Special mandrel tool for dynamic balance of belt wheel of high-precision machine tool

A pulley, high-precision technology, applied in the direction of expanding the mandrel, etc., to eliminate positioning gap errors, improve dynamic balance accuracy, and ensure stability and balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

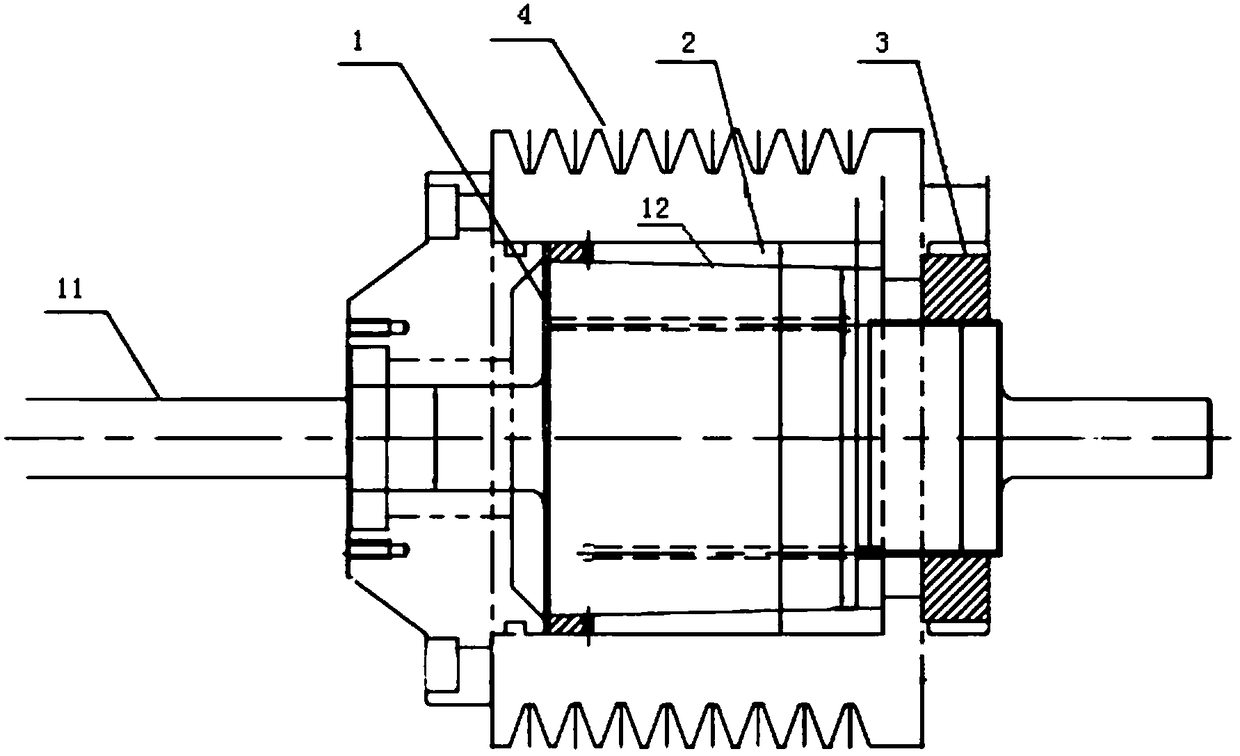

[0016] Such as figure 1 As shown, the special mandrel tooling for the dynamic balance of the high-precision machine tool pulley includes the mandrel body 1, the spring expansion sleeve 2 and the lock nut 3.

[0017] Both ends of the mandrel body 1 are outer round terminals 11 with a size of Φ30h6, which are used for connecting to a dynamic balancing machine tool. The middle part of the mandrel body 1 is a tapered outer circle 12 with a taper of 1:20, and the tapered outer circle 12 is used to match and connect the pulley 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com