Sewage pump

A technology of sewage pump and sewage outlet, applied in the direction of pump, pump element, non-variable-capacity pump, etc., can solve the problems of reducing drainage efficiency, poor shock absorption of sewage pump, pipeline blockage, etc., so as to improve drainage efficiency and avoid pipeline blockage. , easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

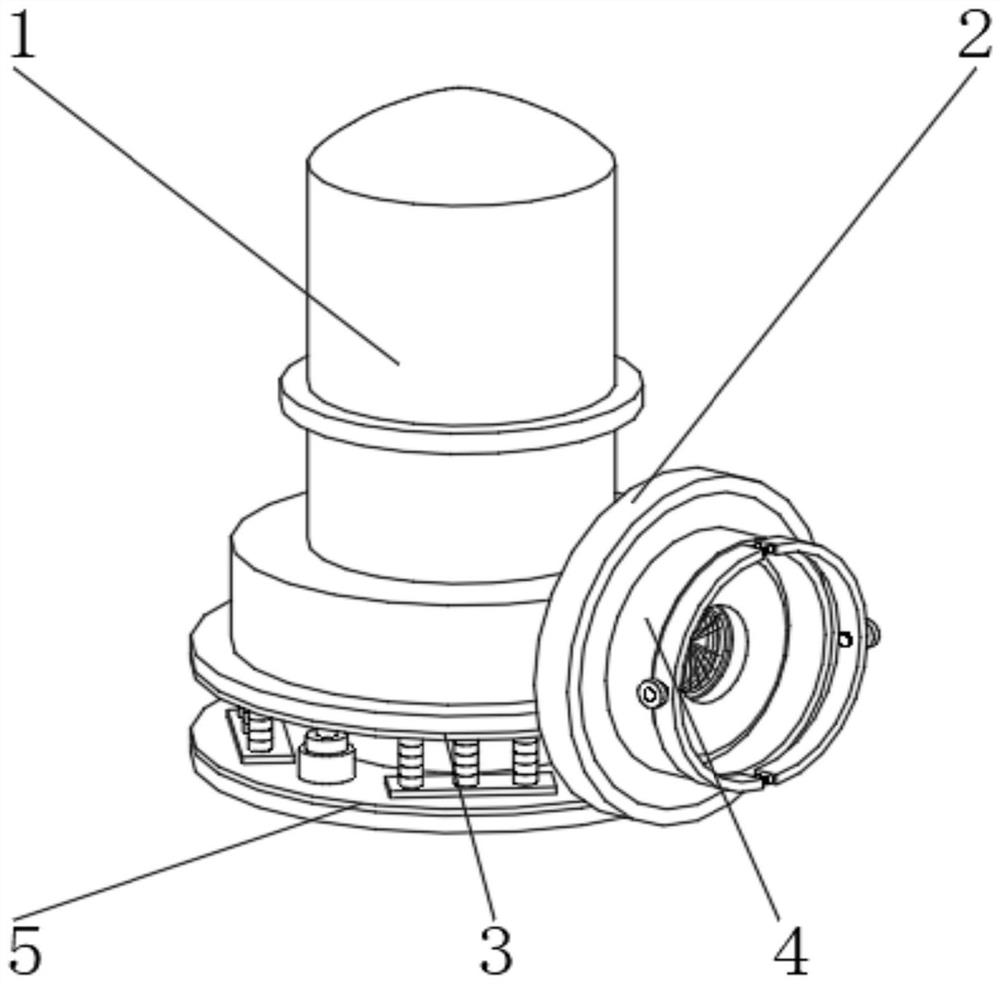

[0023] see Figure 1-5 , the present invention provides a technical solution: a sewage pump, comprising a pump body 1, the outer wall of the pump body 1 is fixedly connected with a sewage outlet 2, the outer surface of the lower end of the pump body 1 is fixedly connected with a chassis 3, and one end of the sewage outlet 2 is A filter fixing mechanism 4 is fixedly connected to the surface, and a shock absorbing mechanism 5 is fixedly connected to the outer surface of one end of the chassis 3 .

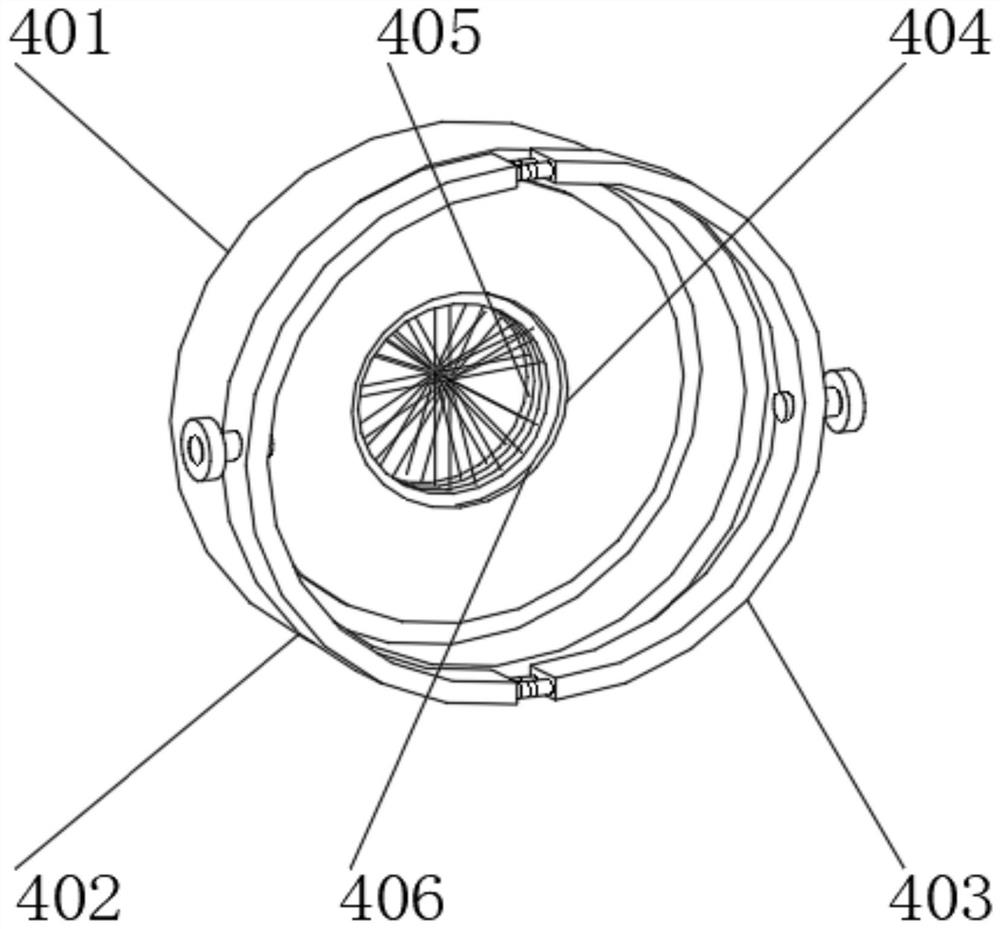

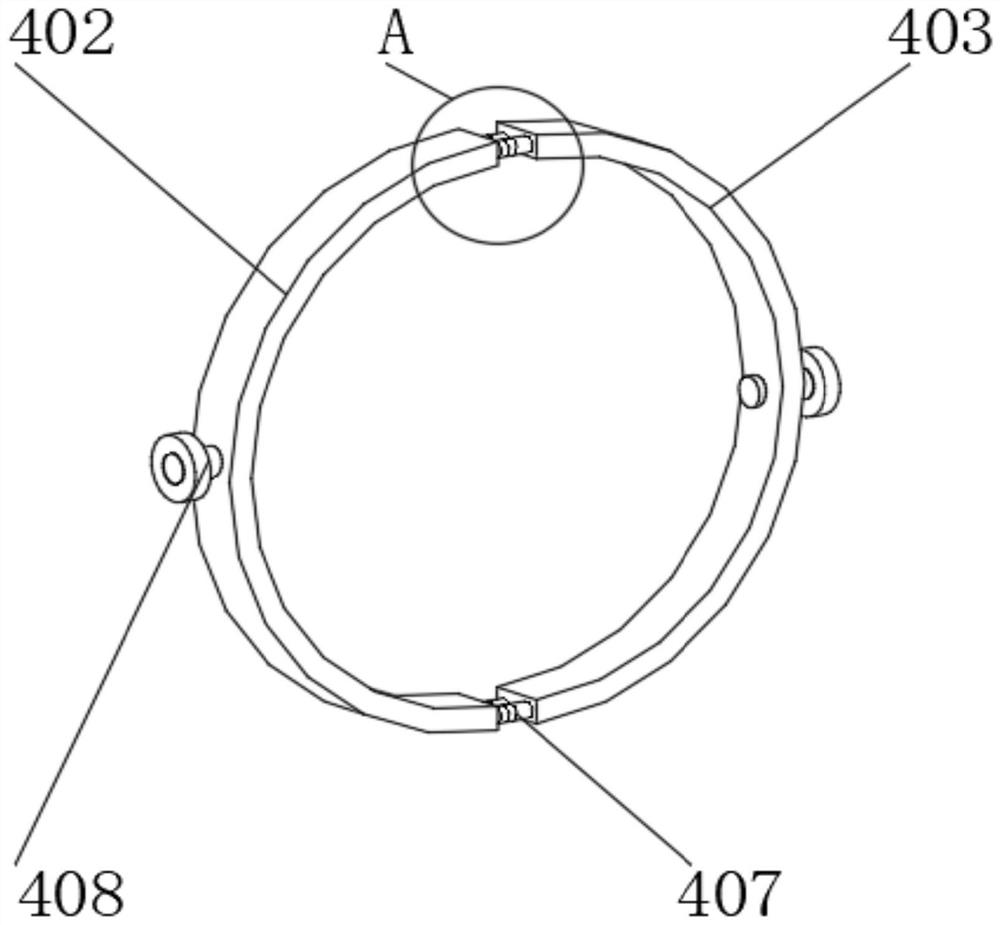

[0024] In this embodiment, by installing and fixing the pipe connecting ring 401 on the sewage outlet 2, when the sewage is discharged, the pipe is inserted into the pipe connecting ring 401, and the pipe mouth is aligned with the connecting port 404, and then the first arc ring 402 Fix the No. 2 arc-shaped ring 403 at the joint between the pipe and the pipe connecting ring 401, tighten the fixing assembly 408, the pipe can be fixed, and the No. 1 spring 407 can change the fixing stre...

Embodiment 2

[0032] Specifically, the damping mechanism 5 includes a No. 1 rubber ring 501, a No. 2 rubber ring 502, a mounting plate 503, a No. 2 spring 504, and a hydraulic column 505. The mounting plate 503 is located at one end of the No. 1 rubber ring 501 and the No. 2 rubber ring 502. , the second spring 504 is located on the outer surface of one end of the mounting plate 503 , and the hydraulic column 505 is located between the first rubber ring 501 and the second rubber ring 502 .

[0033] In this embodiment, the shock-absorbing mechanism 5 is beneficial to the shock-absorbing of the sewage pump and avoids its strong shaking.

[0034] Specifically, the mounting plate 503 is installed on one end of the No. 1 rubber ring 501 and the No. 2 rubber ring 502 through a set screw, and the outer surface of one end of the mounting plate 503 is welded to the outer surface of one end of the No. 2 spring 504. The number of springs 504 is several groups.

[0035] In this embodiment, by installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com