A multi-stage small wedge-shaped cutting blasting shock absorption method

A technology of wedge-shaped undercutting and undercutting hole, applied in blasting and other directions, can solve the problems of large blasting distance and area of the first section undercutting hole, large blasting clamping effect, poor blasting surface conditions, etc. Empty surface conditions, reducing vibration speed, controlling blasting vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

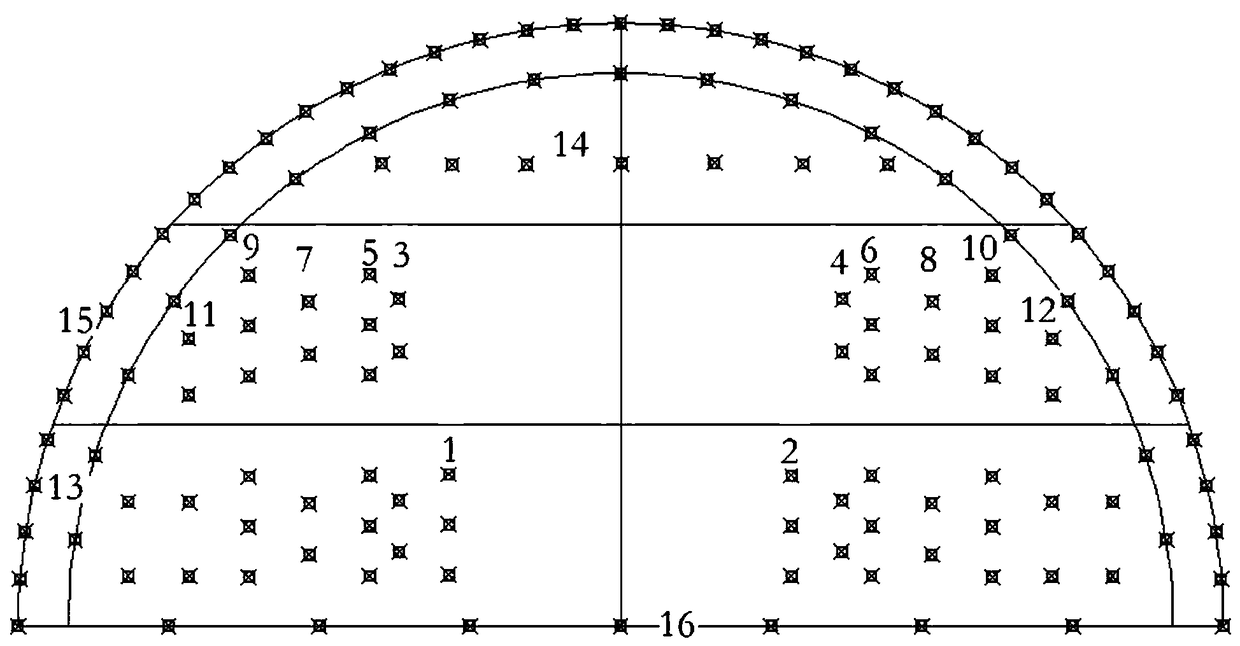

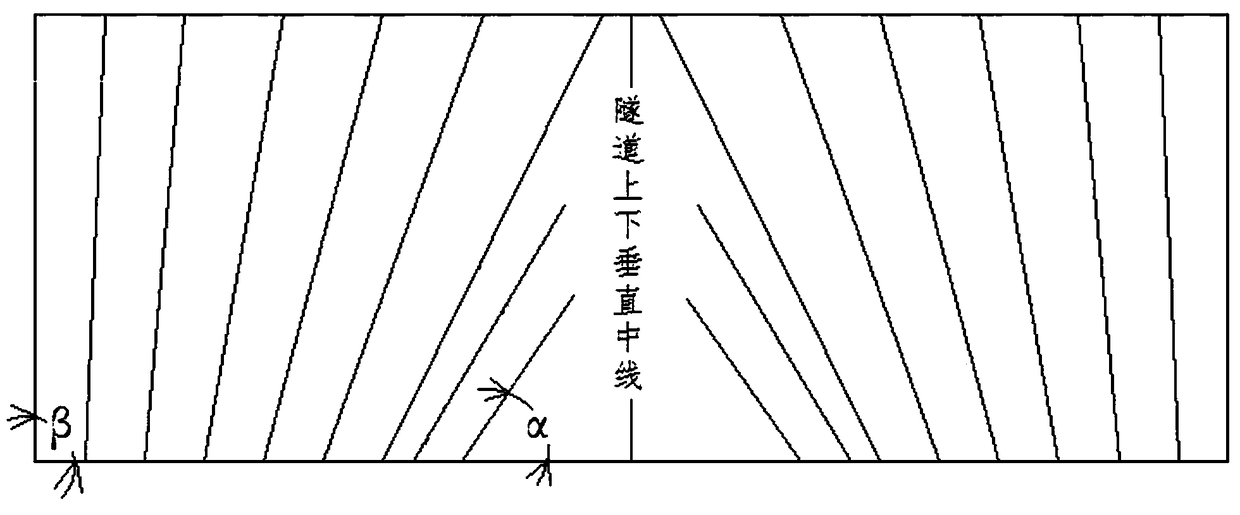

[0033] In the blasting construction of a certain tunnel, 16 sections of blastholes were set on the tunnel face, the first to eighth sections were cut holes, the ninth to 14th sections were auxiliary holes, the fifteenth section was the peripheral eyehole, and the sixteenth section was the bottom plate eye; the horizontal spacing between sections 1 and 3 is controlled between 45cm and 60cm according to the drilling angle; the horizontal spacing between sections 3 and 5 is 35cm, and the vertical blast hole spacing is evenly arranged and not less than 50cm; sections 11 and 9 , The horizontal spacing between sections 7 and 5 is 60cm, and the vertical blasthole spacing is evenly arranged and not less than 50cm; the blasthole spacing of peripheral holes is 45cm-50cm; the bottom plate hole blasthole spacing is 130cm; the 13th section auxiliary hole blasthole spacing is 80cm; the angle between the slot hole and the face of the first section of cutout is 58°, and the angle gradually inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com