Patents

Literature

49results about How to "Reduce the amount of explosives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

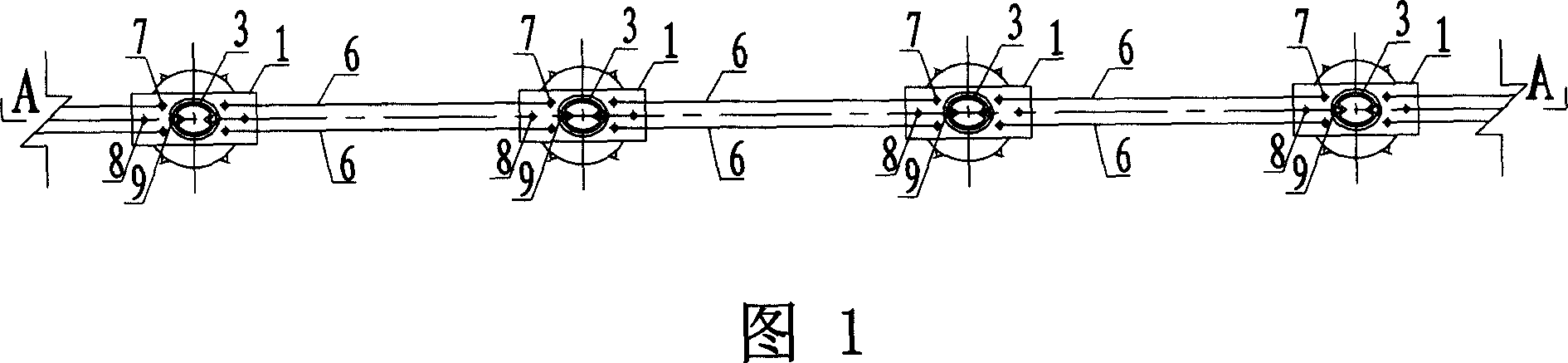

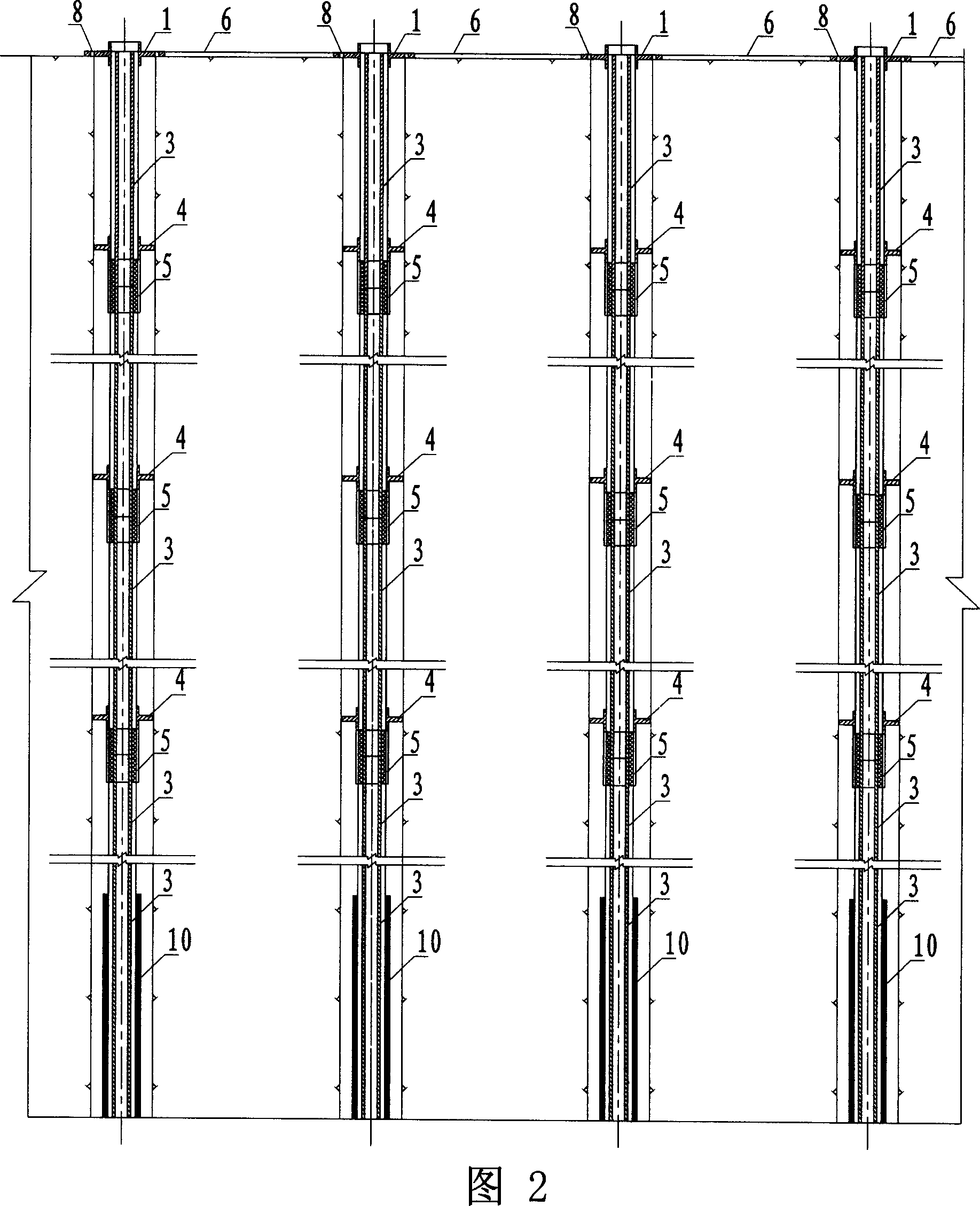

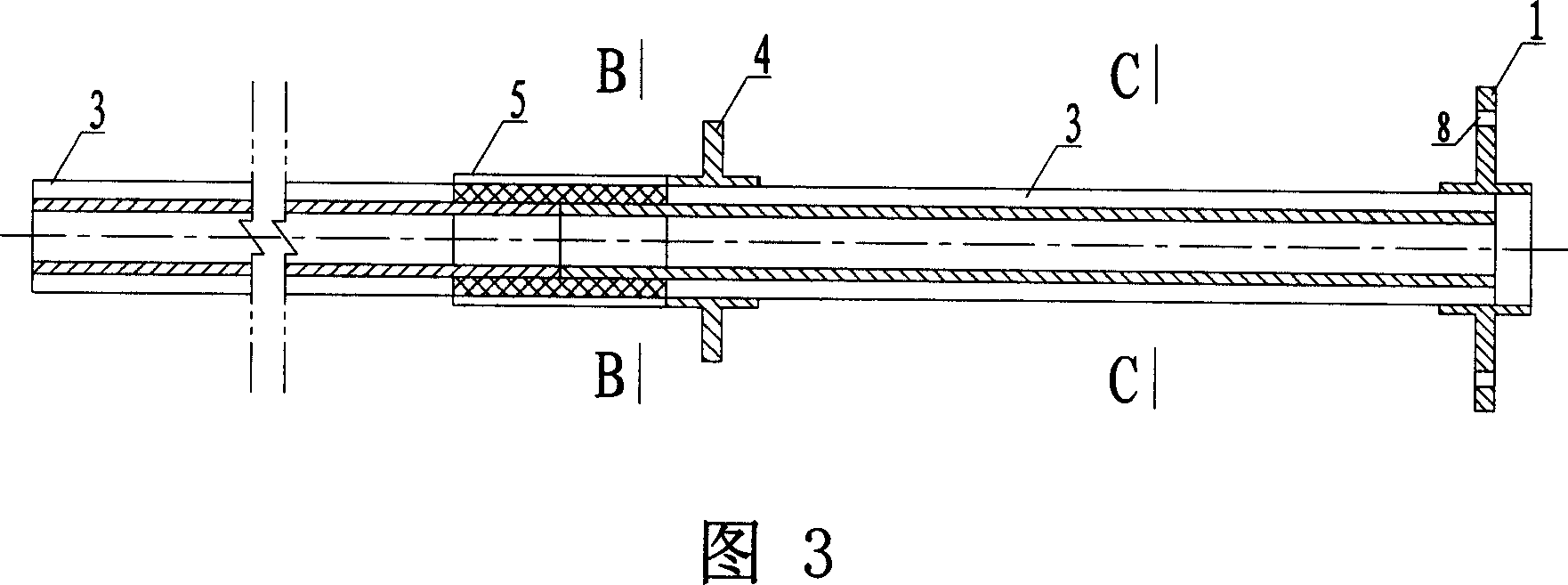

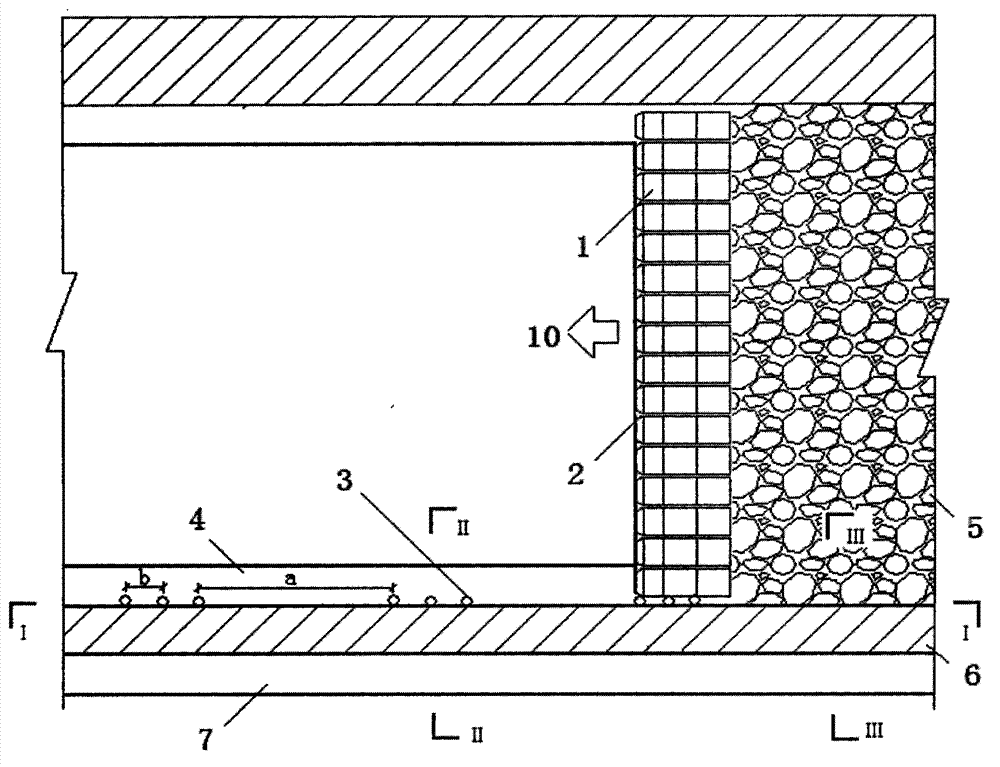

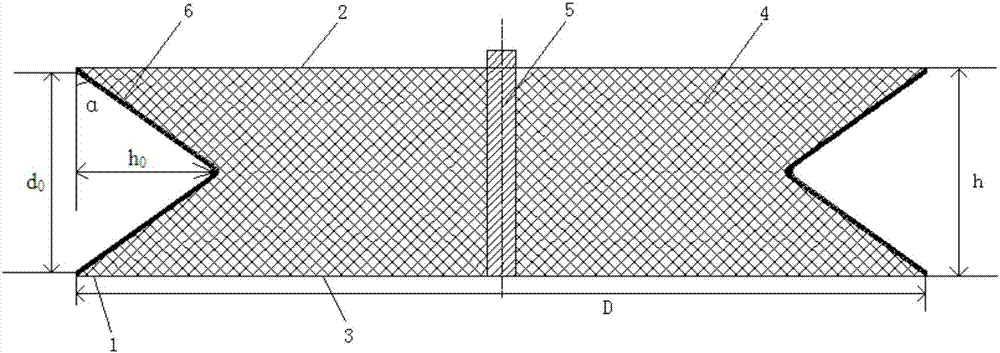

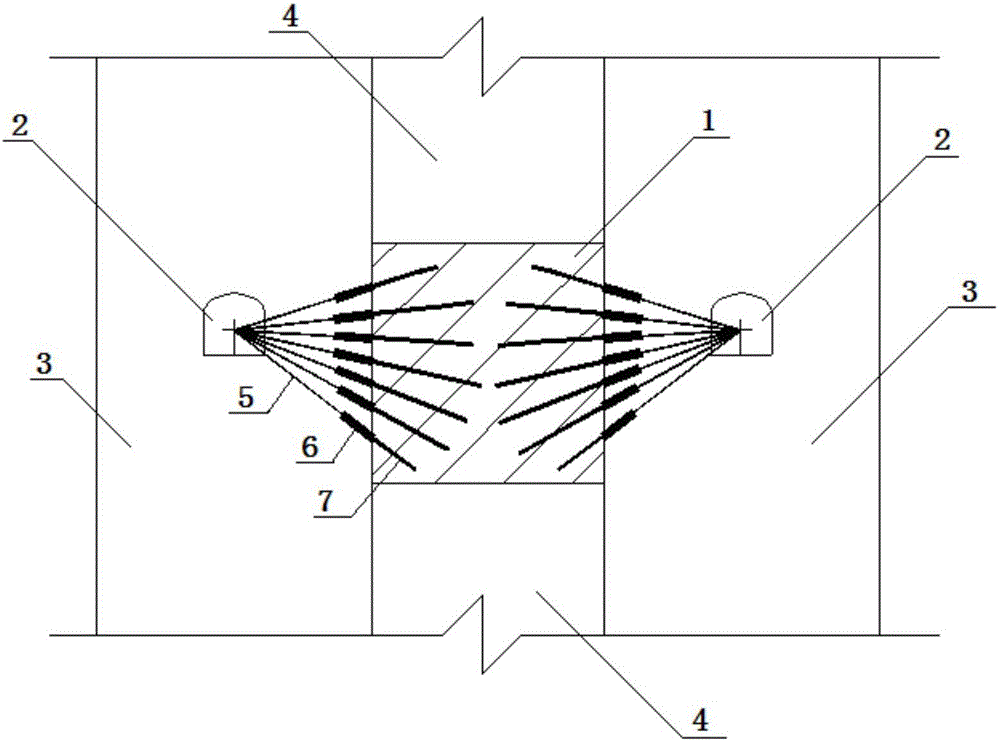

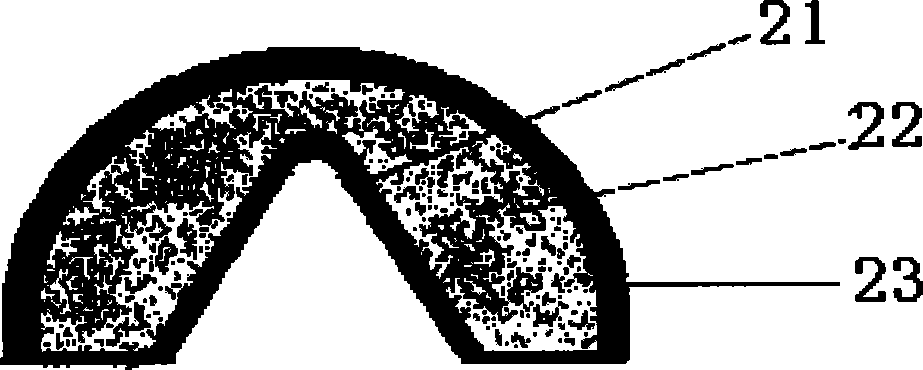

Method of energy cumulative presplitting and smoothsurface blasting and special device therof

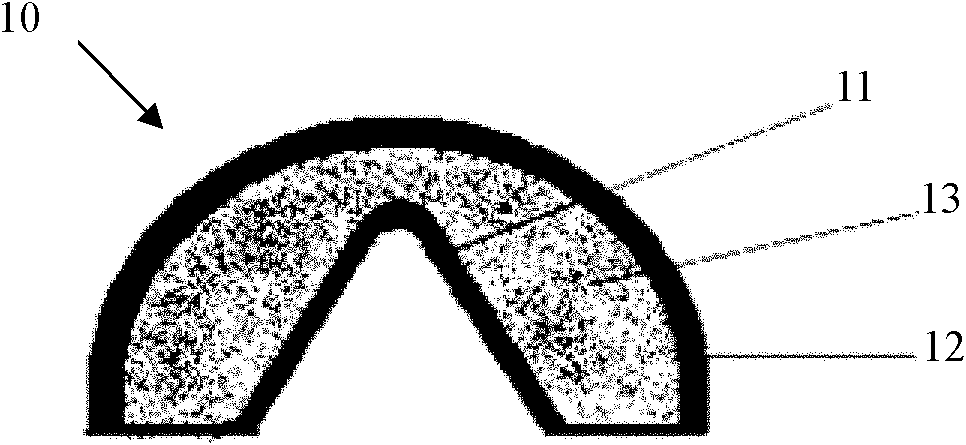

ActiveCN101033932AIncrease profitEnhance blasting forceBlasting cartridgesBlastingBinding energyDetonator

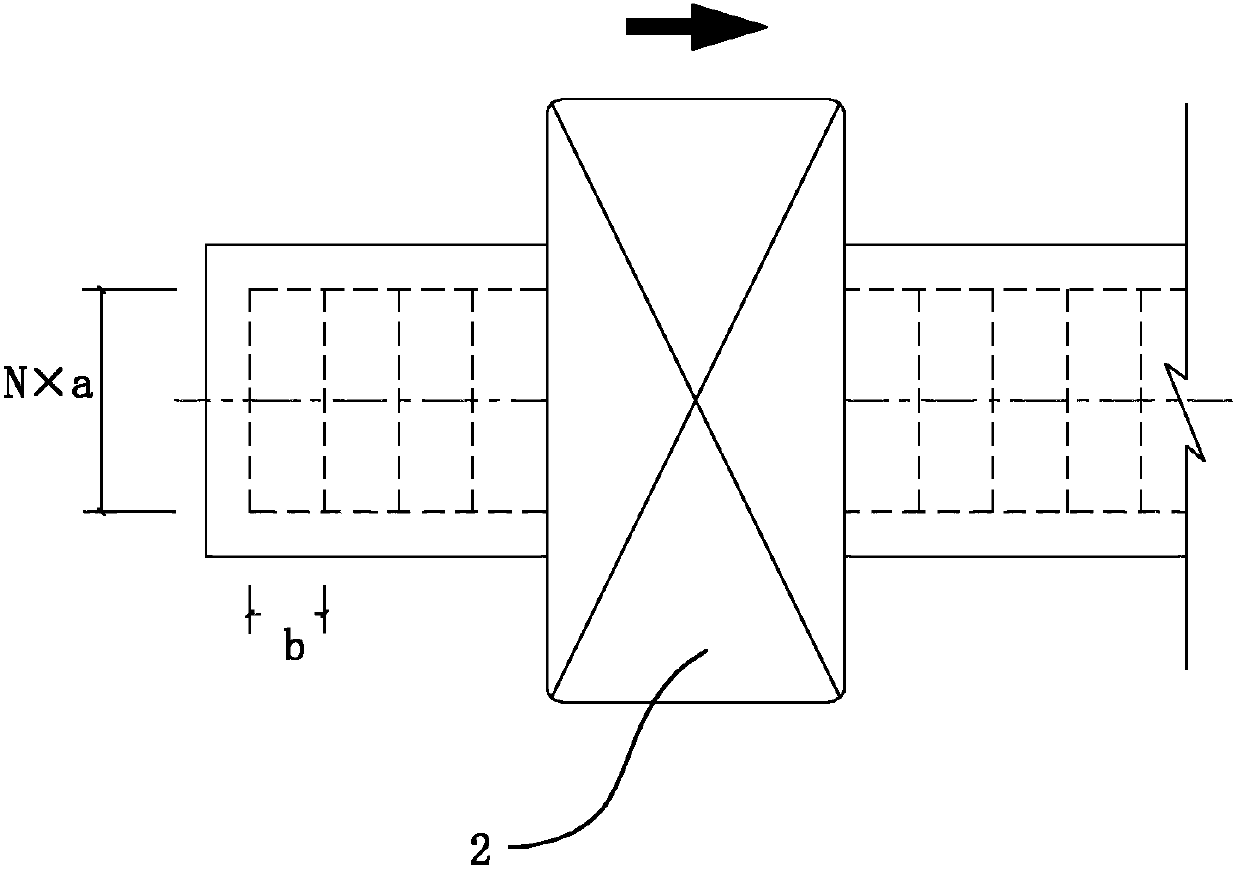

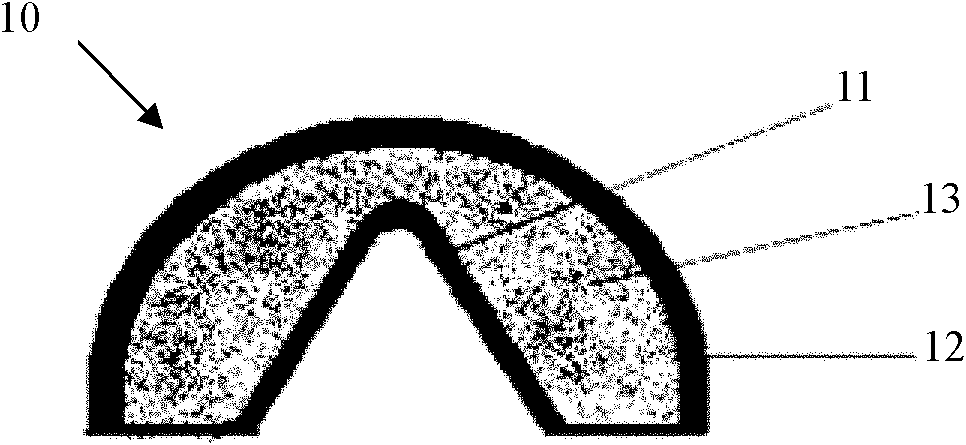

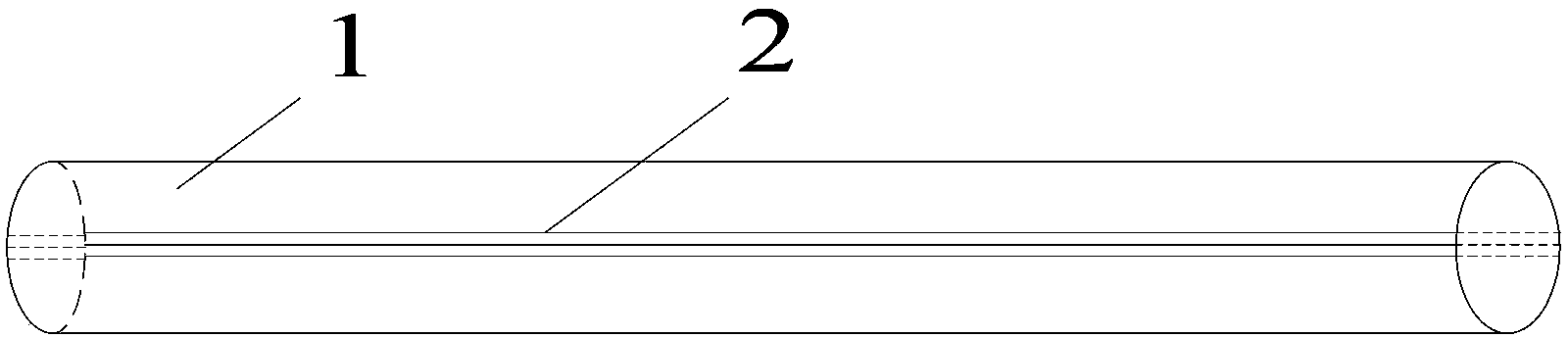

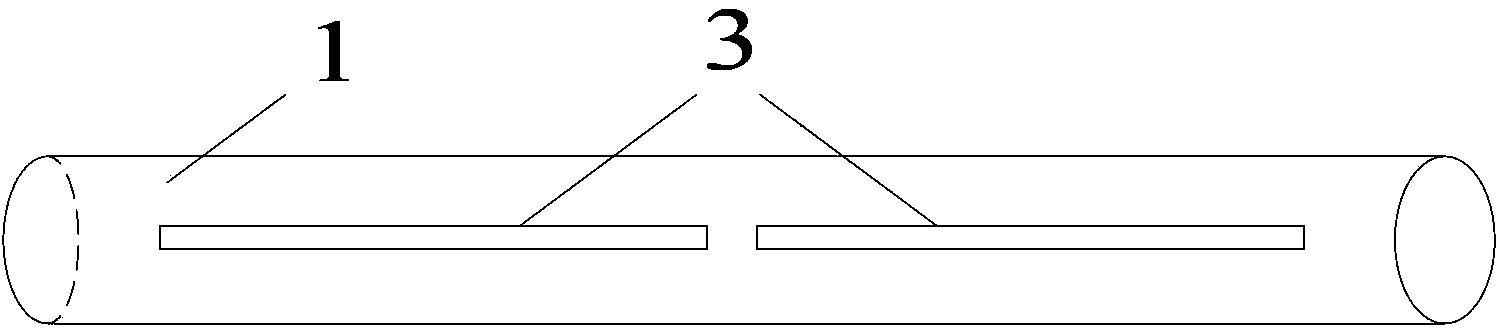

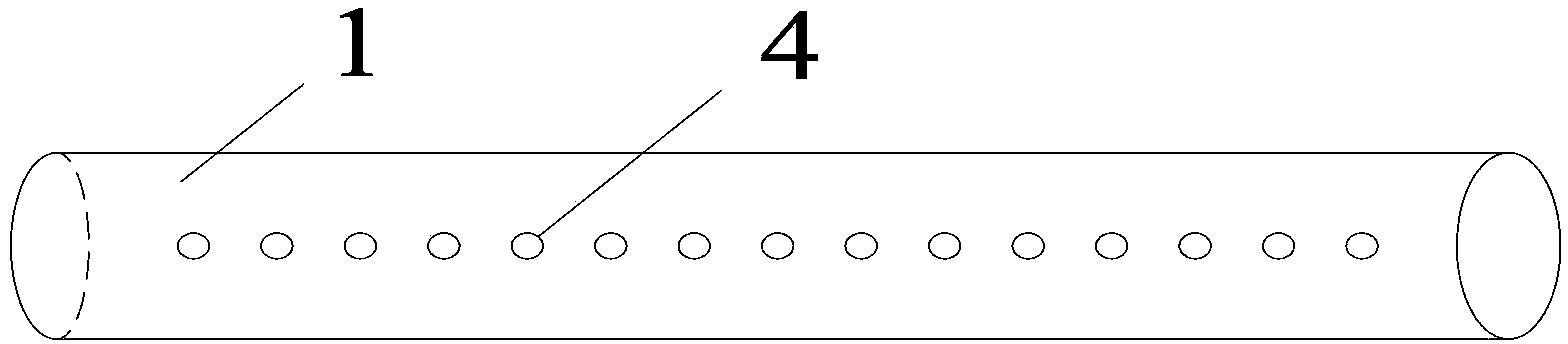

It is a special-purpose device used for two-directional energy-focusing and smooth blasting, post standard knot of multisection energy-gathering pipe which is in the double ''V'' shaped energy-accumulating groove which is set on the pipewall full of detonator, each post standard knot is linked with connection casing on which there is energy-accumulating groove, centering ring in the hole is noosed on the standard joint of the binding energy tube so that the center lines of the upper and the lower energy-gathering groove like V shape are in the same surface in the blasthole. Orifice centering rings of the two V- shaped central whose orientation is the same with V- shaped energy-gathering groove are set on the noose annulus wall at the ground end of energy -gathering pipe at orifice of blasthole, which makes the center line of each energy-gathering groove like a V shape forms a surface of centering and coinciding with blasting surface in each blasthole and among. After detonating explosive, make shaped charge jet spark along initial small crack that forms while the crack begins to form, then forms presplitting or smooth blasting surface, and finish energy-gathering presplitting and smooth blasting. The invention can enhance utilization ratio of demolishing energy and debase quantity of drilled holes, the influence of destroying rock mass kept down is little and the blasting surface is more level.

Owner:SINOHYDRO BUREAU 8 CO LTD

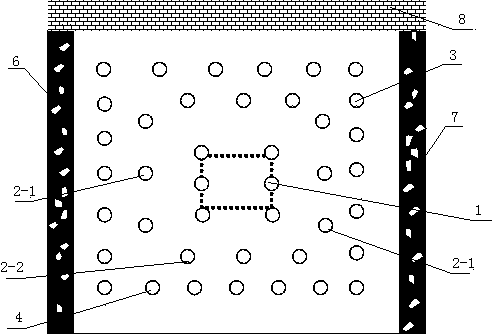

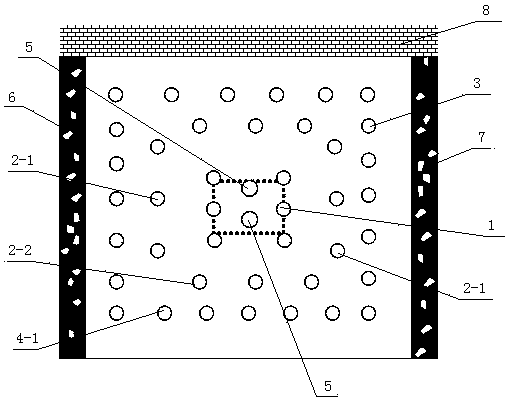

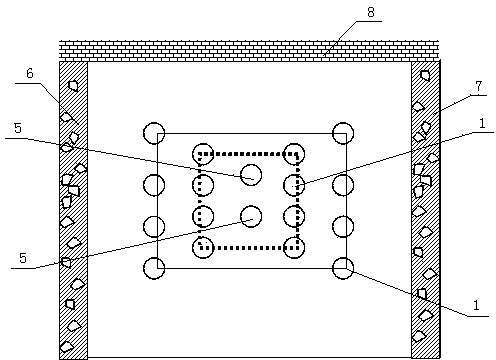

Gob-side entry driving surrounding rock control method using remaining small pillars

InactiveCN103244180AReduce overhang lengthBreach of integrityMining devicesBlastingEngineeringDeep hole

The invention discloses a gob-side entry driving surrounding rock control method using remaining small pillars. The method includes: distributing blast holes of different angles and depths in a working face conveying chute during extraction on an upper region working face, preforming a weak face in a certain area of a basic roof to damage completeness of a basic roof rock stratum by deep hole presplitting, and allowing a suspension arch of the basic roof to break at predetermined positions under the action of roof pressure after extraction of the working face. Therefore, the length of the hanging arch of the lateral basic roof of a gob is shortened, gob lateral abutment pressure is reduced, roadway pressure is relieved during gob-side entry driving in a lower region using remaining small pillars, and maintenance of a roadway is facilitated.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

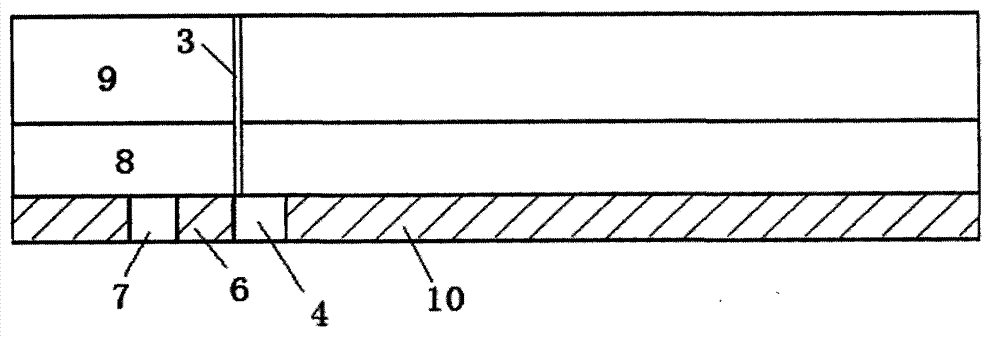

Deep-buried tunnel blasting excavation effect control method

The invention discloses a deep-buried tunnel blasting excavation effect control method. The method comprises the steps that 1, the main stress level and direction of the heading face of a tunnel to be excavated are determined before blasting excavation; 2, according to the drilling and blasting design scheme with single fire dynamite as a core control index, blast holes are formed and explosive payload is designed on the heading face of the tunnel to be excavated; 3, a circle of conical cutting holes pointing to a center hollow hole of an original cutting hole section is added into the formed original cutting hole section, and breaking holes in the outmost circle are used as buffer holes; 4, on the basis of the excavation blasting design scheme, blasting internetworking is carried out on the blast holes except for the conical cutting holes; 5, blasting is carried out by the adoption of a micro-differential blasting method. The deep-buried tunnel blasting excavation effect control method can control excavation disturbance evoked by deep rock strain energy transient release and blasting loads at the same time so as to achieve active control over the deep rock damage and rock blast, and can be widely applied for control over blasting excavation and deep blasting mining disturbance of deep-buried underground engineering in the hydraulic and hydroelectric engineering field, the traffic field, the mine field and the like.

Owner:WUHAN UNIV

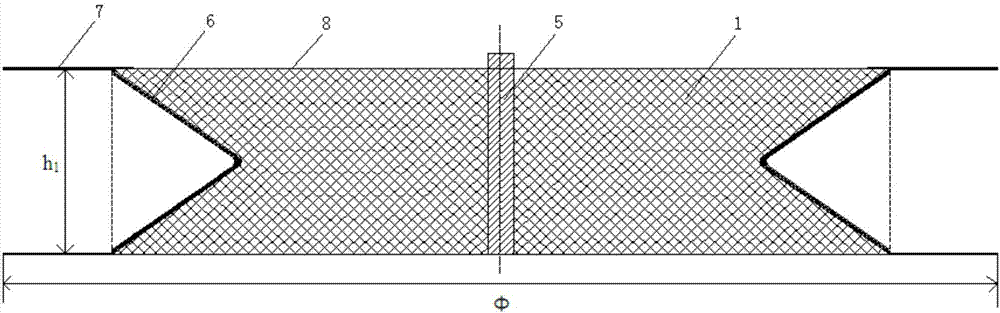

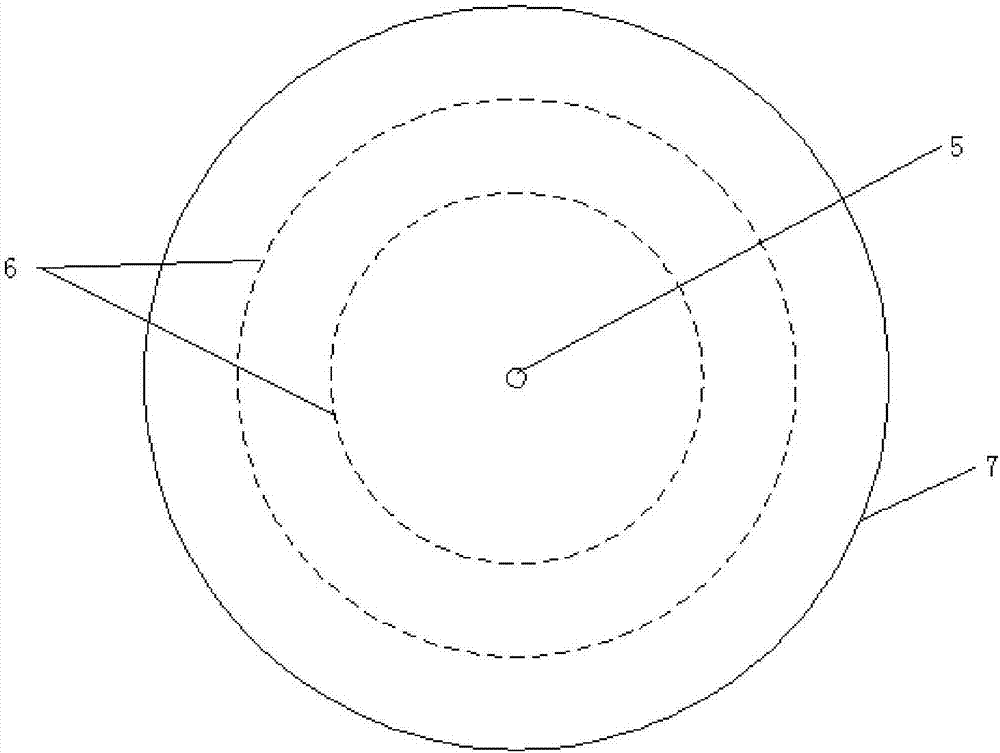

Circumferential planar jet energy-gathering cutter and application method thereof

The present invention is a circular planar jet energy-concentrating cutter and its use method. The cutter includes a ring body, the upper end and the lower end of the ring body are respectively provided with an upper end cover and a lower end cover, and a cavity is formed between the upper end cover, the lower end cover and the ring body. The cavity is filled with explosives, the upper end cover and the lower end cover are inserted with a detonator, the outer wall of the ring is provided with a V-shaped groove along the horizontal direction, and the V-shaped opening of the V-shaped groove faces the outside of the ring body. In this design, the numerical model and field experiment research and demonstration of the design are carried out in combination with the blasting fracture mechanism of rocks and the mechanical basis of crack expansion, as well as the principle of energy-concentrating blasting. The results show that the annular plane jet energy-concentrating cutter can not only effectively solve the problem of large block rate and root foundation in deep hole blasting in open steps, but also reduce the amount of explosives, fully improve the energy utilization rate of explosives, reduce production costs, and increase productivity. Moreover, the design is simple to operate and easy to use, and can be flexibly stacked and used according to the hardness and strength of different rocks.

Owner:LIAONING TECHNICAL UNIVERSITY

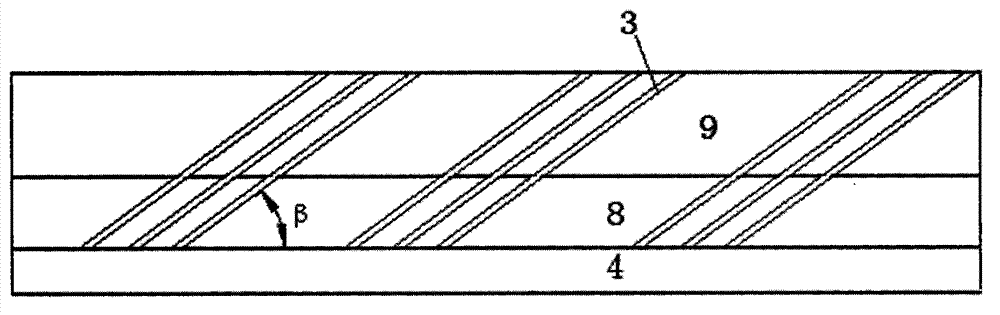

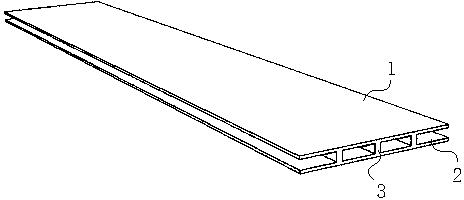

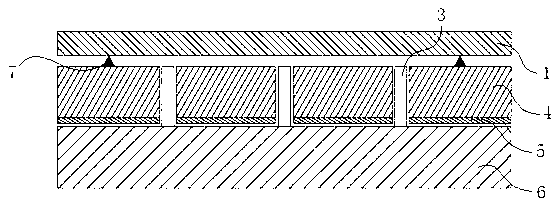

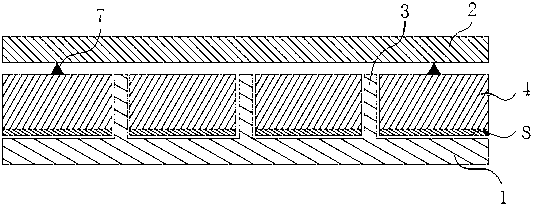

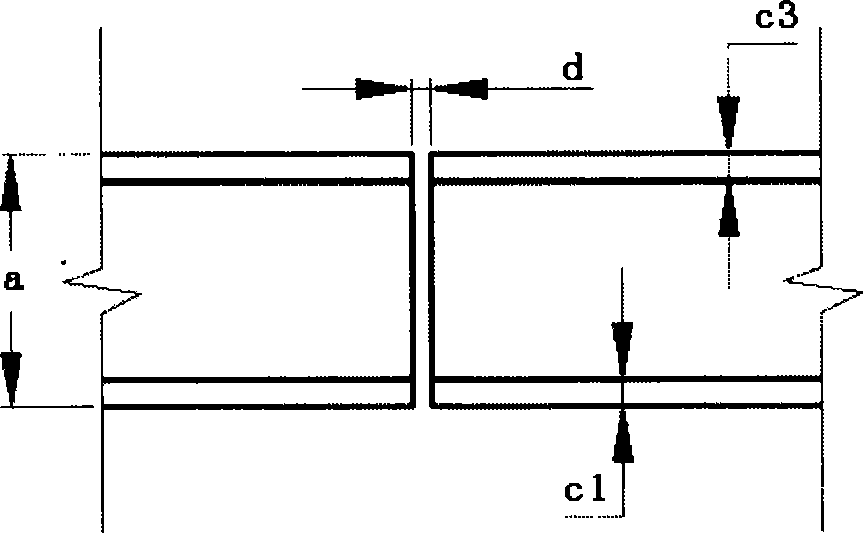

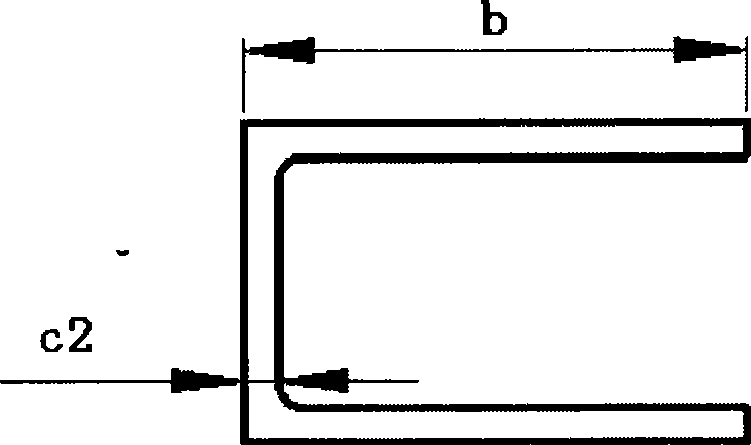

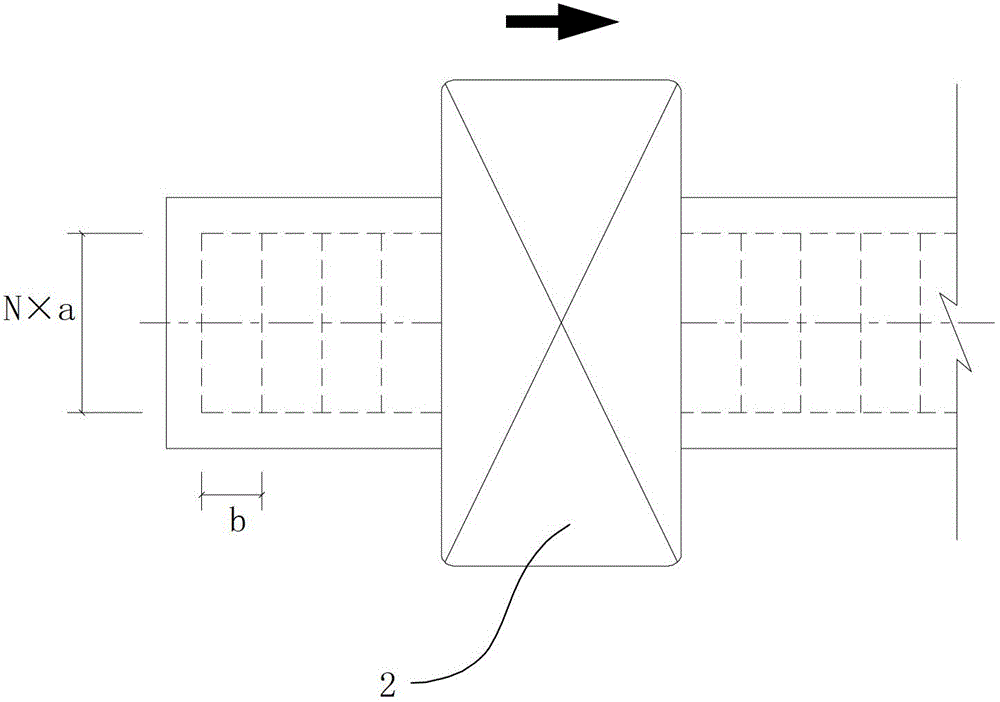

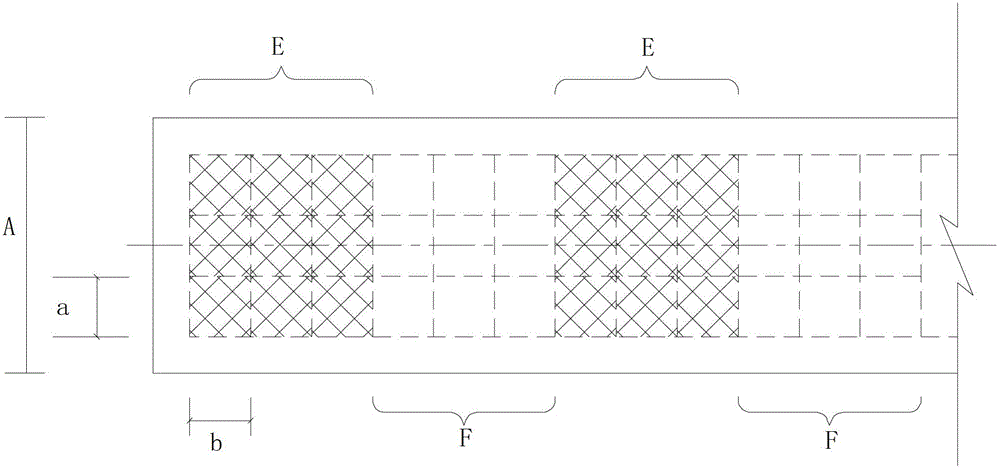

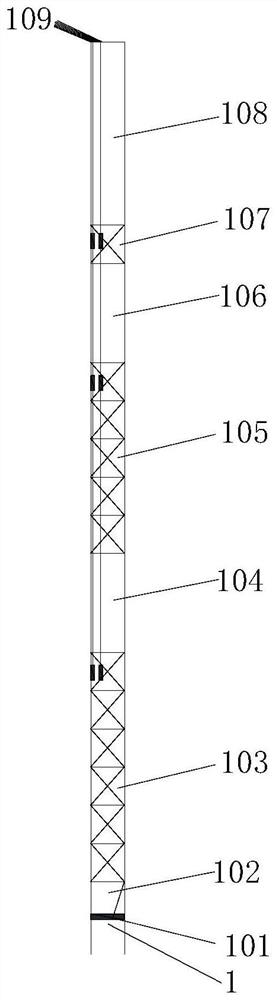

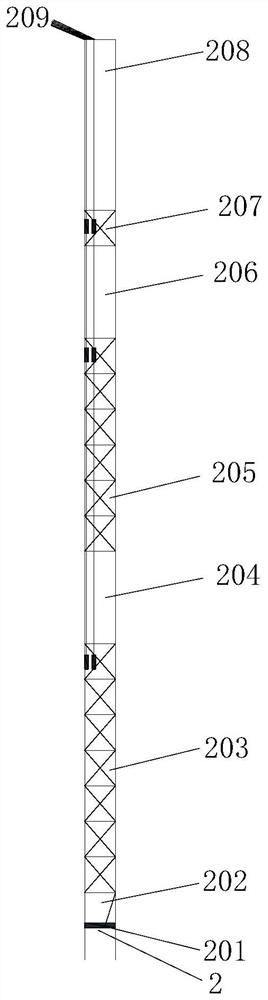

Explosive welding method of arranging multiple reinforcing ribs between large-area double-layer steel plates

InactiveCN103071908AReduce the amount of explosivesImprove economyNon-electric welding apparatusDetonationSheet steel

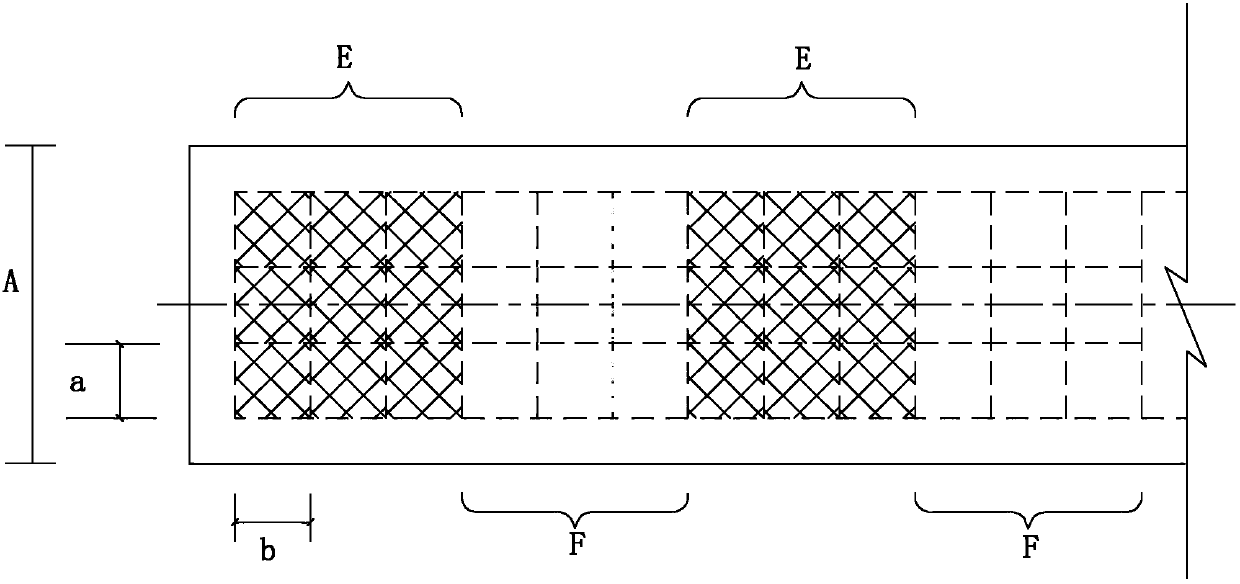

The invention discloses an explosive welding method of arranging multiple reinforcing ribs between large-area double-layer steel plates. The explosive welding method comprises the following steps of first-stage explosive welding: respectively fixing a die plate I, a die plate II and the reinforcing ribs on a base plate in a spot welding way, putting gap posts on the die plate I, putting an upper panel on the gap posts, arranging explosive on the upper surface of the upper panel, and carrying out the explosive welding; and second-stage explosive welding: overturning welded object obtained in the first stage, taking away the die plate I and the die plate II, filling a die plate III, covering the die plate I on the die plate III, putting the gap posts on the die plate I, putting a lower panel on the gap posts, arranging explosive on the upper surface of the lower panel, and carrying out the explosive welding. According to the explosive welding method disclosed by the invention, compared with the explosive loading amount adopted in an engineering practice in the past, the explosive loading amount is saved by about 18%; a boundary effect subduction method, which refers to a method of additionally arranging lengthened plates at two ends of a cover plate along a detonation spread direction, is adopted; and the explosive using amount is reduced, the welding rate is up to 100%, the strength of a combination interface exceeds that of base material, and the explosive method has the advantage of manufacturing large-area reinforcing rib double-layer steel structural components in good quality and low price.

Owner:中国人民解放军理工大学野战工程学院 +2

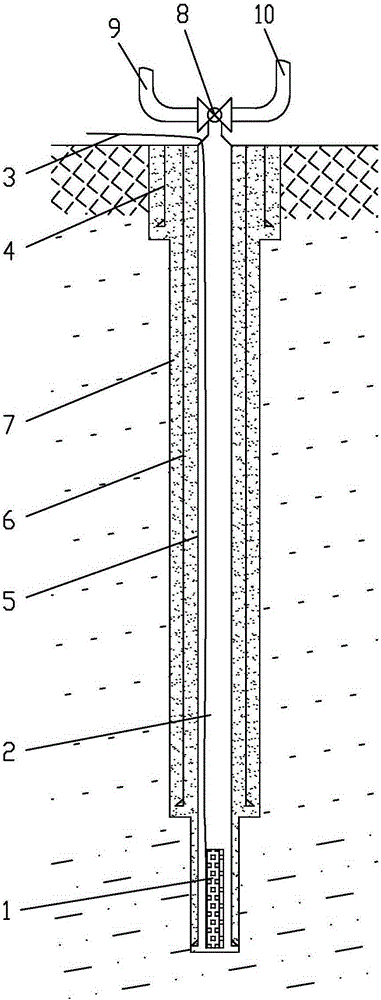

Reservoir permeability-increasing method of water pressure blasting crack initiation and CO2 carried with proppant fracturing

The invention discloses a reservoir permeability-increasing method of water pressure blasting crack initiation and CO2 carried with proppant fracturing. The method comprises the steps of charging, water injection and hole sealing, water pressure blasting and supercritical or liquid-state CO2 fracturing, wherein well drilling and well cementation are conducted before charging, and well drilling is formed by means of a production casing; when necessary, at least one intermediate casing is arranged between a surface casing and a production casing; before fracturing is conducted, by means of a sand mixing pump, fully mixing is conducted on ceramsite proppant and supercritical or liquid-state CO2 according to the set ratio, and necessary additives are added to form spare fracturing fluid; during the fracturing, real-time monitoring on fracture extending is conducted by means of a microseismic monitor to monitor the range of influence of cracks accurately. The reservoir permeability-increasing method of water pressure blasting crack initiation and CO2 carried with proppant fracturing has the advantages that advantages that two types of permeability-increasing methods are fully utilized, permeability characteristics of a low-permeability oil-gas reservoir are effectively improved, oil and gas production is greatly improved, the service life of an oil and gas well is prolonged, and safety, effectiveness and green and environmental protection are achieved.

Owner:CHONGQING UNIV

Explosion stoping method for horizontal ore pillar of sublevel caving mining method

ActiveCN106014414AProtect yourself from harmLittle personal injuryUnderground miningBlastingMineralogy

The invention discloses an explosion stoping method for a horizontal ore pillar of a sublevel caving mining method. The explosion stoping method comprises the following steps: (1) drilling a fan-shaped medium-length hole; (2) filling stripy emulsified explosive; (3) filling sand bags; (4) exploding a horizontal ore pillar, and the like. The explosion stoping method for the horizontal ore pillar of the sublevel caving mining method is small in danger, high in security and good in explosion effect, and the horizontal ore pillar is high in explosion stoping efficiency and relatively low in stoping cost.

Owner:FUJIAN HAIXIA KEHUA FUXING CONSTR ENG CO LTD

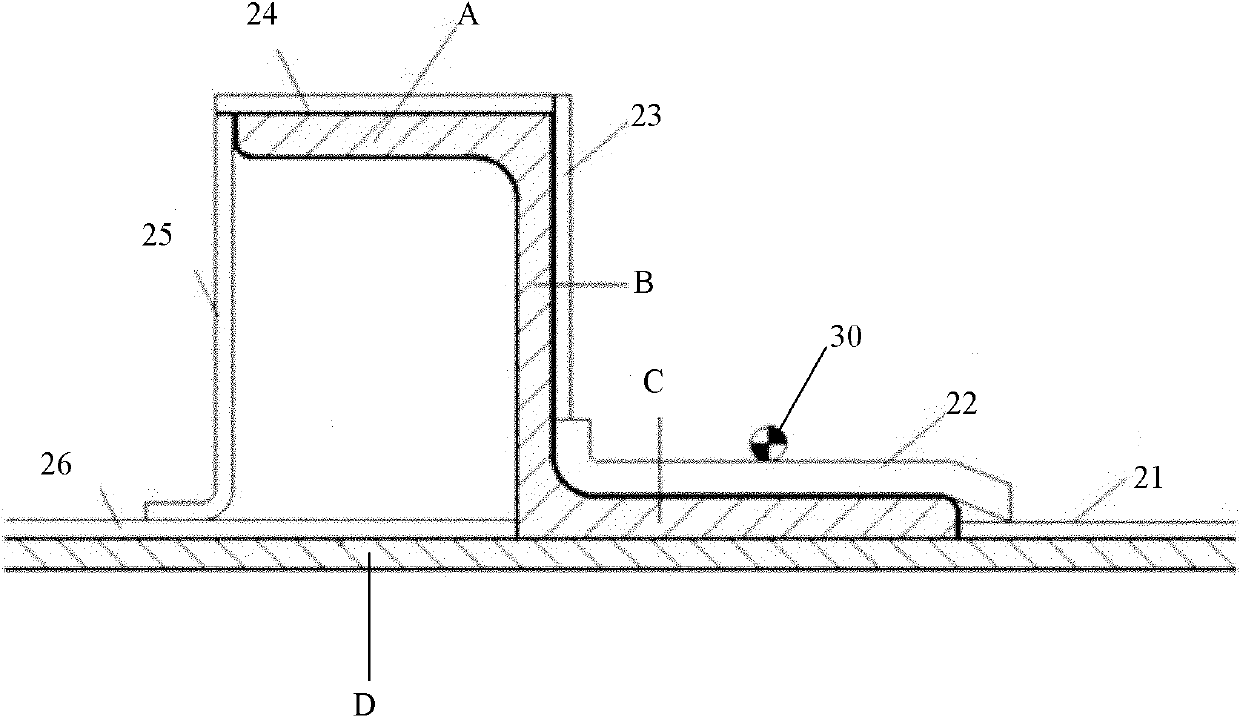

Cutting method for emergency opening lock catch of passenger plane test flight service cabin door

InactiveCN101487681AReduce the amount of explosivesReduce dosageEmergency apparatusBlastingPrimacordEngineering

The invention discloses a cutting method for a lock catch when a service door is emergently opened during test flight of passenger plane. The method includes the followings: (1) choice of cutting position: the cutting position is chosen to be at the inner side of the lock catch close to the edge of the service door; (2) determination of incision parameters: the incision is U-shaped, and the length and the width are respectively equal to the width and depth of a U-shaped groove of the lock catch; (3) choice of cutter: a flexible cutter is used, and the cutting ability is 1.25-1.35 times of the maximum thickness among three sections of the lock catch; (4) installation of cutter: the cutter is configured to be U-shaped and tightly stuck with the surface of the inner side of the lock catch; (5) initiation of cutter: after an insensitive electric detonator receives signals of explosion initiation, a silver micro-primacord fuse is initiated, and the primacord fuse is connected with the cutter through an energy amplifier; the energy amplifier carries out initiation on the cutter and cuts off the lock catch. The cutting method of the lock catch in the invention is fast and high-efficient, thereby avoiding the defect of connection of a plurality of cutters and having the benefit for the safety of test flight staff.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

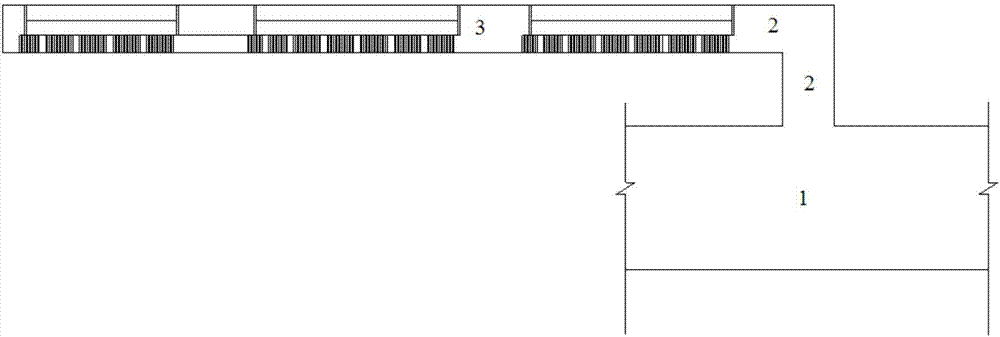

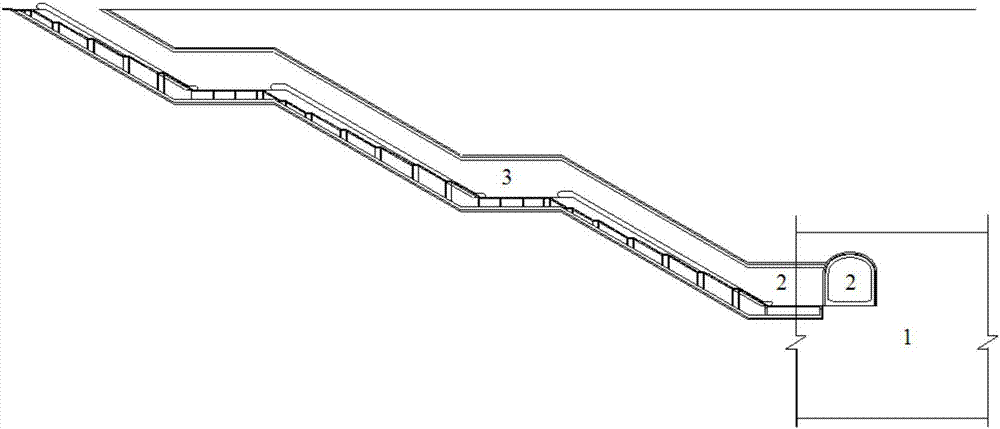

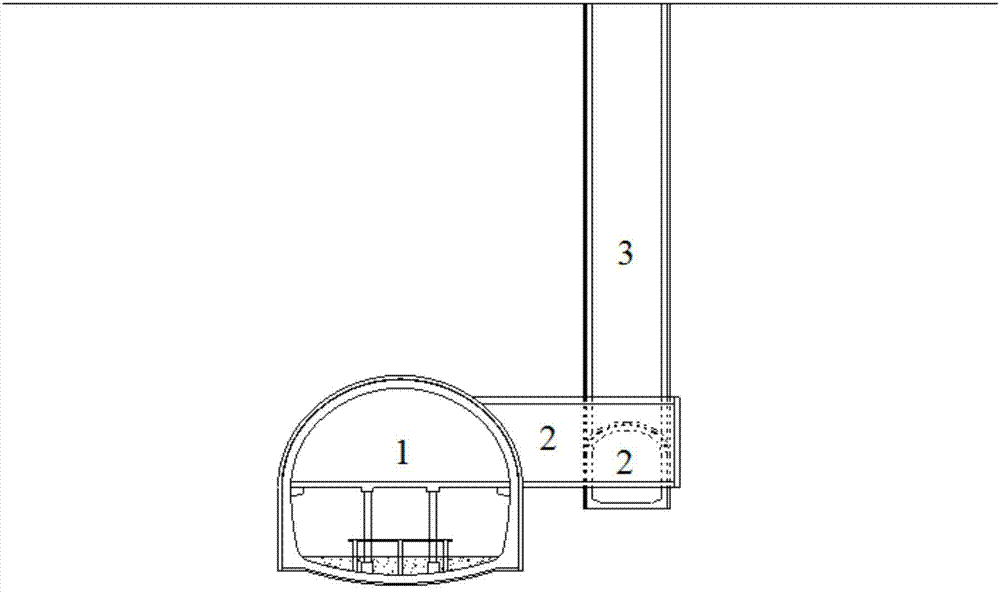

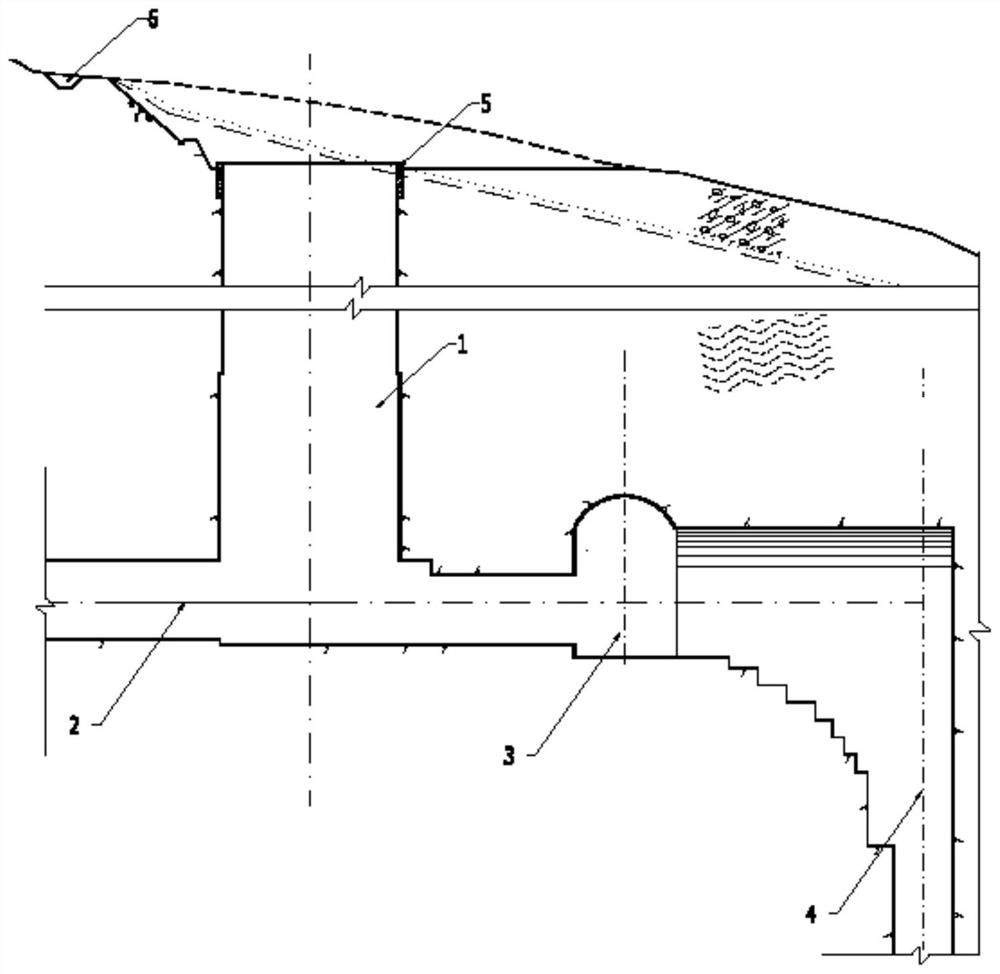

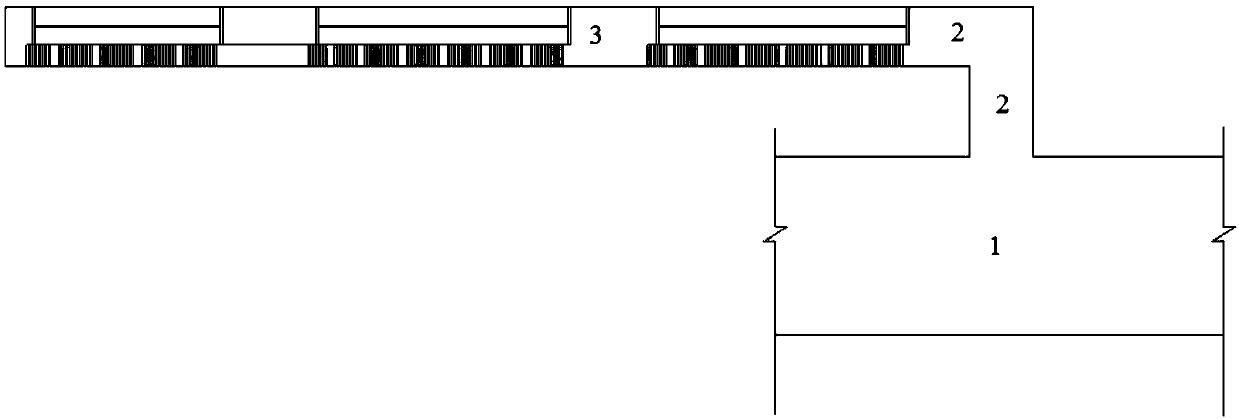

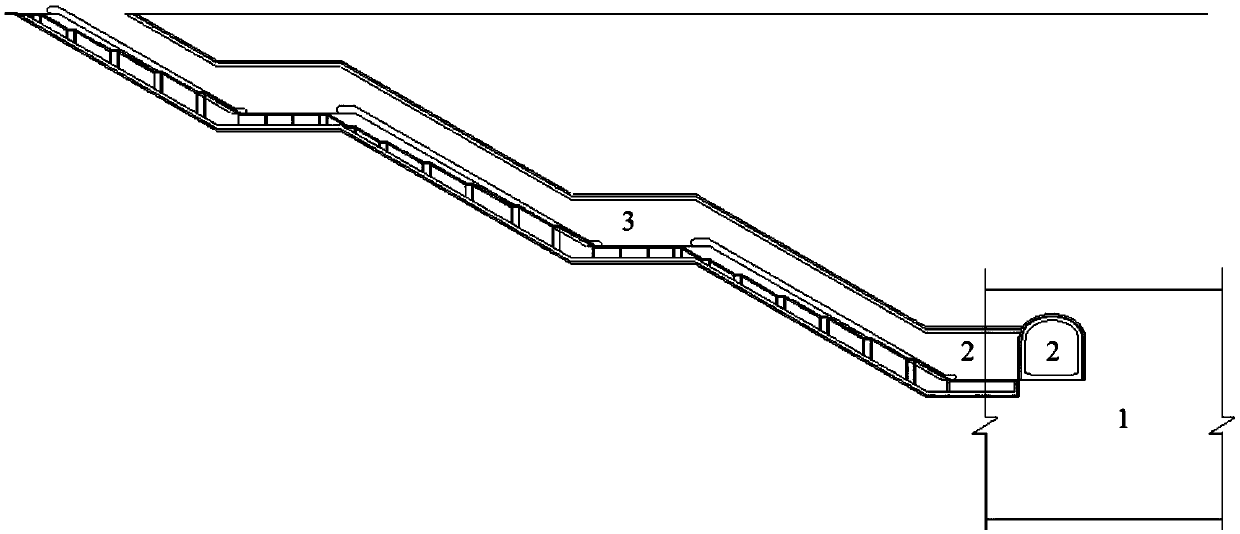

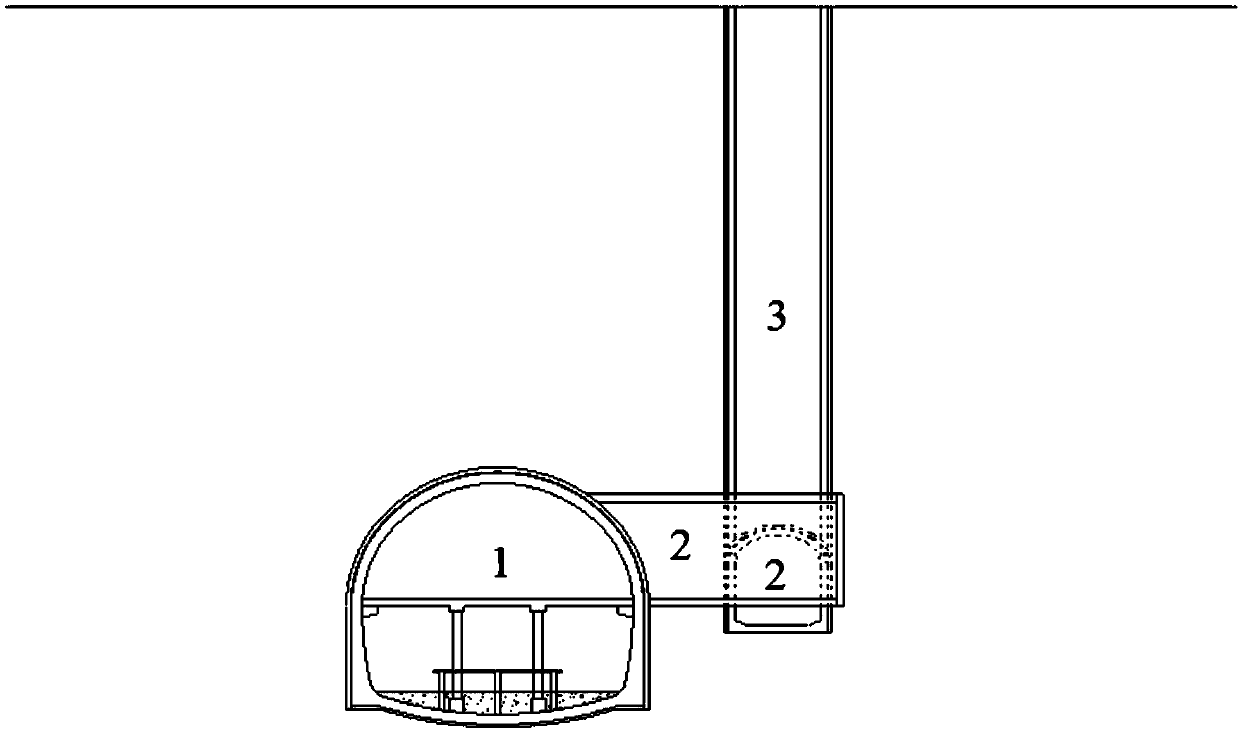

Rapid construction method for subsurface section of passageway of subsurface subway station in rock stratum

The invention discloses a rapid construction method for a subsurface section of a passageway of a subsurface subway station in a rock stratum. The rapid construction method comprises the following steps: taking a small-cross-section inclined pilot tunnel which is constructed in advance and connects an open excavation section to a station as a slag discharge channel; constructing a subsurface section from the open excavation section to the subway station; conveying residue soil generated in an operation process of the subsurface section into the slag discharge channel by using an excavator or a forklift; conveying the residue soil to a tunnel position of a connection section between the station and the passageway by great gradient of the slag discharge channel; and conveying the residue soil to the ground via a station construction channel by a slag car. The problems are solved that in the traditional method for constructing the subsurface section of the passageway of the subsurface subway station in the rock stratum, risks are high and the efficiency is low in a process of excavating from the open excavation section to the station and discharging slag, and the profile cannot be controlled easily when a tunnel is excavated from the station to the open excavation section; construction safety, construction progress and construction quality are guaranteed.

Owner:CRRC CONSTR ENG CO LTD

Construction method of compact underwater rubble bed

The invention discloses a construction method of a compact underwater rubble bed, which comprises the steps of: 1) accepting a base groove; 2) riprapping a bed; 3) measuring cross section of the bed before blasting; 4) positioning by a positioning boat; 5) artificially adding and arranging explosive; 6) blasting in various sections and various regions; 7) measuring the cross section of the bed after blasting; and 8) detecting and accepting. The construction method of the compact underwater rubble bed is low in requirement on locating precision; the construction method just needs to distribute explosive packages in the region rather than precisely arrange the explosive packages on a fixed point, and is unnecessary to pre-level, therefore, the construction is simple; the explosive demand is lower and the explosive amount is reduced by 20-40%, to reduce harmful influence of the blasting on the surrounding environment; fewer processes are required, the explosive package is simple to arrange, the economic performance is good and the cost is lower; since the explosive package is arranged in a manner to contacting to the earth, the stability of the explosion propagation network is good and the anti-explosion rate is low; and the construction quality is good, and the rubble body is compact and reliable.

Owner:NINGBO KENING EXPLOSION TECH PROJECT

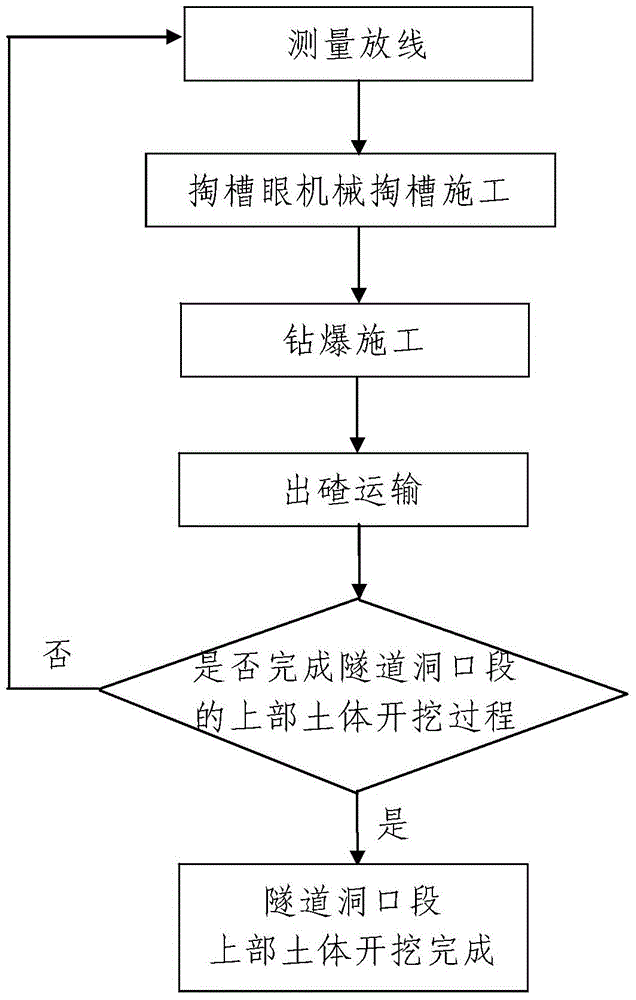

Shallow-buried large-span rock tunnel portal section weak blasting excavation construction method

The invention discloses a shallow-buried large-span rock tunnel portal section weak blasting excavation construction method. A benching tunneling method is adopted for excavating a tunnel portal section of a constructed rock tunnel from the back side to the front side; and during the excavation on the tunnel portal section, the processes comprises 1, upper step excavation and upper part early-stage support construction (during the excavation of an upper part soil body of the tunnel portal section, excavation is performed in a plurality of excavation sections from the back side to the front side, and each excavation section adopts the same excavation method and adopts a mechanical channeling and weak blasting combining method for excavation; during the excavation on any one excavation section, the processes include surveying and setting out, channeling construction by a channeling drilling machine, drilling blasting construction and slag discharge transportation); and 2, lower step excavating and lower part early-stage support construction. The method provided by the invention has the advantages that the steps are simple; the design is reasonable; the investment cost is low; the realization is convenient; the use effect is good; the excavation process of the tunnel port section can be simply, conveniently and fast completed; and the harmful effect of the blasting can be effectively reduced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Rock drilling and explosion method for mining

InactiveCN103742136AGrooves are deep and levelReduce the amount of explosivesSlitting machinesDrill bitPetrology

The invention discloses a rock drilling and exposition method for mining, and relates to a rock drilling and explosive falling method during the mining process. The method is characterized in that: a hollow hole is arranged in a cutting center during the cutting process, the hollow hole is created by a big drill bit, the hollow hole is not loaded with explosive; 6 to 8 small hollow holes are arranged around the hollow hole, each small hollow hole is filled with explosive, after the explosion, a deep cutting is formed; two flank holes are not filled with explosive and are hollow holes too; the amount of the explosive in the auxiliary hole can bring down the rocks in the periphery, and after the explosion, the two side are neat and smooth. The method has the advantages that: cutting is deep and neat, the overall using amount of explosive is less, the falling ores are more, and the safety coefficient is higher.

Owner:JINCHUAN GROUP LIMITED

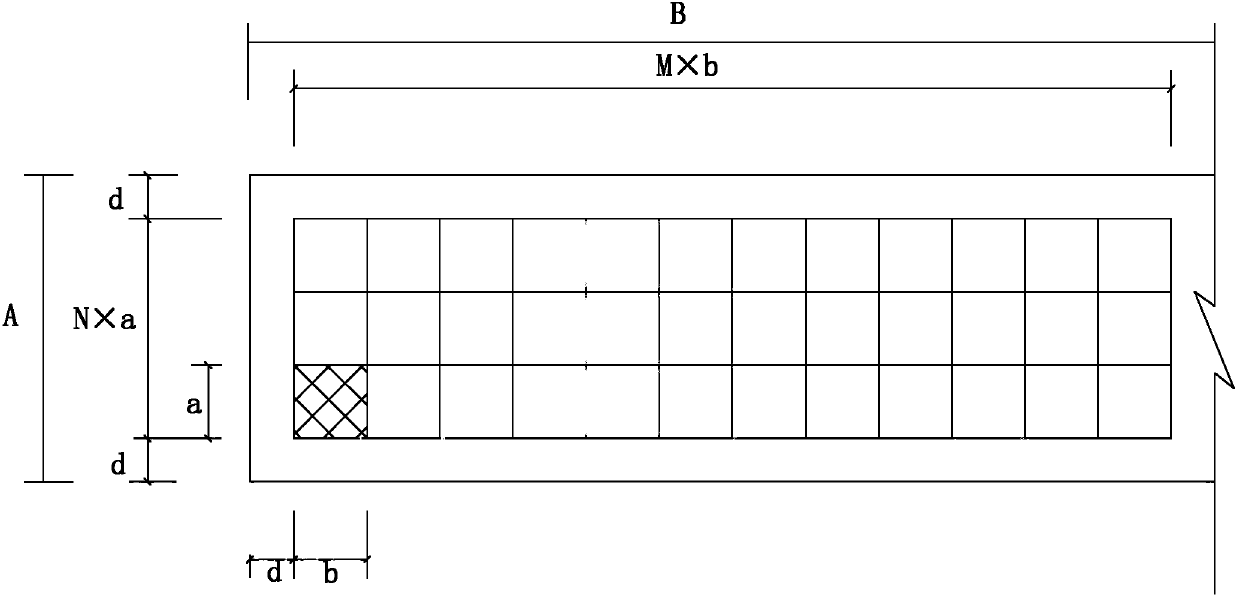

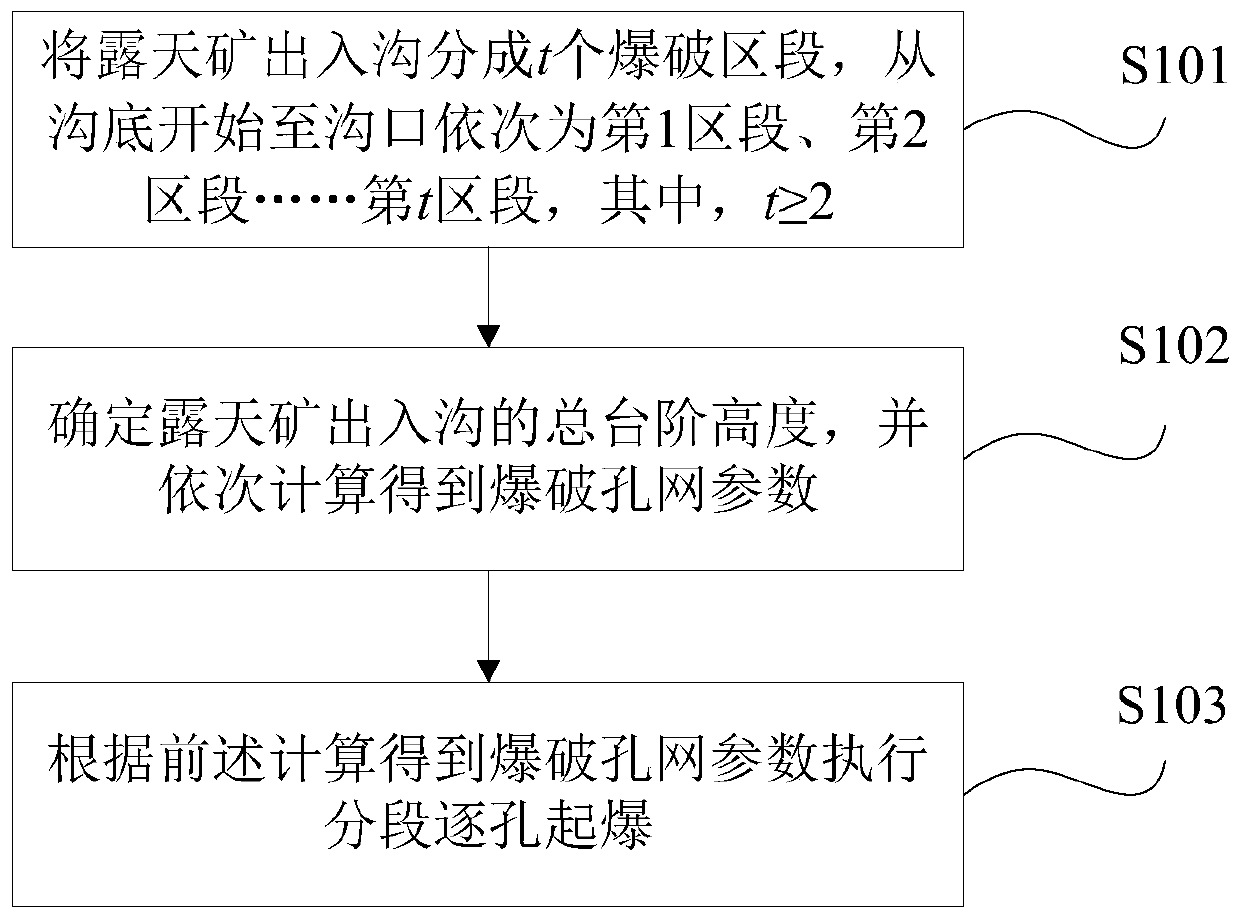

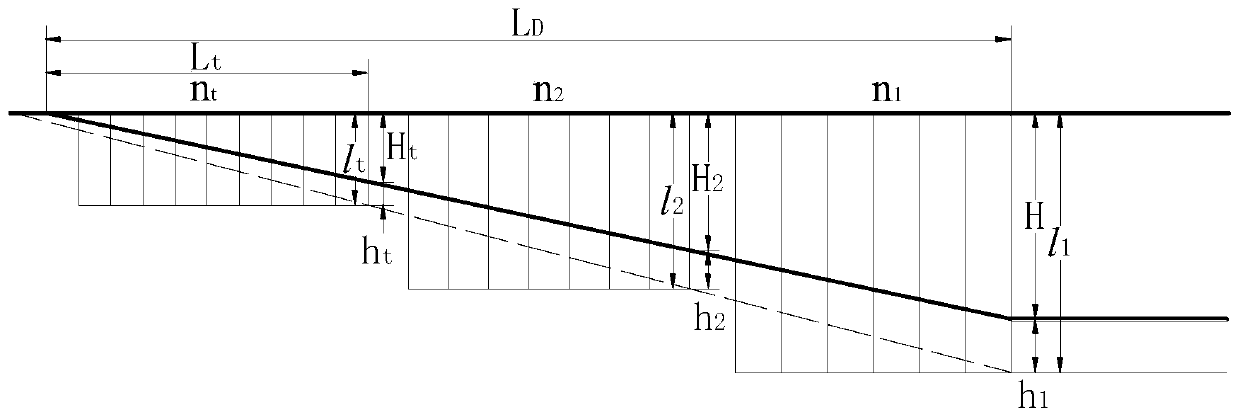

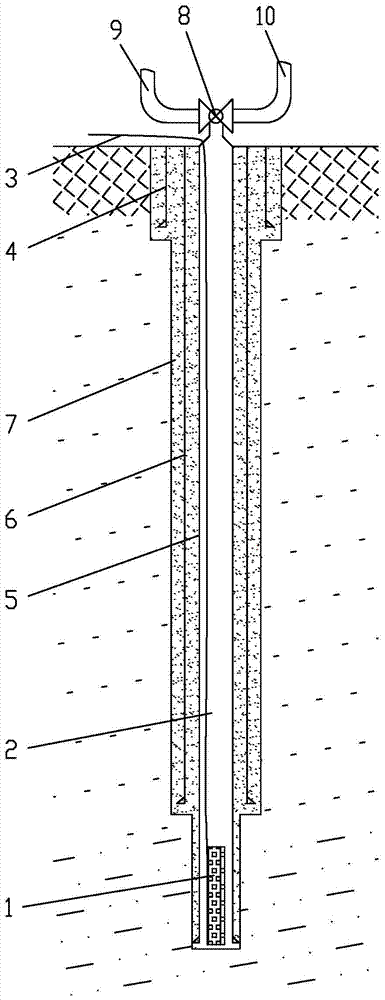

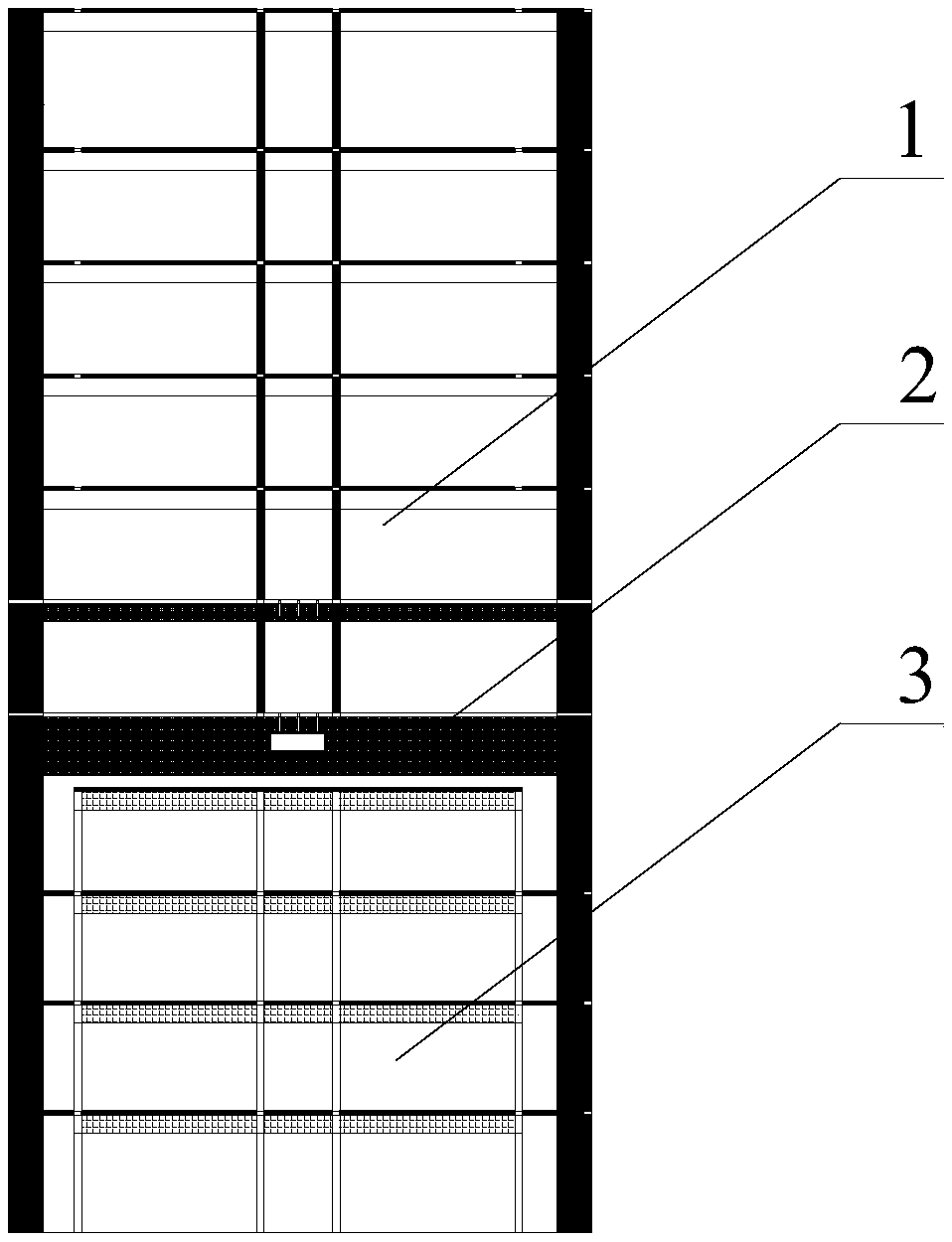

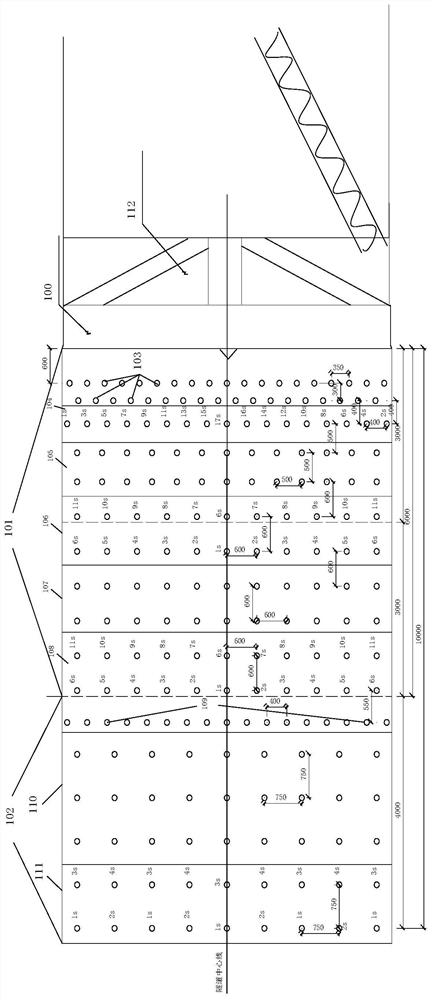

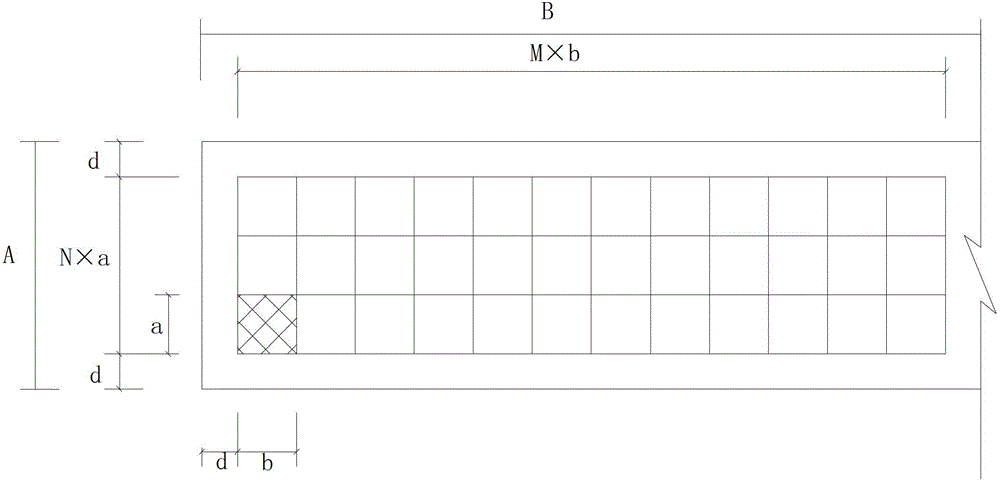

Open pit mine main access segment blasting hole net parameter determination method

InactiveCN110285731AQuality improvementImprove operational efficiencyBlastingDesign optimisation/simulationBlasting vibrationRoad surface

The invention discloses an open pit mine main access segment blasting hole net parameter determination method and belongs to the technical field of blasting engineering. The open pit mine main access segment blasting hole net parameter determination method comprises of dividing an open pit mine main access into t (t is greater than or equal to 2) blasting segments including the first segment, the second segment, ...... and the tth segment; determining the total step height of the open pit mine main access and conducting calculation in sequence to obtain blasting hole net parameters; and implementing segment blasting hole by hole according to the calculated blasting hole net parameters. By acquiring the known easily obtained parameters and through the formula and principle, other hole net parameters of segment blasting are obtained scientifically and accurately; and the construction time and cost can be saved. Moreover, through the hole-by-hole blasting technology, the single-segment blasting explosive quantity can be reduced, the influence of the blasting vibration strength on the slope stability is reduced, the road surface quality of the main access is improved, and the running efficiency of an automobile is improved.

Owner:湖北三鑫金铜股份有限公司

A hydraulic blasting crack-co 2 Reservoir permeability enhancement method for fracturing with proppant

The invention discloses a reservoir permeability-increasing method of water pressure blasting crack initiation and CO2 carried with proppant fracturing. The method comprises the steps of charging, water injection and hole sealing, water pressure blasting and supercritical or liquid-state CO2 fracturing, wherein well drilling and well cementation are conducted before charging, and well drilling is formed by means of a production casing; when necessary, at least one intermediate casing is arranged between a surface casing and a production casing; before fracturing is conducted, by means of a sand mixing pump, fully mixing is conducted on ceramsite proppant and supercritical or liquid-state CO2 according to the set ratio, and necessary additives are added to form spare fracturing fluid; during the fracturing, real-time monitoring on fracture extending is conducted by means of a microseismic monitor to monitor the range of influence of cracks accurately. The reservoir permeability-increasing method of water pressure blasting crack initiation and CO2 carried with proppant fracturing has the advantages that advantages that two types of permeability-increasing methods are fully utilized, permeability characteristics of a low-permeability oil-gas reservoir are effectively improved, oil and gas production is greatly improved, the service life of an oil and gas well is prolonged, and safety, effectiveness and green and environmental protection are achieved.

Owner:CHONGQING UNIV

Blasting demolition method of prestressed beams of complex building structure

InactiveCN108613602AReduce intensitySolve problems that are difficult to disassembleBlastingPre stressEngineering

The invention relates to the technical field of building construction, and in particular to a blasting demolition method of prestressed beams of a complex building structure. The method comprises thefollowing steps that 1), the ultimate tensile strength of the prestressed beams is calculated, blast holes are drilled in the prestressed beams, and explosives capable of damaging the structural stability of the prestressed beams are buried into the blast holes; 2), blasting points are arranged on the portions, above the prestressed beams and below the prestressed beams, of a building structure; and 3), the blasting points on the building structure are sequentially detonated until the structure is all completely collapsed. The method has the characteristics of reasonable design, safety, reliability and simplicity and convenience in construction, and is suitable for demolition blasting of the prestressed beams of the various complex-structure buildings.

Owner:中铁四院集团工程建设有限责任公司

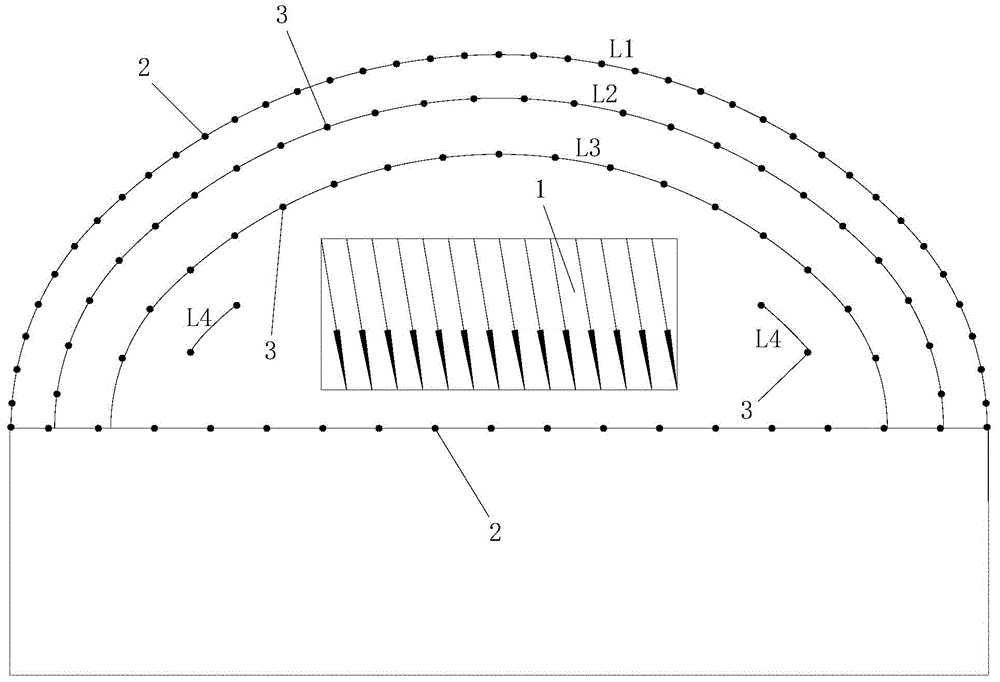

Smooth blasting method for tunneling

PendingCN114001605AReduce consumptionImprove the utilization rate of blast holesBlastingTunnelsStructural engineeringMechanical engineering

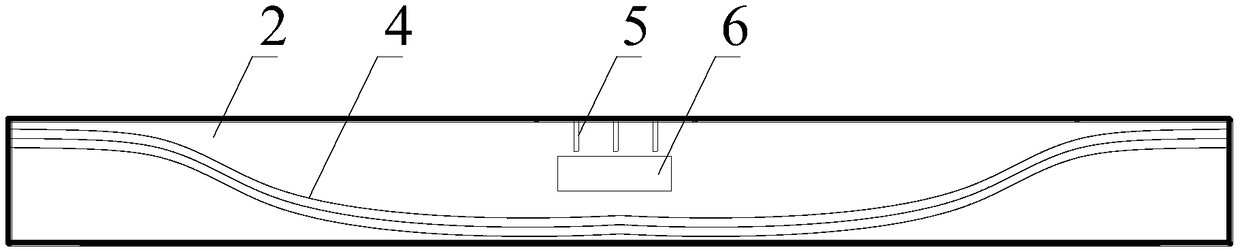

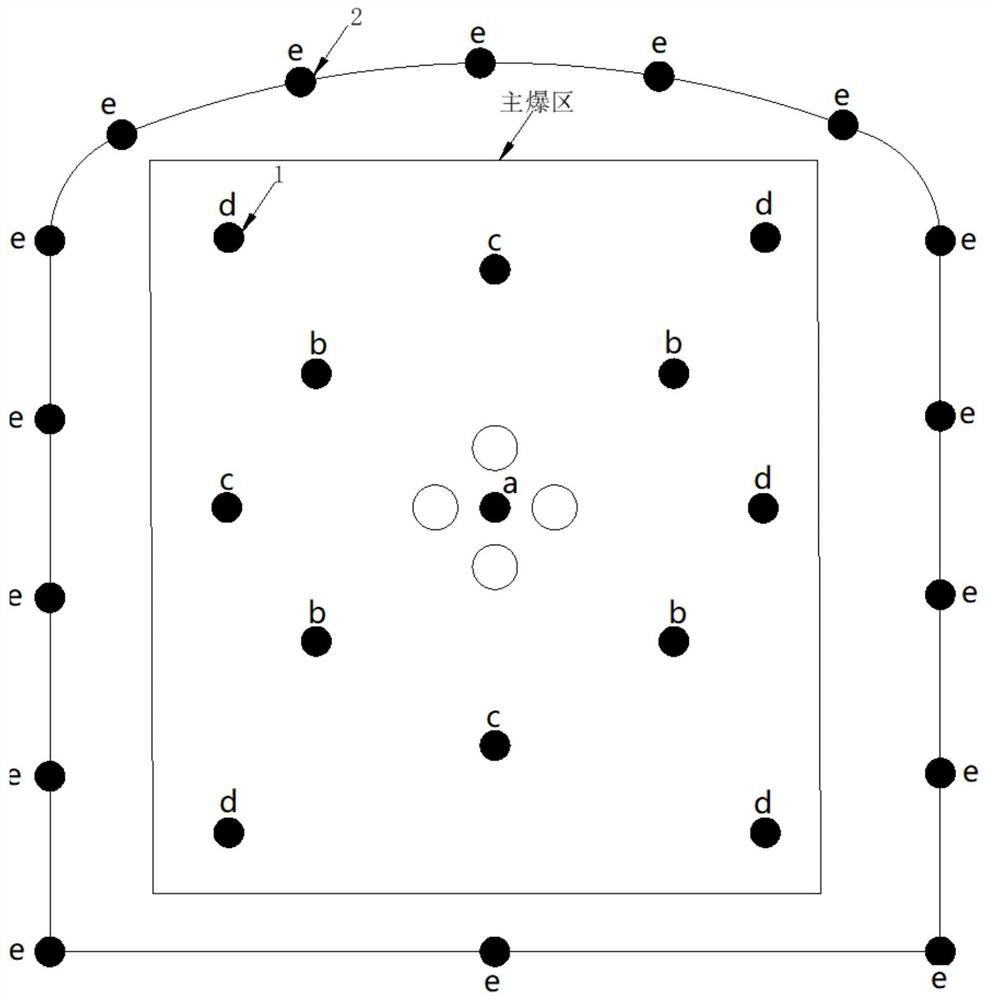

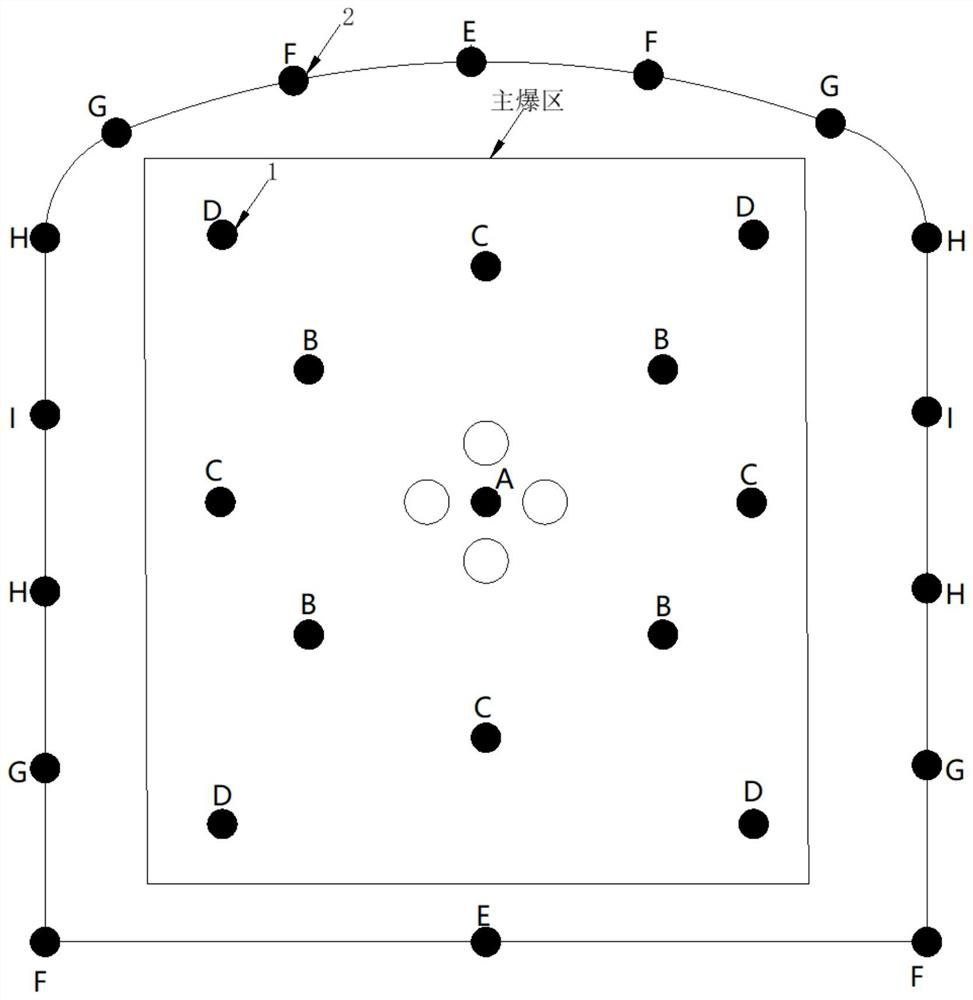

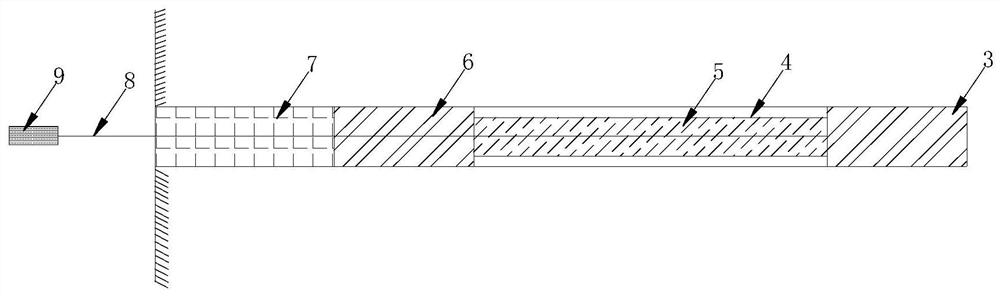

The invention relates to a smooth blasting method for tunneling, and belongs to the technical field of blasting engineering. According to the method, a peripheral smooth blasting hole charging structure of axial non-coupling water interval shaped charge blasting is adopted, a main blasting area and an edge blasting area of a tunneling tunnel face are determined firstly, a main blasting center hole is formed in the center of the main blasting area, and a plurality of large-diameter empty holes are symmetrically formed with the main blasting center hole as the center; a plurality of layers of main blasting holes are symmetrically formed in the outer side of the large-diameter empty hole with the main blasting center hole as the center, and a plurality of peripheral smooth blasting holes are formed in the edge blasting area; an axial non-coupling main blasting hole charging structure is arranged in a main blasting center hole and a main blasting hole of the main blasting area, and a peripheral smooth blasting hole charging structure for axial non-coupling water interval shaped charge blasting is arranged in a peripheral smooth blasting hole; and the main blasting center hole, the main blasting holes and the peripheral smooth blasting holes are sequentially detonated hole by hole. The jet flow formed by the energy gathering groove and the water bag generate a 'water wedge' effect in the blasting process to promote the initial crack growth of the rock, and water mist is formed to reduce the dust concentration in the blasting process.

Owner:KUNMING UNIV OF SCI & TECH

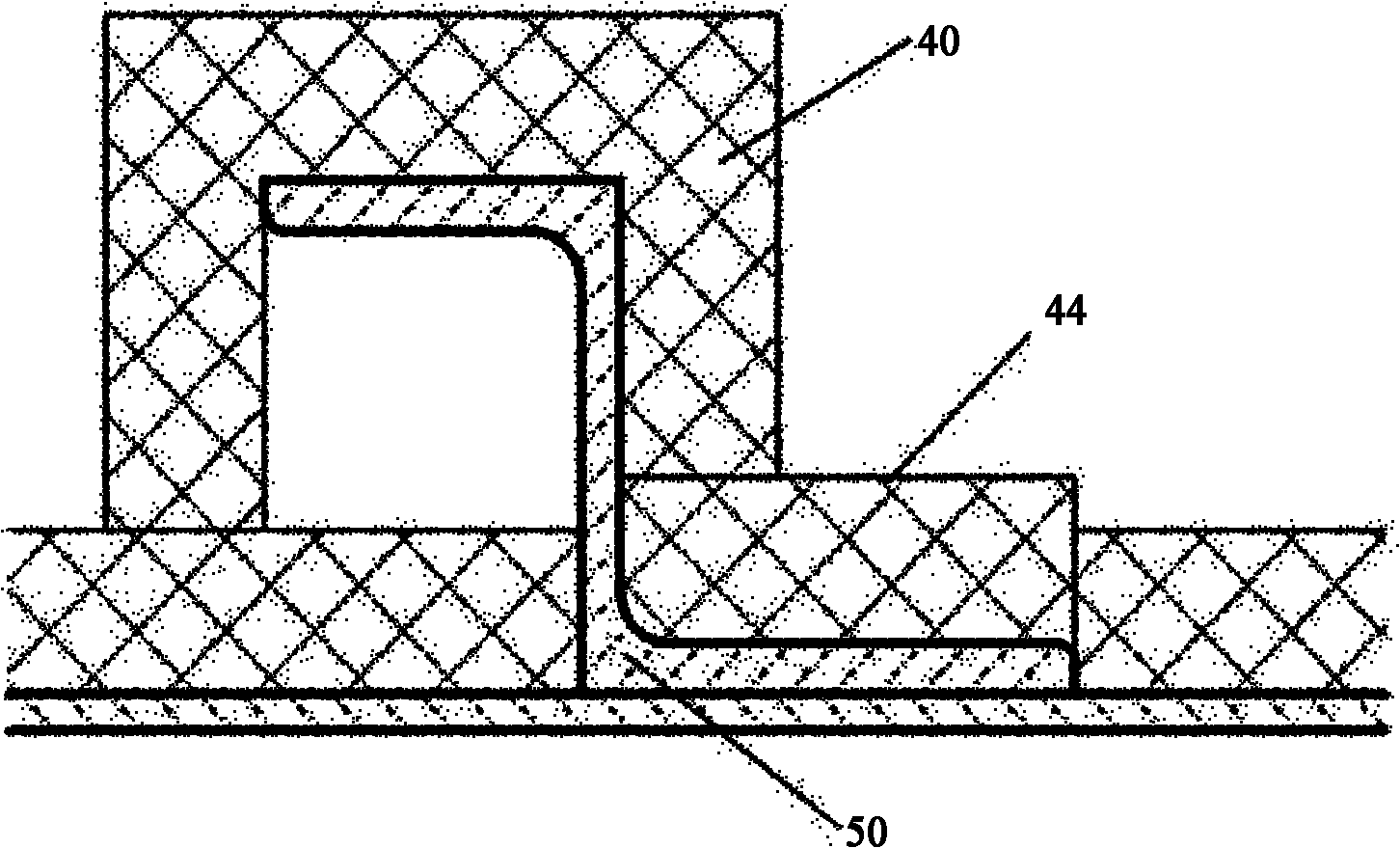

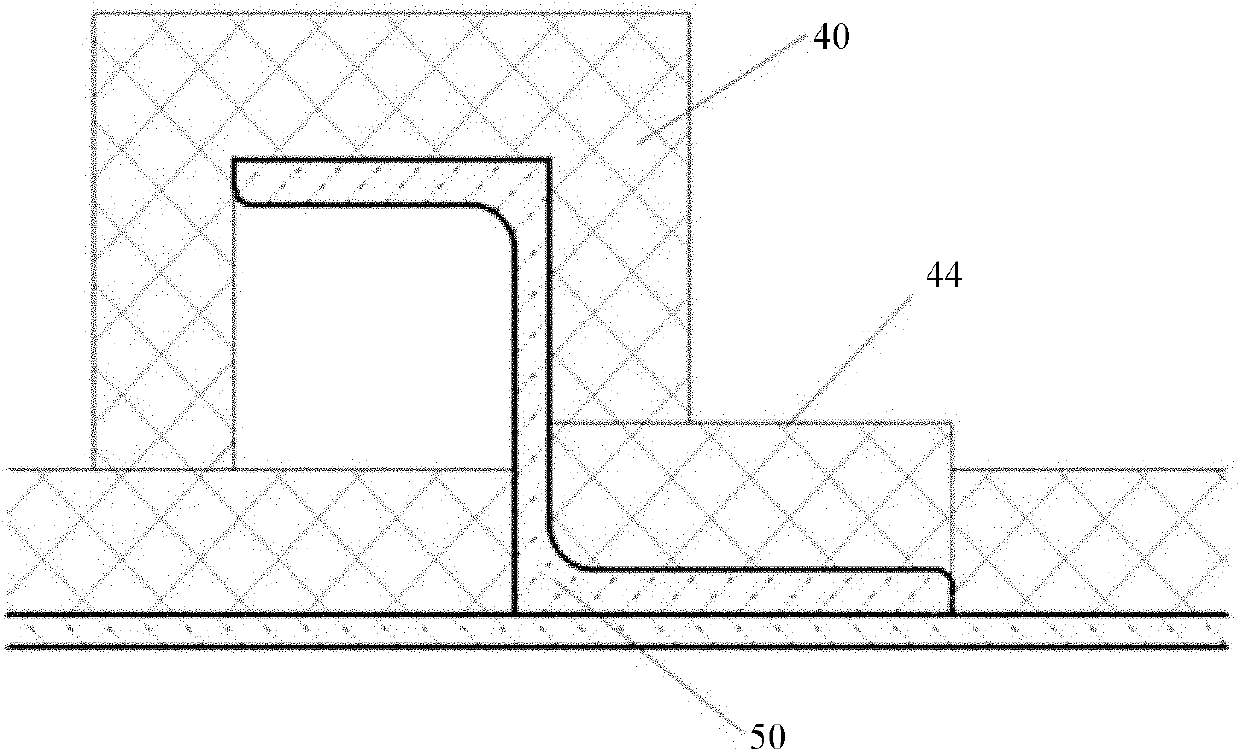

Cumulative cutting method for wall-thickness variable metal component with bent cross section

InactiveCN102042785AContinuous and reliable explosion transmissionCutting safetyBlastingEngineeringMechanical engineering

The invention provides a cumulative cutting method for a wall-thickness variable metal component with a bent cross section. In the method, cutters with different explosive charge quantities are adopted according to different wall thicknesses, and the method is beneficial to the reduction of the explosive dosage relative to other explosive charging modes. A protective device made of a composite material not only has the protective effect on explosion dangers, but also guarantees the proper matching of relative positions of an adopted flexible cumulative cutter and the surface of a bent metal component; and an accurate explosion propagation technology that a jet flow generated by one flexible cumulative cutter is used for detonating another flexible cumulative cutter adjacent to the flexible cumulative cutter is adopted to ensure that various types of cumulative cutters can be detonated continuously and reliably so as to reliably and safely cut a wall-thickness viable metal component with a bent cross section.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

Boulder blasting treatment method used before operation of cutter head of shield tunneling machine

ActiveCN109596022AReduce the amount of explosivesReduce the problem of excessive blasting energy in one shotBlastingEngineeringShield tunneling

The invention discloses a boulder blasting treatment method used before operation of a cutter head of a shield tunneling machine. The method comprises following steps that S1, the position 6000 mm infront of the cutter head of the shield tunneling machine serves as the boundary line, the range away from the cutter head by within 6000 mm is divided as the primary blasting treatment area, and the range away from the cutter head by more than 6000 mm is divided as the subsequent blasting treatment area; S2, blasting holes are formed; S3, explosives are contained in the blasting holes; and S4, blasting begins. The blasting area is divided into the primary blasting treatment area and the subsequent blasting treatment area, in the primary blasting treatment area nearby the cutter head, the holedistribution amount is increased, the explosive amount in each blasting hole is reduced, through the manner of staggering the blasting time of the blasting holes, the problem of too large one-time blasting energy is solved, and the phenomenon that energy generated by one-time blasting is too large, and the shield tunneling machine is affected is avoided.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD +1

Gob-side entry driving surrounding rock control method using remaining small pillars

InactiveCN103244180BReduce overhang lengthBreach of integrityMining devicesBlastingEngineeringDeep hole

The invention discloses a gob-side entry driving surrounding rock control method using remaining small pillars. The method includes: distributing blast holes of different angles and depths in a working face conveying chute during extraction on an upper region working face, preforming a weak face in a certain area of a basic roof to damage completeness of a basic roof rock stratum by deep hole presplitting, and allowing a suspension arch of the basic roof to break at predetermined positions under the action of roof pressure after extraction of the working face. Therefore, the length of the hanging arch of the lateral basic roof of a gob is shortened, gob lateral abutment pressure is reduced, roadway pressure is relieved during gob-side entry driving in a lower region using remaining small pillars, and maintenance of a roadway is facilitated.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

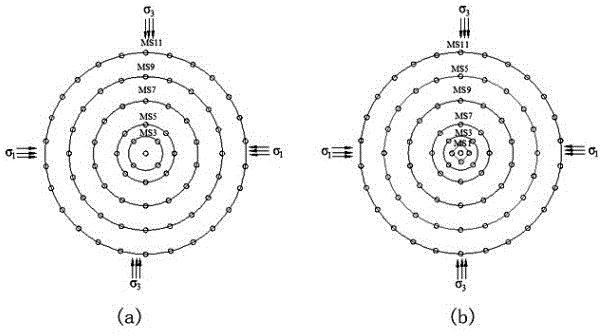

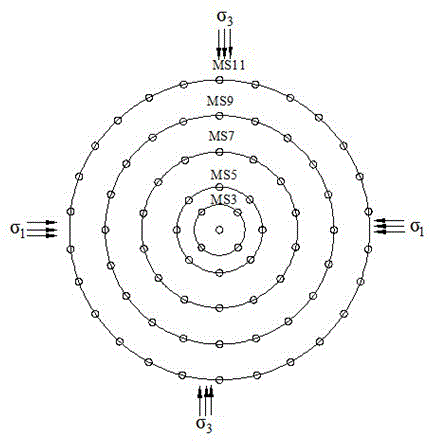

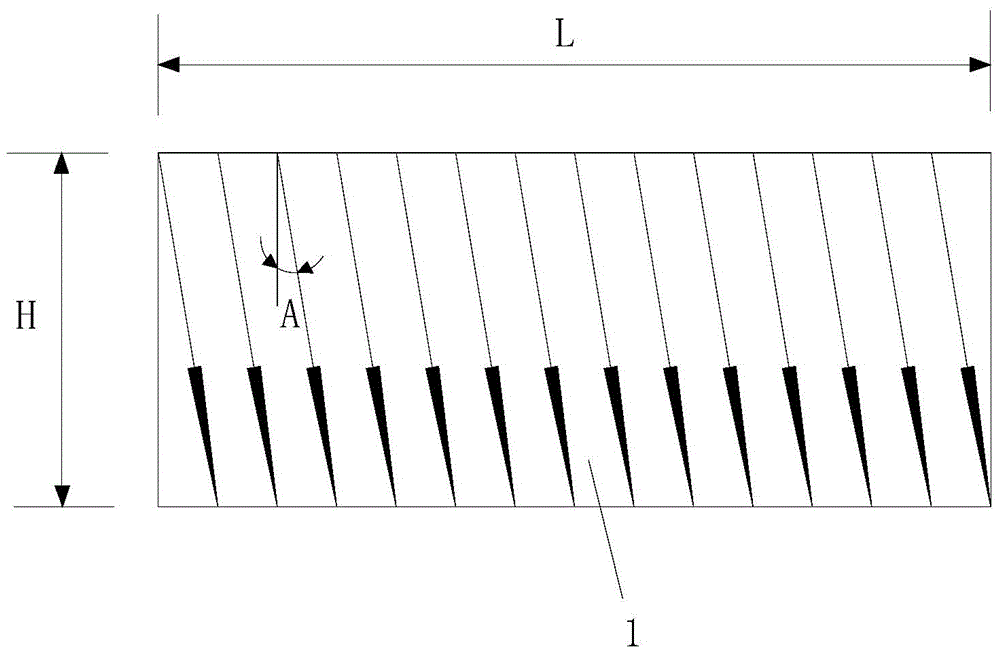

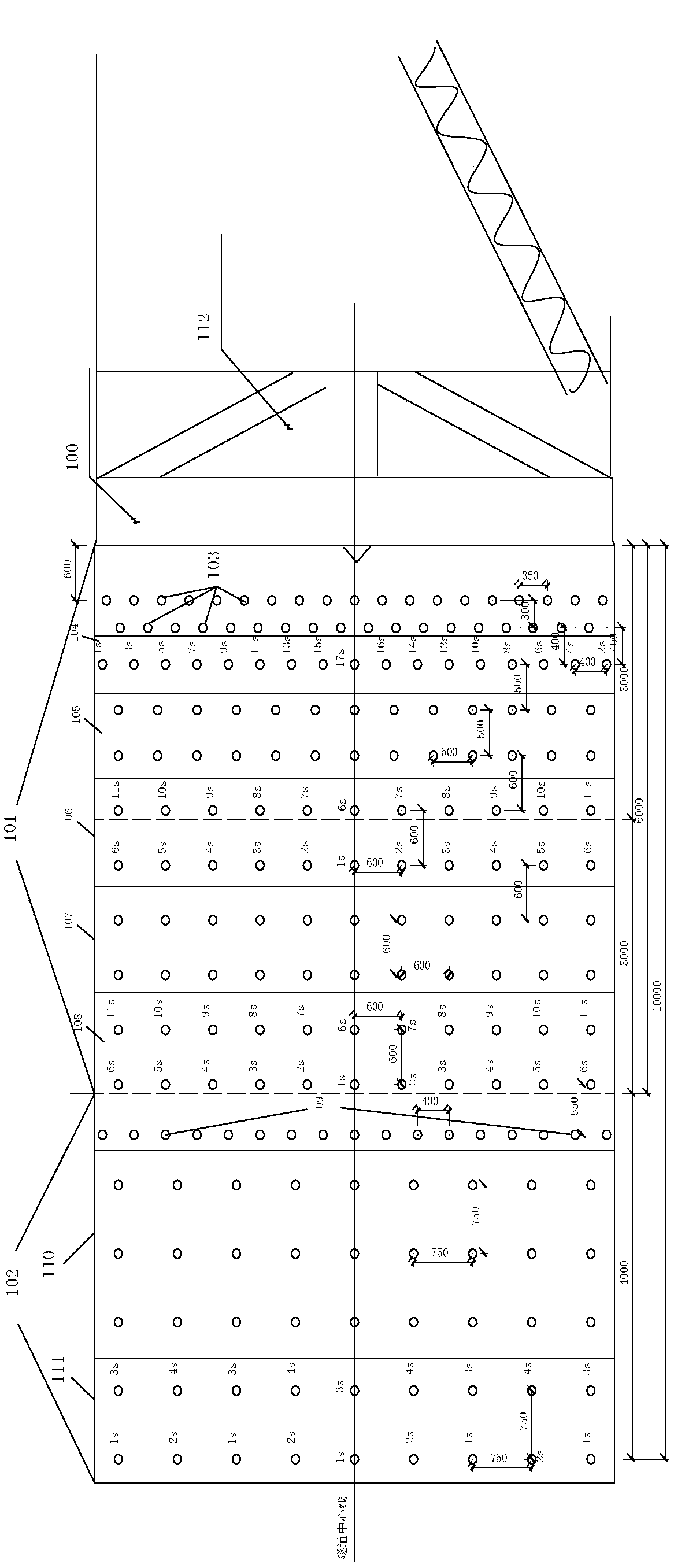

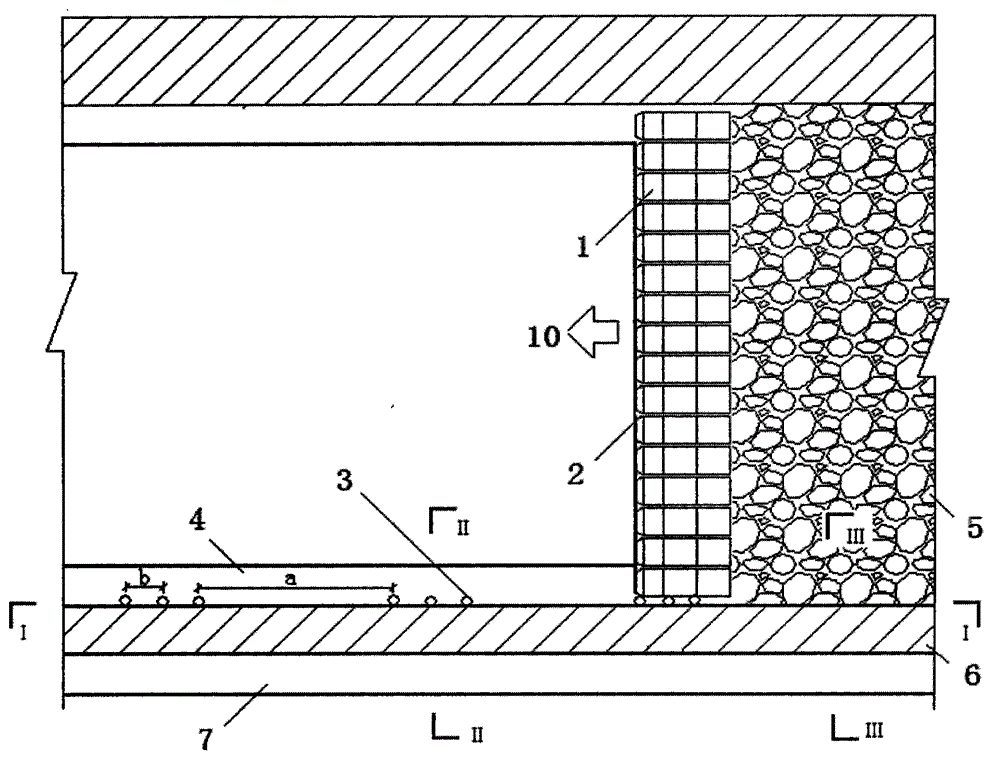

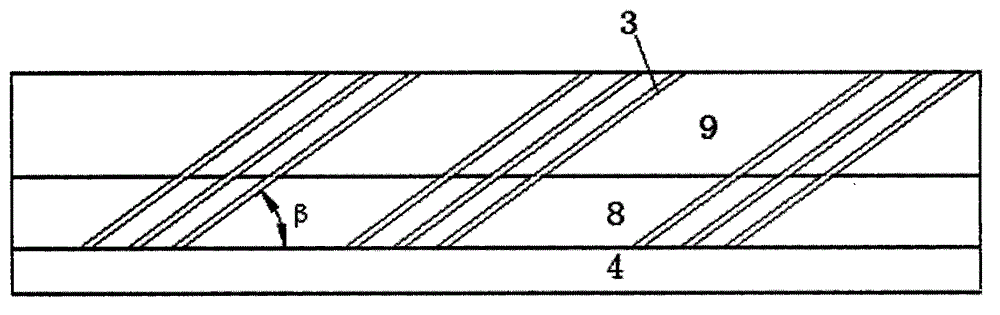

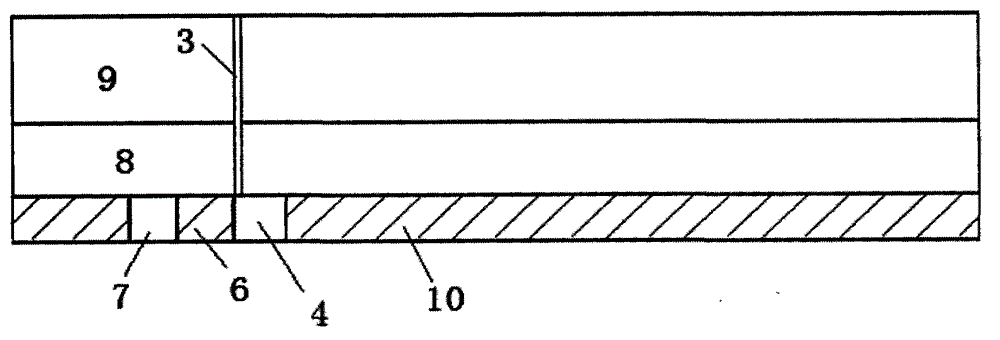

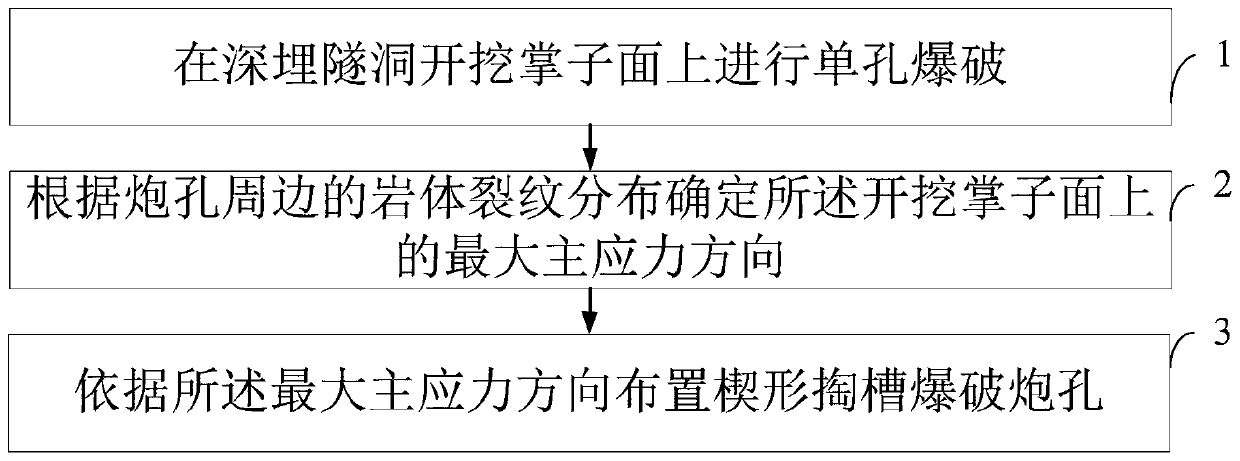

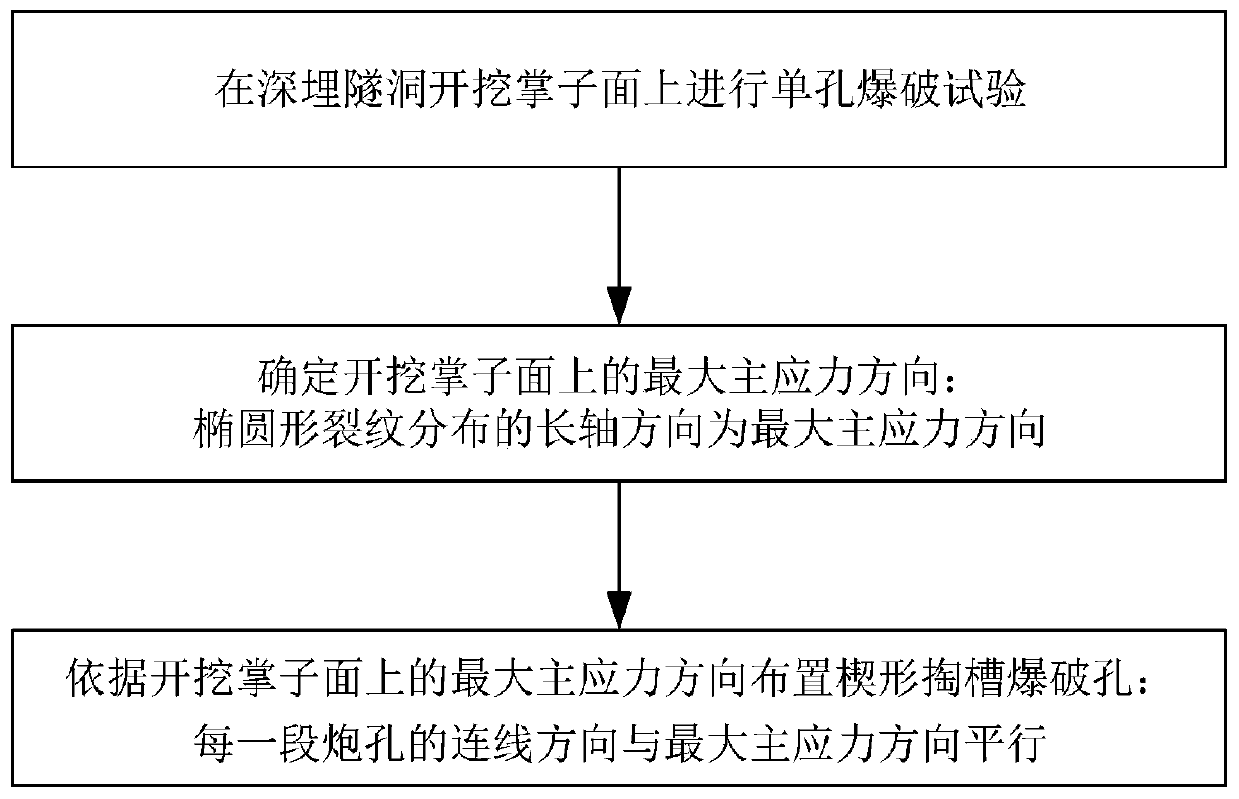

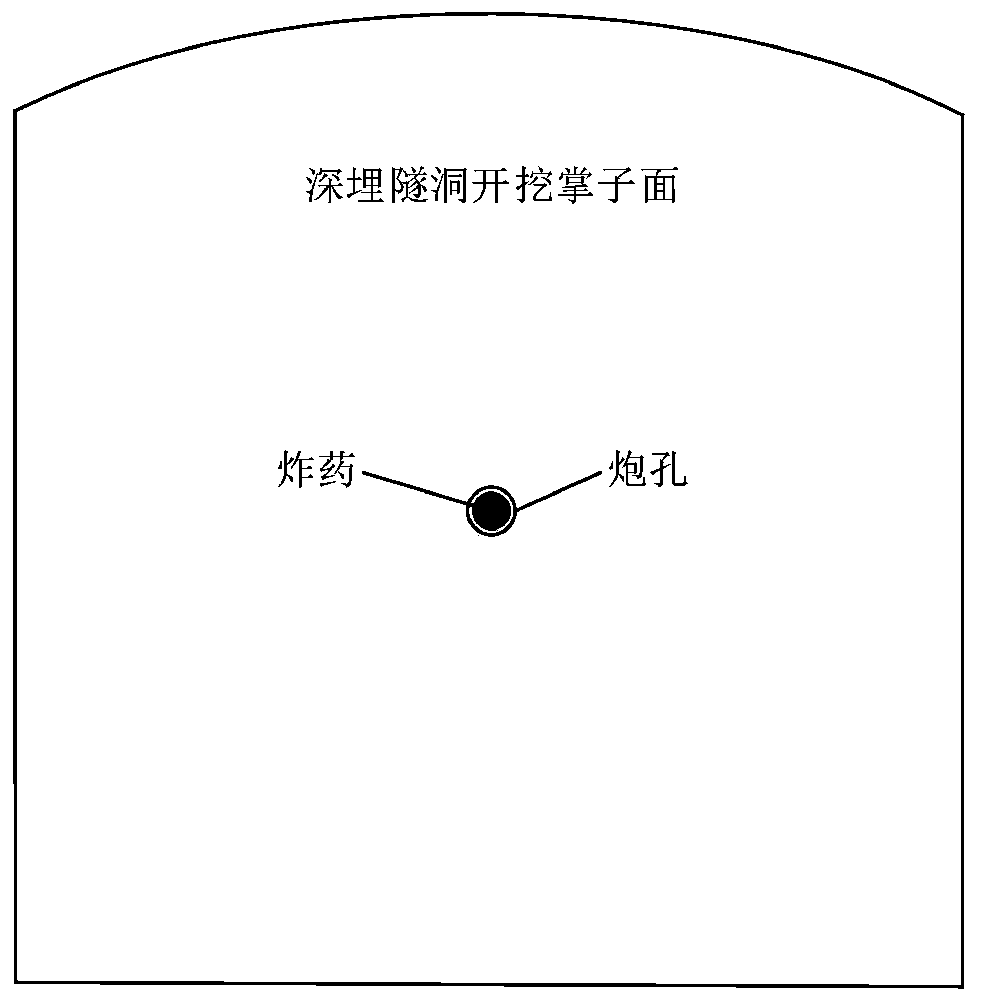

Wedge-shaped underholing blast hole arrangement method suitable for deep-buried tunnel blasting excavation

ActiveCN111102892AGuaranteed excavation cycle footageImprove good performanceBlastingTunnelsTEX-explosiveWedge shape

The invention discloses a wedge-shaped underholing blast hole arrangement method suitable for deep-buried tunnel blasting excavation. The wedge-shaped underholing blast hole arrangement method comprises the steps that a single-hole blasting test is conducted on a deep-buried tunnel excavation tunnel face; the maximum main stress direction on the excavation tunnel face is determined according to rock mass crack distribution around blast holes; and wedge-shaped underholing blasting blast hole arrangement is determined according to the maximum main stress direction. By arranging the wedge-shapedunderholing blasting blast holes in the maximum main stress direction on the excavation tunnel face, rock mass blasting cracks are advantageously expanded and broken, the using amount of explosives for underholing blasting is decreased, the underholing effect is improved, and designed tunnel excavation footage driving cycle is guaranteed.

Owner:NANCHANG UNIV

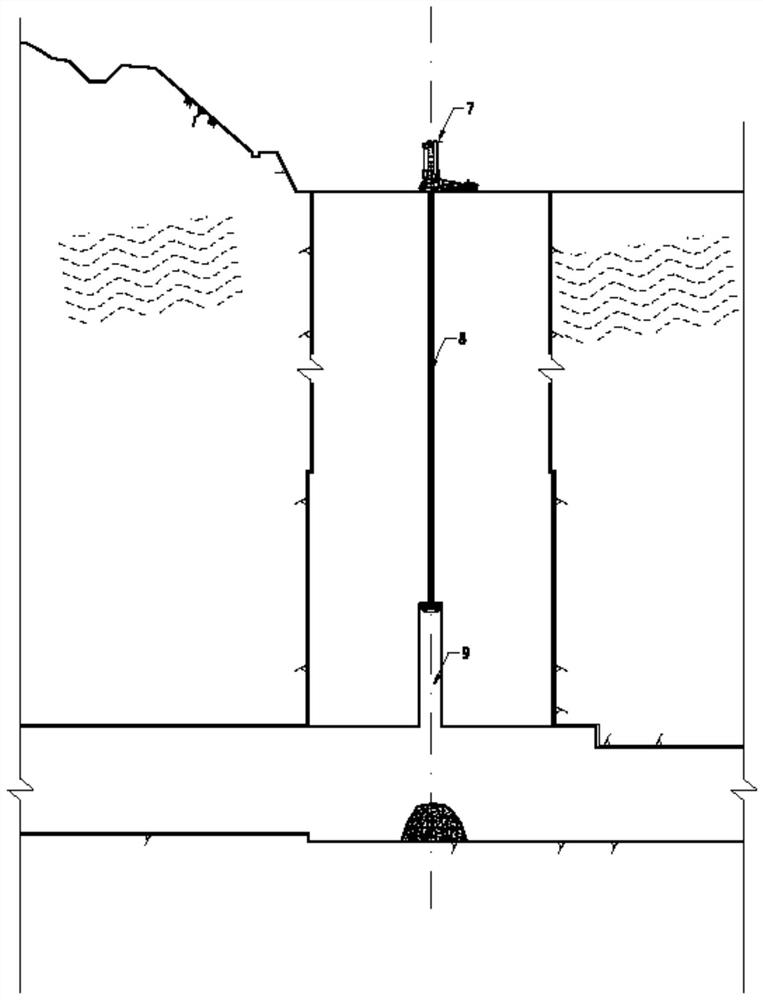

Construction method for rapidly expanding and excavating large-section surge shaft through one-time drilling and blasting of ultra-deep hole

PendingCN114319264AImprove efficacyImprove construction progressWater-power plantsHydro energy generationSlagArchitectural engineering

The invention relates to the technical field of surge shaft construction, in particular to a construction method for rapidly expanding and excavating a large-section surge shaft through one-time drilling and blasting of an ultra-deep hole, which comprises the following steps of: S1, constructing a pressure regulating upper and lower construction channel to form a construction platform; s2, a raise boring machine is adopted for small pilot well construction, and a small pilot well with the diameter being 1.4 m is formed; s3, expanding excavation is conducted on the small pilot well through ultra-deep hole millisecond blasting in two procedures, and a slag slipping well with the diameter being 4.8 m is formed; s4, fore shaft concrete construction; and S5, expanding excavation is conducted on the shaft of the surge shaft through partition line production. The method has the characteristics of low construction safety risk, reasonable procedure arrangement and parallel construction of various operations, overcomes the defects of low tunneling and well expanding speed, low efficiency, high labor intensity, poor safety and the like of a common method, a cage hanging method and a cage climbing method, accelerates the well completion progress of the large-area vertical shaft, greatly reduces the construction difficulty and the construction cost, and ensures the engineering quality.

Owner:中国能源建设集团广西水电工程局有限公司

Rapid construction method for underground excavation section of subway station entrance and exit in rocky strata

The invention discloses a rapid construction method for a subsurface section of a passageway of a subsurface subway station in a rock stratum. The rapid construction method comprises the following steps: taking a small-cross-section inclined pilot tunnel which is constructed in advance and connects an open excavation section to a station as a slag discharge channel; constructing a subsurface section from the open excavation section to the subway station; conveying residue soil generated in an operation process of the subsurface section into the slag discharge channel by using an excavator or a forklift; conveying the residue soil to a tunnel position of a connection section between the station and the passageway by great gradient of the slag discharge channel; and conveying the residue soil to the ground via a station construction channel by a slag car. The problems are solved that in the traditional method for constructing the subsurface section of the passageway of the subsurface subway station in the rock stratum, risks are high and the efficiency is low in a process of excavating from the open excavation section to the station and discharging slag, and the profile cannot be controlled easily when a tunnel is excavated from the station to the open excavation section; construction safety, construction progress and construction quality are guaranteed.

Owner:CRRC CONSTR ENG CO LTD

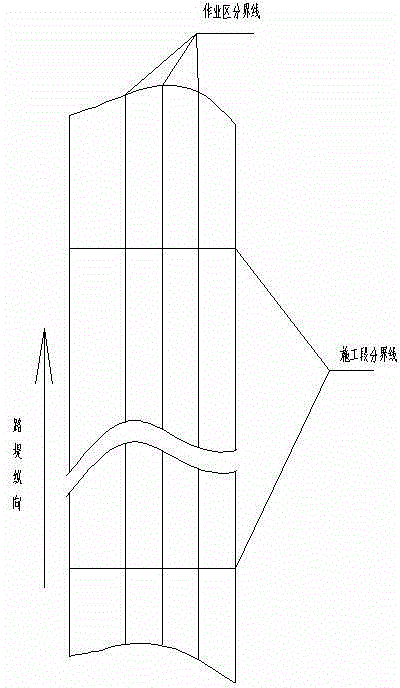

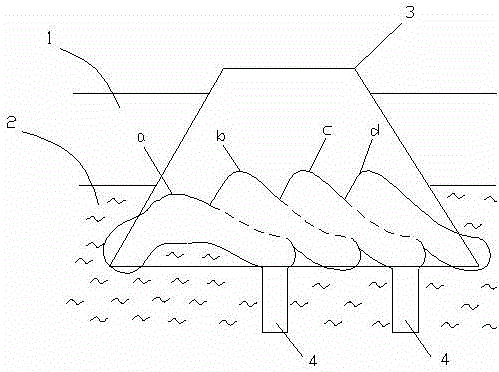

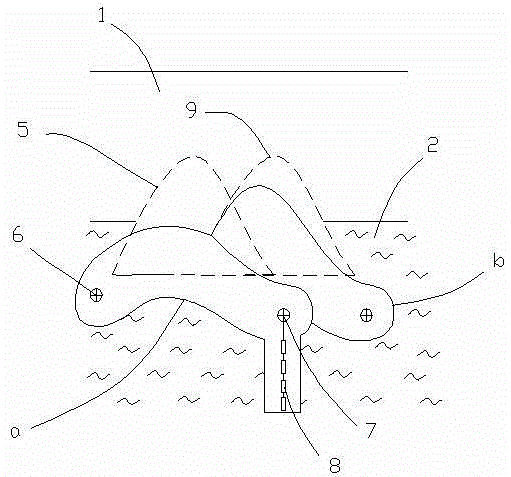

Horizontal explosive compaction land reclamation road building method

InactiveCN104631249AAvoid pile upReduce the amount of replacementRoadwaysClimate change adaptationEcological environmentContinuous operation

The invention discloses a horizontal explosive compaction land reclamation road building method. In the method, the construction efficiency can be improved by adopting the continuous operation in the same operation area between the adjacent construction sections and sequence operation in different operation areas; during explosion operation, a pile foundation is formed by arranging a pile foundation explosive bag, and the silt displacement amount can be decreased by utilizing bearing force provided by the pile foundation; the horizontal explosive compaction land reclamation road building method has the beneficial technical effects that the construction efficiency is high, the engineering quantity is less, the explosive amount can be effectively reduced, and the high damage to the ecological environment can be avoided.

Owner:陈绍文 +6

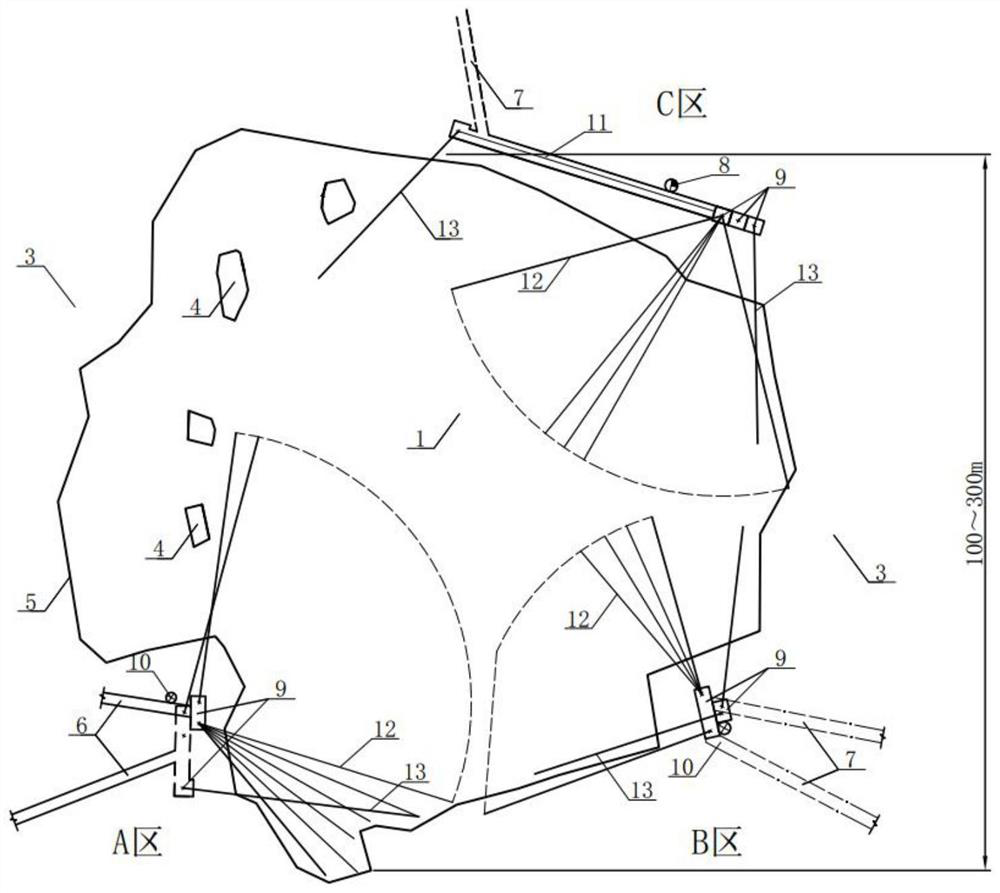

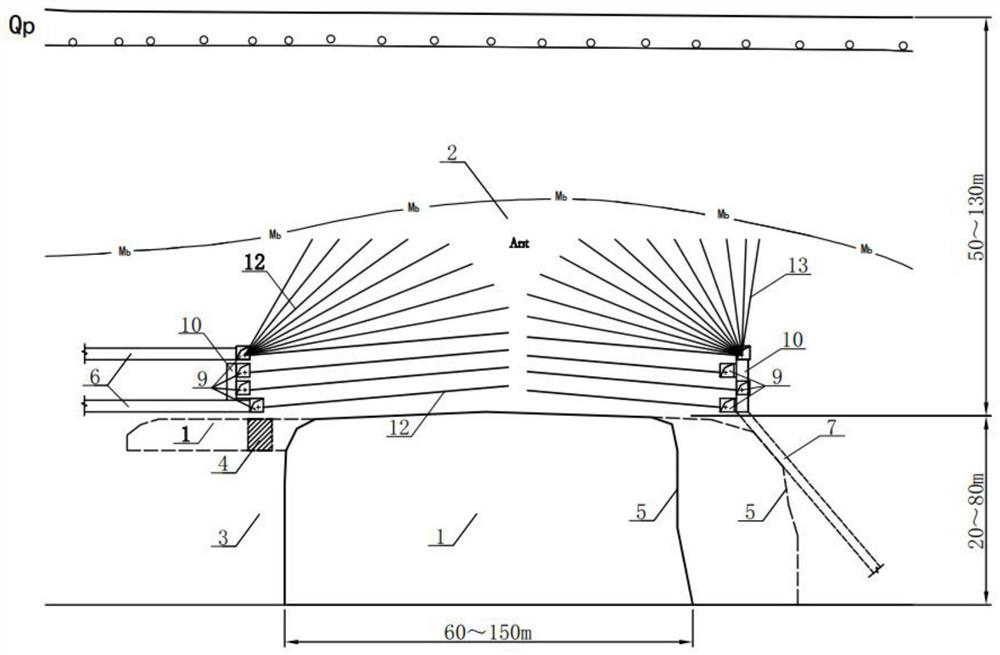

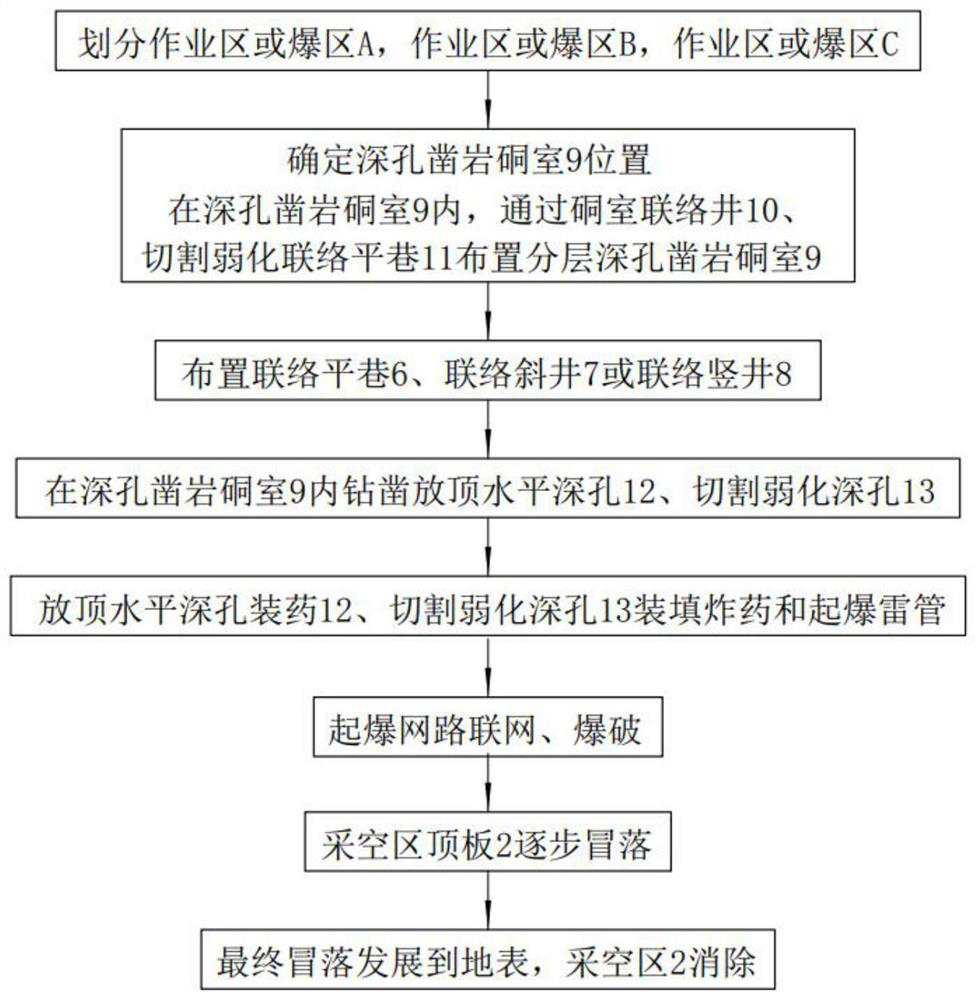

Method for caving large goaf of underground mine and eliminating goaf

PendingCN114810209AReduce the amount of explosivesLow costMining devicesBlastingMining engineeringTEX-explosive

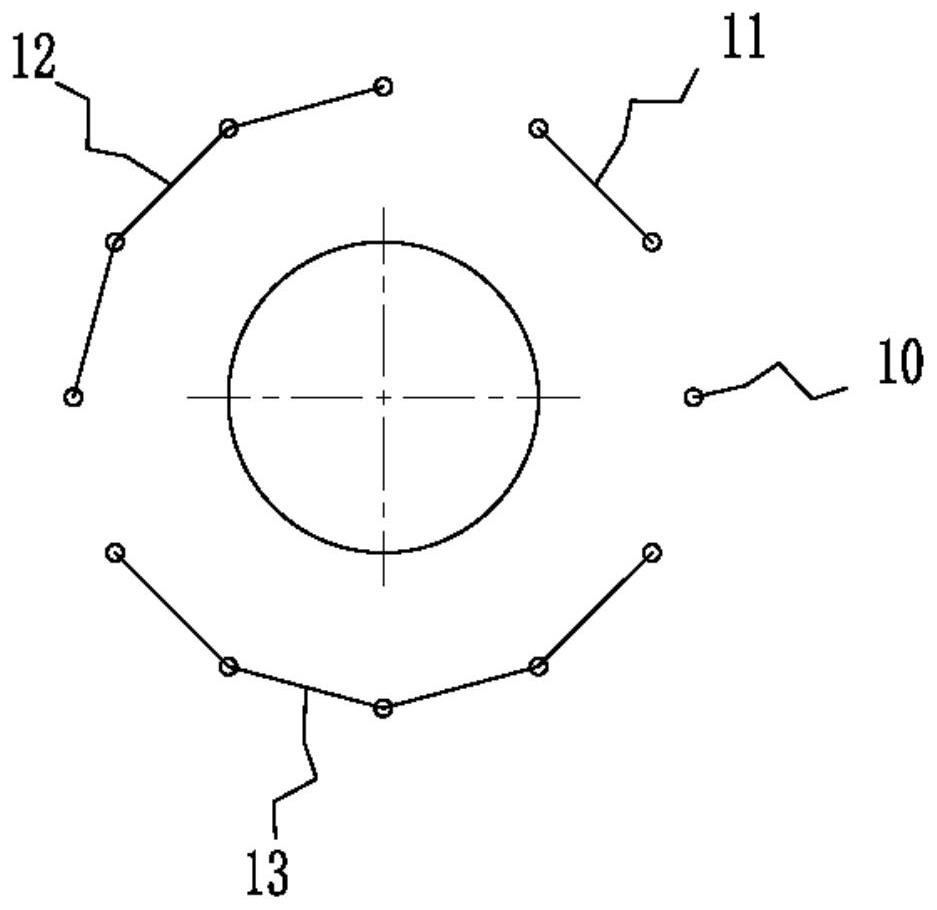

The invention discloses a method for caving a large goaf of an underground mine and eliminating the goaf. The method comprises the following steps: dividing 2-6 operation areas or explosion areas in a goaf surrounding rock (3) on the periphery of the goaf (1); 3-6 deep hole drilling chambers (9) are arranged in the goaf surrounding rock (3) in each operation area or explosion area, and the deep hole drilling chambers (9) of all layers are communicated through chamber connection wells (10); the method comprises the following steps: arranging a roadway project, namely a connection gate way (6), a connection inclined shaft (7) or a connection raise, between an existing project and a deep hole drilling chamber (9); a caving horizontal deep hole (12) is formed in the deep hole drilling chamber (9) on the middle-lower layer, and a horizontal and upward fan-shaped cutting weakening deep hole (13) is formed in the deep hole drilling chamber (9) on the upper layer. According to the method, the underground engineering amount, the explosive amount of deep hole blasting and the harm caused by air shock waves brought by large-area caving of the goaf are reduced, the construction cost is reduced, and potential safety hazards existing in the large goaf are eliminated.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

A blasting treatment method for boulders in front of the shield cutter head

ActiveCN109596022BReduce the amount of explosivesReduce the problem of excessive blasting energy in one shotBlastingExplosive AgentsArchitectural engineering

The invention discloses a boulder blasting treatment method used before operation of a cutter head of a shield tunneling machine. The method comprises following steps that S1, the position 6000 mm infront of the cutter head of the shield tunneling machine serves as the boundary line, the range away from the cutter head by within 6000 mm is divided as the primary blasting treatment area, and the range away from the cutter head by more than 6000 mm is divided as the subsequent blasting treatment area; S2, blasting holes are formed; S3, explosives are contained in the blasting holes; and S4, blasting begins. The blasting area is divided into the primary blasting treatment area and the subsequent blasting treatment area, in the primary blasting treatment area nearby the cutter head, the holedistribution amount is increased, the explosive amount in each blasting hole is reduced, through the manner of staggering the blasting time of the blasting holes, the problem of too large one-time blasting energy is solved, and the phenomenon that energy generated by one-time blasting is too large, and the shield tunneling machine is affected is avoided.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD +1

Construction method of compact underwater rubble bed

The invention discloses a construction method of a compact underwater rubble bed, which comprises the steps of: 1) accepting a base groove; 2) riprapping a bed; 3) measuring cross section of the bed before blasting; 4) positioning by a positioning boat; 5) artificially adding and arranging explosive; 6) blasting in various sections and various regions; 7) measuring the cross section of the bed after blasting; and 8) detecting and accepting. The construction method of the compact underwater rubble bed is low in requirement on locating precision; the construction method just needs to distribute explosive packages in the region rather than precisely arrange the explosive packages on a fixed point, and is unnecessary to pre-level, therefore, the construction is simple; the explosive demand is lower and the explosive amount is reduced by 20-40%, to reduce harmful influence of the blasting on the surrounding environment; fewer processes are required, the explosive package is simple to arrange, the economic performance is good and the cost is lower; since the explosive package is arranged in a manner to contacting to the earth, the stability of the explosion propagation network is good and the anti-explosion rate is low; and the construction quality is good, and the rubble body is compact and reliable.

Owner:NINGBO KENING EXPLOSION TECH PROJECT

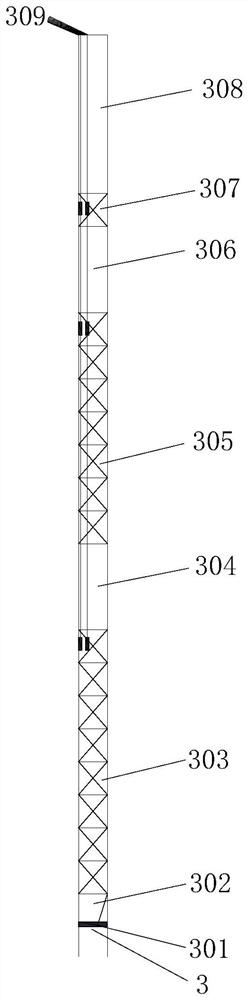

Deep-hole groove-broaching top-breaking gangue-returning-free charging structure and operation method thereof

The invention provides a deep hole groove broaching top breaking gangue returning-free charging structure which comprises a plurality of blast holes distributed in a groove area of a top breaking area, the blast holes are distributed in a circle layer mode from inside to outside, the blast holes in each circle layer are evenly distributed, and corresponding blasting assemblies are arranged in the blast holes in the outermost circle layer. Corresponding blasting assemblies or empty devices are arranged in the blast holes in the inner ring layer, and the blast hole empty devices are used as free faces and air outlet holes. The invention further provides an operation method of the deep hole groove broaching top breaking gangue returning-free charging structure. According to the method, blasting is sequentially carried out from inside to outside and from bottom to top, the last section of blasting provides a compensation space for the next section of blasting, and the time interval between the sections is obtained through a theoretical computer and on-site actual application; rock breaking can be effectively achieved, and the conditions that sintering extrusion is dead and a front blasting belt damages a rear blasting hole are avoided, so that the problem of gangue back-flushing after groove pulling and top breaking is solved, and unnecessary safety risks are avoided.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD

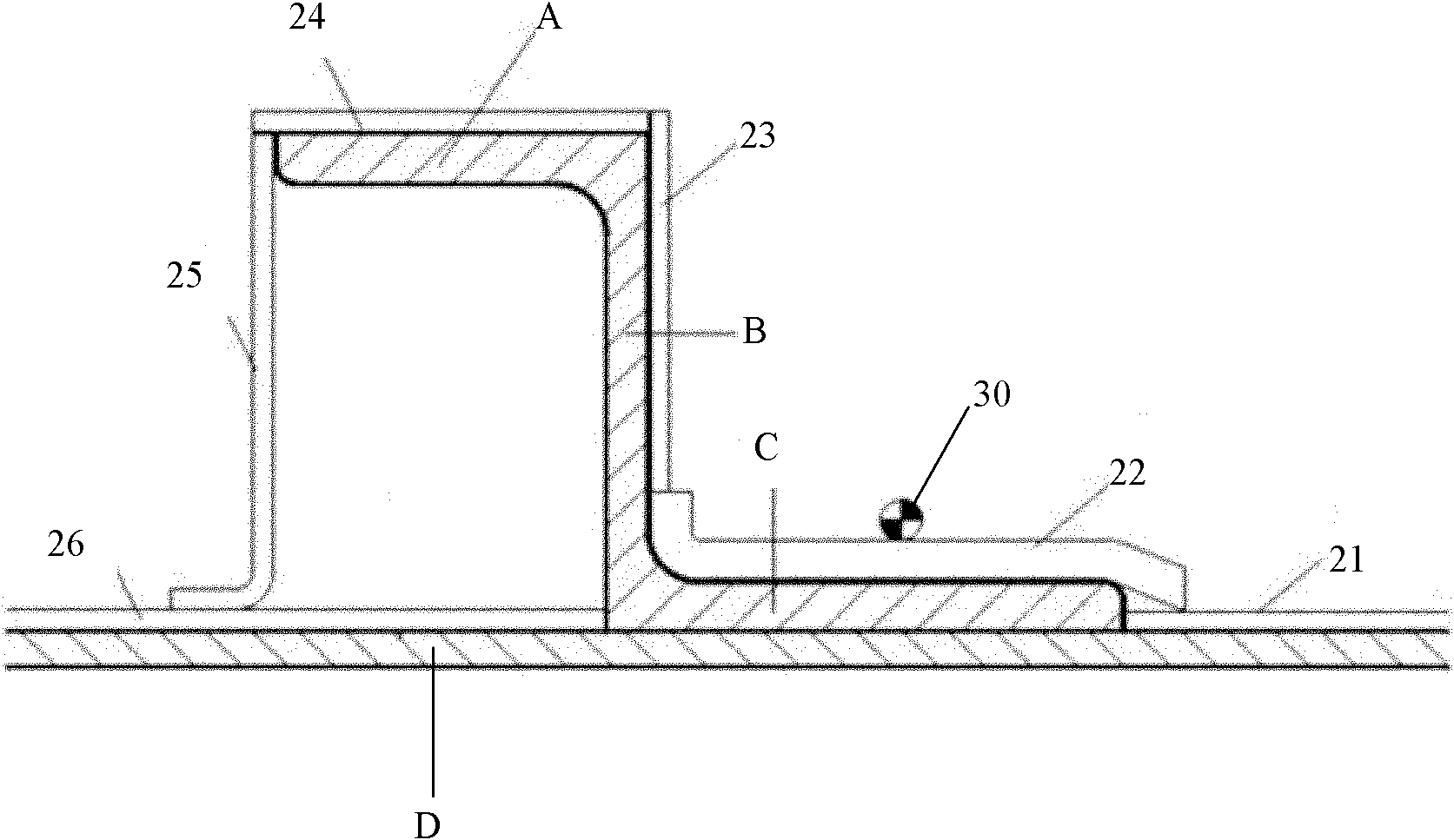

Device special for in-hole positioning, orientating and propelling of tunnel directional fracture blasting shaped charge

The invention discloses a device special for in-hole positioning, orientating and propelling of a tunnel directional fracture blasting shaped charge. The device is formed by assembling main components such as a hollow gun pole provided with a positioning scale and a sliding positioning ring, an orientating sleeve provided with an orientating sliding groove and a bayonet, an orientating push rod of which the two ends are respectively connected with an orientating handle and a circular cartridge baffle piece, and the like. By the device, a shaped tube kerf in a blast hole is orientated precisely out of a hole by adjusting the direction of the handle, and the angle deviation can be controlled within the range of 5 to 10 degrees, so that a blasting fracture surface in a good shape is obtained; and the device has a simple overall structure and does not have special requirements on a conventional drilling process, and is convenient to operate and beneficial to promotion of the engineering application of an orientated shaped blasting technology.

Owner:CENT SOUTH UNIV

Underground mine laneway engineering or ore breaking engineering dust fall water pressure blasting process

PendingCN114396840AReduce concentrationReduce ventilation costsBlastingTunnelsExplosive AgentsMining engineering

The invention relates to a dust fall water pressure blasting process for underground mine laneway engineering or ore breaking engineering. The dust fall water pressure blasting process comprises the following steps that S1, underholing holes, peripheral holes and auxiliary holes are formed in a working face, and the underholing holes are formed in the lower position of the center of a section; the peripheral holes are arranged on a contour line of a roadway surface, the top holes and the side holes are parallel to each other according to smooth blasting requirements, and all the bottom holes are positioned on the same surface; the auxiliary holes are uniformly formed between the underholing holes and the peripheral holes; and S2, cartridges and water bags are sequentially and firstly arranged in the blast holes, the blast holes are filled with stemming, and the number of the water bags arranged in the blast holes is determined according to the remaining space of the blast holes. The method has the advantages that the concentration of poisonous and harmful gas and dust is effectively reduced, the ventilation cost is reduced, the explosive amount is reduced, and the economic benefit is improved. The device is suitable for construction places with small space, difficult ventilation and difficult explosive supply.

Owner:中矿金业股份有限公司

Cumulative cutting method for wall-thickness variable metal component with bent cross section

InactiveCN102042785BContinuous and reliable explosion transmissionCutting safetyBlastingEngineeringMechanical engineering

The invention provides a cumulative cutting method for a wall-thickness variable metal component with a bent cross section. In the method, cutters with different explosive charge quantities are adopted according to different wall thicknesses, and the method is beneficial to the reduction of the explosive dosage relative to other explosive charging modes. A protective device made of a composite material not only has the protective effect on explosion dangers, but also guarantees the proper matching of relative positions of an adopted flexible cumulative cutter and the surface of a bent metal component; and an accurate explosion propagation technology that a jet flow generated by one flexible cumulative cutter is used for detonating another flexible cumulative cutter adjacent to the flexible cumulative cutter is adopted to ensure that various types of cumulative cutters can be detonated continuously and reliably so as to reliably and safely cut a wall-thickness viable metal component with a bent cross section.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com