Balancing device and method for multistage blisk

A technology of integral blisks and balance devices, which is applied in measuring devices, static/dynamic balance tests, and machine/structural component tests, etc. It can solve problems such as over-positioning, difficult assembly, and affecting the balance accuracy of the overall blisks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

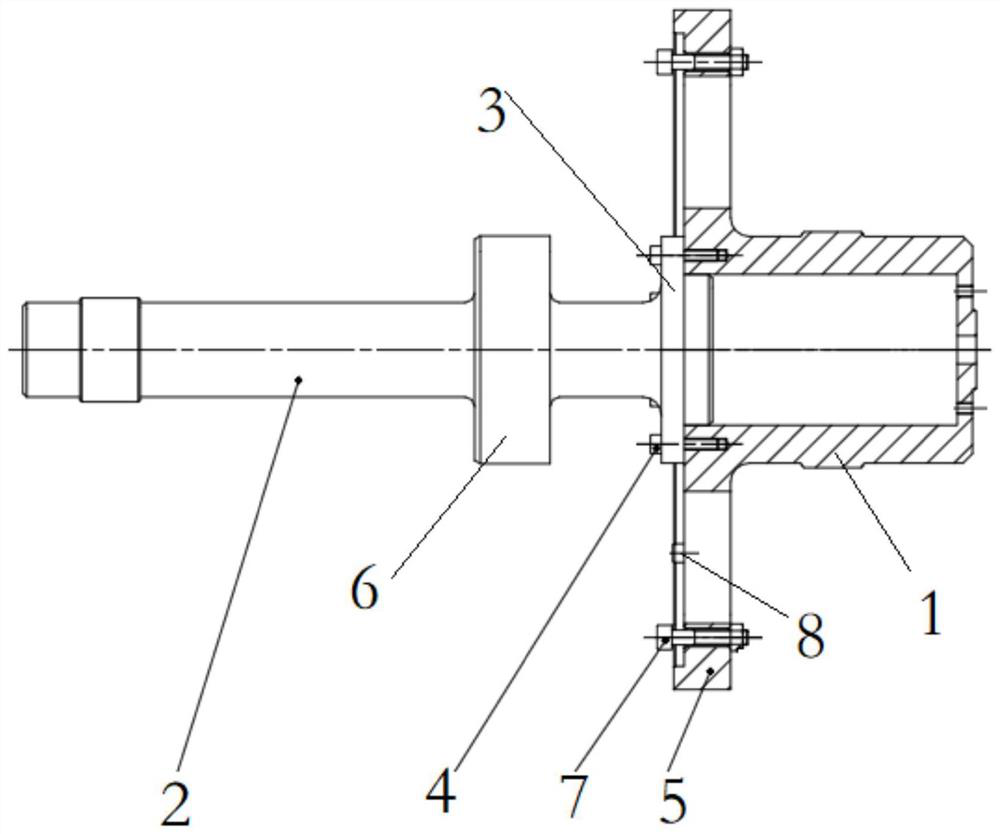

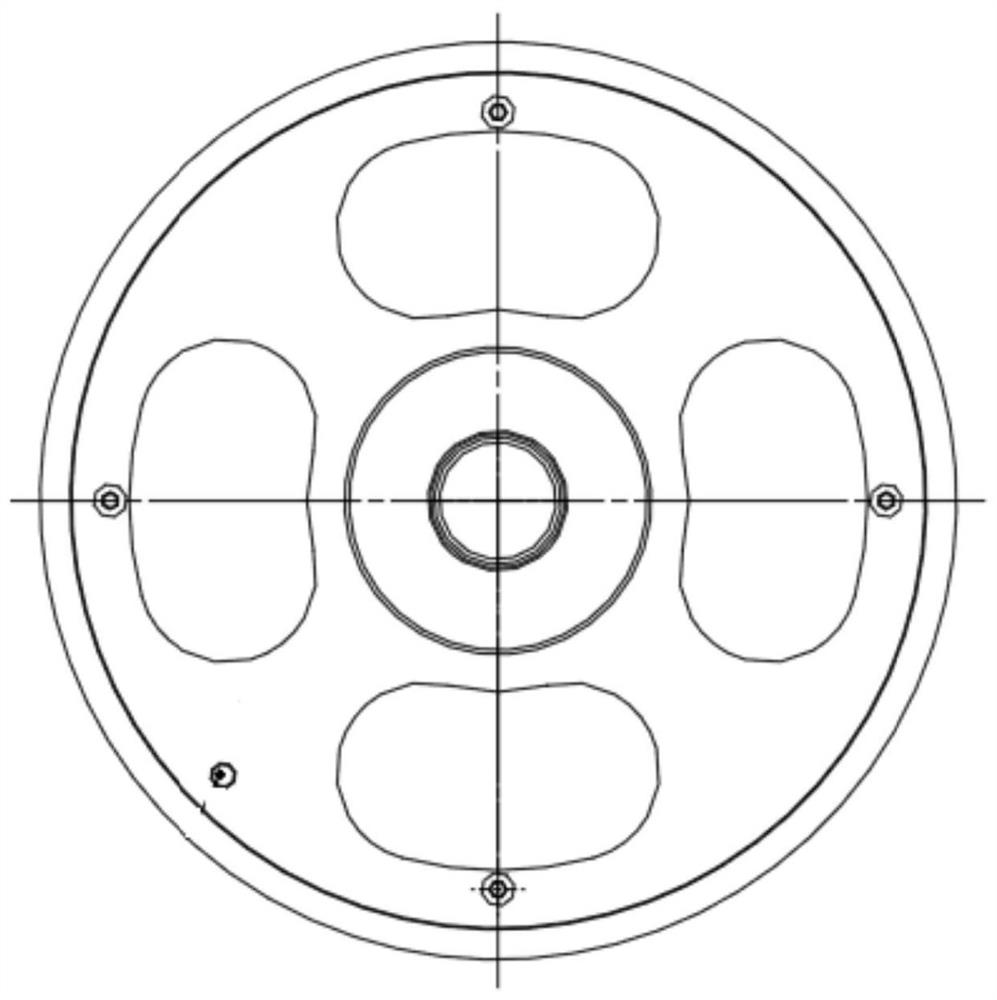

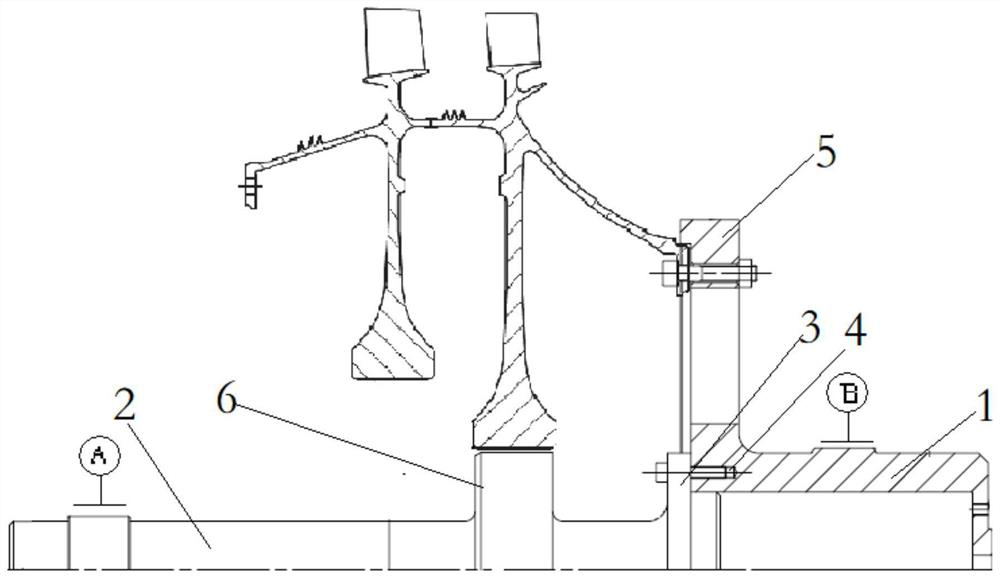

[0033] Such as figure 1 As shown, a multi-stage overall blisk balance device includes a positioning ring 1 and a balance shaft 2. A balance shaft installation hole is provided in the middle of the positioning ring 1, and one end of the balance shaft 2 is fixed in the balance shaft installation hole of the positioning ring 1. , the outer periphery of the positioning ring 1 is provided with a positioning platform 5, the positioning platform 5 is provided with a plurality of positioning ring notches along the circumferential direction of the positioning ring, the balance shaft 2 is provided with a blisk positioning ring 6, and the diameter of the blisk positioning ring 6 is the same as that to be balanced The minimum inner ring diameter of the multi-stage blisk is the same, and the minimum distance from the end of the blisk positioning ring 6 to the end of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com