Molds for turbines of automotive turbochargers

A turbocharger and turbine technology, which is applied in the field of turbine molds, can solve the problems that the mold is difficult to guarantee the molding size and quality, the space for weight removal is limited, and the working conditions are harsh, so as to ensure the size, facilitate modification and processing, and improve molding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described in conjunction with the following examples.

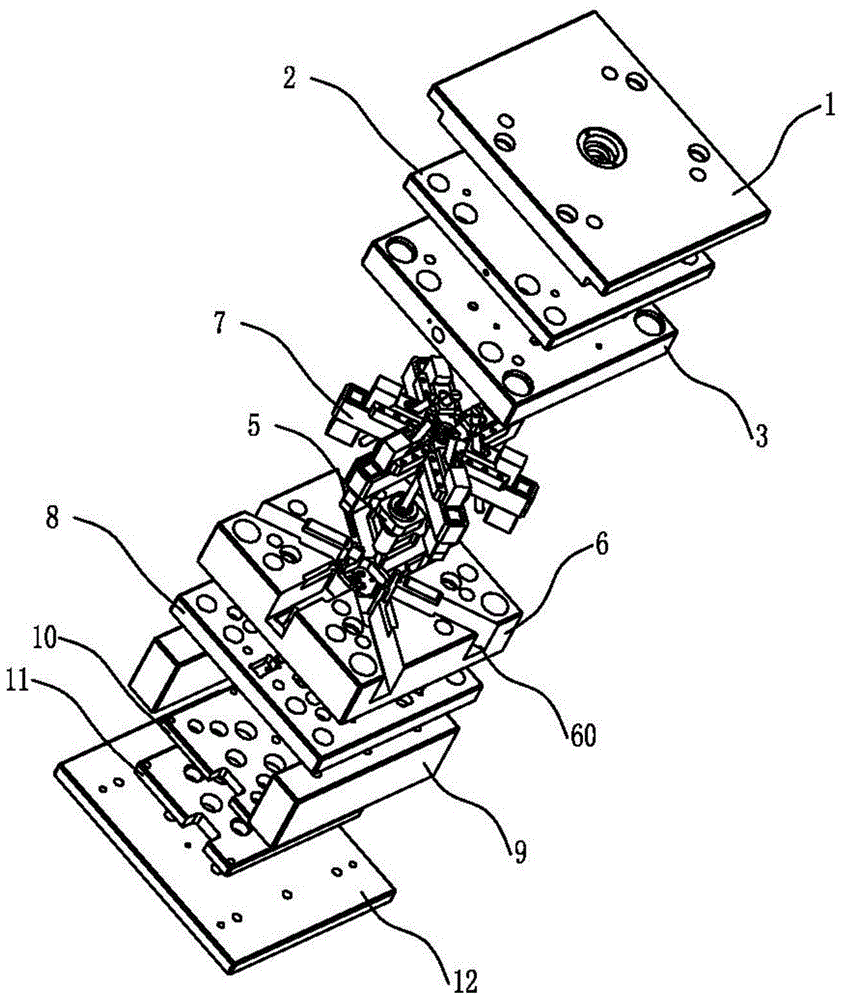

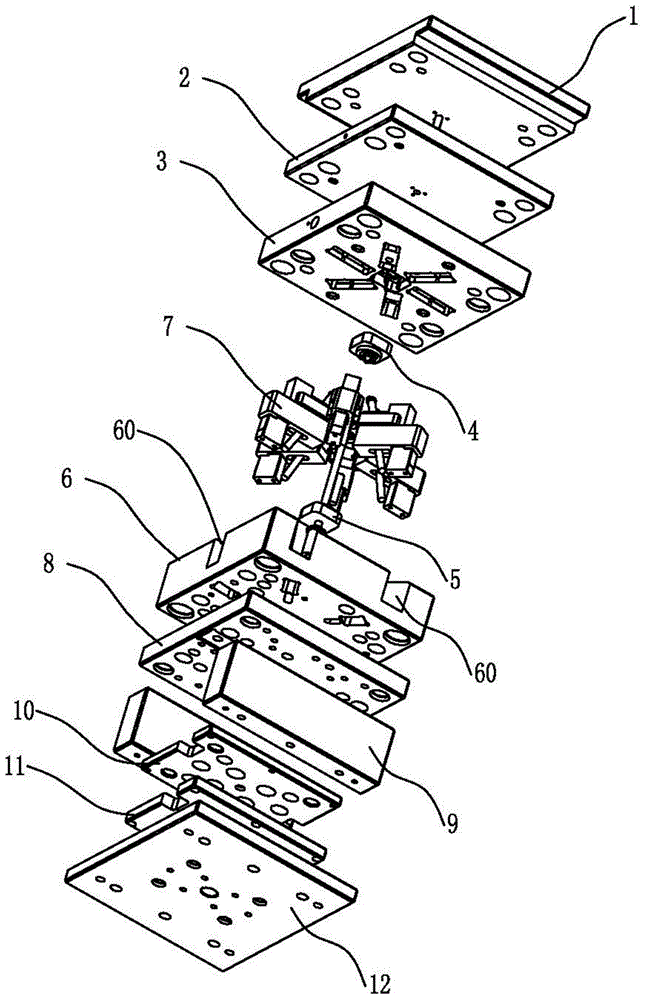

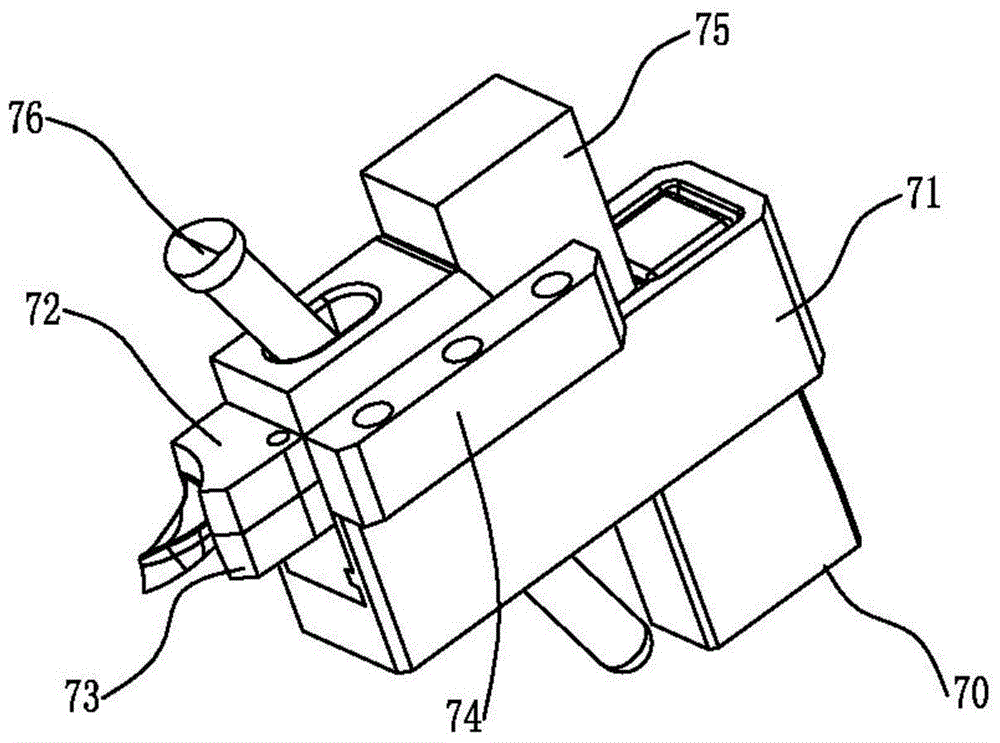

[0034] The mold that the present invention creates is used for the turbine of automobile turbocharger, as figure 1 with figure 2 As shown, it includes fixed mold bottom plate 1, stripper plate 2, fixed template 3, fixed mold core 4, row assembly 7, movable mold core 5, movable template 6, movable mold backing plate 8, square iron 9 and The movable die bottom plate 12 is a face needle plate 10 and a bottom needle plate 11 arranged in sequence between the two square irons 9 . The fixed mold core 4 is arranged in the mold cavity of the fixed template 3 , and the movable mold core 5 is arranged in the mold cavity of the movable template 6 . The main channel extending downward from the fixed mold bottom plate 3 is divided into three secondary runners extending to the fixed mold core 4 at the fixed mold plate 3, and the three secondary runners are evenly distributed around the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com