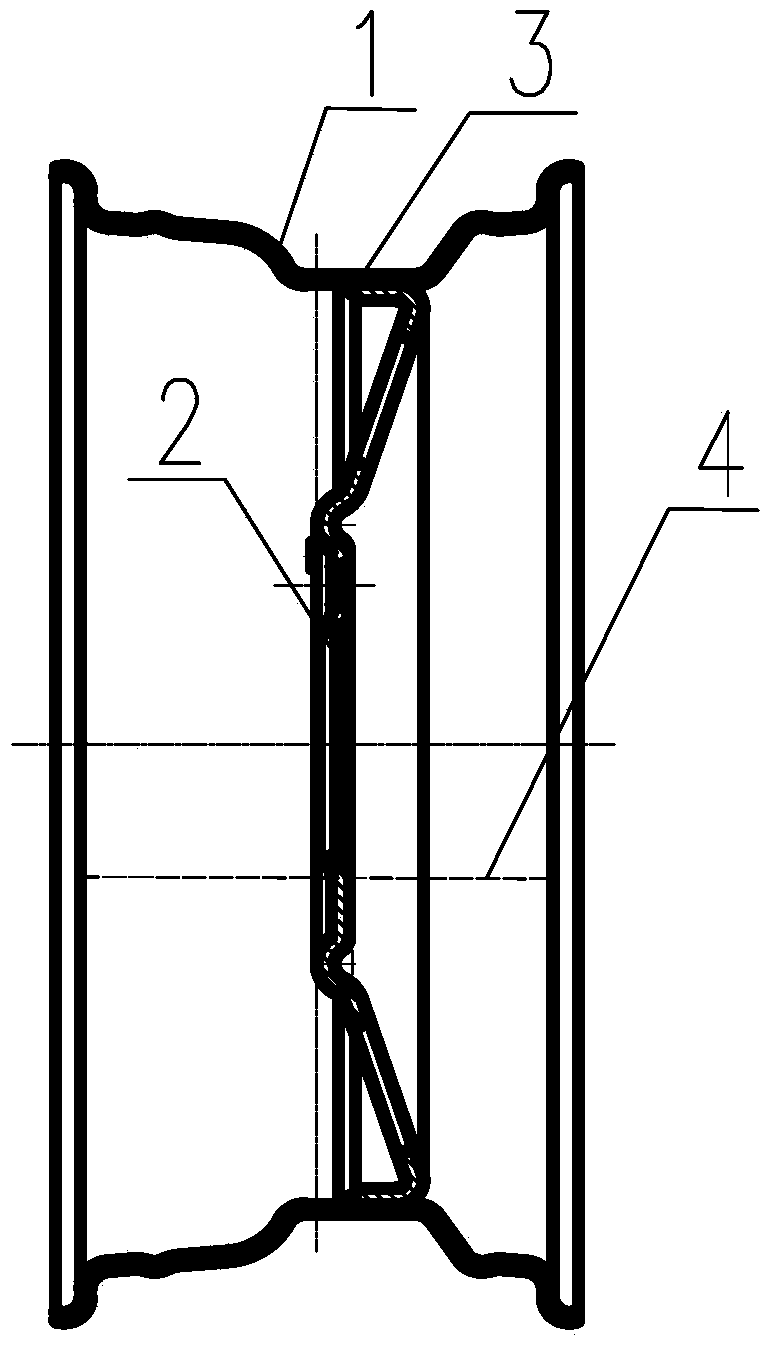

Integrated plate welded-joint-free vehicle wheel and forming method of integrated plate welded-joint-free vehicle wheel

A molding method and an integrated technology, applied in the direction of web-type wheels, wheels, rims, etc., can solve the problems of poor overall strength and rigidity of the wheels, prone to fatigue fractures, complicated air-tightness inspections, etc., to achieve light weight, The effect of balanced quality and large force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

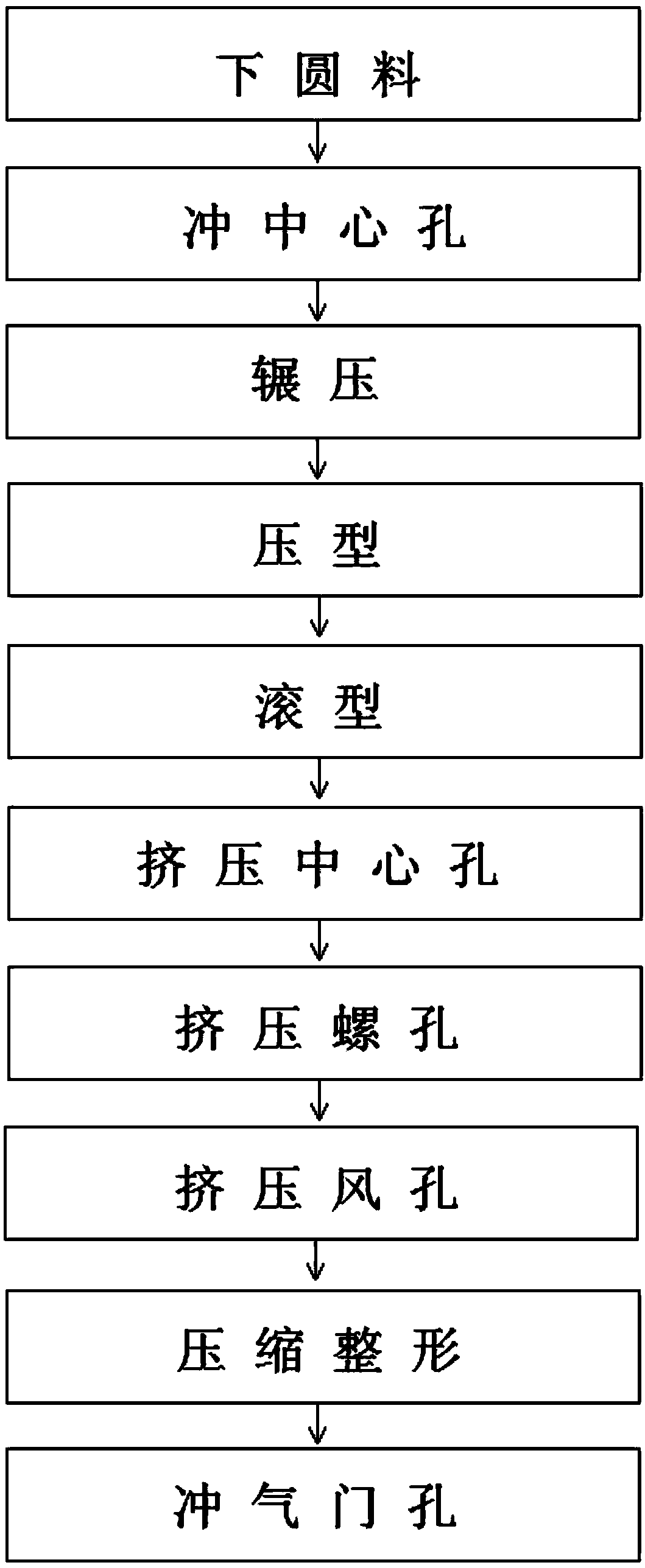

[0040] The method for forming an integral plate seamless wheel according to the present invention will be further described below based on specific examples and accompanying drawings, but the specific examples and related descriptions do not constitute improper limitations to the technical solution of the present invention.

[0041] figure 2 It shows a schematic flow chart of an embodiment of the method for forming an integral sheet metal seamless wheel according to the present invention. Figure 3-Figure 14 The steps are shown separately. Such as Figure 2-Figure 14 As shown, the present embodiment manufactures the one-piece sheet metal seamless wheel according to the following steps:

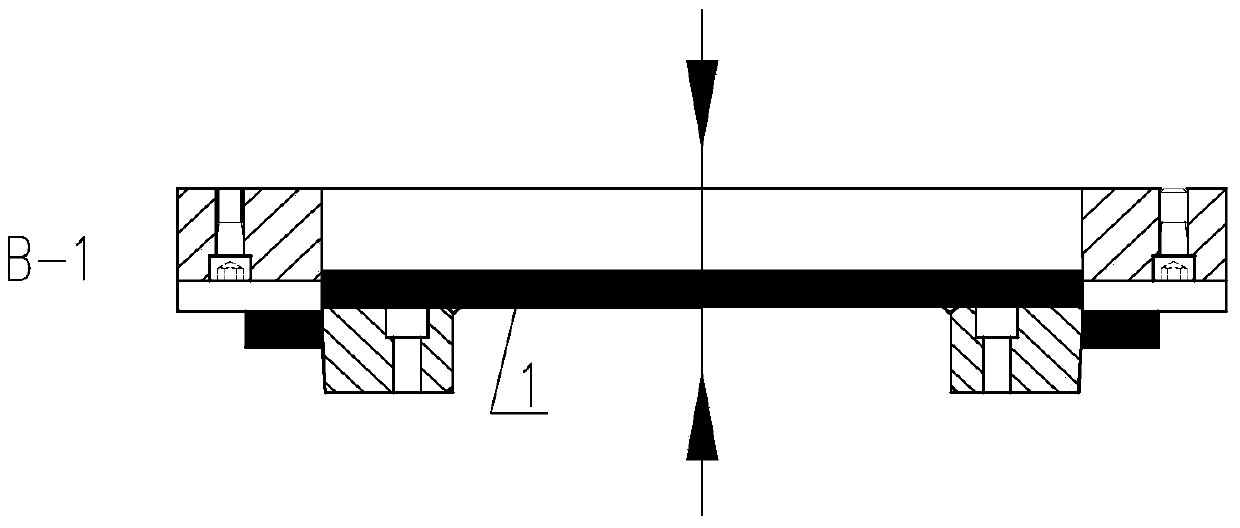

[0042] B-1: Bottom round material 1( image 3 ).

[0043] B-2: Punch the center hole 2 on the round material 1 ( Figure 4 ).

[0044] B-3: Place the round material in the rolling form 3 whose outer contour is circular, and use two rolling wheels 4 arranged symmetrically along the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com