Crisscross package assembly of universal coupler

A universal coupling and cross wrap technology, applied in the direction of couplings, elastic couplings, engine components, etc., can solve the problem of low concentricity between the intermediate shaft of the coupling and the fork heads at both ends, and the coupling cannot be processed. , assembly site adjustment, inability to carry out convenient replacement and maintenance, etc., to achieve the effect of convenient manufacturing and assembly, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

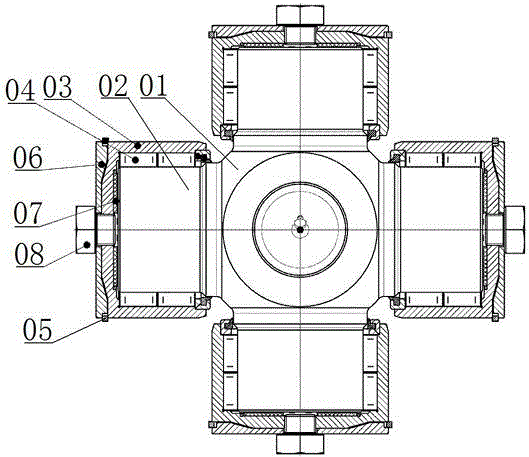

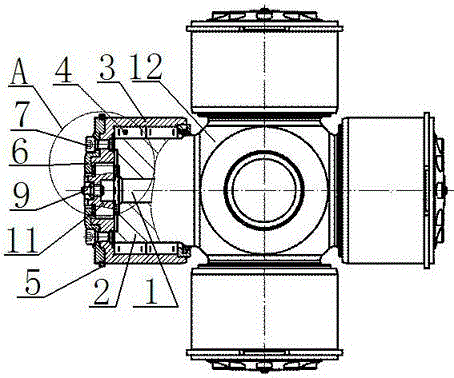

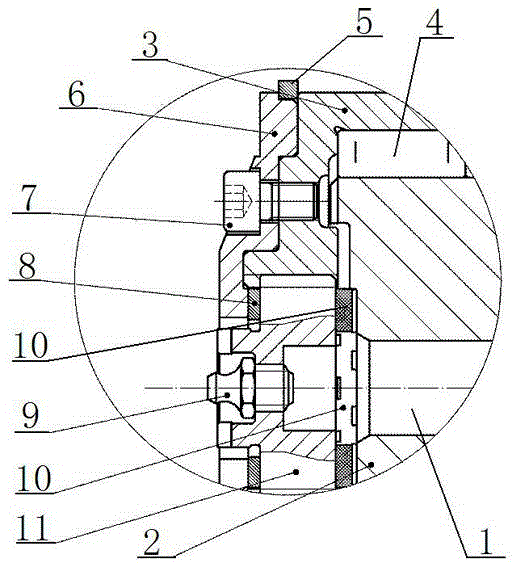

[0019] see figure 2 , image 3 and Figure 4 : the present invention comprises cross shaft 12, has four shaft heads 2 on this cross shaft 12, is provided with oil storage hole 1 on each shaft head 2, and on each shaft head 2 through cylindrical roller 4, guide ring and anti The dust ring is set with the bearing outer ring 3, the cylindrical roller 4 is arranged between the outer surface of the shaft head 1 and the inner surface of the bearing outer ring 3, the guide ring and the dust ring are arranged between the inner end of the bearing outer ring 3 and the shaft head 1 Between the journals, the bearing outer ring 3 forms an interference connection with the fork hole on the coupling. The diameter of the inner hole of the outer end surface of the bearing outer ring 3 is larger than the diameter of the oil storage hole 1, and an inner thread is provided on the inner hole of the outer end surface of the bearing outer ring 3, and the inner hole of the outer end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com