A brake disc processing technology

A processing technology and brake disc technology, applied in the field of brake disc processing technology, can solve the problems affecting the stability and controllability of the whole vehicle, safety hazards, direction deviation and other problems, so as to reduce process turnover bumps and improve service life , transforming clever effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A brake disc processing technology, comprising the following steps:

[0033] Step 1: Coarse and fine car brake disc small end 1 two friction surfaces;

[0034] Step 2: The two friction surfaces of the large end 2 of the rough and fine car brake disc;

[0035] Step 3: Machining the holes at the big end and small end of the brake disc;

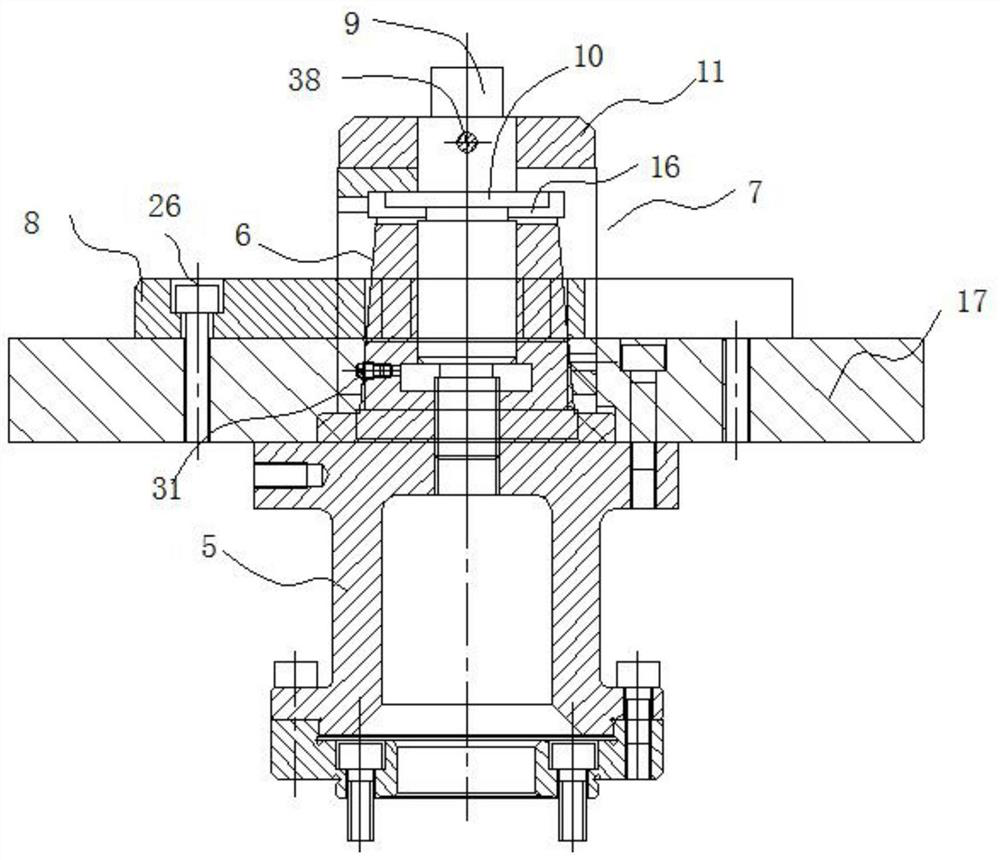

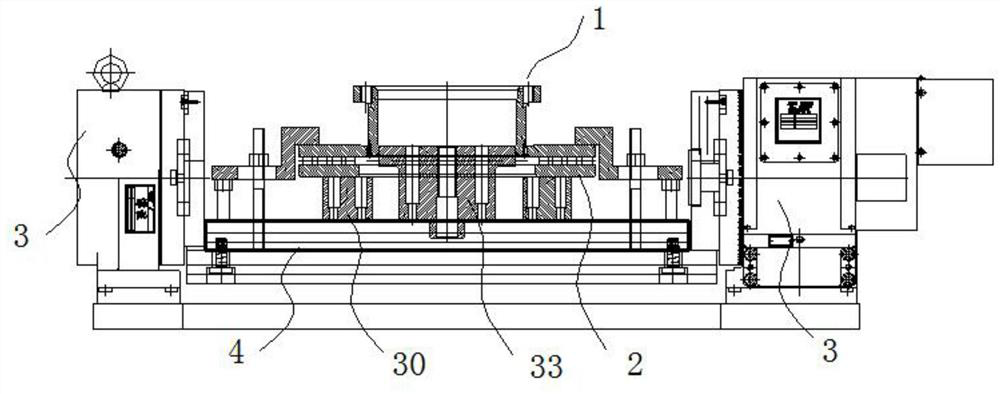

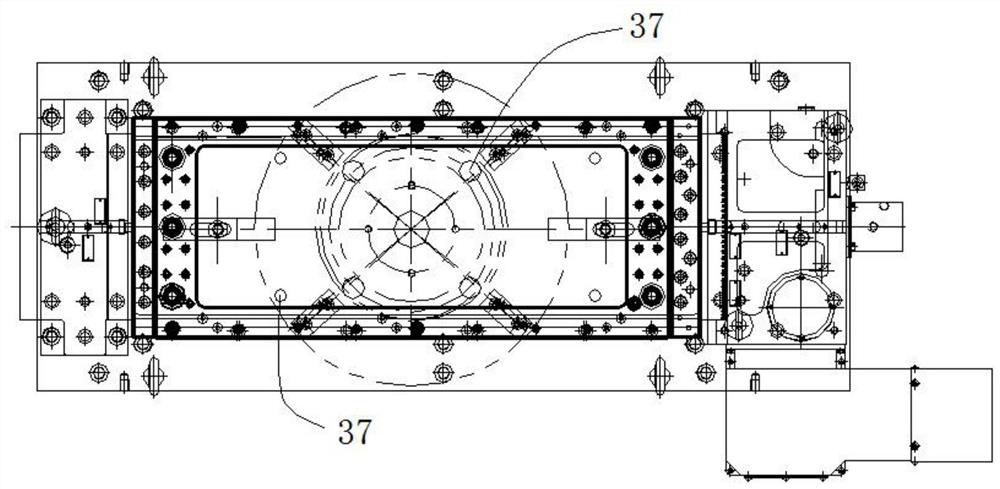

[0036] Step 4: Dynamic balance de-duplication detection;

[0037] In step 3, each hole of the big end and the small end is processed on a machine tool with a fourth-axis rotary table; figure 2 As shown, the fourth-axis rotary table includes two mounting bases 3 and a bottom plate 4 that is rotatably mounted between the two mounting bases and clamped with a brake disc. The processing through hole 37 corresponding to the hole to be processed at the big end, the pad 30 supporting the brake disc is also provided on the base plate, and a stop disc is pressed against the brake disc between the brake disc and the base plate. The fixture on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com