A blasting treatment method for boulders in front of the shield cutter head

A processing method and technology of shield cutter head, applied in blasting and other directions, can solve the problems of high cost, reduced rock mass integrity, large rock block volume, etc., and achieve the effect of reducing excessive energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0030] A method for blasting a boulder in front of a shield cutterhead, comprising the following steps:

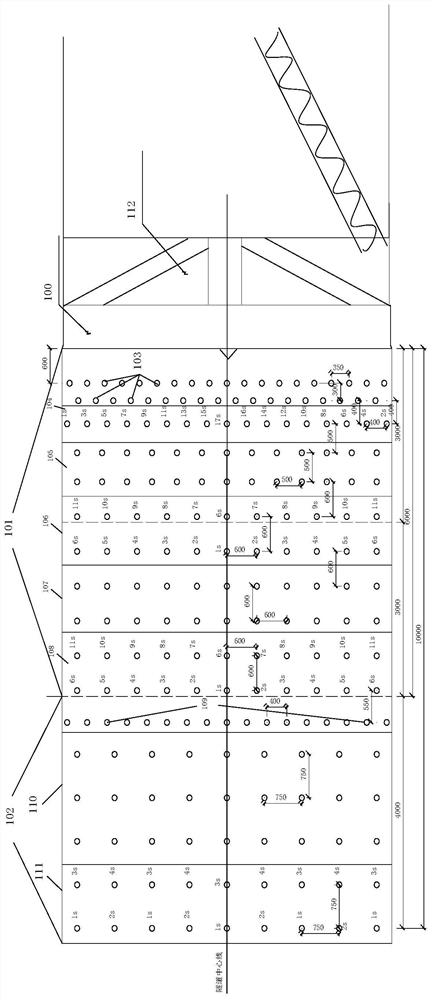

[0031] S1. Taking the 6000mm in front of the cutterhead 100 of the shield machine as the dividing line, divide the range that is less than or equal to 6000mm from the cutterhead as the first blasting treatment area 101, and the range that is greater than 6000mm from the cutterhead is the subsequent blasting treatment area 102, such as figure 1 shown. That is to blast and deal with the boulders in the range of 6000mm in front of the cutter head first, and then continue to blast and deal with the boulders forward. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com