Construction method of compact underwater rubble bed

A technology of riprap foundation bed and construction method, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of poor quasi-explosion reliability, high construction cost, and large harmful effects, and achieve low positioning accuracy requirements, good construction quality, and harmful effects. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

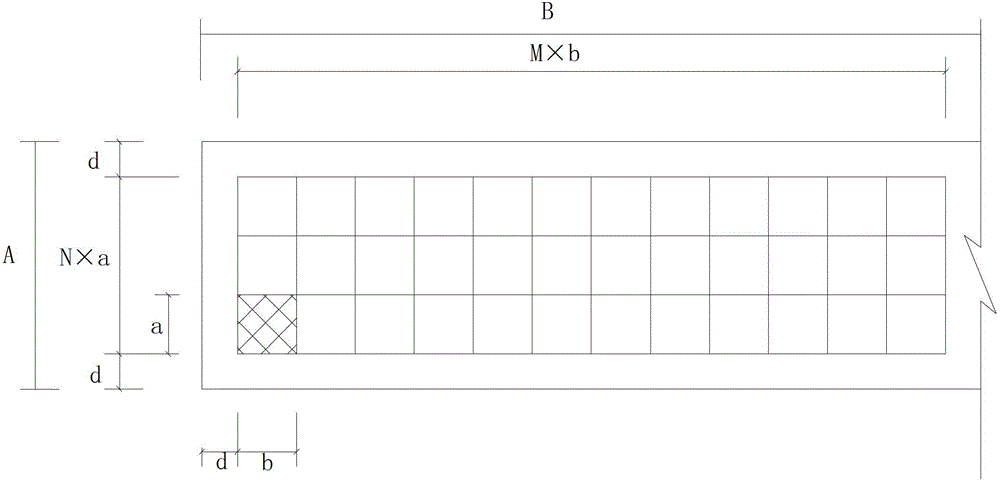

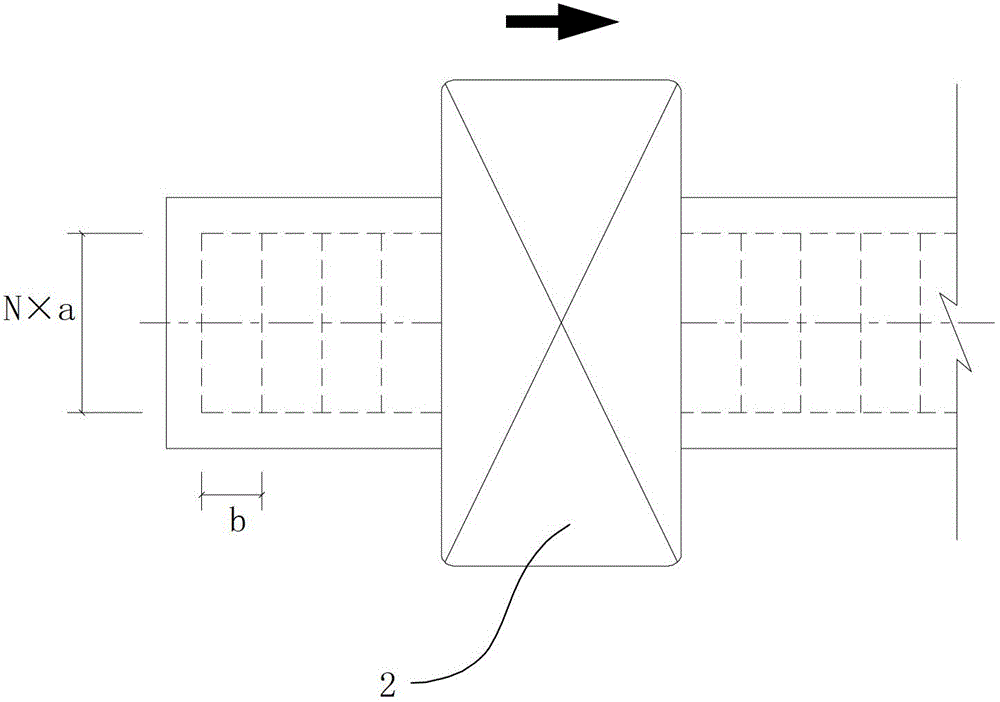

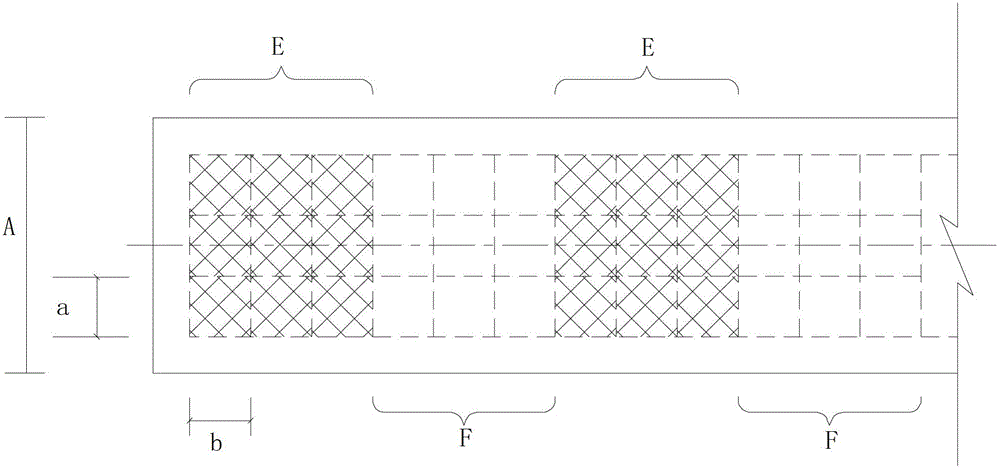

[0046] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

[0047] The fundamental principle of the compaction of underwater rockfill bed is that the pores between the rock rappels are reduced, which leads to an increase in the density of the rock rappels, that is, through the relative displacement between the rocks, the supporting structure between adjacent rock particles changes. The support structure tends to be more stable, and the bearing capacity of the rubble bed is greatly improved. In this way, after the foundation bed is placed with a gravity structure such as a caisson, the amount of settlement itself is small.

[0048] From the perspective of macroscopic effects, when the explosive package explodes on the surface of the riprap base bed, the compaction of the riprap base bed is caused by the combination of compression and fragmentation in the near area, explosive vibration in the middle area, and vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com