Patents

Literature

49results about How to "Improve dynamic balance accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

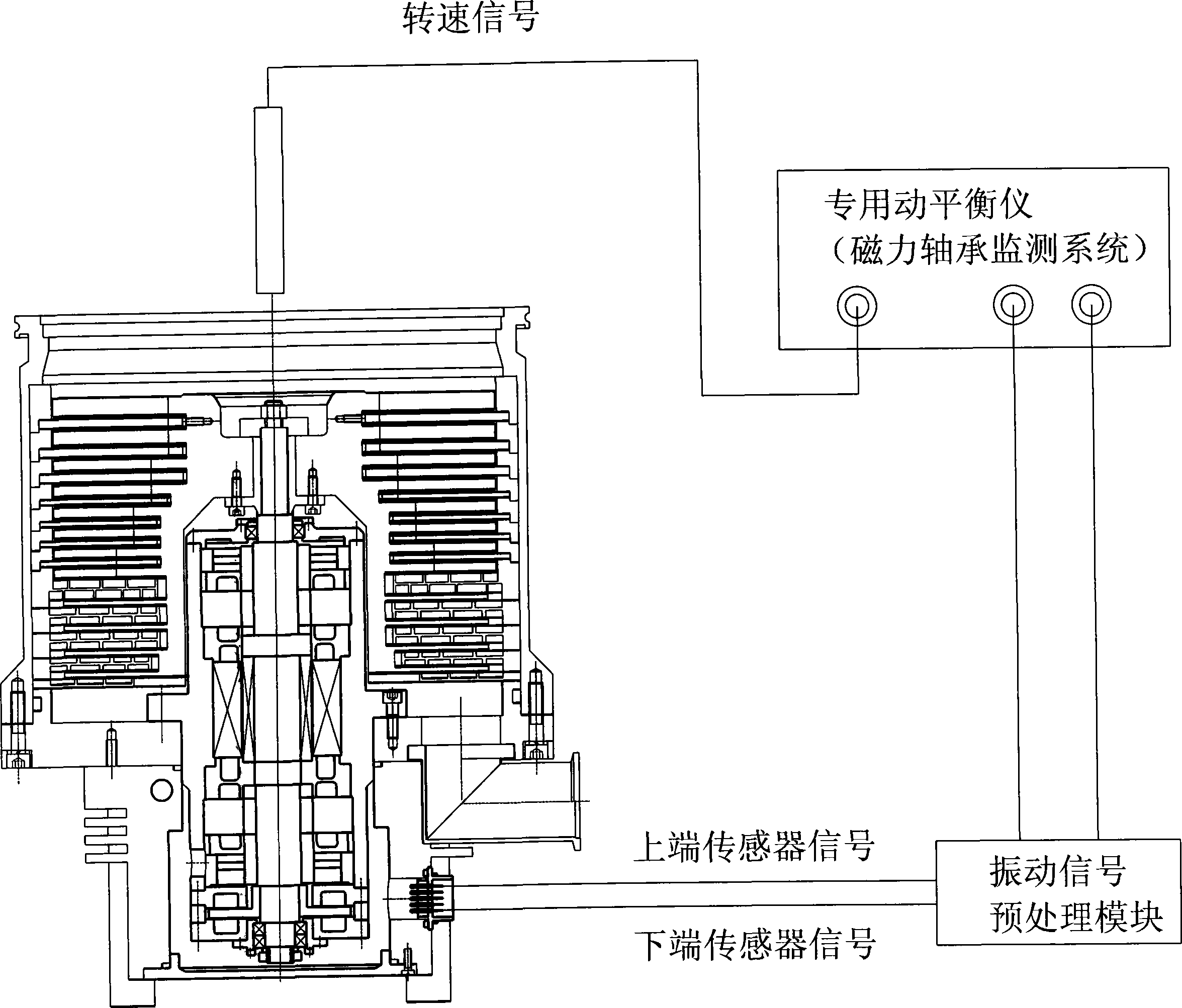

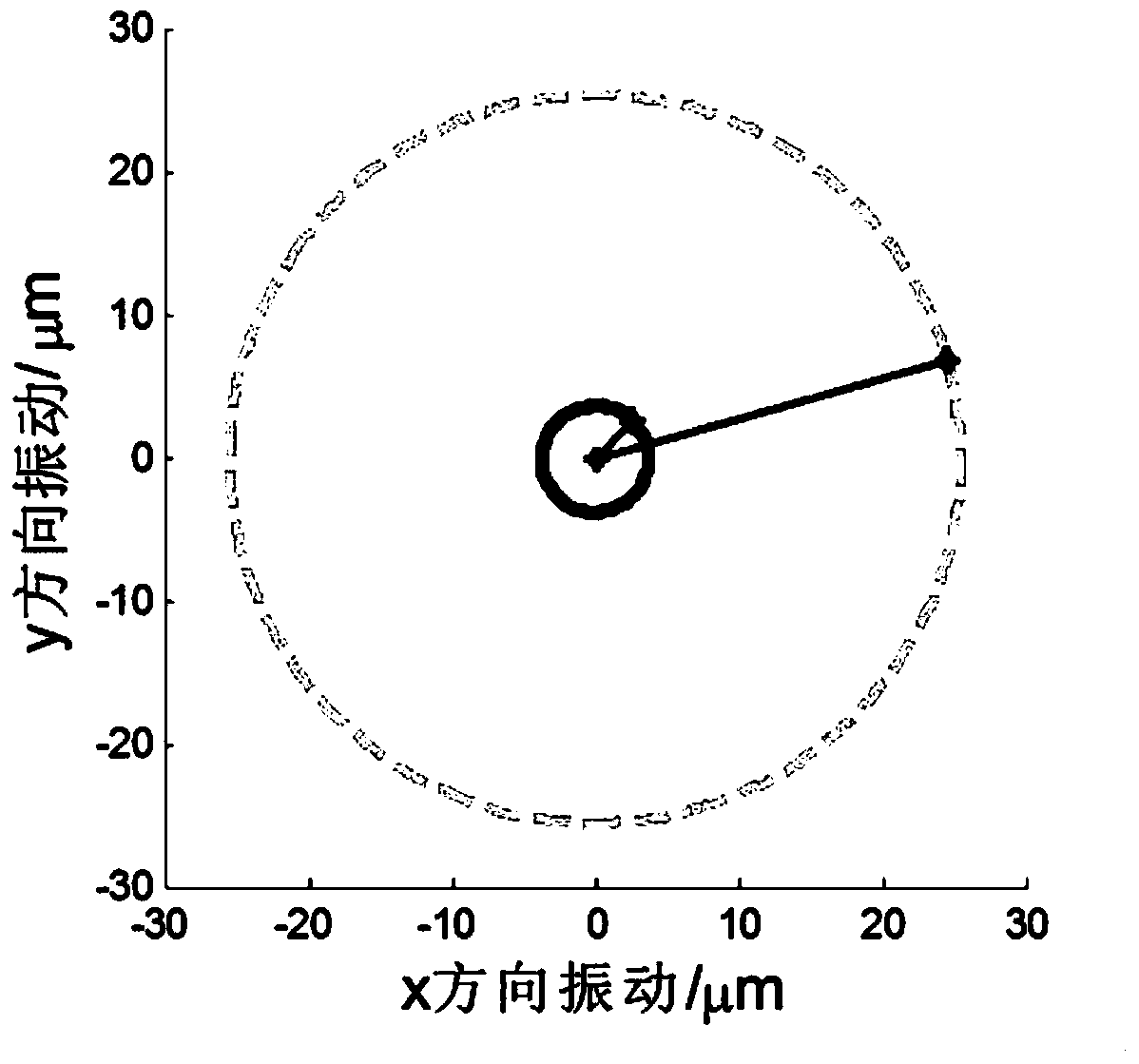

Method for regulating magnetic levitation vacuum molecular pump rotor dynamic balance

InactiveCN101187589AImprove dynamic balance accuracyHigh precisionStatic/dynamic balance measurementFistMagnetic bearing

The invention discloses a method for adjusting dynamic balance of a rotor of a magnetic suspension vacuum molecular pump, which particularly comprises fist, detecting an actual vibrating signal of a rotor which is obtained by a sensor directly from a rotor of a magnetic bearing, second, collecting rotor speed and phase signal, third, doing an isolating process of direct current composition to the vibrating signal of the rotor which is obtained, fourth, doing a real-time filtering process to the vibrating signal according to the rotor speed, obtaining vibrating signals with the same frequency of the rotor, fifth, finishing corresponding dynamic balance algorism in post period by utilizing a dynamic balancing device or an observation system which is operated in a magnetic suspension vacuum molecular pump, and doing a dynamic balance to the rotor according to the result of the dynamic balance algorism, sixth, repeating the steps untill the rotor achieves a needed dynamic balancing accuracy. The method of the invention has the advantages of high accuracy of a vibrating value which is collected, high dynamic balance accuracy, and balancing behavior of the rotor is completely consistent with the final actual operating behavior, which is beneficial for simplifying dynamic balancing equipment.

Owner:浙江飞旋科技有限公司

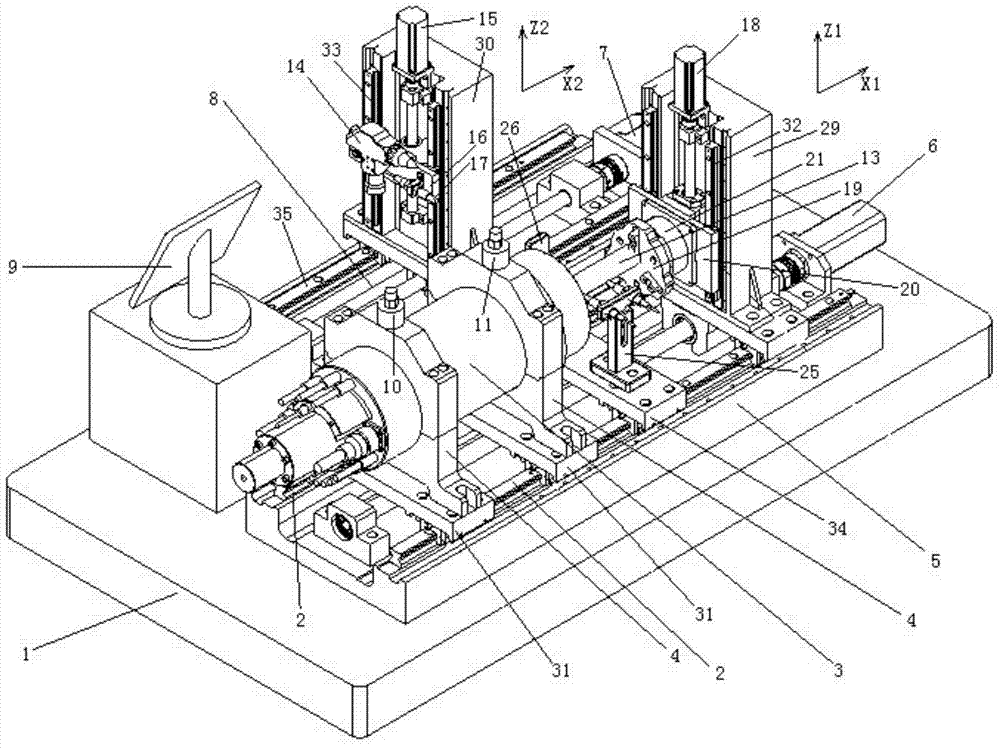

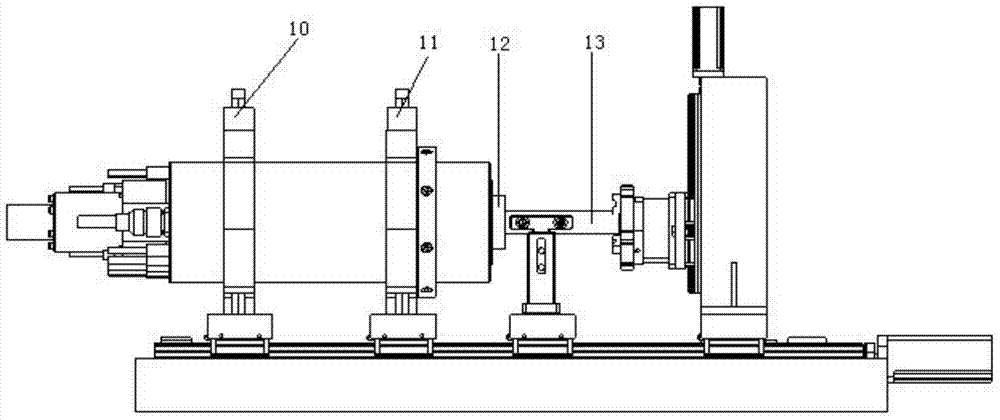

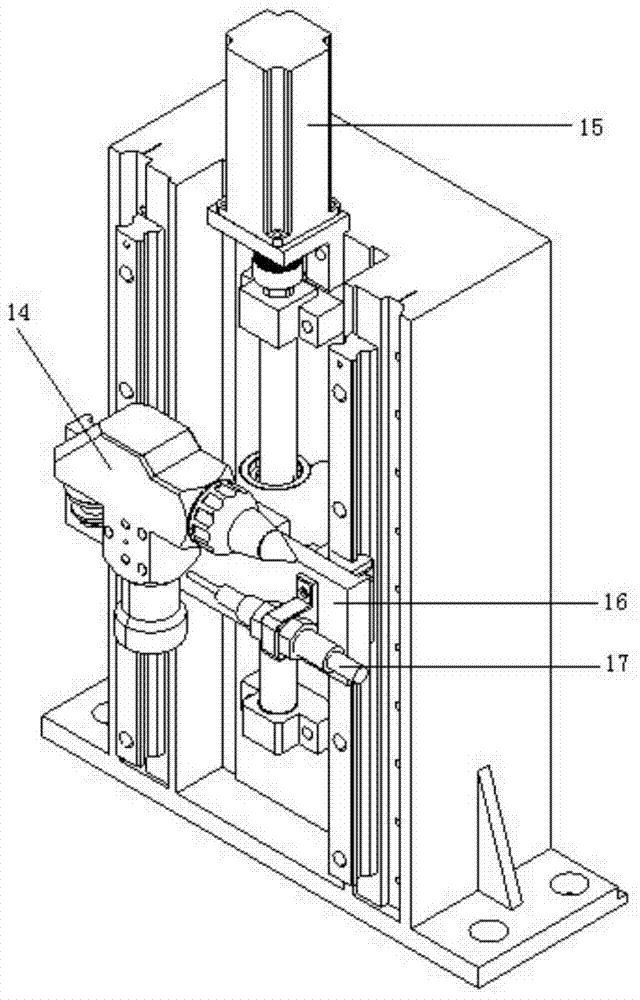

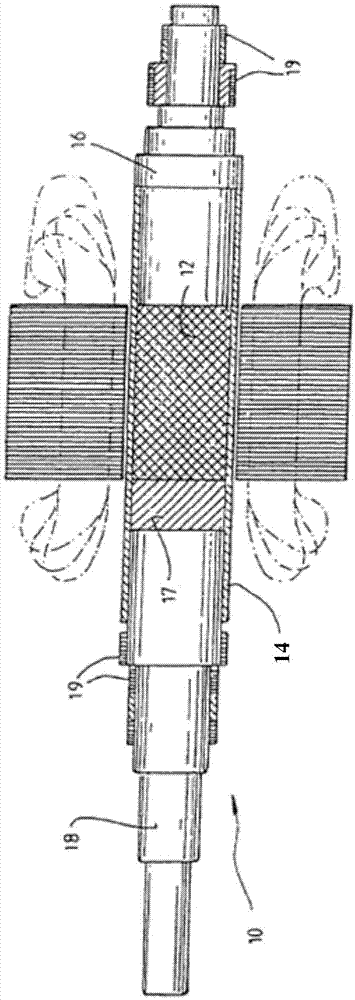

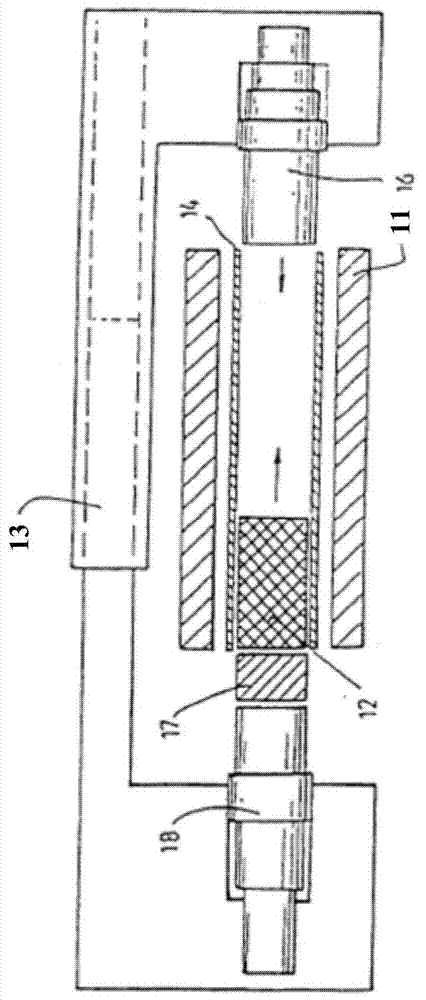

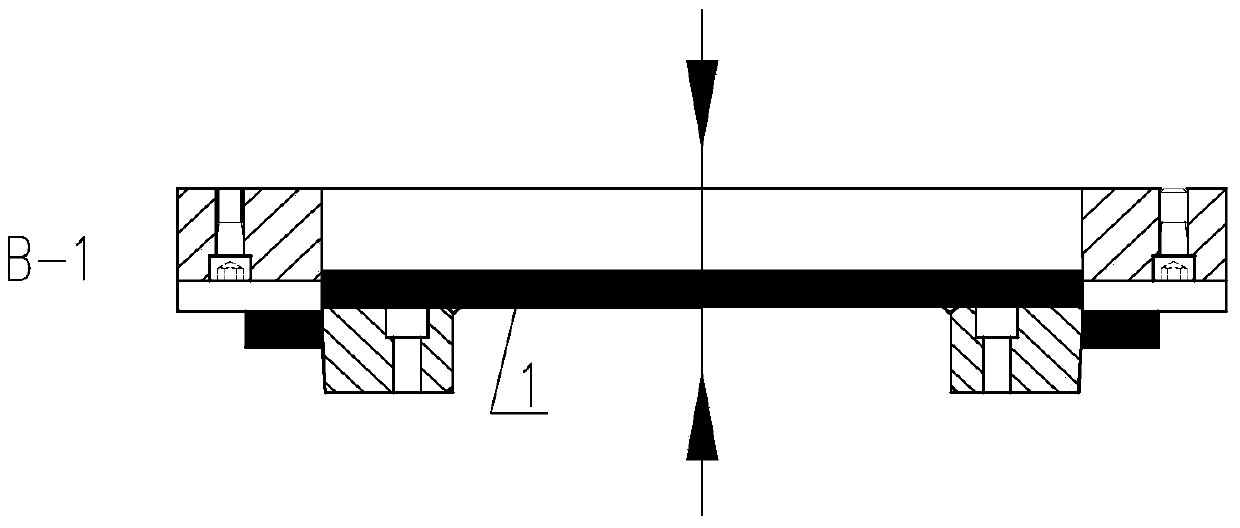

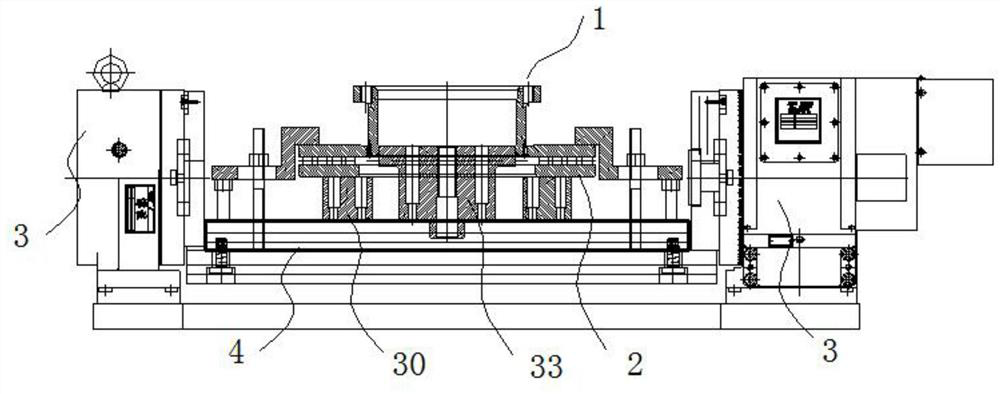

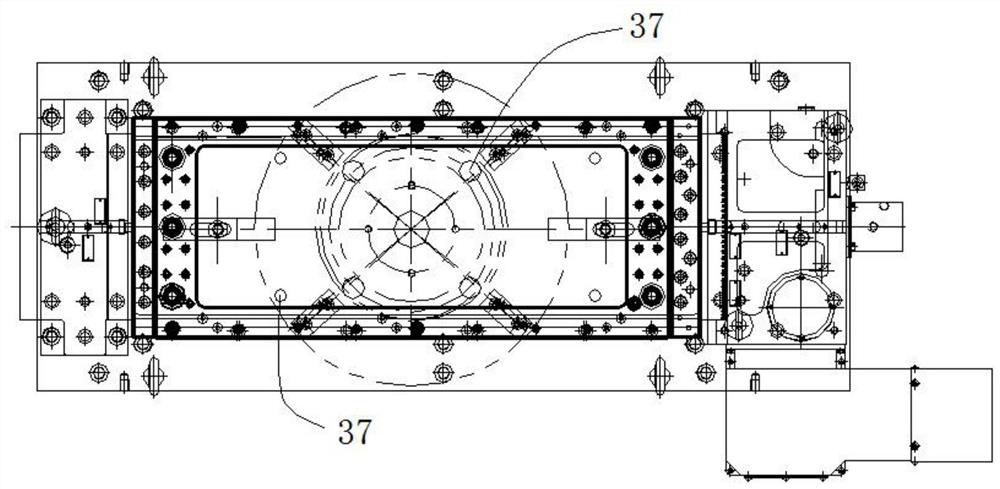

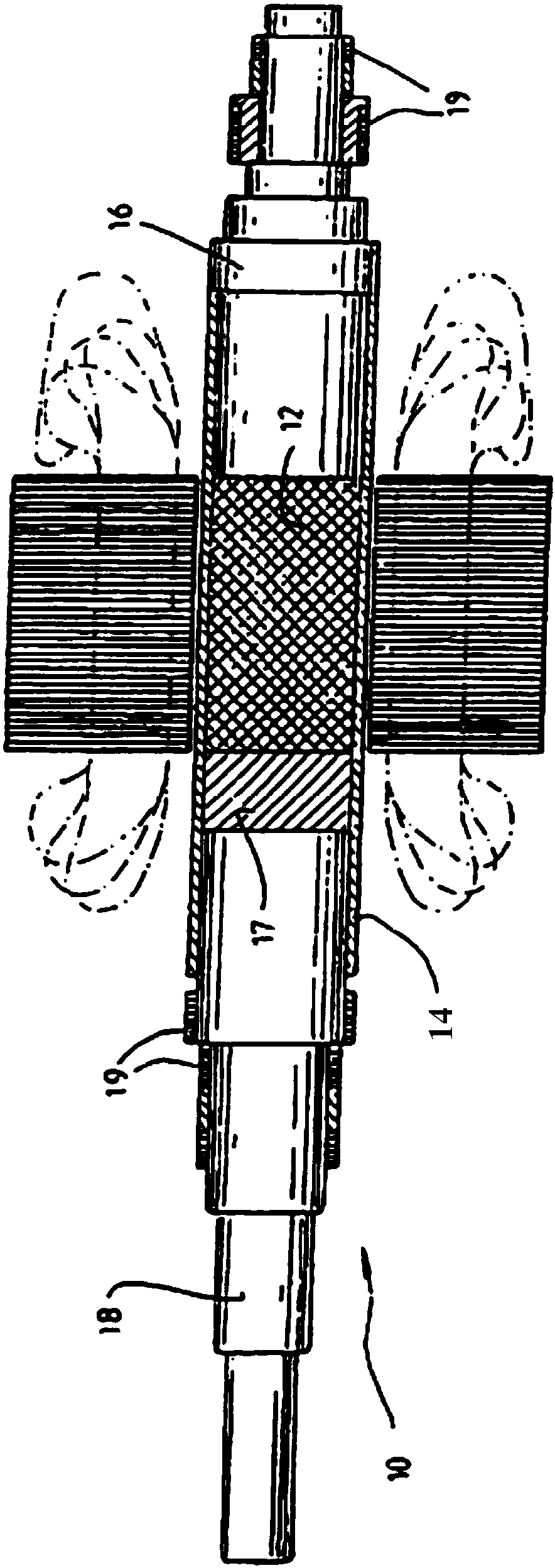

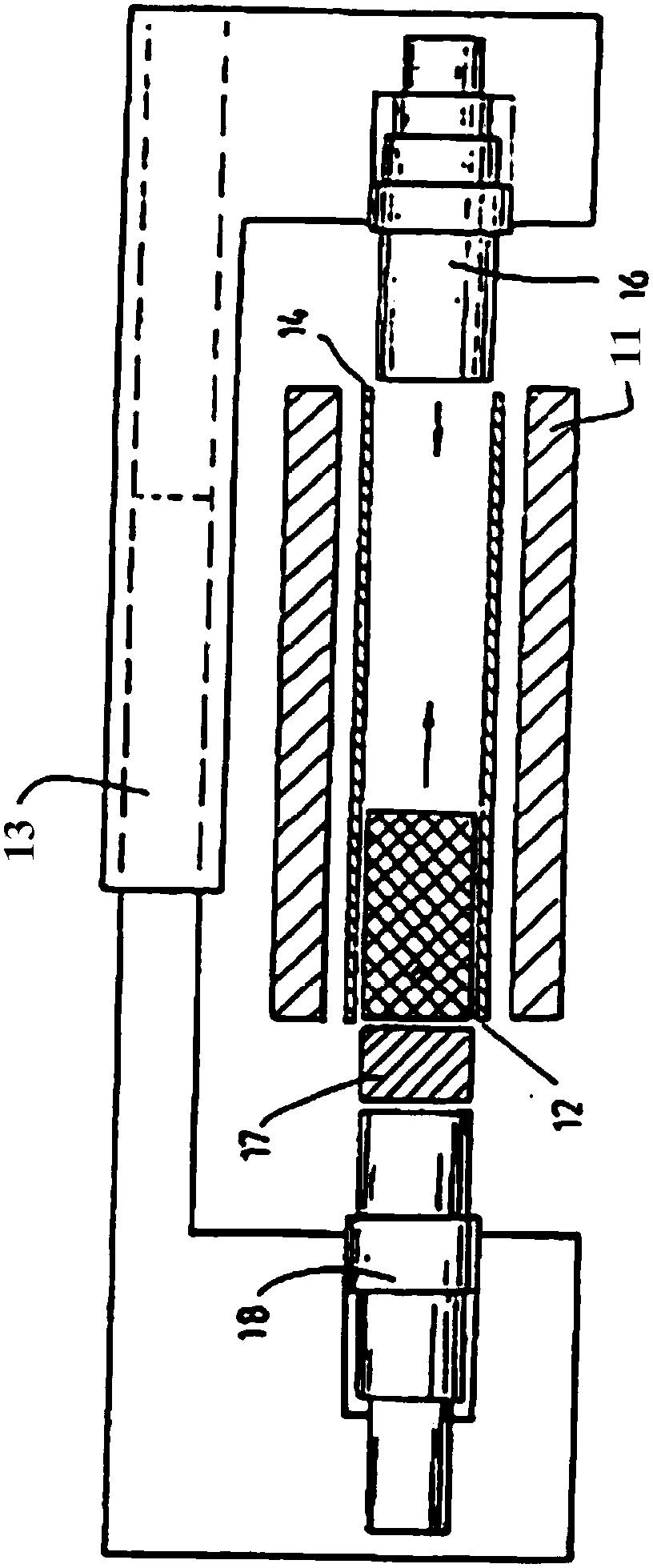

High-speed main shaft complete machine intelligent dynamic balance device

ActiveCN104764563AAvoid Balance Accuracy LossImprove dynamic balance accuracyStatic/dynamic balance measurementVibration testingDynamic balanceTorque motor

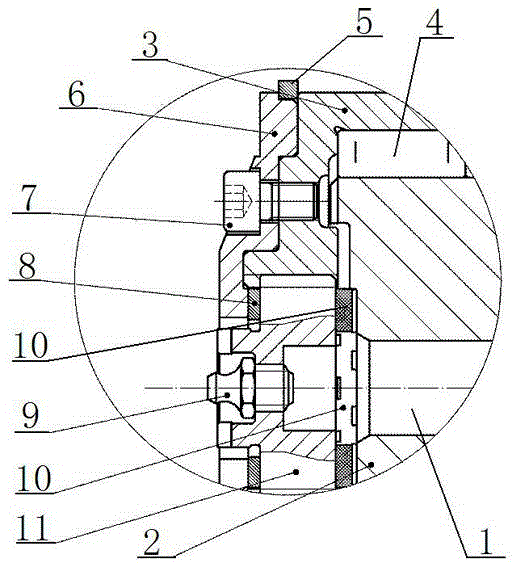

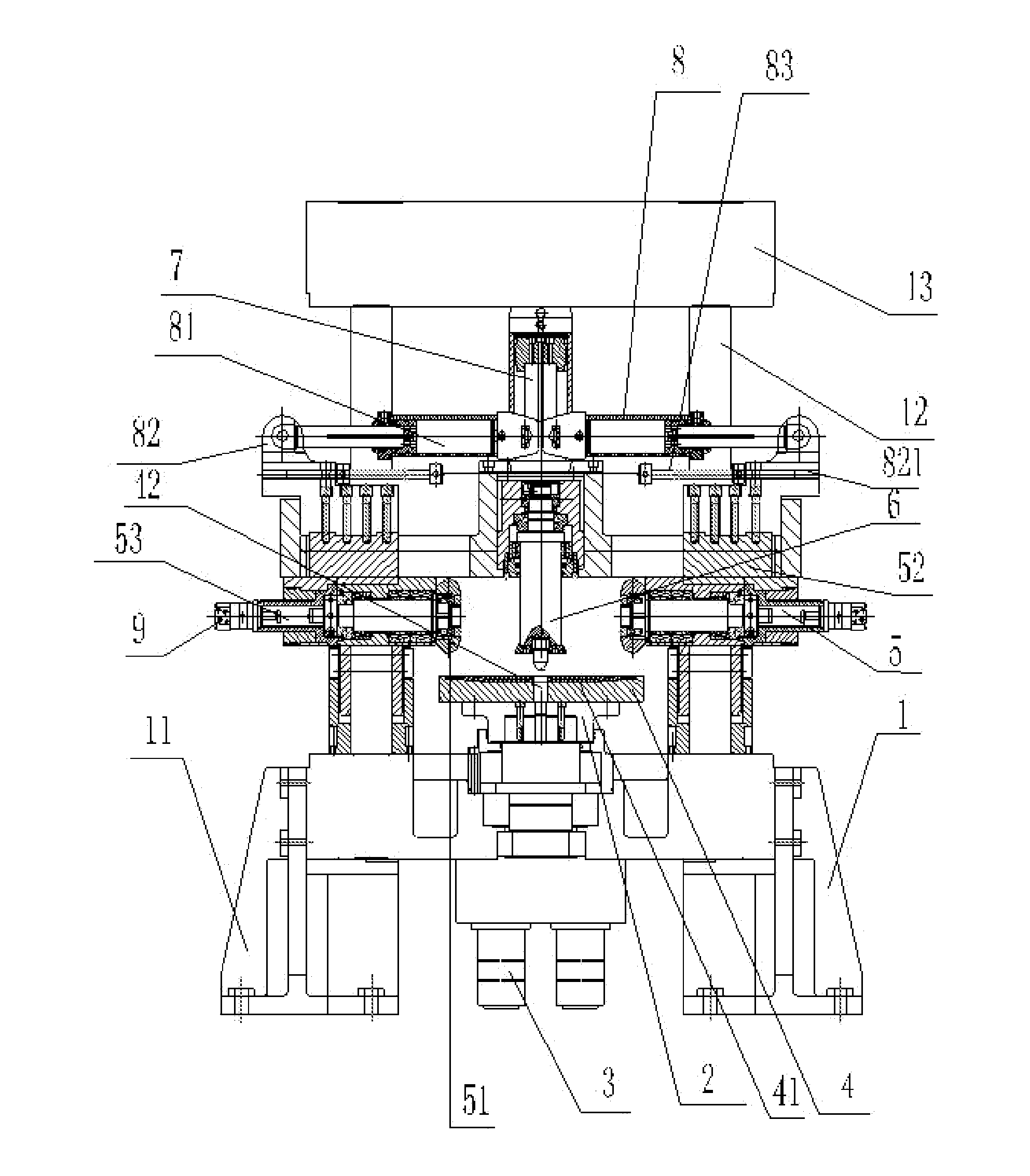

The invention discloses a high-speed main shaft complete machine intelligent dynamic balance device which comprises a main shaft system fixed connecting part, a rotor automatic clamping and rotating part, a laser automatic aligning and de-weighting part and an unbalance detecting part. A high-speed main shaft of the main shaft system fixed connecting part is fixed to a main shaft positioning base. A vibration testing core bar is installed at the front end of the main shaft. A pneumatic claw of the rotor automatic clamping and rotating part can automatically clamp the vibration testing core bar and can be fixedly connected with a torque motor. The laser automatic aligning and de-weighting part comprises a positioned light source, a de-weighting machining light source and a position sensitive device. A balance weight disc is installed at the tail end of a main shaft rotor. The unbalance detecting part comprises an acceleration sensor, a displacement sensor, a phase demodulation sensor and an industrial computer for computing the unbalance amount. Compared with a traditional dynamic balancing device, the high-speed main shaft complete machine intelligent dynamic balance device has the advantages that no manual interference is needed, the main shaft does not need to be detached, the rotor is driven by a matched variable-frequency device, the actual working conditions are easily simulated, and the dynamic balance accuracy and efficiency are effectively improved.

Owner:XIDIAN UNIV

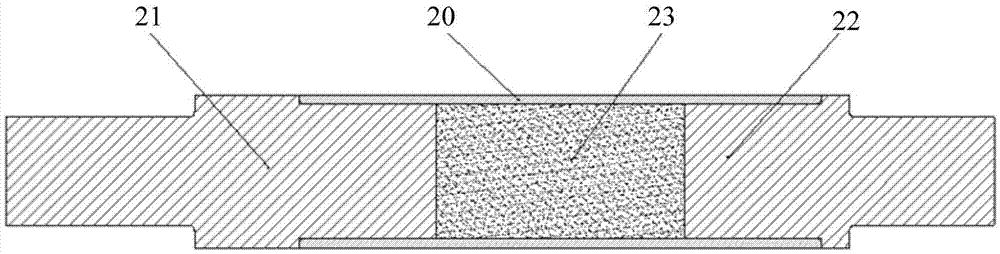

Shafting structure for motor, and assembling method

ActiveCN105449895AReduce in quantityReduce assembly coaxiality is difficult to guarantee the problemMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineryStructural engineering

The invention discloses a shafting structure for a motor, and an assembling method. The shafting structure comprises a front-segment shaft (62), a rear-segment shaft (63), annular magnetic steel (61) and an alloy sheath (60), wherein the rear-segment shaft (63) successively comprises a first shaft joint (631) and a second shaft joint (633) from front to back, and the diameter of the first shaft joint (631) is smaller than that of the second shaft joint (633); the annular magnetic steel (61) sleeves the first shaft joint (631) of the rear-segment shaft (63); the external diameter of the rear end of the front-segment shaft (62) is the same as the external diameter of the annular magnetic steel (61); and the alloy sheath (60) sleeves the front-segment shaft (62) and the annular magnetic steel (61). According to the scheme provided by the invention, the shafting structure and the assembling method overcome the defects of complex structure, large assembling difficulty, poor safety and the like in the prior art and also have the advantages of simple structure, small assembling difficulty and good safety.

Owner:GREE ELECTRIC APPLIANCES INC +1

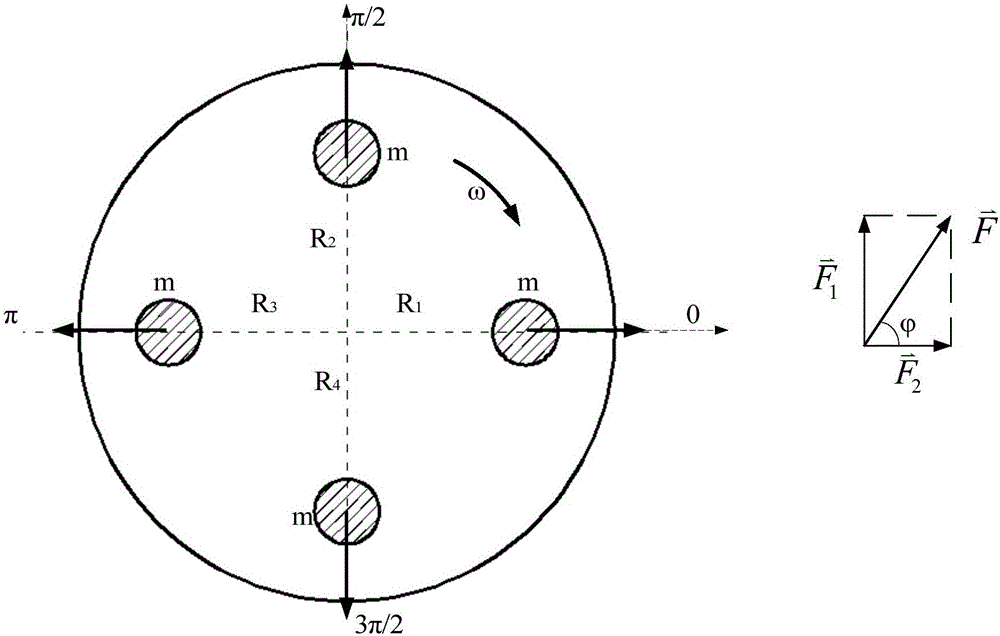

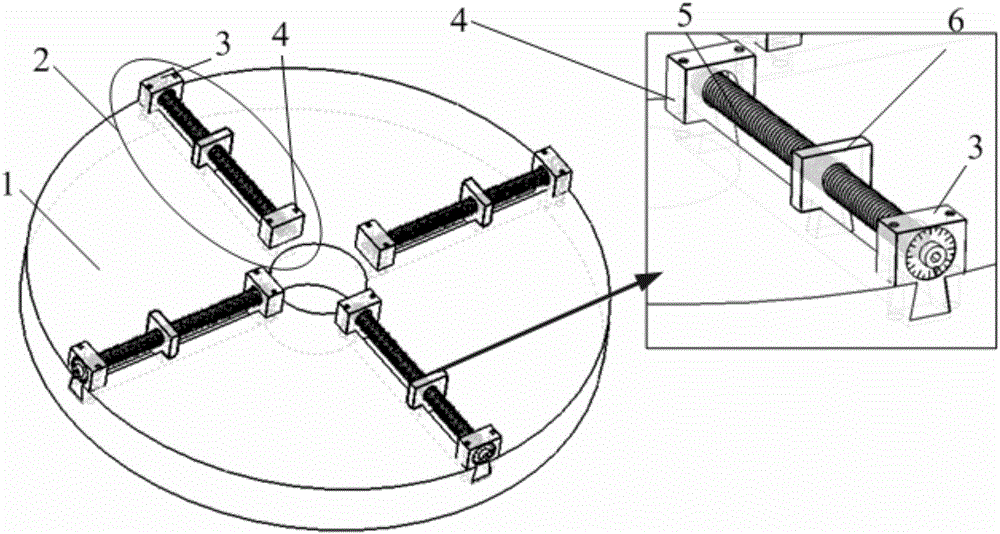

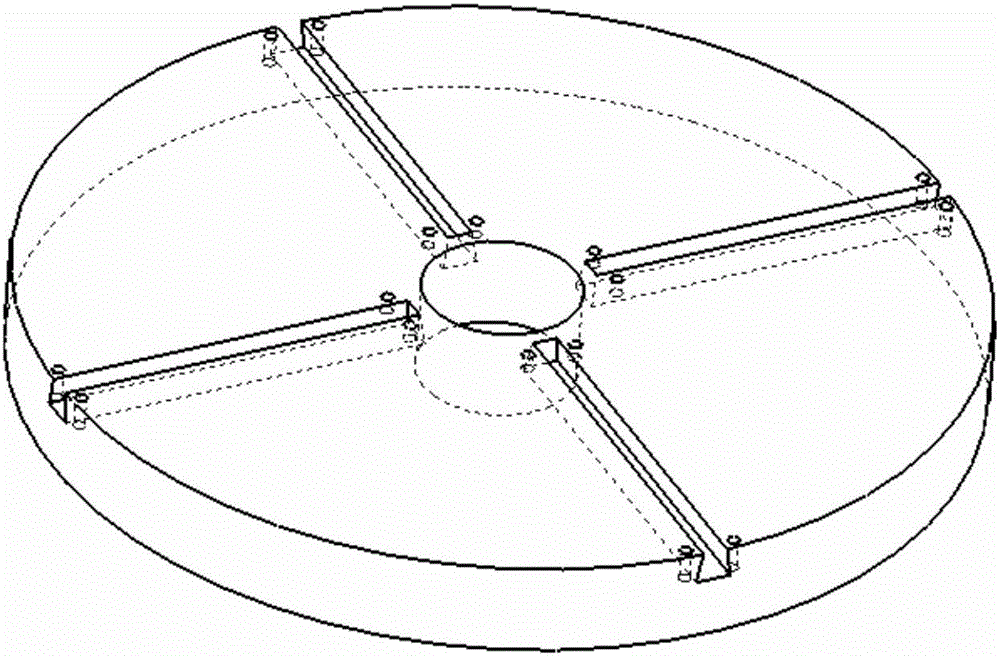

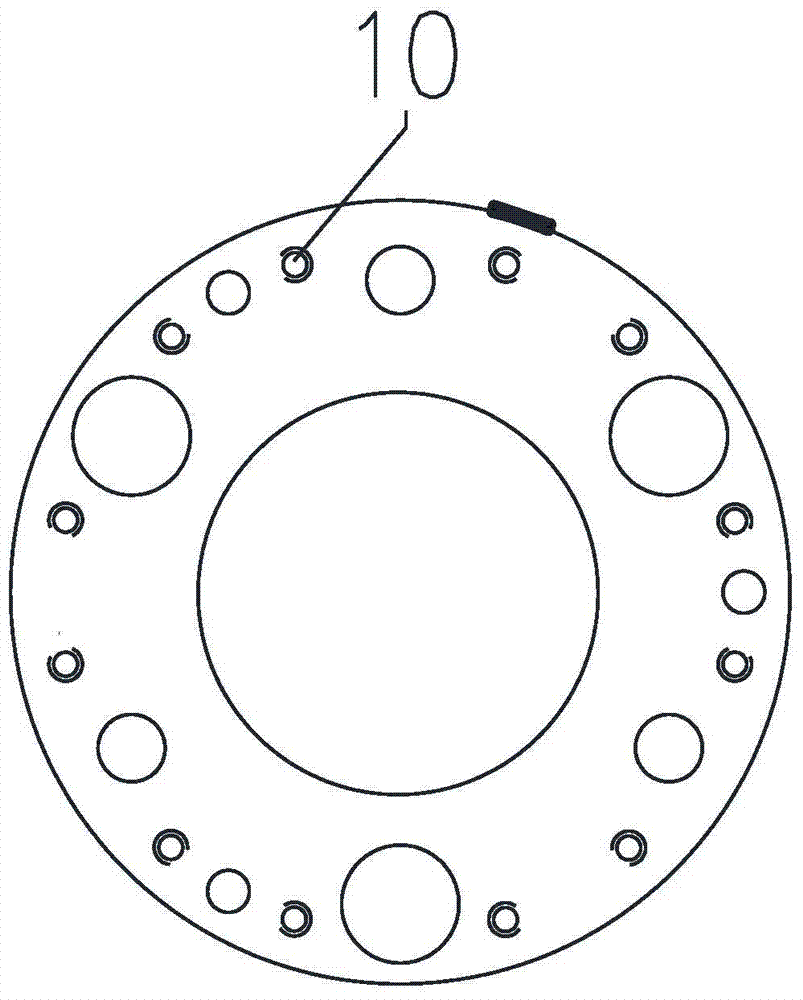

Rotary machinery dynamic balance quick weight-countering adjustment device and method

ActiveCN106768643AEasy to adjust and calculateSave on-site balancing timeStatic/dynamic balance measurementDynamic balanceEngineering

The present invention discloses a rotary machinery dynamic balance quick weight-countering adjustment device. The device comprises a balance disc and at least one pair of weight-countering adjusting components mounted on the balance disc, wherein the weight-countering adjusting components are distributed at equal intervals along the radial direction of the disc surface of the balance disc. According to the rotary machinery dynamic balance quick weight-countering adjustment device of the invention, after weight-countering mass, a weight-countering position and a weight-countering angle are obtained through a traditional dynamic balance algorithm, counterweights are not needed to be temporarily processed on a site, operation such as welding the counterweights is not required, and therefore, field dynamic balance time can be greatly decreased; as for field dynamic balance according to which a weight-countering position is provided with a cylinder or a shaft sleeve, it only needs to reserve adjustment holes, and a special wrench can be adopted to conveniently and fast adjust the weight-countering adjustment device of the invention through the adjustment holes, and therefore, field workload can be greatly decreased; and since the adjustment of the positions of the counterweights can be carried out through screw rods, and the positions of the counterweights can be adjusted very precisely, and the precision of dynamic balance is improved. The weight-countering adjustment algorithm of the invention is easy to understand and can facilitate field personnel to carry out adjustment and calculation.

Owner:STATE GRID CORP OF CHINA +2

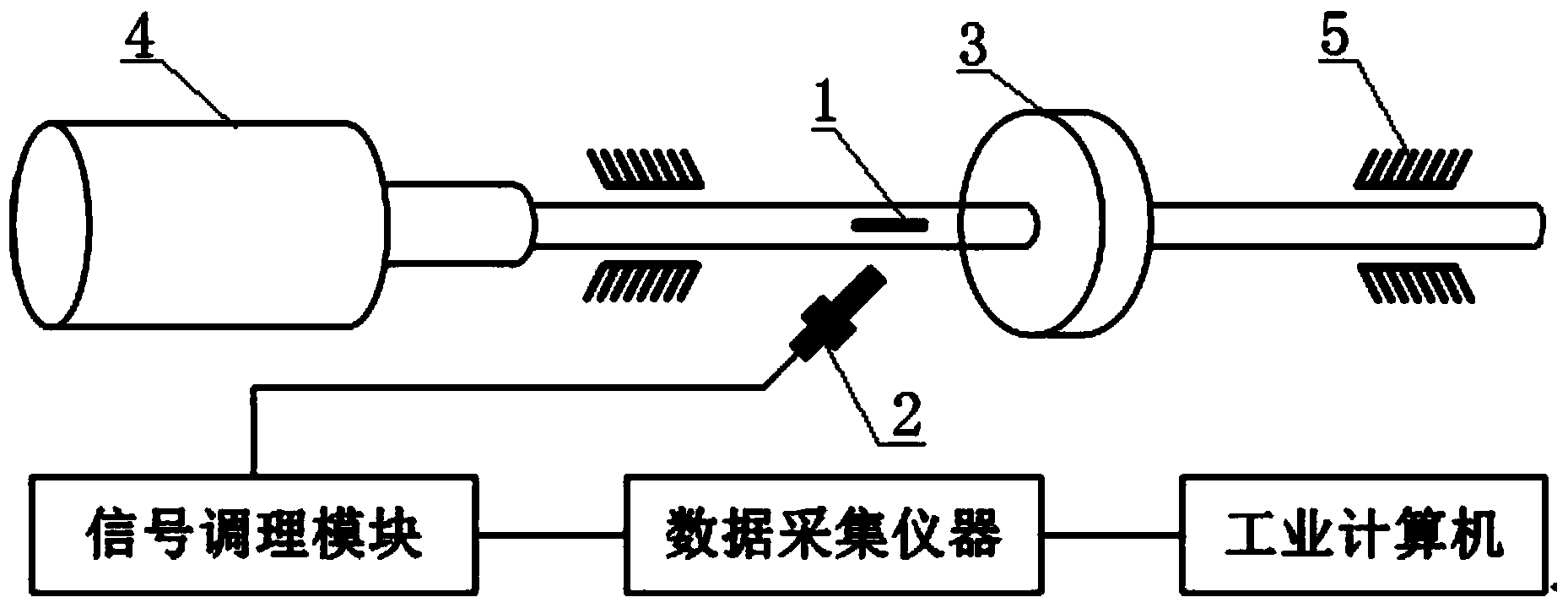

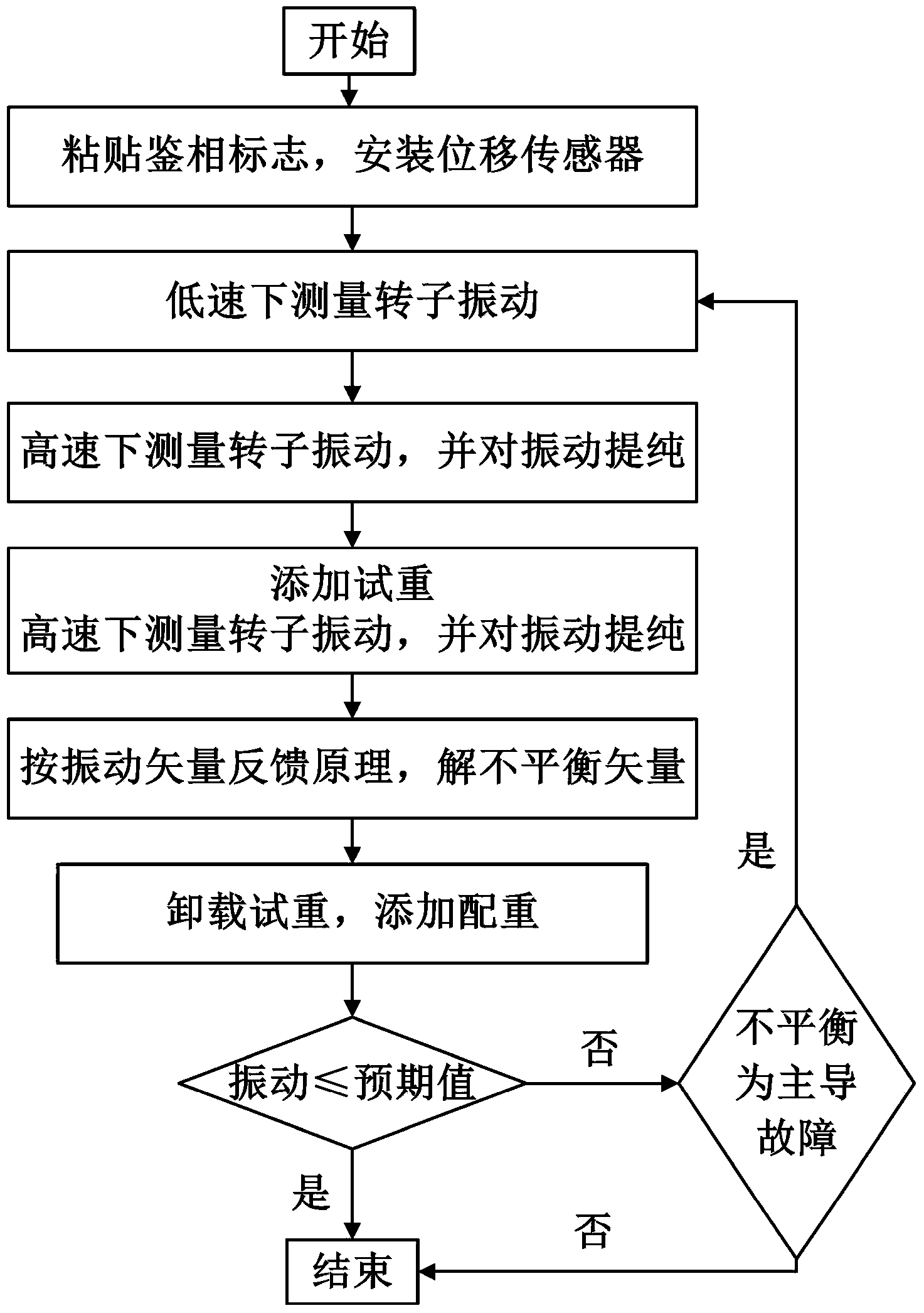

Dynamic balancing method for high-speed rotors

ActiveCN104165729AGuaranteed Accurate AcquisitionImprove dynamic balance accuracyStatic/dynamic balance measurementLow speedDynamic balance

The invention belongs to the technical field of rotating equipment fault diagnosis and control, and particularly relates to a dynamic balancing method for high-speed rotors. According to the method, on the basis of acquiring vibration information of a rotor, vibration data at high speed and vibration data at low speed are cut down at the same scale through post processing, the interference of rotor measurement section profile error, phase discrimination mark, electromagnetic interference, bending and other non-imbalance factors is eliminated, and purification of unbalanced vibration is realized. Compared with a traditional dynamic balancing method, the method ensures precise acquisition of unbalanced vibration data and obviously improves the precision of dynamic balancing, and the method needs no phase discrimination sensors, reduces the dependence of a system to the installation space and reduces the complexity and the development cost of the system. Besides, the method has a wide range of applications, has a simple process, is conductive to the realization of computerized control, and has good practical application values.

Owner:XIDIAN UNIV

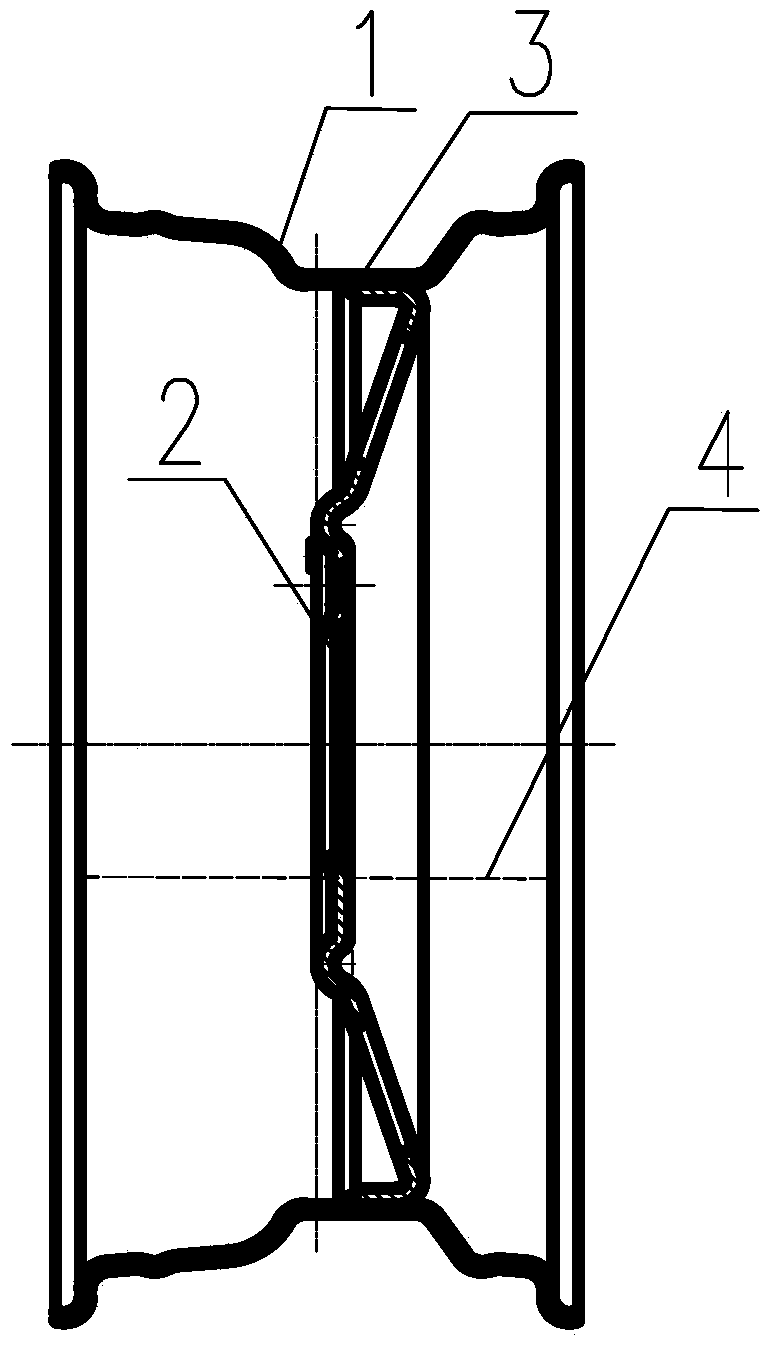

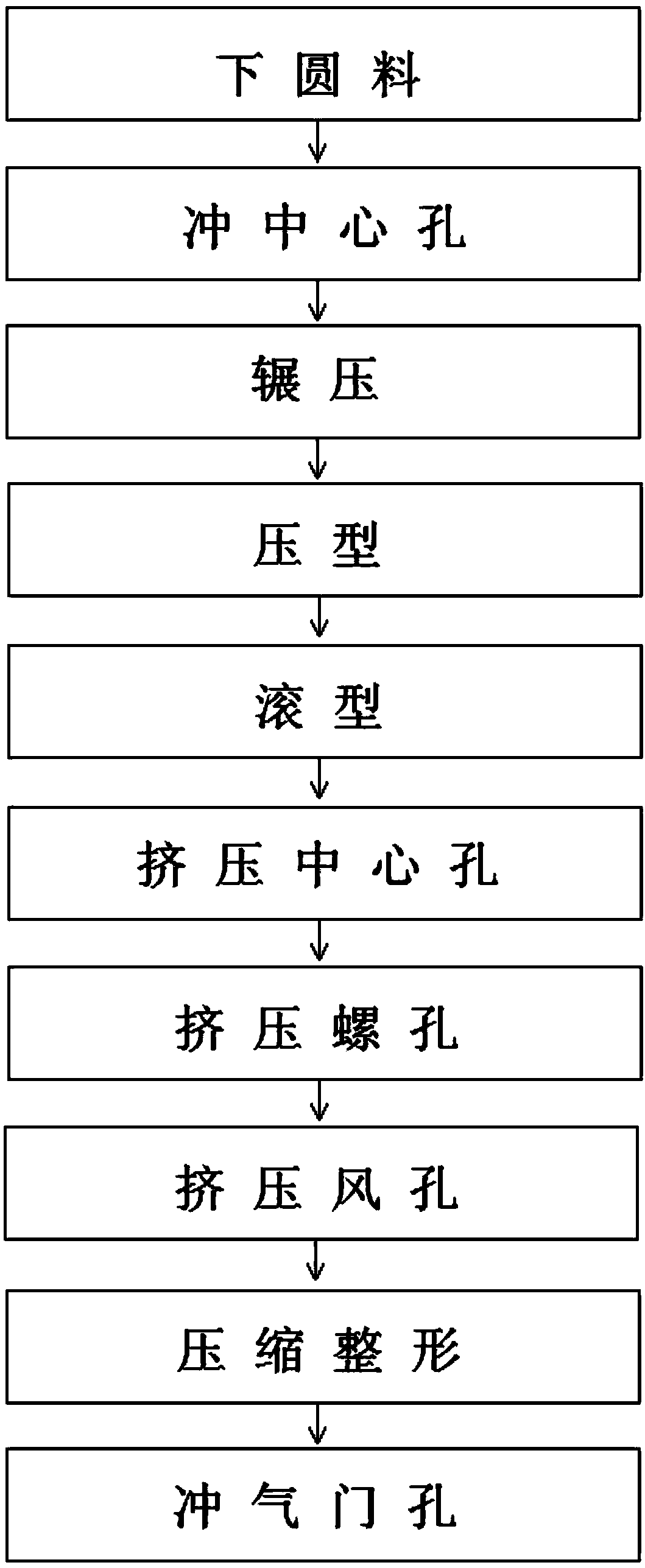

Integrated plate welded-joint-free vehicle wheel and forming method of integrated plate welded-joint-free vehicle wheel

InactiveCN104191900AReduce consumptionImprove bending fatigue lifeRimsMetal-working apparatusAir tightnessAutomotive engineering

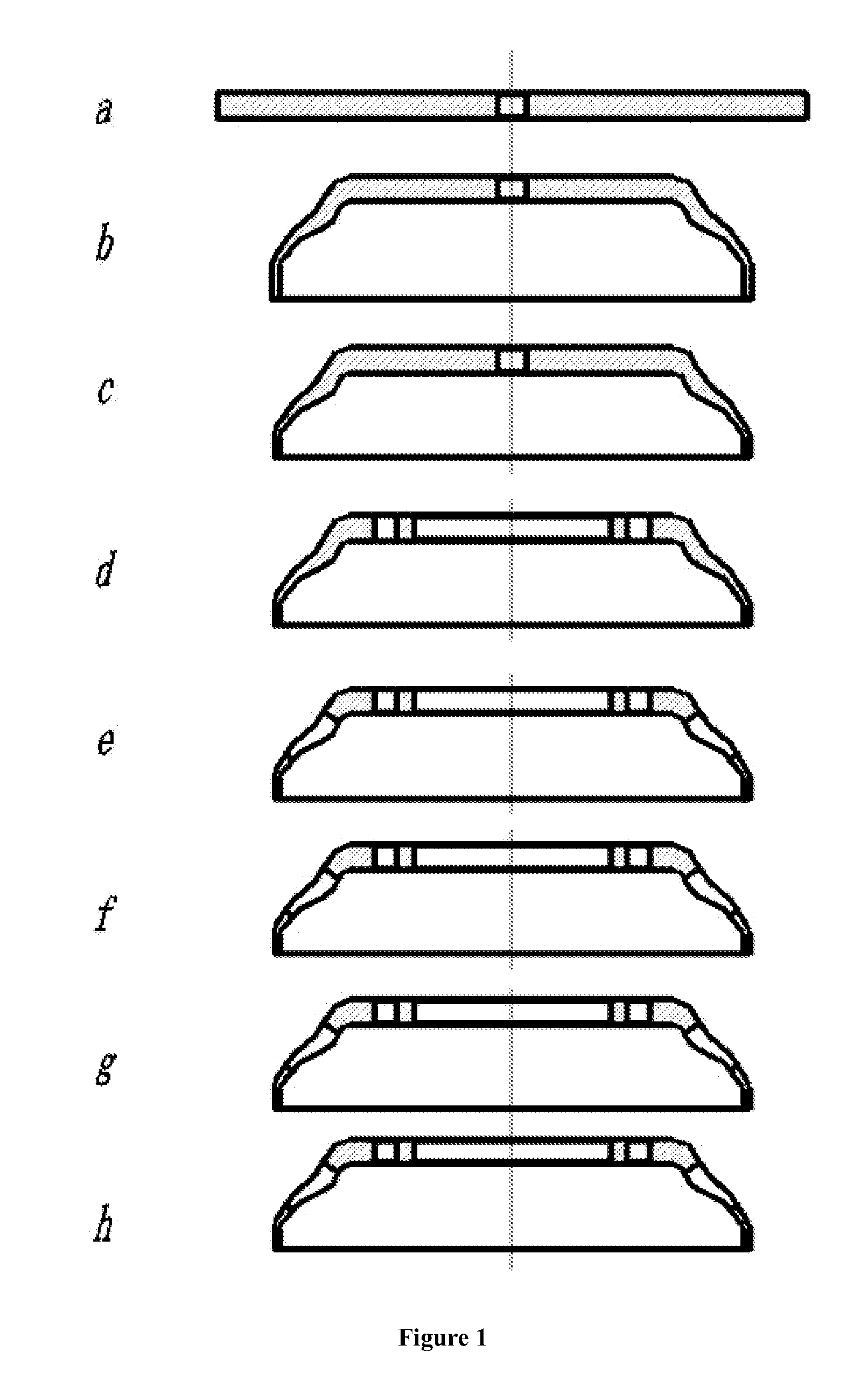

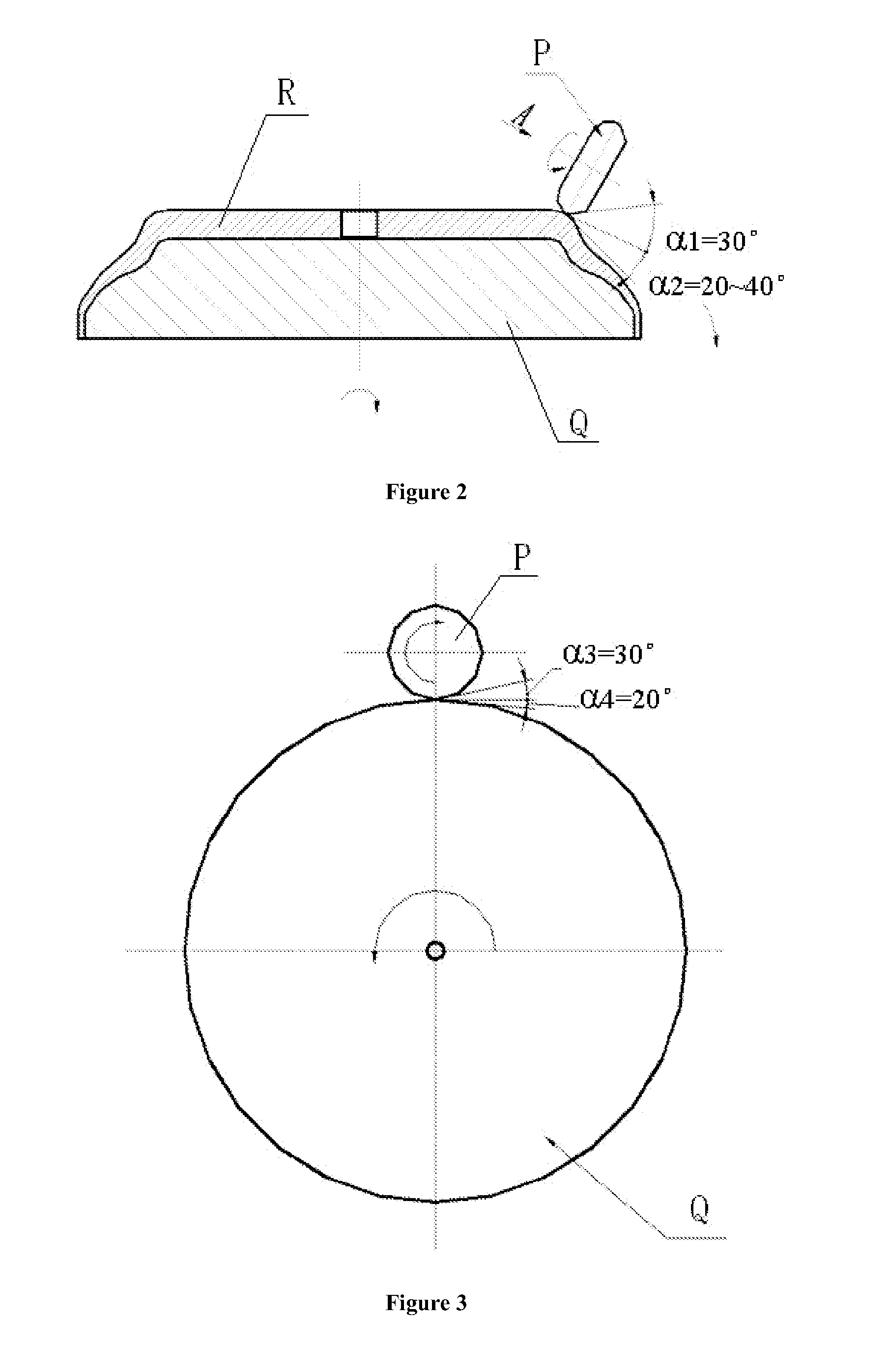

The invention discloses a forming method of an integrated plate welded-joint-free vehicle wheel. The forming method includes the following steps: conducting rolling, preliminarily forming a rim and spokes, conducting roll forming, and conducting compression shaping to manufacture the integrated plate welded-joint-free vehicle wheel. According to the forming method of the integrated plate welded-joint-free vehicle wheel, due to the fact that the plate welded-joint-free vehicle wheel is formed through cold rolling, cold roll forming and cold extruding, energy consumption is reduced by 45% to 55%, and the material cost is reduced by 5% to 15%; meanwhile, the strength of the vehicle wheel is improved by 20% to 30%. By means of the forming method, the unequal-thickness vehicle wheel which is unequal in section thickness and meets the mechanical strength requirement at the same time can be formed in a cold rolling mode; in addition, the accuracy grade of the vehicle wheel can be greatly increased, and the deflection amount and the jerk amount of the vehicle wheel are reduced to be minimum; in addition, the vehicle wheel produced with the method is better in safety performance, and the conventional air-tight test is not needed; correspondingly, the invention further discloses the integrated plate welded-joint-free vehicle wheel manufactured with the forming method of the integrated plate welded-joint-free vehicle wheel.

Owner:SHANGHAI XINGPU SPINFORMING WHEEL

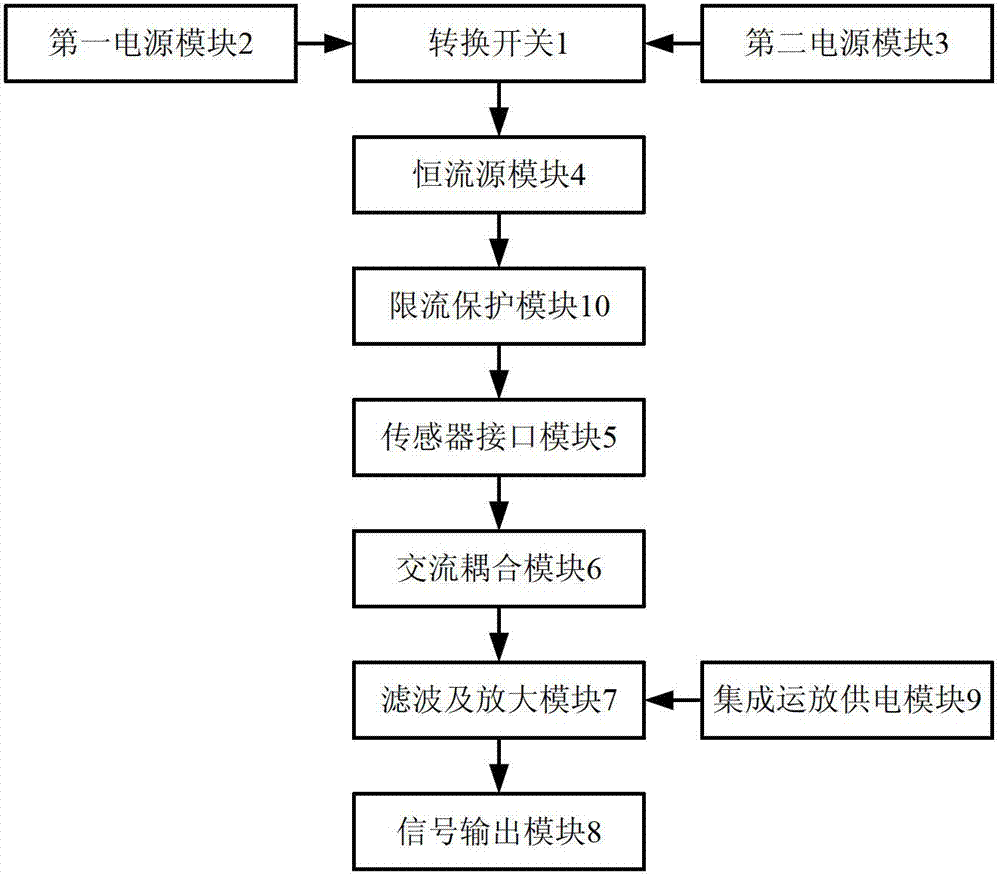

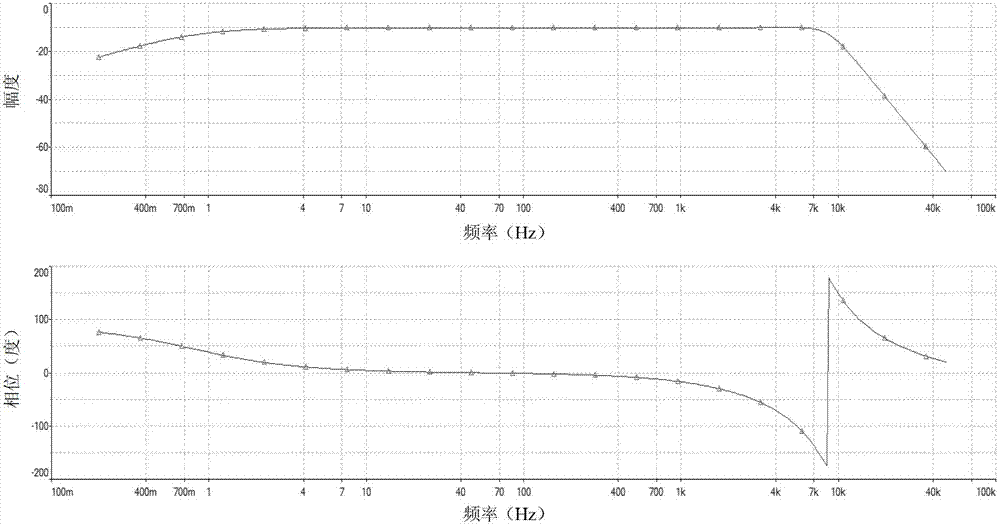

Signal conditioning device used for inductively coupled plasma (ICP) acceleration sensor

InactiveCN103197100AReduce balance errorImprove dynamic balance accuracyAcceleration measurement using interia forcesPhase shiftedDynamic balance

The invention provides a signal conditioning device used for an inductively coupled plasma (ICP) acceleration sensor. The signal conditioning device used for the ICP acceleration sensor comprises a first power supply module, a second power supply module, a constant flow source module, a sensor interface module, an alternating current coupling module, a filtering and amplifying module, a signal output module and an integrated operational amplifier power supply module, wherein the first power supply module and the second power supply module are respectively connected with a change-over switch, the constant flow source module is connected with the change-over switch and connected with the first power supply module and the second power supply module under the control of the change-over switch, the sensor interface module is connected with the ICP acceleration sensor, the ICP acceleration sensor outputs a detecting signal according to constant current when works, the alternating current coupling module is connected with the sensor interface module, the filtering and amplifying module is connected with the alternating current coupling module, the signal output module is connected with the filtering and amplifying module, and the integrated operational amplifier power supply module is connected with the filtering and amplifying module. According to the signal conditioning device used for the ICP acceleration sensor, phase changes of signals in a certain range can be little after the signals through filtering, accordingly balance errors caused by phase shift in rotor dynamic balancing are reduced, and dynamic balance quality is improved.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

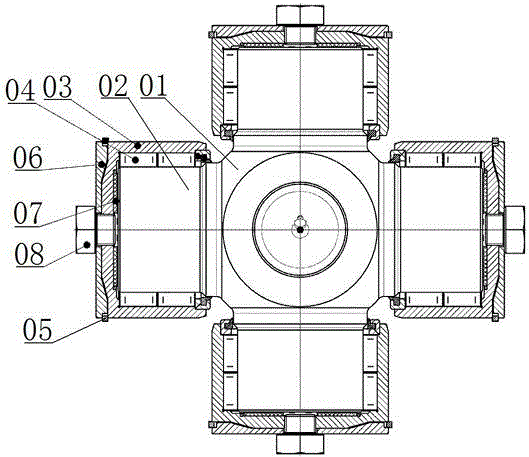

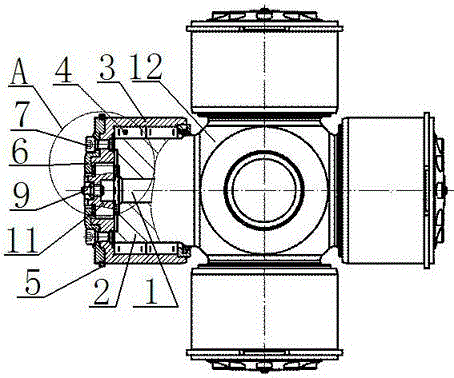

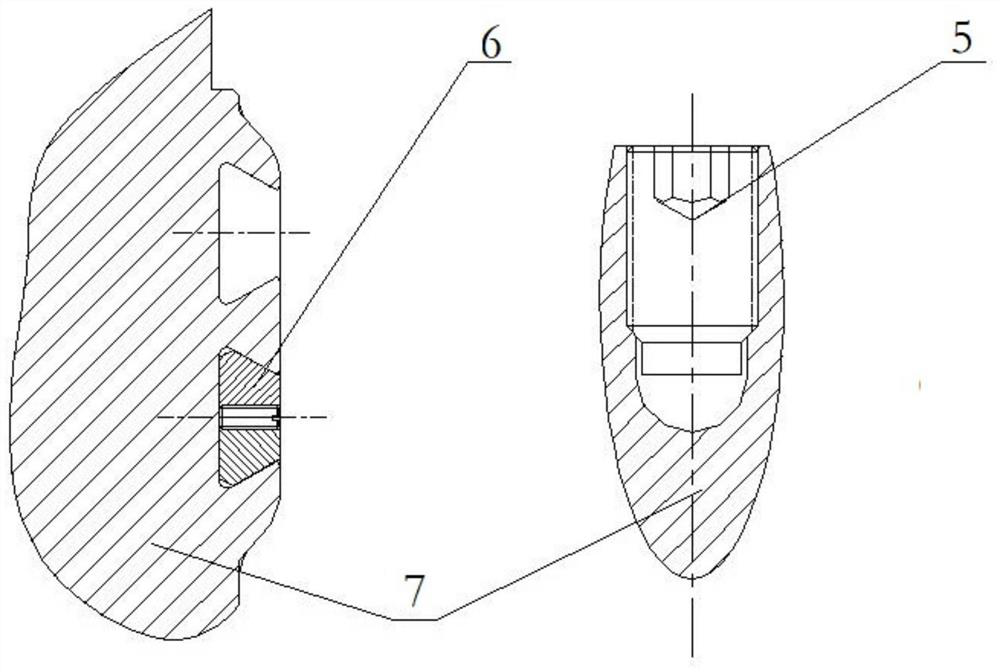

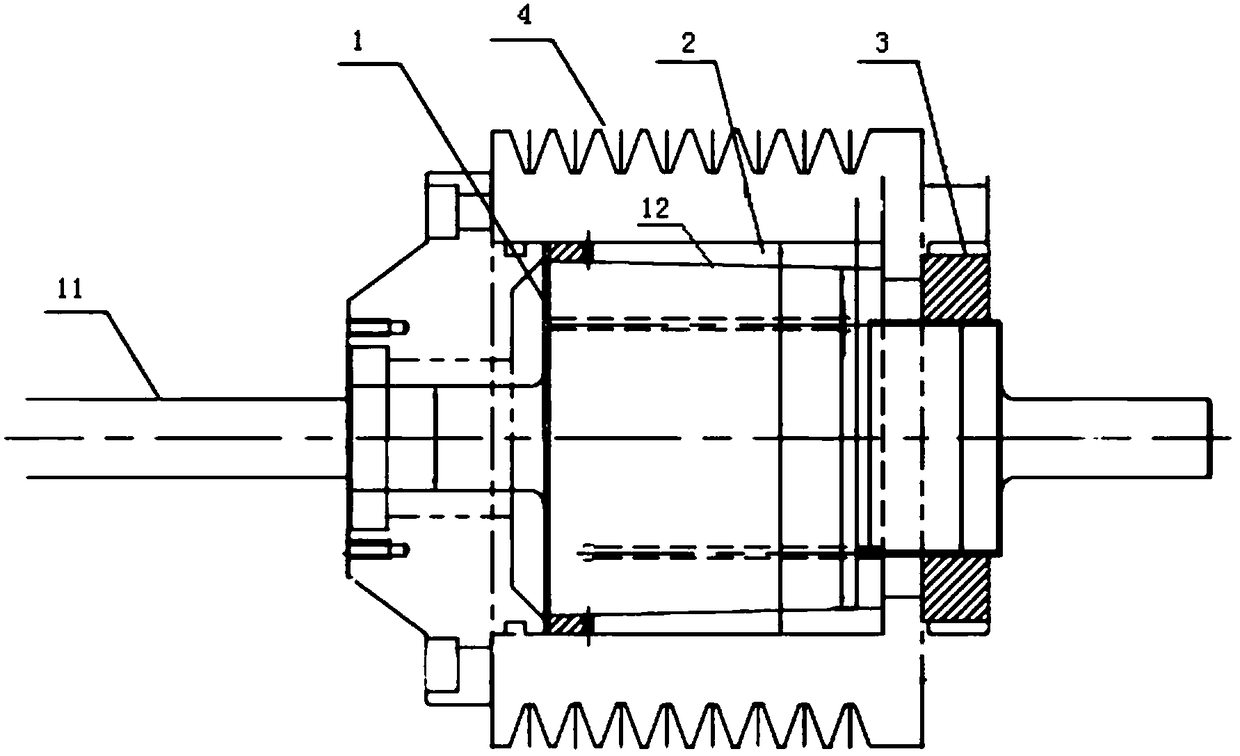

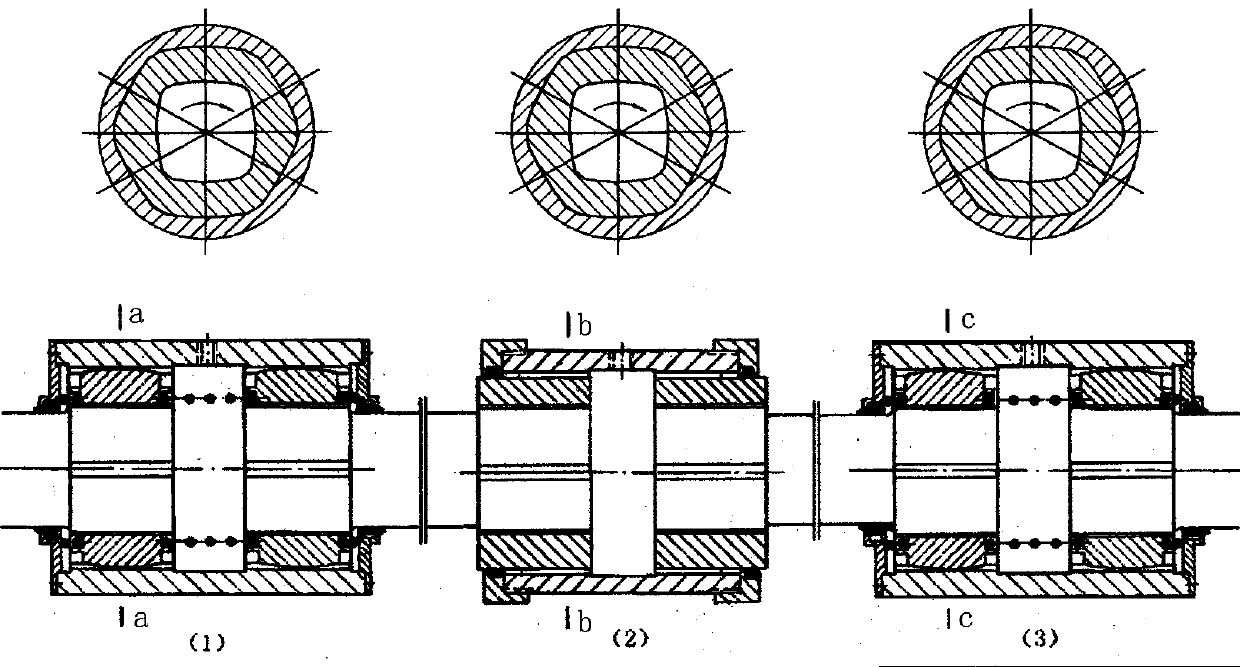

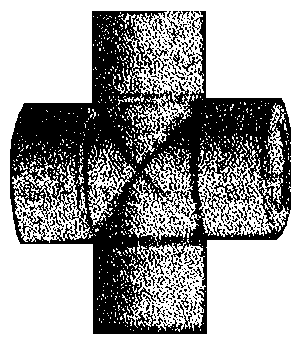

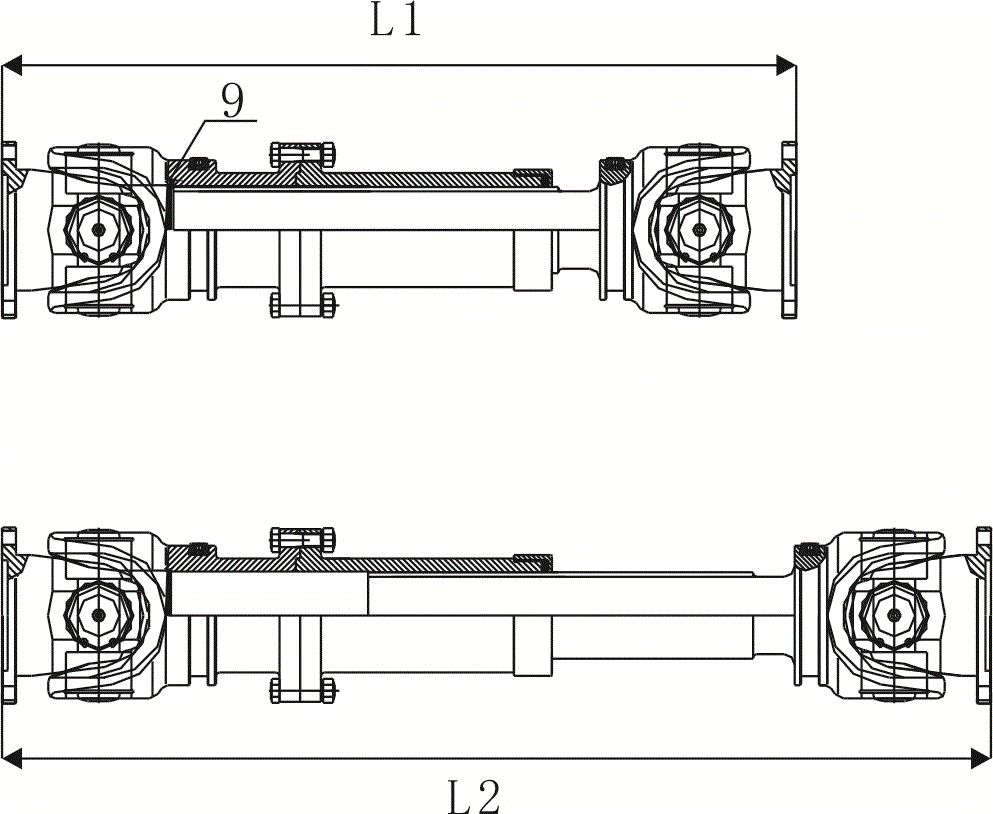

Crisscross package assembly of universal coupler

InactiveCN102720774AHigh concentricityImprove dynamic balance accuracyYielding couplingEngine lubricationEngineeringDynamic balance

The invention discloses a crisscross package assembly of a universal coupler, which comprises a crisscross shaft; four shaft heads are arranged on the crisscross shaft; an oil storage hole is arranged in each shaft head, and a bearing outer ring is sleeved on each shaft head; the diameter of the inner hole of the outer end surface of the bearing outer ring is more than that of the oil storage hole; an adjusting nut is connected onto the inner hole of the outer end surface of the bearing outer ring through a thread; the outer end surface of the bearing outer ring is connected with an end cover which limits the adjusting nut; and when the crisscross package assembly is applied to the coupler, the concentricity of a middle shaft on the coupler and fork heads on both ends is adjusted through the adjusting nut. According to the crisscross package assembly of the universal coupler, the processing, assembly and other errors of the coupler can be effectively, precisely and reliably adjusted, the concentricity of the middle shaft on the coupler and the fork heads on both ends is improved, so that the dynamic balance precision of the coupler in use is improved; and meanwhile, great convenience is provided for the replacement and the maintenance of the parts of the crisscross package assembly.

Owner:DEYANG LIDA BASIC PARTS

Rolling forming method of wheel disc

InactiveUS20120117806A1Large deformationStrong forceRimsMetal-working apparatusDynamic balanceExplorator

The invention provides a rolling forming method of wheel disc, which comprises the following steps: (1) Baiting a circular blank; (2) placing the circular blank in a cavity of a rolling explorator and adopting at least two rolling wheels symmetrically arranged along the circumferential direction of the rolling explorator to perform planar synchronous staggered rolling on the circular blank in the cavity of the rolling explorator; (3) performing trimming and sizing; and (4) stretch forming. The rolling forming method of wheel disc of this invention can precisely form various geometric sections with gradual deformation. The formed product has a uniform mass in the axial direction and the circumferential direction, and has a high dynamic balance precision. The invention can make the blank deform precisely, enhance the production efficiency, and reduce the cost, therefore the invention has good application and popularization prospect.

Owner:SHANGHAI XINGPU SPINFORMING WHEEL

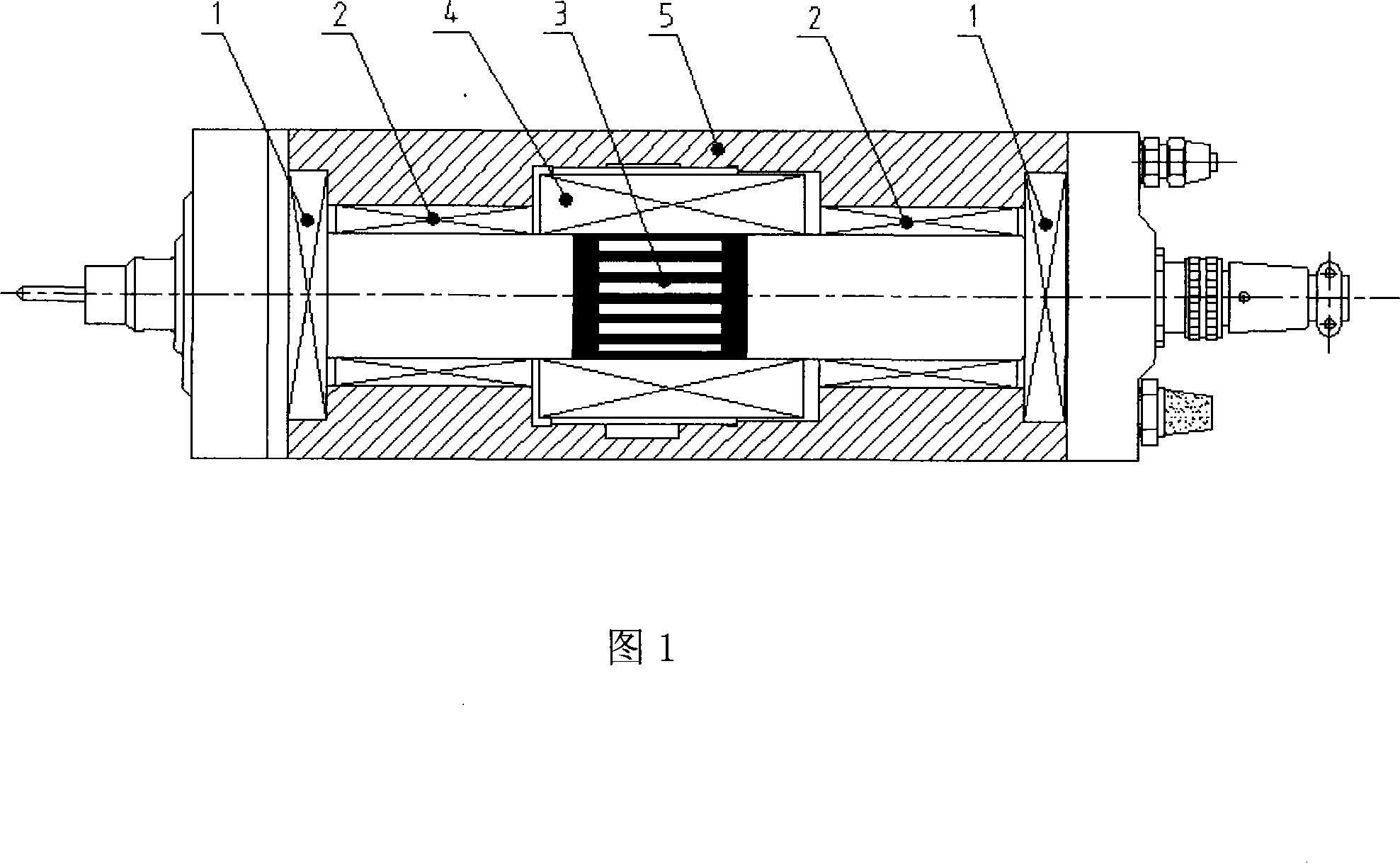

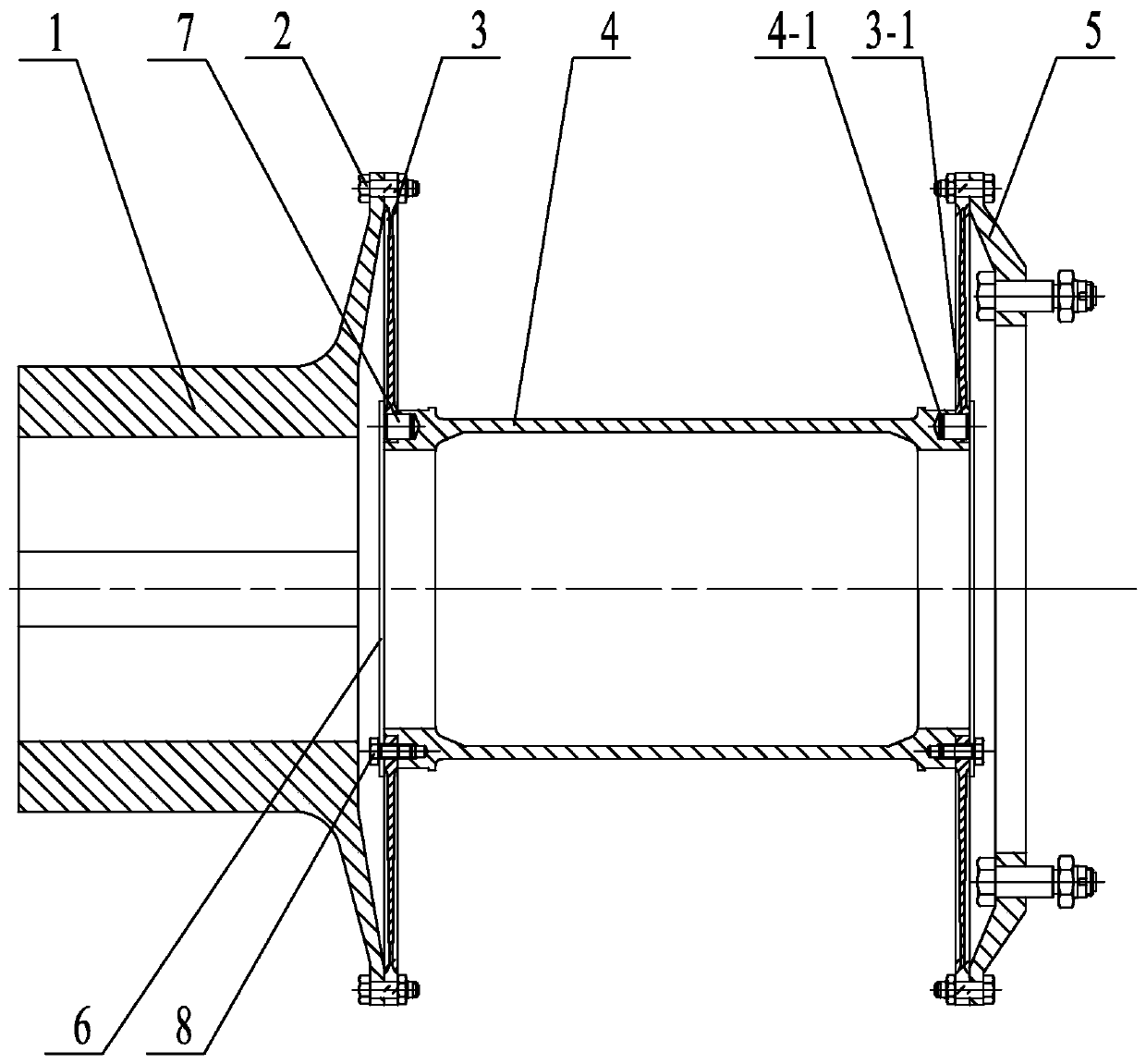

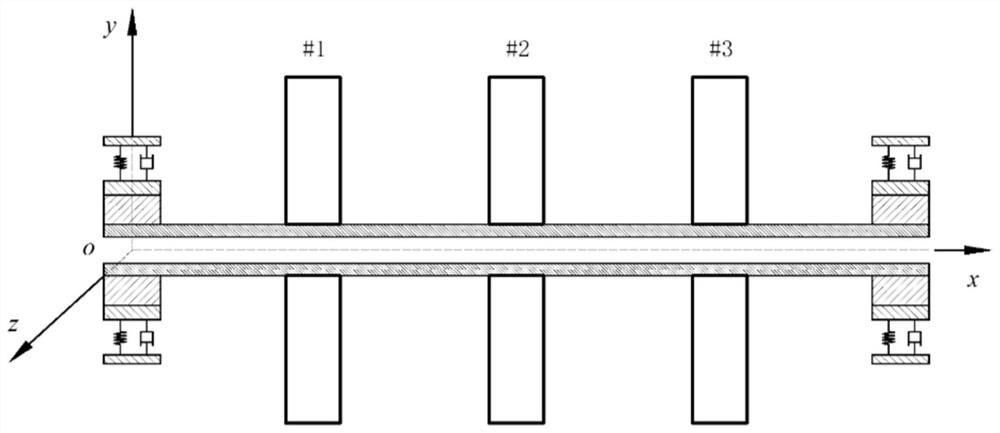

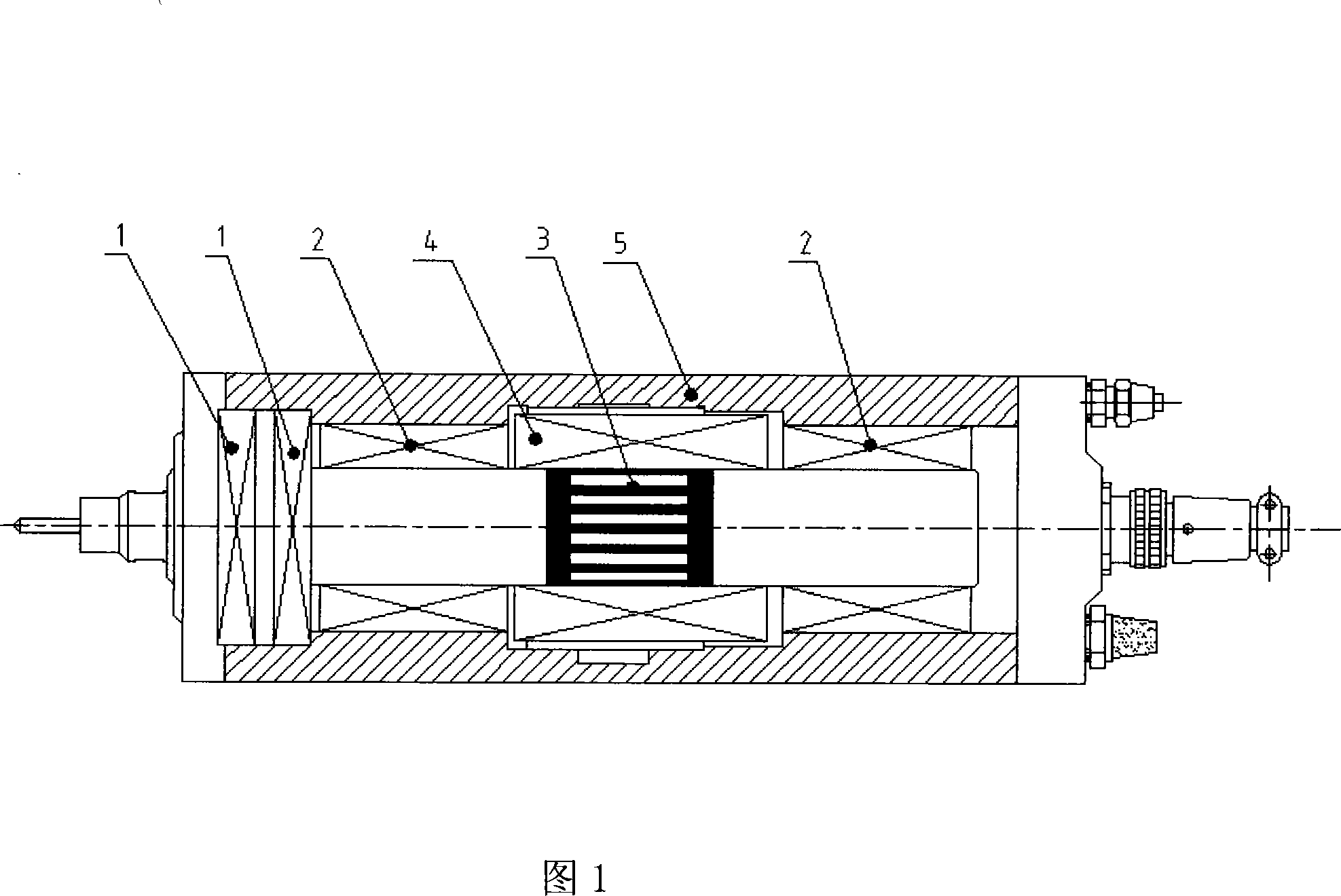

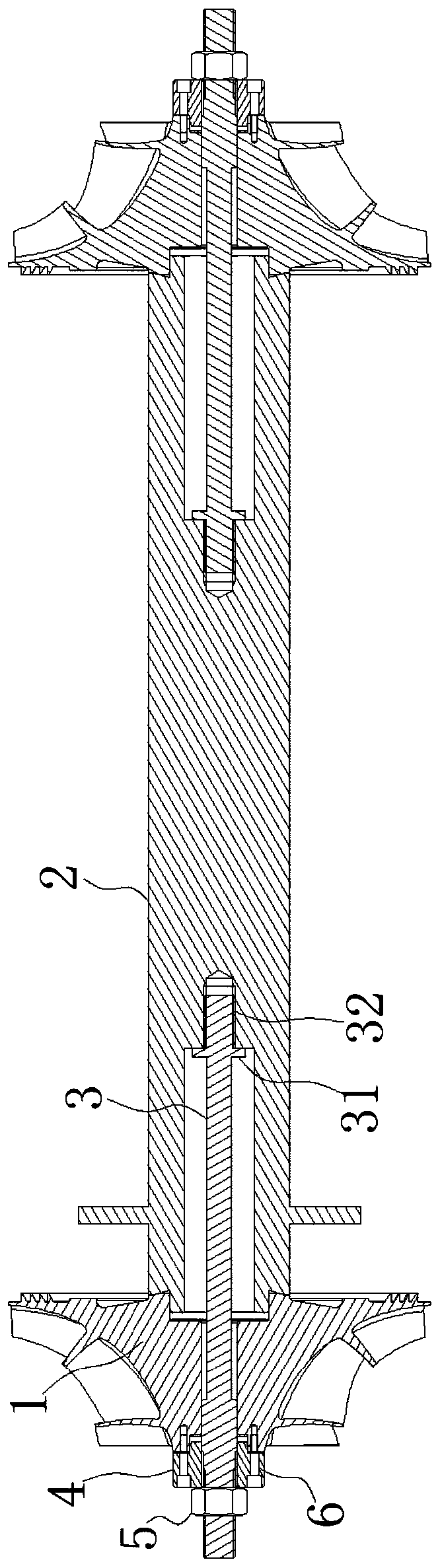

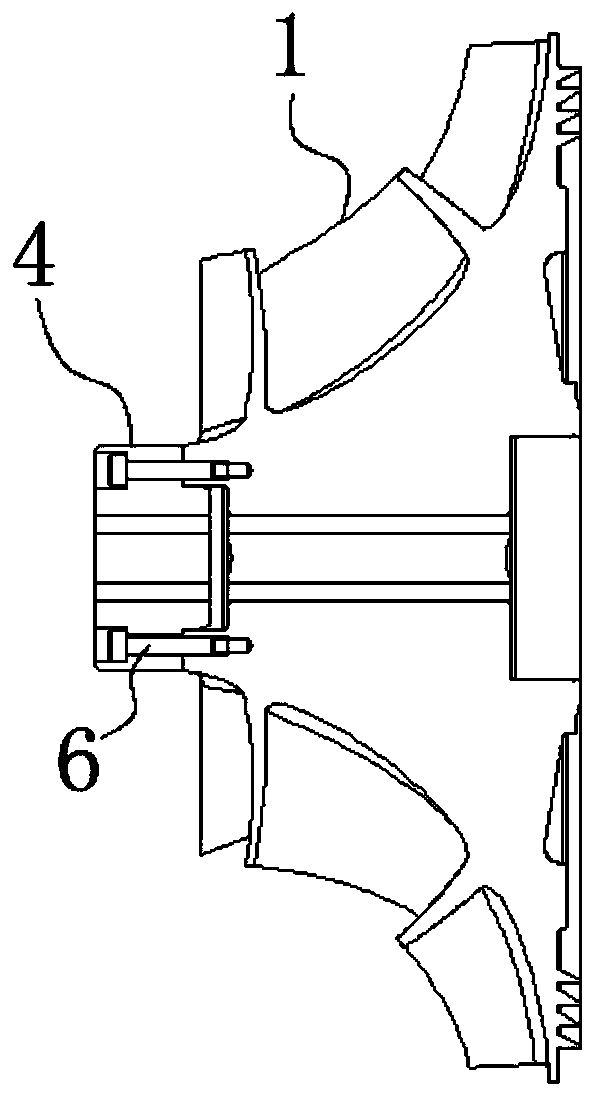

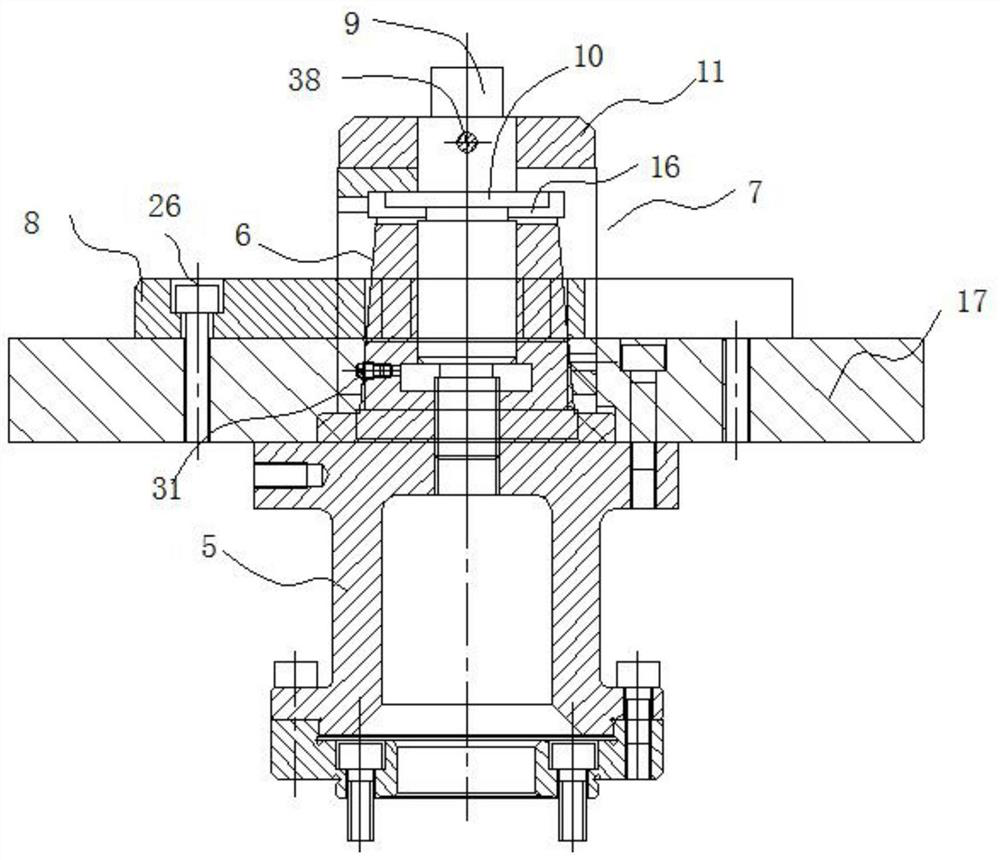

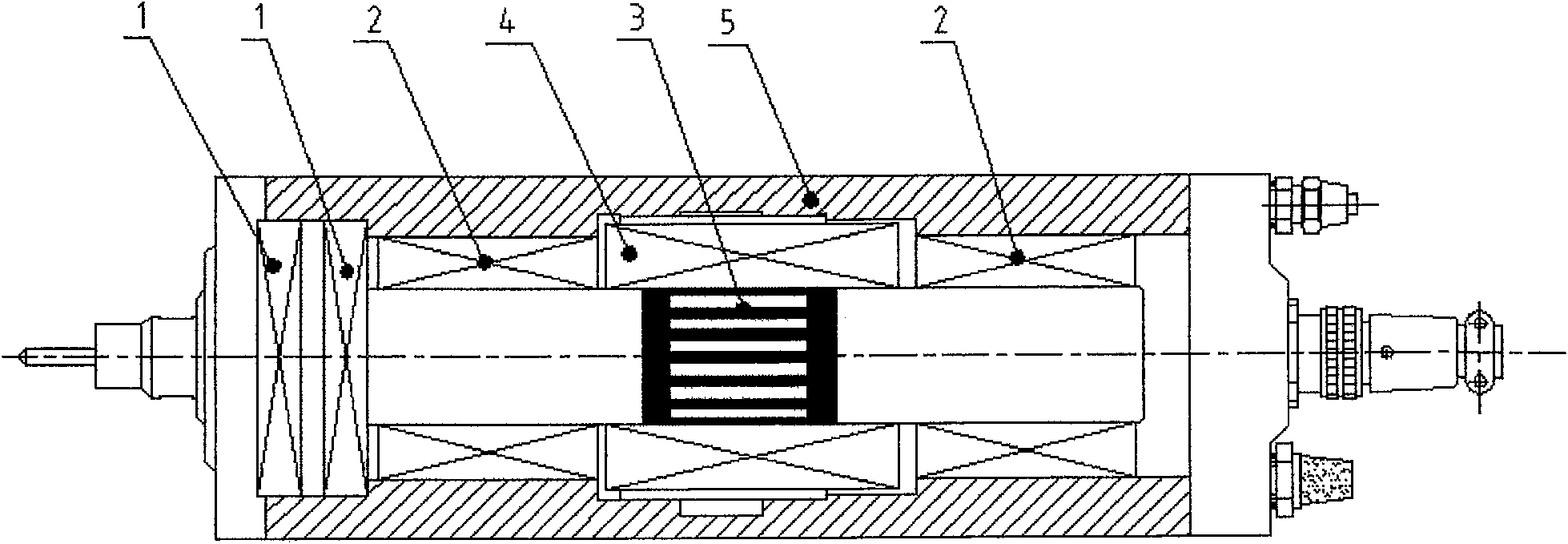

An electric spindle design adopting electromagnetism anti-thrusting and air static pressure radial bearing support

InactiveCN101217243ASimple structureNo lubricationAsynchronous induction motorsMechanical energy handlingUltra high speedElectricity

The invention relates to an electric spindle design adopting an electromagnetic anti-thrust and a radial bearing support. According to the outline dimension limit and the stiffness requirement of the electric spindle, the two ends inside a shell (5) of the electric spindle is provided with an electromagnetic anti-thrust bearing (1), which eliminates the electromagnetic interference between the two ends, is beneficial for the design and concentration of the power supply line of the electromagnetic anti-thrust bearing and ensures the radial stiffness of a rotor-rotating shaft integrated shaft system (3). The two sides inside the shell of the electric spindle are symmetrically provided with aerostatic pressure radial bearings (2) so as to support the shaft system (3). The symmetric aerostatic pressure radial bearings can reduce the vibration of the shaft system when the electric motor is in the state of operation with super high speed and ensure the radial stiffness. The rotor-rotating shaft integrated shaft system makes the squirrel-cage bar of the rotor of the electric motor and the rotating shaft into an integrated structure and the corresponding position of a stator (4) arranged in the middle section and the shell of the electric spindle, that is the position of the squirrel-cage bar, adopts copper alloys directly welded in a groove to reduce the creep deformation of the rotor bar, reduce the vibration value of the shaft system and improve the power rate and the structural strength.

Owner:LUOYANG BEARING SCI & TECH CO LTD

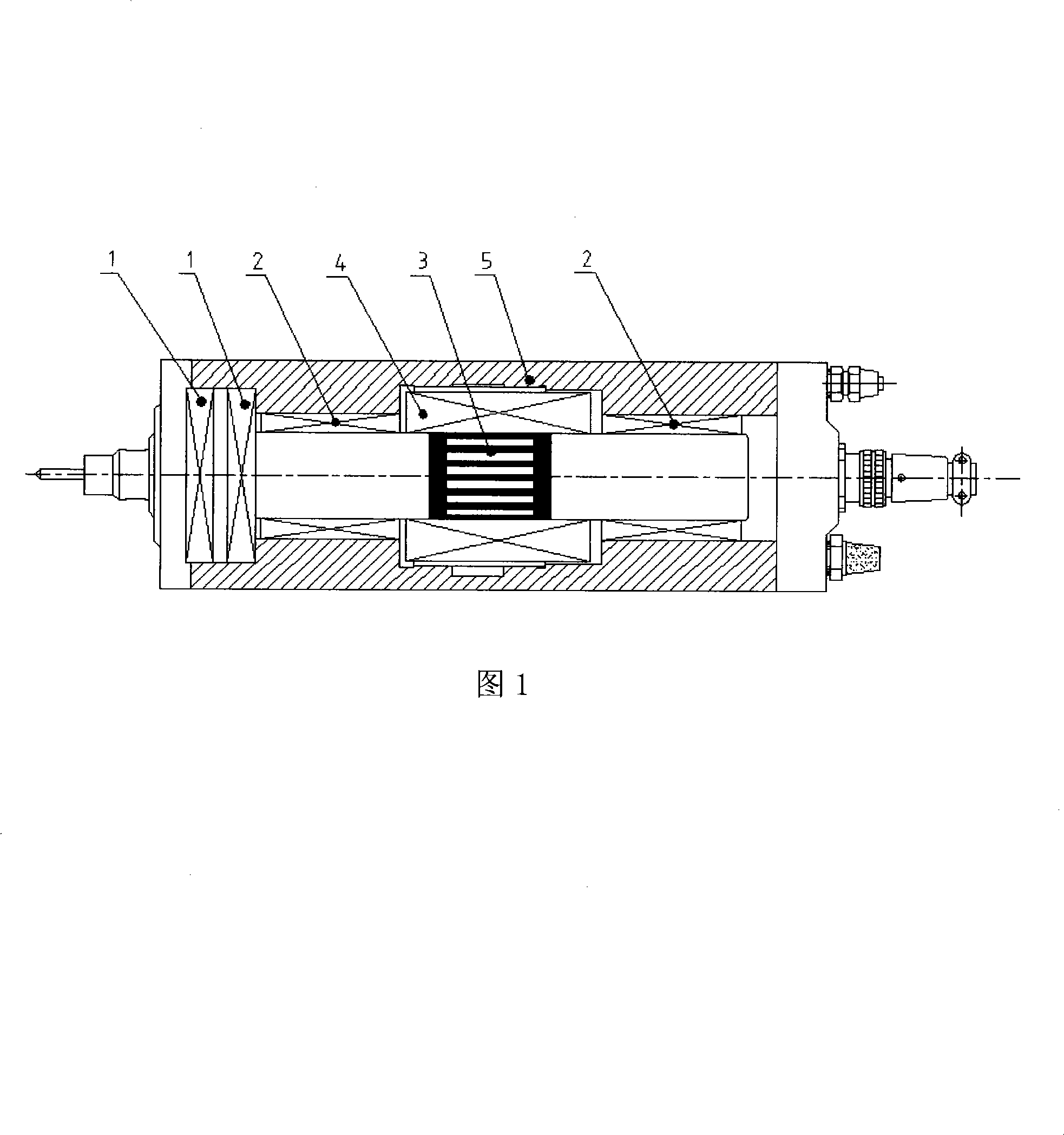

An electric spindle design adopting air static pressure anti-thrusting and air static pressure radial bearing support

InactiveCN101217241ACompact structureEasy to installAsynchronous induction motorsMechanical energy handlingThrust bearingEngineering

The invention relates to an electric spindle design adopting an aerostatic pressure anti-thrust and an aerostatic pressure radial bearing support. According to the outline dimension limit and the stiffness requirement of the electric spindle, the front end inside a shell (5) of the electric spindle is centrally provided with two aerostatic pressure anti-thrust bearings (1), thus leading the space utilization to be optimized and the structure to be compact, and at the same time the two aerostatic pressure anti-thrust bearings lead a supply air line convenient to centralize and install and provides the needed radial stiffness for a rotor-rotating shaft integrated shaft system (3). The two sides of a stator (4) are symmetrically provided with an aerostatic pressure radial bearing (2) so as to support the rotor-rotating shaft integrated shaft system, reduce the vibration of the shaft system (3) and ensure the radial stiffness. The rotor-rotating shaft integrated shaft system makes the squirrel-cage bar of the rotor of the electric motor and the rotating shaft into the integrated structure and the corresponding position of the stator arranged in the middle section and the shell of the electric spindle, that is the position of the squirrel-cage bar, adopts copper alloys directly welded in a groove of the integrated shaft system so as to reduce the creep deformation of the squirrel-cage bar, reduce the vibration value of the integrated shaft system and improve the power rate and the structural strength.

Owner:LUOYANG BEARING SCI & TECH CO LTD

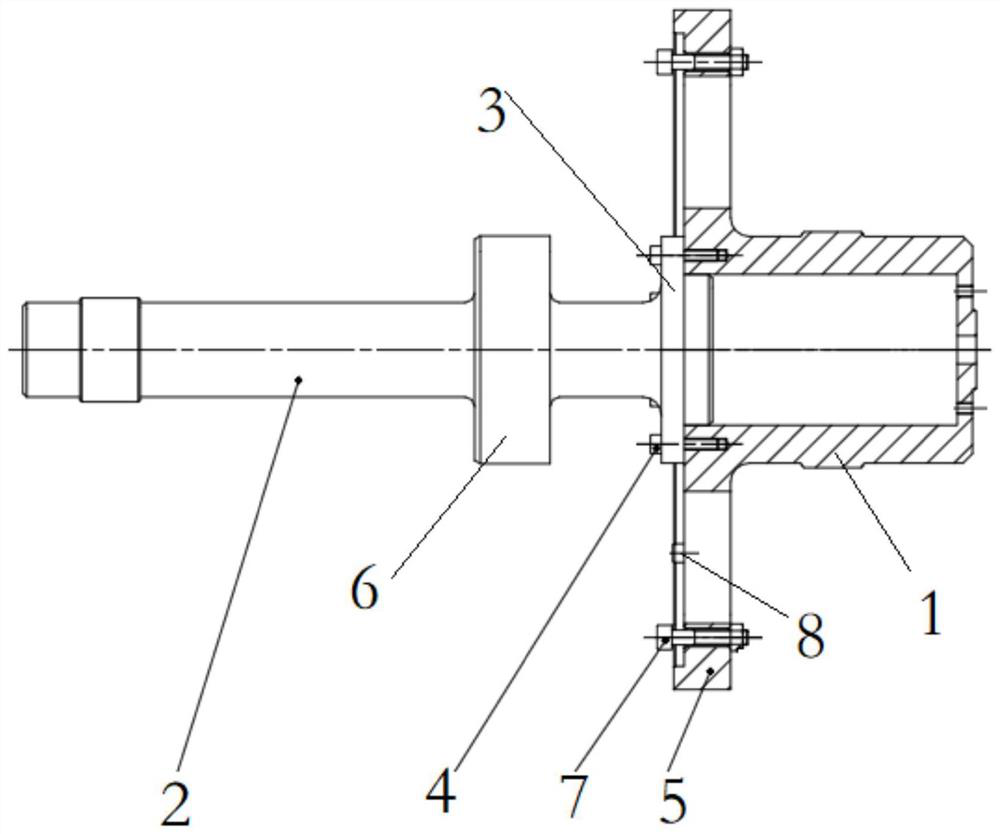

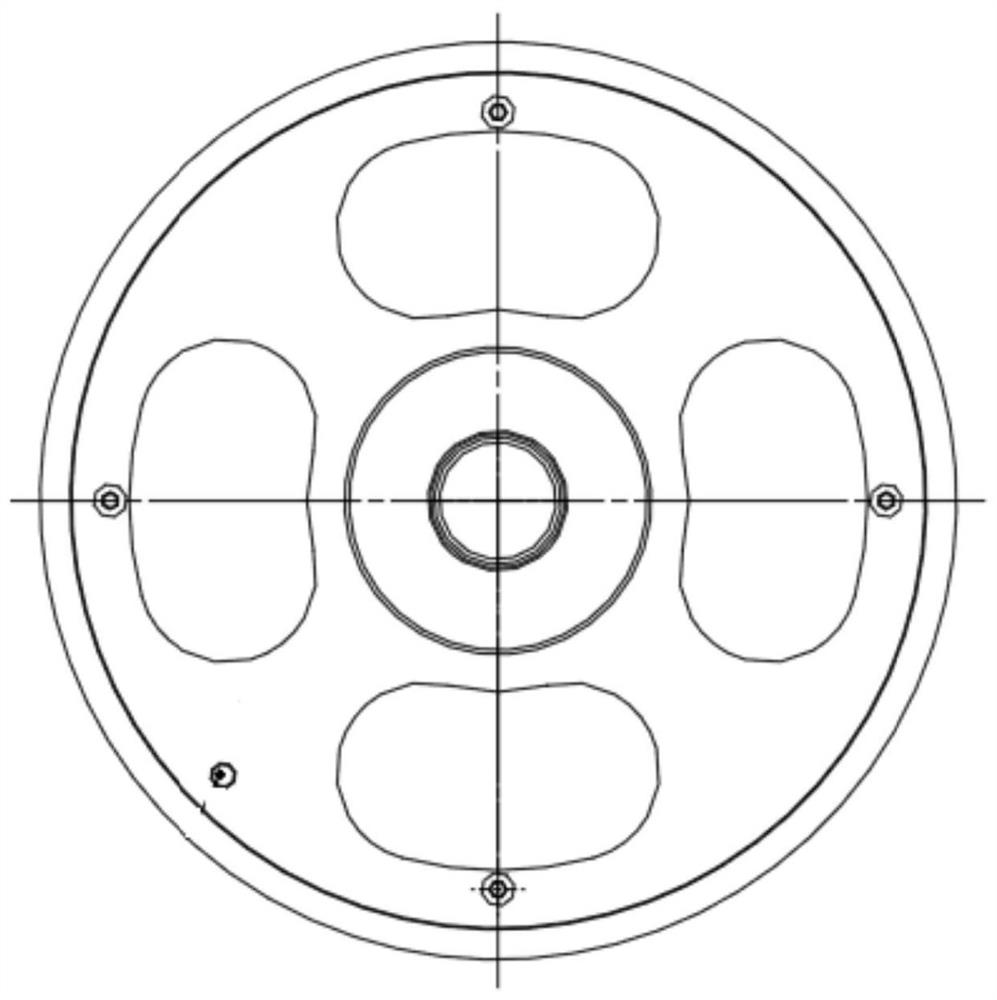

Diaphragm disc coupling for connecting BPRT speed changing clutch

The invention relates to a diaphragm disc coupling for connecting a BPRT speed changing clutch, and relates to the technical field of mechanical transmission. The diaphragm disc coupling aims to solvethe problems that the axial size of an existing diaphragm disc coupling is large, the mass is large, consequently the unit dynamic balance precision is low, and the unit operation stability is affected. The diaphragm disc coupling comprises an input flange, an intermediate shaft, an output flange and two diaphragm discs, the shape of the intermediate shaft is a hollow shell with openings in the two ends, the two ends of the intermediate shaft are each provided with one diaphragm disc, the diaphragm discs and the intermediate shaft are positioned through a plurality of positioning pins, the middle portions of the outer side ends of the diaphragm discs are provided with positioning plates, the end surfaces of the outer sides of the positioning plates are uniformly provided with a pluralityof connecting bolts in the circumferential direction, the tail ends of the connecting bolts penetrate through the diaphragm discs, the connecting bolts rotate on the end face of the intermediate shaft, and flange plates of the input flange and the output flange are fixedly connected to the outer circumference of the outer side end of one diaphragm disc through the multiple connecting bolts. The diaphragm disc coupling is used for connecting the BPRT speed changing clutch.

Owner:HARBIN GUANGHAN POWER TRANSMISSION +1

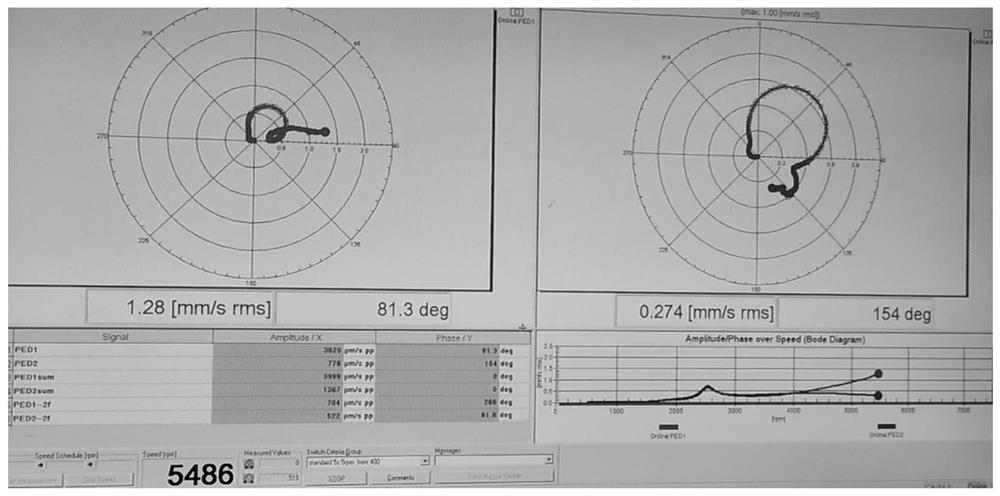

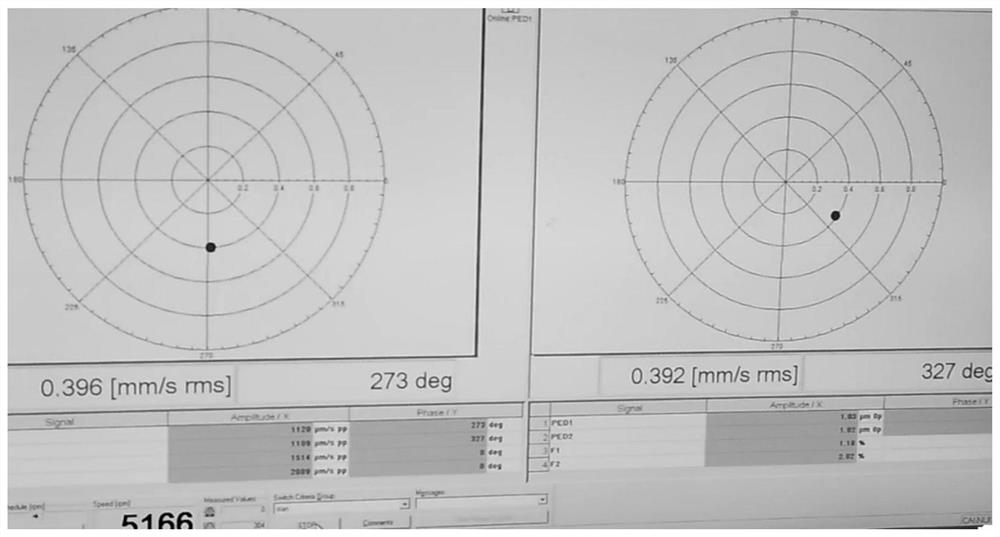

Constrained high-speed dynamic balance mechanical calculation method

ActiveCN111898238AGuaranteed uptimeIntensity Value GuaranteeGeometric CADSustainable transportationDynamic balanceEngineering

The invention discloses a constrained high-speed dynamic balance mechanical calculation method, which comprises the following steps of: calculating an influence coefficient through driving, trial weight and measurement, and establishing an influence coefficient matrix; establishing a Lagrange function according to constraint conditions of a dynamic balance standard: solving a counterweight optimalvalue by utilizing a KKT condition; and adding and reducing weight, and driving to correct a dynamic balance result. By adding constraints to the intensity value at the key rotating speed, the intensity value of the key rotating speed is further reduced on the premise of ensuring overall vibration reduction, and stable operation of the rotor is ensured. The method provided by the invention is suitable for dynamic balance mechanical calculation of turbomachinery rotors which have high requirements on residual unbalance and of which the working rotating speed at least exceeds a first-order critical rotating speed. And low-cost operability of constrained high-speed dynamic balance calculation can be realized. Operators only need to input the magnitude of the constraint intensity value on a program panel, and the magnitude and phase of the balance weight and the estimated value of the residual unbalance amount can be obtained through full-automatic calculation and analysis of a program.

Owner:TIANJIN UNIV +1

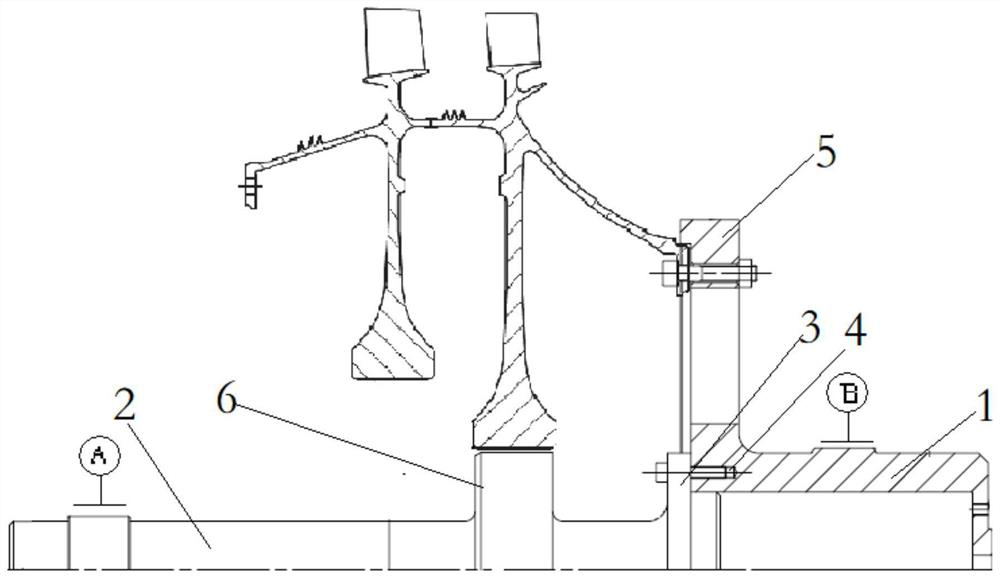

Balancing device and method for multistage blisk

ActiveCN112179564AGuaranteed installation dimensional accuracyAvoid positioningStatic/dynamic balance measurementControl engineeringControl theory

The invention discloses a balancing device and method for a multistage blisk. A positioning ring and a balancing shaft are adopted to form the balancing device, one end of the balancing device is of an opening structure, a balancing shaft mounting hole is formed in the middle of the positioning ring, one end of the balancing shaft is fixed in the balancing shaft mounting hole of the positioning ring, and a plurality of positioning ring spigots are formed in a positioning table in the circumferential direction of the positioning ring; a blade disc positioning ring is arranged on the balance shaft, the diameter of the blade disc positioning ring is the same as the diameter of the minimum inner ring of the multistage integral blade disc to be balanced, a spigot of the multistage integral blade disc to be balanced is fixedly connected with a spigot of the positioning ring on the positioning table, and the multistage integral blade disc to be balanced is supported through the blade disc positioning ring and fixedly connected through a unilateral spigot. The mounting edge spigot mounting size precision is ensured, and over-positioning is avoided. The device is simple in structure, single-side fixing is adopted, supporting balance is achieved on the other side of the balance shaft, installation and assembly are convenient, the balance clamp needs to be disassembled easily when materials are taken out in the balance process, and the balance quality and efficiency are greatly improved.

Owner:AECC AVIATION POWER CO LTD

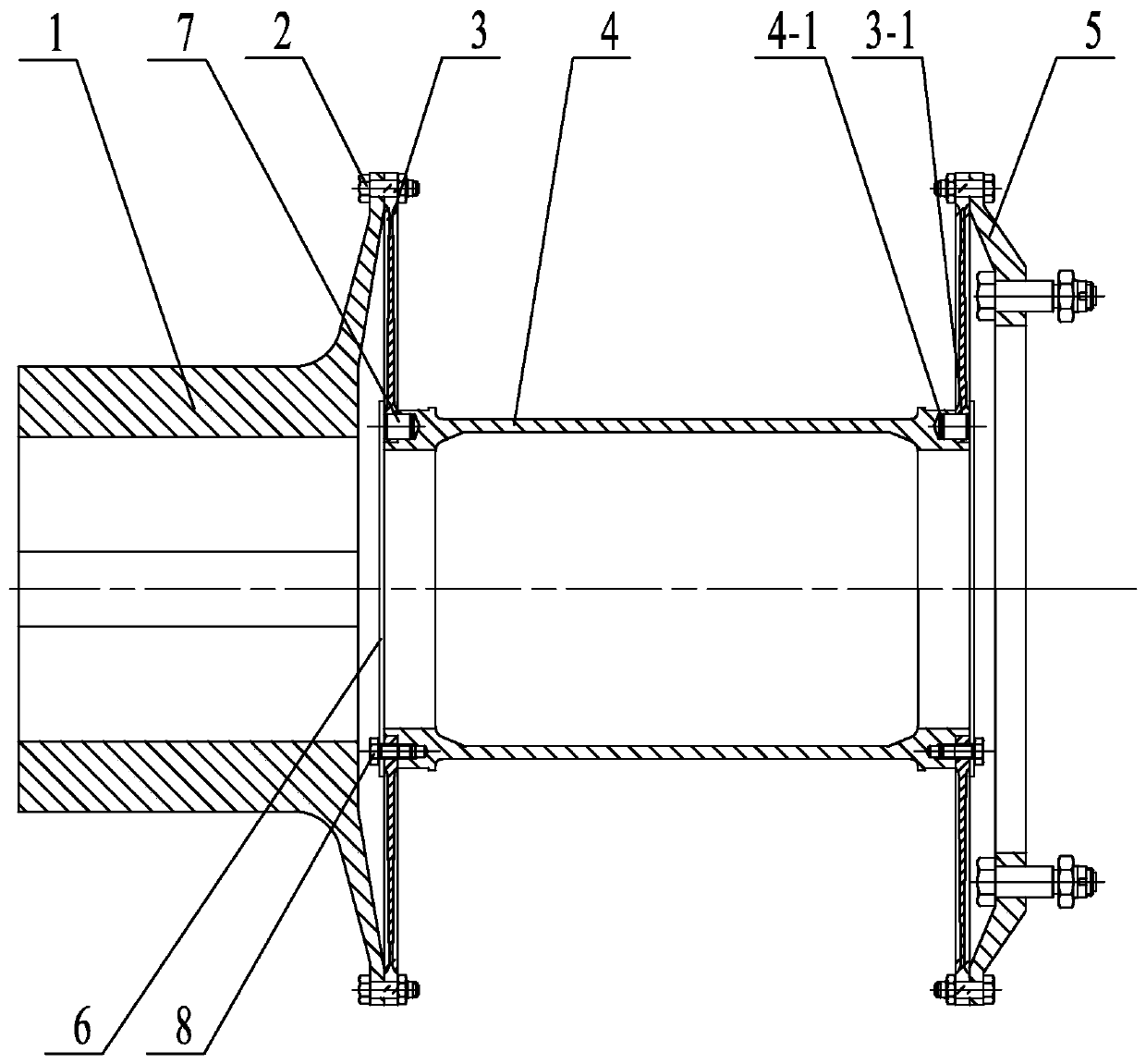

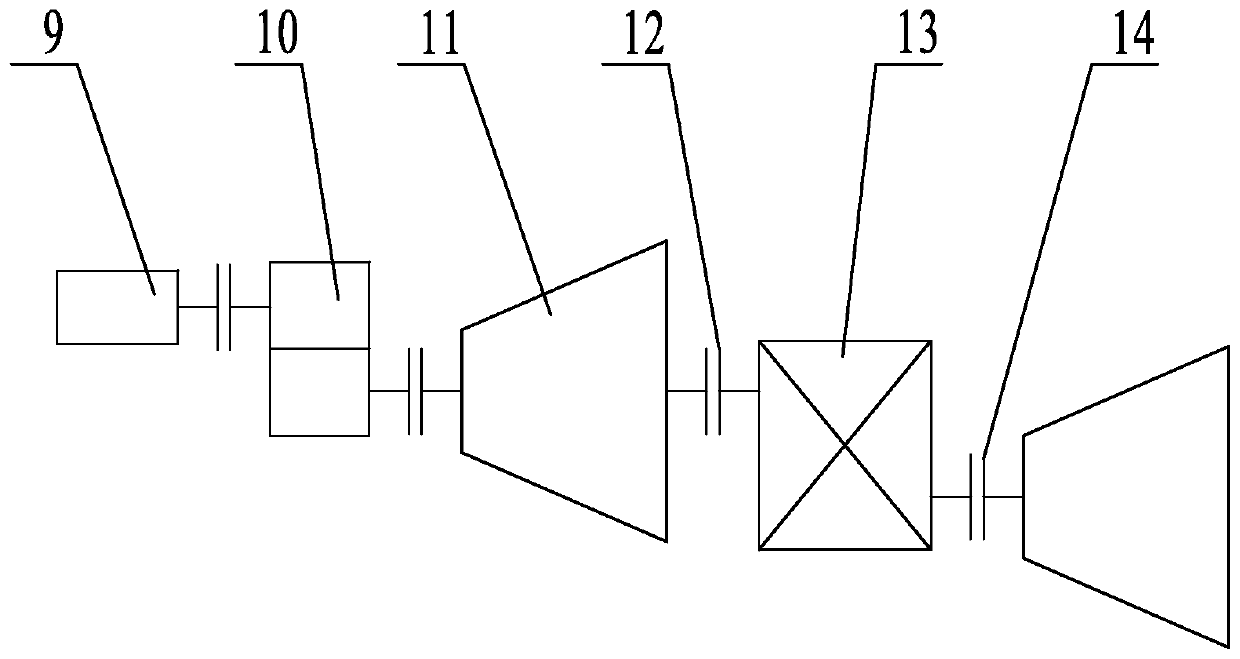

An electric spindle design adopting air static pressure anti-thrusting and electromagnetism radical bearing support

ActiveCN101217240ACompact structureEasy to installMechanical energy handlingBearingsThrust bearingEngineering

The invention relates to an electric spindle design adopting an aerostatic pressure anti-thrust and an electromagnetic radial bearing support. According to the outline dimension limit and the stiffness requirement of the electric spindle, the front end inside a shell (5) of the electric spindle is centrally provided with two aerostatic pressure anti-thrust bearings (1), so as to leads the space utilization to be optimized, and the structure to be compact and at the same time the two aerostatic pressure anti-thrust bearings lead a supply air line to be convenient to centralize and install and provides the needed radial stiffness for a rotor-rotating shaft integrated shaft system (3). The two sides of a stator (4) are symmetrically provided with an electromagnetic radial bearing (2) so as to support the rotor-rotating shaft integrated shaft system, reduce the vibration of the shaft system (3) and ensure the radial stiffness. The rotor-rotating shaft integrated shaft system makes a squirrel-cage bar of the rotor of the electric motor and the rotating shaft into the integrated structure and the corresponding position of the stator arranged in the middle section and the shell of the electric spindle, that is the position of the squirrel-cage bar, adopts copper alloys directly welded in a groove so as to reduce the creep deformation of the squirrel-cage bar, reduce the vibration and improve the power rate and the structural strength.

Owner:LUOYANG BEARING RES INST CO LTD

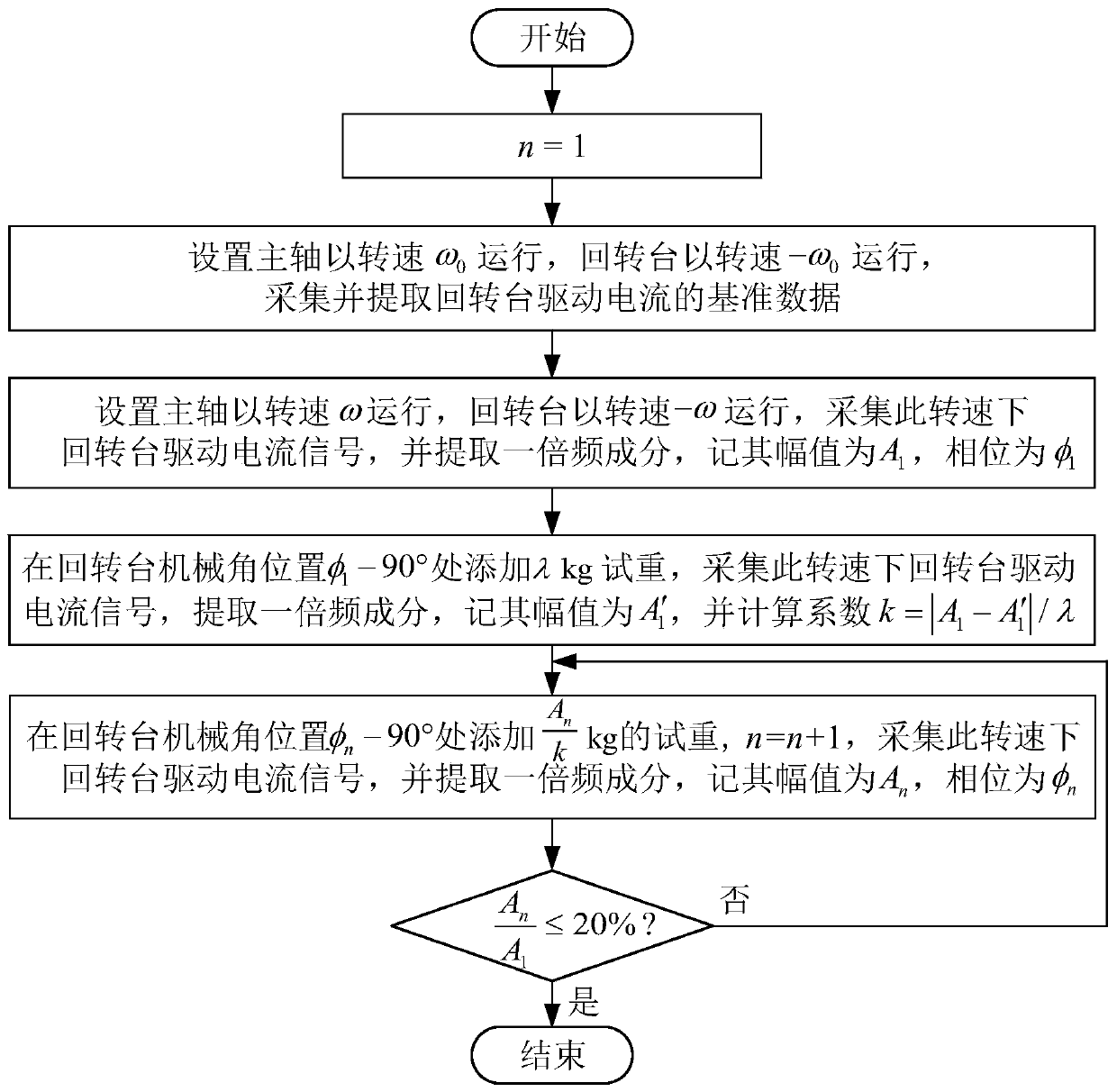

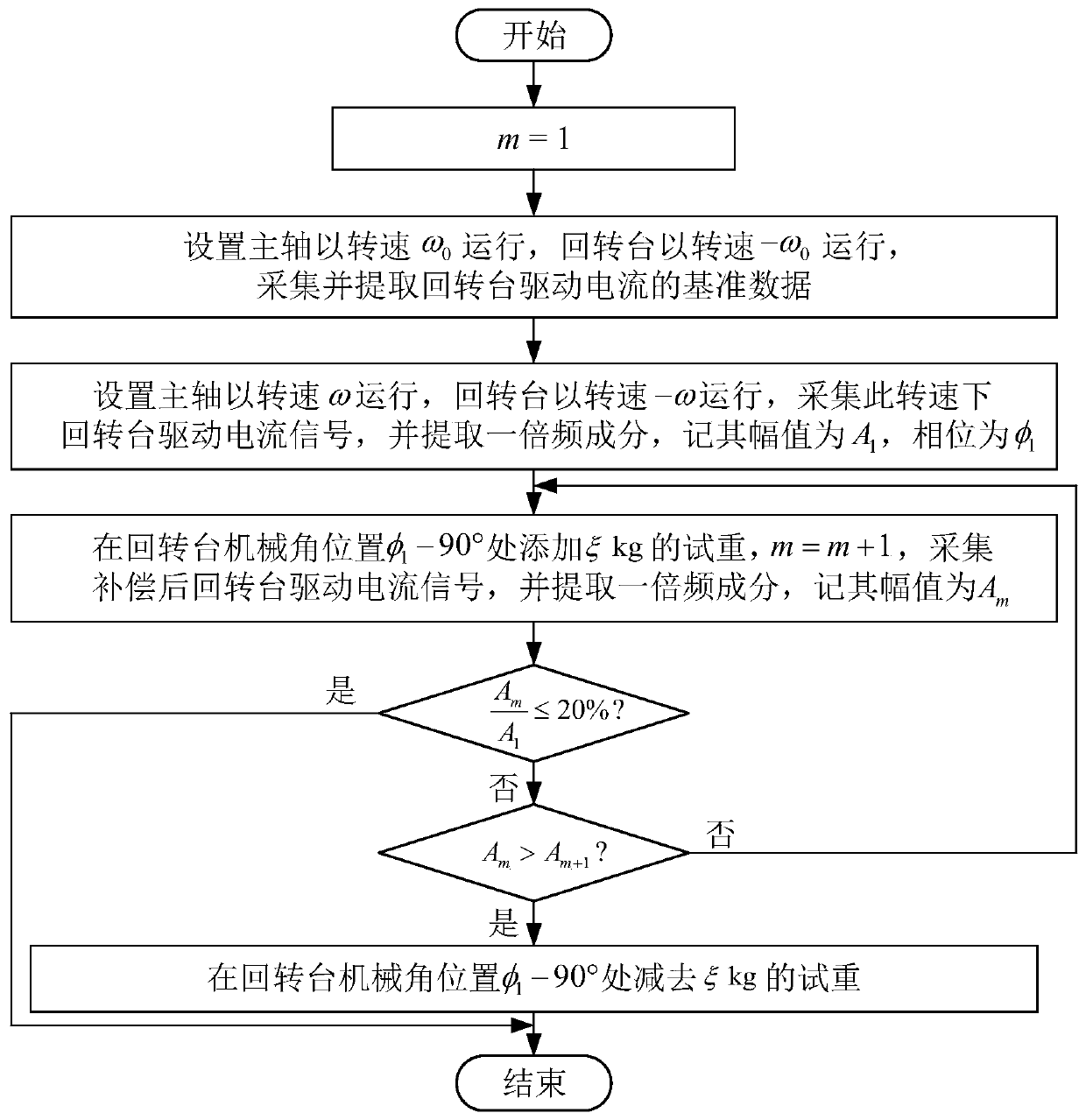

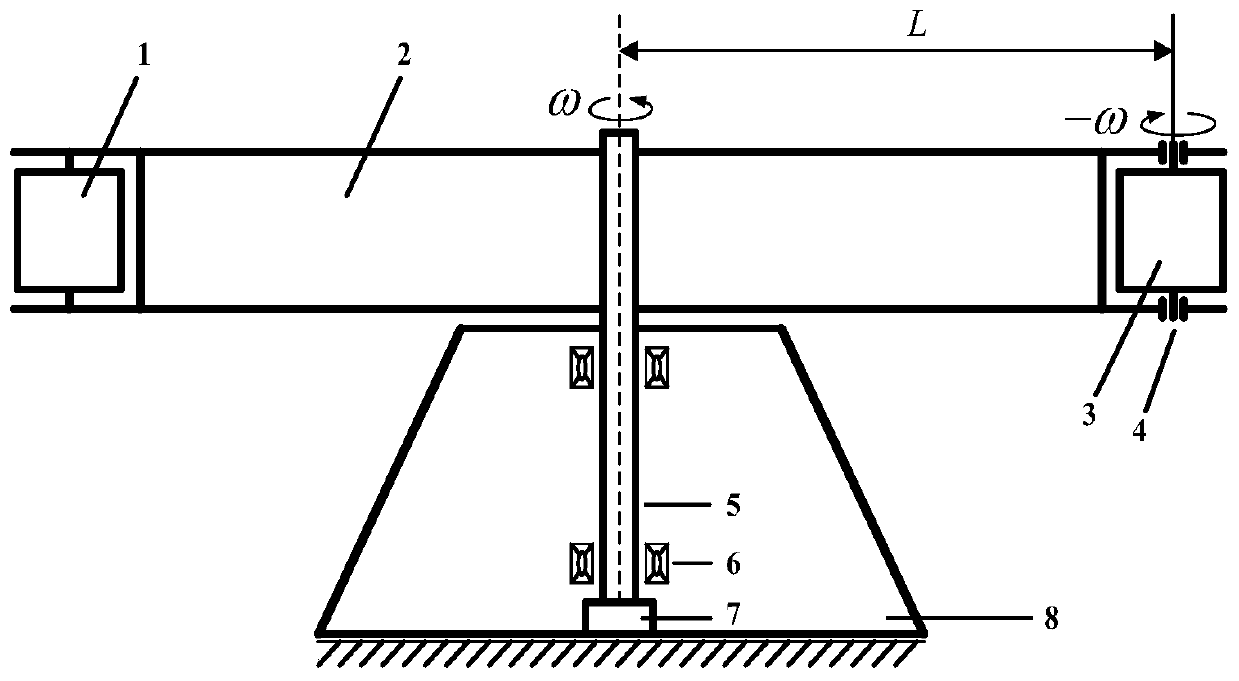

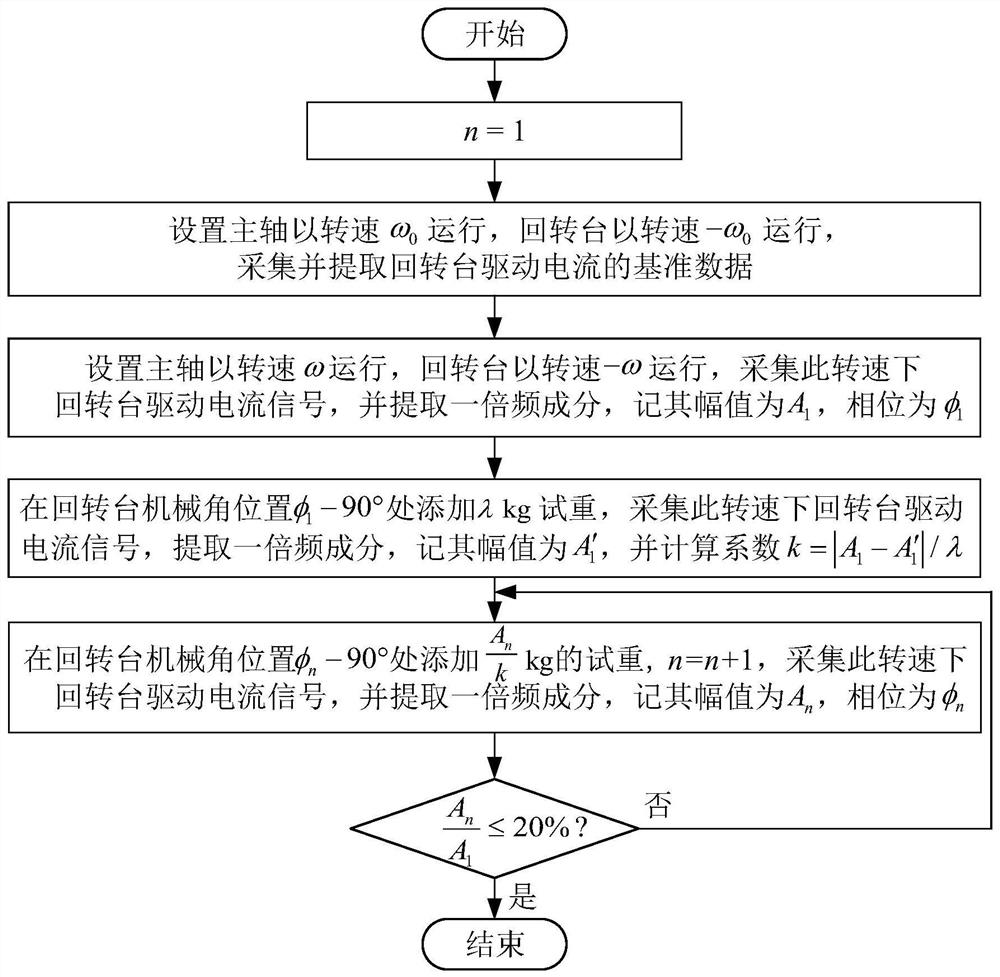

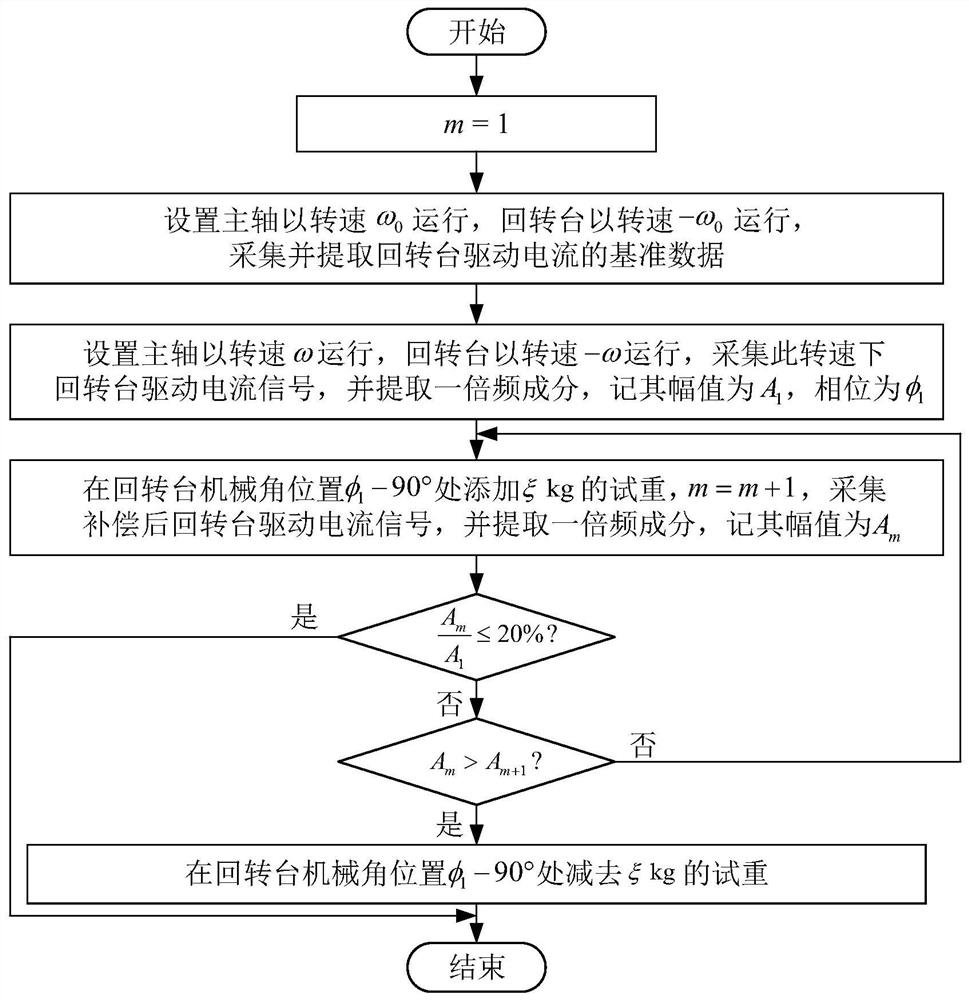

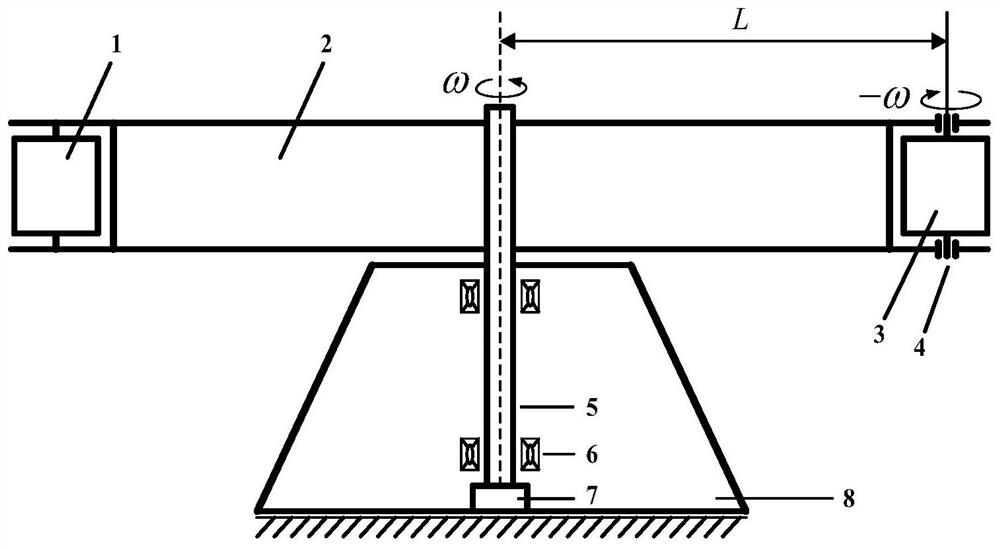

Driving current based dynamic balance method of rotary table of double-axis precision centrifuge machine

ActiveCN109847952ASolve the problem of dynamic balanceHigh sensitivityCentrifugesDriving currentDynamic balance

The invention discloses a driving current based dynamic balance method of a rotary table of a double-axis precision centrifuge machine, and belongs to the technical field of mechanical rotor dynamic balance. In order to solve the problems that an existing dynamic balance method of a rotary table of a precision centrifugal machine is low in dynamic imbalance identification precision, complex in operation and calculation process, large in time consumption and the like, a double-shaft precise centrifugal machine main shaft is arranged to operate at a small rotating speed omega 0, and the rotary table operates at a rotating speed -omega 0 to collect the reference data of the driving current of the rotary table; the double-shaft precise centrifugal machine main shaft is arranged to be operatedat the working rotating speed omega, the rotary table operates at the rotating speed -omega, the driving current data of the rotary table are collected, and a one time frequency component of current is extracted; and the double-shaft precision centrifugal machine is arranged to operate at the rotating speed omega, accurate identification is carried out on the dynamic unbalance value of the rotarytable through a mode of adding test mass according to the obtained frequency multiplication of the current, and balancing is carried out. The method does not depend on any external precise sensor, theidentification precision of the shafting dynamic imbalance of the rotary table is higher, the method is simple and feasible, multiple experiments are not needed, and the method is more practical fromthe engineering application angle.

Owner:HARBIN INST OF TECH

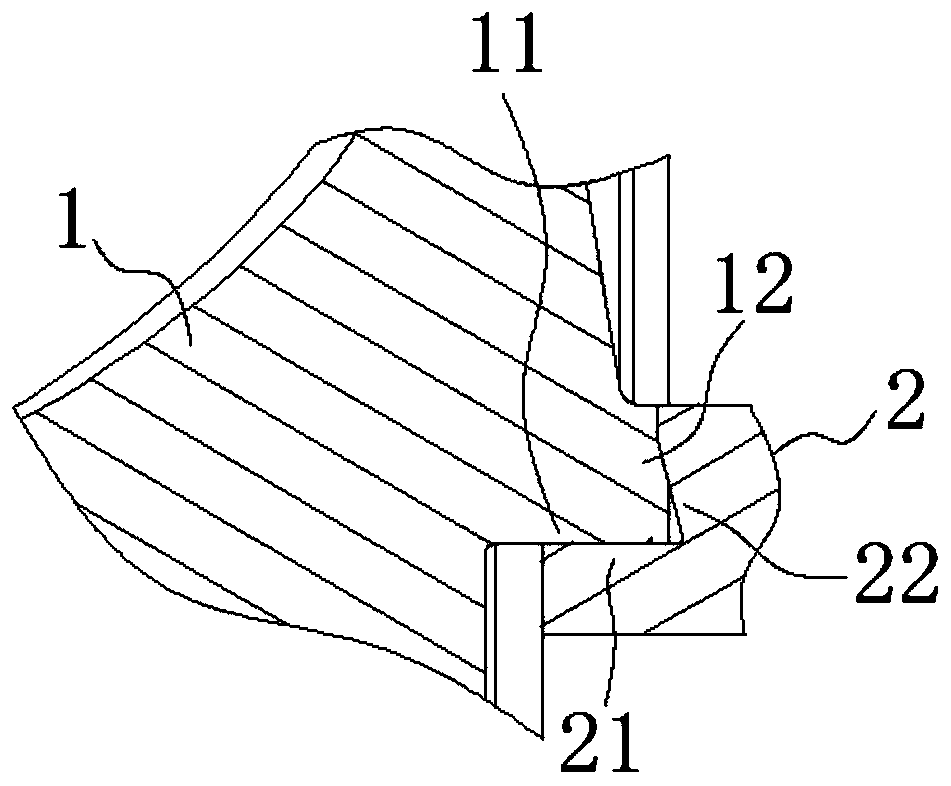

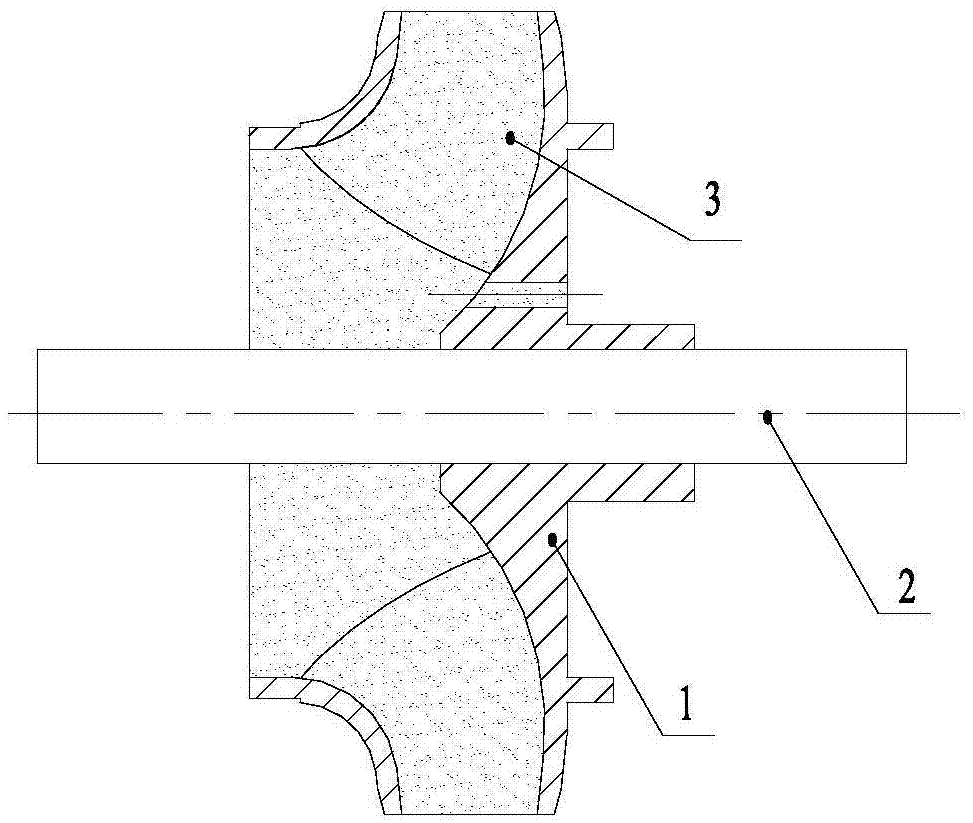

Self-locking centrifugal compressor impeller structure

PendingCN110017300AIncrease preloadImprove dynamic balance accuracyPump componentsPumpsInterference fitDynamic balance

The invention discloses a self-locking centrifugal compressor impeller structure, and relates to the technical field of compressor impeller structures. The technical problem of low connection reliability between an impeller and a rotor shaft of a centrifugal compressor in the prior art is solved. The self-locking centrifugal compressor impeller structure comprises an impeller and a rotor shaft, the end face of the impeller is provided with an outer conical surface, the end face of the rotor shaft is provided with an inner conical surface, the outer conical surface is connected with the inner conical surface through transition fit or interference fit, and the rotor shaft locks the impeller. Due to the fact that the impeller rotated at a high speed is expanded outwards under the action of self centrifugal force and work heating, the structural design that the outer conical surface of the impeller makes contact with the inner conical surface of the rotor shaft is added on the basis of seam allowance fit between the impeller and the rotor shaft in the prior art, the inner conical surface of the rotor shaft can limit the outward expansion effect of the outer conical surface of the impeller, so that dynamic balance precision in the working process of the rotor shaft and the impeller is favorably maintained, and the maximum transferable torque is improved.

Owner:上海优社动力科技有限公司

Marine steam turbine rotor field dynamic balance structure

PendingCN113790085AImprove dynamic balance accuracyEasy to operateBlade accessoriesMachines/enginesMarine engineeringDynamic balance

The invention aims at providing a marine steam turbine rotor field dynamic balance structure. The structure comprises a rotor, the rotor is a high-power marine steam turbine flexible rotor, and the rotor is provided with field dynamic balance structures at a first-stage wheel disc, a last-stage wheel disc, a thrust disc and a coupler side flange. According to the structure, multi-plane combined adjustment can be carried out on a plurality of positions of the outer sides of the first-stage wheel disc and the last-stage wheel disc of the rotor, the rotor thrust disc and the coupler output flange. The rotor dynamic balance precision can be improved by adjusting the quality of a dynamic balance block and a screw, and the operability is very high. The dynamic balance precision of the marine steam turbine rotor can be guaranteed for a long time, the safe and stable operation requirements are met, and high expenditure and long-period maintenance for opening a cylinder in a ship cabin and returning the cylinder to a factory for high-speed dynamic balance are saved.

Owner:中国船舶重工集团公司第七0三研究所

A brake disc processing technology

ActiveCN111347062BGuaranteed stabilityExtended service lifeAuxillary equipmentTurning machinesBrakeDynamic balance

Owner:SHENGRUI TRANSMISSION

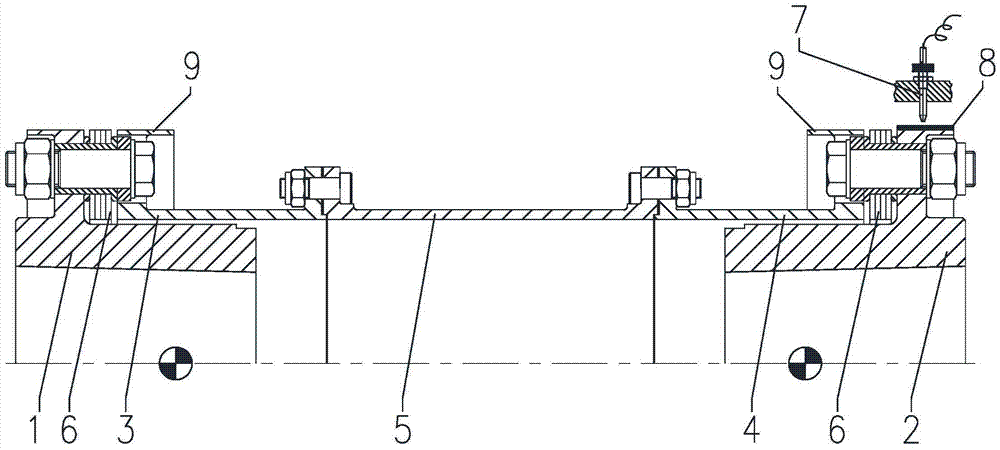

Special mandrel tool for dynamic balance of belt wheel of high-precision machine tool

PendingCN109434145AEliminate positioning gap errorsImprove dynamic balance accuracyExpansion mandrelsTransmission beltDynamic balance

The invention aims to provide a special mandrel tool for dynamic balance of a belt wheel of a high-precision machine tool, and the special mandrel tool is used for solving the technical problem abouthow to improve dynamic balance performance of a machine tool transmission belt wheel. The special mandrel tool for dynamic balance of the belt wheel of the high-precision machine tool comprises a mandrel body, a spring tightening sleeve and a locking nut, wherein the two ends of the mandrel body are equipped with outer circular terminals which are connected with a dynamic balance machine tool, andthe middle part of the mandrel body is equipped with a taper outer circle which is matched with a belt wheel hole; and the spring tightening sleeve is arranged between the taper outer circle and thebelt wheel hole, and a the locking nut for tightening the spring tightening sleeve is mounted between the mandrel body and the outer end of the belt wheel. The special mandrel tool has the beneficialeffects that: positioning gap errors between the outer circle of the dynamic balance mandrel and the belt wheel hole in the prior art are completely eliminated, and dynamic balance precision of the belt wheel can be greatly improved, so that stability and balance of the machine tool are guaranteed.

Owner:JINAN FIRST MACHINE TOOL GROUP

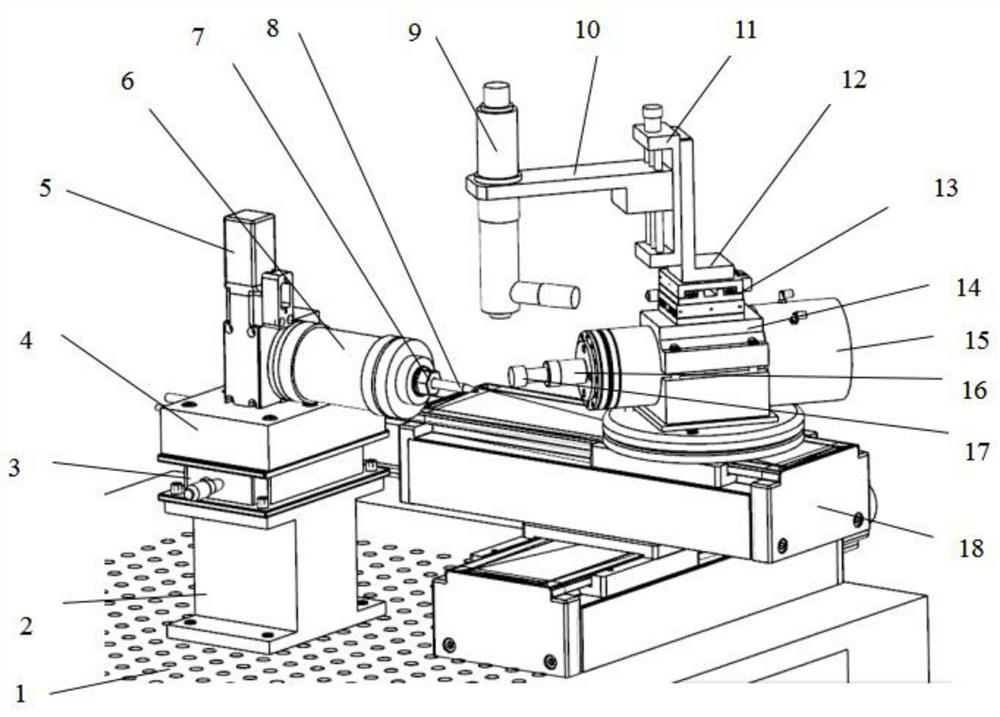

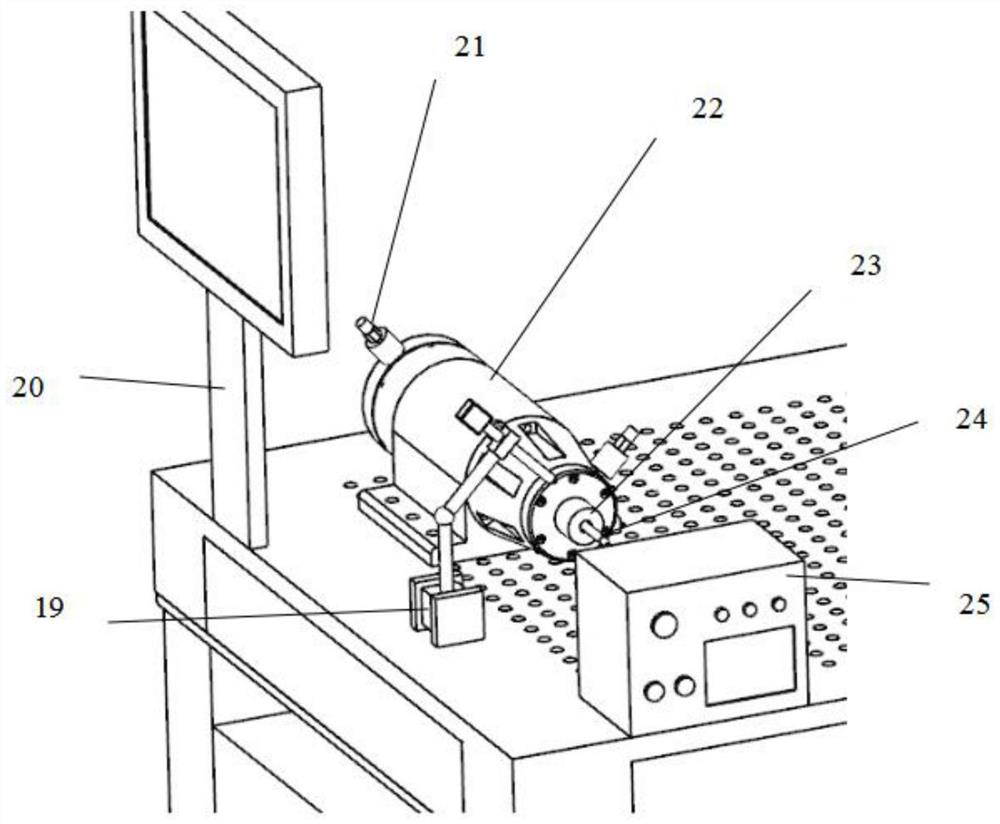

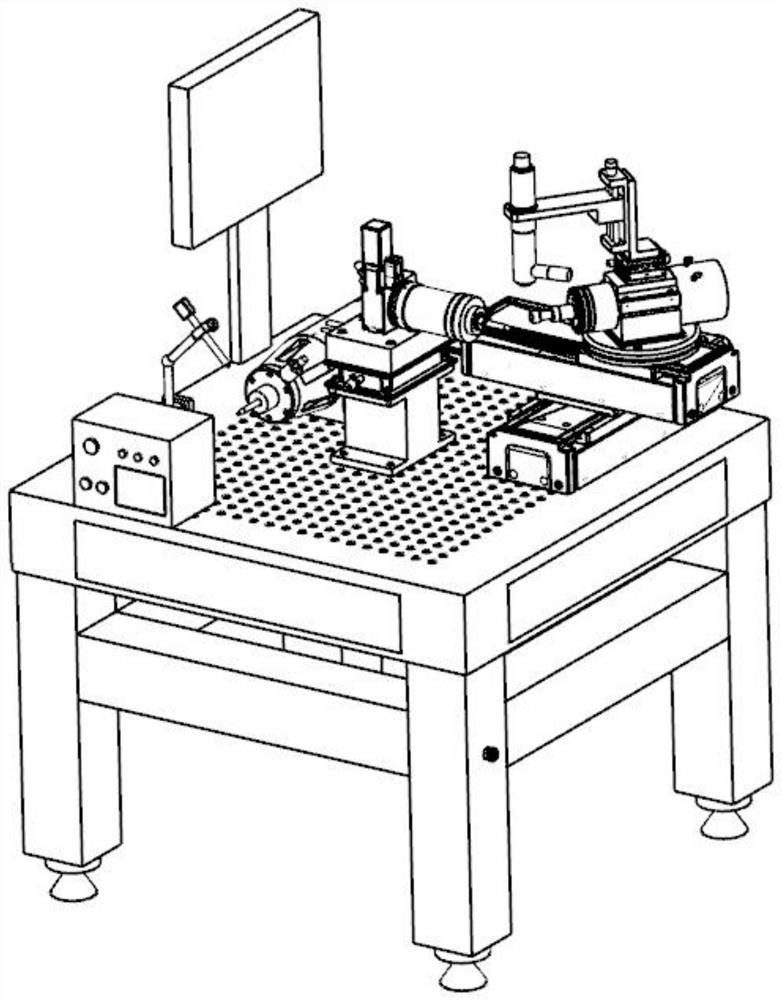

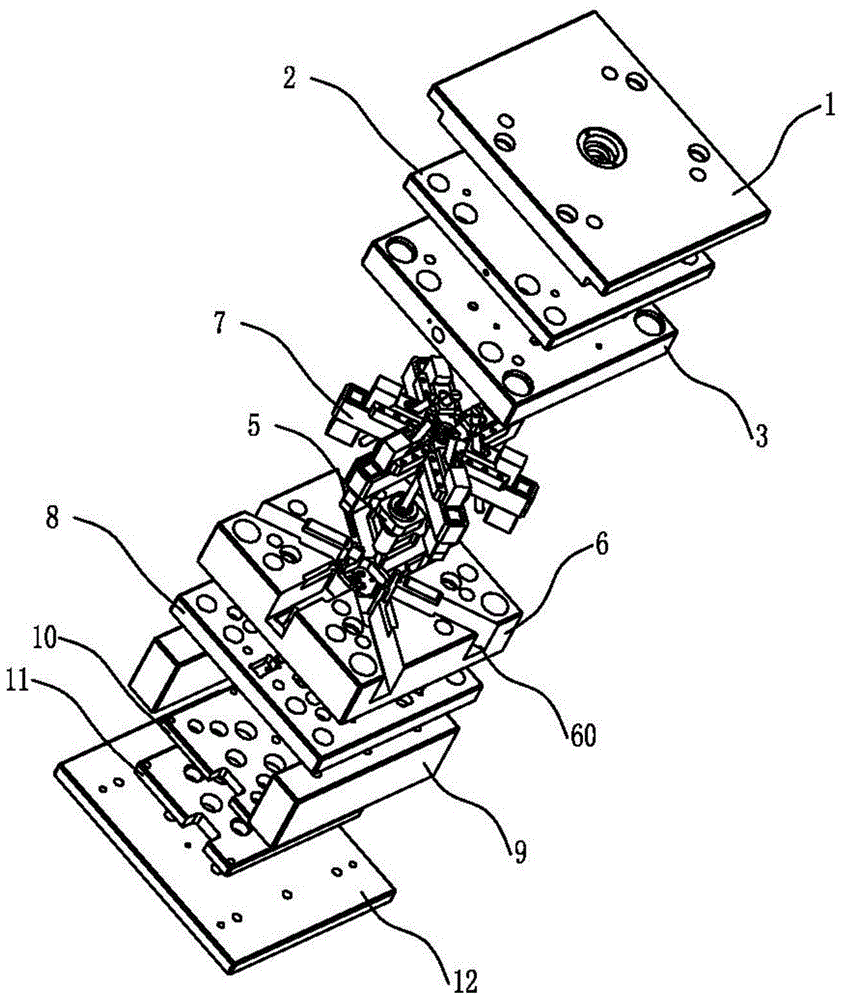

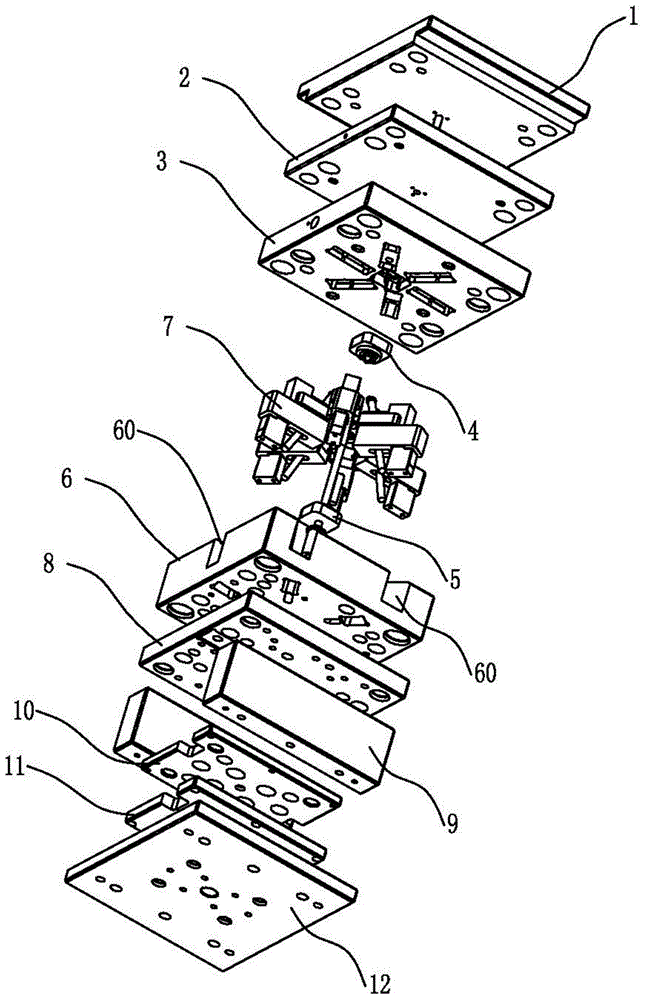

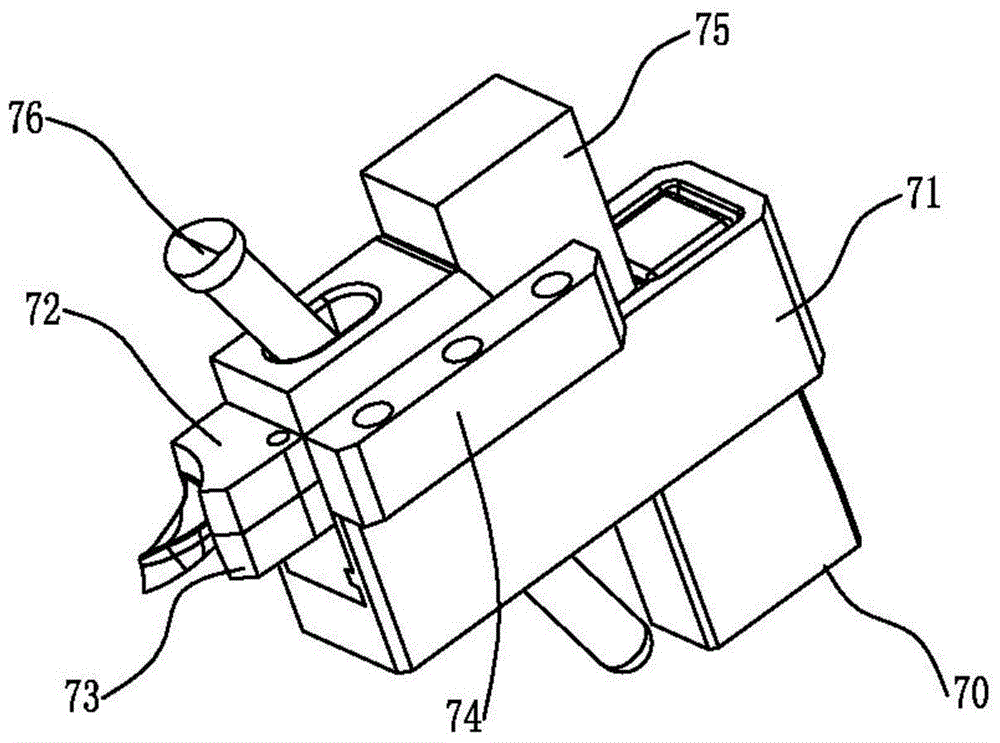

A dynamic balance test and correction system for diamond micro-diameter milling cutter

ActiveCN111595517BImprove detection accuracyImprove dynamic balance accuracyStatic/dynamic balance measurementRotary stageMilling cutter

The invention discloses a dynamic balance test and correction system for a diamond micro-diameter milling cutter. The system includes two parts: a micro-grinding workbench and a dynamic balance measurement workbench, wherein: the micro-grinding workbench includes a precision air-floating spacer Vibration platform, base, precision motion table, piezoelectric ceramics, electric control rotary table, collet, CCD camera, CCD mounting frame, vertical one-dimensional precision guide rail, connecting plate, two-dimensional precision motion platform A, grinding axis Mounting frame, high-speed grinding spindle, pneumatic chuck A, grinding wheel grinding head, two-dimensional precision motion platform B; the dynamic balance measurement table includes photoelectric sensor, industrial computer, vibration sensor, dynamic balance spindle, pneumatic chuck B and Dynamic balancer. The system can detect the dynamic balance of the micro-milling cutter and deal with the unbalanced amount, and can solve the problem that the precision of the diamond micro-milling cutter is reduced during the micro-milling process due to the dynamic unbalanced amount after the diamond micro-milling cutter is prepared or worn.

Owner:HARBIN INST OF TECH

Fully Dynamically Balanced Couplings

ActiveCN104977124BImprove shock absorptionImprove coaxialityYielding couplingStatic/dynamic balance measurementCouplingPhase imbalance

Fully dynamically balanced couplings, including half-couplings at the power input end, half-couplings at the power output end, input end jackets, output end jackets, intermediate sections, diaphragm sets, infrared probes, key phase magnetic strips and accessories Heavy flange; the input end sheath and the output end sheath are respectively set on the shaft hubs of the power input half coupling and the power output half coupling through the counterweight flange; the input end sheath passes through the intermediate section It is connected with the output end sheath; the diaphragm group is set between the input end sheath, the output end sheath and the intermediate section; the key phase magnetic strip is set on the power input end half coupling or the power output end half coupling method on the blue plate; the infrared probe is set on the upper end of the key phase magnetic strip; the counterweight flange is provided with a counterweight screw hole. For the unit equipped with the coupling of the present invention, the key phase magnetic strip, the infrared probe and the shaft vibration detection instrument of the unit itself can be used together to determine the unbalanced mass and phase, and only one stop is required. The screw plug of unbalanced mass is screwed into the heavy screw hole to obtain accurate dynamic balance of the unit.

Owner:沈阳申克动力机械有限公司

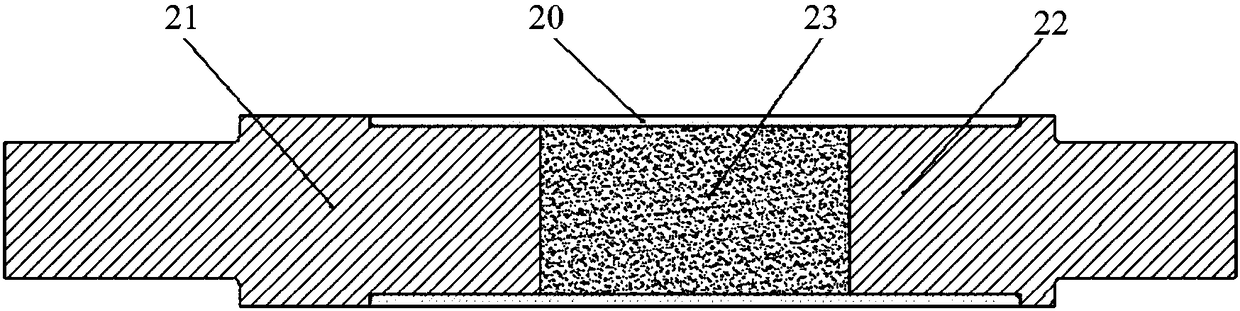

Shaft system structure and assembly method for electric motor

ActiveCN105449895BReduce in quantityReduce assembly coaxiality is difficult to guarantee the problemMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringAlloy

The invention discloses a shafting structure for a motor, and an assembling method. The shafting structure comprises a front-segment shaft (62), a rear-segment shaft (63), annular magnetic steel (61) and an alloy sheath (60), wherein the rear-segment shaft (63) successively comprises a first shaft joint (631) and a second shaft joint (633) from front to back, and the diameter of the first shaft joint (631) is smaller than that of the second shaft joint (633); the annular magnetic steel (61) sleeves the first shaft joint (631) of the rear-segment shaft (63); the external diameter of the rear end of the front-segment shaft (62) is the same as the external diameter of the annular magnetic steel (61); and the alloy sheath (60) sleeves the front-segment shaft (62) and the annular magnetic steel (61). According to the scheme provided by the invention, the shafting structure and the assembling method overcome the defects of complex structure, large assembling difficulty, poor safety and the like in the prior art and also have the advantages of simple structure, small assembling difficulty and good safety.

Owner:GREE ELECTRIC APPLIANCES INC +1

Molds for turbines of automotive turbochargers

ActiveCN104550713BImprove dynamic balance accuracyPush in timeFoundry mouldsFoundry coresTurbochargerDynamic balance

Owner:JIANGSU WANLI MACHINERY

A Dynamic Balancing Method for Rotary Table of Double-axis Precision Centrifuge Based on Driving Current

ActiveCN109847952BSolve the problem of dynamic balanceHigh sensitivityCentrifugesDriving currentDynamic balance

The invention discloses a driving current based dynamic balance method of a rotary table of a double-axis precision centrifuge machine, and belongs to the technical field of mechanical rotor dynamic balance. In order to solve the problems that an existing dynamic balance method of a rotary table of a precision centrifugal machine is low in dynamic imbalance identification precision, complex in operation and calculation process, large in time consumption and the like, a double-shaft precise centrifugal machine main shaft is arranged to operate at a small rotating speed omega 0, and the rotary table operates at a rotating speed -omega 0 to collect the reference data of the driving current of the rotary table; the double-shaft precise centrifugal machine main shaft is arranged to be operatedat the working rotating speed omega, the rotary table operates at the rotating speed -omega, the driving current data of the rotary table are collected, and a one time frequency component of current is extracted; and the double-shaft precision centrifugal machine is arranged to operate at the rotating speed omega, accurate identification is carried out on the dynamic unbalance value of the rotarytable through a mode of adding test mass according to the obtained frequency multiplication of the current, and balancing is carried out. The method does not depend on any external precise sensor, theidentification precision of the shafting dynamic imbalance of the rotary table is higher, the method is simple and feasible, multiple experiments are not needed, and the method is more practical fromthe engineering application angle.

Owner:HARBIN INST OF TECH

Dynamic balance testing method for simulating mass of media in pump impeller runner

ActiveCN106930958AReduce vibrationImprove dynamic balance accuracyPump componentsPump controlImpellerDynamic balance

The invention belongs to the technical field of vane pumps and particularly relates to a dynamic balance testing method for simulating the mass of media in a pump impeller runner. The dynamic balance testing method for simulating the mass of the media in the pump impeller runner comprises the first step of medium adhesion, the second step of cooling and solidification, the third step of taking out of excess materials, the fourth step of modification of unbalance and the fifth step of removal of the simulated media. By means of the dynamic balance testing method for simulating the mass of the media in the pump impeller runner, the technical problems that impeller mass unbalance can still be caused when an impeller subjected to dynamic balance testing in air and modification is in practical use, and pump vibration is aggravated are solved. As for the method, the testing conditions are approximate to actual conditions, the dynamic balance precision of the impeller can be remarkably improved, therefore vibration of a pump in operation is reduced, and the method is suitable for occasions having high requirements for pump vibration under special application conditions.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

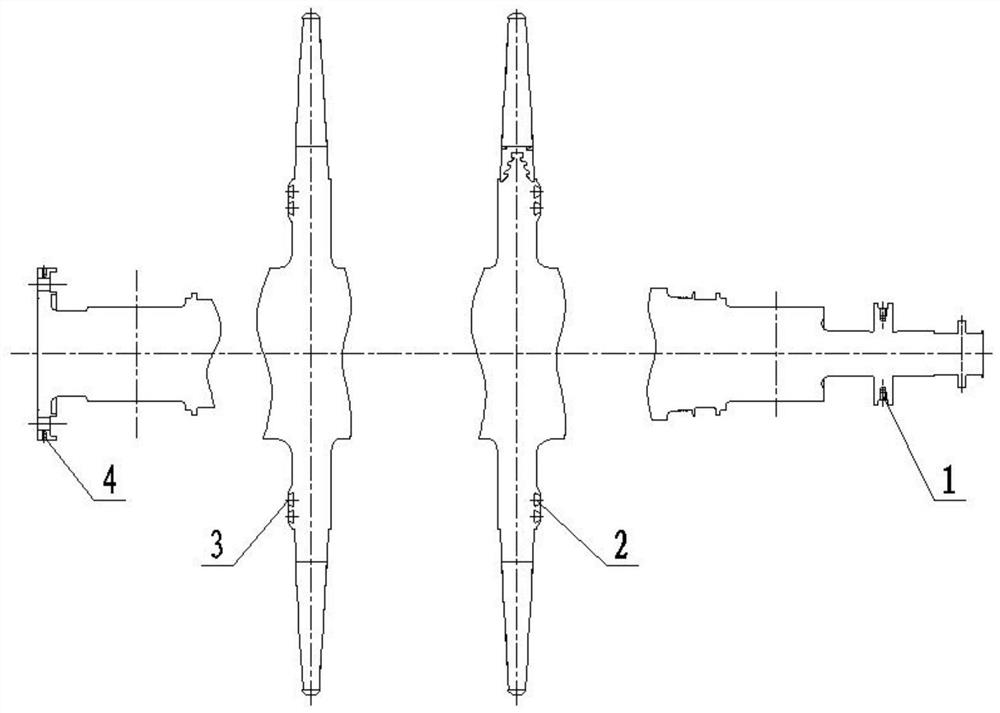

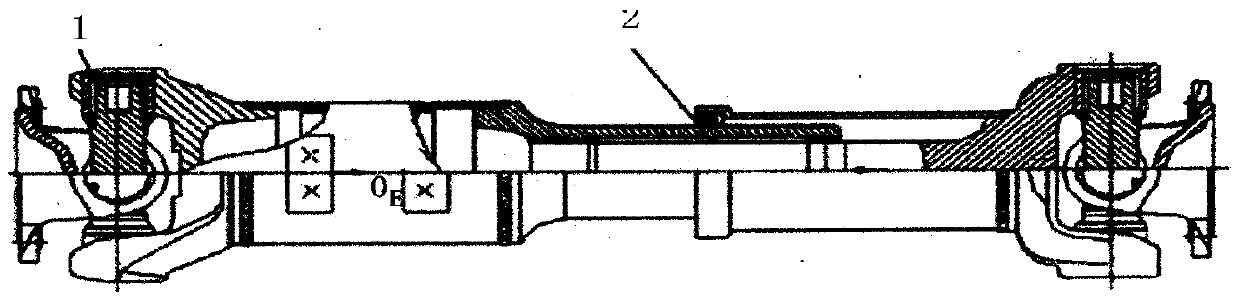

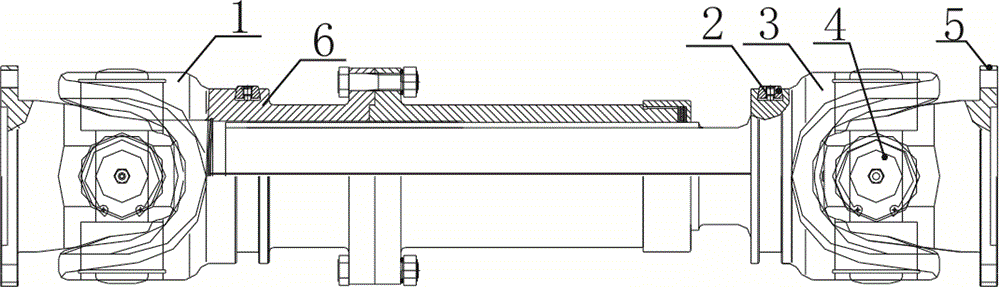

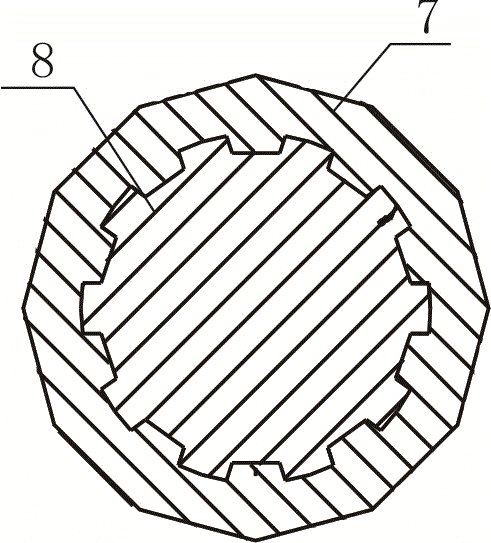

Equidistant molded surface transmission shaft

PendingCN111043176AImprove dynamic balance accuracyDynamic balance accuracy without vibrationYielding couplingMilling equipment detailsPhysicsEngineering

The invention discloses an equidistant molded surface transmission shaft which is composed of two parts. The cross universal joint of an original transmission shaft is replaced with equidistant spherical couplings ((1), (3) in figure 4). Spline connection in the original transmission shaft is replaced by equidistant arc surface connection ((2) in figure 4). The axial cross section of the equidistant spherical coupling is an equidistant spherical surface ((1) in figure 4). The radial cross section of the equidistant spherical coupling is an equidistant arc surface ((1)a-a in figure 4). During working, the torque is transmitted by using the equidistant arc surface, the axial corner deviation is adjusted by using the equidistant spherical surface, and equidistant arc surface holes are milledand ground the by using an equidistant arc surface hole machine tool.

Owner:沈阳等距科技有限公司

Long telescoping cardan shaft

InactiveCN106195040AStable transfer strengthGuaranteed transmission strengthYielding couplingActuatorsCouplingTorque transmission

The invention discloses a long telescoping cardan shaft. The long telescoping cardan shaft comprises a spline housing set, a spline and balancing grooves, wherein the spline is arranged inside the spline housing set and outside a spline shaft, and the balancing grooves are formed in the spline housing set and the spline shaft. The spline housing set comprises a spline housing, a jaw which is in positioning connection with the spline housing through a spigot, a reamed hole bolt and a nut. According to the long telescoping cardan shaft, the spline housing and the spline shaft are matched through the spline, and long telescoping torque transmission of an SWP-type universal coupling is achieved; and under the adjusting action of balancing blocks, the cardan shaft can still guarantee the dynamic equilibrium during long telescoping torque transmission.

Owner:CSR ZIYANG TRANSMISSION

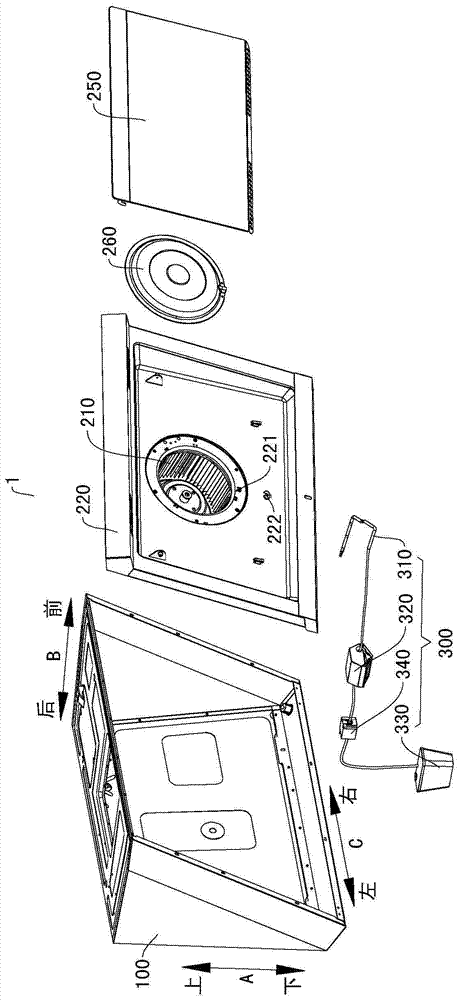

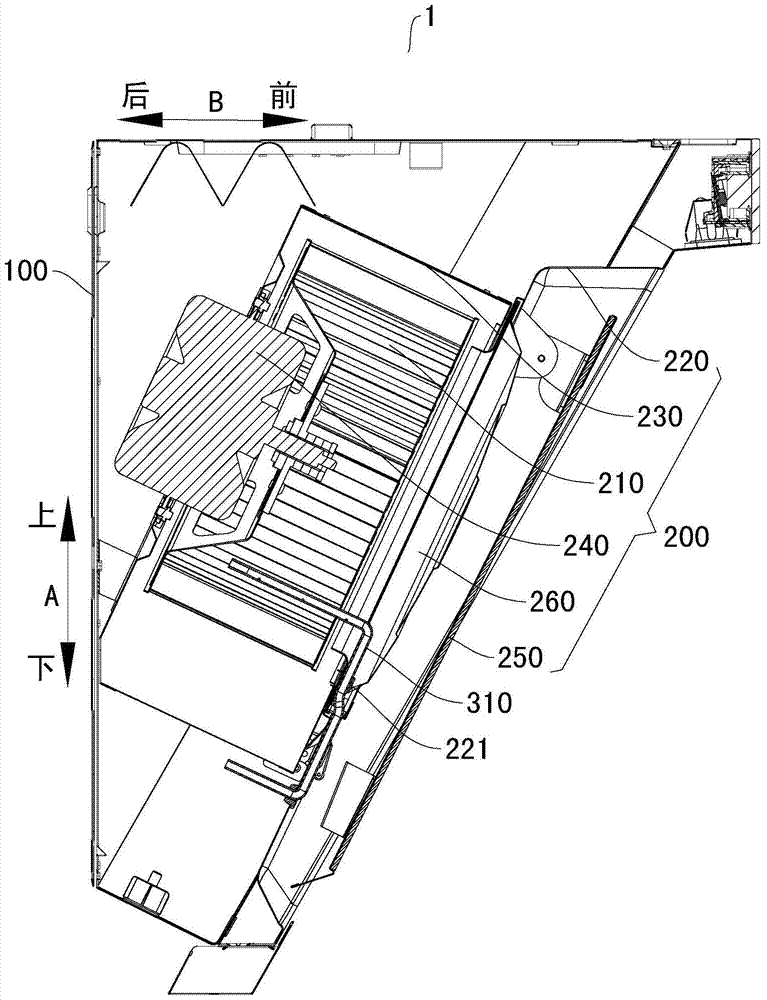

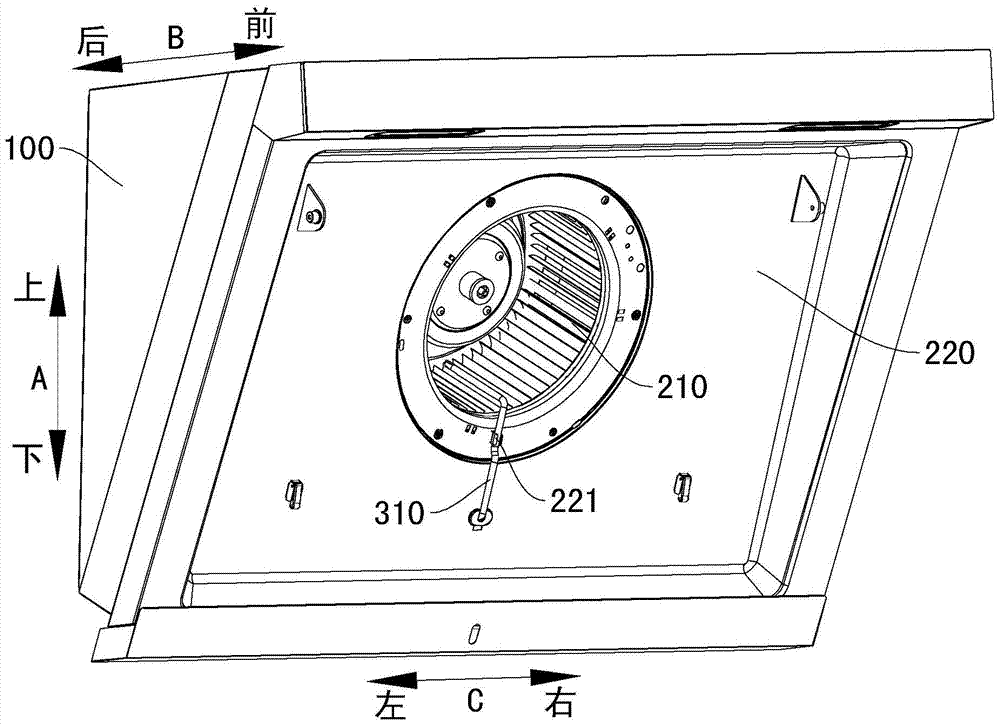

grease pump

ActiveCN104421986BReduce noiseExtended service lifeDomestic stoves or rangesLighting and heating apparatusImpellerEngineering

The invention discloses a range hood comprising a casing, a draught fan volute assembly and a cleaning device, wherein the draught fan volute assembly is mounted on the casing and comprises an impeller with blades; the cleaning device is mounted on the casing and is provided with a spray pipe, the spray pipe is provided with spray holes, and the spray holes are positioned in an inner cavity of the impeller and are used for cleaning a part of the blades at the lowest position. The range hood of the embodiment can realize automatic cleaning, and has the advantages of small noise, long service life, reliable performance and the like.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

An electric spindle design adopting air static pressure anti-thrusting and electromagnetism radical bearing support

ActiveCN100561833CSimple structureNo lubricationMechanical energy handlingBearingsMagnetic bearingThrust bearing

An electric spindle supported by aerostatic pressure thrust and electromagnetic radial bearings. According to the external dimension limitation and rigidity requirements of the electric spindle, two airstatic pressure stoppers are centrally arranged in the end of the electric spindle housing (5) close to the output end. The push bearing (1) optimizes space utilization and compact structure, and at the same time facilitates the concentration and installation of air supply pipelines, and provides the required axial stiffness for the rotor-rotating shaft integrated shafting (3); when installing the stator (4) Electromagnetic radial bearings (2) are symmetrically arranged on both sides to support the integrated rotor-rotating shaft shafting system, reduce the vibration of the shafting system (3) and ensure its radial stiffness; The bar and the rotating shaft are made as an integral structure, and the position corresponding to the stator installed in the electric spindle shell, that is, the squirrel cage bar is directly welded in the groove with copper alloy to reduce the creep deformation of the squirrel cage bar and reduce vibration. Improve electrical conductivity and structural strength.

Owner:LUOYANG BEARING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com