A micro-vibration blasting method for deep hole steps

A deep-hole ladder and micro-vibration technology, which is applied in the fields of highways, water conservancy and hydropower construction projects, municipal public works, and railways, can solve the problems of affecting construction progress and low construction efficiency, so as to improve efficiency, reduce single-sound dose, The Effect of Reducing the Vibration Velocity of Blasting Particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

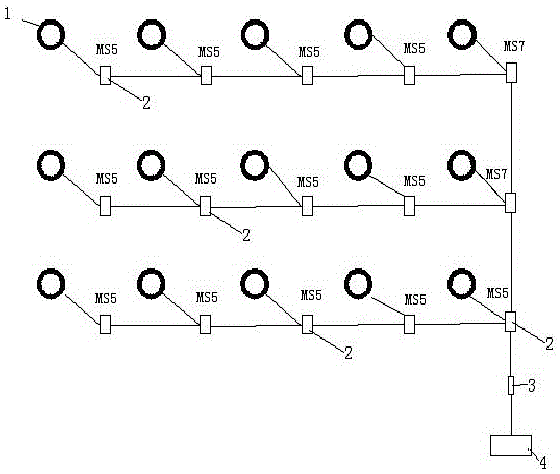

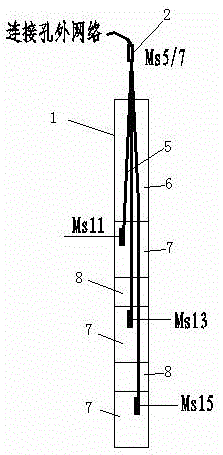

[0010] Such as figure 2 As shown, the single blasting hole of the step blasting is charged in stages and blocked in stages, that is, the blockage section 6 at the hole and the blockage section 8 in the hole, and the charge section 7 in the hole adopts MS15, MS13, and MS11 respectively from bottom to top. Section millisecond differential time delay detonator, and lead it to the orifice, the orifice blocking section 6 is long blocking. Corresponding to each hole in the mining outside the hole, MS5 segment of millisecond differential delay detonator is connected in series, and an MS7 millisecond differential delay detonator is added in series between the first row of holes to the second row of holes, and the second row of holes to the third row of holes. Ensure single-hole single-shot, and finally form a single-hole single-shot blasting network. The millisecond differential delay detonator outside each hole is connected to the millisecond differential delay detonator in the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com