Dynamic balance testing method for simulating mass of media in pump impeller runner

A test method and technology of pump impellers, which are applied to components of pumping devices for elastic fluids, pumps, pump controls, etc., can solve problems such as increased pump vibration, unbalanced impeller mass, and different quality, and reduce vibration , Improve the effect of dynamic balance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

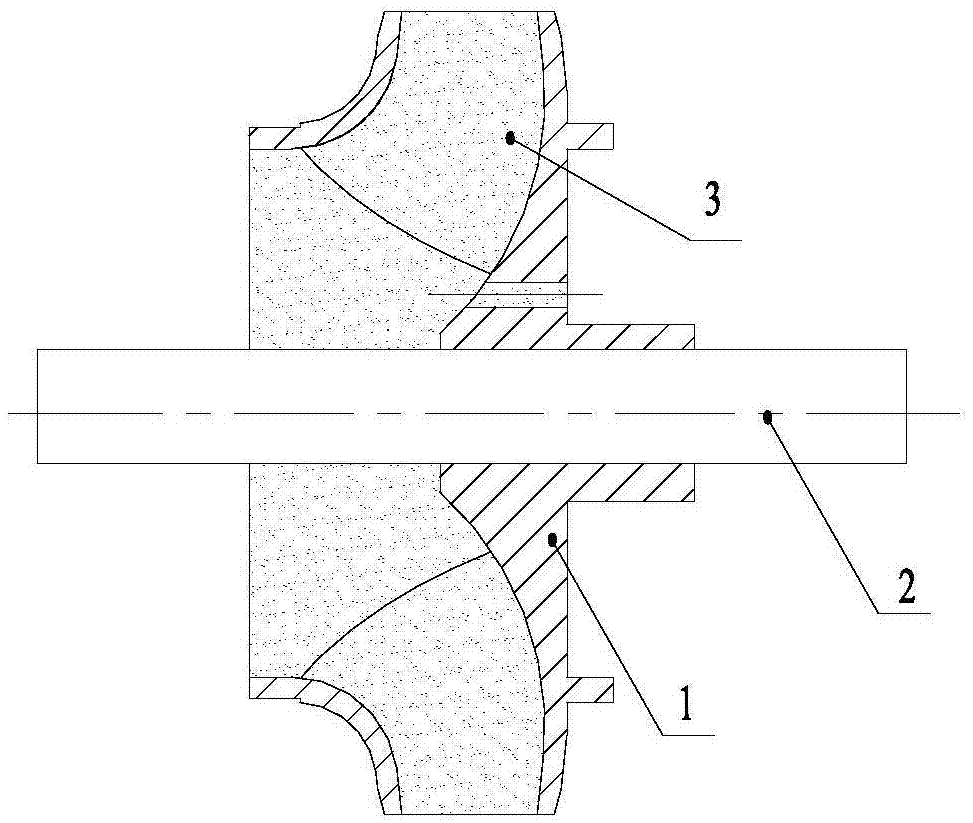

[0022] A dynamic balance test method for simulating the medium quality in the pump impeller channel of the present invention will be described in detail below with reference to the drawings and embodiments.

[0023] In order to simulate the quality of the medium in the flow channel between two adjacent blades of the impeller, first select the medium material with the same or similar density as the medium conveyed by the pump. The medium material is solid at room temperature and can be attached to the impeller parts and in the impeller flow channel. Liquid at high temperatures and can be filled into or purged from the impeller flow passages.

[0024] Fill the above materials in the impeller flow channel under high temperature conditions to simulate the medium quality in the impeller flow channel, and then cool to room temperature so that the material adheres to the impeller parts and does not fall off in the impeller flow channel, and then removes the impeller front cover and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com