Method for regulating magnetic levitation vacuum molecular pump rotor dynamic balance

A vacuum molecular pump and rotor dynamic balancing technology, which is applied in static/dynamic balance testing, machine/structural component testing, measuring devices, etc., can solve problems such as inability to directly measure rotor vibration, low balance accuracy, and low balance speed , to achieve the effect of simplifying dynamic balancing equipment and high dynamic balancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

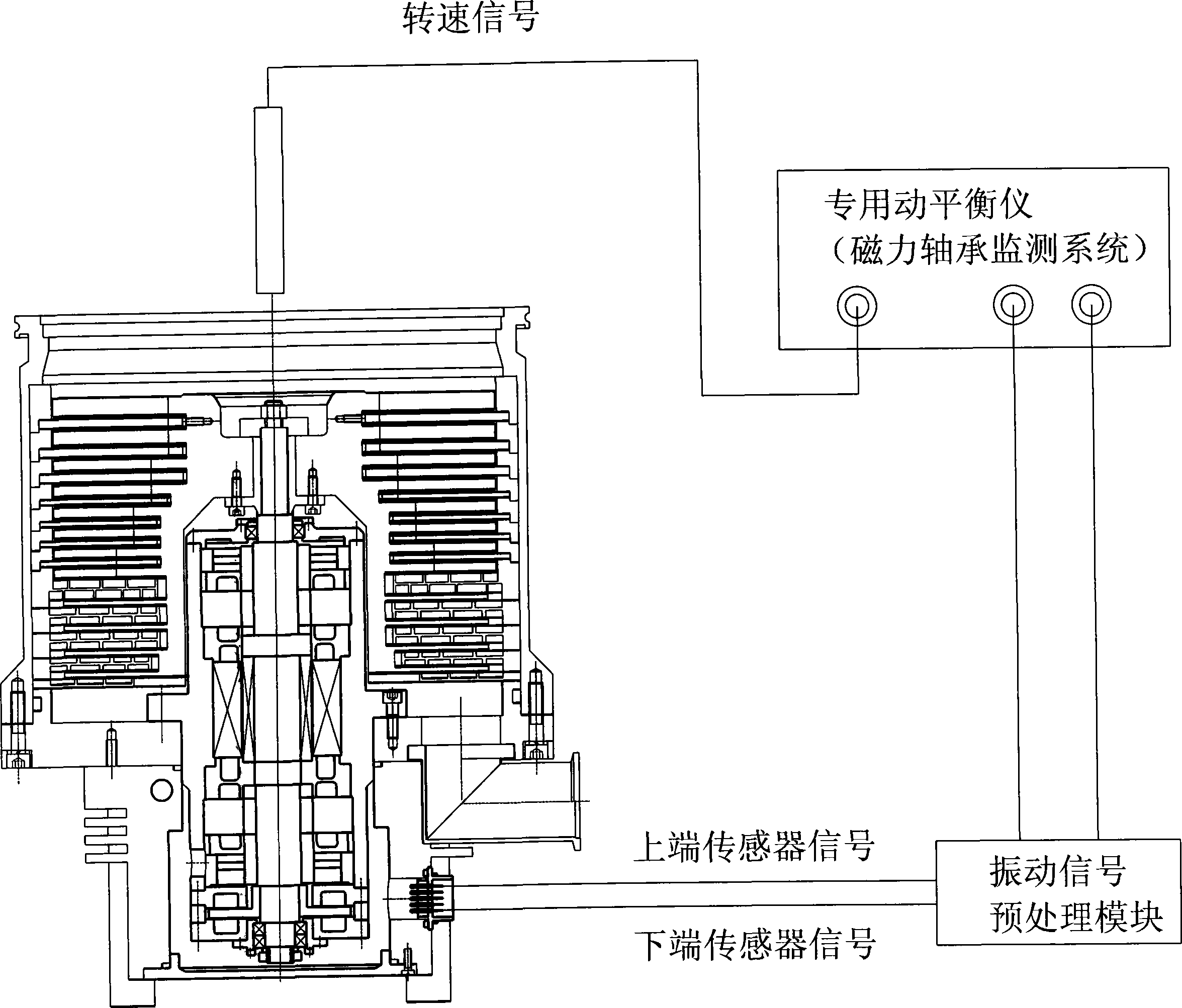

[0016] As shown in the accompanying drawings, when applying the method of the present invention to adjust the dynamic balance of the rotor of the magnetic levitation vacuum molecular pump, first, the actual vibration signal of the rotor is directly obtained from the rotor position detection sensor of the magnetic bearing, and the rotational speed and phase signal of the rotor are collected at the same time; then, with The known method carries out the isolation processing of the DC component to the obtained rotor vibration signal, and performs real-time filtering processing on the rotor vibration signal in a known manner according to the collected rotor speed and phase signal, so as to obtain the same-frequency vibration signal of the rotor; finally, use The dynamic balance instrument or the operation monitoring system of the magnetic levitation vacuum molecular pump completes the corresponding dynamic balance algorithm in the later stage, and performs dynamic balance on the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com