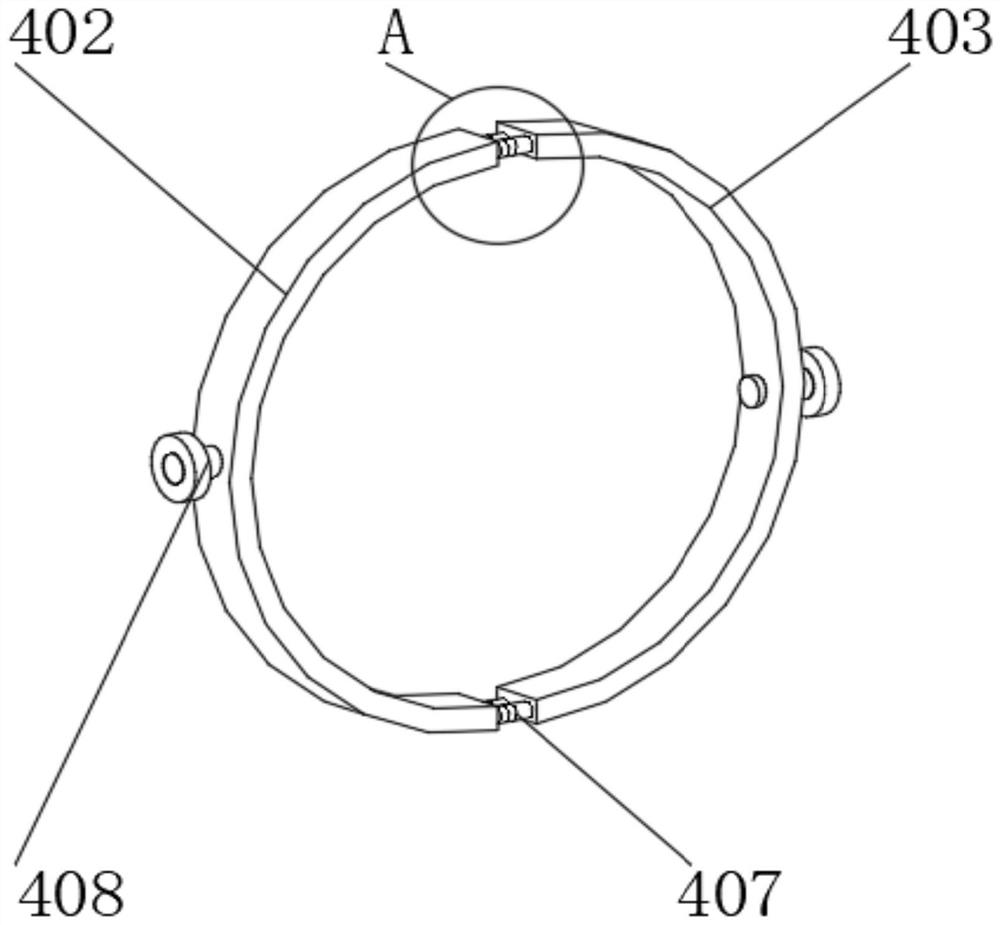

Sewage pump

The invention discloses a sewage pump in the field of sewage pumps, which comprises a pump body, the outer wall of the pump body is fixedly connected with a sewage outlet, the outer surface of the lower end of the pump body is fixedly connected with a chassis, the outer surface of one end of the sewage outlet is fixedly connected with a filtering fixing mechanism, and the outer surface of one end of the chassis is fixedly connected with a damping mechanism. The filtering fixing mechanism comprises a pipeline connecting ring, a first arc-shaped ring, a second arc-shaped ring, a connecting opening, a first filter screen, a second filter screen, a first spring and a fixing assembly, wherein the first arc-shaped ring and the second arc-shaped ring are located on the outer wall of the pipeline connecting ring, and the connecting opening is located in the middle of the pipeline connecting ring; the first filter screen and the second filter screen are located on the inner wall of the connecting opening. The pipeline is stably connected with the sewage outlet, installation and fixation are not limited, and impurities in sewage can be filtered, so that the pipeline is prevented from being blocked, and the drainage efficiency is improved; according to the arrangement, the damping performance is good, large noise cannot be generated, and shaking is not prone to occurring.

Owner:YANGZHOU HONGYUE MECHANICAL CO LTD

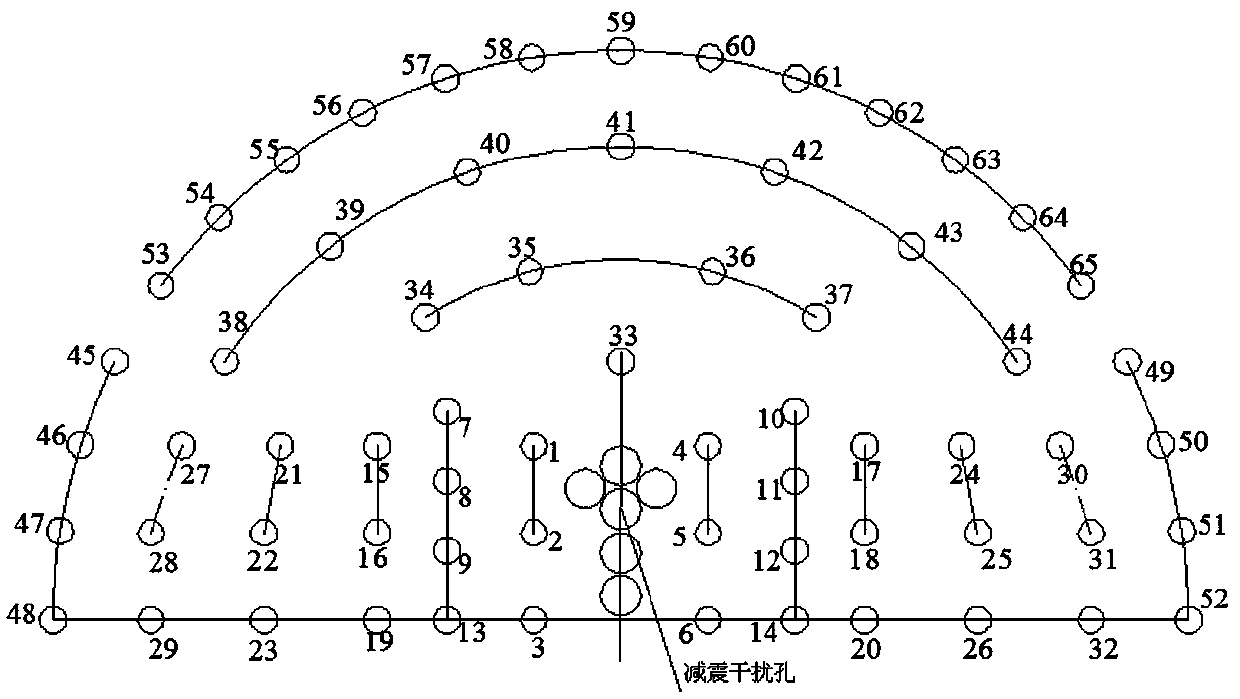

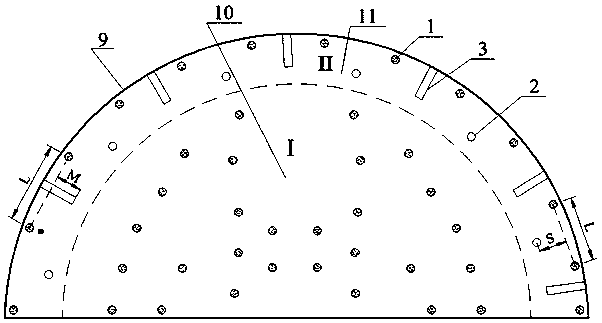

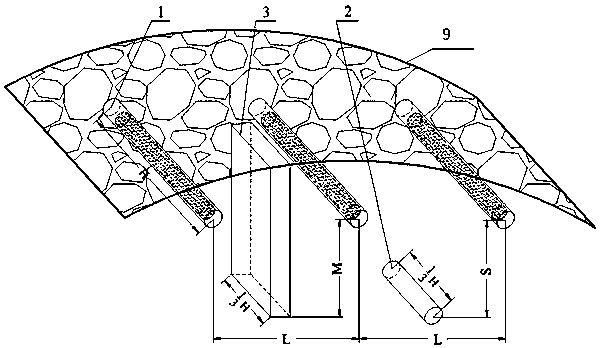

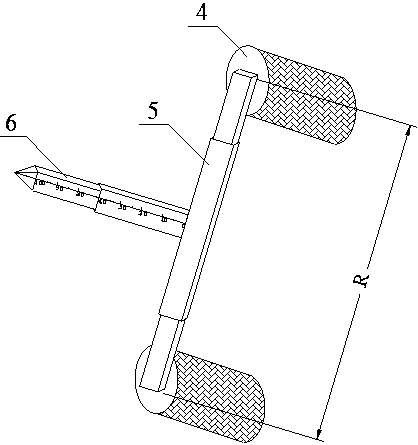

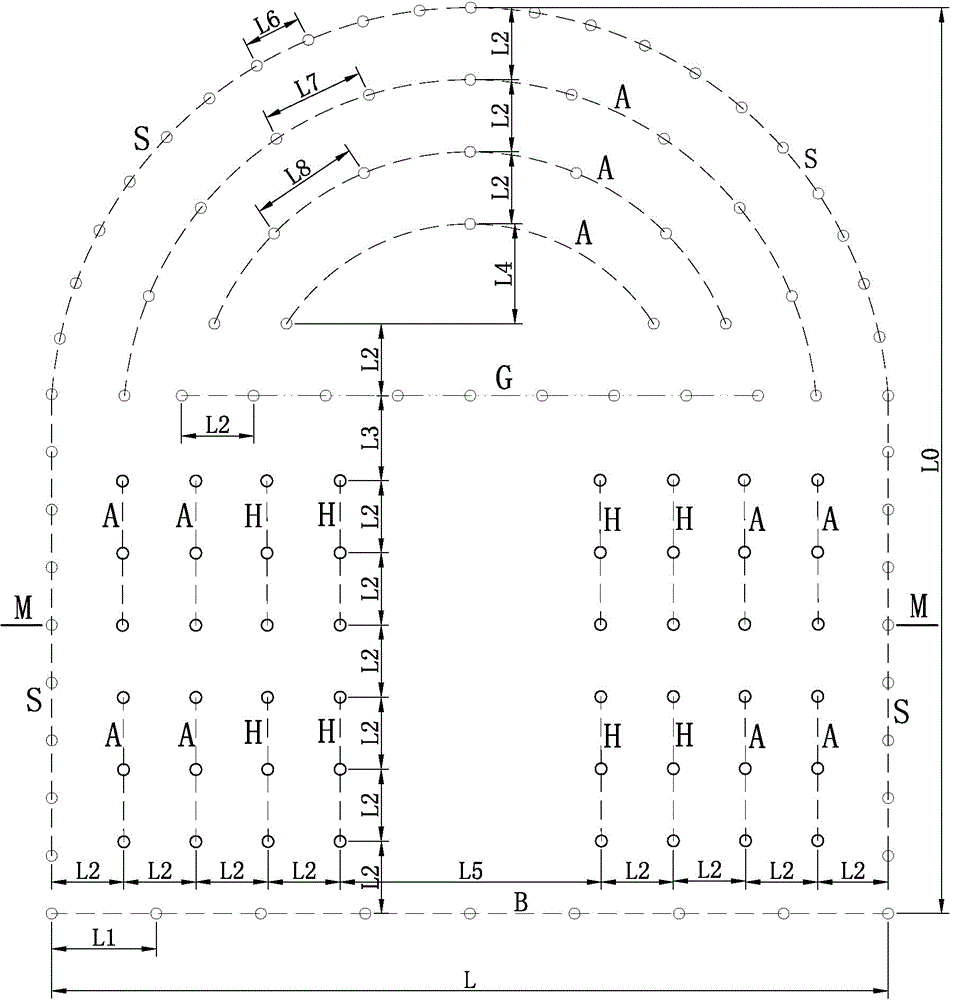

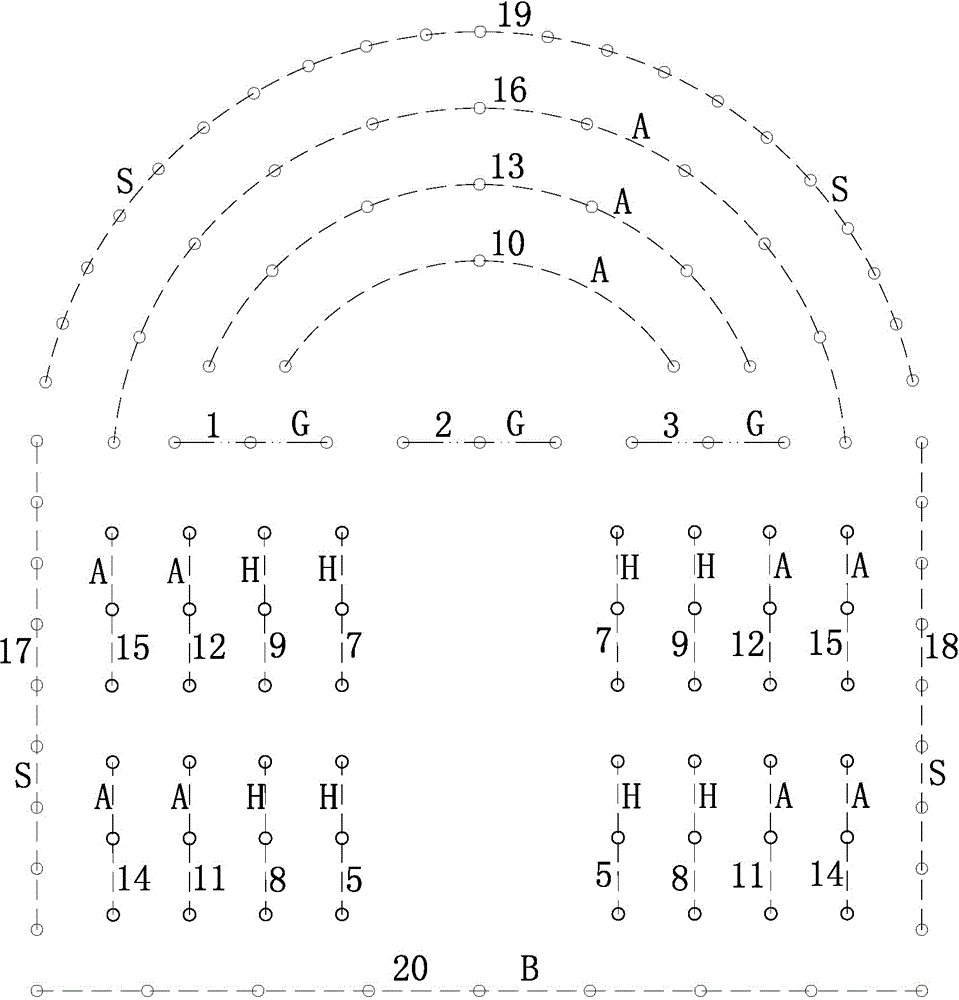

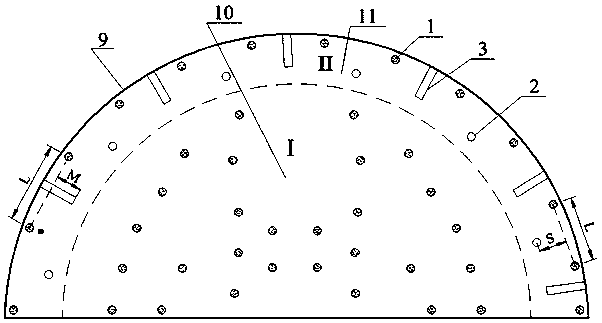

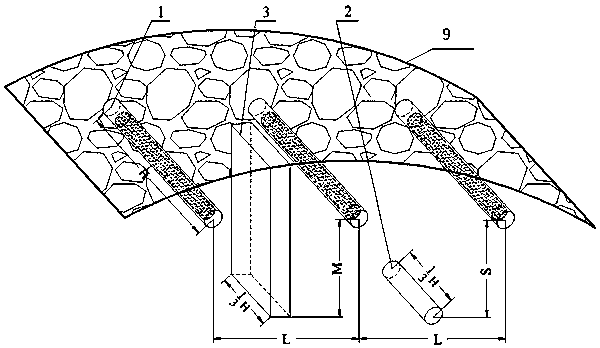

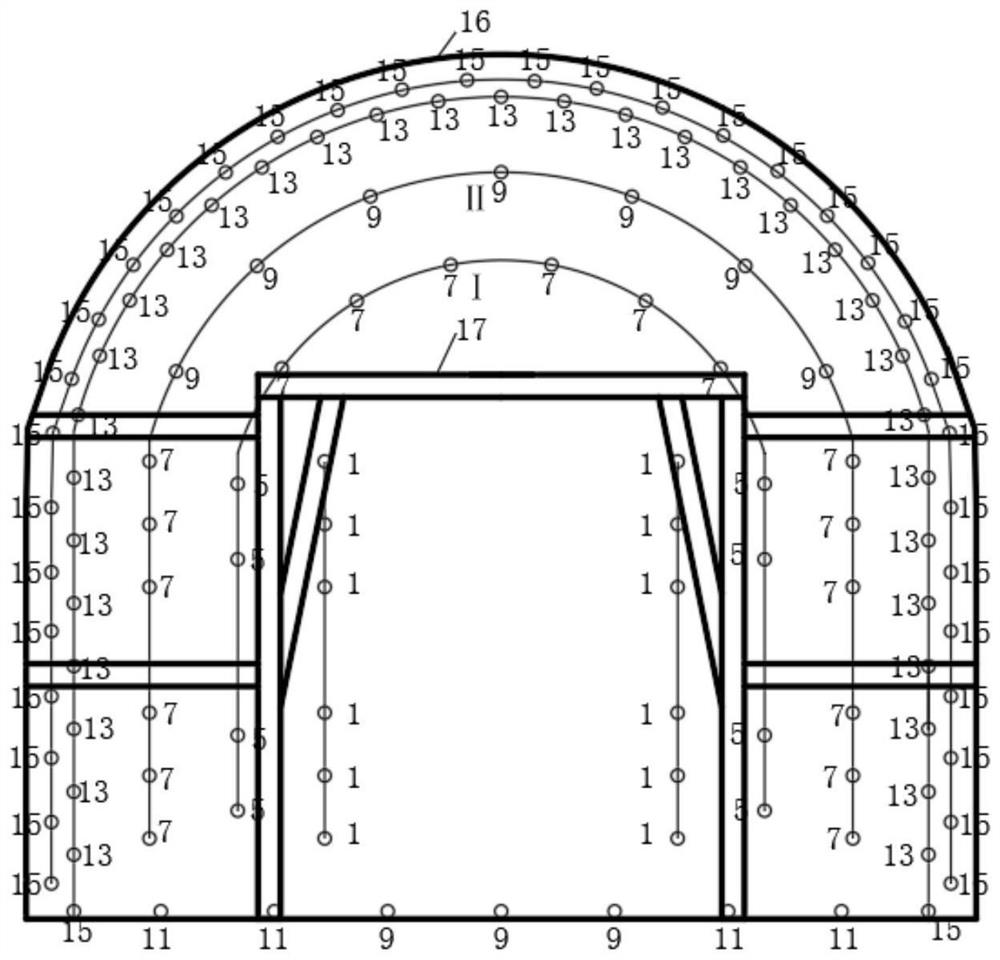

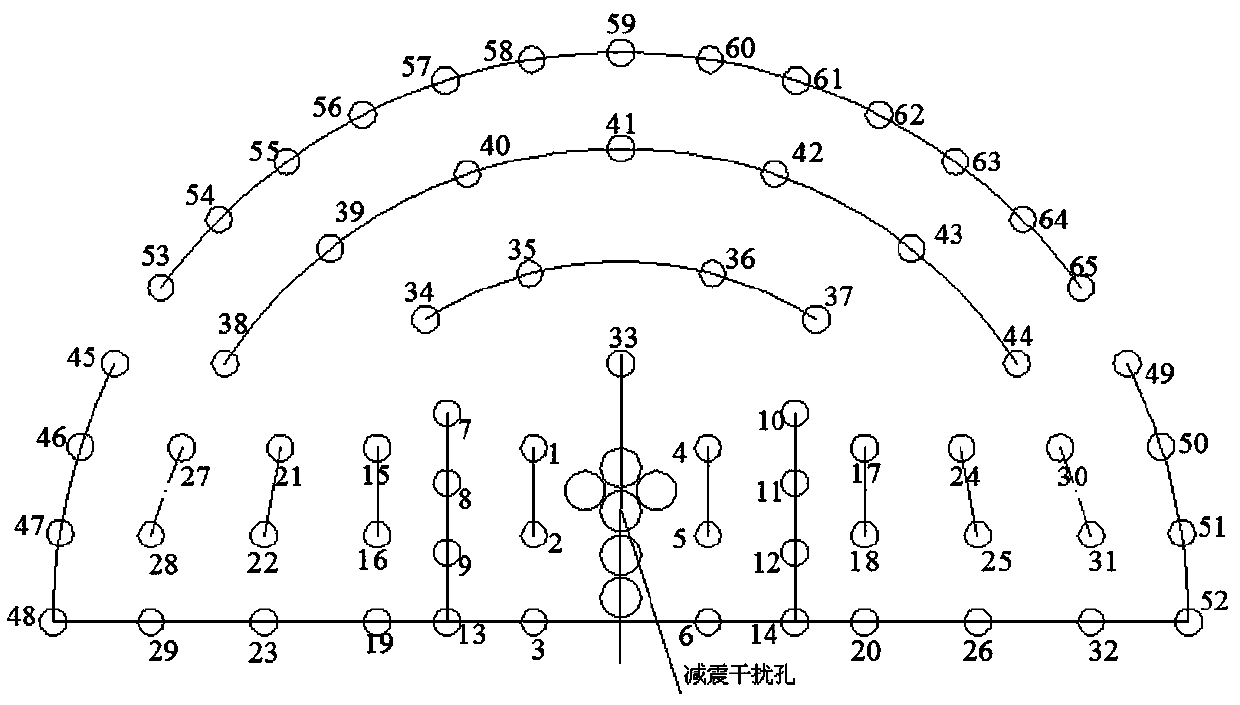

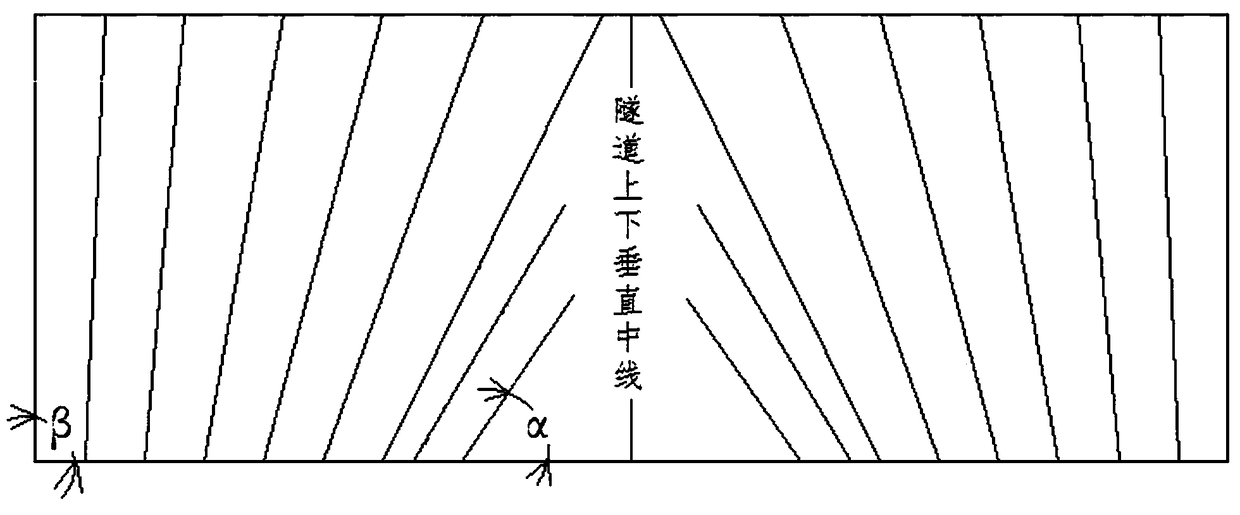

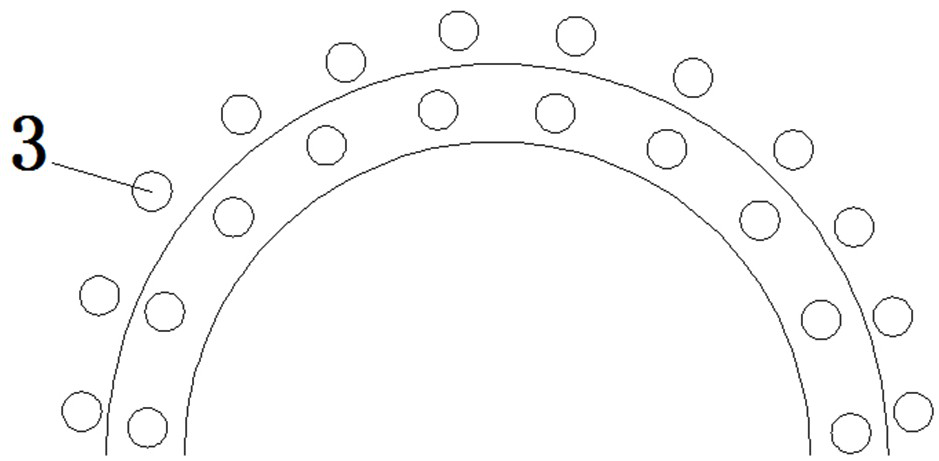

Method for preventing vibration of smooth blasting in tunnel

The invention relates to a method for preventing vibration of smooth blasting in a tunnel. The method comprises the following step of drilling a plurality of shock absorbing holes and a plurality of shock absorbing grooves in a spaced manner in a smooth blasting area in the tunnel, wherein each shock absorbing hole is located between twoadjacent peripheral holes and each shock absorbing groove islocated between two adjacentperipheral holes; furthermore, the shock absorbing holes are formed in the sides, far away from the earth surface, of the peripheral holes, the connecting distance betweeneverytwo adjacent peripheral holes is L, the vertical distance of connecting lines between the shock absorbing hole and the two corresponding adjacentperipheral holes is S which is equal to 0.4L; andeach shock absorbing holeis located inthe midperpendicular of a connecting line of the two corresponding peripheral holes. According to the method, construction on the earth surface is avoided and theshock absorbing effect is good. By forming the shock absorbing holes and the shock absorbing grooves in a spaced fit manner, part of energy generated byexplosive after exploding is absorbed by the shock absorbing holes and the shock absorbing grooves in peripheral hole blasting, so that the upward propagated energy can be reduced, and vibration and damage tothe earth surface are reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

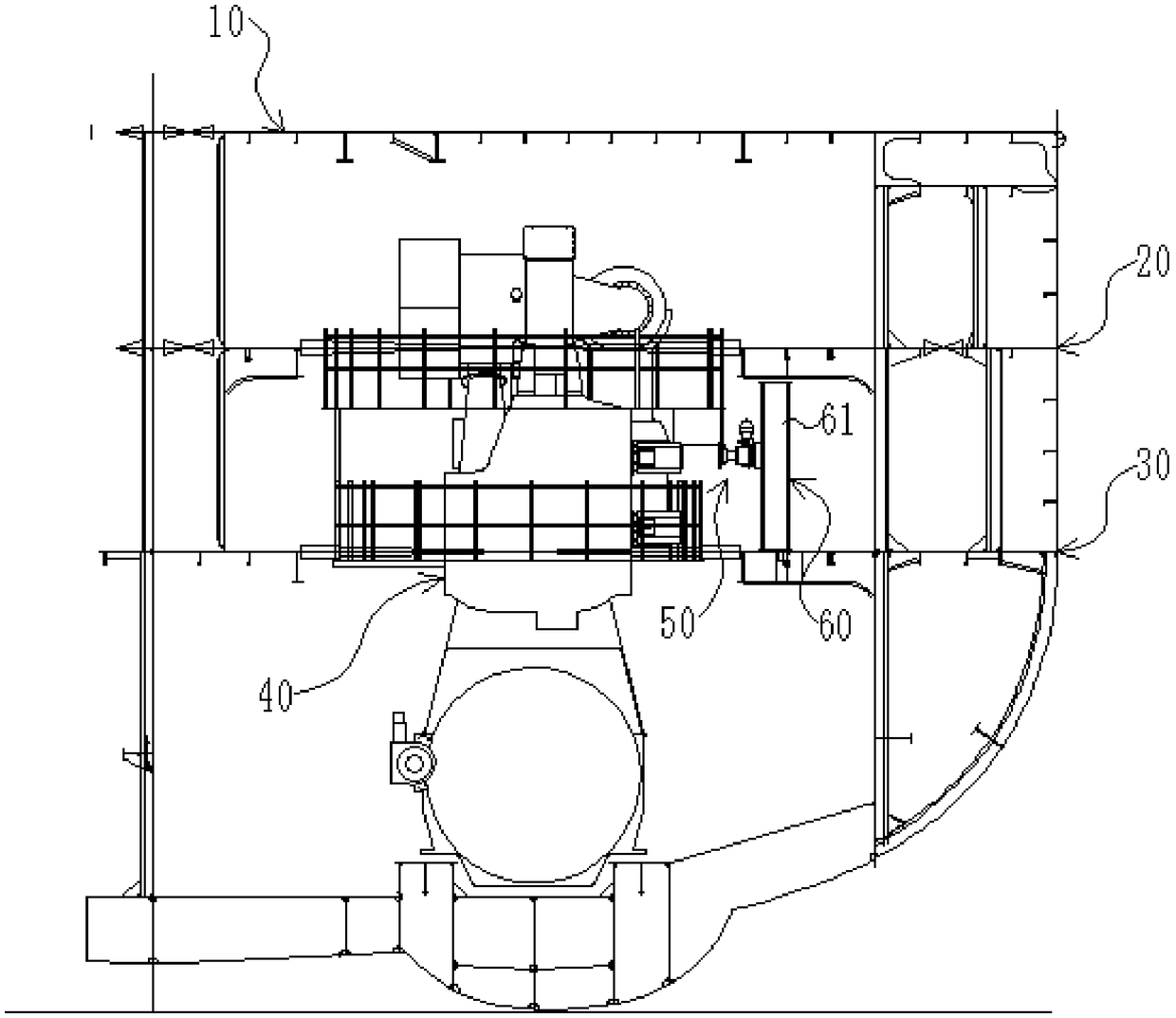

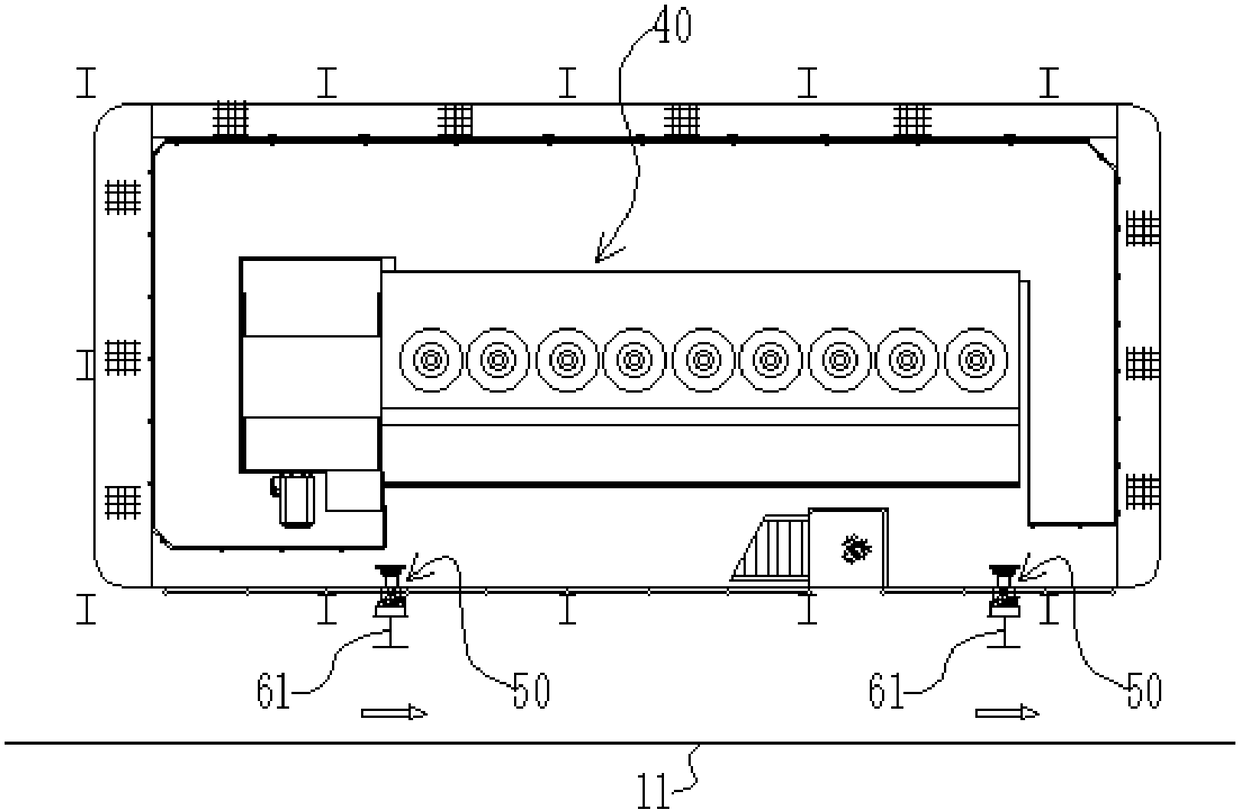

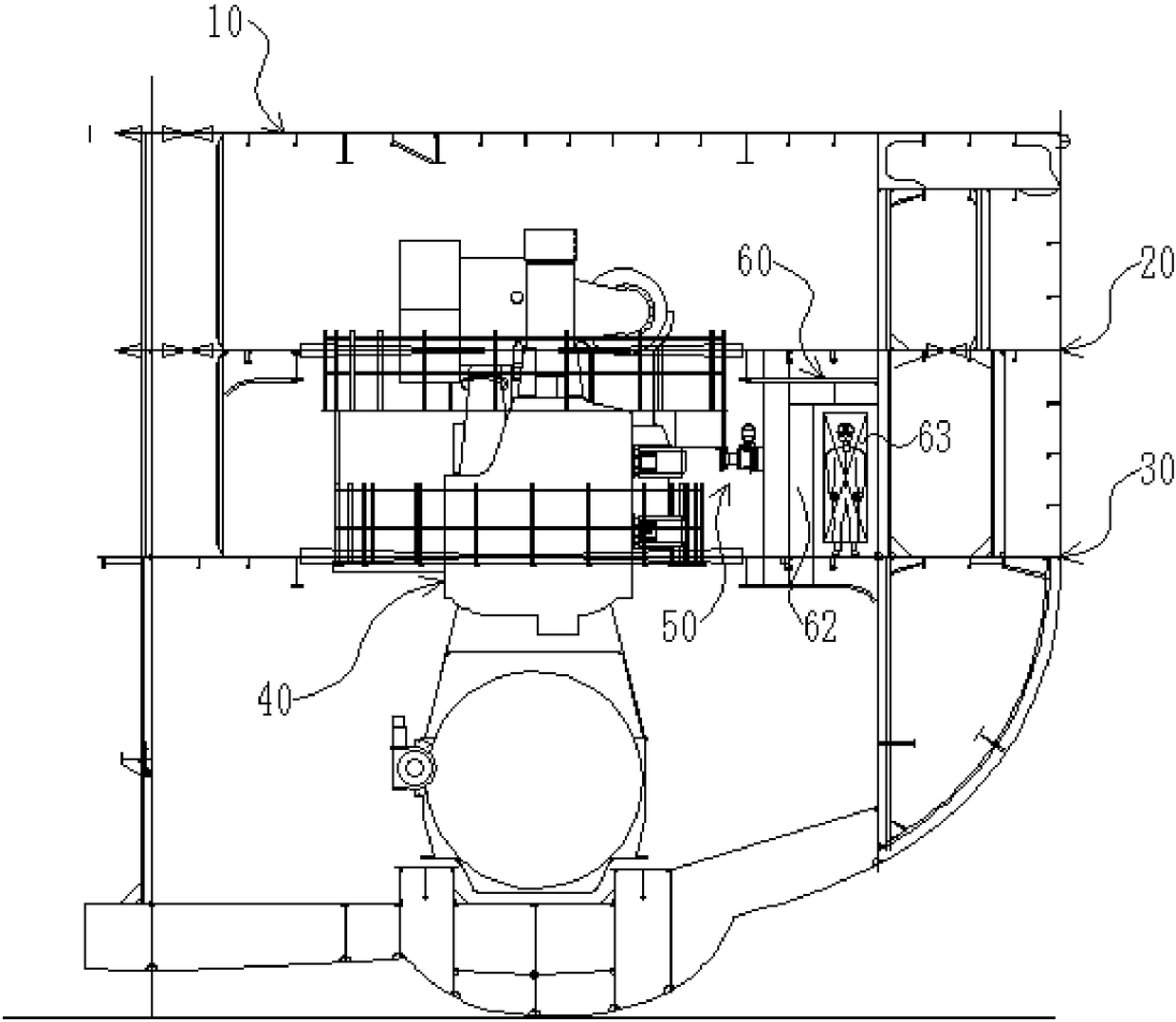

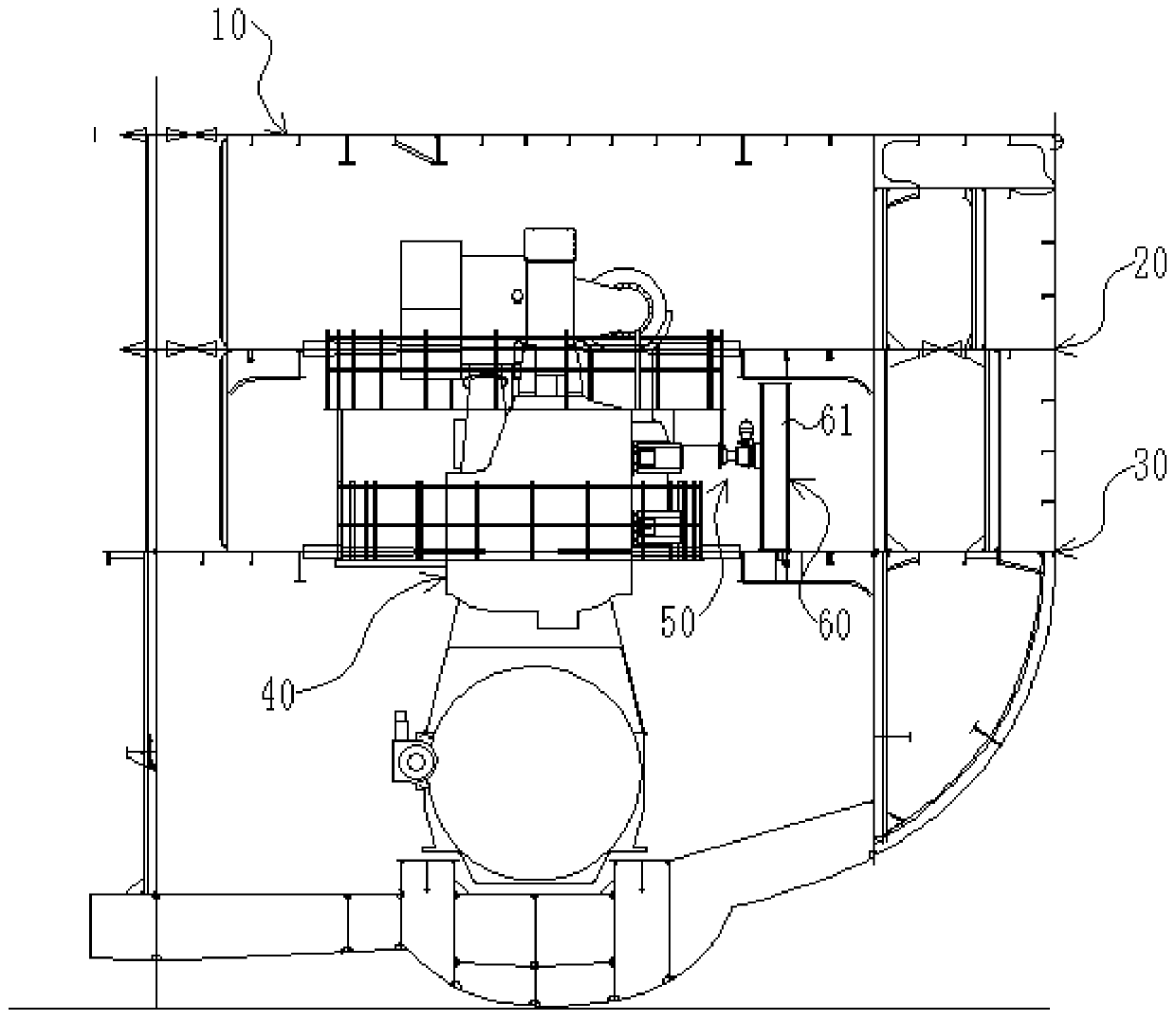

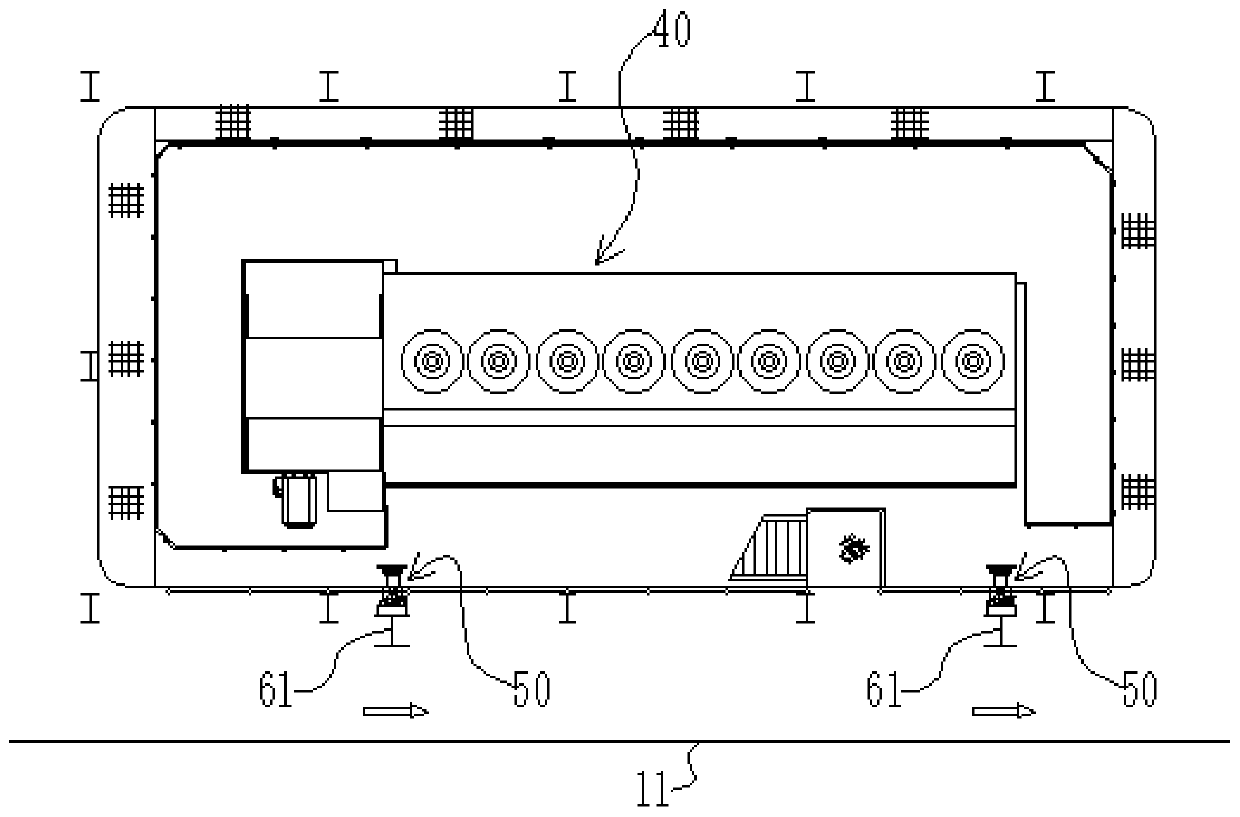

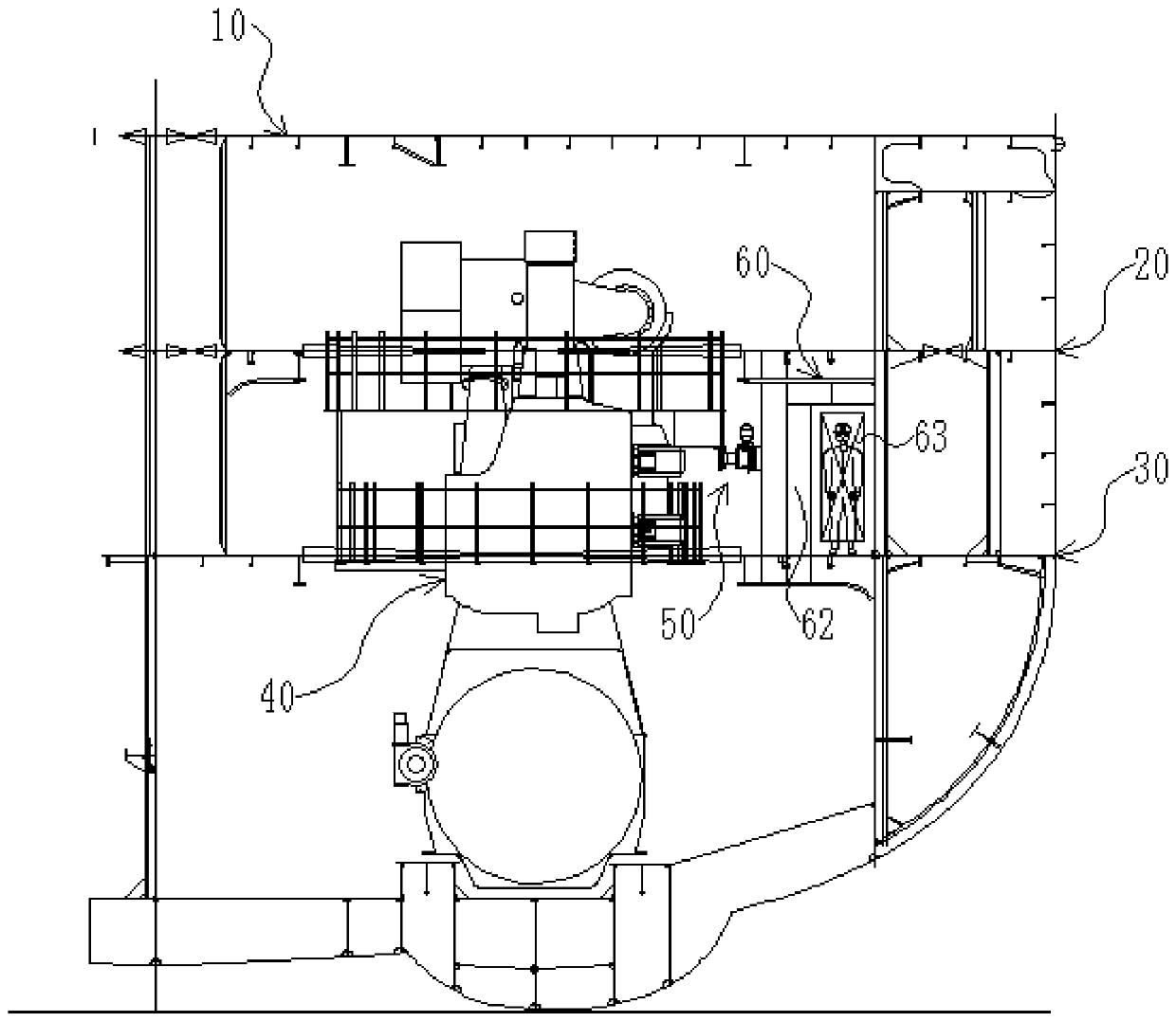

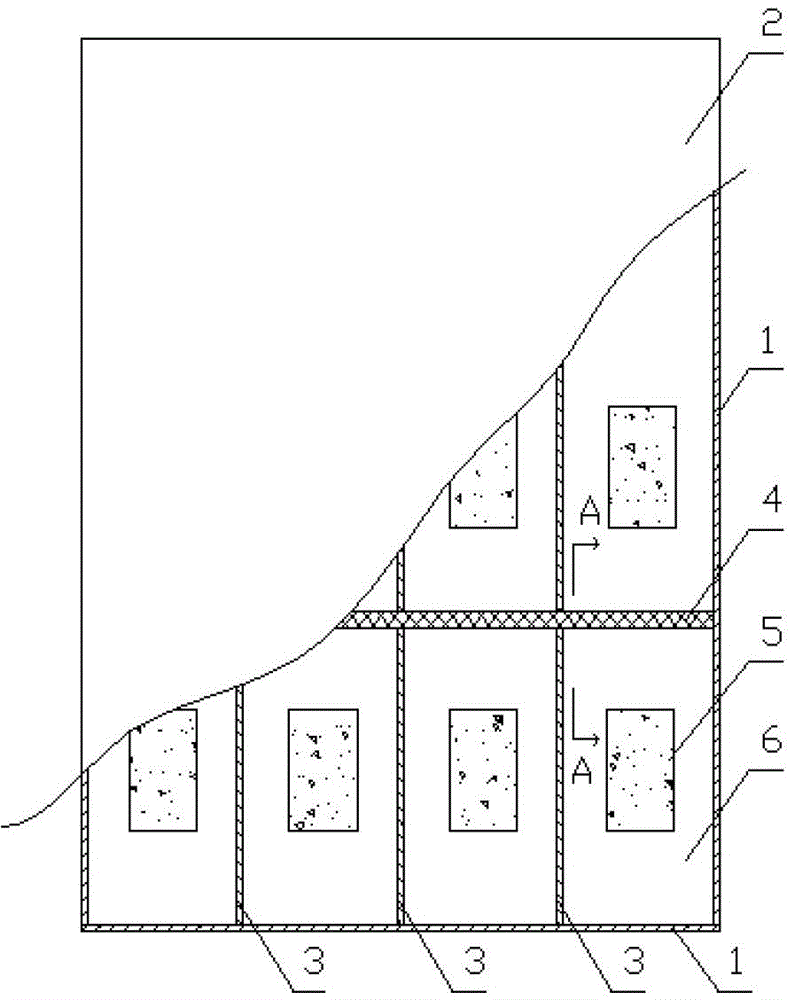

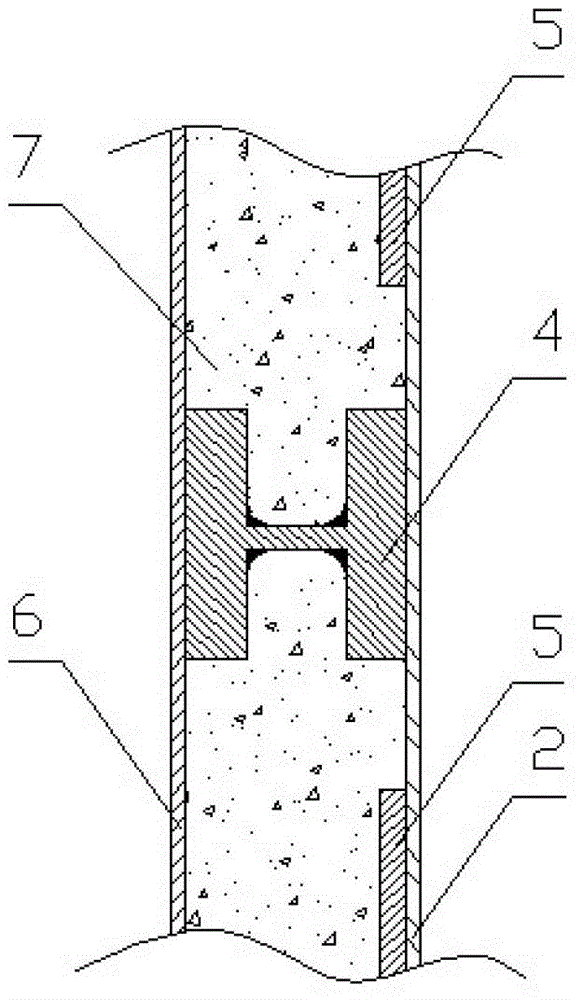

Ship mainframe cross brace reinforcement structure and ship

ActiveCN108128434AIncrease lateral stiffnessReduce lateral vibration velocityPower plants being motor-drivenHull partsMarine engineeringCrew

The invention provides a ship mainframe cross brace reinforcement structure and a ship, and relates to the technical field of ship construction. The ship mainframe cross brace reinforcement structureand the ship are designed to solve the problems that existing ship mainframe cross brace reinforcement structures cannot effectively enhance the transverse rigidity of joints of cross braces, correspondingly mainframe vibration cannot be effectively suppressed, and the layout of pipelines and passing of crews are inconvenient. The ship mainframe cross brace reinforcement structure is fixed to cross braces, a longitudinal passage is formed between the ship mainframe cross brace reinforcement structure and a longitudinal bulkhead, the ship mainframe cross brace reinforcement structure includes partial longitudinal bulkheads, and the partial longitudinal bulkheads are fixed to the main structure of the ship. The ship includes a ship body and the ship mainframe cross brace reinforcement structure. According to the ship mainframe cross brace reinforcement structure and the ship, the transverse rigidity of joints of the cross braces can be enhanced, and the technical problems that layout ofthe pipelines and passing of the crews are inconvenient are solved while the vibration of a mainframe is effectively suppressed.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Vibration absorbing method for cut presplitting blasting

InactiveCN102927867BReduce vibration speedReduce the maximum blasting vibration velocityBlastingDetonatorEmulsion explosive

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Electronic apparatus use environment detecting method, electronic apparatus performance optimizing method and electronic apparatus

ActiveUS8925399B2Shorten speedReduce volumeDevices with sensorUsing mechanical meansAccelerometerAcceleration Unit

Apparatus and method use a vibrator and an accelerometer of electronic apparatus for detecting the use environment of the electronic apparatus, and according to the use environment a method and electronic apparatus are provided for optimizing the performance of the electronic apparatus according to the use environment of the electronic apparatus. The method for detecting use environment comprises: determining the basic parameters of the electronic apparatus; searching for the acceleration thresholds of the electronic apparatus according to the determined basic parameters of the electronic apparatus; and determining the use environment according to the detected acceleration of the electronic apparatus and the found acceleration thresholds of the electronic apparatus. The use environment of the electronic apparatus may be detected by the vibrator and accelerometer of the electronic apparatus, thereby optimizing the performance of the electronic apparatus according to the use environment.

Owner:SONY CORP

A method for vibration protection of smooth surface blasting in tunnel

The invention relates to a method for preventing vibration of smooth blasting in a tunnel. The method comprises the following step of drilling a plurality of shock absorbing holes and a plurality of shock absorbing grooves in a spaced manner in a smooth blasting area in the tunnel, wherein each shock absorbing hole is located between twoadjacent peripheral holes and each shock absorbing groove islocated between two adjacentperipheral holes; furthermore, the shock absorbing holes are formed in the sides, far away from the earth surface, of the peripheral holes, the connecting distance betweeneverytwo adjacent peripheral holes is L, the vertical distance of connecting lines between the shock absorbing hole and the two corresponding adjacentperipheral holes is S which is equal to 0.4L; andeach shock absorbing holeis located inthe midperpendicular of a connecting line of the two corresponding peripheral holes. According to the method, construction on the earth surface is avoided and theshock absorbing effect is good. By forming the shock absorbing holes and the shock absorbing grooves in a spaced fit manner, part of energy generated byexplosive after exploding is absorbed by the shock absorbing holes and the shock absorbing grooves in peripheral hole blasting, so that the upward propagated energy can be reduced, and vibration and damage tothe earth surface are reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

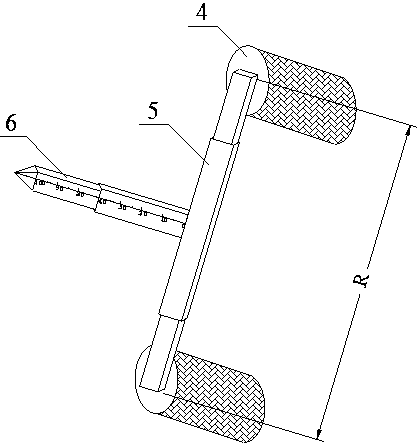

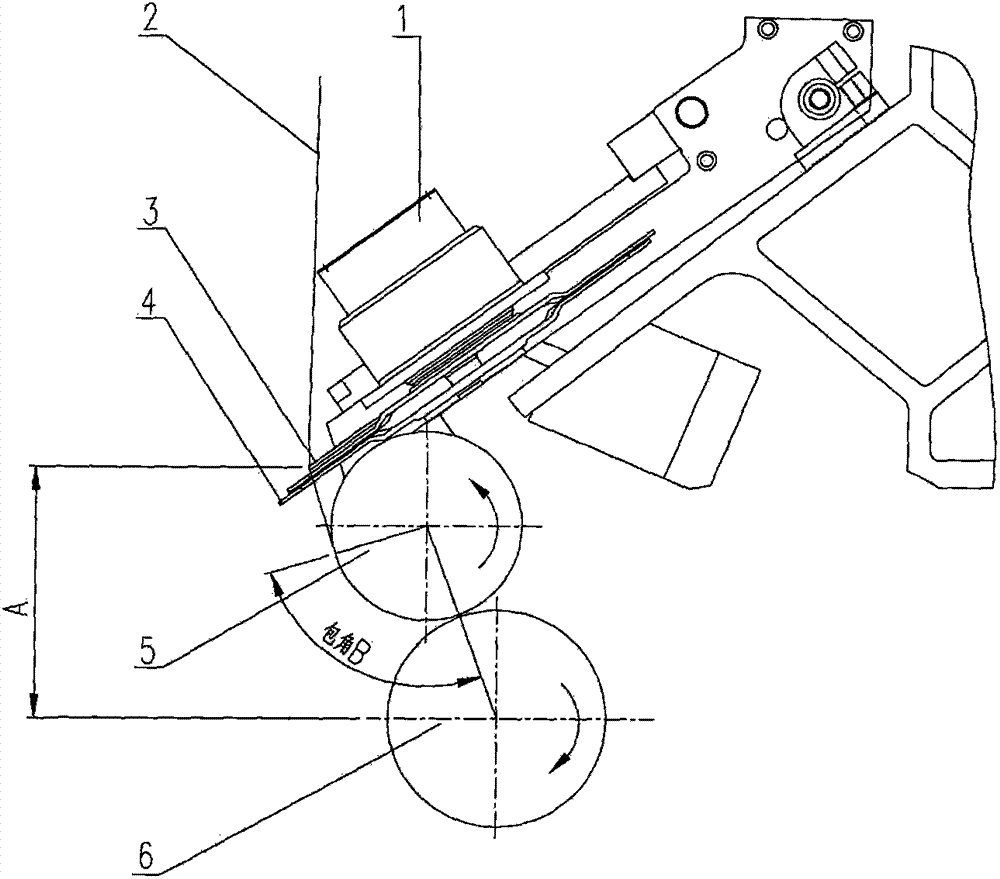

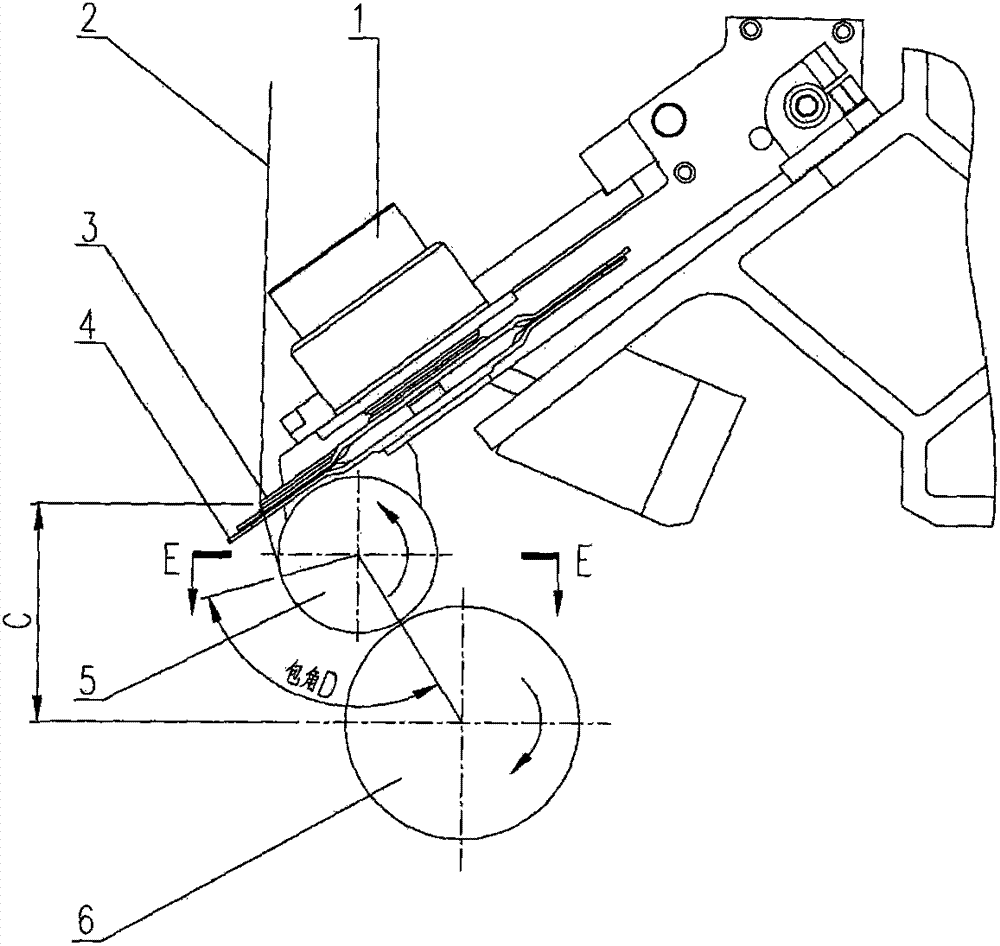

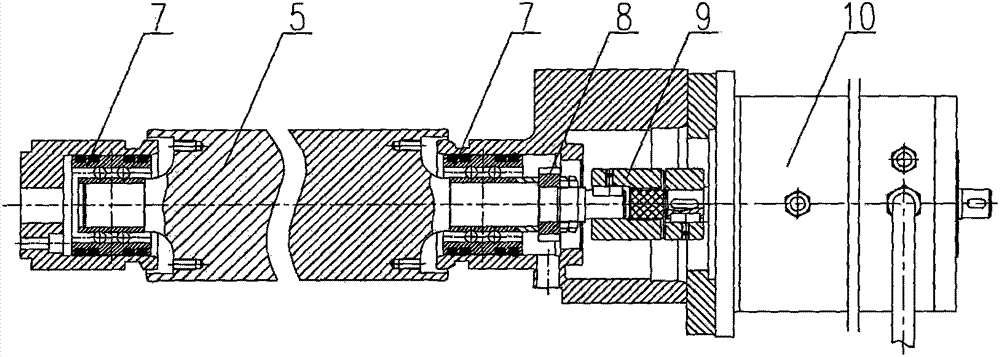

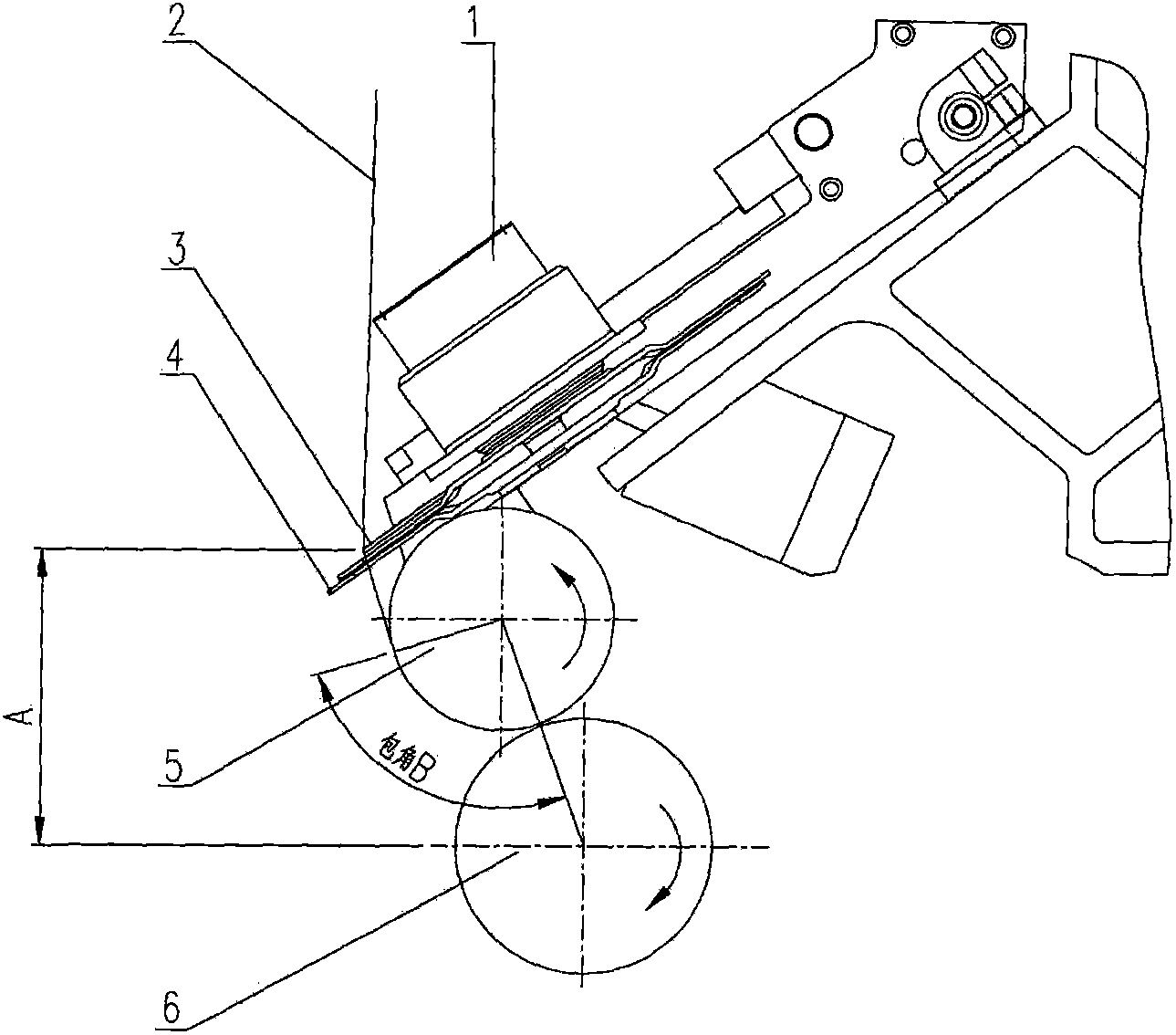

Press roll for filament winding head

The invention relates to a chemical filament winding device, in particular to a small-diameter press roll for a chemical filament winding head. The press roll body is a solid roll body; shaft heads at two ends of the press roll are supported by bearings; one end of a press roll shaft is connected with a motor through a coupling; a speed measuring wheel is arranged between the bearings and the coupling; the press roll body is equipped with a balancing hole; and the length C of a filament bundle between a forming board and a bobbin chuck shaft is less than A, and a wrap angle D of the filament bundle on the press roll is greater than a wrap angle B. By utilizing the press roll device for the chemical filament winding head, winding speed of the chemical filament winding head is increased;d meanwhile, forming and unwinding properties of a spinning cake are improved.

Owner:北京德厚朴化工技术股份有限公司

Press roll for filament winding head

The invention relates to a chemical filament winding device, in particular to a small-diameter press roll for a chemical filament winding head. The press roll body is a solid roll body; shaft heads at two ends of the press roll are supported by bearings; one end of a press roll shaft is connected with a motor through a coupling; a speed measuring wheel is arranged between the bearings and the coupling; the press roll body is equipped with a balancing hole; and the length C of a filament bundle between a forming board and a bobbin chuck shaft is less than A, and a wrap angle D of the filament bundle on the press roll is greater than a wrap angle B. By utilizing the press roll device for the chemical filament winding head, winding speed of the chemical filament winding head is increased;d meanwhile, forming and unwinding properties of a spinning cake are improved.

Owner:北京德厚朴化工技术股份有限公司

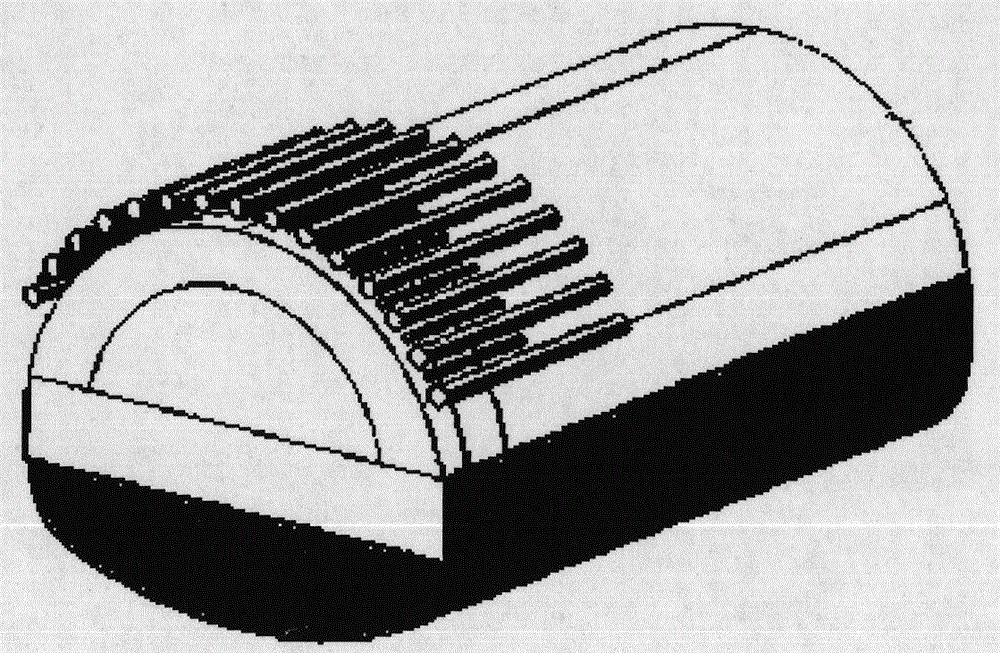

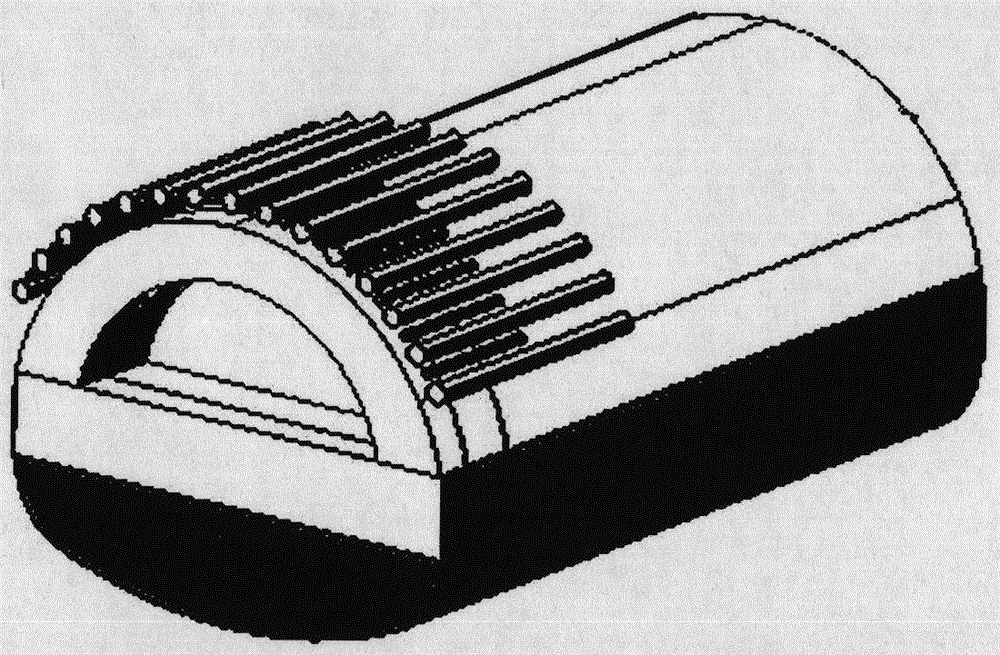

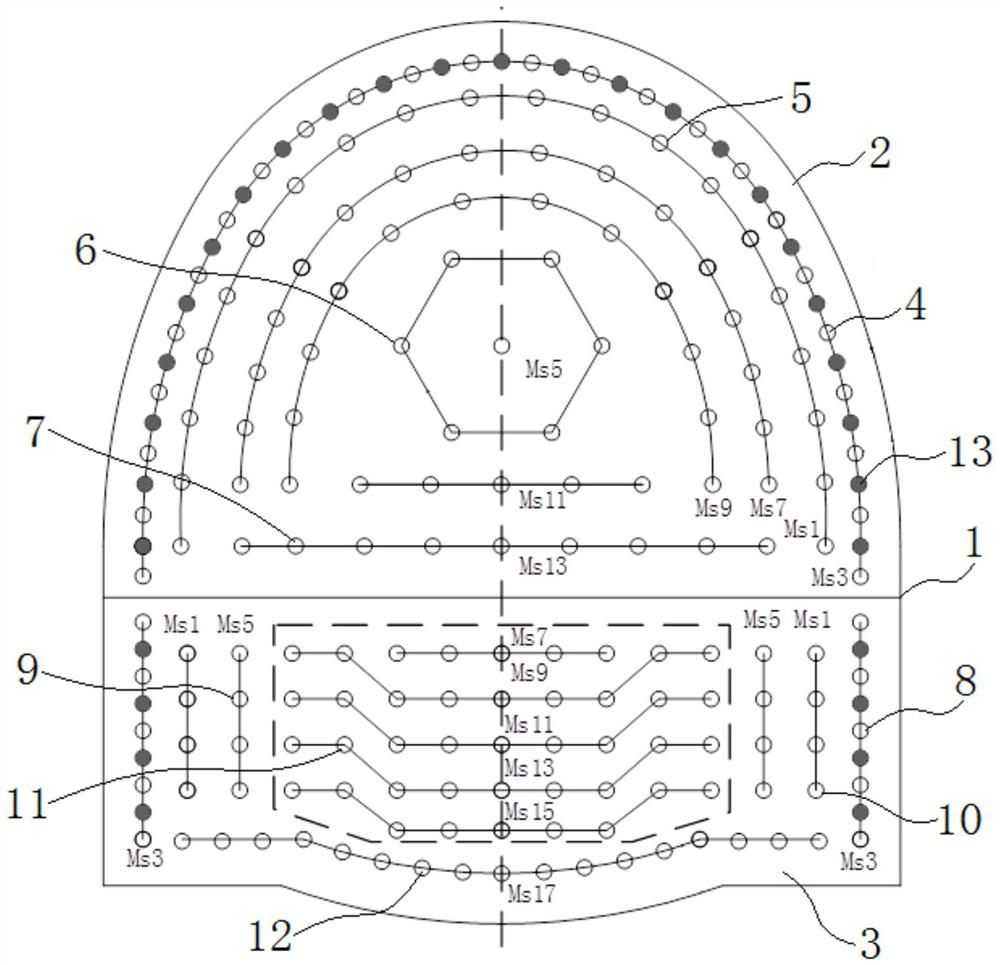

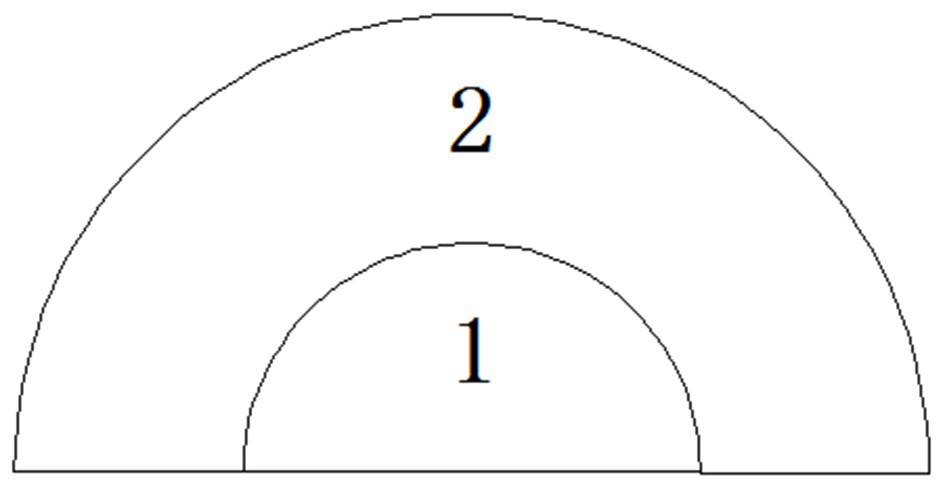

Shock-absorbing method of ring-shaped layered blasting for shallow-buried large-section tunnel passing through existing buildings

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

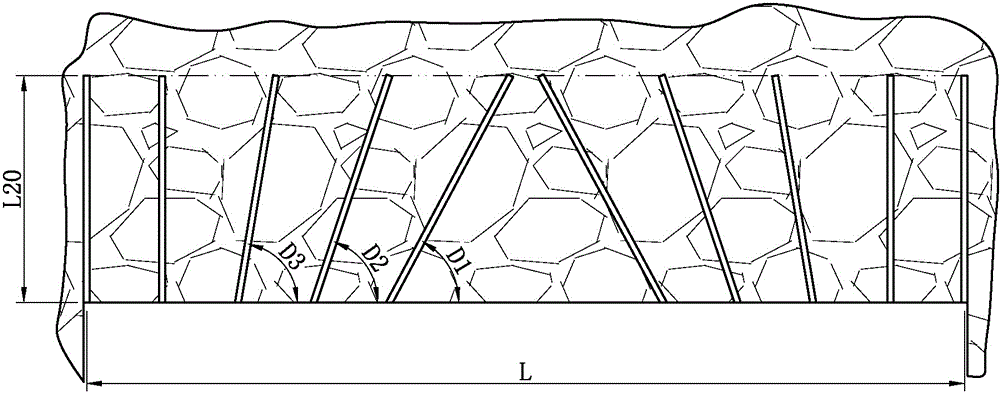

A construction method for reducing blasthole control over and under-excavation in an inclined flat-curve tunnel

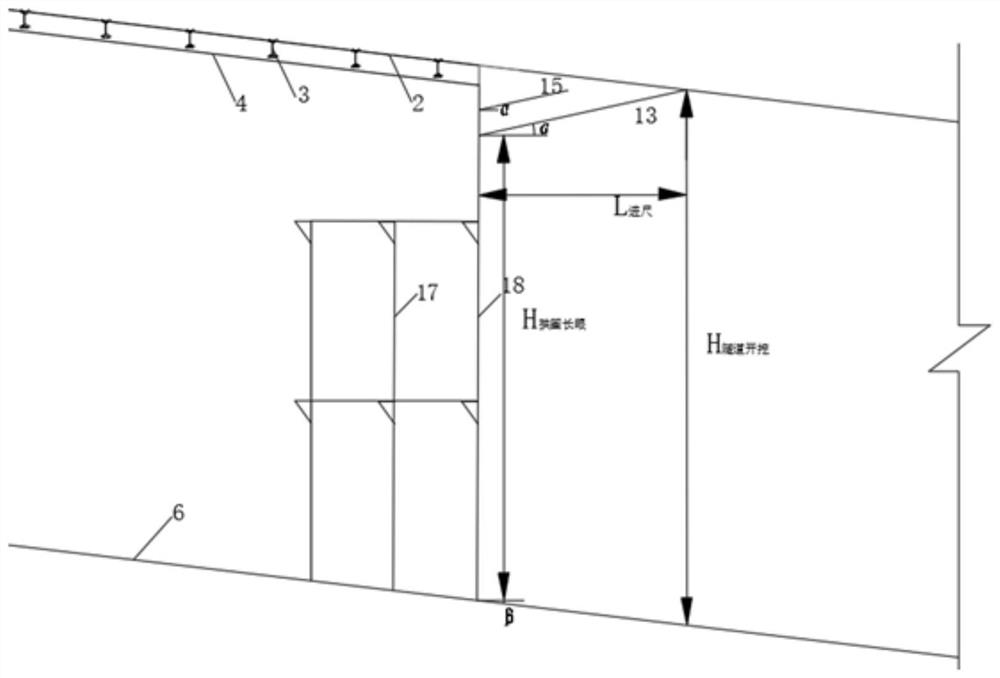

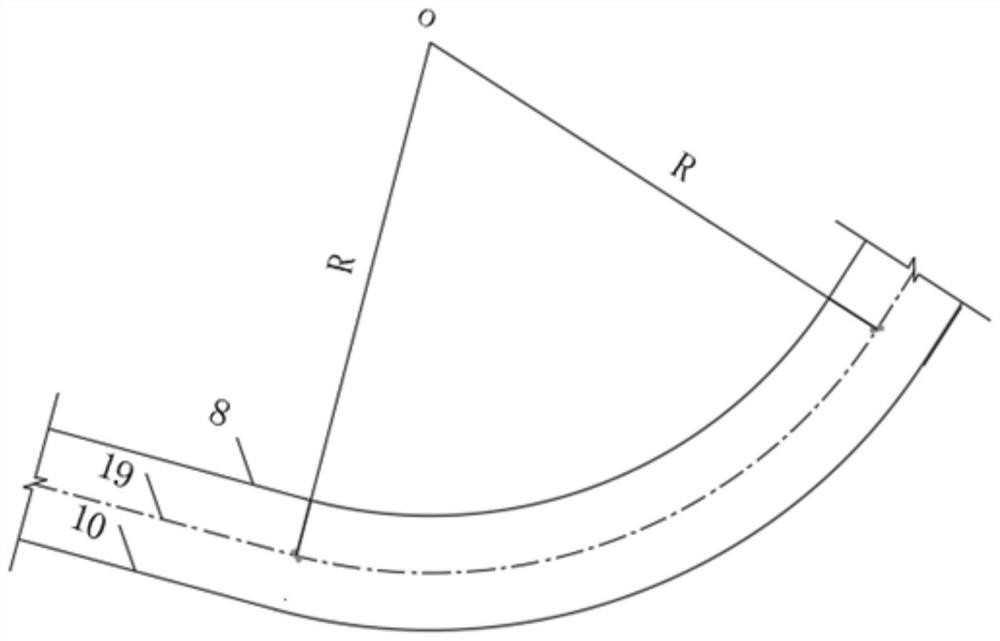

ActiveCN111521081BEasy to operateReduce vibration speedHydro energy generationBlastingArchitectural engineeringStructural engineering

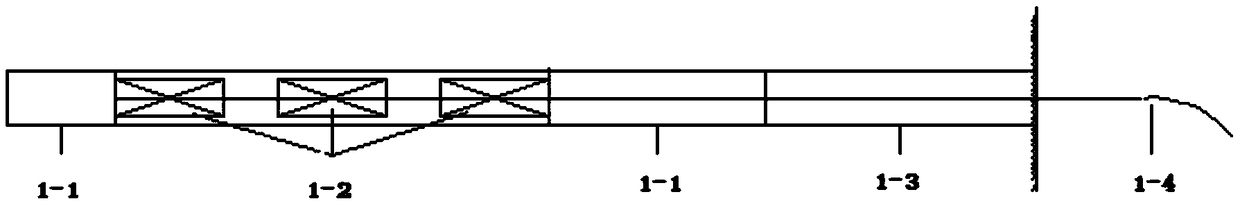

The invention discloses a construction method for reducing blasting and under-excavation in an inclined flat-curve tunnel. The method includes: designing a construction method, optimizing a tunnel excavation contour; , Peripheral long eye and peripheral short eye, the undercut eye is symmetrically spaced on both sides of the tunnel centerline, the undercut eye is arranged on the outside of the undercut eye, and the undercut eye and the undercut eye are arranged at intervals; the peripheral long eye and the peripheral The short eyes are evenly spaced along the tunnel excavation outline and located inside the tunnel excavation outline, and the peripheral short eye is arranged on the tunnel face between the peripheral long eye and the reaming eye. The beneficial effects of the present invention are as follows: the blasthole construction method of the present invention comprehensively considers the influence of factors such as the tunnel inclination angle and the side wall of the flat-curve tunnel, and proposes a peripheral hole arrangement form pertinently, which is consistent with the existing universality. Compared with the method of blasting holes in the tunnel, the amount of over- and under-excavation is reduced.

Owner:CHINA CONSTR RAILWAY INVESTMENT & CONSTR GRP CO LTD +1

A tunnel differential control blasting method

The invention discloses a tunnel millisecond blasting method. The method comprises the following steps of 1, distributing of blast holes, the number of the blast holes and the blasting parameters of the blast holes are designed, wherein the blasting parameters of the blast holes comprise hole diameters, hole distances, resistance lines and depth of a periphery hole, an reliever hole and a cut hole; 2, the blast holes are drilled in a tunnel boring face to be blasted; 3, explosive loading is carried out on the blast holes drilled in the tunnel boring face; 4, blocking and compacting is carriedout on the blast holes filled with explosive; 5, time delay setting is carried out on digital electronic detonators in all the blast holes; and 6, after the time delay setting is finished, wire connecting is carried out, and sequential detonation is conducted after determining that no errors exist. Compared with an existing millisecond blasting technology which is complex in blasting mechanism anddoes not have explicit theory and practice supports, the tunnel millisecond blasting method has the advantages that the different cut blasting methods are adopted for different surrounding rocks andfield conditions, so that the purposes of improving blasting efficiency, reducing the vibration speed and saving financial resources are achieved.

Owner:北京住总集团有限责任公司 +1

DC propulsion motor

InactiveCN101114790BNormal functioningReduce radial forceDC commutatorWorking environmentEngineering

The invention relates to a direct current propulsion motor which belongs to the field of motor technology, which is particularly suitable for the direct current propulsion motor which is used for medium vessel and large vessel. The invention comprises a rotor and a stator, wherein the rotor comprises an armature core, an armature winding, a radical ventilation duct, a commutator and a rotating shaft; the armature winding which is distributed on the external circumference surface of the armature core is inverted 'V'-shaped; the inverted 'V'-shaped armature winding consists of an inverted 'V'-shaped upper coil of winding insulation and an inverted 'V'-shaped lower coil of winding insulation which are both of half-style structure and are embedded into an inverted 'V'-shaped skewed slot of thearmature core. The invention has the advantages that: the radial electromagnetic force of the motor is reduced; the amplitude and the vibration noise are reduced; the working environment is improved;the electromagnetic vibration of a whole motor base is reduced; the electromagnetic vibration in the whole speed range of the motor is assuredly promoted to be restricted to the greatest degree; theoperation effect is better; and the function is much better exerted.

Owner:中国船舶重工集团公司第七一二研究所

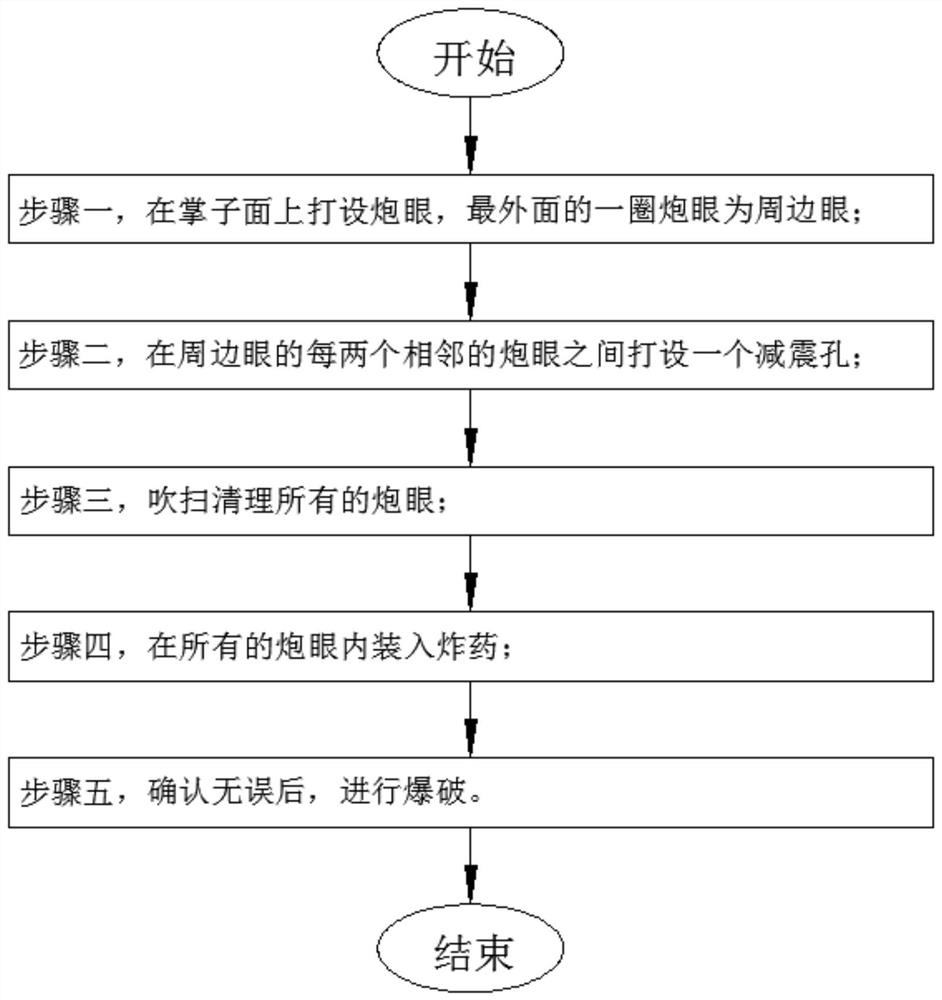

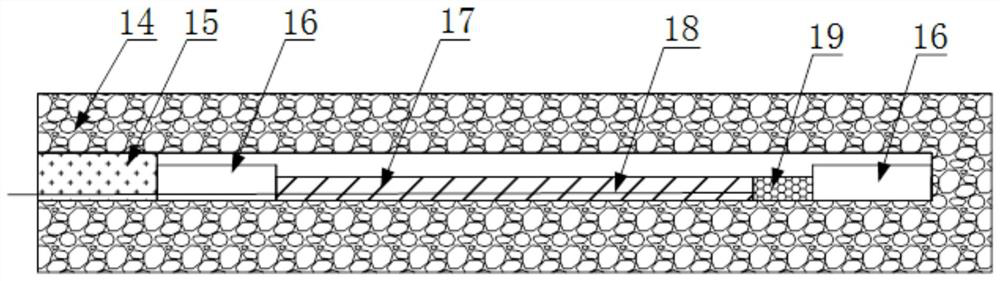

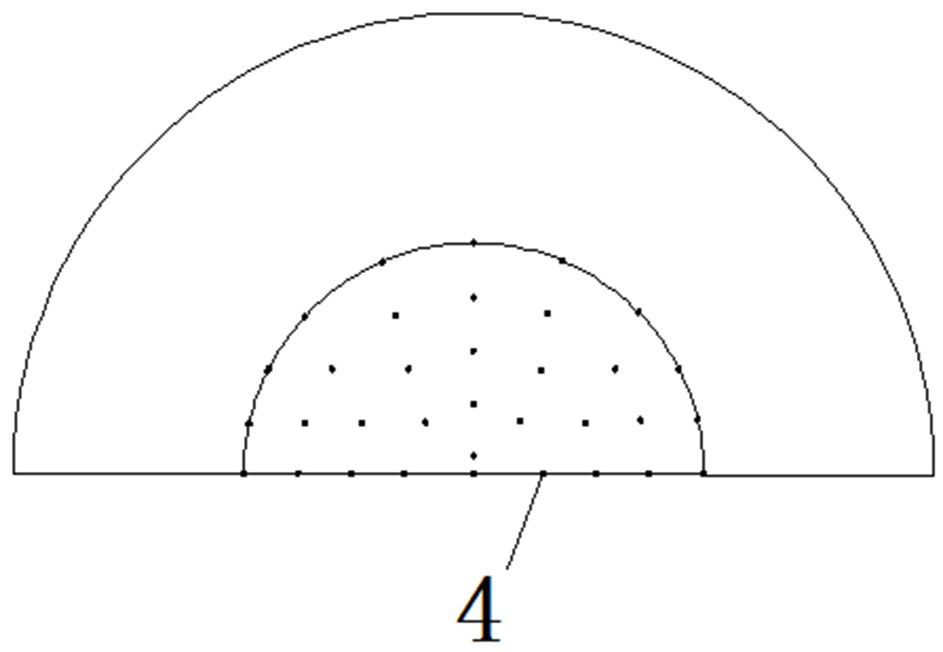

A pre-splitting blasting damping method

ActiveCN109839043BReduce transmissionReduce vibration speedBlastingTunnelsDetonationExplosive Agents

The invention discloses a pre-splitting blasting shock absorbing method, which comprises the following steps: step 1, drilling blastholes on the face of the tunnel, the outermost circle of blastholes being peripheral holes; A shock-absorbing hole is drilled between adjacent blastholes; Step 3, blowing and cleaning all blastholes; Step 4, loading explosives in all blastholes; and Step 5, blasting after confirmation is correct. The present invention can separate the rock mass plane of the excavated face part from the surrounding rock mass within a certain depth through the shock absorbing holes and the prescribed blasting sequence to form a shock isolation ditch, effectively reducing the impact of blasting on the excavated hole contour. The vibration velocity of the rock mass is improved, thereby improving the shock absorption effect.

Owner:GUANGXI UNIV +1

A micro-vibration blasting method for deep hole steps

ActiveCN103307939BReduce vibration speedImprove the efficiency of blasting excavationBlastingDetonatorEngineering

Owner:SINOHYDRO BUREAU 14 CO LTD +1

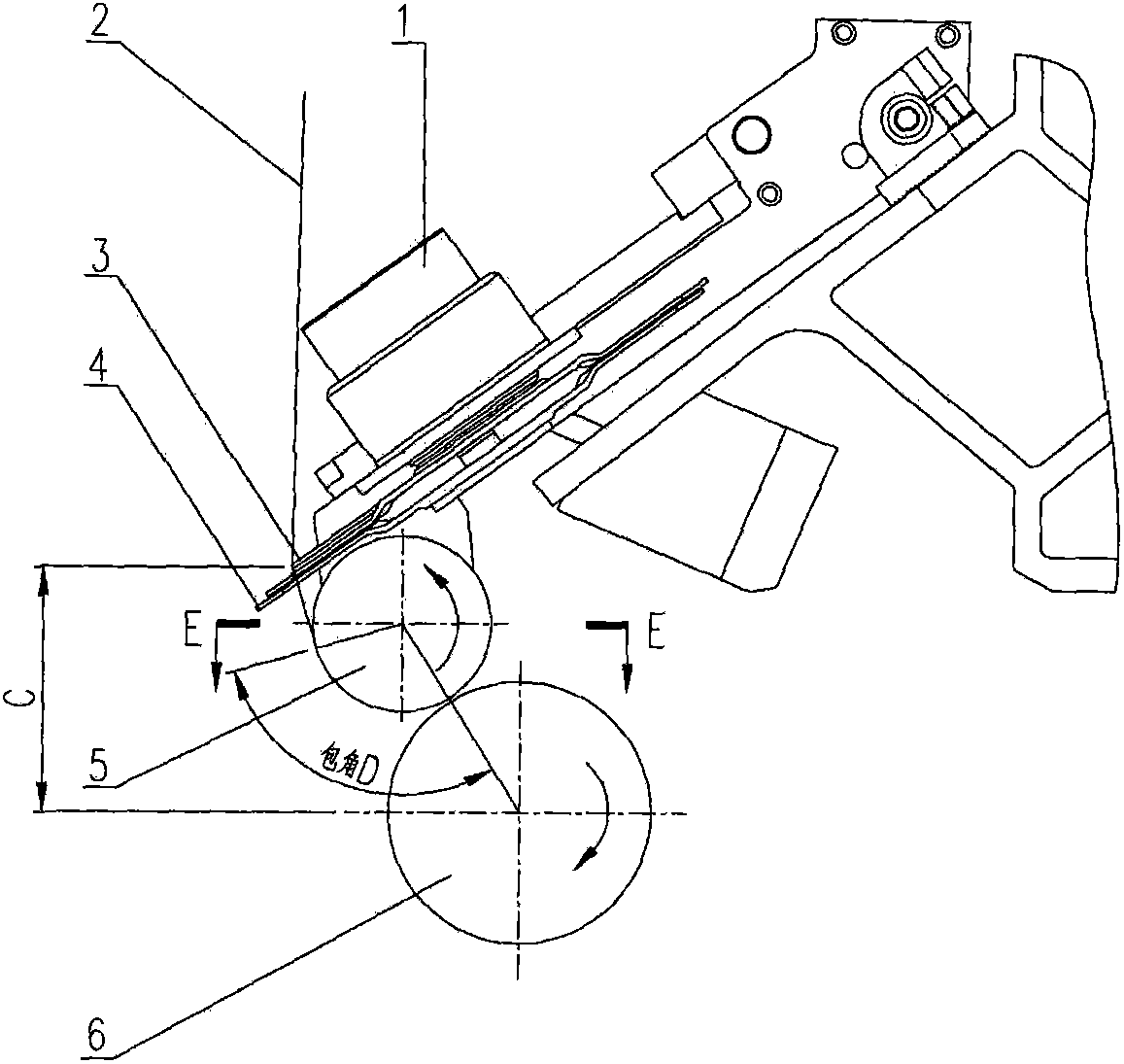

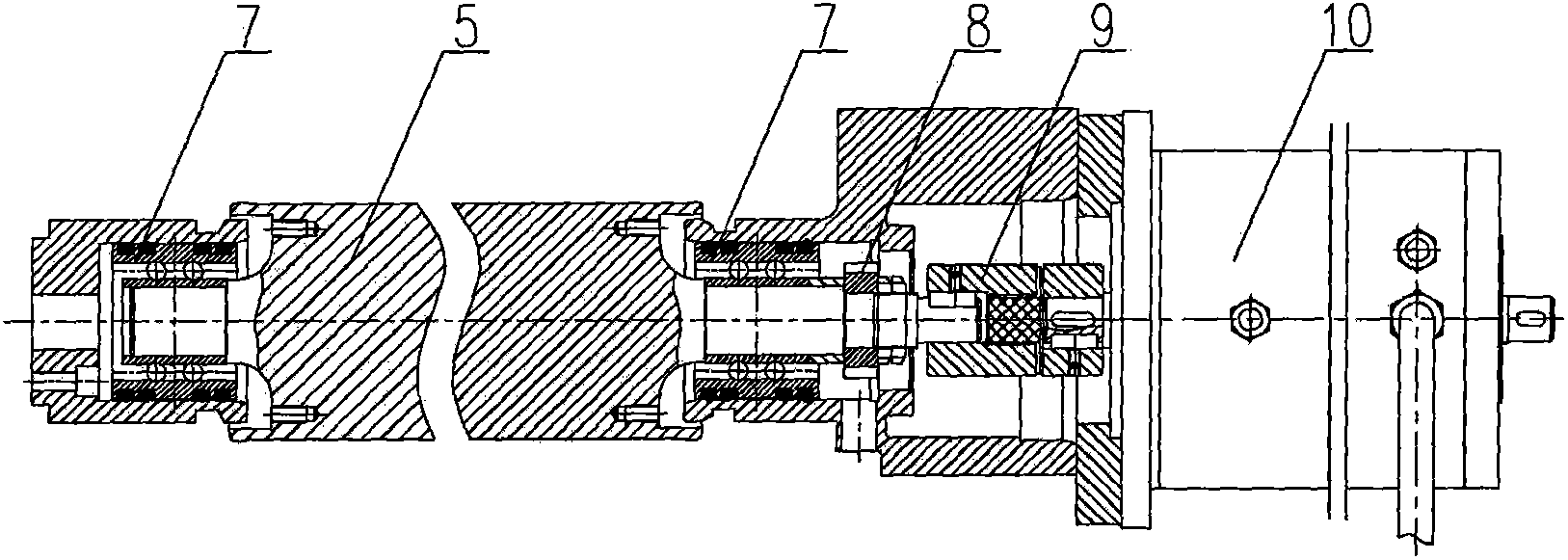

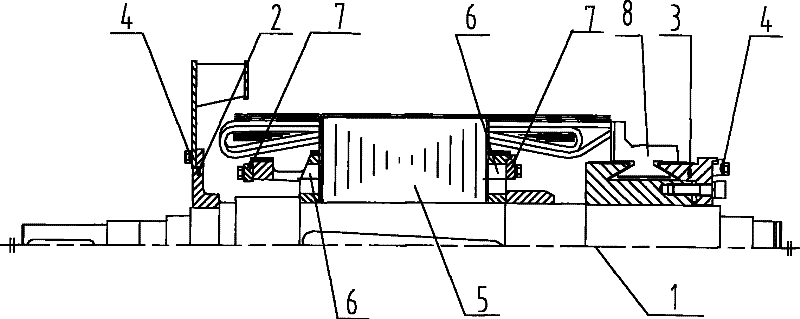

Secondary dynamic balance checking structure and method used for DC motor

InactiveCN101431281BImprove dynamic balance accuracyReduce vibration speedStatic/dynamic balance measurementCentering/balancing rotorsPhysicsLacquer

The invention discloses a twice correction dynamical balance structure used for a DC electrical motor, comprising an electrical motor body, wherein, first balance weights are additionally installed on a balance bed and a commutator pressure ring at the two ends of an armature of the electrical motor body respectively, and magnet core pressure rings are respectively installed at the two ends of a magnet core; the balance structure also comprises second balance weights are respectively installed on the two magnet core pressure rings, and a plurality of balance weight installation screw holes are installed on the end surfaces of the two magnet core pressure rings so as to install the second balance weights. The method comprises the following steps: the first correction dynamical balance; inserting line and dipping lacquer; and the second correction dynamical balance. In the invention, the dynamical balance is pre-corrected on an armature core which is not inserted with the line, so as tofirst adjust the residual unbalance generated by the same plate difference of a stamped steel and the error caused by manufacturing and processing of a commutator on the magnet core to a certain precision required; the second correction balance is carried out after the line is inserted, thus being conducive to improving the dynamical balance precision of the whole DC electrical motor, and effectively reducing the vibration velocity and the noise of the electrical motor, and improving the performance of the electrical motor.

Owner:SHANGHAI NANYANG ELECTRICAL MACHINERY

A multi-stage small wedge-shaped cutting blasting shock absorption method

The invention discloses a multi-stage small wedge-shaped cutting blasting shock absorbing method, which mainly includes the following steps: A) arranging several blasting sections on the tunnel surface through a laser pointer and controlling the contour lines of each section; B) controlling each blasting section The angle and depth of blast holes on the section, C) purge and clean the cut holes, auxiliary holes, peripheral holes and bottom plate holes that have been drilled, D) put the emulsion explosive and millisecond nonel detonator into the corresponding cut holes, In the auxiliary eye, the peripheral eye and the bottom plate eye, E) connect each detonator, and detonate according to the order of "cutting eye, auxiliary eye, peripheral eye and bottom plate eye" after confirmation; the present invention changes the existing large wedge-shaped cutting It is a multi-stage small wedge-shaped cut. By controlling the angle and depth of the blast hole on each initiation section and filling the increased initiation section with explosives, the condition of the air surface of the next stage of blasting is improved, thereby reducing the effect of blasting clamping; The vibration speed caused by cutting blasting is reduced, and the blasting vibration is effectively controlled.

Owner:CHINA COMM SOUTH ROAD & BRIDGE CO LTD

The reinforced structure of the ship's main engine cross brace and the ship

ActiveCN108128434BGuaranteed normal operationIncrease connection areaPower plants being motor-drivenHull partsMarine engineeringCross bracing

The invention provides a ship mainframe cross brace reinforcement structure and a ship, and relates to the technical field of ship construction. The ship mainframe cross brace reinforcement structureand the ship are designed to solve the problems that existing ship mainframe cross brace reinforcement structures cannot effectively enhance the transverse rigidity of joints of cross braces, correspondingly mainframe vibration cannot be effectively suppressed, and the layout of pipelines and passing of crews are inconvenient. The ship mainframe cross brace reinforcement structure is fixed to cross braces, a longitudinal passage is formed between the ship mainframe cross brace reinforcement structure and a longitudinal bulkhead, the ship mainframe cross brace reinforcement structure includes partial longitudinal bulkheads, and the partial longitudinal bulkheads are fixed to the main structure of the ship. The ship includes a ship body and the ship mainframe cross brace reinforcement structure. According to the ship mainframe cross brace reinforcement structure and the ship, the transverse rigidity of joints of the cross braces can be enhanced, and the technical problems that layout ofthe pipelines and passing of the crews are inconvenient are solved while the vibration of a mainframe is effectively suppressed.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Construction method for reducing blasting vibration of structure close to urban tunnel

PendingCN112539686AReduce vibration speedMeet the requirements of vibration speedBlastingDetonatorArchitectural engineering

The invention discloses a construction method for reducing blasting vibration of a structure close to an urban tunnel. The method comprises the following steps of a, during construction, moving cutting holes downwards to be away from an upper protected structure, arranging double-layer small guide pipes within the range of 4 m in front of and behind an underneath pass section, performing advance support, enabling the length of the small guide pipes to be 4 m, enabling the distance between every two adjacent small guide pipes to be 30 cm, performing construction once every other arch frame, driving locking foot anchor pipes strictly according to the designed depth, adding the locking foot anchor pipes at the arch waist, and effectively welding L-shaped ribs and locking feet; b, dividing anexcavation area at the upper part of the tunnel into a first area and a second area, firstly slotting a hole in the first area at the middle lower part of the step, arranging a blast hole and an electronic detonator detonating line, and carrying out blasting excavation of the first area with the excavation process of 0.5m to 1m to form a pilot tunnel so as to provide a complete free surface for other blast holes; and c, after the construction passes through the adjacent structure, arranging a second-area cutting hole, arranging a blast hole and an electronic detonator detonating line, carryingout blasting excavation of the second area, and finally expanding excavation to a designed contour line.

Owner:中钢集团郑州金属制品研究院股份有限公司 +1

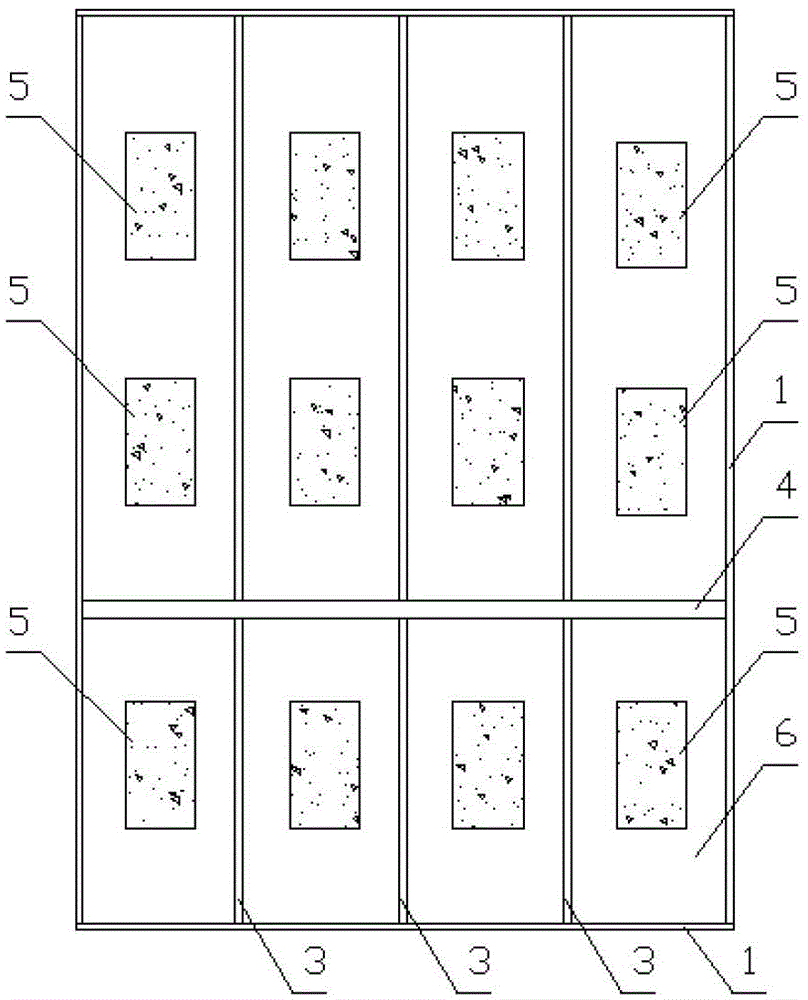

Composite Vibration and Sound Insulation Structure for Ship Compartment Walls

The invention discloses a composite damping soundproof structure of a ship compartment bulkhead. The structure comprises outer panels, inner panels, a frame, rib boards, damping masses, damping blocks and stuffing. Damping masses connected with left and right frame bars of the frame are horizontally disposed on the larger-than-1 / 3-height part of the frame from bottom to top. The rib boards connected with the frame and the damping masses and distributed at equal intervals are vertically disposed in upper and lower frames of the frame, and a plurality of cavities are formed inside and filled with the stuffing, and at least one damping block is regularly disposed on at least one layer of panels of the outer and inner panels. The compartment bulkhead structure has the functions of damping and sound proofing, vibration noise of the inside of a ship compartment is reduced effectively, fireproofing capacity of the ship compartment bulkhead is improved evidently, modular manufacturing and building of ships is facilitated, manufacturing time of ship compartment equipment is shortened effectively, and building efficiency is improved. The composite damping soundproof structure of the ship compartment bulkhead has promising application prospect.

Owner:AVIC WEIHAI SHIPYARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com