Diaphragm disc coupling for connecting BPRT speed changing clutch

A coupling and clutch technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of low dynamic balance accuracy of the unit, affecting the stability of the unit, and large axial size, achieving light weight, Improve running stability and reduce the effect of hanging weight on the shaft end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

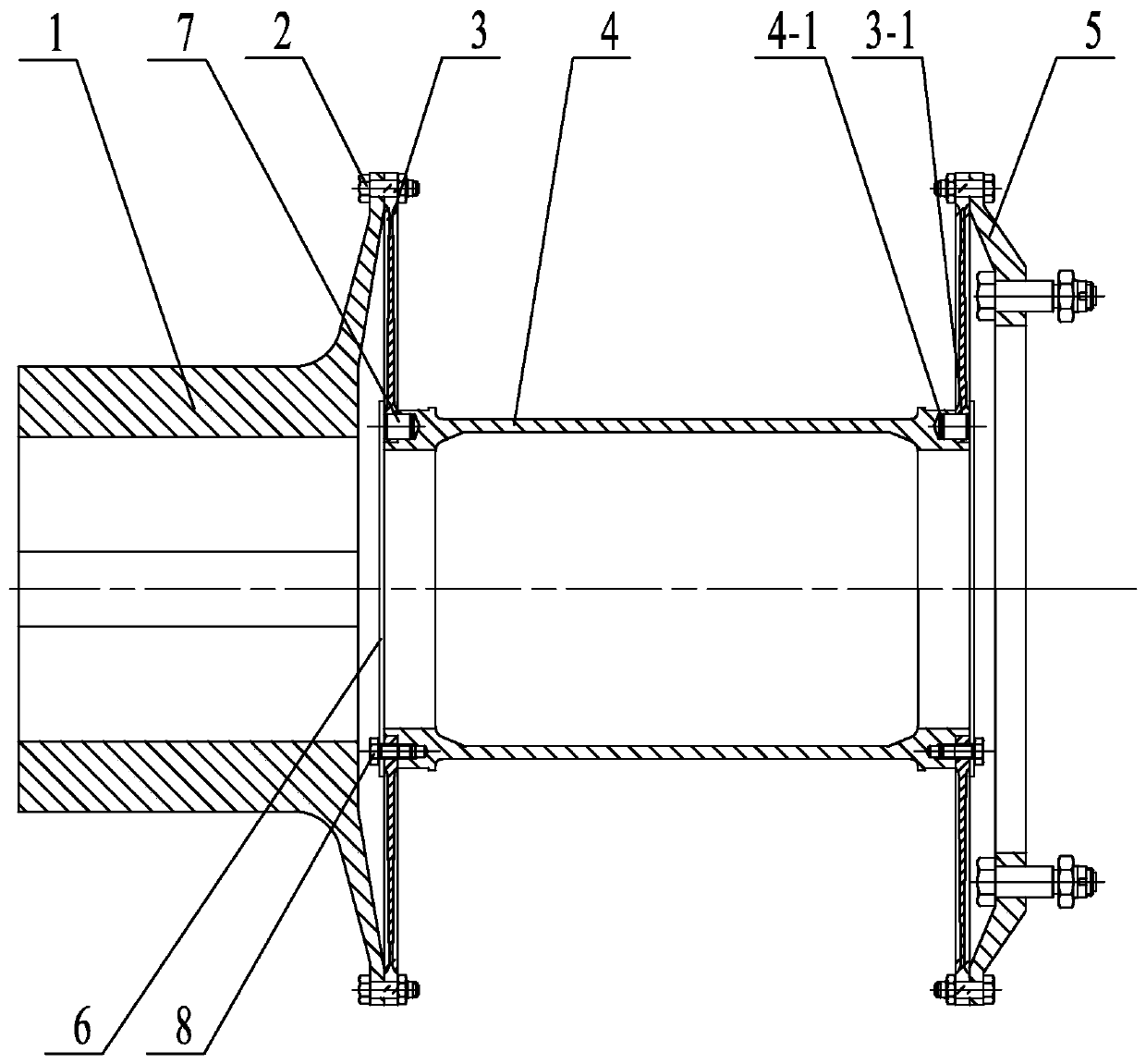

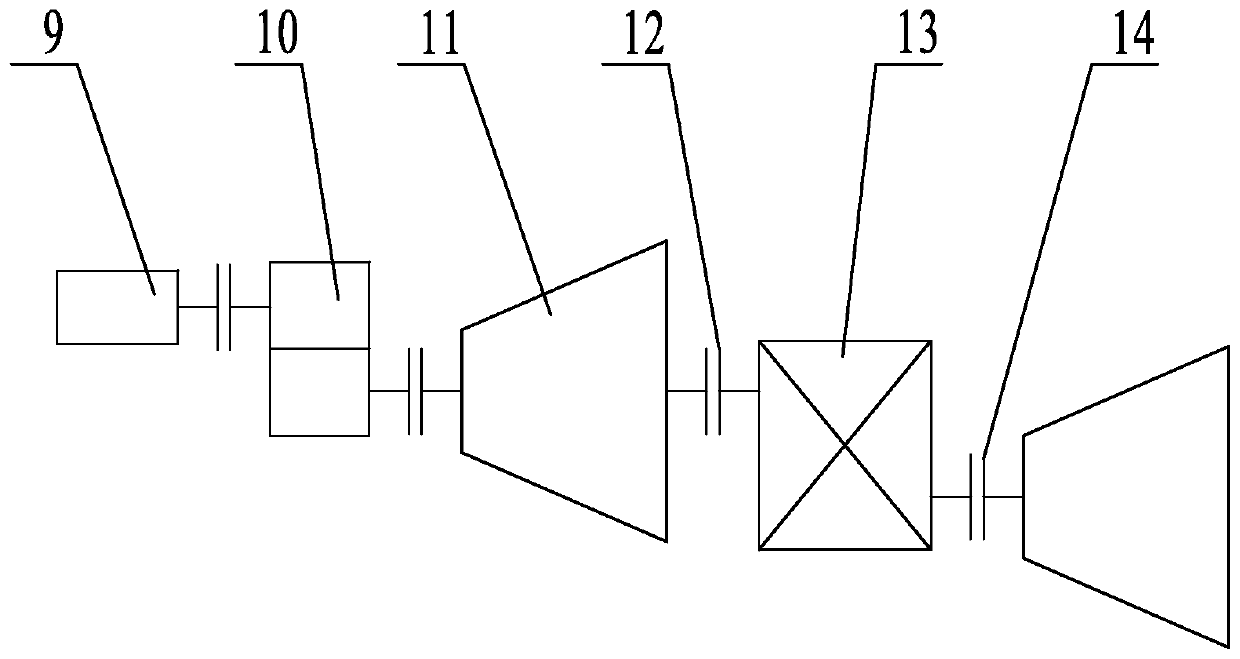

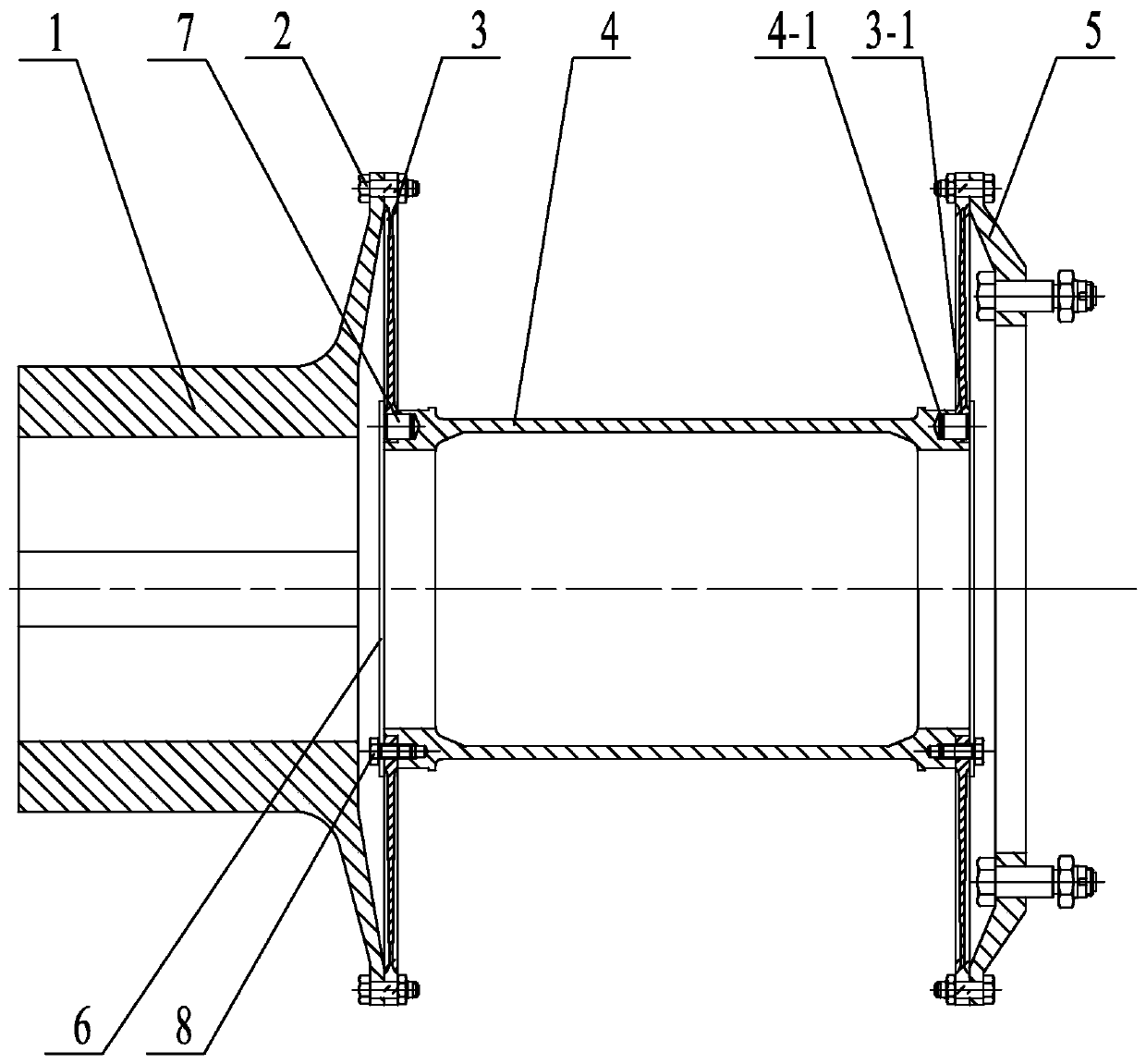

[0010] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment. A diaphragm coupling for connecting a BPRT transmission clutch in this embodiment includes an input flange 1, an intermediate shaft 4, an output flange 5, and two diaphragms 3. The shape of the intermediate shaft 4 is It is a hollow shell with both ends open. A diaphragm 3 is provided at both ends of the intermediate shaft 4 respectively. The diaphragm 3 and the intermediate shaft 4 are positioned by a plurality of positioning pins 7. The middle part of the outer end of the diaphragm 3 is provided with a There is a positioning plate 6, and the outer end surface of the positioning plate 6 is evenly distributed with a plurality of connecting bolts 8 along the circumferential direction. The ends of the connecting bolts 8 pass through the diaphragm 3 and are screwed on the end surface of the intermediate shaft 4. The flanges of the flange 5 are fixedly connected to the outer circumfere...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 To describe this embodiment, the input flange 1 , the membrane disc 3 , the intermediate shaft 4 and the positioning plate 6 described in this embodiment are all arranged coaxially. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a plurality of pin holes 4-1 are evenly arranged on both end surfaces of the intermediate shaft 4 in this embodiment along the circumferential direction, and each pin hole 4-1 is respectively inserted with a positioning pin 7 A plurality of pin holes 3-1 are evenly distributed along the circumferential direction on the end surface of the membrane disc 3, and the pin holes 3-1 are set on the outside of the positioning pin 7, and the positioning pin 7 is arranged on the inside of the positioning plate 6. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com